Study on the Relationship between Different Wastewater Treatment Technologies and Effluent Standards in Jilin Liaohe River Basin Based on the Coupled Model of AHP and Fuzzy TOPSIS Method

Abstract

1. Introduction

1.1. Background

1.2. Development of Coupled Multi-Criteria Decision Models (MCDM)

1.3. Main Contributions of This Paper

1.4. The Next Main Structure of This Article

2. Materials and Methods

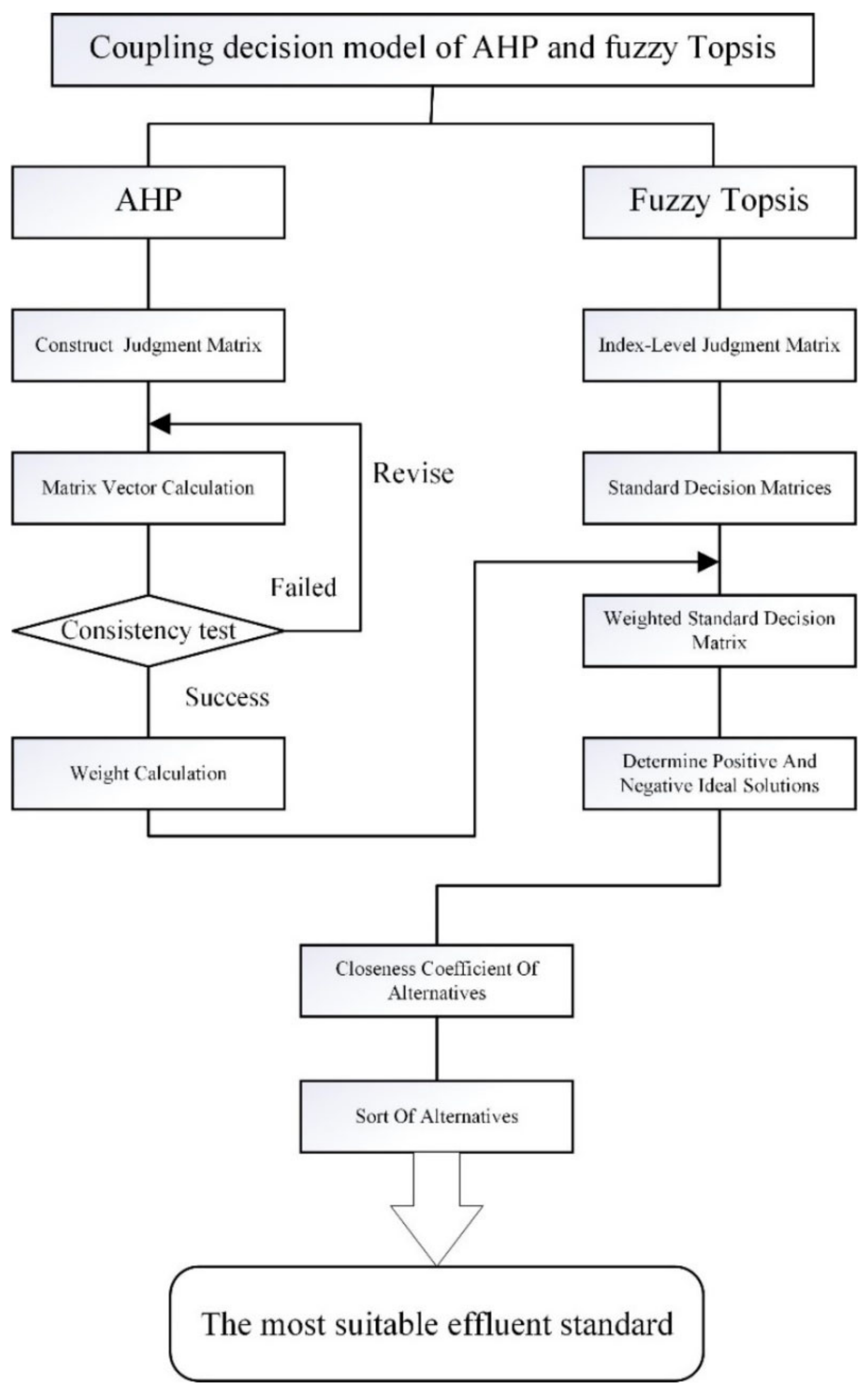

2.1. AHP and Fuzzy TOPSIS Coupling Model

2.1.1. AHP Calculation Procedure

- (1)

- Build the hierarchical model

- (2)

- Construction of judgment matrix

- (3)

- Hierarchical single ranking and its consistency test

2.1.2. Calculation Process of Fuzzy TOPSIS Method

- 1.

- Construct a decision matrix

- 2.

- Calculate the weighted normalization matrix

- 3.

- Determine the fuzzy PIS and NIS of each index

- 4.

- Calculate the distance between the evaluation object and the optimal and inferior solutions

- 5.

- Calculate the proximity of each evaluation object to the optimal solution

- 6.

- Rank each evaluation object according to the degree of proximity and determine the evaluation effect.

2.2. GHG Generation Calculation

- (1)

- Amount of methane generated from COD removal

- (2)

- GHG emissions from sludge treatment

- (3)

- CO2 emissions from electricity consumption in wastewater treatment plants

- (4)

- Electricity calculation for wastewater plants

3. Case Study

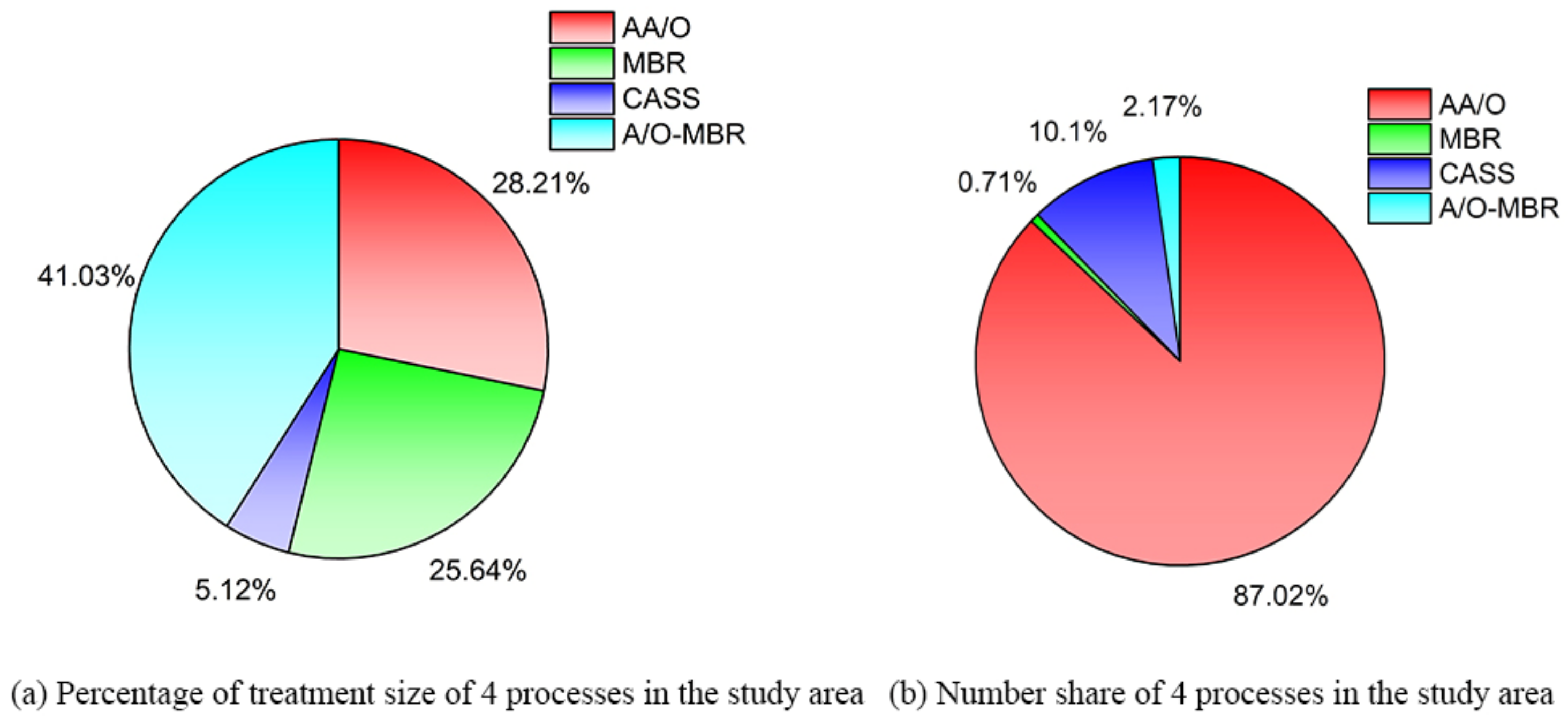

3.1. Study Area Overview

3.2. AHP Construction of Index System

- (1)

- Environmental benefits

- (2)

- Economic benefits

- (3)

- Social benefits

3.3. AHP Index System Scenario Analysis

3.4. AHP Weighting Analysis

3.5. Options and Attribute Values

3.6. Indicator Values

3.7. Simulation Results

4. Conclusions

- (1)

- The model results show that, with the effluent COD as the index, the effluent standard is 30 mg/L for A2/O and CASS processes as appropriate, whereas the effluent standard is 50 mg/L for MBR and A/O-MBR.

- (2)

- At the criterion level, different processes pay different attention to the environment (C1) and economy (C2) for their own technical characteristics and the actual context of use in the basin, with the technologies DS1 and DS2 chosen for large water plants paying more attention to C1 and the technologies DS3 and DS4 chosen for small water plants paying more attention to C2. The focus of attention of each technology at the indicator level is different, I2 is the most important indicator for DS1, I2, I1 and I5 are important indicators for DS2, I6 is the most important indicator for DS3 and I5 is the most important indicator for DS4, the fluctuation of the indicator weight has a greater potential to affect the choice of the optimal solution, when making similar environmental decision problems, the weight of the indicator needs to be focused on the situation.

- (3)

- Although some of the results of each process are similar, the actual weight distribution is not the same, the same process used in large water plants, CASS process CA3 and CA4 weights are similar, whereas CA3 in the A2/O advantage is obvious, because CASS process operating costs are relatively low, the economic benefits of low weight, local pollution control pressure can also choose CA4. MBR and A/O-MBR The technology chosen for small water plants, the options are ranked the same, with CA1 weighting of 0.962 for the A/O-MBR process, which is more suitable for the process in the basin’s lenient effluent standards.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- U.S. Environmental Protection Agency. Greenhouse Gas Inventory Report: Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2009; EPA: Washington, DC, USA, 2011.

- Bao, Z.; Sun, S.; Sun, D. Assessment of greenhouse gas emission from A/O and SBR wastewater treatment plants in Beijing, China. Int. Biodeterior. Biodegrad. 2016, 108, 108–114. [Google Scholar] [CrossRef]

- Delre, A.; Mnster, J.; Scheutz, C. Greenhouse gas emission quantification from wastewater treatment plants, using a tracer gas dispersion method. Sci. Total Environ. 2017, 605, 258–268. [Google Scholar] [CrossRef] [PubMed]

- Su, J.J.; Liu, B.Y.; Chang, Y.C. Emission of greenhouse gas from livestock waste and wastewater treatment in Taiwan. Agric. Ecosyst. Environ. 2003, 95, 253–263. [Google Scholar] [CrossRef]

- Brannon, E.Q. Greenhouse Gas Emissions from Biological Nutrient Removal During Wastewater Treatment; University of Rhode Island: Kingston, NY, USA, 2017. [Google Scholar]

- Bao, Z.; Sun, S.; Sun, D. Characteristics of direct CO2 emissions in four full-scale wastewater treatment plants. Desalination Water Treat. 2015, 54, 1070–1079. [Google Scholar] [CrossRef]

- Malila, R.; Lehtoranta, S.; Viskari, E.L. The role of source separation in nutrient recovery–comparison of alternative wastewater treatment systems. J. Clean. Prod. 2019, 219, 350–358. [Google Scholar] [CrossRef]

- Yan, C.; Zhang, H.; Li, B.; Wang, D.; Zhao, Y.J.; Zheng, Z. Effects of influent C/N ratios on CO2 and CH4 emissions from vertical subsurface flow constructed wetlands treating synthetic municipal wastewater. J. Hazard. Mater. 2012, 203, 188–194. [Google Scholar] [CrossRef] [PubMed]

- Singh, P.; Kansal, A. Energy and GHG accounting for wastewater infrastructure. Resour. Conserv. Recycl. 2018, 128, 499–507. [Google Scholar] [CrossRef]

- Mamais, D.; Noutsopoulos, C.; Dimopoulou, A.; Stasinakis, A.; Lekkas, T.D. Wastewater treatment process impact on energy savings and greenhouse gas emissions. Water Sci. Technol. 2015, 71, 303–308. [Google Scholar] [CrossRef] [PubMed]

- Shahabadi, M.B.; Yerushalmi, L.; Haghighat, F. Impact of process design on greenhouse gas (GHG) generation by wastewater treatment plants. Water Res. 2009, 43, 2679–2687. [Google Scholar] [CrossRef] [PubMed]

- Bodzek, D.; Janoszka, B.; Dobosz, C.; Warzecha, L.; Bodzek, M. Determination of polycyclic aromatic compounds and heavy metals in sludges from biological sewage treatment plants. J. Chromatogr. A 1997, 774, 177–192. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, Y.; Quan, X.; Chen, H. Enhanced anaerobic digestion of waste activated sludge digestion by the addition of zero valent iron. Water Res. 2014, 52, 242–250. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; He, J.; Zhang, P.; Zhang, J. Ultrasonic reduction of excess sludge from activated sludge system II: Urban sewage treatment. J. Hazard. Mater. 2009, 164, 1105–1109. [Google Scholar] [CrossRef] [PubMed]

- Shehu, M.S.; Manan, Z.A.; Alwi, S.R.W. Optimization of thermo-alkaline disintegration of sewage sludge for enhanced biogas yield. Bioresour. Technol. 2012, 114, 69–74. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Yang, J.; Liu, H.; Zhang, J. Sludge ozonation: Disintegration, supernatant changes and mechanisms. Bioresour. Technol. 2009, 100, 1505–1509. [Google Scholar] [CrossRef]

- Zaker, A.; Chen, Z.; Wang, X.; Zhang, Q. Microwave-assisted pyrolysis of sewage sludge: A review. Fuel Process. Technol. 2019, 187, 84–104. [Google Scholar] [CrossRef]

- Chen, Y.C.; Kuo, J. Potential of greenhouse gas emissions from sewage sludge management: A case study of Taiwan. J. Clean. Prod. 2016, 129, 196–201. [Google Scholar] [CrossRef]

- Duan, B.; Zhang, W.; Zheng, H.; Wu, C.; Zhang, Q.; Bu, Y. Disposal Situation of Sewage Sludge from Municipal Wastewater Treatment Plants (WWTPs) and Assessment of the Ecological Risk of Heavy Metals for Its Land Use in Shanxi, China. Int. J. Environ. Res. Public Health 2017, 14, 823. [Google Scholar] [CrossRef]

- Yang, G.; Fan, M.; Zhang, G. Emerging contaminants in surface waters in China—A short review. Environ. Res. Lett. 2014, 9, 074018. [Google Scholar] [CrossRef]

- Dong, B.; Liu, X.; Dai, L.; Dai, X.H. Changes of heavy metal speciation during high-solid anaerobic digestion of sewage sludge. Bioresour. Technol. 2013, 131, 152–158. [Google Scholar] [CrossRef]

- Yang, C.; Meng, X.Z.; Chen, L.; Xia, X.Q. Polybrominated diphenyl ethers in sewage sludge from Shanghai, China: Possible ecological risk applied to agricultural land. Chemosphere 2011, 85, 418–423. [Google Scholar] [CrossRef]

- Schulz, A.; Obenaus, F.; Egerland, B.; Reicherter, E. Elimination costs for different wastewater compounds. Water Sci. Technol. 2003, 47, 119–124. [Google Scholar] [CrossRef] [PubMed]

- Zhou, P.; Ang, B.W.; Poh, K.L. Decision analysis in energy and environmental modeling: An update. Energy 2006, 31, 2604–2622. [Google Scholar] [CrossRef]

- Bognár, F.; Szentes, B.; Benedek, P. Development of the PRISM Risk Assessment Method Based on a Multiple AHP-TOPSIS Ap-proach. Risks 2022, 10, 213. [Google Scholar] [CrossRef]

- Mathew, M.; Chakrabortty, R.K.; Ryan, M.J. Selection of an optimal maintenance strategy under uncertain conditions: An interval type-2 fuzzy AHP-TOPSIS method. IEEE Trans. Eng. Manag. 2020, 69, 1121–1134. [Google Scholar] [CrossRef]

- Du, Y.; Chen, W.; Cui, K.; Zhang, K. Study on damage assessment of earthen sites of the Ming Great Wall in Qinghai Province based on Fuzzy-AHP and AHP-TOPSIS. Int. J. Archit. Herit. 2019, 14, 903–916. [Google Scholar] [CrossRef]

- Liu, B.; Tang, J.; Li, Z.; Yan, Y.; Chen, J.S. Optimal selection of sewage treatment technologies in town areas: A coupled multi-criteria decisionmaking model. Environ. Manag. 2020, 66, 709–721. [Google Scholar] [CrossRef]

- Liu, B.; Tang, J.; Qu, Y.; Yang, Y.; Lyu, H.; Dai, Y.D.; Li, Z.Y. A GIS-Based Method for Identification of Blindness in Former Site Selection of Sewage Treatment Plants and Exploration of Optimal Siting Areas: A Case Study in Liao River Basin. Water 2022, 14, 1092. [Google Scholar] [CrossRef]

- Dai, C.; Tang, J.; Li, Z.; Duan, Y.C.; Qu, Y.K.; Yang, Y.; Lyu, H.; Zhang, D.; Wang, Y.T. Index System of Water Resources Development and Utilization Level Based on Water-Saving Society. Water 2022, 14, 802. [Google Scholar] [CrossRef]

- Anaokar, G.; Khambete, A.; Christian, R. Evaluation of a performance index for municipal wastewater treatment plants using MCDM–TOPSIS. Int. J. Technol. 2018, 9, 715–726. [Google Scholar] [CrossRef]

- Zorpas, A.A.; Pociovălişteanu, D.M.; Georgiadou, L.; Voukkali, I. Environmental and technical evaluation of the use of alternative fuels through multi-criteria analysis model. Prog. Ind. Ecol. Int. J. 2016, 10, 3–15. [Google Scholar] [CrossRef]

- Yang, Q.; Yu, X. Evaluation of rural water environment governance in Changzhou. IOP Conf. Ser. Earth Environ. Sci. 2021, 804, 042026. [Google Scholar] [CrossRef]

- Bexek, J.C. (Ed.) Pattern Recognition with Fuzzy Objective Function Algorithm; Springer Science & Business Media: Melbourne, VI, Australia, 1981. [Google Scholar]

- Saaty, T.L. The Analytic Hierarchy Process; Springer: Berlin/Heidelberg, Germany, 1980; p. 324. [Google Scholar]

- Hwang, C.L.; Yoon, K. Methods for Multiple Attribute Decision Making. Multiple Attribute Decision Making; Springer: Berlin/Heidelberg, Germany, 1981; pp. 58–191. [Google Scholar]

- Chen, S.J.; Hwang, C.L. Fuzzy Multiple Attribute Decision Making Methods; Springer: Berlin/Heidelberg, Germany, 1992; pp. 289–486. [Google Scholar]

| Scale | Meaning |

|---|---|

| 1 | Two elements are of equal importance |

| 3 | Two elements are slightly more important than one another |

| 5 | Two elements are more important than one another |

| 7 | Two elements are very important compared to one another |

| 9 | Two elements are absolutely more important than one another |

| 2, 4, 6, 8 | Adjacent intermediate numbers |

| reciprocal | If the ratio of the importance of element i to j is then the ratio of the importance of j to i is 1 |

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| RI | 0.00 | 0.00 | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 |

| Guidelines | Indicators | Properties | |

|---|---|---|---|

| Environmental Benefit C1 | GHG generation I1 | GHG generation A1 | A11 The amount of methane generated from the removal of COD |

| A12 Amount of greenhouse gases from sludge treatment | |||

| A13 CO2 emissions from electricity consumption | |||

| WFZ contribution I2 | Pollution load A2 | ||

| Resource recovery I3 | Reclaimed water reuse A3 | ||

| Economic benefit C2 | Sludge treatment cost I4 | Sludge treatment cost A4 | |

| Power consumption cost I5 | Power consumption cost A5 | ||

| OAM cost I6 | OAM cost A6 | ||

| Social Benefit C3 | Public evaluation I7 | Malodorous gas generation A7 | |

| Influenced by cold climate I8 | Affected by cold climate A8 | ||

| Stability I9 | Stability A9 | ||

| Risk assessment I10 | Risk assessment A10 | ||

| Objective Criteria | C1 | C2 | C3 | C1 Indicators | I1 | I2 | I3 | |

|---|---|---|---|---|---|---|---|---|

| Environmental benefits (C1) | 1 | 3 | 4 | GHG generation (I1) | 1 | 1/3 | 2 | |

| Economic benefits (C2) | 1/3 | 1 | 1 | WFZ contribution (I2) | 3 | 1 | 3 | |

| Social benefits (C3) | 1/4 | 1 | 1 | Resource recovery (I3) | 1/2 | 1/3 | 1 | |

| CR = 0.0089 | CR = 0.0518 | |||||||

| C2 Indicators | I4 | I5 | I6 | C3 Indicators | I7 | I8 | I9 | I10 |

| Sludge treatment cost (I4) | 1 | 1/4 | 1/4 | Public evaluation (I7) | 1 | 1/3 | 1/3 | 1/3 |

| Power consumption cost (I5) | 4 | 1 | 2 | Affected by cold climate (I8) | 3 | 1 | 1/2 | 1/2 |

| OAM costs (I6) | 4 | 1/2 | 1 | Stability (I9) | 3 | 2 | 1 | 1/2 |

| Risk assessment (I10) | 3 | 2 | 2 | 1 | ||||

| CR = 0.0518 | CR = 0.0456 |

| Objective Criteria | C1 | C2 | C3 | C1 Indicators | I1 | I2 | I3 | |

|---|---|---|---|---|---|---|---|---|

| Environmental benefits (C1) | 1 | 2 | 3 | GHG generation (I1) | 1 | 1/2 | 2 | |

| Economic benefits (C2) | 1/2 | 1 | 2 | WFZ contribution (I2) | 2 | 1 | 3 | |

| Social benefits (C3) | 1/3 | 1/2 | 1 | Resource recovery (I3) | 1/2 | 1/3 | 1 | |

| CR = 0.0089 | CR = 0.0089 | |||||||

| C2 Indicators | I4 | I5 | I6 | C3 Indicators | I7 | I8 | I9 | I10 |

| Sludge treatment cost(I4) | 1 | 1/3 | 1/3 | Public evaluation (I7) | 1 | 1/3 | 1/3 | 1/3 |

| Power consumption cost (I5) | 3 | 1 | 2 | Affected by cold climate (I8) | 3 | 1 | 1 | 1/2 |

| OAM costs (I6) | 3 | 1/2 | 1 | Stability (I9) | 3 | 1 | 1 | 1/2 |

| Risk assessment (I10) | 3 | 2 | 2 | 1 | ||||

| CR = 0.0517 | CR = 0.0694 |

| Objective Criteria | C1 | C2 | C3 | C1 Indicators | I1 | I2 | I3 | |

|---|---|---|---|---|---|---|---|---|

| Environmental benefits (C1) | 1 | 1/2 | 2 | GHG generation (I1) | 1 | 2 | 2 | |

| Economic benefits (C2) | 2 | 1 | 3 | WFZ contribution (I2) | 1/2 | 1 | 2 | |

| Social benefits (C3) | 1/2 | 1/3 | 1 | Resource recovery (I3) | 1/2 | 1/2 | 1 | |

| CR = 0.0089 | CR = 0.0517 | |||||||

| C2 Indicators | I4 | I5 | I6 | C3 Indicators | I7 | I8 | I9 | I10 |

| Sludge treatment cost (I4) | 1 | 1/3 | 1/4 | Public evaluation (I7) | 1 | 1/4 | 1/4 | 1/4 |

| Power consumption cost (I5) | 3 | 1 | 1/3 | Affected by cold climate (I8) | 4 | 1 | 1/2 | 1/2 |

| OAM costs (I6) | 4 | 3 | 1 | Stability (I9) | 4 | 2 | 1 | 2 |

| Risk assessment (I10) | 4 | 2 | 1/2 | 1 | ||||

| CR = 0.013 | CR = 0.0457 |

| Objectives Criteria | C1 | C2 | C3 | C1 Indicators | I1 | I2 | I3 | |

|---|---|---|---|---|---|---|---|---|

| Environmental benefits (C1) | 1 | 1/5 | 1/2 | GHG generation (I1) | 1 | 1 | 2 | |

| Economic benefits (C2) | 5 | 1 | 5 | WFZ contribution (I2) | 1 | 1 | 3 | |

| Social benefits (C3) | 2 | 5 | 1 | Resource recovery (I3) | 1/2 | 1/3 | 1 | |

| CR = 0.0521 | CR = 0.0176 | |||||||

| C2 Indicators | I4 | I5 | I6 | C3 Indicators | I7 | I8 | I9 | I10 |

| Sludge treatment cost(I4) | 1 | 1/4 | 1/2 | Public evaluation (I7) | 1 | 1/5 | 1/5 | 1/5 |

| Power consumption cost (I5) | 4 | 1 | 1/3 | Affected by cold climate (I8) | 5 | 1 | 1/3 | 1/3 |

| OAM costs (I6) | 2 | 3 | 1 | Stability (I9) | 5 | 3 | 1 | 1 |

| Risk assessment (I10) | 5 | 3 | 1 | 1 | ||||

| CR = 0.013 | CR = 0.0457 |

| CASS | A2/O | MBR | A/O = MBR | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wi | Wj | Wi | Wi | Wj | Wi | Wi | Wj | Wi | Wi | Wj | Wi | |

| Environmental Benefit (C1) | 0.6327 | 0.5390 | 0.2973 | 0.1149 | ||||||||

| GHG generation (I1) | 0.2519 | 0.1594 | 0.2973 | 0.1602 | 0.4905 | 0.1458 | 0.3873 | 0.0445 | ||||

| WFZ contribution (I2) | 0.5889 | 0.3726 | 0.5390 | 0.2905 | 0.3119 | 0.0927 | 0.4429 | 0.0051 | ||||

| Resource recovery (I3) | 0.1593 | 0.1008 | 0.1638 | 0.0883 | 0.1976 | 0.0587 | 0.1698 | 0.0195 | ||||

| Economic benefits (C2) | 0.0518 | 0.2973 | 0.5390 | 0.7028 | ||||||||

| Sludge treatment cost (I4) | 0.1103 | 0.0212 | 0.1416 | 0.0421 | 0.1199 | 0.0646 | 0.1307 | 0.0919 | ||||

| Power consumption cost (I5) | 0.5437 | 0.1046 | 0.5247 | 0.1560 | 0.2721 | 0.1467 | 0.6768 | 0.4757 | ||||

| OAM costs (I6) | 0.3460 | 0.0666 | 0.3338 | 0.0992 | 0.6080 | 0.3277 | 0.1925 | 0.1353 | ||||

| Social benefits (C3) | 0.1749 | 0.1638 | 0.1638 | 0.1149 | ||||||||

| Public evaluation (I7) | 0.0981 | 0.0171 | 0.0954 | 0.0156 | 0.0756 | 0.0124 | 0.062 | 0.0113 | ||||

| Affected by cold climate (I8) | 0.2081 | 0.0364 | 0.2535 | 0.0415 | 0.2134 | 0.0350 | 0.1786 | 0.0326 | ||||

| Stability (I9) | 0.2875 | 0.0503 | 0.3514 | 0.0575 | 0.4166 | 0.0682 | 0.3797 | 0.0692 | ||||

| Risk assessment (I10) | 0.4063 | 0.0710 | 0.2997 | 0.0491 | 0.2944 | 0.0482 | 0.3797 | 0.0692 | ||||

| Properties | 50 mg/L (CA1) | 40 mg/L (CA2) | 30 mg/L (CA3) | 20 mg/L (CA4) | |

|---|---|---|---|---|---|

| GHG generation I1 | I11 The amount of methane generated from the removal of COD | 12,072 | 12,474 | 12,877 | 13,279 |

| I12 Amount of greenhouse gases from sludge treatment | 3066 | 3168 | 3270 | 3373 | |

| I13 CO2 emissions from electricity consumption | 1014 | 1073 | 1134 | 1196 | |

| Total | 16,153 | 16,716 | 17,281 | 17,848 | |

| WFZ contribution I2 (t/a) | 456 | 365 | 274 | 183 | |

| Reclaimed water reuse I3 | Low | Lower | Mid | High | |

| Sludge treatment cost I4 ($/a) | 86,012 | 88,879 | 91,746 | 94,613 | |

| Electricity costs I5 ($/a) | 92,080 | 95,149 | 98,219 | 101,288 | |

| OAM costsI6 | Low | Lower | Mid | High | |

| Odor generation I7 | Low | Lower | Mid | High | |

| Cold climate treatment effect I8 | High | Mid | Mid | Low | |

| Stability I9 | High | Higher | Mid | Low | |

| Risk Assessment I10 | High | Mid | Mid | Low | |

| Properties | 50 mg/L (CA1) | 40 mg/L (CA2) | 30 mg/L (CA3) | 20 mg/L (CA4) | |

|---|---|---|---|---|---|

| GHG generation I1 | I11 The amount of methane generated from the removal of COD | 18,921 | 19,551 | 20,182 | 20,813 |

| I12 Amount of greenhouse gases from sludge treatment | 4805 | 4965 | 5126 | 5286 | |

| I13 CO2 emissions from electricity consumption | 1590 | 1682 | 1777 | 1874 | |

| Total | 25,316 | 26,199 | 27,085 | 27,973 | |

| WFZ contribution I2 (t/a) | 715 | 572 | 429 | 286 | |

| Reclaimed water reuse I3 | Low | Lower | Mid | High | |

| Sludge treatment cost I4 ($/a) | 134,890 | 139,386 | 143,883 | 148,379 | |

| Electricity costs I5 ($/a) | 144,314 | 149,125 | 153,935 | 158,746 | |

| OAM costs I6 | Low | Lower | Mid | High | |

| Odor generation I7 | Low | Lower | Mid | High | |

| Cold climate treatment effect I8 | High | Mid | Mid | Low | |

| Stability I9 | High | Higher | Mid | Low | |

| Risk Assessment I10 | High | Mid | Mid | Low | |

| Properties | 50 mg/L (CA1) | 40 mg/L (CA2) | 30 mg/L (CA3) | 20 mg/L (CA4) | |

|---|---|---|---|---|---|

| GHG generation I1 | I11 The amount of methane generated from the removal of COD | 169 | 174 | 180 | 185 |

| I12 Amount of greenhouse gases from sludge treatment | 43 | 44 | 46 | 47 | |

| I13 CO2 emissions from electricity consumption | 14 | 15 | 16 | 17 | |

| Total | 226 | 234 | 242 | 250 | |

| WFZ contribution I2 (t/a) | 6 | 5 | 4 | 3 | |

| Reclaimed water reuse I3 | Low | Lower | Mid | High | |

| Sludge treatment cost I4 ($/a) | 1204 | 1244 | 1284 | 1325 | |

| Electricity costs I5 ($/a) | 1289 | 1332 | 1375 | 1418 | |

| OAM costs I6 | Low | Lower | Mid | High | |

| Odor generation I7 | Low | Lower | Mid | High | |

| Cold climate treatment effect I8 | High | Mid | Mid | Low | |

| Stability I9 | High | Higher | Mid | Low | |

| Risk Assessment I10 | High | Mid | Mid | Low | |

| Properties | 50 mg/L (CA1) | 40 mg/L (CA2) | 30 mg/L (CA3) | 20 mg/L (CA4) | |

|---|---|---|---|---|---|

| GHG generation I1 | I11 The amount of methane generated from the removal of COD | 324 | 335 | 346 | 356 |

| I12 Amount of greenhouse gases from sludge treatment | 82 | 85 | 88 | 91 | |

| I13 CO2 emissions from electricity consumption | 27 | 29 | 30 | 32 | |

| Total | 434 | 449 | 464 | 480 | |

| WFZ contribution I2 (t/a) | 12 | 10 | 7 | 5 | |

| Reclaimed water reuse I3 | Low | Lower | Mid | High | |

| Sludge treatment cost I4 ($/a) | 2312 | 2389 | 2466 | 2543 | |

| Electricity costs I5 ($/a) | 2475 | 2557 | 2640 | 2722 | |

| OAM costs I6 | Low | Lower | Mid | High | |

| Odor generation I7 | Low | Lower | Mid | High | |

| Cold climate treatment effect I8 | High | Mid | Mid | Low | |

| Stability I9 | High | Higher | Mid | Low | |

| Risk Assessment I10 | High | Mid | Mid | Low | |

| Indicator | CA1 | CA2 | CA3 | CA4 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GHG generation I1 | 0.0956 | 0.1275 | 0.1594 | 0.0478 | 0.0797 | 0.1116 | 0.0000 | 0.0319 | 0.0638 | 0.0000 | 0.0000 | 0.0319 |

| WFZ contribution I2 | 0.0000 | 0.0000 | 0.0745 | 0.1118 | 0.1863 | 0.2608 | 0.2236 | 0.2981 | 0.3726 | 0.2981 | 0.3726 | 0.3726 |

| Reclaimed water reuse I3 | 0.0837 | 0.1046 | 0.1046 | 0.0628 | 0.0837 | 0.1046 | 0.0314 | 0.0523 | 0.0732 | 0.0000 | 0.0209 | 0.0418 |

| Sludge treatment cost I4 | 0.0170 | 0.0212 | 0.0212 | 0.0127 | 0.0170 | 0.0212 | 0.0064 | 0.0106 | 0.0148 | 0.0000 | 0.0042 | 0.0085 |

| Electricity costs I5 | 0.0533 | 0.0666 | 0.0666 | 0.0400 | 0.0533 | 0.0666 | 0.0200 | 0.0333 | 0.0466 | 0.0000 | 0.0133 | 0.0266 |

| OAM costs I6 | 0.0103 | 0.0137 | 0.0171 | 0.0051 | 0.0086 | 0.0120 | 0.0000 | 0.0034 | 0.0068 | 0.0000 | 0.0000 | 0.0034 |

| Odor generation I7 | 0.0000 | 0.0202 | 0.0403 | 0.0302 | 0.0504 | 0.0706 | 0.0605 | 0.0806 | 0.1008 | 0.0806 | 0.1008 | 0.1008 |

| Cold climate treatment effect I8 | 0.0218 | 0.0291 | 0.0364 | 0.0109 | 0.0182 | 0.0255 | 0.0000 | 0.0073 | 0.0146 | 0.0000 | 0.0000 | 0.0073 |

| Stability I9 | 0.0302 | 0.0402 | 0.0503 | 0.0151 | 0.0252 | 0.0352 | 0.0000 | 0.0101 | 0.0201 | 0.0000 | 0.0000 | 0.0101 |

| Risk Assessment I10 | 0.0426 | 0.0568 | 0.0710 | 0.0213 | 0.0355 | 0.0497 | 0.0000 | 0.0142 | 0.0284 | 0.0000 | 0.0000 | 0.0142 |

| Indicator | CA1 | CA2 | CA3 | CA4 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GHG generation I1 | 0.1282 | 0.1602 | 0.1602 | 0.0961 | 0.1282 | 0.1602 | 0.0481 | 0.0801 | 0.1121 | 0.0000 | 0.0320 | 0.0641 |

| WFZ contribution I2 | 0.0000 | 0.0000 | 0.0581 | 0.0872 | 0.1453 | 0.2034 | 0.1743 | 0.2324 | 0.2905 | 0.2324 | 0.2905 | 0.2905 |

| Reclaimed water reuse I3 | 0.0000 | 0.0177 | 0.0353 | 0.0265 | 0.0442 | 0.0618 | 0.0530 | 0.0706 | 0.0883 | 0.0706 | 0.0883 | 0.0883 |

| Sludge treatment cost I4 | 0.0253 | 0.0337 | 0.0421 | 0.0126 | 0.0211 | 0.0295 | 0.0000 | 0.0084 | 0.0168 | 0.0000 | 0.0000 | 0.0084 |

| Electricity costs I5 | 0.0936 | 0.1248 | 0.1560 | 0.0468 | 0.0780 | 0.1092 | 0.0000 | 0.0312 | 0.0624 | 0.0000 | 0.0000 | 0.0312 |

| OAM costs I6 | 0.0794 | 0.0992 | 0.0992 | 0.0595 | 0.0794 | 0.0992 | 0.0298 | 0.0496 | 0.0694 | 0.0000 | 0.0198 | 0.0397 |

| Odor generation I7 | 0.0094 | 0.0125 | 0.0156 | 0.0047 | 0.0078 | 0.0109 | 0.0000 | 0.0031 | 0.0062 | 0.0000 | 0.0000 | 0.0031 |

| Cold climate treatment effect I8 | 0.0249 | 0.0332 | 0.0415 | 0.0125 | 0.0208 | 0.0291 | 0.0000 | 0.0083 | 0.0166 | 0.0000 | 0.0000 | 0.0083 |

| Stability I9 | 0.0345 | 0.0460 | 0.0575 | 0.0173 | 0.0288 | 0.0403 | 0.0000 | 0.0115 | 0.0230 | 0.0000 | 0.0000 | 0.0115 |

| Risk Assessment I10 | 0.0295 | 0.0393 | 0.0491 | 0.0147 | 0.0246 | 0.0344 | 0.0000 | 0.0098 | 0.0196 | 0.0000 | 0.0000 | 0.0098 |

| Indicator | CA1 | CA2 | CA3 | CA4 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GHG generation I1 | 0.0875 | 0.1166 | 0.1458 | 0.0437 | 0.0729 | 0.1021 | 0.0000 | 0.0292 | 0.0583 | 0.0000 | 0.0000 | 0.0292 |

| WFZ contribution I2 | 0.0000 | 0.0000 | 0.0185 | 0.0278 | 0.0464 | 0.0649 | 0.0556 | 0.0742 | 0.0927 | 0.0742 | 0.0927 | 0.0927 |

| Reclaimed water reuse I3 | 0.0000 | 0.0117 | 0.0235 | 0.0176 | 0.0294 | 0.0411 | 0.0352 | 0.0470 | 0.0587 | 0.0470 | 0.0587 | 0.0587 |

| Sludge treatment cost I4 | 0.0517 | 0.0646 | 0.0646 | 0.0388 | 0.0517 | 0.0646 | 0.0194 | 0.0323 | 0.0452 | 0.0000 | 0.0129 | 0.0258 |

| Electricity costs I5 | 0.1174 | 0.1467 | 0.1467 | 0.0880 | 0.1174 | 0.1467 | 0.0440 | 0.0734 | 0.1027 | 0.0000 | 0.0293 | 0.0587 |

| OAM costs I6 | 0.2622 | 0.3277 | 0.3277 | 0.1966 | 0.2622 | 0.3277 | 0.0983 | 0.1639 | 0.2294 | 0.0000 | 0.0655 | 0.1311 |

| Odor generation I7 | 0.0074 | 0.0099 | 0.0124 | 0.0037 | 0.0062 | 0.0087 | 0.0000 | 0.0025 | 0.0050 | 0.0000 | 0.0000 | 0.0025 |

| Cold climate treatment effect I8 | 0.0210 | 0.0280 | 0.0350 | 0.0105 | 0.0175 | 0.0245 | 0.0000 | 0.0070 | 0.0140 | 0.0000 | 0.0000 | 0.0070 |

| Stability I9 | 0.0409 | 0.0546 | 0.0682 | 0.0205 | 0.0341 | 0.0477 | 0.0000 | 0.0136 | 0.0273 | 0.0000 | 0.0000 | 0.0136 |

| Risk Assessment I10 | 0.0289 | 0.0386 | 0.0482 | 0.0145 | 0.0241 | 0.0337 | 0.0000 | 0.0096 | 0.0193 | 0.0000 | 0.0000 | 0.0096 |

| Indicator | CA1 | CA2 | CA3 | CA4 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GHG generation I1 | 0.0267 | 0.0356 | 0.0445 | 0.0134 | 0.0223 | 0.0312 | 0.0000 | 0.0089 | 0.0178 | 0.0000 | 0.0000 | 0.0089 |

| WFZ contribution I2 | 0.0000 | 0.0000 | 0.0010 | 0.0015 | 0.0026 | 0.0036 | 0.0031 | 0.0041 | 0.0051 | 0.0041 | 0.0051 | 0.0051 |

| Reclaimed water reuse I3 | 0.0000 | 0.0039 | 0.0078 | 0.0059 | 0.0098 | 0.0137 | 0.0117 | 0.0156 | 0.0195 | 0.0156 | 0.0195 | 0.0195 |

| Sludge treatment cost I4 | 0.0735 | 0.0919 | 0.0919 | 0.0551 | 0.0735 | 0.0919 | 0.0276 | 0.0460 | 0.0643 | 0.0000 | 0.0184 | 0.0368 |

| Electricity costs I5 | 0.3806 | 0.4757 | 0.4757 | 0.2854 | 0.3806 | 0.4757 | 0.1427 | 0.2379 | 0.3330 | 0.0000 | 0.0951 | 0.1903 |

| OAM costs I6 | 0.1082 | 0.1353 | 0.1353 | 0.0812 | 0.1082 | 0.1353 | 0.0406 | 0.0677 | 0.0947 | 0.0000 | 0.0271 | 0.0541 |

| Odor generation I7 | 0.0068 | 0.0090 | 0.0113 | 0.0034 | 0.0057 | 0.0079 | 0.0000 | 0.0023 | 0.0045 | 0.0000 | 0.0000 | 0.0023 |

| Cold climate treatment effect I8 | 0.0196 | 0.0261 | 0.0326 | 0.0098 | 0.0163 | 0.0228 | 0.0000 | 0.0065 | 0.0130 | 0.0000 | 0.0000 | 0.0065 |

| Stability I9 | 0.0415 | 0.0554 | 0.0692 | 0.0208 | 0.0346 | 0.0484 | 0.0000 | 0.0138 | 0.0277 | 0.0000 | 0.0000 | 0.0138 |

| Risk Assessment I10 | 0.0415 | 0.0554 | 0.0692 | 0.0208 | 0.0346 | 0.0484 | 0.0000 | 0.0138 | 0.0277 | 0.0000 | 0.0000 | 0.0138 |

| CASS | A2/O | MBR | A/O-MBR | |||||

|---|---|---|---|---|---|---|---|---|

| Ci | Sort | Ci | Sort | Ci | Sort | Ci | Sort | |

| CA1 | 0.333 | 4 | 0.427 | 4 | 0.765 | 1 | 0.962 | 1 |

| CA2 | 0.527 | 3 | 0.563 | 3 | 0.718 | 2 | 0.774 | 2 |

| CA3 | 0.686 | 1 | 0.630 | 1 | 0.480 | 3 | 0.474 | 3 |

| CA4 | 0.674 | 2 | 0.584 | 2 | 0.323 | 4 | 0.275 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Tang, J.; Duan, Y.; Qu, Y.; Sun, F.; Li, Z. Study on the Relationship between Different Wastewater Treatment Technologies and Effluent Standards in Jilin Liaohe River Basin Based on the Coupled Model of AHP and Fuzzy TOPSIS Method. Sustainability 2023, 15, 1264. https://doi.org/10.3390/su15021264

Yang Y, Tang J, Duan Y, Qu Y, Sun F, Li Z. Study on the Relationship between Different Wastewater Treatment Technologies and Effluent Standards in Jilin Liaohe River Basin Based on the Coupled Model of AHP and Fuzzy TOPSIS Method. Sustainability. 2023; 15(2):1264. https://doi.org/10.3390/su15021264

Chicago/Turabian StyleYang, Yao, Jie Tang, Yucong Duan, Yunke Qu, Feihu Sun, and Zhaoyang Li. 2023. "Study on the Relationship between Different Wastewater Treatment Technologies and Effluent Standards in Jilin Liaohe River Basin Based on the Coupled Model of AHP and Fuzzy TOPSIS Method" Sustainability 15, no. 2: 1264. https://doi.org/10.3390/su15021264

APA StyleYang, Y., Tang, J., Duan, Y., Qu, Y., Sun, F., & Li, Z. (2023). Study on the Relationship between Different Wastewater Treatment Technologies and Effluent Standards in Jilin Liaohe River Basin Based on the Coupled Model of AHP and Fuzzy TOPSIS Method. Sustainability, 15(2), 1264. https://doi.org/10.3390/su15021264