Biomaterials and Regenerative Agriculture: A Methodological Framework to Enable Circular Transitions

Abstract

:1. Introduction

2. Materials and Methods

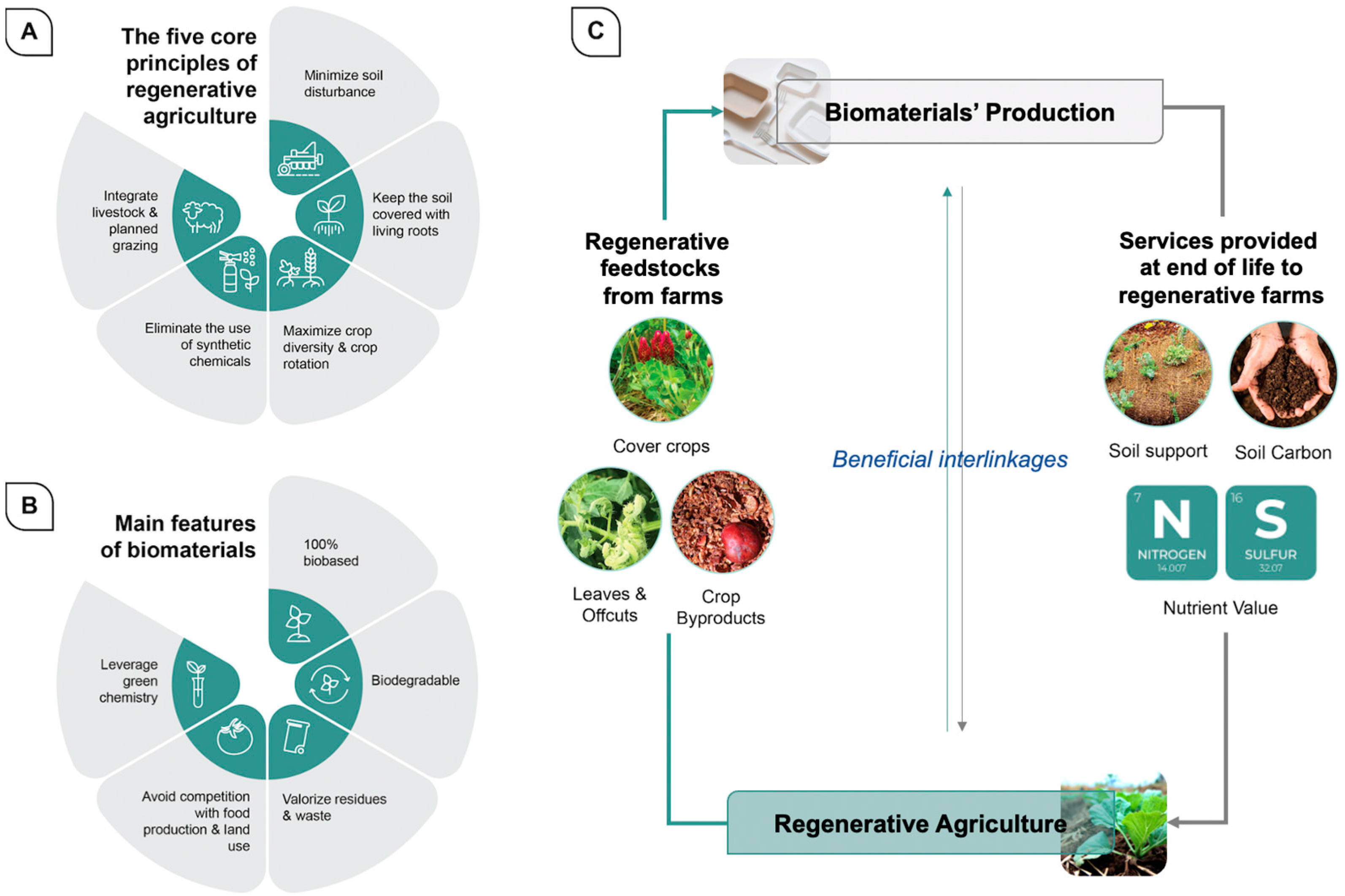

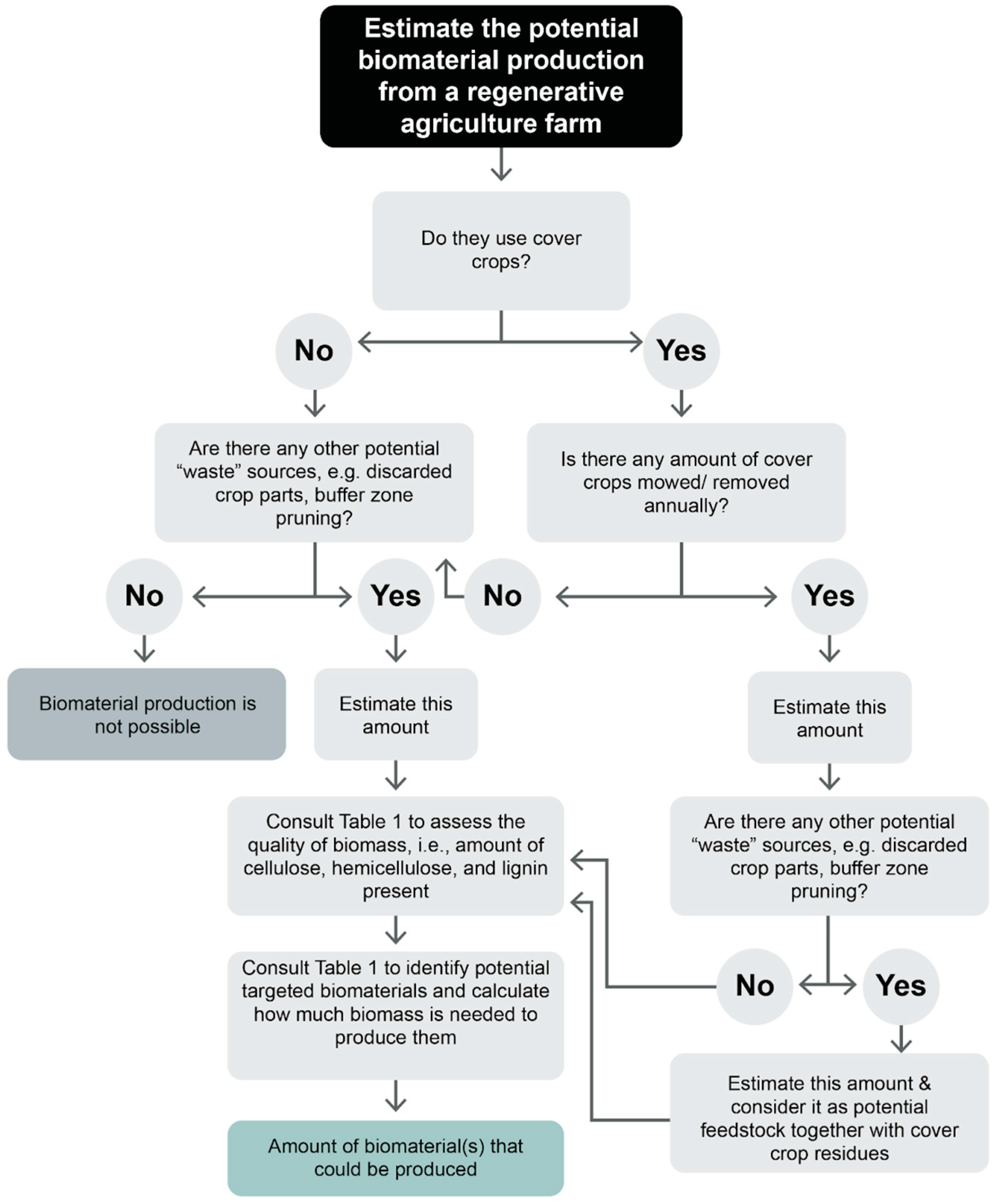

2.1. Could Regenerative Agriculture Serve as a Resource for Biomaterials Production?

| Lignocellulosic Biomass Source | Typical Composition [% wt.] | Examples of Derived Biomaterials | Reference | |||

|---|---|---|---|---|---|---|

| Cellulose | Hemicellulose | Lignin | Other * | |||

| Cover crop residues | ||||||

| Abruzzi rye | 25% | 25% | 3% | 46% | Biobased and compostable biopolymers, such as bio-polyethylene (bio-PE), bio-polypropylene (bio-PP), and poly(lactic) acid (PLA) | [23,36] |

| Black oat | 25% | 21% | 2% | 52% | ||

| Crimson clover | 25% | 10% | 3% | 62% | ||

| Hairy vetch | 27% | 14% | 5% | 54% | ||

| Winter barley | 20% | 21% | 1% | 53% | ||

| Main crop residues | ||||||

| Corn stover | 29–61% | 10–32% | 3–35% | 5–17% | PLA, cellulose films (e.g., cellophane), thermoplastic starch, lignocellulosic fibers, starch-based bioplastics | [39,40,41,42,43,44,45] |

| Rice straw | 28–43% | 19–27% | 5–36% | 8–48% | PLA, rice straw bioplastics and biofilms for packaging, straws, plates, and coffee cups | [43,44,46,47,48,49] |

| Wheat straw | 29–51% | 10–39% | 5–30% | 1–7% | PLA, wheat straw bioplastics for packaging, straws, plates, and coffee cups | [46,48,50] |

| Sugarcane bagasse | 40–60% | 18–57% | 18–32% | 3–15% | Bio-PE from sugarcane ethanol; bio-polyethylene terephthalate (bio-PET); biocomposites of sugarcane fibers with PLA or bio-PE for textiles and building materials; CNCs for biocomposites; foam trays and films for packaging | [44,48,49,51,52,53,54,55,56] |

| Main crop by-products and processing waste | ||||||

| Apple pomace | 39% | 29% | 20% | 12% | Apple-pectin leather, biopolymer films, fiberboards and biocomposites after mixing w/pectin, citric acid, glycerol, or biopolymers | [56,57,58,59] |

| Grape pomace | 18% | 7% | 52% | 23% | Biocomposites and biopolymer films, e.g., by mixing w/PLA, low-methoxyl pectin (LMP), and glycerol | [56] |

| Olive pomace | 25% | 34% | 34% | 7% | Biocomposites of dried and ground olive pomace w/biopolymers, e.g., PLA | [56] |

| Coconut husk | 34% | 21% | 27% | 18% | Biocomposites of untreated/silane–/sodium hydroxide-treated biomass fibers w/biopolymers, e.g., PLA, gluten polymers, and tapioca biopolymer | [56] |

| Banana peels and fibers | 63% | 19% | 5% | 13% | ||

| Pineapple leaf fibers | 66% | 20% | 4% | 10% | ||

| Mango peel | 9% | 14% | 4% | 63% | ||

| Orange waste | 19–22% | 11–21% | <1% | 55–70% | Orange waste powder biofilms after blending with maleic anhydride; fiberboards after mixing w/pectin and/or glycerol | [58,60] |

| Forestry residues and woody biomass | ||||||

| Hardwood | 38–55% | 17–40% | 18–31% | 3% | Biodegradable packaging films; cellulosic fibers, such as viscose, lyocell, modal, cellulose acetate, and cellulose triacetate; cellulose-based biocomposites, e.g., when blended w/PLA | [44,61,62,63] |

| Softwood | 33–50% | 22–40% | 25–35% | 2–3.5% | ||

| Leaves and residues from herbaceous plants | 15–95% | 20–85% | 0–40% | 4–9% | Natural dyes and pigments; blended w/biopolymers, e.g., PLA and polyethylene glycol (PEG), to form biocomposites for pharmaceutical, cosmetic, and biomedical use | [44,64,65,66] |

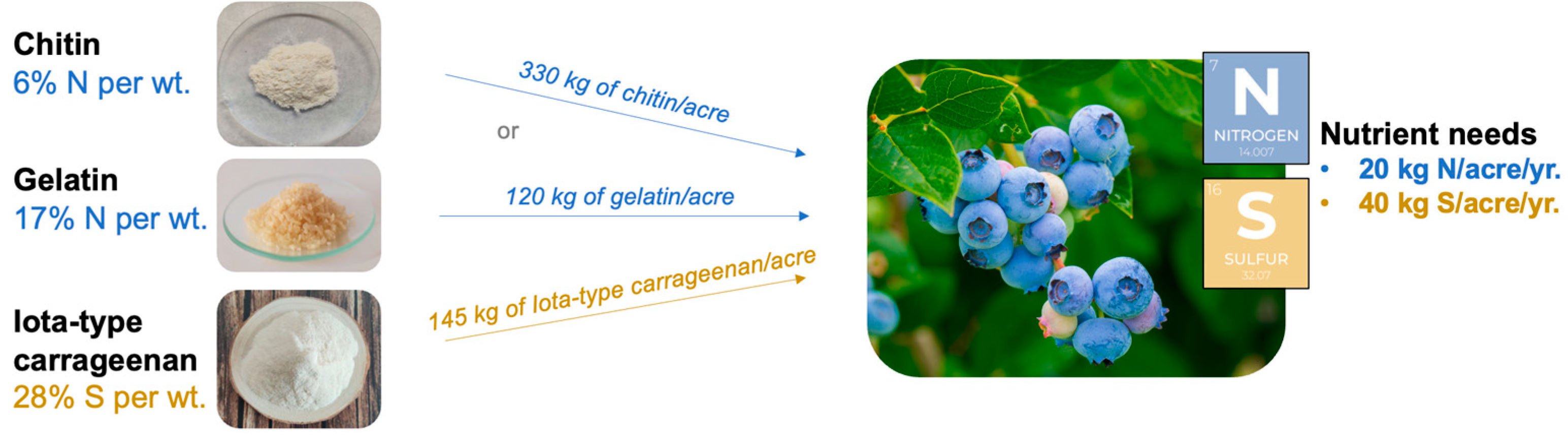

2.2. Could Biomaterials Serve as a Resource for Regenerative Agriculture?

| Biopolymer/Biomaterial Ingredient | Nutrient Content (%) | Reference |

|---|---|---|

| Chitin | N: 6% | [72,73] |

| Chitosan | N: 6–7% | [74] |

| Sodium alginate | Na: 4% | [75] |

| iota-Carrageenan | S/SO42−: 28–30% | [76,77] |

| kappa-Carrageenan | S/SO42−: 25–30% | [77] |

| Gelatin | N: 17–18% | [78,79] |

| Keratin | N: 15–18%; S/SO42−: 2–5% | [80] |

| Casein | N: 13%; P: 1% | [81,82] |

| Collagen | N: 18% | [83] |

| Whey protein | N: 13% | [84] |

| Calcium carbonate | Ca: 40% | [85] |

| Egg shells | Ca: 38% | [86] |

| Mussel shells | Ca: 38% | [87] |

| Oyster shells | Ca: 38% | [87] |

| Silk fibroin | N: 18% | [88,89] |

3. Results

3.1. The Case of Great Lakes Region, Michigan, USA

3.2. Biomaterials That Could Be Sourced from Regenerative Fields in Great Lakes Region, Michigan, USA

3.3. Potential Beneficial Biomaterials Services for Regenerative Farms in Great Lakes Region, Michigan, USA

4. Discussion

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Energy Agency: The Future of Petrochemicals. Available online: https://www.iea.org/reports/the-future-of-petrochemicals (accessed on 5 August 2023).

- Yale Environment 360: The Plastics Pipeline: A Surge of New Production Is on the Way. Available online: https://e360.yale.edu/features/the-plastics-pipeline-a-surge-of-new-production-is-on-the-way (accessed on 5 August 2023).

- Rosenboom, J.G.; Langer, R.; Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef] [PubMed]

- Fernandez, J.G.; Dritsas, S. The biomaterial age: The transition toward a more sustainable society will be determined by advances in controlling biological processes. Matter 2020, 2, 1352–1355. [Google Scholar] [CrossRef]

- Ritchie, H.; Roser, M. Plastic Pollution. 2018. Available online: https://ourworldindata.org/plastic-pollution (accessed on 14 July 2023).

- UN Environment Programme: Our Planet Is Chocking on Plastic. Available online: https://www.unep.org/interactives/beat-plastic-pollution/?gclid=CjwKCAjw5MOlBhBTEi-wAAJ8e1ssCIc8iH3pn72w_yrdo9f9AOO0kSrTvFRZl0tJ7yqbe2a6F0wIv0hoCN8YQAvD_BwE (accessed on 14 July 2023).

- Hamilton, L.A.; Feit, S. Plastic & Climate: The Hidden Costs of a Plastic Planet. 2019. Available online: https://www.ciel.org/wp-content/uploads/2019/05/Plastic-and-Climate-FINAL-2019.pdf (accessed on 14 July 2023).

- Hernández, V.; Ibarra, D.; Triana, J.F.; Martínez-Soto, B.; Faúndez, M.; Vasco, D.A.; Gordillo, L.; Herrera, F.; García-Herrera, C.; Garmulewicz, A. Agar Biopolymer Films for Biodegradable Packaging: A Reference Dataset for Exploring the Limits of Mechanical Performance. Materials 2022, 15, 3954. [Google Scholar] [CrossRef] [PubMed]

- Nanda, S.; Azargohar, R.; Dalai, A.K.; Kozinski, J.A. An assessment on the sustainability of lignocellulosic biomass for biorefining. Renew. Sustain. Energy Rev. 2015, 50, 925–941. [Google Scholar] [CrossRef]

- European Commission—Energy, Climate Change, Environment: Biobased, Biodegradable and Compostable Plastics. Available online: https://environment.ec.europa.eu/topics/plastics/biobased-biodegradable-and-compostable-plastics_en (accessed on 14 July 2023).

- Yaradoddi, J.S.; Banapurmath, N.R.; Ganachari, S.V.; Soudagar, M.E.M.; Mubarak, N.M.; Hallad, S.; Hugar, S.; Fayaz, H. Biodegradable carboxymethyl cellulose based material for sustainable packaging application. Sci. Rep. 2020, 10, 21960. [Google Scholar] [CrossRef]

- Azmin, S.N.H.M.; Nor, M.S.M. Development and characterization of food packaging bioplastic film from cocoa pod husk cellulose incorporated with sugarcane bagasse fibre. J. Bioresour. Bioprod. 2020, 5, 248–255. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation—Regenerative Agriculture. Available online: https://ellenmacarthurfoundation.org/articles/regenerative-agriculture (accessed on 14 July 2023).

- US EPA—Global Greenhouse Gas Emissions Data. Available online: https://www.epa.gov/ghgemissions/global-greenhouse-gas-emissions-data (accessed on 14 July 2023).

- Schreefel, L.; Schulte, R.P.O.; De Boer, I.J.M.; Schrijver, A.P.; Van Zanten, H.H.E. Regenerative agriculture—The soil is the base. Glob. Food Secur. 2020, 26, 100404. [Google Scholar] [CrossRef]

- Newton, P.; Civita, N.; Frankel-Goldwater, L.; Bartel, K.; Johns, C. What Is Regenerative Agriculture? A Review of Scholar and Practitioner Definitions Based on Processes and Outcomes. Front. Sustain. Food Syst. 2020, 4, 194. [Google Scholar] [CrossRef]

- Tan, S.S.; Kuebbing, S.E. A synthesis of the effect of regenerative agriculture on soil carbon sequestration in Southeast Asian croplands. Agric. Ecosyst. Environ. 2023, 349, 108450. [Google Scholar] [CrossRef]

- Schreefel, L.; Van Zanten, H.H.E.; Groot, J.C.J.; Timler, C.J.; Zwetsloot, M.J.; Schrijver, A.P.; Creamer, R.E.; Schulte, R.P.O.; de Boer, I.J.M. Tailor-made solutions for regenerative agriculture in the Netherlands. Agric. Syst. 2022, 203, 103518. [Google Scholar] [CrossRef]

- Breuer, A.; Janetschek, H.; Malerba, D. Translating sustainable development goal (SDG) interdependencies into policy advice. Sustainability 2019, 11, 2092. [Google Scholar] [CrossRef]

- Conti, C.; Zanello, G.; Hall, A. Why are agri-food systems resistant to new directions of change? A systematic review. Glob. Food Secur. 2021, 31, 100576. [Google Scholar] [CrossRef]

- Spangler, K.; Schumacher, B.L.; Bean, B.; Burchfield, E.K. Path dependencies in US agriculture: Regional factors of diversification. Agric. Ecosyst. Environ. 2022, 333, 107957. [Google Scholar] [CrossRef]

- The Nature Conservancy—Agriculture in the Great Lakes. Available online: https://www.nature.org/en-us/about-us/where-we-work/priority-landscapes/great-lakes/great-lakes-agriculture-/ (accessed on 14 July 2023).

- Shahi, N.; Joshi, G.; Min, B. Potential sustainable biomaterials derived from cover crops. Bioresources 2020, 15, 5641–5652. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef]

- Maryland Department of Agriculture. Available online: https://mda.maryland.gov/resource_conservation/counties/Tip6.pdf (accessed on 15 July 2023).

- Carlson, S.; Stockwell, R. Research priorities for advancing adoption of cover crops in agriculture-intensive regions. J. Agric. Food Syst. Community Dev. 2013, 3, 125–129. [Google Scholar] [CrossRef]

- Andrews, S.S. Crop Residue Removal for Biomass Energy Production: Effects on Soils and Recommendations. USDA White Paper. 2006. Available online: https://www.nrcs.usda.gov/sites/default/files/2022-10/Crop_Residue_Removal_for_Biomass_Energy_Production.pdf (accessed on 15 July 2023).

- Nelson, R.G. Resource assessment and removal analysis for corn stover and wheat straw in the Eastern and Midwestern United States—Rainfall and wind-induced soil erosion methodology. Biomass Bioenergy 2002, 22, 349–363. [Google Scholar] [CrossRef]

- Perlack, R.D.; Wright, L.L.; Turhollow, A.F.; Graham, R.L.; Stokes, B.J.; Erbach, D.C. Biomass as Feedstock for a Bioenergy and Bioproducts Industry: The Technical Feasibility of a Billion-Ton Annual Supply. Oak Ridge National Laboratory Technical Report. 2005. Available online: https://info.ornl.gov/sites/publications/Files/Pub57812.pdf (accessed on 15 July 2023).

- Shinners, K.J.; Binversie, B.N.; Savoie, P. Harvest and storage of wet and dry corn stover as a biomass feedstock. In Proceedings of the 2003 American Society of Agricultural and Biological Engineers ASABE Annual Meeting, Las Vegas, NV, USA, 27–30 July 2003. [Google Scholar]

- Karlen, D.L.; Andrews, S.S.; Wienhold, B.J.; Zobeck, T.M. Soil quality assessment: Past, present and future. J. Integr. Biosci. 2008, 6, 3–14. [Google Scholar]

- Sokhansanj, S.; Kumar, A.; Turhollow, A.F. Development and implementation of integrated biomass supply analysis and logistics model (IBSAL). Biomass Bioenergy 2006, 30, 838–847. [Google Scholar] [CrossRef]

- Wilhelm, W.W.; Johnson, J.M.; Hatfield, J.L.; Voorhees, W.B.; Linden, D.R. Crop and soil productivity response to corn residue removal: A literature review. Agron. J. 2004, 96, 1–17. [Google Scholar] [CrossRef]

- Al-Kaisi, M. How Much Crop Residue to Remove. Iowa State University Extension and Outreach. 2012. Available online: https://crops.extension.iastate.edu/cropnews/2012/04/how-much-crop-residue-remove (accessed on 15 July 2023).

- Wilhelm, W.W.; Johnson, J.M.; Karlen, D.L.; Lightle, D.T. Corn stover to sustain soil organic carbon further constrains biomass supply. Agron. J. 2007, 99, 1665–1667. [Google Scholar] [CrossRef]

- Shaghaleh, H.; Xu, X.; Wang, S. Current progress in production of biopolymeric materials based on cellulose, cellulose nanofibers, and cellulose derivatives. RSC Adv. 2018, 8, 825–842. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Ji, Y.; Bourg, V.; Bilgen, M.; Meredith, J.C. Chitin-and cellulose-based sustainable barrier materials: A review. Emergent Mater. 2020, 3, 919–936. [Google Scholar] [CrossRef]

- Re-FREAM Website. Available online: https://re-fream.eu/syntropia/ (accessed on 15 July 2023).

- Woźniak, M.; Ratajczak, I.; Wojcieszak, D.; Waśkiewicz, A.; Szentner, K.; Przybył, J.; Borysiak, S.; Goliński, P. Chemical and structural characterization of maize stover fractions in aspect of its possible applications. Materials 2021, 14, 1527. [Google Scholar] [CrossRef] [PubMed]

- Mensah, M.B.; Jumpah, H.; Boadi, N.O.; Awudza, J.A. Assessment of quantities and composition of corn stover in Ghana and their conversion into bioethanol. Sci. Afr. 2021, 12, e00731. [Google Scholar] [CrossRef]

- Rentoy, F.A.M.; Angot, D.R.; Mabaquiao, J.R.; Larroder, A. Development of Cellulose-Based Bioplastic from Corn Stalks. Publiscience 2020, 1–6. Available online: http://www.publiscience.org/development-of-cellulose-based-bioplastic-from-corn-stalks/ (accessed on 15 July 2023).

- Chong, T.Y.; Law, M.C.; Chan, Y.S. The potentials of corn waste lignocellulosic fibre as an improved reinforced bioplastic composites. J. Polym. Environ. 2021, 29, 363–381. [Google Scholar] [CrossRef]

- Marichelvam, M.K.; Jawaid, M.; Asim, M. Corn and rice starch-based bio-plastics as alternative packaging materials. Fibers 2019, 7, 32. [Google Scholar] [CrossRef]

- Machado, G.; Santos, F.; Lourega, R.; Mattia, J.; Faria, D.; Eichler, P.; Auler, A. Biopolymers from lignocellulosic biomass: Feedstocks, production processes, and applications. In Lignocellulosic Biorefining Technologies, 1st ed.; Ingle, A.P., Chandel, A.K., da Silva, S.S., Eds.; Wiley: Hoboken, NJ, USA, 2020; pp. 125–158. [Google Scholar]

- Stoyanova, N.; Spasova, M.; Manolova, N.; Rashkov, I.; Kamenova-Nacheva, M.; Staleva, P.; Tavlinova-Kirilova, M. Electrospun PLA-Based Biomaterials Loaded with Melissa officinalis Extract with Strong Antioxidant Activity. Polymers 2023, 15, 1070. [Google Scholar] [CrossRef]

- Bakker, R.R.C.; Elbersen, H.W.; Poppens, R.P.; Lesschen, J.P. Rice Straw and Wheat Straw-Potential Feedstocks for the Biobased Economy. NL Agency Ministry of Economic Affairs. 2013. Available online: https://edepot.wur.nl/288866 (accessed on 15 July 2023).

- Bilo, F.; Pandini, S.; Sartore, L.; Depero, L.E.; Gargiulo, G.; Bonassi, A.; Federici, S.; Bontempi, E. A sustainable bioplastic obtained from rice straw. J. Clean. Prod. 2018, 200, 357–368. [Google Scholar] [CrossRef]

- Maraveas, C. Production of sustainable and biodegradable polymers from agricultural waste. Polymers 2020, 12, 1127. [Google Scholar] [CrossRef]

- Varghese, S.A.; Pulikkalparambil, H.; Promhuad, K.; Srisa, A.; Laorenza, Y.; Jarupan, L.; Nampitch, T.; Chonhenchob, V.; Harnkarnsujarit, N. Renovation of Agro-Waste for sustainable food packaging: A Review. Polymers 2023, 15, 648. [Google Scholar] [CrossRef] [PubMed]

- Eco World Website. What Is Wheat Straw Plastic? Available online: https://ecoworldonline.com/what-is-wheat-straw-plastic/ (accessed on 15 July 2023).

- Sabara, Z.; Mutmainnah, A.; Kalsum, U.; Afiah, I.N.; Husna, I.; Saregar, A.; Umam, R. Sugarcane bagasse as the source of nanocrystalline cellulose for gelatin-free capsule shell. Int. J. Biomater. 2022, 2022, 9889127. [Google Scholar] [CrossRef] [PubMed]

- Mokhena, T.C.; Mochane, M.J.; Motaung, T.E.; Linganiso, L.Z.; Thekisoe, O.M.; Songca, S.P. Sugarcane bagasse and cellulose polymer composites. In Sugarcane-Technology and Research, 1st ed.; Bosco de Oliveira, A., Ed.; IntechOpen: London, UK, 2018; pp. 225–240. [Google Scholar]

- Melesse, G.T.; Hone, F.G.; Mekonnen, M.A. Extraction of Cellulose from Sugarcane Bagasse Optimization and Characterization. Adv. Mater. Sci. Eng. 2022, 2022, 1712207. [Google Scholar] [CrossRef]

- Savastano Jr, H.; Santos, S.F.; Agopyan, V. Sustainability of vegetable fibres in construction. In Sustainability of Construction Materials, 1st ed.; Khatib, J.M., Ed.; Woodhead Publishing: Sawston, UK, 2009; pp. 55–81. [Google Scholar]

- Mahmud, M.A.; Anannya, F.R. Sugarcane bagasse-A source of cellulosic fiber for diverse applications. Heliyon 2021, 7, e07771. [Google Scholar] [CrossRef] [PubMed]

- Gowman, A.C.; Picard, M.C.; Lim, L.T.; Misra, M.; Mohanty, A.K. Fruit waste valorization for biodegradable biocomposite applications: A review. Bioresources 2019, 14, 10047–10092. [Google Scholar] [CrossRef]

- Materiom Website. Apple-Pectin Leather Recipe. Available online: https://materiom.org/recipe/707 (accessed on 15 July 2023).

- Bátori, V. Fruit Wastes to Biomaterials: Development of Biofilms and 3D Objects in a Circular Economy System. Doctoral Thesis, University of Borås, Borås, Sweden, 2019. [Google Scholar]

- Gustafsson, J.; Landberg, M.; Bátori, V.; Åkesson, D.; Taherzadeh, M.J.; Zamani, A. Development of bio-based films and 3D objects from apple pomace. Polymers 2019, 11, 289. [Google Scholar] [CrossRef] [PubMed]

- Ayala, J.R.; Montero, G.; Coronado, M.A.; García, C.; Curiel-Alvarez, M.A.; León, J.A.; Sagaste, C.A.; Montes, D.G. Characterization of orange peel waste and valorization to obtain reducing sugars. Molecules 2021, 26, 1348. [Google Scholar] [CrossRef]

- Tarasov, D.; Leitch, M.; Fatehi, P. Lignin–carbohydrate complexes: Properties, applications, analyses, and methods of extraction: A review. Biotechnol. Biofuels 2018, 11, 1–28. [Google Scholar] [CrossRef]

- Xia, Q.; Chen, C.; Yao, Y.; Li, J.; He, S.; Zhou, Y.; Li, T.; Pan, X.; Yao, Y.; Hu, L. A strong, biodegradable and recyclable lignocellulosic bioplastic. Nat. Sustain. 2021, 4, 627–635. [Google Scholar] [CrossRef]

- Ferrari, F.; Striani, R.; Fico, D.; Alam, M.M.; Greco, A.; Esposito Corcione, C. An Overview on Wood Waste Valorization as Biopolymers and Biocomposites: Definition, Classification, Production, Properties and Applications. Polymers 2022, 14, 5519. [Google Scholar] [CrossRef]

- Oliaei, E.; Olsén, P.; Lindström, T.; Berglund, L.A. Highly reinforced and degradable lignocellulose biocomposites by polymerization of new polyester oligomers. Nat. Commun. 2022, 13, 5666. [Google Scholar] [CrossRef] [PubMed]

- Materiom Website. Natural Dye—Sage Dye Recipe. Available online: https://materiom.org/recipe/172 (accessed on 15 July 2023).

- Materiom Website. Pigment with Burnt Japanese Knotweed (Leaves) Recipe. Available online: https://materiom.org/recipe/605 (accessed on 15 July 2023).

- University of California, Sustainable Agriculture Research and Education Program Website. Solution Center for Nutrient Management: Crop Nutrient Requirements. Available online: https://ucanr.edu/sites/Nutrient_Management_Solutions/stateofscience/Meet_Crop_Nutrient_Requirements/ (accessed on 15 July 2023).

- Pittenger, D. California Master Gardener Handbook, 2nd ed.; Division of Agriculture and Natural Resources, University of California: Oakland, CA, USA, 2014; p. 50. [Google Scholar]

- Heliae Website. 10 Regenerative Agriculture Practices Every Grower Should Follow. Available online: https://heliae.com/10-regenerative-agriculture-practices/#Composting (accessed on 15 July 2023).

- Wortmann, C.S.; Klein, R.N.; Shapiro, C.A. Harvesting Crop Residues. University of Nebraska Lincoln, Extension, Institute of Agriculture and Natural Resources. 2012. Available online: https://extensionpublications.unl.edu/assets/pdf/g1846.pdf (accessed on 15 July 2023).

- Herbert, S.J.; Liu, Y.; Liu, G. Decomposition of Cover Crop Biomass and Nitrogen Release. University of Massachusetts Amherst, Center for Agriculture, Food, and the Environment. Available online: https://ag.umass.edu/sites/ag.umass.edu/files/research-reports/1997-01-decomposition-of-cover-crops-biomass-and-nitrogen-release.pdf (accessed on 15 July 2023).

- Tshinyangu, K.K.; Hennebert, G.L. Protein and chitin nitrogen contents and protein content in Pleurotus ostreatus var. columbinus. Food Chem. 1996, 57, 223–227. [Google Scholar] [CrossRef]

- Kumeta, Y.; Inami, K.; Ishimaru, K.; Yamazaki, Y.; Sameshima-Saito, R.; Saito, A. Thermogravimetric evaluation of chitin degradation in soil: Implication for the enhancement of ammonification of native organic nitrogen by chitin addition. Soil Sci. Plant Nutr. 2018, 64, 512–519. [Google Scholar] [CrossRef]

- Ssekatawa, K.; Byarugaba, D.K.; Wampande, E.M.; Moja, T.N.; Nxumalo, E.; Maaza, M.; Sackey, J.; Ejobi, F.; Kirabira, J.B. Isolation and characterization of chitosan from Ugandan edible mushrooms, Nile perch scales and banana weevils for biomedical applications. Sci. Rep. 2021, 11, 4116. [Google Scholar] [CrossRef]

- SPICEOLOGY Website. Sodium Alginate. Available online: https://spiceology.com/products/sodium-alginate/ (accessed on 15 July 2023).

- Thermo Fisher Scientific Website. Carrageenan, Iota Type. Available online: https://www.fishersci.com/shop/products/carrageenan-iota-type-thermo-scientific/AAJ6060322 (accessed on 15 July 2023).

- Necas, J.; Bartosikova, L. Carrageenan: A review. Vet. Med. 2013, 58, 187–205. [Google Scholar] [CrossRef]

- Schrieber, R.; Gareis, H. Gelatin Handbook: Theory and Industrial Practice; Wiley: Hoboken, NJ, USA, 2017. [Google Scholar]

- Garden Myths Website. Gelatin Powder for Plants—Is It a Good Source of Nitrogen? Available online: https://www.gardenmyths.com/gelatin-powder-plants-source-nitrogen/ (accessed on 15 July 2023).

- Sharma, S.; Gupta, A. Sustainable management of keratin waste biomass: Applications and future perspectives. Braz. Arch. Biol. Technol. 2016, 59, e16150684. [Google Scholar] [CrossRef]

- USJersey Website. Milk Marketing: True Protein vs. Total Protein. Available online: https://www.usjersey.com/Portals/0/NAJ/2_Docs/TrueProteinExplained_NAJ_1999.pdf (accessed on 15 July 2023).

- Science Direct Website. Casein. Available online: https://www.sciencedirect.com/topics/pharmacology-toxicology-and-pharmaceutical-science/casein (accessed on 15 July 2023).

- Mariotti, F.; Tomé, D.; Mirand, P.P. Converting nitrogen into protein—Beyond 6.25 and Jones’ factors. Crit. Rev. Food Sci. Nutr. 2008, 48, 177–184. [Google Scholar] [CrossRef]

- Cerbulis, J.; Farrell, H.M., Jr. Composition of milks of dairy cattle. I. Protein, lactose, and fat contents and distribution of protein fraction. J. Dairy Sci. 1975, 58, 817–827. [Google Scholar] [CrossRef]

- Nagwa Website. Question Video: Calculating the Percentage Composition of a Ternary Compound. Available online: https://www.nagwa.com/en/videos/407190505318/#:~:text=So%20the%20final%20answer%20for,%2C%20and%20oxygen%3A%2048%20percent (accessed on 15 July 2023).

- UK Essays Website. Calcium Carbonate Composition of Brown and White Eggshells. Available online: https://www.ukessays.com/essays/chemistry/calcium-carbonate.php?vref=1 (accessed on 15 July 2023).

- Hamester, M.R.R.; Balzer, P.S.; Becker, D. Characterization of calcium carbonate obtained from oyster and mussel shells and incorporation in polypropylene. Mater. Res. 2012, 15, 204–208. [Google Scholar] [CrossRef]

- Ngo, H.T.; Bechtold, T. Analysis of the fibroin solution state in calcium chloride/water/ethanol for improved understanding of the regeneration process. Fibres Text. East. Eur. 2018, 26, 43–50. [Google Scholar] [CrossRef]

- Vickery, H.B.; Block, R.J. The Basic Amino Acids of Silk Fibroin. The Determination of the Basic Amino Acids Yielded by Proteins. J. Biol. Chem. 1931, 93, 105–112. [Google Scholar] [CrossRef]

- USDA Natural Resources Conservation Service Website. Great Lakes Restoration Initiative. Available online: https://www.nrcs.usda.gov/wps/portal/nrcs/detailfull/national/programs/initiatives/?cid=nrcsdev11_023903 (accessed on 15 July 2023).

- NFWF Website. Sustain Our Great Lakes Program. Available online: https://www.nfwf.org/programs/sustain-our-great-lakes-program (accessed on 15 July 2023).

- US EPA Website. Facts and Figures about the Great Lakes. Available online: https://www.epa.gov/greatlakes/facts-and-figures-about-great-lakes (accessed on 15 July 2023).

- Michigan Department of Agriculture & Rural Development Website. Michigan Agriculture Facts and Figures. Available online: https://www.michigan.gov/-/media/Project/Websites/mdard/documents/business-development/mi_ag_facts_figures.pdf?rev=9ca97e867d0d40b392470b02a2694e50 (accessed on 15 July 2023).

- Michigan Harmful Algal Bloom Reports Website. Available online: https://mdhhs.maps.arcgis.com/apps/webappviewer/index.html?id=b05d6b7498ca4ce29a586f1f2b9cefeb (accessed on 15 July 2023).

- Google Maps Website. North America Map. Available online: https://www.google.com/maps/@39.2152718,-99.2522544,4.37z?entry=ttu (accessed on 26 September 2023).

- USDA Website. U.S. Apple Production, by State. Available online: https://www.ers.usda.gov/data-products/chart-gallery/gallery/chart-detail/?chartId=75112 (accessed on 15 July 2023).

- Earth First Farm Website. Available online: https://www.earthfirstfarms.com/ (accessed on 15 July 2023).

- Perussello, C.A.; Zhang, Z.; Marzocchella, A.; Tiwari, B.K. Valorization of apple pomace by extraction of valuable compounds. Compr. Rev. Food Sci. Food Saf. 2017, 16, 776–796. [Google Scholar] [CrossRef] [PubMed]

- Shalini, R.; Gupta, D.K. Utilization of pomace from apple processing industries: A review. J. Food Sci. Technol. 2010, 47, 365–371. [Google Scholar] [CrossRef] [PubMed]

- Vendruscolo, F.; Albuquerque, P.M.; Streit, F.; Esposito, E.; Ninow, J.L. Apple pomace: A versatile substrate for biotechnological applications. Crit. Rev. Biotechnol. 2008, 28, 1–12. [Google Scholar] [CrossRef]

- Bhushan, S.; Kalia, K.; Sharma, M.; Singh, B.; Ahuja, P.S. Processing of apple pomace for bioactive molecules. Crit. Rev. Biotechnol. 2008, 28, 285–296. [Google Scholar] [CrossRef] [PubMed]

- Hoffman, M.J.; Hittinger, E. Inventory and transport of plastic debris in the Laurentian Great Lakes. Mar. Pollut. Bull. 2017, 115, 273–281. [Google Scholar] [CrossRef] [PubMed]

- RESET Website. Eatapple: A Fruity Alternative to the Plastic Straw. Available online: https://en.reset.org/eatapple-fruit-based-alternative-plastic-straw-06142018/ (accessed on 15 July 2023).

- Rebocho, A.T.; Pereira, J.R.; Freitas, F.; Neves, L.A.; Alves, V.D.; Sevrin, C.; Grandfils, C.; Reis, M.A. Production of medium-chain length polyhydroxyalkanoates by Pseudomonas citronellolis grown in apple pulp waste. Appl. Food Biotechnol. 2019, 6, 71–82. [Google Scholar]

- Nuo Website. Available online: https://www.nuo-design.com/ (accessed on 15 July 2023).

- BIOPHILICA Website. Available online: https://www.biophilica.co.uk/ (accessed on 15 July 2023).

- Better Way Farms Website. Available online: https://www.betterwayfarms.com/ (accessed on 15 July 2023).

- Elieh-Ali-Komi, D.; Hamblin, M.R. Chitin and chitosan: Production and application of versatile biomedical nanomaterials. Int. J. Adv. Res. 2016, 4, 411. [Google Scholar]

- Sanandiya, N.D.; Ottenheim, C.; Phua, J.W.; Caligiani, A.; Dritsas, S.; Fernandez, J.G. Circular manufacturing of chitinous bio-composites via bioconversion of urban refuse. Sci. Rep. 2020, 10, 4632. [Google Scholar] [CrossRef]

- Wilhelm Scherer, H. Sulfur in soils. J. Plant Nutr. Soil Sci. 2009, 172, 326–335. [Google Scholar] [CrossRef]

- Gao, X.; Chen, X.; Zhang, J.; Guo, W.; Jin, F.; Yan, N. Transformation of chitin and waste shrimp shells into acetic acid and pyrrole. ACS Sustain. Chem. Eng. 2016, 4, 3912–3920. [Google Scholar] [CrossRef]

- Dziedzic, I.; Kertmen, A. Methods of Chitosan Identification: History and Trends. Lett. Appl. NanoBioSci. 2023, 12, 94. [Google Scholar]

- Reddy, A.A. The soil health card Scheme in India: Lessons learned and challenges for replication in other developing countries. J. Nat. Resour. Policy Res. 2019, 9, 124–156. [Google Scholar] [CrossRef]

- Questell-Santiago, Y.M.; Galkin, M.V.; Barta, K.; Luterbacher, J.S. Stabilization strategies in biomass depolymerization using chemical functionalization. Nat. Rev. Chem. 2020, 4, 311–330. [Google Scholar] [CrossRef] [PubMed]

- Taherzadeh, M.J.; Karimi, K. Pretreatment of lignocellulosic wastes to improve ethanol and biogas production: A review. Int. J. Mol. Sci. 2008, 9, 1621–1651. [Google Scholar] [CrossRef]

- Zhu, H.; Ma, Q.; Sheng, J.; Yang, R. Freeze–thaw repetition as an auxiliary method to promote efficient separation of hemicellulose from poplar. Green Chem. 2020, 22, 942–949. [Google Scholar] [CrossRef]

- General Mills Website. Regenerative Agriculture. Available online: https://www.generalmills.com/how-we-make-it/healthier-planet/environmental-impact/regenerative-agriculture (accessed on 15 July 2023).

- Rodale Institute Website. Regenerative Organic Agriculture and Climate Change: A Down-to-Earth Solution to Global Warming. Available online: https://rodaleinstitute.org/wp-content/uploads/rodale-white-paper.pdf (accessed on 15 July 2023).

- American Meadows Website. How to Select Cover Crops for the Home Garden. Available online: https://www.americanmeadows.com/grass-and-groundcover-seeds/how-to-select-cover-crops-for-the-home-garden#problem-solve (accessed on 15 July 2023).

- Washington State University, Center for Sustaining Agriculture and Natural Resources Website. Ecological Theories, Meta-Analysis, and the Benefits of Monocultures. Available online: https://csanr.wsu.edu/theories-meta-analysis-monocultures/ (accessed on 15 July 2023).

- Great Lakes Protection Fund Website. Available online: https://glpf.org/ (accessed on 15 July 2023).

- Grand Traverse Conservation District Website. The Great Lakes Incubator Farm. Available online: https://natureiscalling.org/glif (accessed on 15 July 2023).

- Bloomberg Website. General Mills Launches Three-Year Regenerative Dairy Pilot in Michigan in Partnership with Foremost Farms and Understanding Ag. Available online: https://www.bloomberg.com/press-releases/2020-06-16/general-mills-launches-three-year-regenerative-dairy-pilot-in-michigan-in-partnership-with-foremost-farms-and-understanding-ag (accessed on 15 July 2023).

- Sierra Club Michigan Chapter Website. Regenerative Agriculture Project. Available online: https://www.sierraclub.org/michigan/regenerative-agriculture-project (accessed on 15 July 2023).

- Michigan State University Website. Student Organic Farm. Available online: https://www.canr.msu.edu/sof/ (accessed on 15 July 2023).

- Verdant Hollow Farms Website. Available online: https://www.verdanthollowfarms.com/ (accessed on 15 July 2023).

- Beaverland Farms Website. Available online: https://www.beaverlandfarms.com/ (accessed on 15 July 2023).

- Shady Side Farm Website. Available online: https://shadysidefarm.com/ (accessed on 15 July 2023).

| Biomass Residue Source | Generated Amount |

|---|---|

| Discarded apples and pulp from cider making | 14–23 tons/year |

| Trimmed biomass from apple trees | 0.93–1.2 tons/year |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stathatou, P.M.; Corbin, L.; Meredith, J.C.; Garmulewicz, A. Biomaterials and Regenerative Agriculture: A Methodological Framework to Enable Circular Transitions. Sustainability 2023, 15, 14306. https://doi.org/10.3390/su151914306

Stathatou PM, Corbin L, Meredith JC, Garmulewicz A. Biomaterials and Regenerative Agriculture: A Methodological Framework to Enable Circular Transitions. Sustainability. 2023; 15(19):14306. https://doi.org/10.3390/su151914306

Chicago/Turabian StyleStathatou, Patritsia Maria, Liz Corbin, J. Carson Meredith, and Alysia Garmulewicz. 2023. "Biomaterials and Regenerative Agriculture: A Methodological Framework to Enable Circular Transitions" Sustainability 15, no. 19: 14306. https://doi.org/10.3390/su151914306