Development of a Municipal Solid Waste Management Life Cycle Assessment Tool for Banepa Municipality, Nepal

Abstract

1. Introduction

2. Materials and Methods

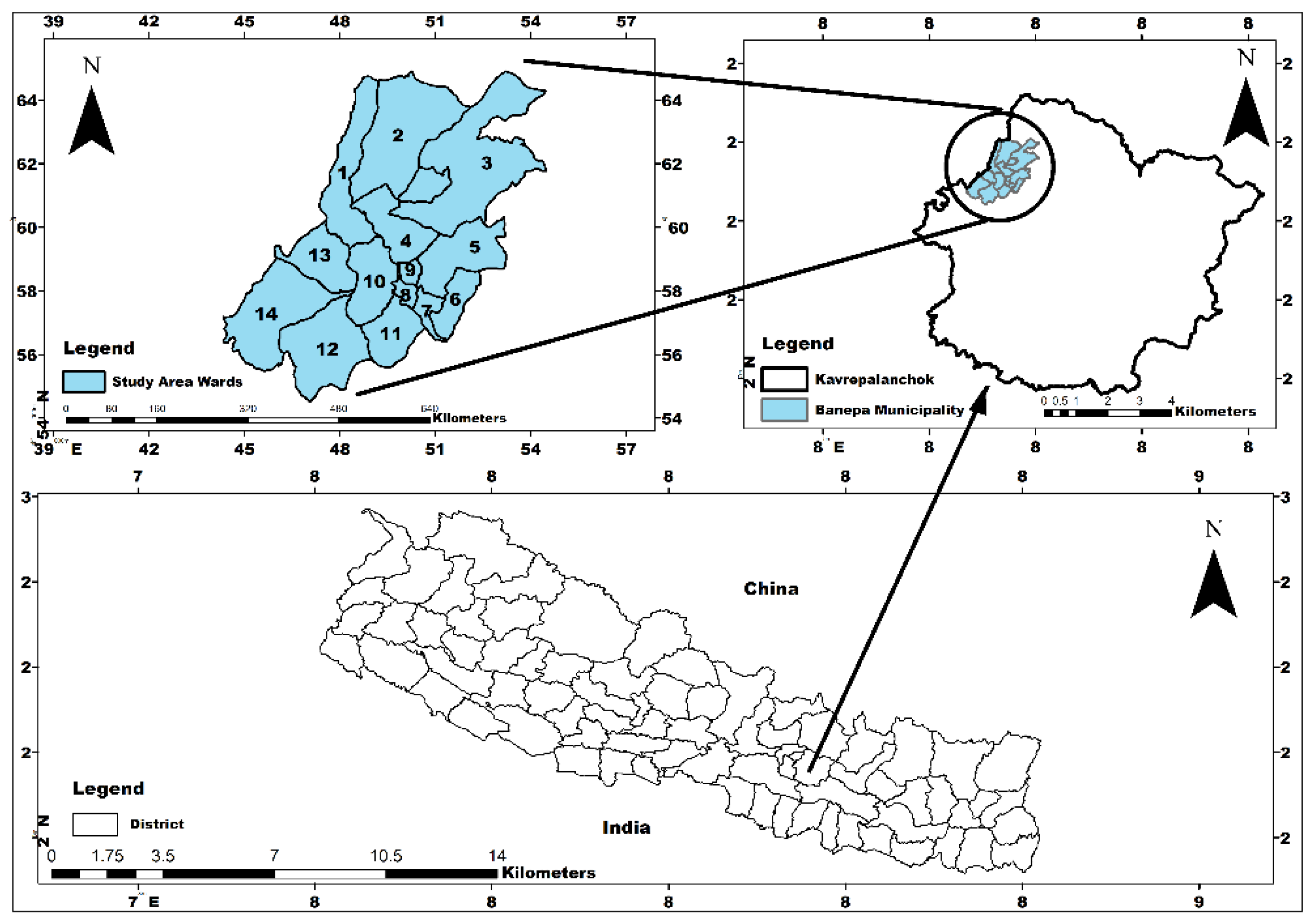

2.1. Study Area and MSW Composition

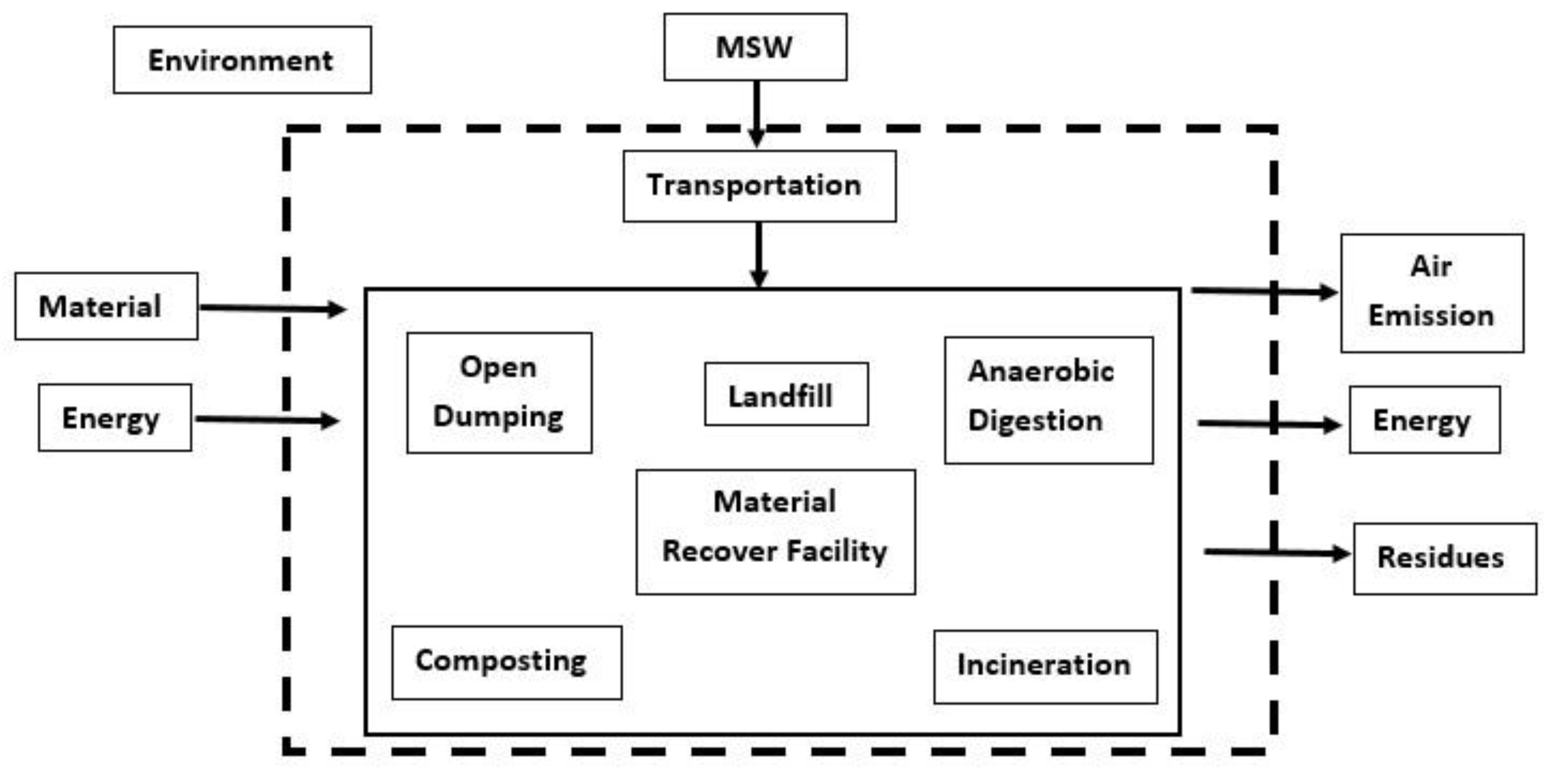

2.2. Life Cycle Assessment

2.3. Goal and Scopes of the Study

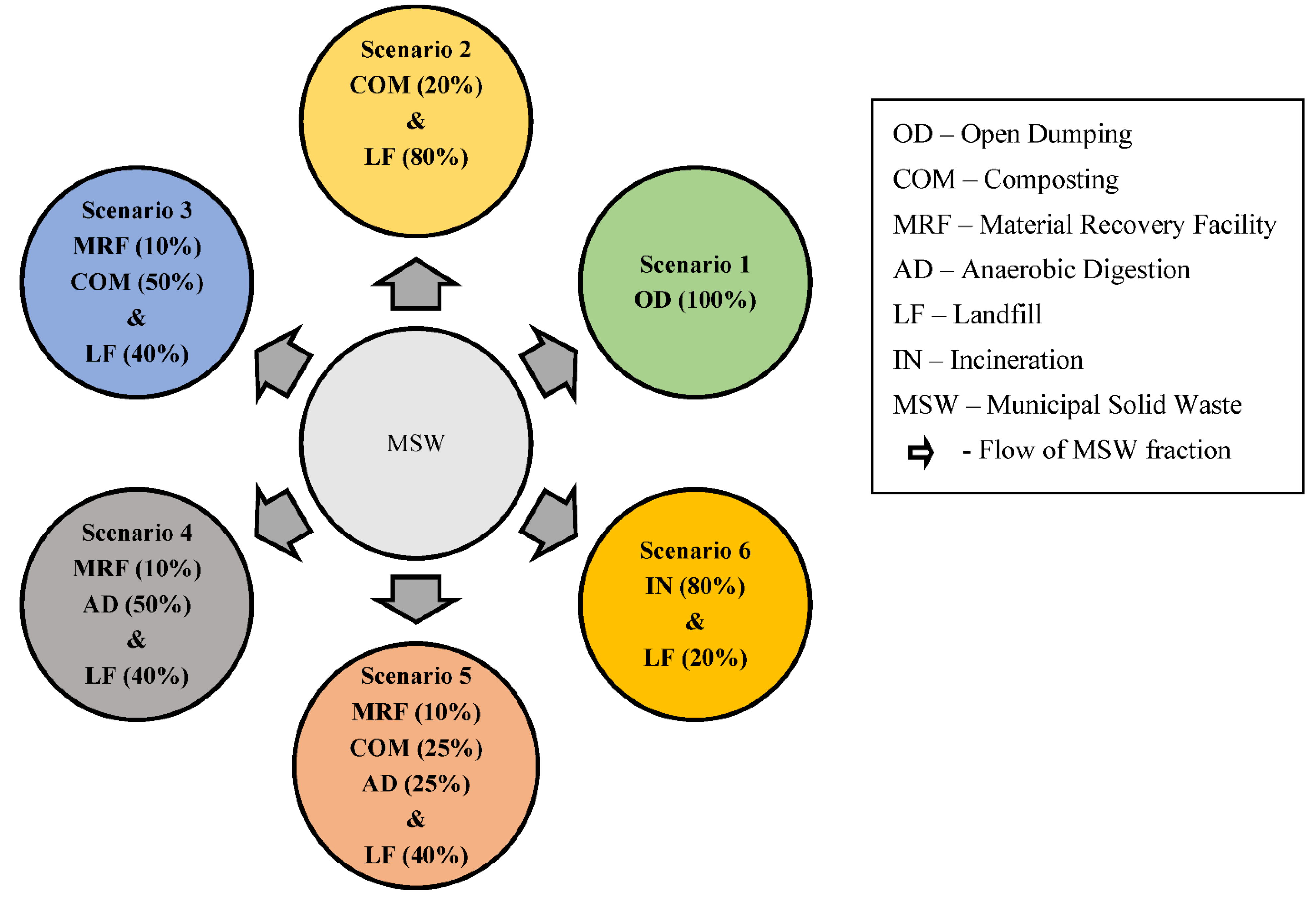

2.4. MSW Management System Scenarios

2.4.1. Scenario 1 (S1): Baseline or Current Scenario:

2.4.2. Scenario 2 (S2): Composting Combined with Landfilling

2.4.3. Scenario 3 (S3): Material Recovery Facility, Composting Combined with Landfilling

2.4.4. Scenario 4 (S4): MRF, AD Combined with Landfilling

2.4.5. Scenario 5 (S5): Material Recovery Facility, Composting, and Anaerobic Digestion Combined with Landfilling

2.4.6. Scenario 6 (S6): Incineration Combined with Landfilling

2.5. Life Cycle Inventory

2.5.1. Transportation

2.5.2. Material Recovery Facility

2.5.3. Composting

2.5.4. Anaerobic Digestion

2.5.5. Landfilling

2.5.6. Incineration

2.6. Sensitivity Analysis and Life Cycle Impact Assessment

3. Results and Discussion

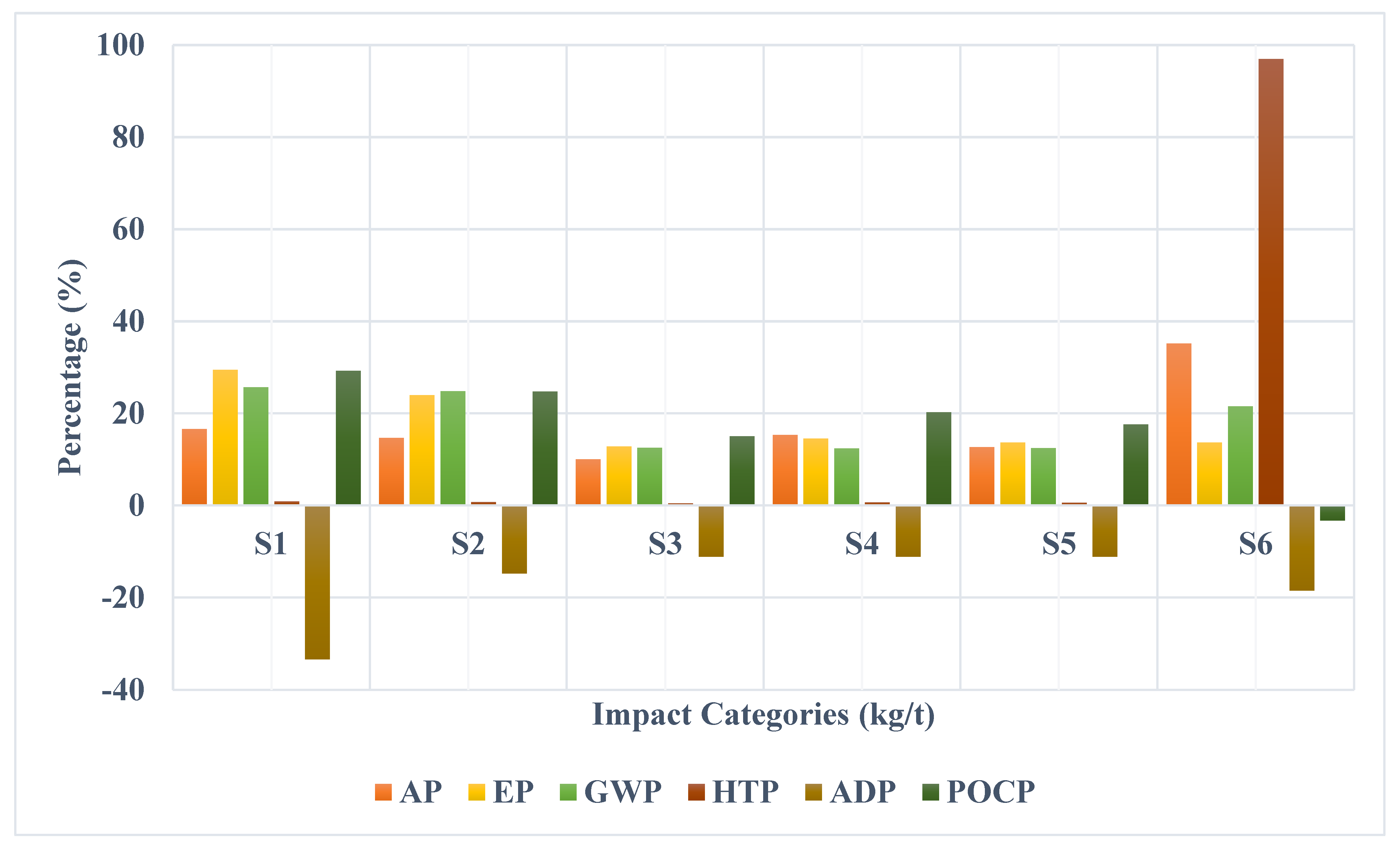

3.1. Environmental Impacts of MSW Management Scenarios

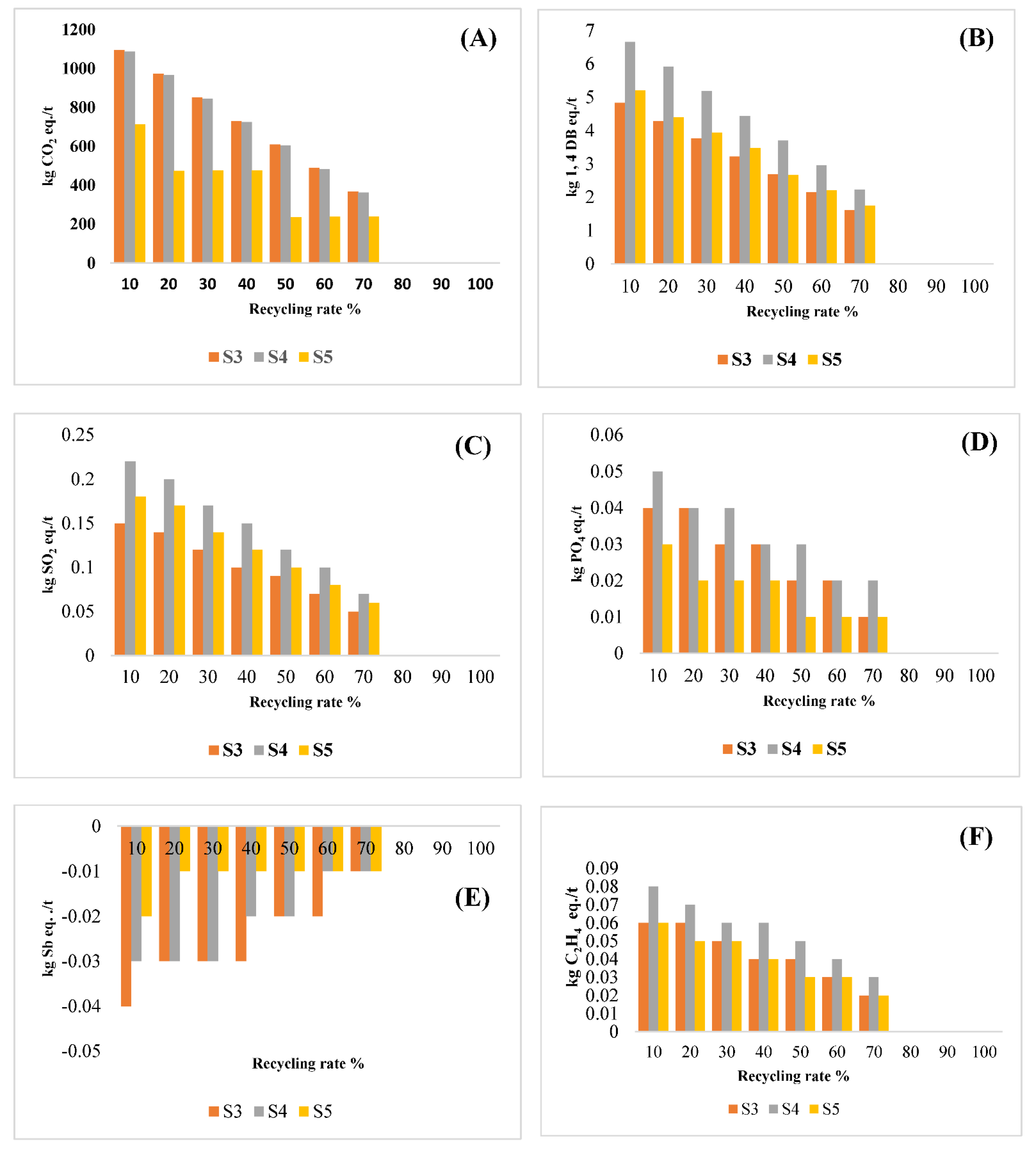

3.2. Sensitivity Analysis

4. Conclusions and Recommendations

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AD | Anaerobic Digestion |

| AP | Acidification Potential |

| CH4 | Methane |

| CO2 | Carbon Dioxide |

| C2H4 | Ethylene |

| CFCs | Chlorofluorocarbons |

| COM | Composting |

| DB | Dichlorobenzene |

| DSTs | Decision Support Tools |

| EP | Eutrophication Potential |

| FEC | Fuel Energy Consumption |

| FU | Functional Unit |

| GHGs | Greenhouse Gases |

| GWP | Global Warming Potential |

| HTP | Human Toxicity Potential |

| ISO | International Organization for Standardization |

| IN | Incineration |

| kWh | Kilowatt Hour |

| Kg | Kilogram |

| Km/L | Kilometer per Litre |

| L | Litre |

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| LCIA | Life Cycle Impact Assessment |

| LFG | Landfill Gas |

| LF | Landfill |

| m3 | Cubic Meter |

| MFA | Material Flow Analysis |

| MSW | Municipal Solid Waste |

| MRF | Material Recovery Facilities |

| MJ | Megajoule |

| Ng | Nanogram |

| N2O | Nitrous Oxide |

| OD | Open Dumping |

| OFMSW | Organic Fraction of Municipal Solid Waste |

| POCP | Photochemical Ozone Creation Potential |

| PO4 | Phosphate |

| Sb | Antimony |

| SO2 | Sulphur Dioxide |

| SWDS | Solid Waste Disposal Sites |

| S1 | Scenario 1 |

| S2 | Scenario 2 |

| S3 | Scenario 3 |

| S4 | Scenario 4 |

| S5 | Scenario 5 |

| S6 | Scenario 6 |

| t | Metric tonne |

| VOCs | Volatile Organic Compounds |

References

- Awasthi, S.K.; Sarsaiya, S.; Kumar, V.; Chaturvedi, P.; Sindhu, R.; Binod, P.; Zhang, Z.; Pandey, A.; Awasthi, M.K. Processing of municipal solid waste resources for a circular economy in China: An overview. Fuel 2022, 317, 123478. [Google Scholar] [CrossRef]

- Logan, M.; Visvanathan, C. Management strategies for anaerobic digestate of organic fraction of municipal solid waste: Current status and future prospects. Waste Manag. Res. 2019, 37, 27–39. [Google Scholar] [CrossRef]

- IPCC. CH4 Emissions from Solid Waste Disposal. In Good Practice Guidance and Uncertainty Management in National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2006; pp. 419–439. Available online: http://www.ipcc-nggip.iges.or.jp/public/gp/bgp/5_1_CH4_Solid_Waste.pdf (accessed on 27 April 2023).

- Uche, M.-A.M. Consideration of Emission Ratios in Integrated Sustainable Municipal Solid Waste Management Planning. In Proceedings of the FIG Congress 2014: Engaging the Challenges-Enhancing the Relevance, Kuala Lumpur, Malaysia, 16–21 June 2014. [Google Scholar]

- Paes, M.X.; de Medeiros, G.A.; Mancini, S.D.; Bortoleto, A.P.; de Oliveira, J.A.P.; Kulay, L.A. Municipal solid waste management: Integrated analysis of environmental and economic indicators based on life cycle assessment. J. Clean. Prod. 2020, 254, 119848. [Google Scholar] [CrossRef]

- Mandpe, A.; Bhattacharya, A.; Paliya, S.; Pratap, V.; Hussain, A.; Kumar, S. Life-cycle assessment approach for municipal solid waste management system of Delhi city. Environ. Res. 2022, 212, 113424. [Google Scholar] [CrossRef] [PubMed]

- Sharma, B.K.; Chandel, M.K. Life cycle assessment of potential municipal solid waste management strategies for Mumbai, India. Waste Manag. Res. 2017, 35, 79–91. [Google Scholar] [CrossRef]

- Rana, R.; Ganguly, R.; Gupta, A.K. Life-cycle assessment of municipal solid-waste management strategies in Tricity region of India. J. Mater. Cycles Waste Manag. 2019, 21, 606–623. [Google Scholar] [CrossRef]

- Khandelwal, H.; Thalla, A.K.; Kumar, S.; Kumar, R. Life cycle assessment of municipal solid waste management options for India. Bioresour. Technol. 2019, 288, 121515. [Google Scholar] [CrossRef]

- Bajracharya, S.; Adhikari, A.; Shrestha, P.P.; Ghimire, A. Life-cycle assessment of solid waste management in Dhulikhel Municipality, Nepal. J. Environ. Eng. Sci. 2022, 17, 147–154. [Google Scholar] [CrossRef]

- Ranabhat, R. Life Cycle Assessment of Municipal Solid Waste Management System in Kathmandu, Nepal. J. Adv. Coll. Eng. Manag. 2016, 1, 97. [Google Scholar] [CrossRef]

- Malla, O.B.; Dangi, M.B.; Khatiwada, N.R. Life Cycle Assessment of Municipal Solid Waste Management in Kathmandu, Nepal. In Abstract Proceedings of 2019 International Conference on Resource Sustainability—Cities (icRS Cities); Elsevier: Amsterdam, The Netherlands; p. 2019. [CrossRef]

- Vea, E.B.; Martinez-Sanchez, V.; Thomsen, M. A review of waste management decision support tools and their ability to assess circular biowaste management systems. Sustainability 2018, 10, 3720. [Google Scholar] [CrossRef]

- ADB. Solid Waste Management in Nepal; Asian Development Bank (ADB): Mandaluyong, Philippines, 2013; Available online: https://www.adb.org/sites/default/files/publication/30366/solid-waste-management-nepal.pdf (accessed on 27 April 2023).

- Rajaeifar, M.A.; Tabatabaei, M.; Ghanavati, H.; Khoshnevisan, B.; Rafiee, S. Comparative life cycle assessment of different municipal solid waste management scenarios in Iran. Renew. Sustain. Energy Rev. 2015, 51, 886–898. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. Amendment. European Standard. 2020. Available online: https://www.iso.org/standard/37456.html (accessed on 1 May 2023).

- McDougall, F.R.; White, P.R.; Franke, M.; Hindle, P. Integrated Solid Waste Management: A Life Cycle Inventory; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Ghimire, A.; Sen, R.; Annachhatre, A.P. Biosolid management options in cassava starch industries of Thailand: Present practice and future possibilities. Procedia Chemistry 2015, 14, 66–75. [Google Scholar] [CrossRef]

- Banepa Municipality. Available online: https://banepamun.gov.np/ (accessed on 27 April 2023).

- Al-Rumaihi, A.; McKay, G.; Mackey, H.R.; Al-Ansari, T. Environmental impact assessment of food waste management using two composting techniques. Sustainability 2020, 12, 1595. [Google Scholar] [CrossRef]

- Kumar, A.; Samadder, S.R. Performance evaluation of anaerobic digestion technology for energy recovery from organic fraction of municipal solid waste: A review. Energy 2020, 197, 117253. [Google Scholar] [CrossRef]

- Ananthakrishnan, R.; Sudhakar, K.; Goyal, A.; Sravan, S.S. Economic feasibility of substituting LPG with biogas for MANIT hostels. Int. J. ChemTech Res. 2013, 5, 891–893. [Google Scholar]

- Ecoscore 2020. Available online: https://ecoscore.be/?locale=en (accessed on 18 June 2023).

- Shrestha, P.K. Leachate Characterization and Management at Sisdol Landfill Site in Nepal. J. Dev. Innov. 2017, 1, 60–83. [Google Scholar]

- Swar, S.S.; Boonnorat, J.; Ghimire, A. Algae-based treatment of a landfill leachate pretreated by coagulation-flocculation. J. Environ. Manag. 2023, 342, 118223. [Google Scholar] [CrossRef]

- Dangi, M.B.; Schoenberger, E.; Boland, J.J. Assessment of environmental policy implementation in solid waste management in Kathmandu, Nepal. Waste Manag. Res. 2017, 35, 618–626. [Google Scholar] [CrossRef] [PubMed]

- Yay, A.S.E. Application of life cycle assessment (LCA) for municipal solid waste management: A case study of Sakarya. J. Clean. Prod. 2015, 94, 284–293. [Google Scholar] [CrossRef]

- IPCC. CH5 Incineration and Open Burning of Waste. Good Practice Guidance and Uncertainty Management in National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2006; Volume 22, pp. 14–24. Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/pdf/5_Volume5/V5_5_Ch5_IOB.pdf (accessed on 27 April 2023).

- Canadian Council of Ministers of the Environment. Biosolids Emissions Assessment Model (BEAM) User’s Guide (BEAM Version 1.3) [Report]; CCME: Winnipeg, MB, Canada, 2009. [Google Scholar]

- Mannheim, V. Perspective: Comparison of end-of-life scenarios of municipal solid waste from viewpoint of life cycle assessment. Front. Built Environ. 2022, 8. [Google Scholar] [CrossRef]

- Avató, J.L.; Mannheim, V. Life Cycle Assessment Model of a Catering Product: Comparing Environmental Impacts for Different End-of-Life Scenarios. Energies 2022, 15, 5423. [Google Scholar] [CrossRef]

- ROU. Life Cycle Inventory and Life Cycle Assessment for Windrow Composting Systems; Recycled Organics Unit (ROU), The University of New South Wales: Sydney, Australia, 2007; p. 166. Available online: https://www.epa.nsw.gov.au/resources/warrlocal/060400-windrow-assess.pdf (accessed on 22 February 2023).

- Møller, J.; Boldrin, A.; Christensen, T.H. Anaerobic digestion and digestate use: Accounting of greenhouse gases and global warming contribution. Waste Manag. Res. 2009, 27, 813–824. [Google Scholar] [CrossRef] [PubMed]

| Inventory for Background Data | |||||||

|---|---|---|---|---|---|---|---|

| Inputs from Technosphere | Unit | S1 | S2 | S3 | S4 | S5 | S6 |

| Diesel | L | 18.52 | 2.67 | 2.47 | 2.47 | 2.80 | 2.40 |

| Electricity | kWh | - | 0.54 | 1.35 | 15.25 | 8.30 | 56.00 |

| By-Product | |||||||

| Compost | T | - | 0.07 | 0.17 | - | 0.08 | - |

| Digestate | T | - | - | - | 0.43 | 0.21 | - |

| Biogas | m3 | - | - | - | 1.50 | 1.50 | - |

| Electricity | kWh | - | - | - | 22.68 | 22.68 | - |

| Heat | MJ | - | - | - | 25.52 | 25.52 | - |

| Inventory for Foreground Data | |||||||

| Air Emission | Unit | S1 | S2 | S3 | S4 | S5 | S6 |

| CO2 eq. | kg | 2004.56 | 1930.60 | 974.82 | 948.19 | 969.53 | 1679.90 |

| PO4 eq. | kg | 0.09 | 0.07 | 0.04 | 0.04 | 0.04 | 1.42 |

| SO2 eq. | kg | 0.24 | 0.21 | 0.15 | 0.23 | 0.19 | 0.52 |

| 1,4 DB eq. | kg | 8.15 | 7.04 | 4.55 | 6.58 | 5.57 | 944.56 |

| Sb eq. | kg | −0.09 | −0.07 | −0.03 | −0.03 | −0.03 | −0.05 |

| C2H4 eq. | kg | 0.12 | 0.10 | 0.06 | 0.08 | 0.07 | −0.01 |

| Activities Contributing to GHG’s | Unit | S1 | S2 | S3 | S4 | S5 | S6 |

| Uncollected Landfill gas | kg CO2 eq./t | 1994.57 | 1928.48 | 964.24 | 964.24 | 964.24 | 482.12 |

| Transportation | 10.00 | 1.30 | 1.30 | 1.30 | 1.30 | 1.30 | |

| Composting | - | 6.12 | 22.33 | - | 11.17 | - | |

| Anaerobic Digestion | - | - | - | 42.00 | 30.06 | - | |

| Incineration | - | - | - | - | - | 1196.14 | |

| Electricity consumption (Treatment option) | - | 0.00 | 0.01 | 0.09 | 0.05 | 0.34 | |

| Diesel Consumption (Treatment Option) | - | 0.72 | 1.98 | 0.19 | 1.09 | - | |

| Activities Causing Benefits | Unit | S1 | S2 | S3 | S4 | S5 | S6 |

| Replacing LPG gas by biogas | kg CO2 eq./t | - | - | - | 44.96 | 22.48 | - |

| Avoidance of inorganic fertilizer (compost) | - | 1.40 | 3.49 | - | 1.75 | - | |

| Avoidance of inorganic fertilizer (digestate) | - | - | - | 9.21 | 4.61 | - | |

| Carbon sequestration from digestate application | - | - | - | 3.40 | 1.70 | - | |

| Carbon sequestration from compost application | - | 4.62 | 11.55 | - | 5.78 | - | |

| Avoidance from electricity generation (AD) | - | - | - | 0.14 | 0.14 | - | |

| Avoidance from fuel consumption (AD) | - | - | - | 1.92 | 1.92 | - | |

| Total GHG’s contribution (kg CO2 eq./t) | 2004.56 | 1930.60 | 974.82 | 948.19 | 969.53 | 1679.90 | |

| Scenario–MSW Management Systems | Acidification Potential, AP (kgSO2 eq./t) | Eutrophication Potential, EP (kg PO4 eq./t) | Global Warming Potential, GWP (kg CO2 eq./t) | Human Toxicity Potential, HTP (kg 1,4-DB eq./t) | Abiotic Depletion Potential, ADP (kg Sb eq./t) | Photochemical Oxidation, POCP (kg C2H4 eq./t) |

|---|---|---|---|---|---|---|

| Scenario 1 (Baseline) | 0.24 | 0.09 | 2004.56 | 8.15 | −0.09 | 0.12 |

| Scenario 2 (Co-LF) | 0.21 | 0.07 | 1930.60 | 7.04 | −0.07 | 0.10 |

| Scenario 3 (MRF-Co-LF) | 0.15 | 0.04 | 974.82 | 4.55 | −0.03 | 0.06 |

| Scenario 4 (MRF-AD-LF) | 0.23 | 0.04 | 948.19 | 6.58 | −0.03 | 0.08 |

| Scenario 5 (MRF-Co-AD-LF) | 0.19 | 0.04 | 969.53 | 5.57 | −0.03 | 0.07 |

| Scenario 6 (MRF-In) | 0.52 | 0.04 | 1679.90 | 944.56 | −0.05 | −0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shrestha, P.P.; Ghimire, A.; Dangi, M.B.; Urynowicz, M.A. Development of a Municipal Solid Waste Management Life Cycle Assessment Tool for Banepa Municipality, Nepal. Sustainability 2023, 15, 9954. https://doi.org/10.3390/su15139954

Shrestha PP, Ghimire A, Dangi MB, Urynowicz MA. Development of a Municipal Solid Waste Management Life Cycle Assessment Tool for Banepa Municipality, Nepal. Sustainability. 2023; 15(13):9954. https://doi.org/10.3390/su15139954

Chicago/Turabian StyleShrestha, Prasesh Pote, Anish Ghimire, Mohan B. Dangi, and Michael A. Urynowicz. 2023. "Development of a Municipal Solid Waste Management Life Cycle Assessment Tool for Banepa Municipality, Nepal" Sustainability 15, no. 13: 9954. https://doi.org/10.3390/su15139954

APA StyleShrestha, P. P., Ghimire, A., Dangi, M. B., & Urynowicz, M. A. (2023). Development of a Municipal Solid Waste Management Life Cycle Assessment Tool for Banepa Municipality, Nepal. Sustainability, 15(13), 9954. https://doi.org/10.3390/su15139954