A Simulation Study on Evaluating the Influence of Impurities on Hydrogen Production in Geological Carbon Dioxide Storage

Abstract

:1. Introduction

2. Theoretical Background

3. Methods

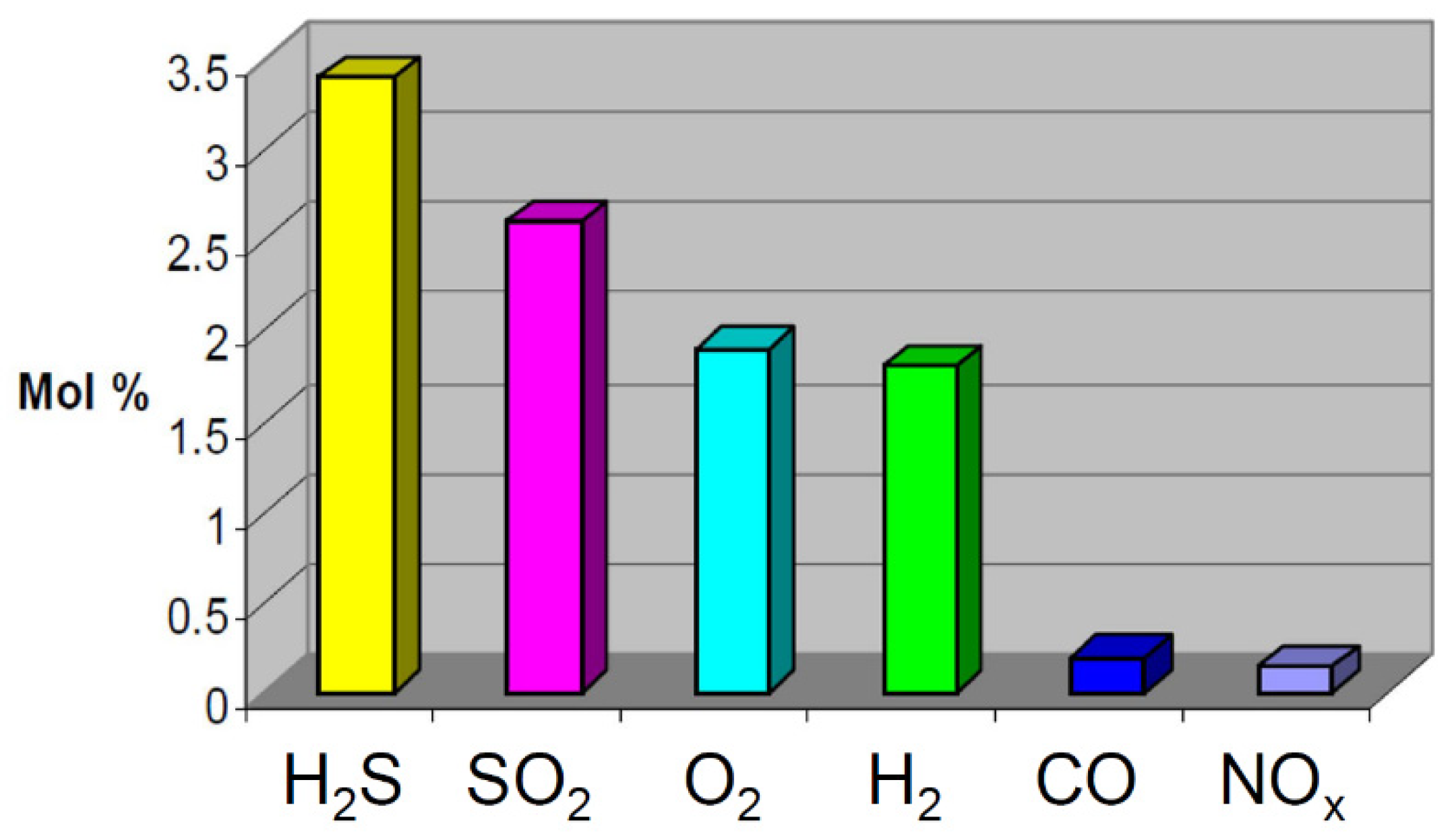

3.1. Fluid Model

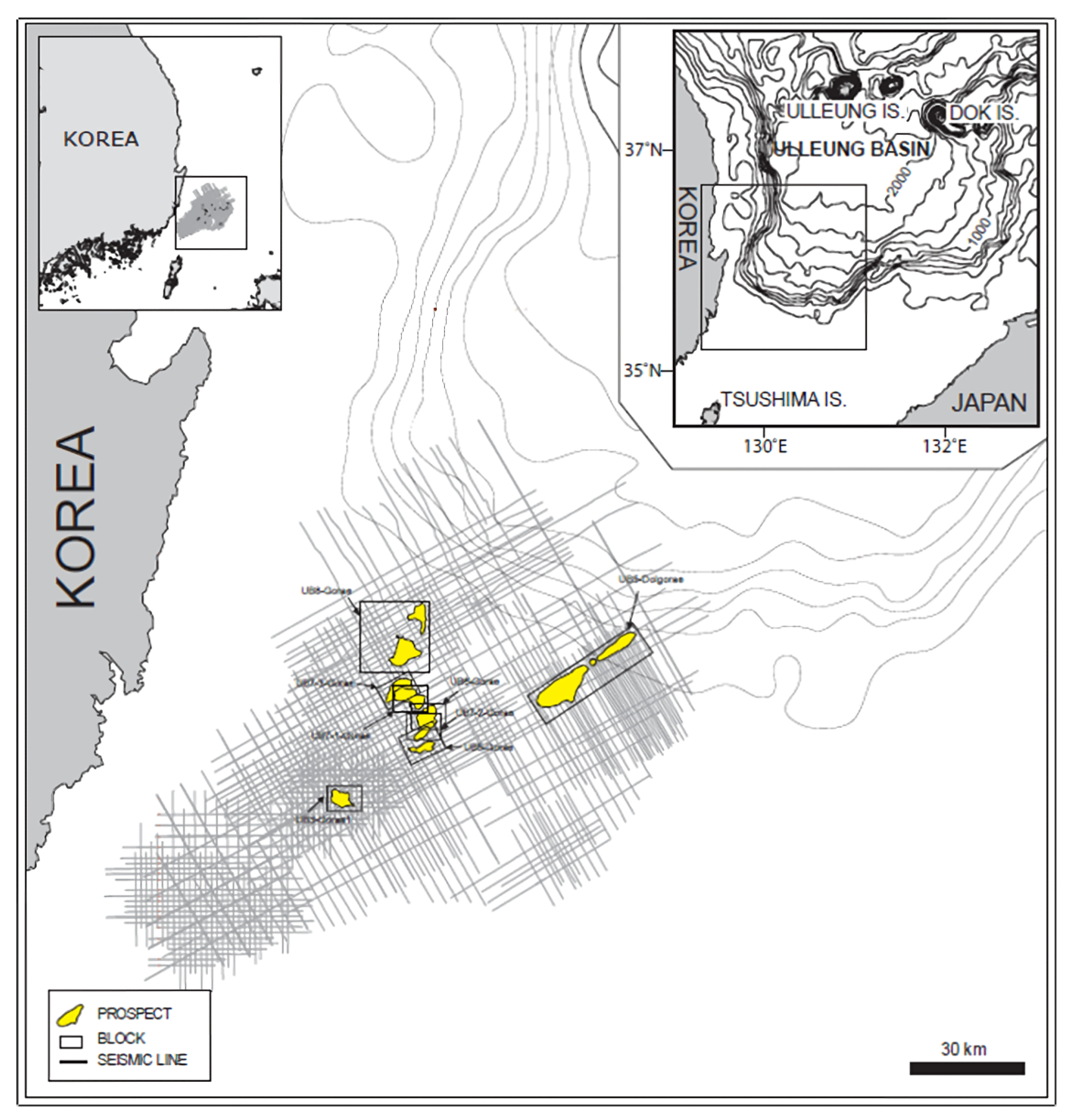

3.2. Reservoir Model

3.3. CO2 Injection Scenarios

4. Analysis of Simulation Results

4.1. Fluid Model Results

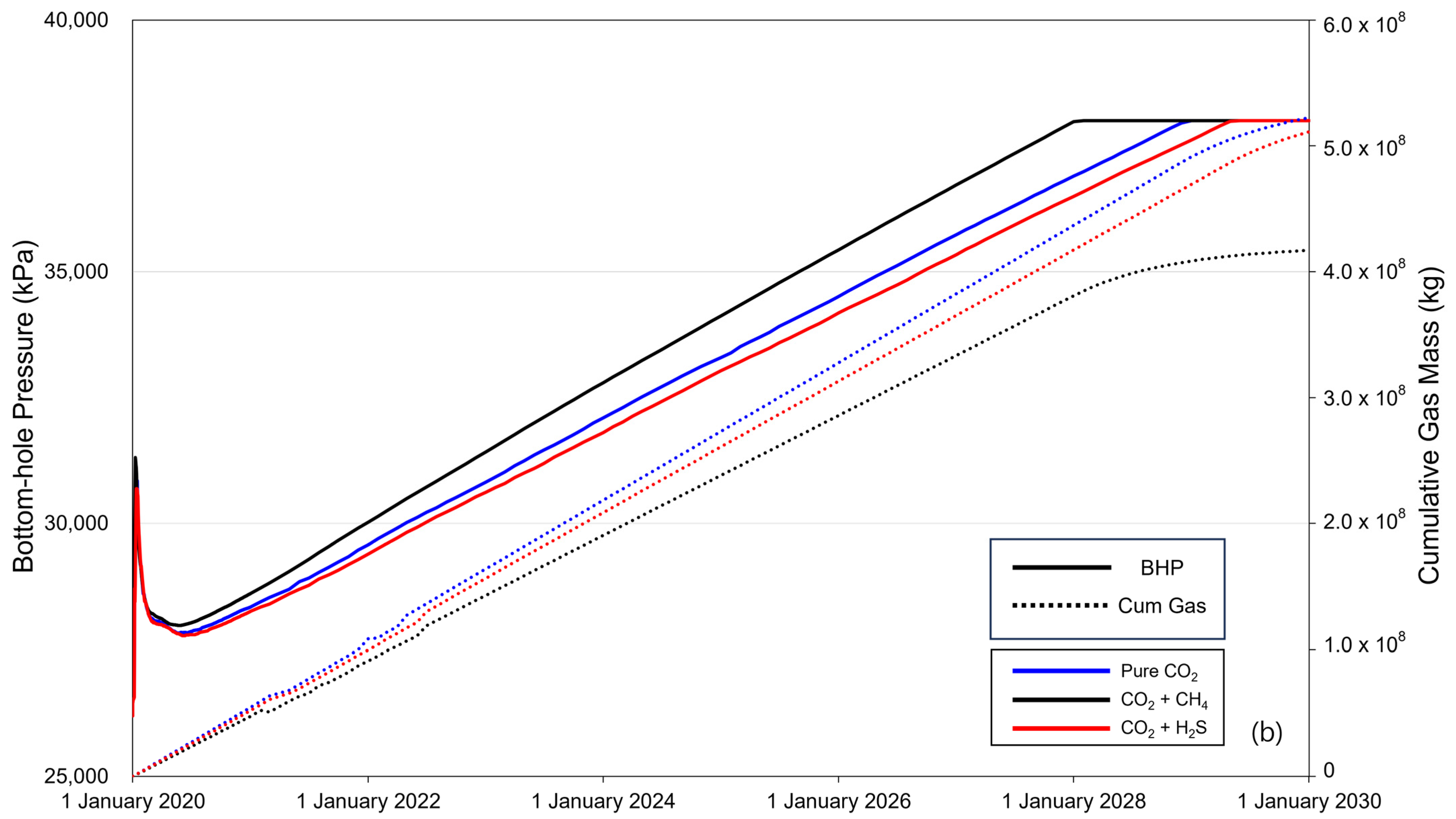

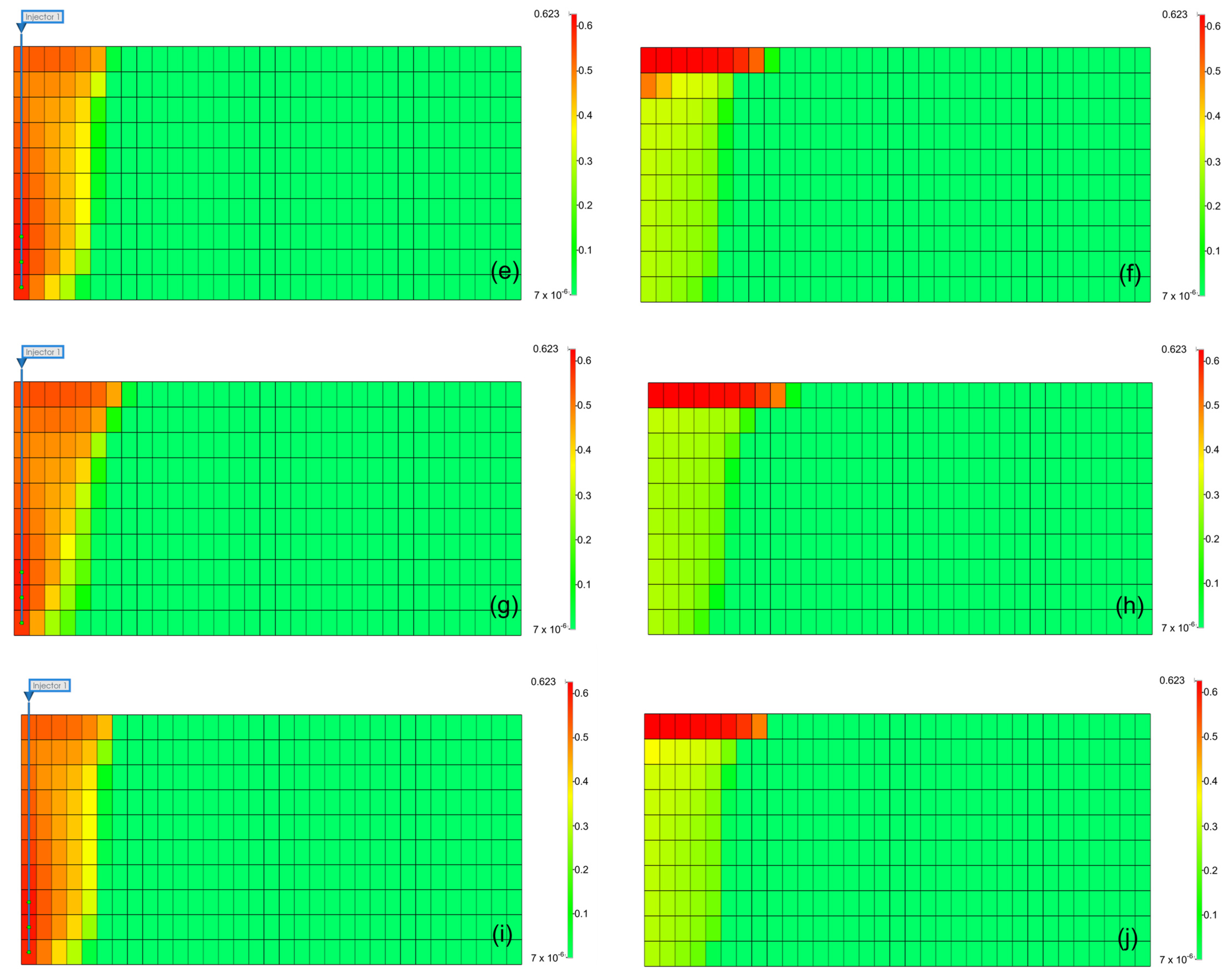

4.2. Dynamic Simulation Model Results

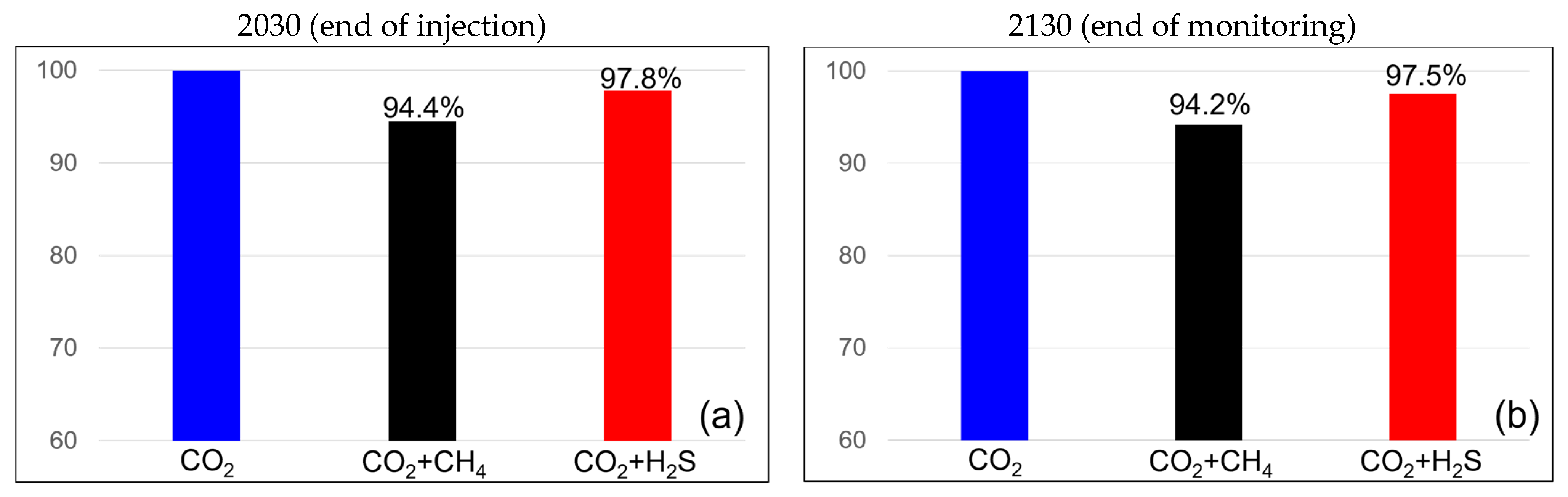

4.3. Effects of Impurities on CO2 Trapping Efficiency

5. Discussion

6. Conclusions

- Impurities affected the CO2 stream under initial reservoir conditions. In the case of methane, the density decreases compared to that of pure CO2, and its volume ratio increases, whereas the viscosity decreases. In contrast, a smaller change in density is shown in H2S than in methane, and its volume decreases relative to the injection concentration, whereas, compared to pure CO2, its viscosity increases;

- When the same amount of gas is injected into the reservoir, reaching the pressure limit of the reservoir occurs more rapidly when methane is present, while that with H2S takes longer than that with pure CO2. The difference in the time required to reach the pressure limit increases with impurity concentration. These phenomena affect the amount of CO2 injected into the stream;

- Once the pressure limit is reached, the injection amounts differ, leading to variations in CO2 storage. Methane present at 3.5% resulted in 95.04% CO2 injection, and at 20%, only 73.16% CO2 was injected. In contrast, with H2S at 3.5%, 96.91% CO2 was injected, and at 20%, 81.99% CO2 was injected. Consequently, methane stores less CO2 relative to the mixture ratio, whereas H2S stores more;

- Methane results in a relatively low density, reducing the contact time between the brine and CO2 and decreasing the dissolution effect. The CO2 volume ratio within the gas mixture also decreases, leading to a reduced amount of CO2 that can be retained in the rock pores;

- When storing CO2 underground, methane causes a rapid increase in BHP and decreases storage efficiency. However, if H2S is not removed and injection occurs with CO2, the BHP increases more slowly than with the pure CO2 injection. Additionally, the volume ratio of CO2 in the mixed gas decreases, leading to improved storage efficiency. For CCS projects, methane impurities in the CO2 stream require removal. In contrast, H2S may not require steps such as desulfurization because it does not significantly impact CO2 storage efficiency. Employing CCS for carbon dioxide emissions containing H2S as an impurity can enable economically viable operations by reducing additional costs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| List of Abbreviations | |

| CO2 | Carbon dioxide |

| H2S | Hydrogen sulfide |

| CCS | Carbon capture and storage |

| LSSVM | Least square support vector machine |

| VLE | Vapor–liquid equilibrium |

| SMR | Steam methane reforming |

| WAG | Water alternating gas |

| EOR | Enhanced oil recovery |

| EGR | Enhanced gas recovery |

| WGS | Water gas shift |

| CMG | Computer modeling group |

| CH4 | Methane |

| H2O | Water |

| H2 | Hydrogen |

| CO | Carbon monoxide |

| C | Carbon |

| O2 | Oxygen |

| MEA | Monoethanolamine |

| COS | Carbonyl sulfide |

| Ar | Argon |

| SOx | Sulfur oxide |

| NOx | Nitrogen oxide |

| N2 | Nitrogen |

| NH3 | Ammonia |

| pH | Power of hydrogen |

| H2CO3 | Carbonic acid |

| H+ | Hydrogen ion |

| HCO3− | Bicarbonate |

| HS− | Bisulfide |

| H3O+ | Hydronium ion |

| PR-EOS | Peng–Robinson equation of state |

| BHP | Bottom-hole pressure |

| Cum Gas | Cumulative gas |

| List of Symbols | |

| Pressure | |

| R | Universal gas constant |

| T | Temperature |

| Volume of mixture | |

| b | Repulsion effect |

| Critical temperature | |

| Critical pressure | |

| Mole fraction | |

| Binary parameter | |

| Fugacity of gas phase | |

| Fugacity of aqueous phase | |

| Fugacity of component | |

| Mole fraction of in the liquid phase | |

| Henry’s constant | |

| Concentration | |

| Time | |

| Fick’s diffusion coefficient | |

| Greek Symbol | |

| Acentric factor |

References

- Ministry of Trade, Industry and Energy. First Master Plan for Implementing the Hydrogen Economy. Available online: https://www.motie.go.kr/motie/ms/nt/announce2/bbs/bbsView.do?bbs_seq_n=67130&bbs_cd_n=6 (accessed on 7 June 2023).

- Wang, J.; Ryan, D.; Anthony, E.J.; Wigston, A. Effect of Impurities on Geological Storage of CO2 2. EAGHIG; Global CCS Institute: Cheltenham, UK, 2011. [Google Scholar]

- Exxon Mobil. Shute Creek. Exxon Mobil Shute Creek Treating Facility Subpart PR Amended Monitoring, Reporting and Verification Plan 2019. Available online: https://www.epa.gov/sites/default/files/2019-12/documents/shutecreekmrvplan2019.pdf (accessed on 6 June 2023).

- Szott, W.; Łętkowski, P.; Gołąbek, A.; Miłek, K. Modelling of the long-term acid gas sequestration and its prediction: A unique case study. Energies 2020, 13, 4701. [Google Scholar] [CrossRef]

- Clark, D.E.; Oelkers, E.H.; Gunnarsson, I.; Sigfússon, B.; Snæbjörnsdóttir, S.Ó.; Aradóttir, E.S.; Gíslason, S.R. Carbfix2: CO2 and H2S mineralization during 3.5 years of continuous injection into basaltic rocks at more than 250 °C. Geochim. Cosmochim. Acta 2020, 279, 45–66. [Google Scholar] [CrossRef]

- Nogueira, M.; Mamora, D.D. Effect of flue-gas impurities on the process of injection and storage of CO2 in depleted gas reservoirs. J. Energy Resour. Technol. 2008, 130, 013301. [Google Scholar] [CrossRef]

- Li, D.; He, Y.; Zhang, H.; Xu, W.; Jiang, X. A numerical study of the impurity effects on CO2 geological in layered formation. Appl. Energy 2017, 199, 107–120. [Google Scholar] [CrossRef]

- Gaus, I.; Azaroual, M.; Czernichowski-Lauriol, I. Reactive transport modelling of the impact of CO2 injection on the clayey cap rock at Sleipner (North Sea). Chem. Geol. 2005, 217, 319–337. [Google Scholar] [CrossRef]

- Cho, J.; Min, B.; Kwon, S.; Park, G.; Lee, K.S. Compositional modeling with formation damage to investigate the effects of CO2-CH4 water alternation gas (WAG) on performance of coupled enhanced oil recovery and geological carbon storage. J. Petrol. Sci. Eng. 2021, 205, 108795. [Google Scholar] [CrossRef]

- Kim, Y.; Jang, H.; Kim, J.; Lee, J. Prediction of storage efficiency on CO2 sequestration in deep saline aquifers using artificial neural network. Appl. Energy 2017, 185, 916–928. [Google Scholar] [CrossRef]

- Sedaghat, M.; Rouhibakhsh, K. Investigation of carbon dioxide capture and storage by a novel LSSVM-GA method. Pet. Sci. Technol. 2020, 38, 421–427. [Google Scholar] [CrossRef]

- Schöneich, S.; May, F.; Vosteen, H.D. Influence of Impurities in CO2-Rich Gas Mixtures on the Storage Capacity of Mature Natural Gas Fields; DGMK/ÖGEW-Frühjahrstagung; Fachbereich Aufsuchung und Gewinnung: Celle, Germany, 2007. [Google Scholar]

- Lee, Y.; Kim, G.; Ki, S.; Seo, J. Development of Conceptual Cost Estimation Model for an Economic Analysis of Steam Methane Reforming based Hydrogen Production. J. Korean Soc. Miner. Energy Resour. Eng. 2022, 59, 193–204. [Google Scholar] [CrossRef]

- Kim, J.W.; Sim, K.S. Hydrogen Production Technologies from Coal. J. Korean Hydrog. Energy Soc. 1996, 7, 193–206. [Google Scholar]

- Aghel, B.; Janati, S.; Wongwises, S.; Shadloo, M.S. Review on CO2 capture by blended amine solutions. Int. J. Greenh. Gas Control 2022, 119, 103715. [Google Scholar] [CrossRef]

- Sanz, W.; Mayr, M.; Jericha, H. Thermodynamic and economic evaluation of an IGCC plant based on the Graz cycle for CO2 capture. In Proceedings of the ASME Turbo Expo 2010: Power for Land, Sea, and Air, Glashow, UK, 14–18 June 2010; pp. 493–503. [Google Scholar] [CrossRef]

- Lavalin, S.N.C. Impact of Impurities on CO2 Capture, Transport and Storage; IEA: Paris, France, 2004. [Google Scholar]

- Metz, B.; Davidson, O.; Cononck, H.; Loos, M.; Meyer, L. IPCC Special Report on Carbon Dioxide Capture and Storage; Cambridge University Press: New York, NY, USA, 2005; pp. 105–179. [Google Scholar]

- IEA Energy Technology Systems Analysis Programme. CO2 Capture and Storage; IEA ETSAP Technology Brief E14. 2010. Available online: https://iea-etsap.org/E-TechDS/PDF/E14_CCS_oct2010_GS_gc_AD_gs.pdf (accessed on 13 June 2023).

- Aminu, M.D.; Nabavi, S.A.; Manovic, V. CO2-brine-rock interactions: The effect of impurities on grain size distribution and reservoir permeability. Int. J. Greenh. Gas Control 2018, 78, 168–176. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, J.; Lan, C.; He, I.; Ko, V.; Ryan, D.; Wigston, A. A study on the impact of SO2 on CO2 injectivity for CO2 storage in a Canadian saline aquifer. Appl. Energy 2016, 184, 329–336. [Google Scholar] [CrossRef]

- Huh, C.; Kang, S.G. Effect of nitrogen impurity on process design of CO2 marine geological storage: Evaluation of equation of state and optimization of binary parameter. J. Korea Soc. 2009, 12, 217–226. [Google Scholar]

- Feizabadi, S.A. An Equation-of-State Based Mathematical Modeling of Four-Phase Flow in Porous Media. Ph.D. Thesis, University of Calgary, Calgary, AB, Canada, 2013. [Google Scholar]

- Nghiem, L.; Sammon, P.; Grabenstetter, J.; Ohkuma, H. Modeling CO2 storage in aquifers with a fully-coupled geochemical EOS compositional simulator. In Proceedings of the SPE/DOE symposium on Improved Oil Recovery, Tulsa, OK, USA, 17–21 April 2004. [Google Scholar]

- Rezk, M.G.; Farid Ibrahim, A.; Adebayo, A.R. Influence of impurities on reactive transport of CO2 during geo-Sequestration in saline aquifer. Fuel 2023, 344, 127994. [Google Scholar] [CrossRef]

- Reid, R.C.; Sherwood, T.K.; Street, R.E. The Properties of Gases and Liquids. Phys. Today 1959, 12, 38–40. [Google Scholar] [CrossRef]

- Ministry of Oceans and Fisheries. Available online: https://www.mof.go.kr/doc/ko/selectDoc.do?menuSeq=971&bbsSeq=10&docSeq=2046 (accessed on 28 August 2023).

- Lee, Y.S.; Park, Y.C.; Kwon, S.I.; Sung, W.M. The feasibility study for CO2 sequestration into deep saline aquifer at Goare-V structure in Korea. J. Korean Soc. Geosyst. Eng. 2008, 45, 381–393. [Google Scholar]

- Kim, N.H.; Jung, H.S.; Kim, G.D.; Jeong, H.; Shin, H.; Kwon, Y.K.; Choe, J. The stability assessment of an aquifer in Pohang Yeongil bay due to CO2 injection. J. Eng. Geol. 2018, 28, 183–192. [Google Scholar]

- Law, D.H.-S.; Bachu, S. Hydrogeological and numerical analysis of CO2 disposal in deep aquifers in the Alberta sedimentary basin. Energy Convers. Manag. 1996, 37, 1167–1174. [Google Scholar] [CrossRef]

- Blanco, S.T.; Rivas, C.; Fernández, J.; Artal, M.; Velasco, I. Influence of methane in CO2 transport and storage for CCS technology. Environ. Sci. Technol. 2012, 46, 13016–13023. [Google Scholar] [CrossRef] [PubMed]

| Description | Possible Impurities |

|---|---|

| CO2 captured from natural gas sweetening | CH4, amines, H2O |

| CO2 captured from heavy oil production and upgrading | H2S, N2, O2, CO, H2O, COS, Ar, SOx, NOx |

| CO2 captured from power plants using post-combustion capture | N2, amines, H2O, O2, NH3, SOx, NOx |

| CO2 captured from power plants using oxy-combustion capture | N2, O2, SO2, H2S, Ar |

| CO2 captured from power plants using pre-combustion capture | H2, CO, N2, H2S, CH4 |

| CCS Site | Capacity (Approximately) |

|---|---|

| Oil and gas fields | 675–1200 Gt |

| Deep saline aquifers | 1000–10,000 Gt |

| Unmineable coal seams | 100–200 Gt |

| Parameter | Value | ||

|---|---|---|---|

| Reservoir temperature (K) | 376.2 K | ||

| Reservoir initial pressure (atm) | 244.8 | ||

| Components | CO2 | CH4 | H2S |

| Critical temperature (K) | 30.1 | −82.8 | 100.1 |

| Critical pressure (atm) | 11.4 | 4.6 | 8.9 |

| Acentric factor | 0.228 | 0.011 | 0.031 |

| Impurity contents in the CO2 stream | 3.5 mol.%, 20 mol.% | ||

| Parameters | Value |

|---|---|

| Grid type | Block type |

| Number of cells | 33 × 33 × 10 (10,890) |

| Grid size | 100 × 100 × 6 m |

| Depth | 2450 m |

| Initial pressure | 24.8 MPa |

| Initial temperature | 103 |

| Horizontal permeability | 50 md |

| Vertical permeability | 5 md |

| Porosity | 16% |

| Thickness | 60 m |

| Initial water saturation | 100% |

| Parameters | Value |

|---|---|

| Maximum bottom-hole pressure | 38 MPa |

| Gas injection rate | 146.4 ton/d |

| Injection period | 10 years |

| Monitoring period | 100 years |

| Impurities | CH4, H2S |

| Impurity contents in the CO2 stream | 3.5%, 20% |

| Parameter | Pure CO2 | CO2-CH4 | CO2-H2S | ||

|---|---|---|---|---|---|

| Impurity Content (mol.%) | - | 3.5 | 20 | 3.5 | 20 |

| Impurity Volume (vol.%) | - | 5.13 | 27.16 | 2.24 | 13.66 |

| Molar mass (g/mol) | 44.01 | 43.03 | 38.42 | 43.66 | 42.02 |

| Molar volume (m3/kmol) | 0.0802 | 0.0824 | 0.0921 | 0.0800 | 0.0776 |

| Density (kg/m3) | 548.50 | 521.97 | 417.25 | 546.07 | 541.78 |

| Viscosity (cp) | 0.045 | 0.043 | 0.037 | 0.045 | 0.046 |

| Parameter | 1 January 2028 | 1 January 2029 | 1 January 2030 |

|---|---|---|---|

| CO2 96.5% + CH4 3.5% | 96.5% | 96.1% | 95.04% |

| CO2 96.5% + H2S 3.5% | 96.5% | 96.5% | 96.91% |

| CO2 80% + CH4 20% | 79.9% | 76.2% | 73.16% |

| CO2 80% + H2S 20% | 80.8% | 80.8% | 81.99% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ko, S.; Kim, S.-M.; Jang, H. A Simulation Study on Evaluating the Influence of Impurities on Hydrogen Production in Geological Carbon Dioxide Storage. Sustainability 2023, 15, 13620. https://doi.org/10.3390/su151813620

Ko S, Kim S-M, Jang H. A Simulation Study on Evaluating the Influence of Impurities on Hydrogen Production in Geological Carbon Dioxide Storage. Sustainability. 2023; 15(18):13620. https://doi.org/10.3390/su151813620

Chicago/Turabian StyleKo, Seungmo, Sung-Min Kim, and Hochang Jang. 2023. "A Simulation Study on Evaluating the Influence of Impurities on Hydrogen Production in Geological Carbon Dioxide Storage" Sustainability 15, no. 18: 13620. https://doi.org/10.3390/su151813620

APA StyleKo, S., Kim, S.-M., & Jang, H. (2023). A Simulation Study on Evaluating the Influence of Impurities on Hydrogen Production in Geological Carbon Dioxide Storage. Sustainability, 15(18), 13620. https://doi.org/10.3390/su151813620