1. Introduction

Many civil engineering and construction projects in harbours face challenges of the recycling of dredged marine sediments [

1,

2,

3]. Dredging is an essential procedure performed regularly in ports and harbours. It aims to increase water depth in ports to ensure and control safe ship transportation. Collected sediments are then deposited and usually employed for industrial purposes as building materials. The examples of application of the dredged marine sediments include manufacture of bricks [

4,

5], construction of roads [

6] or construction of base courses in runways and pavements [

7]. However, collected raw marine sediments are unsuitable for direct reuse due to the poor engineering properties (low strength, stiffness and compaction, high moisture, and viscosity characteristics of soil), and contamination with toxic pollutants [

8,

9]. Therefore, recycled soil used for pavements and construction industry needs to be stabilized before reuse, since during exploitation it undergoes significant plastic deformations due to the high traffic loads. To withstand such loads, it is essential to improve its resilient characteristics, which include elastic and plastic strain responses [

10]. In addition, dredged soil should be treated in order to improve its ecological properties and to reduce environmental hazards prior to reuse [

11].

Since the recycling of dredged marine sediments is of great significance to sustainable development, economic prosperity, societal needs and well-being, many approaches have been developed with the aim of optimization of the soil treatment process in coastal engineering works: reducing the costs of works [

12], improving the workflow process [

13], increasing the effectiveness of stabilization [

14,

15], and immobilization of the environmental pollutants [

16]. To solve these problems, many approaches have been developed to optimize soil treatment for reusing it as safe and environmentally-friendly construction material [

17]. These include solidification/stabilization (s/s) of soil to increase its strength and workability [

18], removal and immobilization of toxic substances, heavy metals and contaminants through leaching [

19,

20,

21,

22] and reducing the high costs of works related to the management and reuse of dredged sediments [

23,

24].

The mechanical behaviour of low performing soils such as dredged sediments can be strengthened with binders. To this end, solidification/stabilization (s/s) is used to increase bearing capacity of soil through the improved strength, and the results are encouraging [

25,

26,

27,

28]. A popular approach to s/s soil processing is to use binders as stabilizing agents, and then apply geotechnical methods of evaluating the soil’s strength and environmental properties [

29,

30]. Apart from this, methods of deep mixing aim to improve soft, high moisture and cohesive clayey soil, which is typical for marine sediments [

31,

32]. Stabilization of soil with binders requires considering soil properties, which differ significantly according to their types and structure: fine-grained clay, middle-grained sand or coarse-grained gravel. In various types of soil, key physio-mechanical parameters differ substantially. This includes different mineral content, moisture, density, cohesion and plasticity, swelling potential, volumetric weight and porosity [

33,

34]. Therefore, the s/s treatment of soil also requires optimal selection binders, which should be adjusted to specific soil types in order to improve the characteristics of strength, compressibility, and bulking [

35].

The literature abounds with diverse approaches of various soil stabilization techniques for improving soil properties. Typically, they include major binders (cement, slag, fly ash or lime) and their blended mixtures [

36,

37,

38]. For example, the effects of fly ash content were investigated in stabilized gravel [

39], clay [

40] and soft soil [

41]. The use of cement, slag and nanosilica was successfully tested to increase the freezing-thawing durability in soft clays [

42]. The benefits of ash-slag cementitious materials were reported for solidification of soft soils [

43]. Furthermore, the effects of the improved lime-based binders were evaluated on different proportions of slag [

44], hydrated Portland cement [

45,

46] and ash [

47] in the admixture content for stabilization of clayey soils. The experimental use of the alkali-based materials was reported for improving properties of sandy clay [

48]. Finally, various types of cement [

49,

50], calcined lime/slag blends [

51] or cement/slag mixtures [

52] were assessed to analyse the behavior of high-moisture content fine-grained soils after stabilization.

New mainstream directions in civil and geotechnical engineering include the use of the optimized blends of novel and alternative admixtures besides the traditional binders used in civil engineering [

53,

54,

55,

56]. Sustainable binders can be used for amendment of strength, durability and absorption of native clayey soil and include novel binders used as admixtures. For instance, these include such novel binders as polymeric materials [

57,

58,

59], pozzolan-blended binders [

60], recycled waste materials [

61] or glass powder [

62]. Such improvements aim at increasing the long-term effects from novel admixtures on soil strength. With this regard, another factor for success in soil stabilization includes a period of treatment [

63,

64]. As a general rule, the effects of s/s process increase with curing time, which is reflected in the development of the physical and mechanical properties of soil. For instance, existing studies reported a difference in mineralogical evolution, compressive strength, porosity, and pH of the s/s soil and cemented materials over curing time, according to the tests taken in key control days [

65,

66]. Other studies evaluated the effects of changed quantity and content of binders on the stabilization of soft soils [

67,

68].

These and many related approaches are based on proposing more efficient binder recipes to improve the engineering properties of soil [

69,

70,

71]. Nevertheless, they still require considering other factors such as the ratio of water with regard to binder content in each test case for the analysis of strength. Hence, besides the selection of binder types, effective soil stabilization requires a dosage of suitable binders and the addition of water in balanced proportions with regard to the structure of soil. Our new formulation of the soil stabilization problem builds on experiments with the water–binder ratio, which affects the hydration process in cementitious materials and is evaluated using seismic methods [

72,

73]. The developed workflow framework is adjusted to sediments collected in the harbour of Port of Oslo as a continuation of our previous work [

74]. Here, we employ a series of engineering and environmental tests to evaluate the engineering properties of soil after stabilization with various w/b ratio.

Evaluating soil strength after stabilization may be performed using either traditional methods with a UCS testing machine, or using applied geophysical methods. These include the non-destructive ultrasonic tests, which are based on the determination of P-wave velocities and compression characteristics of the soil [

75]. The goal of such methods is to evaluate the increase in cementation of soil through recorded P-wave’s velocity, which increases along with densities, stiffness and strength of materials [

76,

77,

78]. Hence, the acoustic acquisition and calculation of the elastic wave velocities serves as an indicator and descriptor of success in soil stabilization. As a result, seismic sonic methods have been used with great success for evaluation of strength properties of the stabilized soil [

79,

80,

81].

Further examples include tested variability of stiffness and damping using analysis of seismic responses [

82] and evaluation of building structures using tuned mass dampers and frequency evaluation of seismic signals [

83]. The effects of the hydration of cement and cementitious binders, used in materials science to study the evolution of soil hardening have been studied previously [

84,

85,

86] and prove the increase of strength and stiffness of stabilized soil. Likewise, the idea of using seismic methods in geotechnical engineering has been used for nondestructive testing for evaluating soil integrity and structural failure based on the relationship between the velocity and the strength and stiffness of materials [

87].

The effects of varying water–binder ratios on the strength of stabilized soil, which rarely occur in practice, make it challenging to conduct tractable investigations and compare how changes in percentage directly affect the material’s properties. The existing studies mostly use a fixed combinations of binders as stabilizing agents and evaluate the soil properties using a given ratio. In contrast, analysis of various water–binder ratios requires a systematic laboratory-based investigation using a series of tests that include multiple observations of soil behaviour processed further by means of the statistical analysis. To fill this gap, this study proposes a research strategy that involves testing multiple soil samples treated with varying combinations of water-to-binder ratio in a stabilizing mixture.

In light of the above discussion, in this paper we study the benefits of exploiting the effects of optimized and parameterized binder proportions taken as factors and water content on strength and deformation of soil. The optimized workflow is proposed to achieve the most effective procedure and reduce high costs of soil processing in the construction industry. The best combination of stabilizing agents for soil treatment ensures the control of the soil quality for geotechnical suitability of foundations before construction works in a harbour. Thus, if the conditional ratio of stabilizing agents is known through modelling, then solidification of soil can be achieved by sampling the specimens at a finite number of trials and checking each test to see if the target stabilization degree is achieved. To this end, we introduce a new method for improving the stabilization efficiency by setting up an updated sampling procedure, which includes four Batches of specimens stabilized with various amounts of water and a combination of binders. Thus, we use the activated carbon (powdered charcoal) for pre-treatment of soil materials one month before the stabilization, and apply the Belite Calcium Sulfoaluminate (BCSA) type cement, which has environmental quality compared to the Portland cement due to low CO2 emissions. The soil pre-treated with these materials demonstrated better environmental characteristics.

4. Results and Discussion

The results from the laboratory-based tests both at LTH and at SGI show that dredged sediment masses are well suited to be stabilized/solidified with an inorganic binder consisting of 30% cement type CEM I (according to CEN 197-1) and 70% ground granulated blast-furnace slag (GGBFS) according to EN 15167-1 [

92]. The first requirement for the amount of binder should be at least 120 kg/m

3. A secondary condition is that the weight ratio between the weight of water contained in a mixture and the weight of the added binder should be ≤5. Besides, it should be pointed out that in the case of high water percentage in the original dredged masses, such as marine sediments with high percentage of water, the secondary condition will be a w/b ≤ 5 result in a higher amount of binder.

4.1. Binder Content Related to Strength

Figure 8 shows a graph, which illustrates variation in the values of compressive strength with different proportions between cement and slag where the effects from binders are clearly visible. Here, the mechanical properties of soil were evaluated against the development of UCS in two ways: first, as a function of stabilization by cement (as it is common in ordinary cement measurements, dark blue coloured), and second, as a function of stabilization with slag (i.e., soil strength measured for a selected soil sample stabilized with slag, brown colour in

Figure 8). These tests were carried out on the dredged masses collected from the Arendal 2 in Gothenburg. In the tests, the total amount of binder remains the same while the ratio between cement and slag varies from 0% slag to 90% slag. Samples with 70% slag give the highest compressive strength. Black dots represent the results from the tests on the Uniaxial Compressive Strength (UCS). Strength development in soil stabilized with varying combinations of cement and slag was evaluated. The best combination of binders was detected to control their effects on strength development, which is obtained at a slag admixture of 70% of the total amount of binder,

Figure 8. In this way, the highest content of binders with the maximal achieved strength in soil samples can be evaluated.

The results of the evaluation of geotechnical properties of soil are based on the performed resonance frequency measurement and tests of UCS. As the resonance frequency measurements are non-destructive, the same specimens were measured on several occasions and the development of the P-wave velocity over time was followed, see

Figure 9. Here, the graph shows a correlation of P-wave velocity in relation to the curing age of the soil. More specifically, the variation of P-wave velocity with different soil samples collected in various test sites and stabilized with cement and slag shows that there is a good linear correlation between the curing time and the mechanical properties of soil indicating a general gain in strength over time of curing, which is reflected in increased velocity of P-waves. The points separating the lines into the segments shown in the image represent measurements of soil. These samples were taken and measured over a control period of time to evaluate the dynamics of P-waves, which indicates gain in strength on a trend line. The samples here were stored at 20 °C. The blue points correspond to the w/b = 5, green points correspond to w/b = 6, and red points correspond to w/b = 7, respectively. Different points give different growth, which can depend on both grain distribution in individual soil samples, and the impurity of content,

Figure 9. The results are comparable for different samples plotted per one gram of binder. This indicates that a significantly earlier time can be used to predict, for example, the 50th day of strength.

In the curves of

Figure 9, we noted an almost linear correlation between the curing time and the increase in speed (i.e., sound velocity) and the frequency of measured P-waves passing the soil samples, which indicates the improvement of the mechanical parameters of soil, such as elastic (Young’s) modulus, and indicates a gain in soil strength over the period of curing. Moreover, one can conclude from the analysis of

Figure 9 that for a selected binder blend (w/b 5–7 for different test sites; see the legend in upper right corner of

Figure 9). Stiffness and strength development (which corresponds to the E modulus) is approximately linearly related to the curing period, and is also well correlated with the values of P-wave, their sound velocity and frequency.

Table 3 summarizes the data on the measured samples and the results of the compressive strength (UCS, kPa) using mechanical tests with varied w/b ratios. More specifically,

Table 3 shows the values of the compressive strength according to the different w/b ratios for specimens collected in various test sites (TS). The measurements of the UCS correspond to the columns 3, 6 and 9 in

Table 3). The UCS tests were carried out according to the existing Swedish standard SS-EN 16907-4 [

110] with recommended deformation rate of 1 mm/min for soil specimens with a height of 100 mm. The results are summarized in

Table 3. For the point 1_2, the w/b = 5–7 were tested for each specimen. As the ratio between water and binder controls the strength, samples with w/b = 5 had higher strength compared to the samples with w/b = 6 or 7, which proved the expected results.

The specimens within the same w/b, for instance, ID No. 1_1 to 1_4, show smaller variation in strength values. The same applies to the other w/b ratios. Test samples No. 1_1 and test body 1_2, however, show a different stiffness compared to other samples. Such variation in stiffness is normal and is explained by natural individual parameters of the soil masses. The results of the tests on the compressive strength and water/binder ratio for specimens collected from the sampling point No. 3 are also shown in the same dataset,

Table 3. Specimen 4_4 from TS 4 obtained a significantly higher strength compared to others with the same w/b and should therefore be considered as an outlier.

4.2. Water–Binder Ratio

Table 4 shows the compressive strength with relation to the effects of changed water/binder ratio (w/b) for the test points No. 5, 6 and 8, and additionally, the P-wave velocity for test site 5. Here, soil stabilized by the blended cement-slag mixtures and water added in various proportions into the mixture indicates good performance in stabilization. This is achieved due to balanced w/b proportions. This combination outperforms that of soil treated by cement-only binders. With regard to the obtained results of the UCS tests, P-wave measurements were performed to analyze the correlation of the P-wave velocity against the compressive strength in evaluated soil samples. Therefore, after testing the P-wave velocity, the values of the compressive strength were calculated based on the recorded data on the speed of waves, which correlate with the strength of the materials. These results are reported in

Table 4.

4.3. Soil Deformation

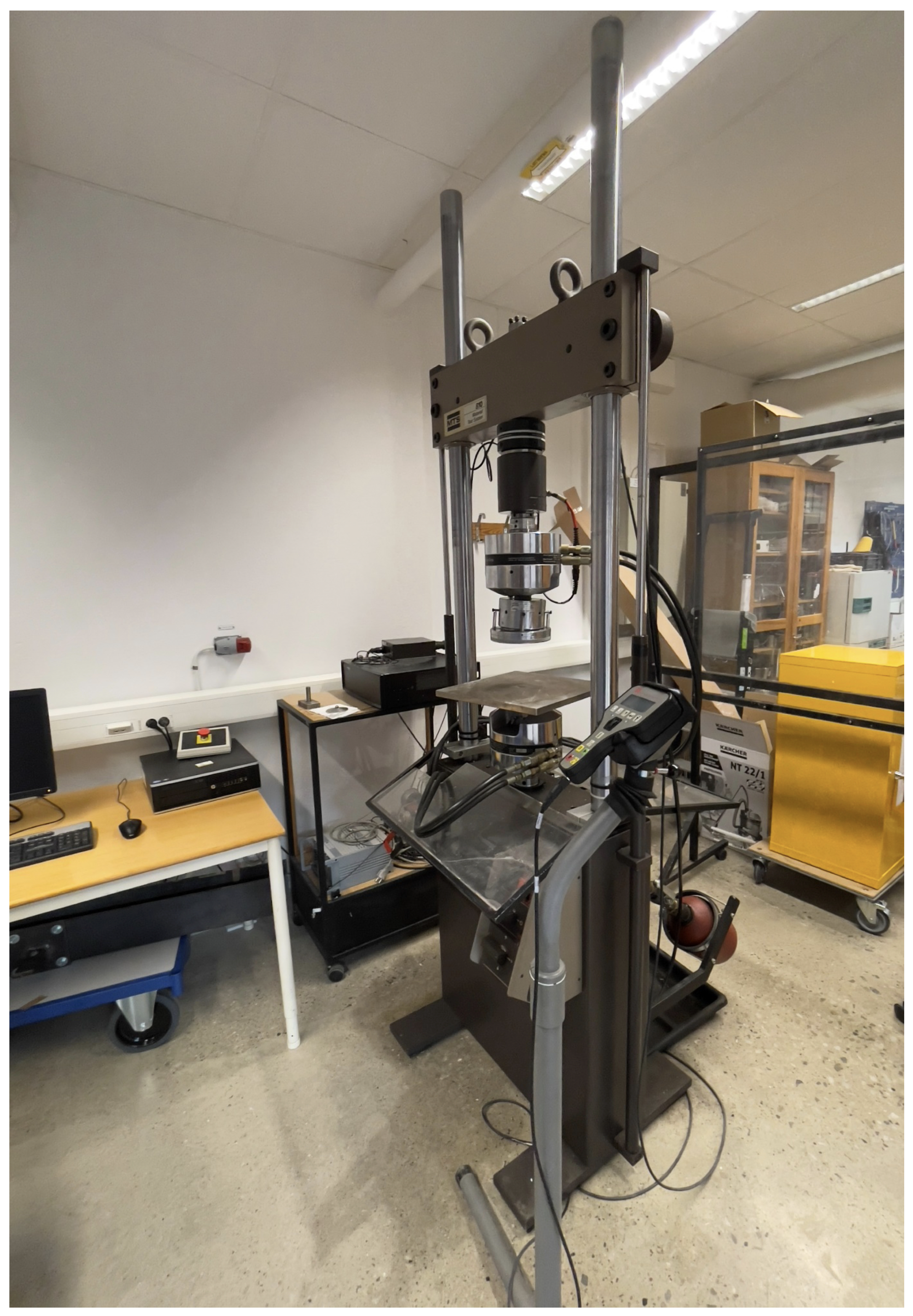

Figure 10 shows a graph of correlation between the pressure (kPa) and relative deformation of the soil specimens collected from the sample tests site point No. 1_2. The values of the compressive strength were categorized as different lines recorded by the measurements of specimens. Overall, the values of the compression did not exceed 900 kPa. Originally recorded by the UCS device, the data were modelled and evaluated statistically using the Statistica software 14.0.1. The effectiveness of the UCS tests is ensured by the high precision measurements and force capacity in the MTS 810 testing machine, which operates for various temperature and soil conditions. The stability precision ensures a wide total range of UCS values, since this MTS 810 machine measures soil strength at a high level of precision. The MTS machine was used for a complete period of testing, i.e., over 60 days, as in case of this study (2 months), which enabled us to analyze the dynamics of gain in strength.

The segments of lines are separated by measured strength values, appearing as fragments on the general trend lines, which depict the dynamics in relative deformation individually for various soil specimens. In contrast to the soil samples from test sites 1 to 8, the use of blended mixtures with different ratios of water/binder in cement/slag blends in tests 11–13 demonstrates more stable results of compression and strength gain. After achieving the peak compression, the deformation values stabilize at approximately 2% of the values in soil samples compared to the original raw materials.

Figure 10.

Correlation between compression (kPa) and relative deformation of 10 specimens collected from the sample test site No. 1_2.

Figure 10.

Correlation between compression (kPa) and relative deformation of 10 specimens collected from the sample test site No. 1_2.

The increase in relative deformation continues rapidly until the values of the compression strength reach 800 kPa, after which they stabilize and then decrease. Possible distortions and noise on the samples 11 to 13 are identified and classified as unstable responses to the content of the binder by the selected soil samples, since these specimens were compressed with relatively low strength that does not exceed 300 kPa. Samples 1 to 8 demonstrate a stable dynamics in measurements. In all cases, the relative deformation was measured until a value of 2.2%. The comparison of the plots for soil samples collected in test sites (TS) from 1 to 13 suggests the direct effects from the water/binder ratio on the hydration of cement that leads to the gain in strength (UCS). Such findings are necessary to account for the identification of the best combinations of binders and w/b ratio, while optimizing binder blends and selecting the proportions of water in recipes.

Figure 11 shows a graph of the pressure-deformation relationship for soil samples collected from the test point No. 3 with three different levels of w/b, which are clearly visible in the graph. Randomly coloured line traces indicate selected sample specimens tested for evaluation of soil deformation. The first number in the numbering is the test point, in this case point No. 1_2. The second number is a serial number. Samples 1 to 4 have w/b = 5, samples 6 to 8 have w/b = 6 and samples 11 to 13 have w/b = 7. The variations in strength prove the expected results with the highest values for w/b = 5 and the lowest strength for w/b = 7, respectively.

As the curves in specimens 11 to 14 are almost identical with regard to the development of relative deformation and do not exceed 200 kPa in maximal values, this indicates that the measurement of UCS tests will give a good prediction of the deformation–strength relationship and will also extrapolate for the strength over the time exceeding the testing period. One can see in

Figure 11 that the highest compression (over 800 kPa) is achieved by the soil collected in test sites 1 to 3. Furthermore, middle values correspond to the soil collected in sites TS 6 to 9 of the testing samples, with maximal values below 330 kPa. The development of the compressive strength is related with the elastic modulus of soil.

Figure 11.

Correlation between the compression (kPa) and relative deformation of 11 specimens from the sample test site No. 3.

Figure 11.

Correlation between the compression (kPa) and relative deformation of 11 specimens from the sample test site No. 3.

Accordingly, for the sample point No. 3, the expected pattern is shown in the same way in soil specimens with values of water/binder ratio between 5–7, see

Figure 11. Here, the fragments of the modelled lines were annotated and randomly coloured using the IDs of soil samples and records on deformation value against the compression (kPa). However, the specimens collected from the sample test point 3_1 exhibit a slightly lower level of strength compared to other two test samples with w/b 5. For samples from the point No. 3, less variation in stiffness was detected compared to the samples collected from the test point No. 1_2. Here, we also demonstrated the relationship between the compressive strength and a relative deformation, which reaches peak at 850 kPa, after which it stabilizes and then decreases.

4.4. P-Wave Velocity vs. UCS

Figure 12 shows a graph of the measured P-wave velocity as a function of the UCS. In this experiment, we evaluated the ability of ultrasonic testing to leverage from the P-wave velocities to strength gain in the soil samples. The variations at a higher strength are completely normal. Since these data are presented by the independent soil samples, we first test P-wave responses passing through specimens of each soil sample test based on their individual characteristics, such as water content, density and grain size. We then evaluate the P-waves in soil samples stabilized with various w/b ratios at the start and end times, and the selected intervals in between. The behaviour of strength over time in samples of soil stabilized by cement approximately resembles the logarithmic curve showing the relationship of the hardening of the materials with their increase in strength.

Then, we extracted the information from the measured records, indicating the P-wave speed changing over the measured time, to evaluate the dynamics in strength gain for each soil sample. The technical details of the P-wave values were recored in the metadata, including wave speed, maximal and mean values with relation to the UCS. The analysis of the graph in

Figure 12 shows the following data. The P-wave velocity shows a stable increase from 415 m/s to 1170 m/s, which is achieved by the compressive strength of 1220 kPa. The speed of P-waves when passing the soil samples was monitored in a straightforward way by measuring the speed from sensors received by the ICP Accelerometer. The development of P-wave velocities continues even after the cementation of the soil mixed with binders during stabilization for a measured period, as depicted in

Figure 12.

Figure 12.

P-wave velocity as a function of the compressive strength. The dotted blue line signifies a general trend for the increase in the compressive strength of soil; blue dots signify values of the compressive strength for measured soil samples.

Figure 12.

P-wave velocity as a function of the compressive strength. The dotted blue line signifies a general trend for the increase in the compressive strength of soil; blue dots signify values of the compressive strength for measured soil samples.

The parabola function well represents the relationship between P-wave velocity and compressive strength in

Figure 12, which clearly depicts its nonlinear nature. The correlation of P-wave-velocity and compressive strength well differs from the curves presented in earlier plots and has a steeper curvature, since it represents the relationship of the speed of the elastic waves on the stiffness or porosity of the solid material. The tests were performed on soil samples, which have varying w/b ratios in the binder mixture cement/slag content. Since the behaviour of elastic waves released by the accelerator and processed back by the receiver differs for samples stabilized with blended mixtures, various values for dots in

Figure 12 well illustrates the effects and minor variations of w/b mixtures in slag-cement binders on soil strength. Nevertheless, the trend curve shows a general direction of the relationship between P-waves and strength in soil as a parabola function. Soil samples stabilized with cement/slag binders and different w/b ratios can be distinguished as individual dots on a graph.

In a sense, long-term stabilized samples exhibit a higher degree of strength and correspondingly high P-wave velocities, while the ones recently stabilized have lower values and are comparable (e.g., for P-wave velocities of 440 or 600 m/s), indicating a similar behavior of the soil. However, the highest P-wave speed values (values over 100 m/s) were recorded for the highest UCS and long-term curing time, showing a higher dispersion of values. This is not surprising, as the balanced viscosity of the water-binder ratio in cementitious binders and their rheological parameters are well-known effective factors for soil strength. The strength is assessed using indirect descriptors that differ for individual samples.

Tests with iteratively changed binder parameters were used to select the best combinations by utilizing various w/b ratios in a recipe of blended binders. The differences in P-wave behavior and UCS indirectly indicate variations in the porosity of soil stabilized with various blended mixes (cement/slag) and w/b ratios, and these are compared with the soil samples recently stabilized, as shown in

Figure 12.

Figure 13 illustrates a graph of the P-wave velocity in relation to the UCS for the Oslo project, compared with selected Swedish projects involving the stabilization of dredged soil sediments. The results obtained in this survey align well with those from the earlier Swedish projects. Thus, with regards to compressive strength and the relationship between P-wave velocity and strength, the test results from this study confirm the expected estimations, as shown in

Figure 13.

The results presented in this study demonstrate that the stabilization of dredged marine sediments with an adjusted ratio of water-binder, evaluated using sonic tests, proves to be an efficient and powerful framework. This approach takes into account multiple variables that affect soil hardening and their attributes.

Figure 13.

P-wave velocity as a function of the UCS.

Figure 13.

P-wave velocity as a function of the UCS.

In

Figure 13, the P-wave velocity has been evaluated from samples collected from Arendal (A), Västerås (V), Oslo (O), and Timrå (two sites T1 and T2) after the curing period. The analysis of the UCS data interprets the degree of cement hydration, indicating the soil stabilization process from the speed of the P-waves that correlate with increased soil strength during stabilization. The maximal level of soil strength is achieved at the w/b ratio of 5 where P-waves reach the recorded velocity of 1161 m/s. Such a good performance has a theoretical explanation of the optimized plasticity and viscosity of the binder recipe, which improves the mechanical properties of the cured soil. In particular, we derive the development of P-wave velocity with curing time up to 60 days to demonstrate the effects from the two factors: the dynamics of strength over time and the influence of water–binder percentage on soil setting.

This part of the study was conducted as a critical test case to comparatively evaluate the behavior of the treated soil samples relative to the locations and environmental conditions of the original raw materials. The regression analysis demonstrates the statistical processing of the data collected in Oslo (represented by black crosses) at the end of the curing period for different combinations of w/b ratios. We visually analyzed the similarity between the curves for these soil samples, which were tested with varied w/b proportions and collected from different locations. The goal was to compare the effects of increasing the ratio of stabilizing agents while decreasing water content.

The graph illustrates a clear visual similarity in curves, with soil collected from the Timrå site exhibiting steeper curves compared to the other locations. This indicates soil samples with the highest percentage of binders relative to water content.

4.5. Environmental Parameters

The results of the environmental engineering tests performed using shake tests are presented in

Table 5 and

Table 6. As a comparison, shake tests were also performed on stabilized samples. However, the shake tests are not completely representative as the material is crushed down to less than 4 mm, which is not the purpose of stabilization/solidification. Nevertheless, these results show a significant reduction in leached heavy metals–arsenic (As); lead (Pb), cadmium (Cd), chromium (Cr), mercury (Hg), nickel (Ni) and zinc (Zn), sum PAH-16 and tributyltenn (TBT), according to the performed shake tests with L/S 10, PAH, PCB and TBT, see

Table 5. The leaching tests were performed using Swedish standard SS-EN 12457-2 [

111]. The extended uncertainty is 51% according to the standard SS-EN 12457-2. It was calculated with a coverage factor equal to 2, which gives a confidence level of approximately 95%.

From a pure civil engineering perspective, it seems more reasonable to model each soil sample as the superposition of factors that include variations in binder proportions and water content [

112,

113,

114]. Shared across all the soil samples of the same probe, such experiments enable us to evaluate the effects of the water–binder dosage on the stabilization process and environmental properties. Thus, such an approach enables us to evaluate leaching of heavy metals and toxic substances, with regard to the individual properties of soil: density, moisture, grain size, type, texture, content of clay/sand, amount of organic matter. In this paper, we demonstrated that this representation allows us to account for the differences between various dosages in water–binder mixtures and their effects on stabilization in the same class of soil samples. Furthermore, we showed the non-linearity in the soil modelling process when we evaluated the relationship between the soil texture and water–binder percentage.

Our results are relevant for the analysis of geotechnical properties of soil since they provide new information about the strength parameters of soil stabilized with various water–binder mixtures. Adjusted proportions of binders allow us to focus on soil hardening through the stabilization workflow with an optimized water–binder ratio. We furthermore demonstrated that the water–binder ratio is an important factor in s/s soil treatment techniques aimed at improving the initially poor engineering properties of dredged marine sediments prior to reuse as construction materials. Thus, the measurements of UCS investigated here provide a concrete illustration of the role of w/b recipes in the hardening of clayey soil (dredged sediments collected from the harbour of Oslo) stabilized with cement/slag in various ratios. Since the ratio of these binders remained constant, and we only changed the water content, this enabled us to see the effects of a stiff/wet binder on the hydration of cement and, thus, soil stabilization with various proportions of water/binder.

5. Conclusions

In this paper, we developed an effective framework for modelling the w/b effects on stabilization of clayey dredged materials collected from the harbour of Oslo, Norway. We proposed two methods for evaluating soil strength stabilized using different water/binder ratios, namely, using UCS tests implemented by the MTS 810 servohydraulic universal testing machine, and using sonic tests with evaluated velocities of pulsed P-waves. Inspired by the existing approaches of seismic methods applied to civil engineering problems [

115,

116], we prove that a combination of state-of-the-art methods with non-destructive seismic tests can model the dependency of soil strength on binder proportions, w/b ratio and curing time. Specifically, the analysis of the presented data shows that the lowest P-wave seismic velocity of 1200 m/s is demonstrated by the highest strength and corresponding UCS values, which is achieved by the optimal proportion of water with the lowest content of binder, i.e., w/b = 7.99, and the lowest absolute content of binder, such as 2.022 mB/g. This shows the performance of physical mechanisms in soil particles operating during the hydration of cement in the process of soil stabilization, and the setting of soil-binder mixtures, which were evaluated by seismic tests.

Under the framework of the presented modelling of stabilized soil properties, it was shown that various w/b dosages provide essential information at the variable feature level for modelling the dependency of soil strength on a binder content. Besides, the improved binder properties enhance key characteristics of the construction materials, such as compressive, tensile and shear strength, ductility and flexure [

117,

118,

119]. Finally, the optimal combination of the w/b ratio is obtained for dredged clayey sediments in a laboratory scale, which can be generalized at the large-scale project level. Hence, as noticed in

Table 4, summarizing the results of the compressive strength in various w/b proportions of binders used for soil stabilization, seismic (P-wave velocities) and mechanical measurements show an agreement in a significant increase in the strength of soil samples over the period of curing with increased binder content and w/b = 5 when the strength measured by UCS tests exceeded 500 kPa, and P-waves were higher than 1000 m/s. This proves positive effects from the water/binder ratio of 5 on clayey soil stabilization.

The proposed modelling of soil properties at a laboratory scale minimizes the costs of the project-run works where large quantities of sediments must be dredged repeatedly for the needs of marine transportation. In view of this, the contributions of the this paper are threefold:

We proved that dependency of strength of clayey soil on w/b ratio can be modelled by a linear combination of tested specimens showing the gain of strength, and the improved ecological properties of soil—leaching of heavy metals and toxic substances.

The assumptions on the effects from the changed w/b dosage on the behaviour of the marine sediments is tested by adding various percentages of admixtures of cement/slag as binders.

We developed a novel framework for testing high-plasticity clayey sediments collected in Oslo harbour, Norway, and proposed two methods for evaluating soil strength using the standard UCS approach and measured P-wave velocities.

We showed that the combination of the P-waves and UCS methods for evaluating soil properties outperforms the standard state-of-the-art approach in two ways.

- –

First, the P-wave velocities are non-destructive tests, which can be performed using portable devices and contain necessary information related to soil strength.

- –

Second, the analyzed sensitivity of the ICP Accelerometer for measured resonance frequencies of sediments proved its high perception to varied levels of stiffness and viscosity of soil samples stabilized with different w/b dosages.

The essential practical advantage of the presented work consists in the optimization of the soil stabilization process in marine harbours prior to construction works where large quantities of soil are to be stabilized. For instance, optimization of the processing of millions of tons of the dredged sediment material using s/s techniques increases cost-effectiveness. Thus, the optimization of s/s techniques in such large-scale projects is crucial. The optimization of the w/b dosage supports finding the best analytical solution for cost-effective s/s treatment of soil from marine harbours, when sediments are collected regularly and in large quantities. Using our data, the information on soil strength depending on the w/b ratio and deformation of clayey soil specimens in the process of compression can be generalized in large-scale projects. Overall, the results of seismic and UCS measurements demonstrated in this study show a similar trend and agreement in the estimated strength of stabilized specimens. The strength increased over the curing time in stabilized soil samples, as indicated by both seismic and UCS measurements.