Comparative Analysis of Direct Operating Costs: Conventional vs. Hydrogen Fuel Cell 19-Seat Aircraft

Abstract

1. Introduction

1.1. Technological Development of Hydrogen Aircraft

1.2. Economical Studies of Hydrogen Aircraft

2. Carriers Operating 19-Seat Aircraft in Europe

- On Mondays and Fridays the carrier operates on the relation. Osijek–Zagreb–Osjek–Pula–Split–Pula–Osjek–Zagreb–Osjek.

- On Tuesday and Thursday the carrier operates on the relation Osijek–Rijeka–Split–Dubrovik–Split–Rijeka–Osjek.

- On Wednesday the aircraft performs two return flights Osjek–Zagreb–Osjek, one in the morning and one in the evening.

3. Direct Operating Cost

3.1. Depreciation, Insurance and Interest Cost

3.2. Aircraft Price

3.3. Maintenance and Crew Cost

3.4. Fuel Cost

3.5. Fees and Charges

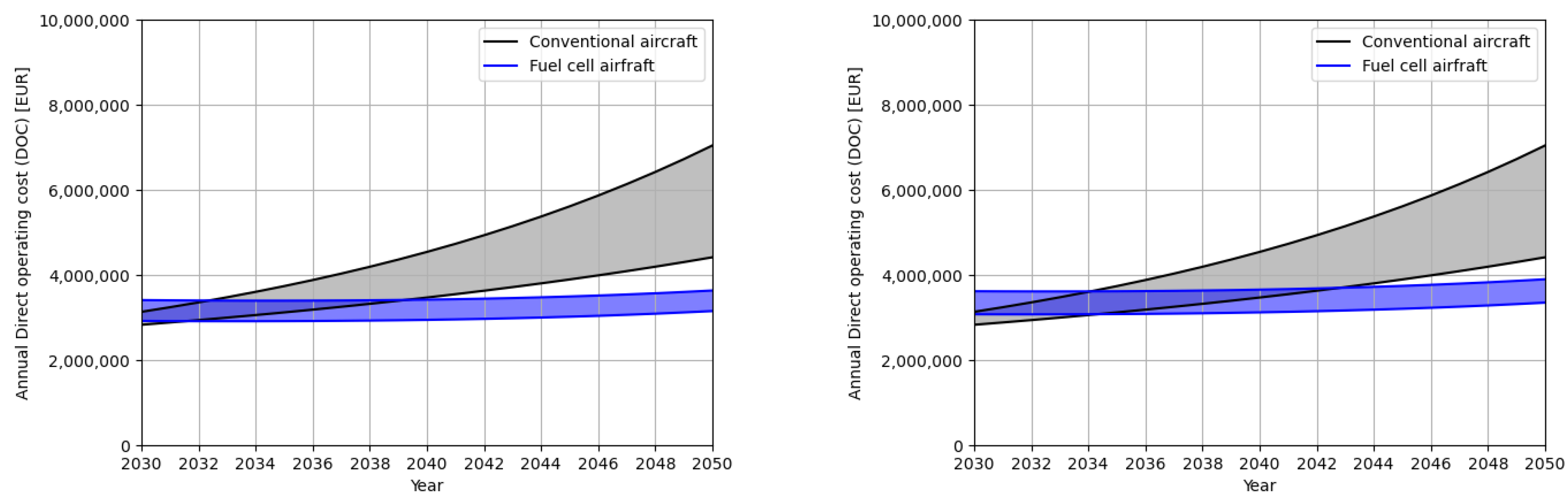

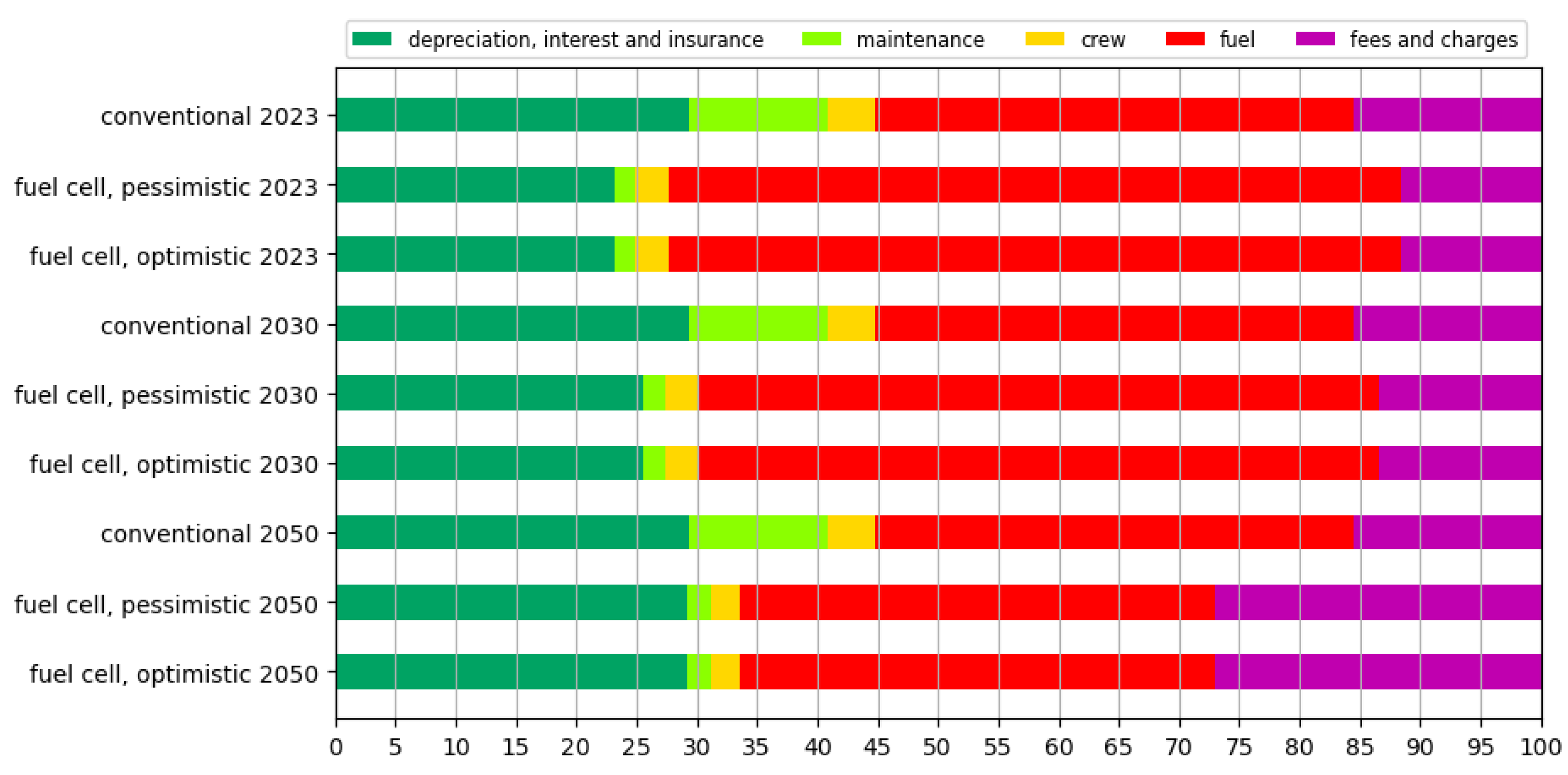

3.6. Time Development of DOC

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AEA | Association of European Airliners |

| AI | Airbus Industries |

| BET | Beechcraft 1900D |

| CRCO | Central Route Charges Office |

| D28 | Dornier 228 NG |

| DLH | Lufthansa |

| DLR | German Aerospace Center |

| DHC | DHC-6 Twin Otter |

| DOC | direct operating cost |

| EU | European Union |

| FSH | Fairchild Swearingen Metroliner |

| IATA | International Air Transport Association |

| ICAO | International Civil Aviation Organization |

| ICE | internal combustion engine |

| IOC | indirect operating cost |

| J31 | British Aerospace Jetstream |

| L410 | Aircraft Industries L410 NG |

| LCI | Labour cost index |

| MTOM | Maximal take-off mass |

| PPI | producer price index |

| UK | United Kingdom |

| Symbol | Definition | Value | Reference |

| Material cost per flight hour for conv. aircraft | 193.96 EUR | [56] | |

| Material cost per flight hour for fuel cell aircraft | 33.945 EUR | [56] | |

| g | gravitational acceleration constant | 9.81 m/s | |

| Annual insurance rate | 0.01 | [54] | |

| Annual interest rate | 0.05 | [56] | |

| Lift to drag ratio in cruise | 18 | [12] | |

| Useful life of aircraft | 20 years | [53] | |

| Power-specific fuel consumption for conv. aircraft | kg/J | [12] | |

| Power-specific fuel consumption for fuel cell aircraft | kg/J | [12] | |

| Service time per flight hour for conv. aircraft | 1.027 h | [56] | |

| Service time per flight hour for fuel cell aircraft | 1.025 h | [56] | |

| Average time between two flights | 0.5 h | [38] | |

| Propeller efficiency | 0.8 | [12] |

| Symbol | Definition |

| Annual cru cost [EUR] | |

| Cabin crew hourly rate [EUR] | |

| Annual depreciation costs [EUR] | |

| Annual direct operating costs [EUR] | |

| Hourly rate of aircraft engineer [EUR] | |

| Fuell cell system price [EUR] | |

| Annual fees and charges [EUR] | |

| Part of airport charge charged per passenger [EUR] | |

| Part of airport charge charged per tonne of MTOM [EUR] | |

| Airport charges cost at the origin airport [EUR] | |

| Airport charges cost at the destination airport [EUR] | |

| Annual parking costs [EUR] | |

| Route charge costs [EUR] | |

| Terminal charge cost [EUR] | |

| Part of airport charge charged per aircraft [EUR] | |

| Annual fuel costs [EUR] | |

| Fuel costs [EUR] | |

| Annual insurance costs [EUR] | |

| Annual interest costs [EUR] | |

| Annual maintenance costs [EUR] | |

| Annual maintenance cost of fuel cells [EUR] | |

| Maintenance cost of fuel cells pef flight hour [EUR] | |

| Material cost per flight hour [EUR/h] | |

| Daily unit rate for parking costs [EUR] | |

| Pilot/co-pilot hourly rate [EUR] | |

| Cost in year Y [EUR] | |

| Cost in 2022 [EUR] | |

| I | Corresponding index rate (Labour index rate, Platts index, producer price index) |

| MTOM of aircraft in tonnes truncated to a whole number (INT 7,8 = 7) [-] | |

| Mass fraction at the beginning of the flight phase [-] | |

| Mass fraction at cruise [-] | |

| Mass fraction at the end of the flight phase [-] | |

| Mission segment mass fractions [-] | |

| Route unit charge [EUR] | |

| Terminal unit charge [EUR] | |

| Fuel capacity of the tank [kg] | |

| Mass of fuel consumed during the flight [kg] | |

| Share of fuel consumed in a flight [-] | |

| Mass of the i-th part of conventional aircraft [kg] | |

| Mass of the i-th part of hydrogen fuel cell aircraft [kg] | |

| Maximum take- off mass [t,kg] | |

| Hourly block hours [h/year] | |

| Annual number of flights [-] | |

| Number of outbound and return flights with the same origin and destination | |

| Annual number of flight hours by aircraft [-] | |

| Number of passengers [-] | |

| Price of aircraft [EUR] | |

| Price of conventional aircraft [EUR] | |

| Price of engine group of hydrogen fuel cell aircraft [EUR] | |

| Power of electric motor [kW] | |

| Price of fuel (kerosene or hydrogen) [EUR/kg] | |

| Power of fuel cell system [kW] | |

| Share of i-th part in the manufacturing cost of a conventional aircraft [-] | |

| Price of the i-th part of a fuel cell aircraft [EUR] | |

| R | Distance between arrival and departure airports [km] |

| Distance travelled by aircraft in cruise flight [m] | |

| Service time per flight hour [h] |

References

- IATA. Air Passenger Market Analysis. 2023. Available online: https://www.iata.org/en/iata-repository/publications/economic-reports/air-passenger-market-analysis2/ (accessed on 13 April 2023).

- ICAO. ICAO Forecasts Complete and Sustainable Recovery and Growth of Air Passenger Demand in 2023. 2023. Available online: https://www.icao.int/Newsroom/Pages/ICAO-forecasts-complete-and-sustainable-recovery-and-growth-of-air-passenger-demand-in-2023.aspx (accessed on 13 April 2023).

- European Commision. EU Climate Action and the European Green Deal. 2021. Available online: https://ec.europa.eu/clima/policies/eu-climate-action_en (accessed on 13 April 2023).

- Dray, L.M.; Evans, A.; Schäfer, A. The Impact of Economic Emissions Mitigation Measures on Global Aircraft Emissions; Institute for Aviation and the Environment, University of Cambridge: Cambridge, UK, 2010; Available online: http://www.atslab.org/wp-content/uploads/2017/01/ATIO2010Dray.pdf (accessed on 12 October 2022).

- Hassan, M.; Payan, A.P.; Pfaender, H.; Garcia, E. Framework Development for Performance Evaluation of the Future National Airspace System. In Proceedings of the 15th AIAA Aviation Technology, Integration, and Operations Conference, Dallas, TX, USA, 22–26 June 2015; Available online: https://www.researchgate.net/profile/Alexia-Payan-2/publication/280114298_Framework_Development_for_Performance_Evaluation_of_the_Future_National_Airspace_System/links/55ba3e9808aec0e5f43e96e8/Framework-Development-for-Performance-Evaluation-of-the-Future-National-Airspace-System.pdf (accessed on 12 October 2022).

- Owen, B.; Lee, D.S.; Lim, L. Flying into the future: Aviation emissions scenarios to 2050. Environ. Sci. Technol. 2010, 44, 2255–2260. [Google Scholar] [CrossRef] [PubMed]

- Timmis, A.J.; Hodzic, A.; Koh, L.; Bonner, M.; Soutis, C.; Schäfer, A.W.; Dray, L. Environmental impact assessment of aviation emission reduction through the implementation of composite materials. Int. J. Life Cycle Assess. 2015, 20, 233–243. [Google Scholar] [CrossRef]

- Schilling, T.; Rötger, T.; Wicke, K. Assessment of the Impact of Radically Climate-Friendly Aviation Technologies. 2016. Avalilable online: https://core.ac.uk/download/pdf/77231037.pdf (accessed on 12 October 2022).

- ICAO. Doc 10075: Assembly Resolutions in Force (as of 6 October 2016). 2016. Available online: https://www.icao.int/meetings/a39/documents/resolutions/10075_en.pdf (accessed on 13 April 2023).

- Air Transport Action Group. Waypoint 2050: An Air Transport Action Group Project. 2020. Available online: https://aviationbenefits.org/media/167187/w2050_full.pdf (accessed on 12 October 2022).

- IATA. Aircraft Technology Roadmap to 2050. 2019. Available online: https://www.iata.org/contentassets/8d19e716636a47c184e7221c77563c93/Technology-roadmap-2050.pdf (accessed on 12 October 2022).

- Marksel, M.; Prapotnik Brdnik, A. Maximum Take-Off Mass Estimation of a 19-Seat Fuel Cell Aircraft Consuming Liquid Hydrogen. Sustainability 2022, 14, 8392. [Google Scholar] [CrossRef]

- Trainelli, L.; Salucci, F.; Comincini, D.; Riboldi, C.E.D.; Rolando, A. Italian Association of Aeronautic and Astronautic. In Proceedings of the XXV International Congress, Rome, Italy, 9–12 September 2019; Available online: https://mahepa.eu/wp-content/uploads/2020/06/Sizing-and-Performance-of-Hydrogen-Driven-Airplanes.pdf (accessed on 24 May 2022).

- Vonhoff, G.L.M. Conceptual Design of Fuel Cell Aircraft. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2021. Available online: https://repository.tudelft.nl/islandora/object/uuid%3A8bd63dec-b67b-496b-92bc-3d5c07ff859f (accessed on 24 May 2022).

- Verstraete, D.; Hendrick, P.; Pilidis, P.; Ramsden, K. Hydrogen fuel tanks for subsonic transport aircraft. Int. J. Hydrogen Energy 2010, 35, 11085–11098. [Google Scholar] [CrossRef]

- Winnefeld, C.; Kadyk, T.; Bensmann, B.; Krewer, U.; Hanke-Rauschenbach, R. Modelling and Designing Cryogenic Hydrogen Tanks for Future Aircraft Applications. Energies 2018, 11, 105. [Google Scholar] [CrossRef]

- Silberhorn, D.; Atanasov, G.; Walther, J.-N.; Zill, T. Assesment of Hydrogen Fuel Tank Integration at Aircraft Level. Available online: https://core.ac.uk/download/pdf/237080603.pdf (accessed on 24 May 2022).

- Subodh, K.M.; Gyekenyesi, J.Z.; Arnold, S.M.; Sullivan, R.M.; Manderscheid, J.M.; Murthy, P.L.N. Review of Current State of the Art and Key Design Issues with Potential Solutions for Liquid Hydrogen Cryogenic Storage Tank Structures for Aircraft Applications. NASA/TM—2006-214346. Available online: https://ntrs.nasa.gov/api/citations/20060056194/downloads/20060056194.pdf (accessed on 24 May 2022).

- Ayar, M.; Karakoc, T.H. Decision mechanism between fuel cell types: A case study for small aircraft. Int. J. Hydrogen Energy 2023, 48, 23156–23167. [Google Scholar] [CrossRef]

- Kazula, S.; de Graaf, S.; Enghardt, L. Review of fuel cell technologies and evaluation of their potential and challenges for electrified propulsion systems in commercial aviation. J. Glob. Power Propuls. Soc. 2023, 7, 43–57. [Google Scholar] [CrossRef]

- DLR, Antares DLR-H2–Out of Operation. Available online: https://www.dlr.de/content/en/articles/aeronautics/research-fleet-nfrastructure/dlr-research-aircraft/antares-dlr-h2-out-of-operation.html (accessed on 24 May 2022).

- Aerospace Testing International, H2FLY to Double the Range of Hydrogen Fuel Cell Test Aircraft. Available online: https://www.aerospacetestinginternational.com/news/electric-hybrid/h2fly-to-double-the-range-of-hydrogen-fuel-cell-test-aircraft.html (accessed on 22 September 2022).

- ZeroAvia. ZeroAvia Secures £12.3m UK Government Grant to Bring 19-Seat Hydrogen-Electric Aviation Powertrain to Market. 2020. Available online: https://www.zeroavia.com/press-release-hyflyer-2-grant (accessed on 22 September 2022).

- Malewar, A. AeroDelft’s Phoenix Two-Seater Aims to be the World’s First Liquid-Hydrogen Aircraft. 2021. Available online: https://www.inceptivemind.com/aerodelft-phoenix-two-seater-worlds-first-liquid-hydrogen-aircraft/18055/ (accessed on 22 September 2022).

- CISION. ZeroAvia Makes Aviation History, Flying World’s Largest Aircraft Powered with a Hydrogen-Electric Engin. 2023. Available online: https://www.prnewswire.com/news-releases/zeroavia-makes-aviation-history-flying-worlds-largest-aircraft-powered-with-a-hydrogen-electric-engine-301726022.html (accessed on 1 February 2023).

- McKinsey. Fuel Cells and Hydrogen 2 Joint Undertaking, Hydrogen-Powered Aviation: A Fact-based Study of Hydrogen Technology, Economics, and Climate Impact by 2050. 2020. Available online: https://data.europa.eu/doi/10.2843/471510 (accessed on 20 September 2022).

- Ploetner, K.O.; Schmidt, M.; Baranowski, D.; Isikveren, A.T.; Hornung, M. Operating cost estimation for electric-powered transport aircraft. In Proceedings of the Aviation Technology, Integration, and Operations Conference, Los Angeles, CA, USA, 12–14 August 2013. [Google Scholar] [CrossRef]

- Monjon, M.; Freire, C. Conceptual Design and Operating Costs Evaluation of a 19-seat All- Electric Aircraft for Re-gional Aviation. In Proceedings of the AIAA Propulsion and Energy 2020 Forum, Virtual event, 24–28 August 2020. [Google Scholar] [CrossRef]

- Shahwan, K. Operating Cost Analysis of Electric Aircraft on Regional Routes 56. 2021. Available online: https://liu.diva-portal.org/smash/get/diva2:1631695/FULLTEXT01.pdf (accessed on 20 September 2022).

- Scholz, A.E.; Trifonov, D.; Hornung, M. Environmental life cycle assessment and operating cost analysis of a conceptual battery hybrid-electric transport aircraft. CEAS Aeronaut. J. 2022, 13, 215–235. [Google Scholar] [CrossRef]

- Ahluwalia, R.K.; Cetinbas, C.F.; Peng, J.; Wang, X.; Papadias, D. Total Cost of Ownership (TCO) Analysis of Hydrogen Fuel Cells in Aviation. 2020. Available online: https://www.energy.gov/sites/prod/files/2020/12/f81/hfto-h2-airports-workshop-2020-ahluwalia (accessed on 24 April 2023).

- Let-410 Turbolet Technical Aata. Available online: https://web.archive.org/web/20190423024417/http://www.let.cz/files/file/KeStazeni/2016/EN_Brochure_L410_UVP-E20.pdf (accessed on 24 May 2022).

- De Havilland Canada DHC-6 Twin Otter Technical Data. Available online: https://www.vikingair.com/twin-otter-series-400/technical-description (accessed on 24 May 2022).

- Dornier 228 Technical Data. Available online: https://web.archive.org/web/20160301232353/http://www.dornier228.com/fileadmin/ruag/DO228NG/PDFs/broschueren/Facts_Booklet_Dornier_228_MR.pdf (accessed on 24 May 2022).

- Beechcraft 1900 Technical Data. Available online: https://web.archive.org/web/20161223060857/http://www.airweb.faa.gov/Regulatory_and_Guidance_Library/rgMakeModel.nsf/0/6be5914ffaf7db0b86257f24005636e2/\protect\T1\textdollarFILE/A24CE_Rev_113.pdf (accessed on 24 May 2022).

- British Aerospace Jetstream Technical Data. Available online: http://www.flugzeuginfo.net/acdata_php/acdata_js31_en.php (accessed on 24 May 2022).

- Donald, D. Encyclopedia of World Aircraft; Prospero Books: Etobicoke, ON, Canada, 1997; p. 388. [Google Scholar]

- OAG Organization. OAG Schedules Analyser. Available online: https://www.oag.com/schedules-analyser (accessed on 16 May 2019).

- Available online: https://en.wikipedia.org/wiki/Aurigny (accessed on 5 July 2023).

- Available online: https://en.wikipedia.org/wiki/British_Eagle (accessed on 5 July 2023).

- Available online: https://en.wikipedia.org/wiki/Isles_of_Scilly_Skybus (accessed on 5 July 2023).

- Available online: https://en.wikipedia.org/wiki/Loganair (accessed on 5 July 2023).

- Available online: https://en.wikipedia.org/wiki/Norlandair (accessed on 5 July 2023).

- Available online: https://en.wikipedia.org/wiki/Sevenair_Air_Services (accessed on 5 July 2023).

- Available online: https://en.wikipedia.org/wiki/Silver_Air_(Czech_Republic) (accessed on 5 July 2023).

- TradeAir. Available online: https://www.trade-air.com/ (accessed on 22 September 2022).

- Available online: https://en.wikipedia.org/wiki or https://en.wikipedia.org/wiki/Transaviabaltika (accessed on 5 July 2023).

- Available online: https://en.wikipedia.org/wiki/Twin_Jet (accessed on 5 July 2023).

- Available online: https://en.wikipedia.org/wiki/Van_Air_Europe (accessed on 5 July 2023).

- Oliver Wyman. Global Fleet & MRO Market Forecast Commentary 2021–2031. Available online: https://www.oliverwyman.com/content/dam/oliver-wyman/v2/media/2021/feb/Global_FLeet_and_MRO_Market_Forecast_2021-2031_OW.pdf (accessed on 20 September 2022).

- Scholz, D. Lecture Notes: Aircraft Design, Hamburg University of Applied Sciences. 2015. Available online: http://HOOU.ProfScholz.de (accessed on 20 September 2022).

- Available online: https://cleansky.paddlecms.net/sites/default/files/2021-10/TE-FGA-TR_en.pdf (accessed on 22 September 2022).

- Hoelzen, J.; Liu, Y.; Bensmann, B.; Winnefeld, C.; Elham, A.; Friedrichs, J.; Hanke-Rauschenbach, R. Conceptual Design of Operation Strategies for Hybrid Electric Aircraft. Energies 2018, 11, 217. [Google Scholar] [CrossRef]

- AOPA FINANCE. Sample Aircraft Loan Rates. Available online: https://finance.aopa.org/resources/2016/july/12/sample-aircraft-loan-rates (accessed on 20 September 2022).

- Marsh. General Aviation Insurance Market: Pricing and Risk Update—Q1 2021. Available online: https://www.marsh.com/au/insights/research/aviation-insurance-market-in-2021-why-rates-are-increasing.html (accessed on 20 September 2022).

- Let Aircraft Industries. Direct Operating Costs (DOC) for L410NG; Leaflat Obtained Directly from a Manufacturer; Let Aircraft Industries: Kunovica, Chech Republic, 2023. [Google Scholar]

- Markish, J. Valuation Techniques for Commercial Aircraft Program Design; Massachusetts Institute of Technology: Cambridge, MA, USA, 2002. [Google Scholar]

- Raymer, D.P. Aircraft Design: A Conceptual Approach, 6th ed.; American Institute of Aeronautics and Astronautics, Inc.: Washington, DC, USA, 2018. [Google Scholar]

- Fuel Cells and Hydrogen Joint Undertaking. Multi—Annual Work Plan 2014–2020. Available online: https://ec.europa.eu/research/participants/data/ref/h2020/other/legal/jtis/fch-multi-workplan_en.pdf (accessed on 20 September 2022).

- Ehelix. Integral Powertrain. Available online: https://integralp.com (accessed on 20 September 2022).

- EMRAX Motors Used for Aviation Applications. Available online: https://emrax.com (accessed on 20 September 2022).

- Cyrospain. Cryogenic Engineering Adapted to the Needs of Each. Available online: https://cryospain.com (accessed on 9 March 2022).

- Stirweld. Hydrogen Cryogenic Tank: A forward-looking Concept for Aeronautics. Available online: https://stirweld.com/en/hydrogen-cryogenic-tank-a-forward-looking-concept-for-aeronautics (accessed on 9 March 2022).

- ERI, SalaryExpert. Available online: https://www.salaryexpert.com (accessed on 20 September 2022).

- U.S. Department of Energy. Extend the Operating Life of Your Motor. Available online: https://www.energy.gov/sites/prod/files/2014/04/f15/extend_motor_operlife_motor_systemts3.pdf (accessed on 20 September 2022).

- Aerospace Technology Institute. Cryogenic Hydrogen Fuel System and Storage: Roadmap Report. 2022. Available online: FZO-PPN-COM-0027-Cryogenic-Hydrogen-Fuel-System-and-Storage-Roadmap-Report.pdf (accessed on 20 September 2022).

- Thompson, S.T.; James, B.D.; Huya-Kouadio, J.M.; Houchins, C.; DeSantis, D.A.; Ahluwalia, R.; Wilson, A.R.; Kleen, G.; Papageorgopoulos, D. Direct hydrogen fuel cell electric vehicle cost analysis: System and high- volume manufacturing description, validation, and outlook. J. Power Sources 2018, 399, 304–313. [Google Scholar] [CrossRef]

- Kleen, G.; Padgett, E. DOE Hydrogen Program Record. Department of Energy USA. 2021. Available online: https://www.hydrogen.energy.gov/pdfs/21001-durability-adjusted-fcs-cost.pdf (accessed on 5 July 2023).

- EUROCONTROL. Adjusted Unit Rates Applicable to September 2022 Flights. Available online: https://www.eurocontrol.int/publication/monthly-adjusted-unit-rates-september-2022 (accessed on 22 September 2022).

- Available online: https://www.eurocontrol.int/ServiceUnits/Dashboard/TerminalUnitRatesInForce.html (accessed on 22 September 2022).

- Kerosene Prices for Different Airports. Available online: https://av-fuel.de/ (accessed on 20 September 2022).

- Kundu, A.J. Aircraft Design, Cambridge Aerospace Series, 1st ed.; Cambridge University Press: New York, NY, USA, 2010. [Google Scholar]

- Roskam, J. Airplane Design. Vol. 8: Airplane Cost Estimation, Design, Development, Manufacturing and Operation, 1st ed.; University of Kansas: Kansas, MI, USA, 1990. [Google Scholar]

- Zagreb Airport. Airport Services Price List. Available online: https://www.zagreb-airport.hr/UserDocsImages/dokumenti/cjenici/Zagreb%20Airport%20Pricelist%20-%20012022.pdf?vel=741404 (accessed on 14 October 2022).

- Split Airport. Price List of Airport Services. Available online: http://www.split-airport.hr/images/CJENIK_ZLS_2021.pdf (accessed on 14 October 2022).

- Dubrovnik Airport. Airport Services and Charges. Available online: https://www.airport-dubrovnik.hr/storage/upload/articles/Cjenik_aerodromskih_usluga_2020_17121.pdf (accessed on 14 October 2022).

- Rijeka Airport. Price List of Airport Regulated Charges. Available online: http://rijeka-airport.hr/pages/sub/36/doc_en/Price-list-regulated-charges-2022.pdf (accessed on 14 October 2022).

- Osjek Airport. Price List of Airport Services. Available online: http://www.osijek-airport.hr/wp-content/uploads/2015/05/CJENIK-USLUGA-U-ZRA%C4%8CNOM-PROMETU-ZL-Osijek.pdf (accessed on 14 October 2022).

- Pula Airport. Price List of Airport Services. Available online: https://airport-pula.hr/wp-content/uploads/2017/09/Cijene-na%C5%A1ih-usluga-kratka-verzija.pdf (accessed on 14 October 2022).

- Quantifying the Opportunity in Green Hydrogen. Available online: https://www.pwc.com/gx/en/industries/energy-utilities-resources/future-energy/green-hydrogen-cost.html (accessed on 20 September 2022).

- Hydrogen Valley. Hydrogen Cost and Sales Prices. Available online: https://www.h2v.eu/analysis/statistics/financing/hydrogen-cost-and-sales-prices (accessed on 20 September 2022).

- STATISTA. Production Costs of Green Hydrogen Worldwide by Select Country in 2020, with a Forecast until 2050. 2021. Available online: https://www-statista-com.ezproxy.lib.ukm.si/statistics/1086695/green-hydrogen-cost-development-by-country/ (accessed on 20 September 2022).

- Kallo, J.; (Institute for Energy Conversion and Storage, Ulm University, Ulm, Germany). Private communication, 2022.

- Connelly, E.; Penev, M.; Elgowainy, A.; Hunter, C. Current Status of Hydrogen Liquefaction Costs, DOE Hydrogen and Fuel Cells Program Record. Available online: https://www.hydrogen.energy.gov/pdfs/19001_hydrogen_liquefaction_costs.pdf (accessed on 22 September 2022).

- Eurostat. Labour Cost Index (LCI). Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Glossary:Labour_cost_index_(LCI) (accessed on 14 October 2022).

- Eurostat. Producer Price Index (PPI). Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Industrial_producer_price_index_overview#Industrial_producer_prices_-development_since_2010 (accessed on 14 October 2022).

- Office for National Statistics. Producer Price Index (PPI). Available online: https://www.ons.gov.uk/economy/inflationandpriceindices/bulletins/producerpriceinflation/august2022#producer-price-inflation-ppi-annual-growth-rates (accessed on 14 October 2022).

- Statistic Iceland. Changes in the Production Price Index. Available online: https://px.hagstofa.is/pxen/pxweb/en/Efnahagur/Efnahagur_visitolur_5_visitalaframleidslu_framleidsluverdeldra/VIS08000b.px/?rxid=12172a07-e919-4793-868a-fbf15dafe29d (accessed on 14 October 2022).

- S&P Global. Jet Fuel Prices. 2022. Available online: https://www.iata.org/en/publications/economics/fuel-monitor/ (accessed on 14 October 2022).

- Hydrogen Council, McKinsey and Company. Hydrogen Insights. 2021. Available online: https://hydrogencouncil.com/wp-content/uploads/2021/02/Hydrogen-Insights-2021.pdf (accessed on 20 May 2023).

| Name | Code | Year | MTOM [kg] | R [km] | P/MTOM [kW/kg] | MTOM/ [kg/m] |

|---|---|---|---|---|---|---|

| Aircraft Industries L410 NG [32] | L410 | 2010 | 7000 | 2750 | 0.181 | 201 |

| DHC-6 Twin Otter [33] | DHC | 2010 | 5670 | 1480 | 0.197 | 145 |

| Dornier 228 NG [34] | D28 | 2009 | 6575 | 2363 | 0.176 | 205 |

| Beechcraft 1900D [35] | BET | 1984 | 7764 | 2306 | 0.246 | 270 |

| British Aerospace Jetstream [36] | BEJ | 1980 | 6600 | 1260 | 0.202 | 276 |

| Fairchild Swearingen Metroliner [37] | FSM | 1969 | 6577 | 1100 | 0.228 | 227 |

| Name | Country | N | Aircraft by Code | R [km] | [h] | ||

|---|---|---|---|---|---|---|---|

| Aurigny [39] | UK, France | 6 | 2 | D28 | 40 (87) 151 | 1365 | 5774 |

| Eagle Air [40] | Iceland | 6 | 3 | BEJ | 113 (222) 325 | 915 | 3876 |

| Isles of Scilly Skybus [41] | UK | 7 | 4 | DHC | 48 (105) 224 | 735 | 5482 |

| Loganair [42] | UK | 42 | 3 | DHC | 92 (165) 224 | 398 | 1226 |

| Norlandair [43] | Iceland | 5 | 3 | DHC | 60 (109) 150 | 315 | 1132 |

| Sevenair Air Services [44] | Portugal | 14 * | 3 * | D28, BEJ | 60 (120) 610 | 870 * | 6958 |

| Silver Air [45] | Italy | 2 | 2 | L410 | 101 (180) 375 | 216 | 447 |

| Trade Air [46] | Croatia | 7 | 1 | L410 | 193 (247) 386 | 1309 | 1664 |

| Transaviabaltika [47] | Estonia | 2 | 2 | BEJ | 122 (154) 187 | 720 | 2461 |

| Twin Jet [48] | French, Germany | 13 | 13 | BEH | 248 (484) 772 | 818 | 7616 |

| Van Air Europe [49] | UK | 5 | 5 | L410 | 100 (166) 293 | 201 | 1182 |

| Route | [km] | [min] | [min] | |

|---|---|---|---|---|

| Zagreb–Osjek | 214 | 45 | 40 | 312 |

| Osjek–Pula | 386 | 75 | 75 | 104 |

| Osjek–Rijeka | 332 | 65 | 50 | 104 |

| Pula–Split | 240 | 50 | 50 | 104 |

| Rijeka–Split | 230 | 40 | 50 | 104 |

| Split–Dubrovnik | 193 | 45 | 40 | 104 |

| Aircraft type | L410 | DHC | D228 |

| Price [EUR] | 6,455,884 | 5,762,358 | 5,793,742 |

| Country | ||||||

|---|---|---|---|---|---|---|

| UK | 21.47 | 38.69 | 21.6 | 68.97 | / | 1.63–3.48 |

| Iceland | 23.22 | 40.90 | 23.00 | / | / | 2.91 |

| French | 20.75 | 39.61 | 22.27 | 73.02 | 196.34 | 1.81–3.38 |

| Portugal | 12.23 | 23.18 | 13.04 | 42.32 | 158.54 | 2.83 |

| Croatia | 8.35 | 16.97 | 9.54 | 50.42 | 323.71 | 1.64–1.67 |

| Estonia | 8.79 | 17.01 | 9.56 | 32.74 | 90.72 | 1.4 |

| Italy | 19.08 | 35.67 | 20.06 | 80.11 | 214.89 | 1.75–1.93 |

| Airport Unit | EUR/Tonne | EUR/Pass. | EUR | EUR/kg |

|---|---|---|---|---|

| Zagreb [74] | 6.38 | 18.35 | 1.69 | |

| Split [75] | 6.38 | 9.6 | 89 | 1.67 |

| Dubrovnik [76] | 6.45 | 11.5 | 1.68 | |

| Rijeka [77] | 23.1 | 21 | 1.68 | |

| Osjek [78] | 6.9 | 9 | 100 | 1.69 |

| Pula [79] | 4 | 9 | 100 | 1.67 |

| Country | UK | Iceland | French | Portugal | Croatia | Estonia | Italy |

|---|---|---|---|---|---|---|---|

| LCI [%] | 2.26 | 5.91 | 1.3 | 2.04 | −0.11 | 5.66 | 1.19 |

| PPI [%] | 2.0 | 2.86 | 1.35 | 1.23 | 1.31 | 2.16 | 1.46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marksel, M.; Prapotnik Brdnik, A. Comparative Analysis of Direct Operating Costs: Conventional vs. Hydrogen Fuel Cell 19-Seat Aircraft. Sustainability 2023, 15, 11271. https://doi.org/10.3390/su151411271

Marksel M, Prapotnik Brdnik A. Comparative Analysis of Direct Operating Costs: Conventional vs. Hydrogen Fuel Cell 19-Seat Aircraft. Sustainability. 2023; 15(14):11271. https://doi.org/10.3390/su151411271

Chicago/Turabian StyleMarksel, Maršenka, and Anita Prapotnik Brdnik. 2023. "Comparative Analysis of Direct Operating Costs: Conventional vs. Hydrogen Fuel Cell 19-Seat Aircraft" Sustainability 15, no. 14: 11271. https://doi.org/10.3390/su151411271

APA StyleMarksel, M., & Prapotnik Brdnik, A. (2023). Comparative Analysis of Direct Operating Costs: Conventional vs. Hydrogen Fuel Cell 19-Seat Aircraft. Sustainability, 15(14), 11271. https://doi.org/10.3390/su151411271