Study on Uniaxial Mechanical Behavior and Damage Evolution Mechanism of Water-Immersed Mudstone

Abstract

:1. Introduction

2. Methodology

2.1. Engineering Background

2.2. Sample Preparation

2.3. Determination of Water Immersion Method

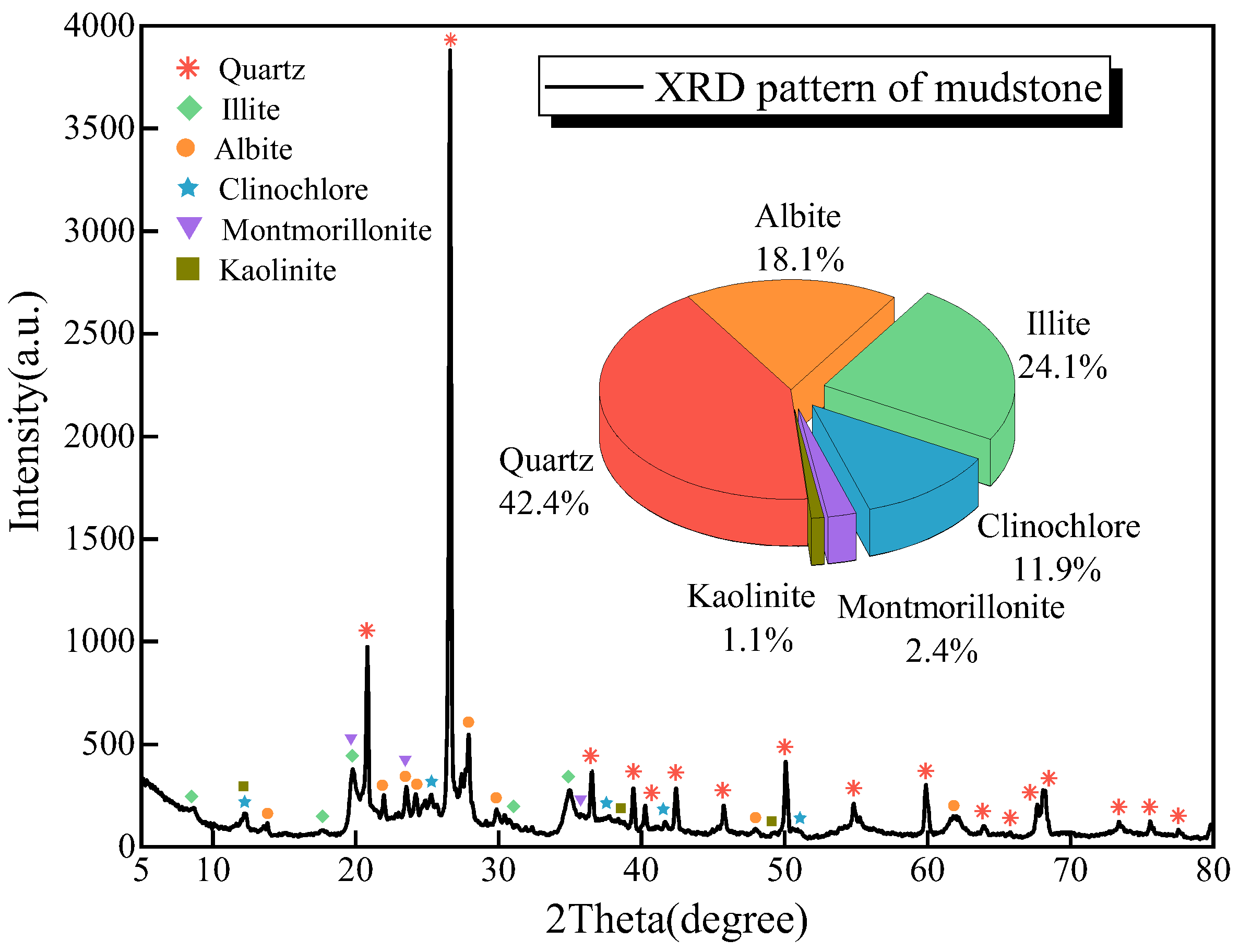

2.4. Composition

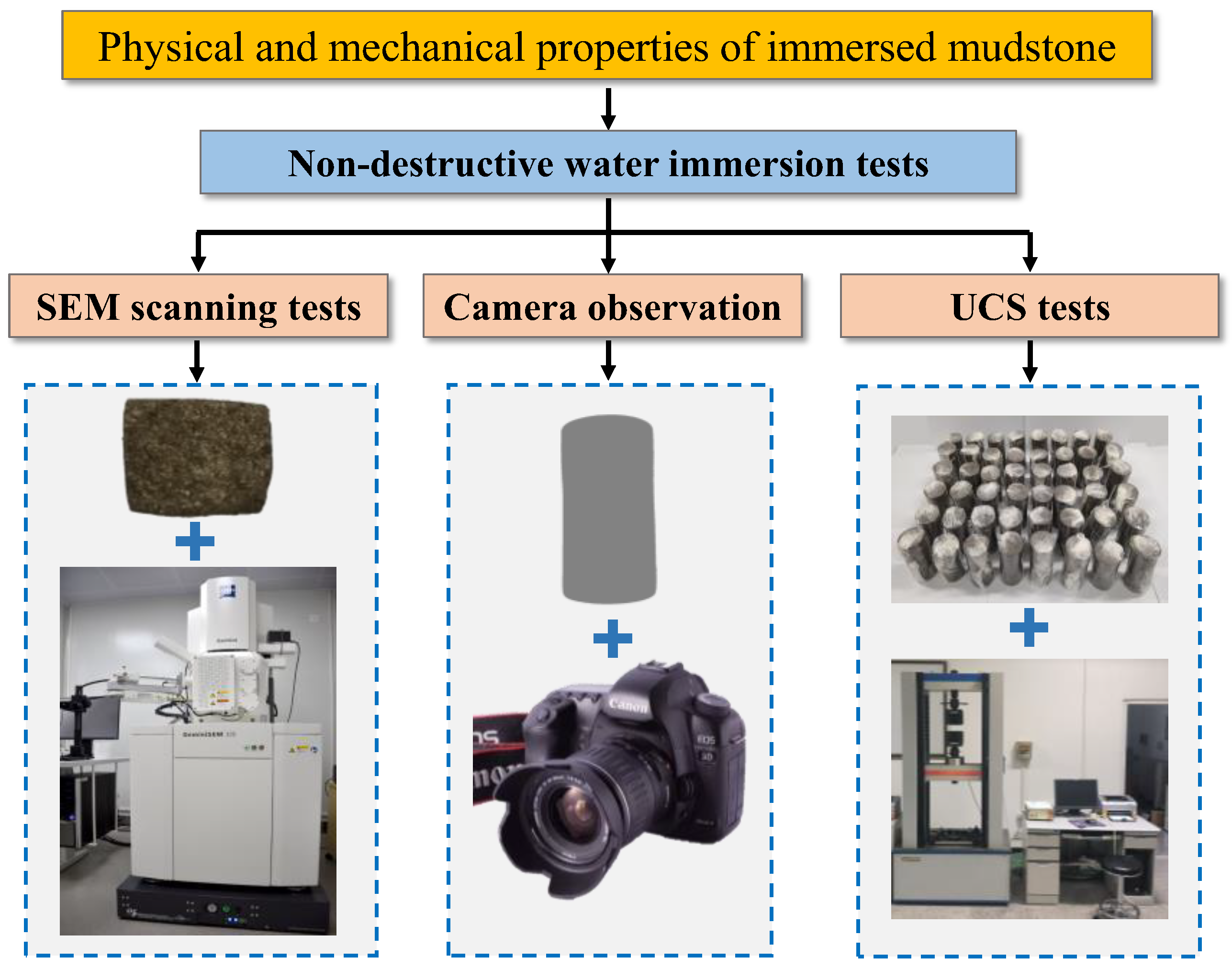

2.5. Test Scheme

3. Results

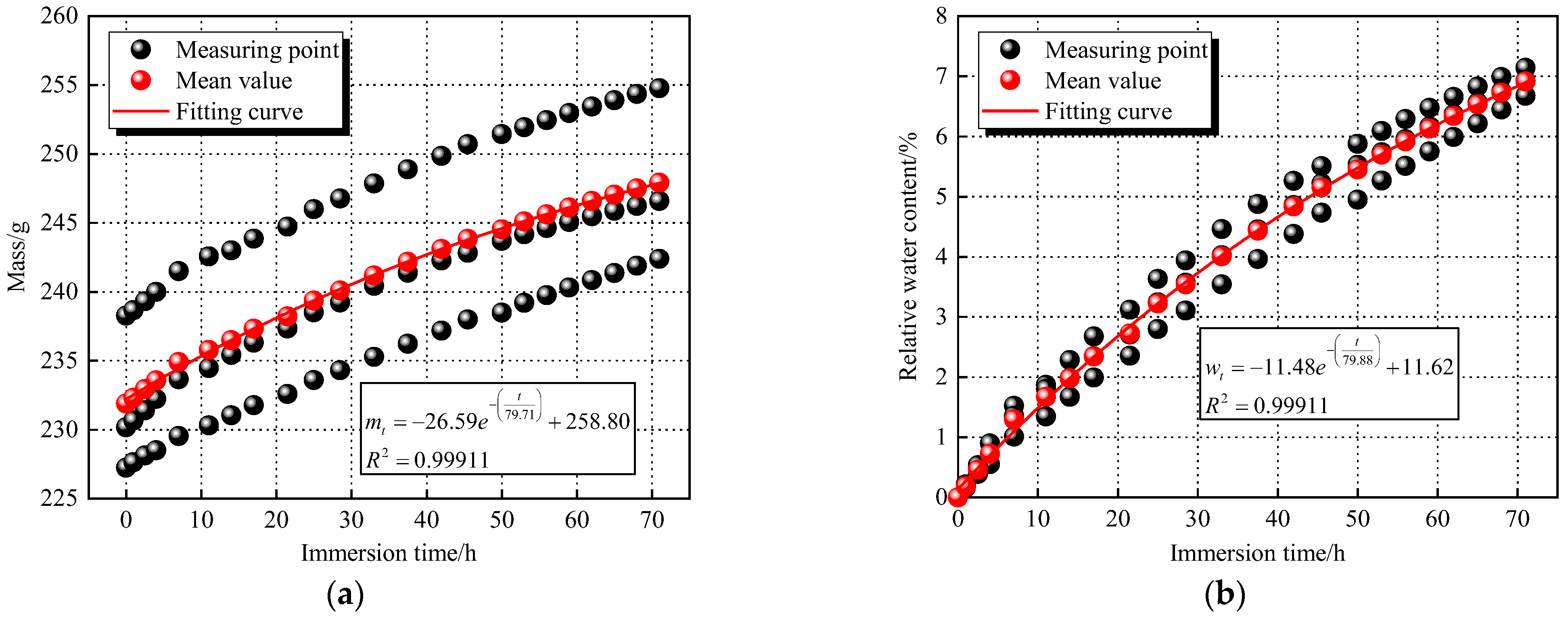

3.1. Deterioration of Macrostructure and Mesostructure of Water-Immersed Mudstone

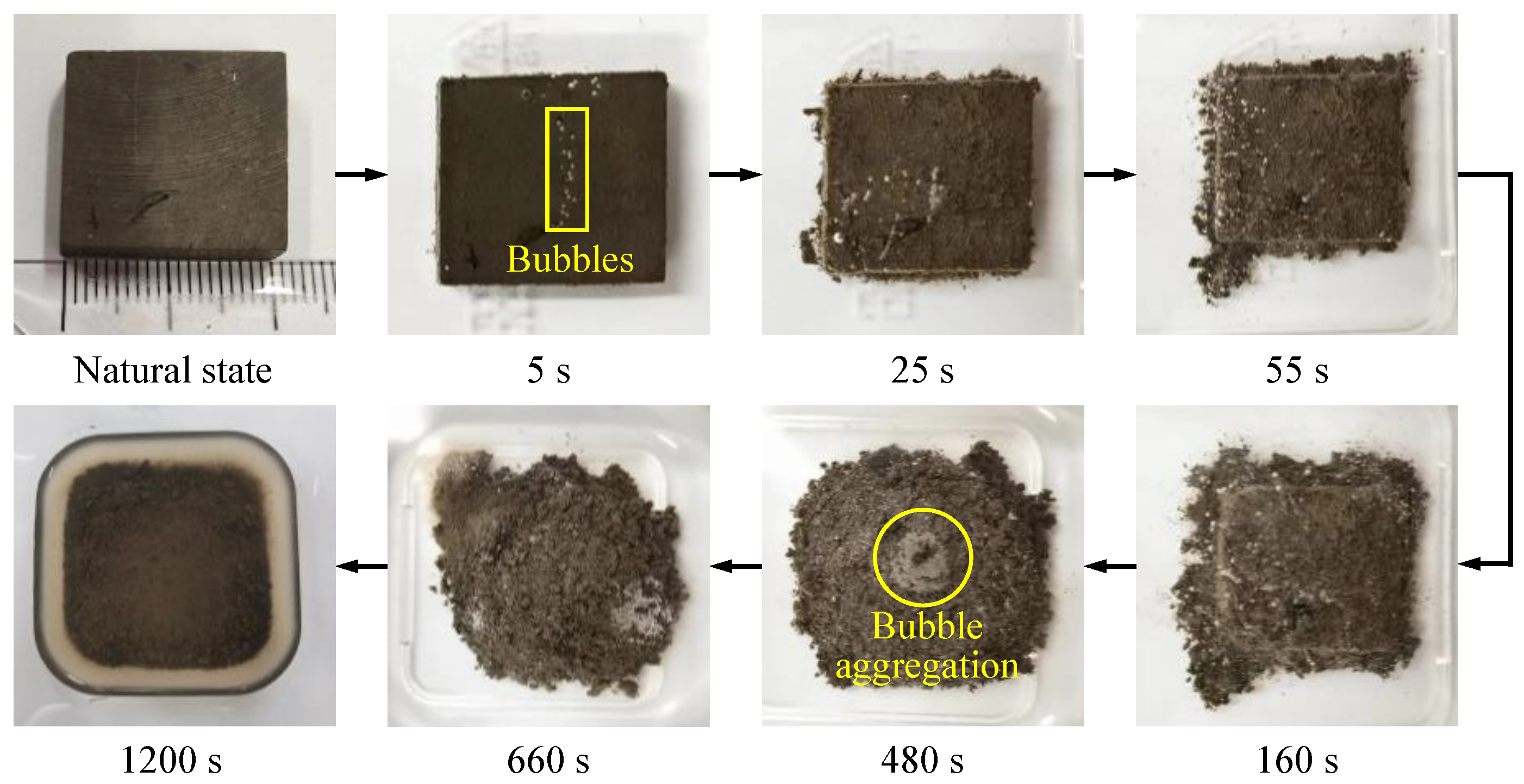

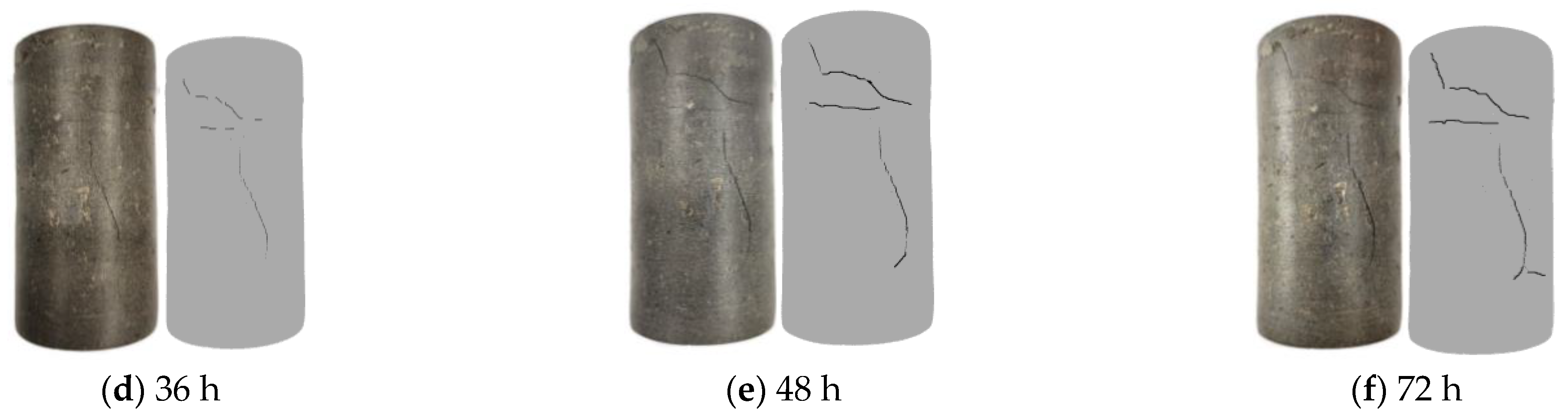

3.1.1. Macrostructure Deterioration

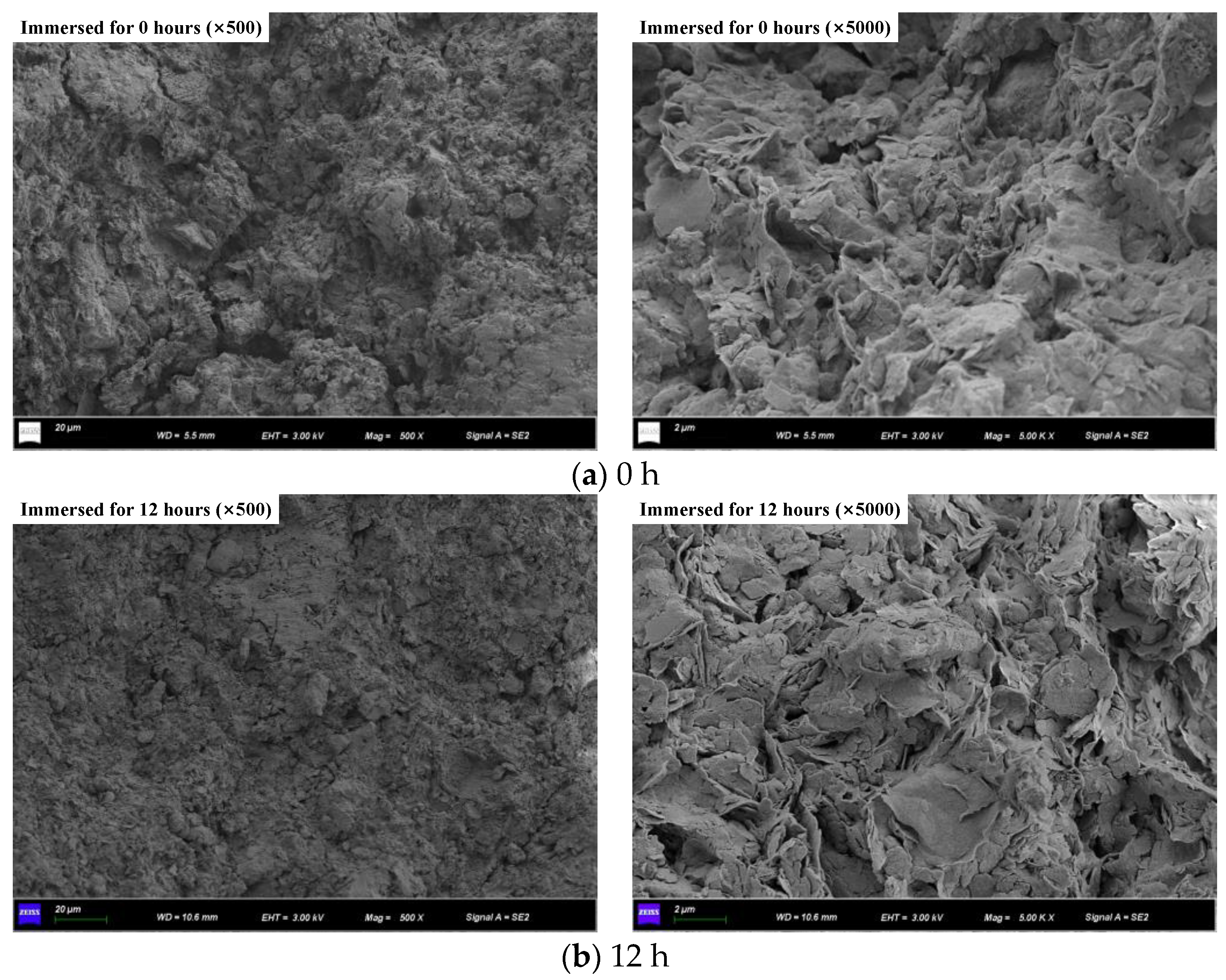

3.1.2. Mesostructure Deterioration

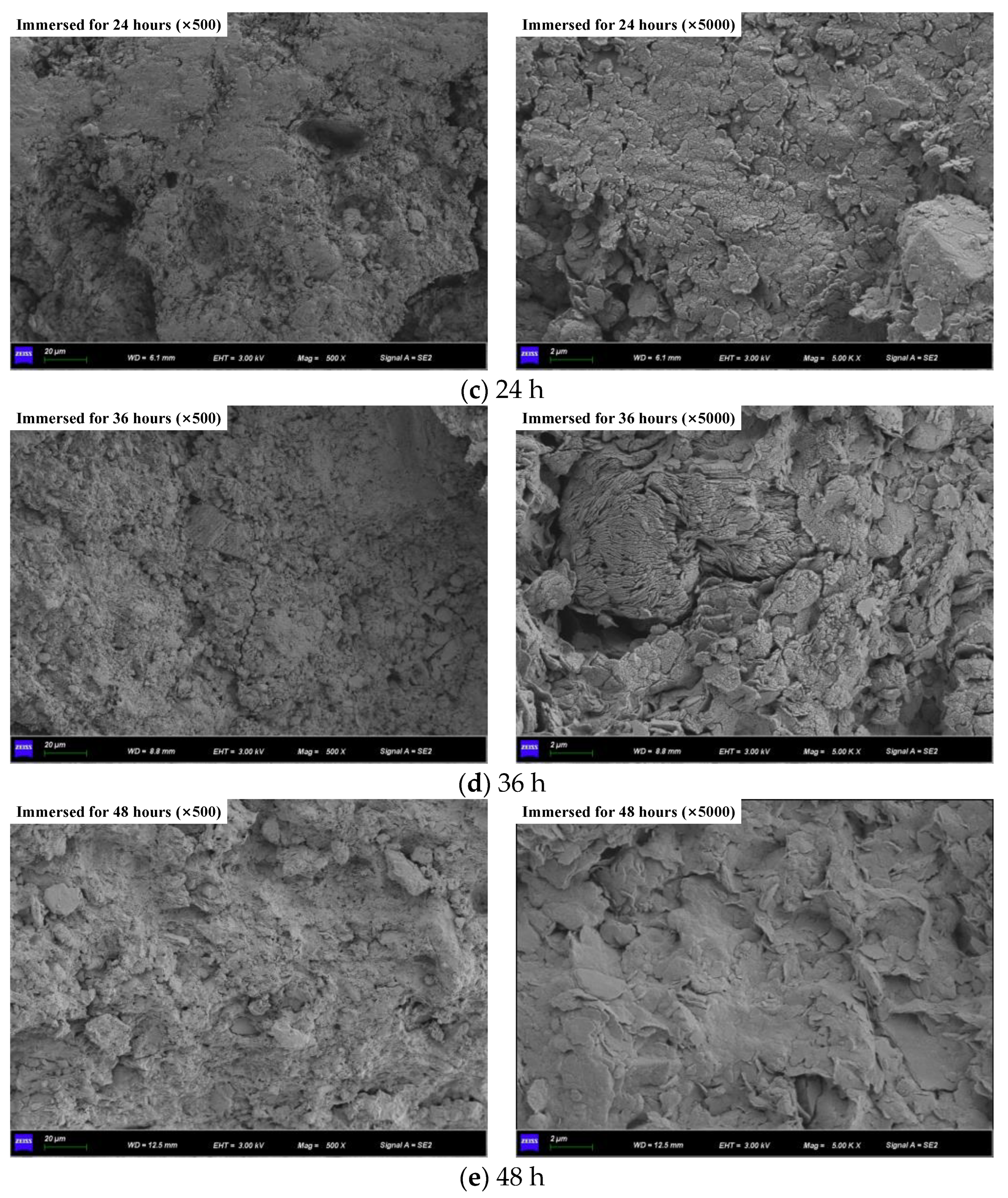

3.2. Uniaxial Compression Experiments

3.2.1. Mechanical Parameters

3.2.2. Macroscopic Failure Characteristics

4. Energy Evolution Law of Mudstone

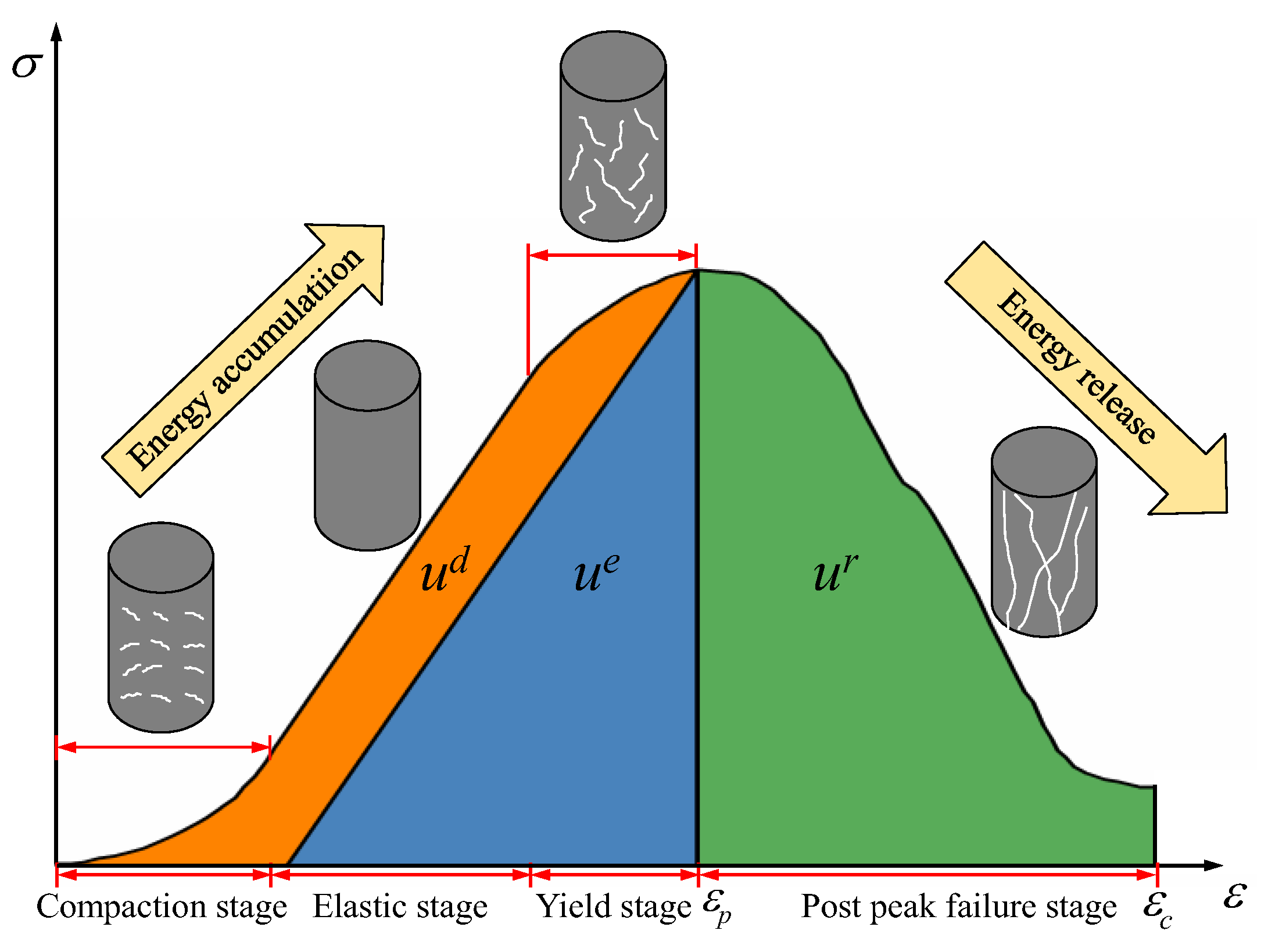

4.1. Strain Energy Calculation Method

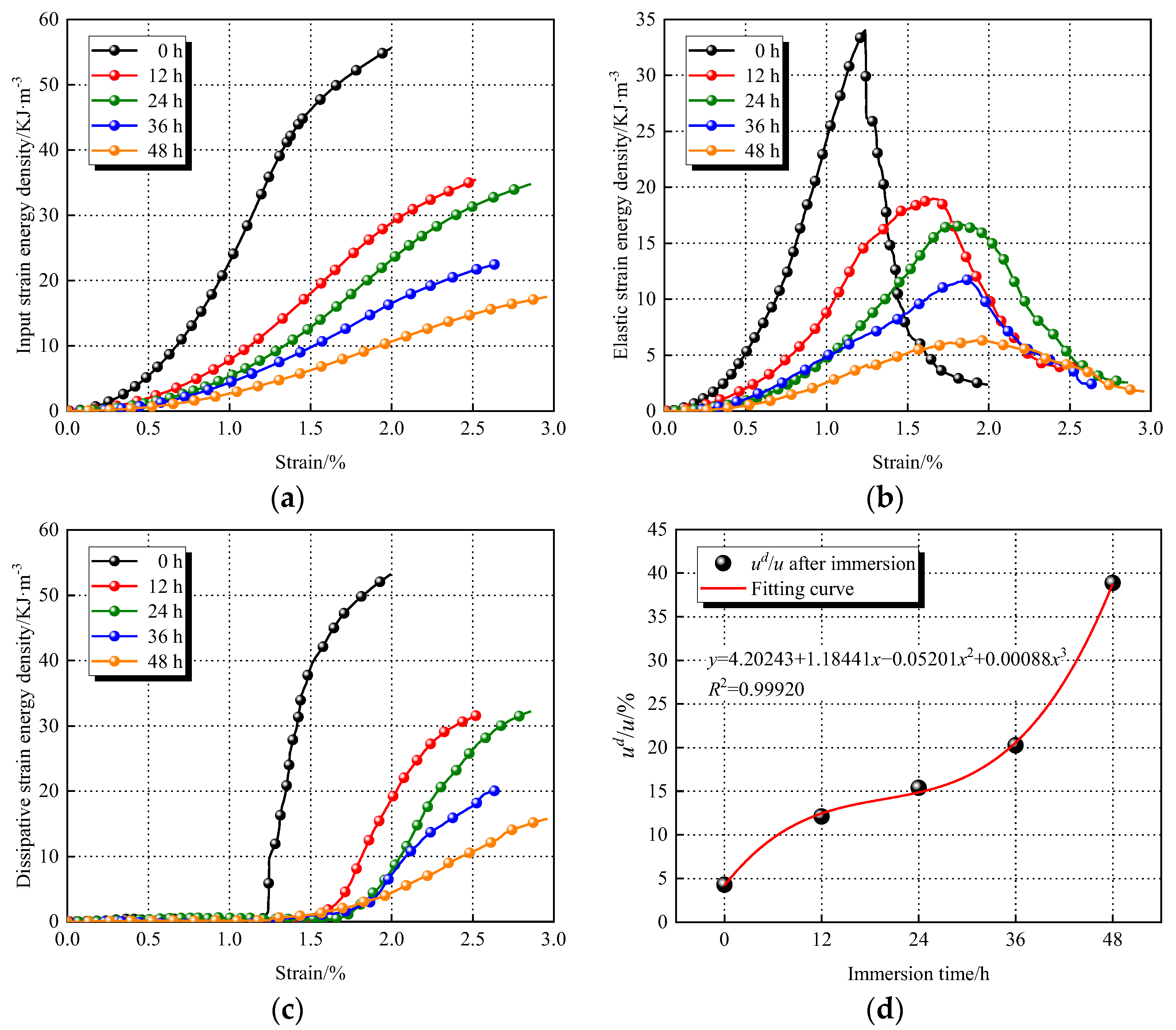

4.2. Characteristics of Energy Evolution

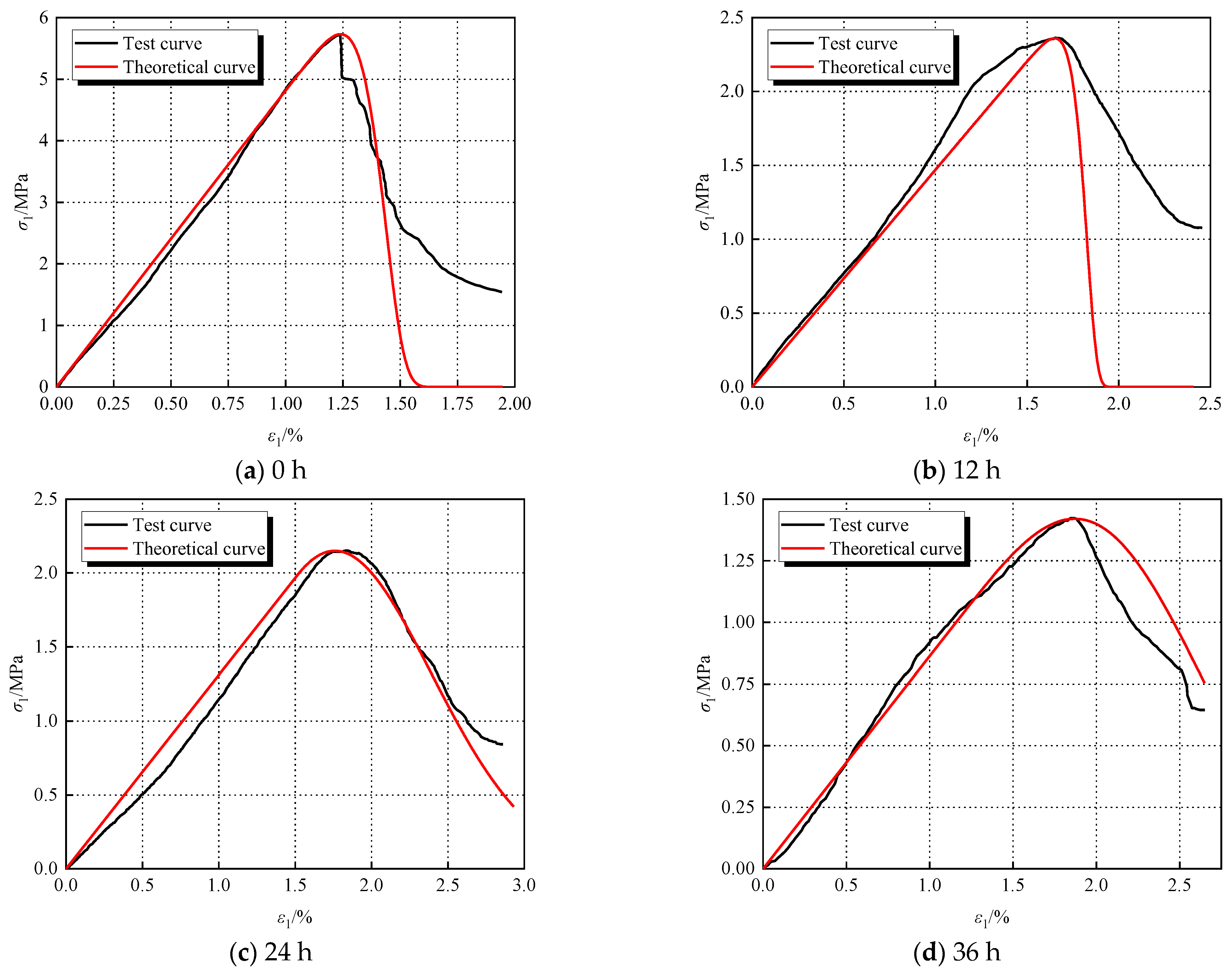

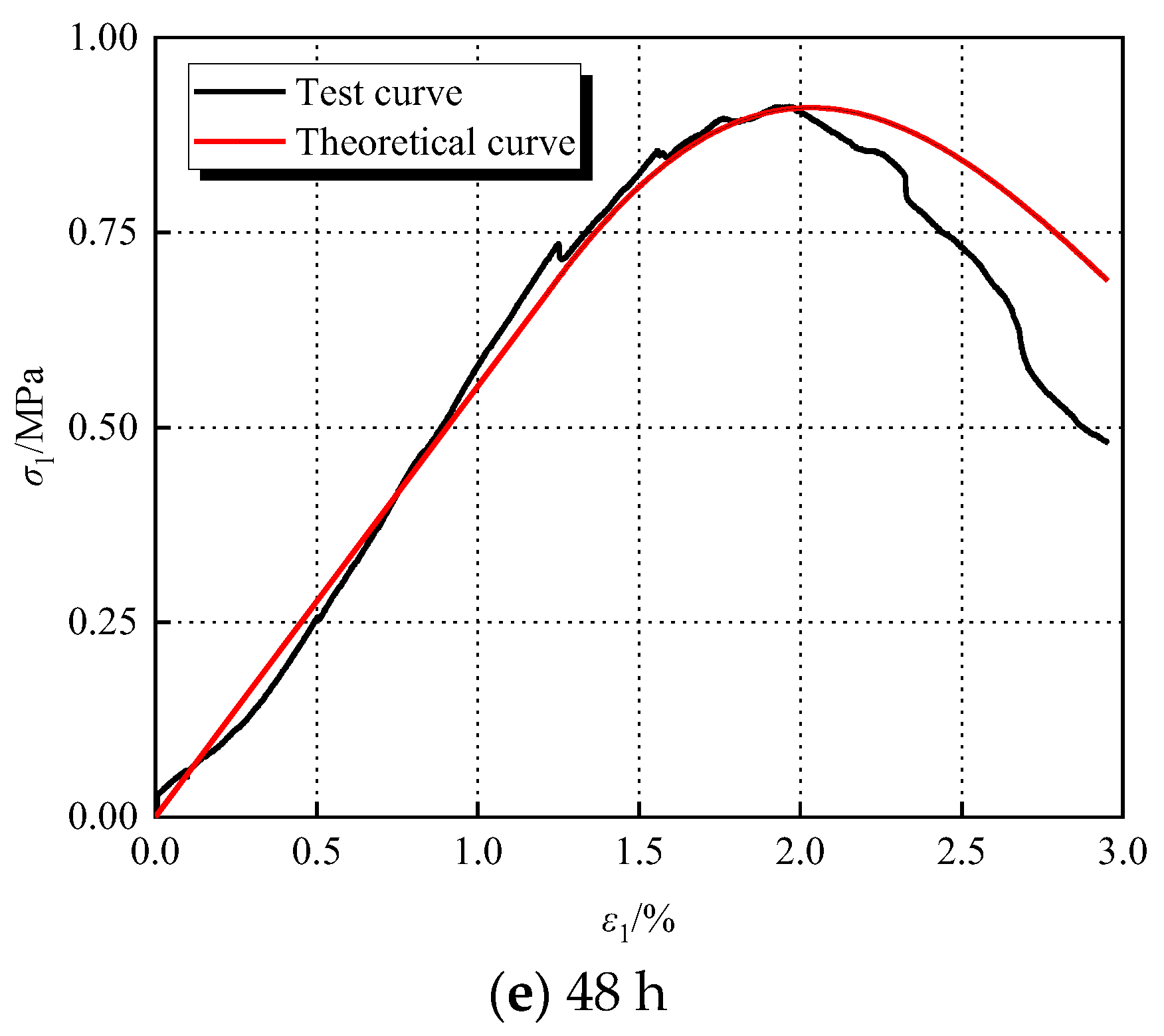

5. Mechanical Damage Behavior of Water-Immersed Mudstone

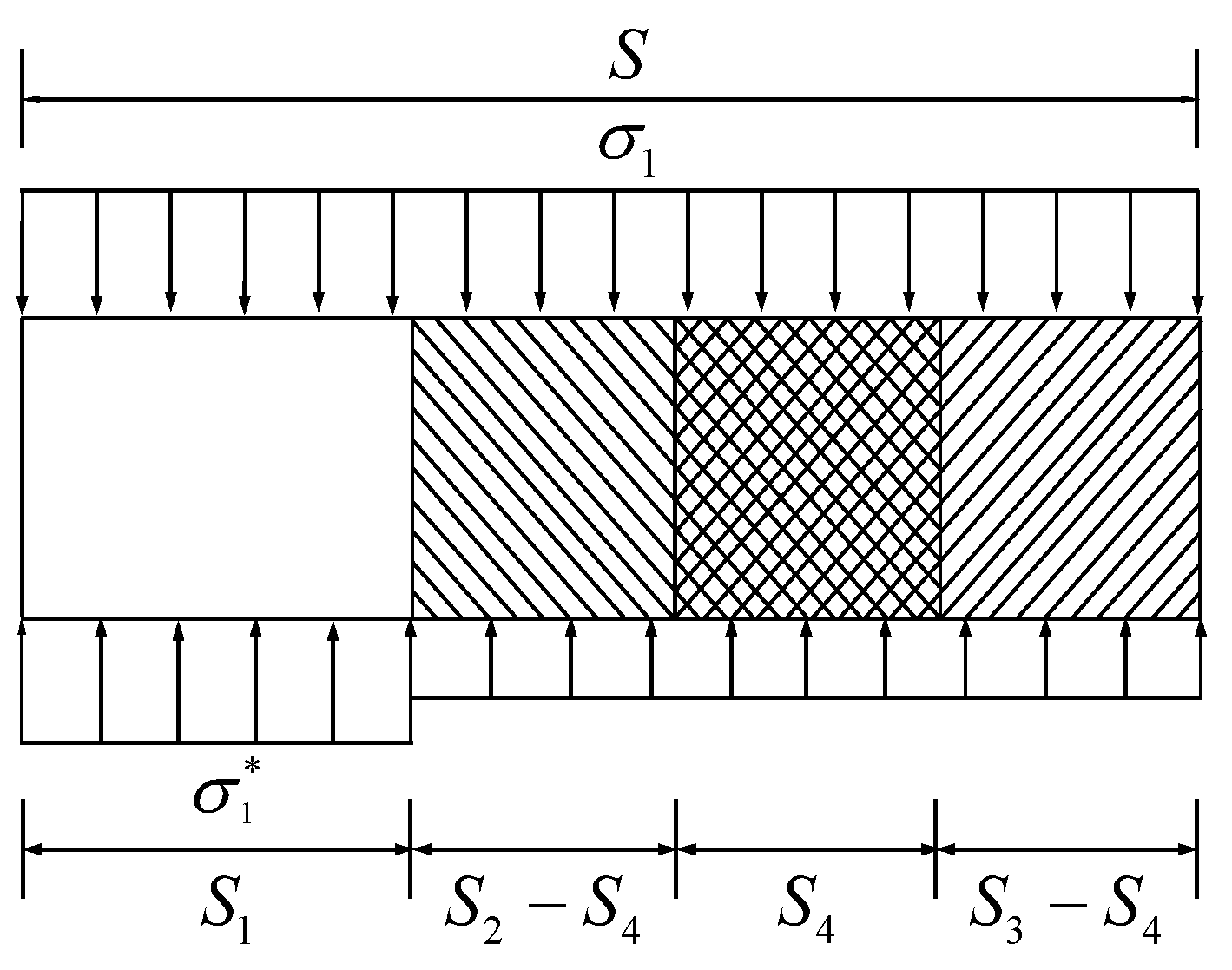

5.1. Geometric Damage Model

5.2. Damage Constitutive Model

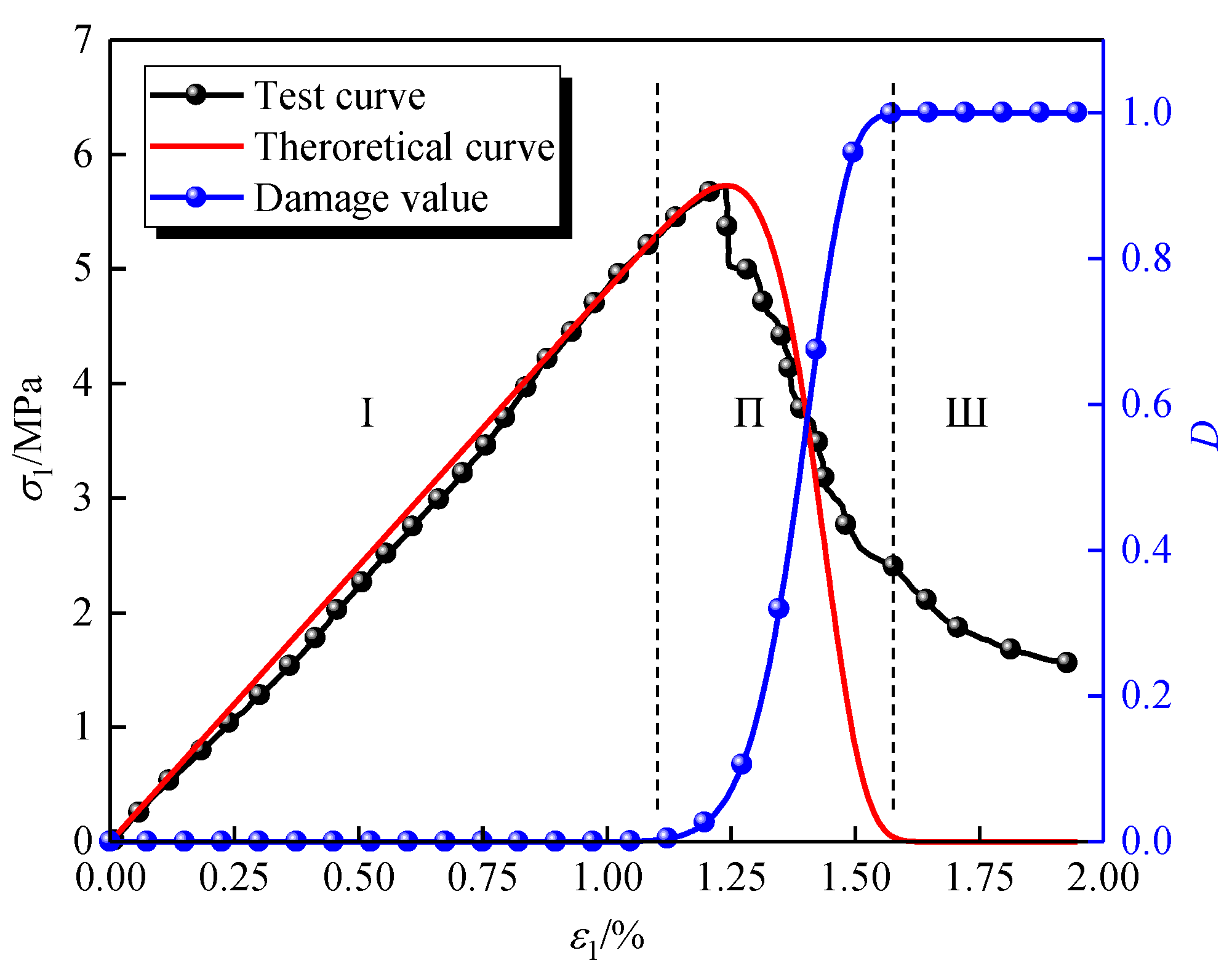

5.3. Damage Evolution Law of Immersed Mudstone

5.4. Immersion Deterioration Mechanism of Mudstone

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, L.Q.; Ju, N.P. Effect of the inclined weak interlayers on the rainfall response of a bedded rock slope. J. Mt. Sci. 2016, 13, 1663–1674. [Google Scholar] [CrossRef]

- Yang, Y.C.; Xing, H.G.; Yang, X.G. Experimental study on the dynamic response and stability of bedding rock slopes with weak interlayers under heavy rainfall. Environ. Earth Sci. 2018, 77, 433. [Google Scholar] [CrossRef]

- Zhong, S.H.; Miao, Y.J. Research on the influence of weak interlayer in open-pit slope on stability. Adv. Civ. Eng. 2021, 2021, 4256740. [Google Scholar] [CrossRef]

- David, C.; Menéndez, B.; Mengus, J.M. X-ray imaging of water motion during capillary imbibition: Geometry and kinetics of water front in intact and damaged porous rocks. J. Geophys. Res. Solid Earth. 2011, 116, B03204. [Google Scholar] [CrossRef]

- Clarke, K.C. Computation of the fractal dimension of topographic surfaces using the triangular prism surface area method. Comput. Geosci. 1986, 12, 713–722. [Google Scholar] [CrossRef]

- Den Brok, S.W.J.; Spiers, C.J. Experimental evidence for water weakening of quartzite by microcracking plus solution-precipitation creep. J. Geol. Soc. Lond. 1991, 148, 541–548. [Google Scholar] [CrossRef]

- Wang, L.L.; Bornert, M.; Héripré, E. The mechanisms of deformation and damage of mudstones: A micro-scale study combining ESEM and DIC. Rock Mech. Rock Eng. 2015, 48, 1913–1926. [Google Scholar] [CrossRef]

- Bian, K.; Liu, J.; Zhang, W. Mechanical behavior and damage constitutive model of rock subjected to water-weakening effect and uniaxial loading. Rock Mech. Rock Eng. 2019, 52, 97–106. [Google Scholar] [CrossRef]

- Ma, H.F.; Song, Y.Q.; Chen, S.J. Experimental investigation on the mechanical behavior and damage evolution mechanism of water-immersed gypsum rock. Rock Mech. Rock Eng. 2021, 54, 4929–4948. [Google Scholar] [CrossRef]

- Vásárhelyi, B. Statistical analysis of the influence of water content on the strength of the miocene limestone. Rock Mech. Rock Eng. 2005, 38, 69–76. [Google Scholar] [CrossRef]

- Mustafa, A.; Mahmoud, M.A.; Abdulraheem, A. Comparative Analysis of Static and Dynamic Mechanical Behavior for Dry and Saturated Cement Mortar. Materials 2019, 12, 3299. [Google Scholar] [CrossRef]

- Cao, M.T.; Yin, S.D. Study on the Tri-axial time-dependent deformation and constitutive model of glauberite salt rock under the coupled effects of compression and dissolution. Energies 2020, 13, 1797. [Google Scholar] [CrossRef]

- Zhou, Z.L.; Cai, X.; Chen, L. Influence of cyclic wetting and drying on physical and dynamic compressive properties of sandstone. Eng. Geol. 2017, 220, 1–12. [Google Scholar] [CrossRef]

- Gao, F.; Wang, Q.L.; Deng, H.W. Coupled effects of chemical environments and freeze–thaw cycles on damage characteristics of red sandstone. Bull. Eng. Geol. Environ. 2017, 76, 1481–1490. [Google Scholar] [CrossRef]

- Tang, L.S.; Zhang, P.C.; Wang, S.J. Testing study on effects of chemical action of aqueous solution on crack propagation in rock. Chin. J. Rock Mech. Eng. 2002, 21, 822–827. [Google Scholar] [CrossRef]

- Liu, L.B.; Zhang, C.; Jiang, W.J. Understanding the sorption behaviors of heavy metal ions in the interlayer and nanopore of montmorillonite: A molecular dynamics study. J. Hazard. Mater. 2021, 416, 125976. [Google Scholar] [CrossRef] [PubMed]

- Hang, P.H.; Wang, J.G.; Liu, S.H. Nonlinear analytical solutions for vertical drainage consolidation of foundations under vacuum-surcharge preloading combined with electroosmosis. Chin. J. Rock Mech. Eng. 2021, 40, 206–216. [Google Scholar] [CrossRef]

- Kuang, L.F.; Zhou, G.Q.; Conrad, B. The micro-mechanism controlling compressibility of saturated clay under high pressure: Status and thoughts. J. China Coal Soc. 2013, 38, 233–238. [Google Scholar] [CrossRef]

- Oueslati, W.; Rhaiem, H.B.; Amara, A.B.H. XRD investigations of hydrated homoionic montmorillonite saturated by several heavy metal cations. Desalination 2011, 271, 139–149. [Google Scholar] [CrossRef]

- Li, G.C.; Li, J.H.; Sun, Y.T. Advance of multi-scale study on both analytic models and water-rock interaction characteristics of mudstone. J. China Coal Soc. 2022, 47, 1138–1154. [Google Scholar] [CrossRef]

- Huang, K.; Yu, F.; Zhang, W. Relationship between capillary water absorption mechanism and pore structure and microfracture of red-layer mudstone in central Sichuan. Bull. Eng. Geol. Environ. 2023, 82, 100. [Google Scholar] [CrossRef]

- Huang, Y.J.; Yang, Z.J.; Ren, W.Y. 3D meso-scale fracture modelling and validation of concrete based on in-situ X-ray Computed Tomography images using damage plasticity model. Int. J. Solids Struct. 2015, 67, 340–352. [Google Scholar] [CrossRef]

- Feng, Z.Y.; Xu, Q.; Luo, X.Y. Microstructure, deformation characteristics and energy analysis of mudstone under water absorption process. Energies 2022, 15, 7511. [Google Scholar] [CrossRef]

- Zhong, Z.B.; Li, A.H.; Deng, R.G. Experimental study on the time-dependent swelling characteristics of red-bed mudstone in Central Sichuan. Chin. J. Rock Mech. Eng. 2019, 38, 76–86. [Google Scholar] [CrossRef]

- Zhou, Z.; Chen, S.X.; Wang, Y.H. Crack evolution characteristics and cracking mechanism of red beds in central sichuan during seepage and swelling. Geofluids 2021, 2021, 9981046. [Google Scholar] [CrossRef]

- Liu, C.D.; Cheng, Y.; Jiao, Y.Y. Experimental study on the effect of water on mechanical properties of swelling mudstone. Eng. Geol. 2021, 295, 106448. [Google Scholar] [CrossRef]

- Yang, J.F.; Li, L.; Lian, H.J. Experimental investigation of the effects of water content on the anisotropy of mode I fracture toughness of bedded mudstones. PLoS ONE 2020, 15, e237909. [Google Scholar] [CrossRef]

- Liu, W.L.; Yan, E.C.; Dai, H. Study on characteristic strength and energy evolution law of Badong formation mudstone under water effect. Chin. J. Rock Mech. Eng. 2020, 39, 311–326. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Liu, W.; Han, L. Disintegration behavior of strongly weathered purple mudstone in drawdown area of three gorges reservoir, China. Geomorphology 2018, 315, 68–79. [Google Scholar] [CrossRef]

- Liu, C.W.; Lu, S.L. Research on mechanism of mudstone degradation and softening in water. Rock Soil Mech. 2000, 21, 28–31. [Google Scholar] [CrossRef]

- Li, G.; Tang, C.A. A statistical meso-damage mechanical method for modeling trans-scale progressive failure process of rock. Int. J. Rock Mech. Min. 2015, 74, 133–150. [Google Scholar] [CrossRef]

- Tang, S.B.; Tang, C.A. Numerical studies on tunnel floor heave in swelling ground under humid conditions. Int. J. Rock Mech. Min. 2012, 55, 139–150. [Google Scholar] [CrossRef]

- Zhou, S.W.; Xia, C.C.; Hu, Y.S. Damage modeling of basaltic rock subjected to cyclic temperature and uniaxial stress. Int. J. Rock Mech. Min. 2015, 77, 163–173. [Google Scholar] [CrossRef]

- Cao, W.G.; Zhao, H.; Li, X. Statistical damage model with strain softening and hardening for rocks under the influence of voids and volume changes. Can. Geotech. J. 2010, 47, 857–871. [Google Scholar] [CrossRef]

- Yang, G.S.; Xie, D.Y.; Zhang, C.Q. CT analysis on mechanic characteristics of damage propagation of rock. Chin. J. Rock Mech. Eng. 1999, 18, 250–254. [Google Scholar]

- Li, S.Y.; Lai, Y.M.; Zhang, S.J. An improved statistical damage constitutive model for warm frozen clay based on Mohr–Coulomb criterion. Cold Reg. Sci. Technol. 2009, 57, 154–159. [Google Scholar] [CrossRef]

- Li, X.; Cao, W.G.; Su, Y.H. A statistical damage constitutive model for softening behavior of rocks. Eng. Geol. 2012, 143–144, 1–17. [Google Scholar] [CrossRef]

- Ma, T.S.; Yang, C.H.; Chen, P. On the damage constitutive model for hydrated shale using CT scanning technology. J. Nat. Gas. Sci. Eng. 2016, 28, 204–214. [Google Scholar] [CrossRef]

- Tang, C.M. Numerical simulation of progressive rock failure and associated seismicity. Int. J. Rock Mech. Min. 1997, 34, 249–261. [Google Scholar] [CrossRef]

- Wang, Z.L.; Li, Y.C.; Wang, J.G. A damage-softening statistical constitutive model considering rock residual strength. Comput. Geosci. 2007, 33, 1–9. [Google Scholar] [CrossRef]

- Ulusay, R. The ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 2007–2014; Springer: Berlin/Heidelberg, Germany, 2015; Volume 74, p. 1499. [Google Scholar]

- Jiang, Q.; Cui, J.; Feng, X.T. Application of computerized tomographic scanning to the study of water-induced weakening of mudstone. Bull. Eng. Geol. Environ. 2014, 73, 1293–1301. [Google Scholar] [CrossRef]

- Huang, H.W.; Che, P. Research on micro-mechanism of softening and argillitization of mudstone. J. Tongji Univ. (Nat. Sci.) 2007, 35, 866–870. [Google Scholar] [CrossRef]

- Mao, H.J.; Guo, Y.T.; Wang, G.J. Evaluation of impact of clay mineral fabrics on hydration process. Rock Soil Mech. 2010, 31, 2723–2728. [Google Scholar] [CrossRef]

- Zhang, Q.G.; Fan, X.Y.; Chen, P. Geomechanical behaviors of shale after water absorption considering the combined effect of anisotropy and hydration. Eng. Geol. 2020, 269, 105547. [Google Scholar] [CrossRef]

- Zhang, Q.G.; Wang, L.Z.; Zhao, P.F. Mechanical properties of lamellar shale considering the effect of rock structure and hydration from macroscopic and microscopic points of view. Appl. Sci. 2022, 12, 1026. [Google Scholar] [CrossRef]

- Gong, F.Q.; Yan, J.Y.; Luo, S. Investigation on the linear energy storage and dissipation laws of rock materials under uniaxial compression. Rock Mech. Rock Eng. 2019, 52, 4237–4255. [Google Scholar] [CrossRef]

- Wang, C.L.; He, B.B.; Hou, X.L. Stress-Energy mechanism for rock failure evolution based on damage mechanics in hard Rock. Rock Mech. Rock Eng. 2020, 53, 1021–1037. [Google Scholar] [CrossRef]

- Peng, R.D.; Xie, H.P.; Ju, Y. Analysis of energy dissipation and damage evolution of sandstone during tensile process. Chin. J. Rock Mech. Eng. 2007, 26, 2526–2531. [Google Scholar] [CrossRef]

- Wang, Z.; Shen, M.R.; Liu, A. Water-Rock interaction characteristics and softening mechanism of calcareous mudstone. J. Southwest Jiaotong Univ. 2015, 50, 1061–1066. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, Y.J.; Hu, X.J. A quasi-brittle fracture investigation of concrete structures integrating random fields with the CSFEM-PFCZM. Eng. Fract. Mech. 2023, 281, 109107. [Google Scholar] [CrossRef]

| Immersion Time/h | Sample Number | /% | E/MPa | UCS/MPa | /% | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mean | Mean | Mean | Mean | |||||||

| 0 | 4 | 0 | 0 | 516.08 | 540.55 | 5.82 | 5.75 | 1.22 | 1.24 | |

| 21 | 0 | 623.91 | 5.71 | 1.26 | ||||||

| 28 | 0 | 481.66 | 5.73 | 1.24 | ||||||

| 12 | 3 | 1.62 | 1.47 | 176.21 | 177.95 | 2.37 | 2.30 | 1.81 | 1.66 | |

| 7 | 1.31 | 210.65 | 2.18 | 1.53 | ||||||

| 10 | 1.47 | 146.99 | 2.36 | 1.65 | ||||||

| 24 | 2 | 2.72 | 2.80 | 125.30 | 131.67 | 2.15 | 2.01 | 1.83 | 1.70 | |

| 5 | 2.73 | 112.62 | 1.86 | 1.53 | ||||||

| 41 | 2.96 | 157.10 | 2.01 | 1.74 | ||||||

| 36 | 6 | 4.63 | 4.81 | 86.32 | 104.11 | 1.42 | 1.47 | 1.87 | 1.75 | |

| 8 | 4.77 | 129.90 | 1.32 | 1.24 | ||||||

| 9 | 5.03 | 96.11 | 1.67 | 2.15 | ||||||

| 48 | 12 | 6.97 | 6.71 | 83.19 | 63.35 | 1.55 | 1.16 | 2.36 | 2.11 | |

| 13 | 6.72 | 58.26 | 0.91 | 1.97 | ||||||

| 32 | 6.43 | 48.60 | 1.03 | 2.00 | ||||||

| Immersion Time/h | u/KJ·m−3 | ue/KJ·m−3 | ud/KJ·m−3 |

|---|---|---|---|

| 0 | 35.56 | 34.03 | 1.53 |

| 12 | 21.59 | 18.98 | 2.61 |

| 24 | 19.67 | 16.64 | 3.03 |

| 36 | 14.71 | 11.73 | 2.98 |

| 48 | 10.34 | 6.32 | 4.02 |

| Immersion Time/h | /MPa | /% | /% | /MPa | ||

|---|---|---|---|---|---|---|

| 0 | 481.66 | 0.812 | 1.24 | 5.73 | 8.256 | 0.006 |

| 12 | 146.99 | 0.713 | 1.65 | 2.36 | 20.806 | 0.011 |

| 24 | 125.30 | 1.601 | 1.83 | 2.15 | 1.952 | 0.009 |

| 36 | 86.32 | 1.202 | 1.87 | 1.42 | 2.795 | 0.014 |

| 48 | 58.26 | 1.150 | 1.97 | 0.91 | 1.793 | 0.019 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Zheng, J.; Ma, H.; Shao, Z.; Yang, J.; Shen, F.; Liu, C. Study on Uniaxial Mechanical Behavior and Damage Evolution Mechanism of Water-Immersed Mudstone. Sustainability 2023, 15, 12499. https://doi.org/10.3390/su151612499

Song Y, Zheng J, Ma H, Shao Z, Yang J, Shen F, Liu C. Study on Uniaxial Mechanical Behavior and Damage Evolution Mechanism of Water-Immersed Mudstone. Sustainability. 2023; 15(16):12499. https://doi.org/10.3390/su151612499

Chicago/Turabian StyleSong, Yanqi, Junjie Zheng, Hongfa Ma, Zhixin Shao, Jiangkun Yang, Fuxin Shen, and Chuanpeng Liu. 2023. "Study on Uniaxial Mechanical Behavior and Damage Evolution Mechanism of Water-Immersed Mudstone" Sustainability 15, no. 16: 12499. https://doi.org/10.3390/su151612499

APA StyleSong, Y., Zheng, J., Ma, H., Shao, Z., Yang, J., Shen, F., & Liu, C. (2023). Study on Uniaxial Mechanical Behavior and Damage Evolution Mechanism of Water-Immersed Mudstone. Sustainability, 15(16), 12499. https://doi.org/10.3390/su151612499