Abstract

The energy supply effect caused by the stiffness difference between roofs and sidewalls is an important factor that induces strain coal bursts. In order to quantitatively reveal the energy supply mechanism of strain coal bursts, this paper first establishes a coal burst energy model of the rock–coal system and proposes the calculation formula of coal burst kinetic energy considering supply energy and the stiffness ratio of rock to coal. Then the whole energy evolution law of the rock–coal system with different stiffness ratios is researched by using the numerical simulation method, and the whole process is divided into three stages. With the decrease in the stiffness ratio, the elastic strain energy of the coal changes little, while its kinetic energy is negatively correlated with the stiffness ratio in a power function. Meanwhile, the elastic strain energy and kinetic energy of the rock have power function relations with the stiffness ratio, too. When the rock–coal system is fractured, the kinetic energy of the coal comes from the release of elastic strain energy from the coal and the energy supplied from the rock. The energy supply rate is between 22% and 35% when the stiffness ratio changes from 3.0 to 0.5, and they show a linear relationship, while the supplied energy has a negative power function relationship with the stiffness ratio.

1. Introduction

A coal burst is a typical dynamic disaster in underground coal mining. Its frequency and intensity increase with the mining depth, which seriously threatens the safety and production of underground workers [1,2,3]. In the next five years or even ten years, the prevention and control of coal bursts will be the focus of much research and poses an urgent problem to be solved in mining engineering.

According to the mechanism of coal bursts, scholars have put forward more than ten theories and described several types of coal bursts from different angles [4,5,6]. Among them, a typical type is a strain coal burst caused by high static stress. A strain coal burst is a sudden event induced by energy accumulation and release, as well as the loss in the dynamic balance of the combined coal and rock mass composed of a roof, sidewall, and floor [7,8]. For a strain coal burst, when the elastic strain energy stored in the coal is greater than the failure dissipation energy, the residual energy will be released in the form of a coal burst [9,10]. However, dynamic damage is unlikely to occur only through the elastic strain energy stored by the coal itself; the surrounding rock mass is required to supply its energy to the coal. According to the stiffness theory [11,12], some experts point out that when the stiffness of the surrounding rock is less than that of the coal, the surrounding rock will supply energy to the damaged coal, thus causing a coal burst [13,14]. Li et al. [15] proposed two concept models to illustrate the energy conversions in a rockburst event, and studied the role of the elastic strain energy released from the surrounding rock mass in rock ejection. Cai et al. [16,17,18] developed one brittle hard rock testing system with a super high and variable loading stiffness, and studied the influence of loading stiffness on the post-peak stress–strain curves and failure modes of rocks. Zhao et al. [19] developed a rock testing system with changeable stiffness, and researched the mechanical behaviors of rock specimens and testing machines under different loading stiffnesses. The above research reveals the influence mechanism of stiffness on the dynamic failure of the coal (or rock) from the stress–strain curve and the failure characteristics.

A coal burst is a dynamic failure phenomenon driven by energy. Therefore, it is better to reveal the essential characteristics of coal bursts by studying the energy evolution law [20,21,22,23]. In the research on the stiffness theory of coal bursts, limited by the test methods, the research on the energy parameters in the current stage is less and generally only involves the analysis of the storage and release of elastic strain energy in the two states of the peak strength point and post-failure [19]. The energy evolution law of the whole process of coal bursts and the energy supply of surrounding rock to the coal are difficult to determine quantitatively, which creates certain limitations for coal burst mechanism research.

In order to quantitatively reveal the stiffness effect on coal burst from the perspective of energy, a rock–coal system model is established by means of numerical simulation, and the energy evolution law and energy supply characteristics of rock and coal under different stiffness combinations are studied. The quantitative relationship between energy parameters and stiffness is obtained.

2. Theoretical Analysis

2.1. Stiffness Theory

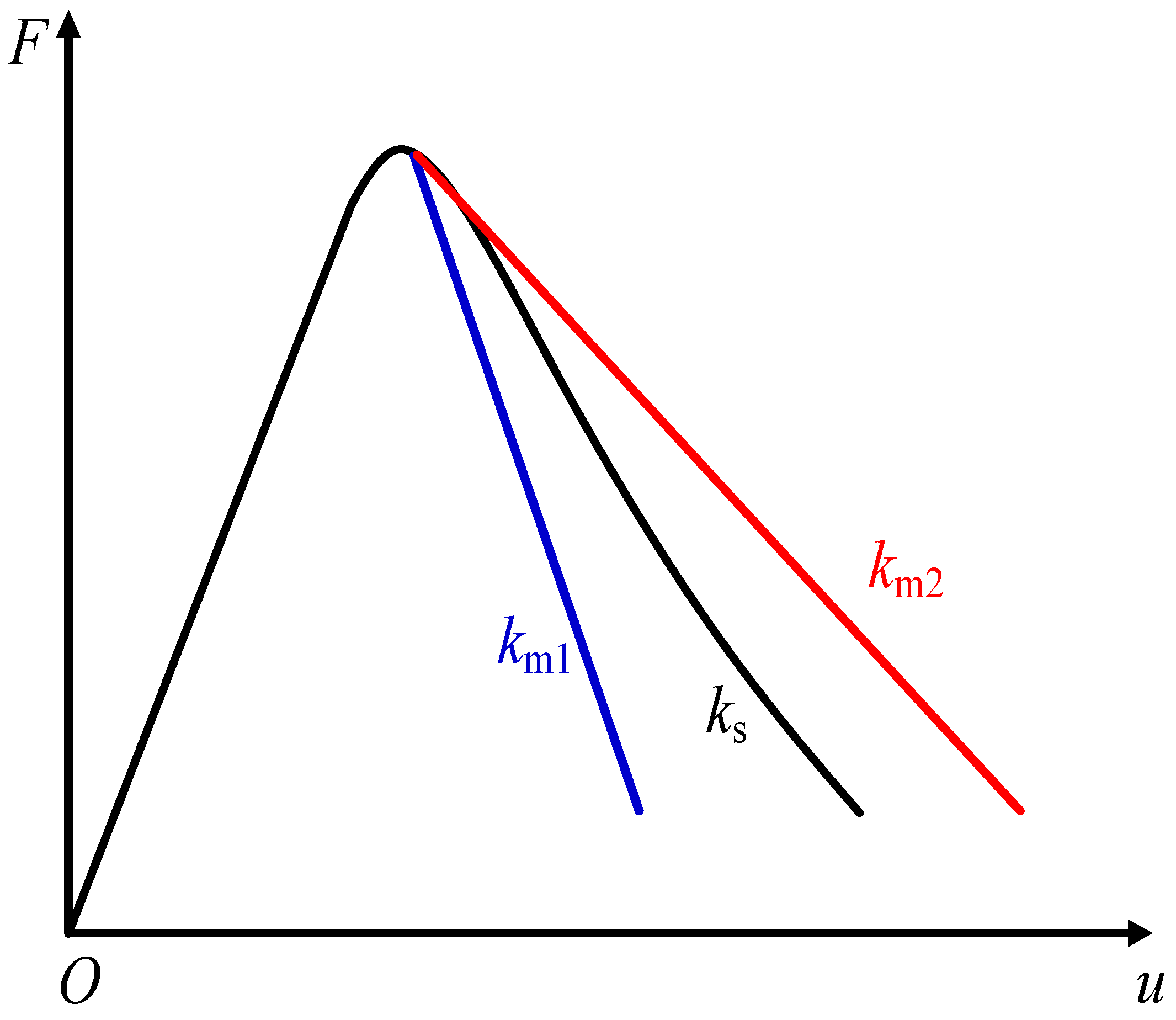

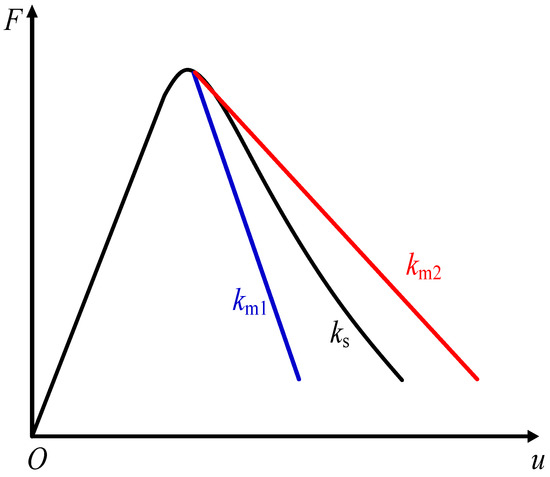

The load–deformation curve during the loading process of the testing machine specimen system is shown in Figure 1. When the specimen is damaged after the peak point, the load of the testing machine and the load of the specimen decrease synchronously, the specimen continues to compress, and the deformation of the testing machine recovers. When the stiffness km1 of the testing machine is greater than the slope ks of the post-peak curve of the specimen, the released elastic strain energy of the testing machine is less than the dissipation energy that causes the fracture of the specimen. In order to fracture the specimen, the testing machine needs to continue to input energy to the specimen. At this moment, the loading process is controllable, and the specimen is statically damaged [24]. When the stiffness km2 of the testing machine is less than the slope ks of the post-peak curve of the specimen, the released elastic strain energy of the testing machine is greater than the dissipation energy that causes the fracture of the specimen, and the residual energy will be converted into kinetic energy of the specimen, thus causing the dynamic failure of the specimen.

Figure 1.

Load–deformation curve of the testing machine specimen system.

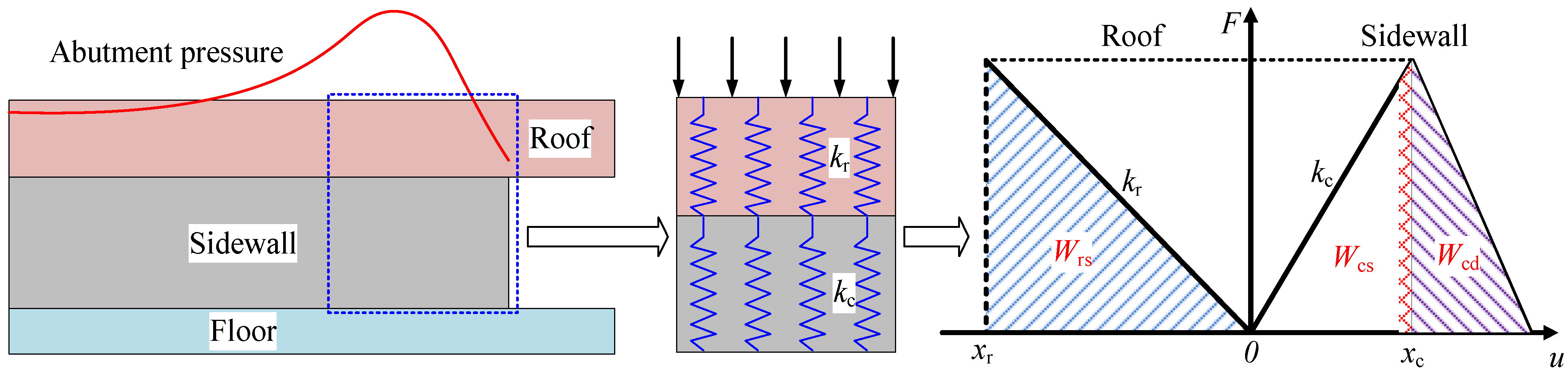

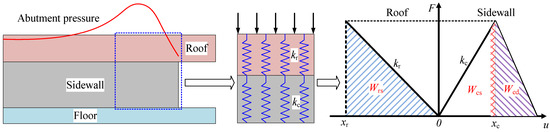

2.2. Coal Burst Model of Rock–Coal System

According to the stiffness theory, the sidewall coal of the roadway is the main burst body in the process of coal burst, and the low-stiffness roof supplies energy to the coal. According to the load and deformation relationship between the roof rock and sidewall coal [25,26], it can be simplified as a series-connected rock–coal system model, as shown in Figure 2. The roof stiffness is kr and the sidewall stiffness is kc, then the relationship between the sidewall deformation xc and the roof deformation xr is:

Figure 2.

Rock–coal system and their loading–deformation relation.

When the overburdened strata load onto the surrounding rock of the roadway, part of the external input energy is stored in the roof rock, and the other part is stored in the sidewall coal. The elastic strain energy Wcs and Wrs of the sidewall and roof are, respectively:

The total elastic strain energy Wts of the rock–coal system is:

The extreme value of elastic strain energy is certain for the same sidewall coal. The smaller the stiffness kr of the roof, the greater the extreme value of the elastic strain energy Wts in the rock–coal system. When the rock–coal system transforms from the equilibrium state to the unstable equilibrium state, more elastic strain energy Wts will be released and the coal burst risk will increase.

When the coal reaches the ultimate strength, it will be fractured under the external load, and its stored elastic strain energy Wcs will be released. When the sidewall coal is considered separately, part of the elastic strain energy Wcs is released in the form of fracture dissipation energy Wcd, and the residual energy is converted into kinetic energy Wck [9], which is calculated as:

For the coal, the greater the elastic strain energy Wcs, the smaller the post-peak fracture dissipation energy Wcd, and more energy will be released in the form of kinetic energy Wck, showing a strong coal burst tendency.

For the rock–coal system, when the coal is fractured, the elastic strain energy Wrs of the roof rock will also be released and a certain amount of energy will be supplied to the coal. Since the strength of rock is generally greater than that of coal, it is assumed that plastic deformation does not occur on the rock. Part of the elastic strain energy Wrs released by the rock is released in the form of kinetic energy Wrk, and the residual energy is the supply energy Wr-c to the coal. The ratio of the supply energy Wr-c to the elastic strain energy Wrs of rock is defined as the energy supply rate α, so the kinetic energy Wck of coal in the rock–coal system is:

α = Wr-c/Wrs

For the rock–coal system, when the stiffness kr of the roof decreases, the elastic strain energy Wrs stored in the rock increases, and more energy in the rock can be supplied to the coal, which causes greater risk of coal burst.

3. Numerical Simulation

The above theoretical analysis qualitatively reveals the energy supply behavior of the low-stiffness roof to the failure of the sidewall coal, and the energy and stiffness influence mechanism of coal burst. In the following, the numerical simulation method is used to quantitatively study the energy evolution law of rock–coal system under different stiffness combinations.

3.1. Simulation Scheme

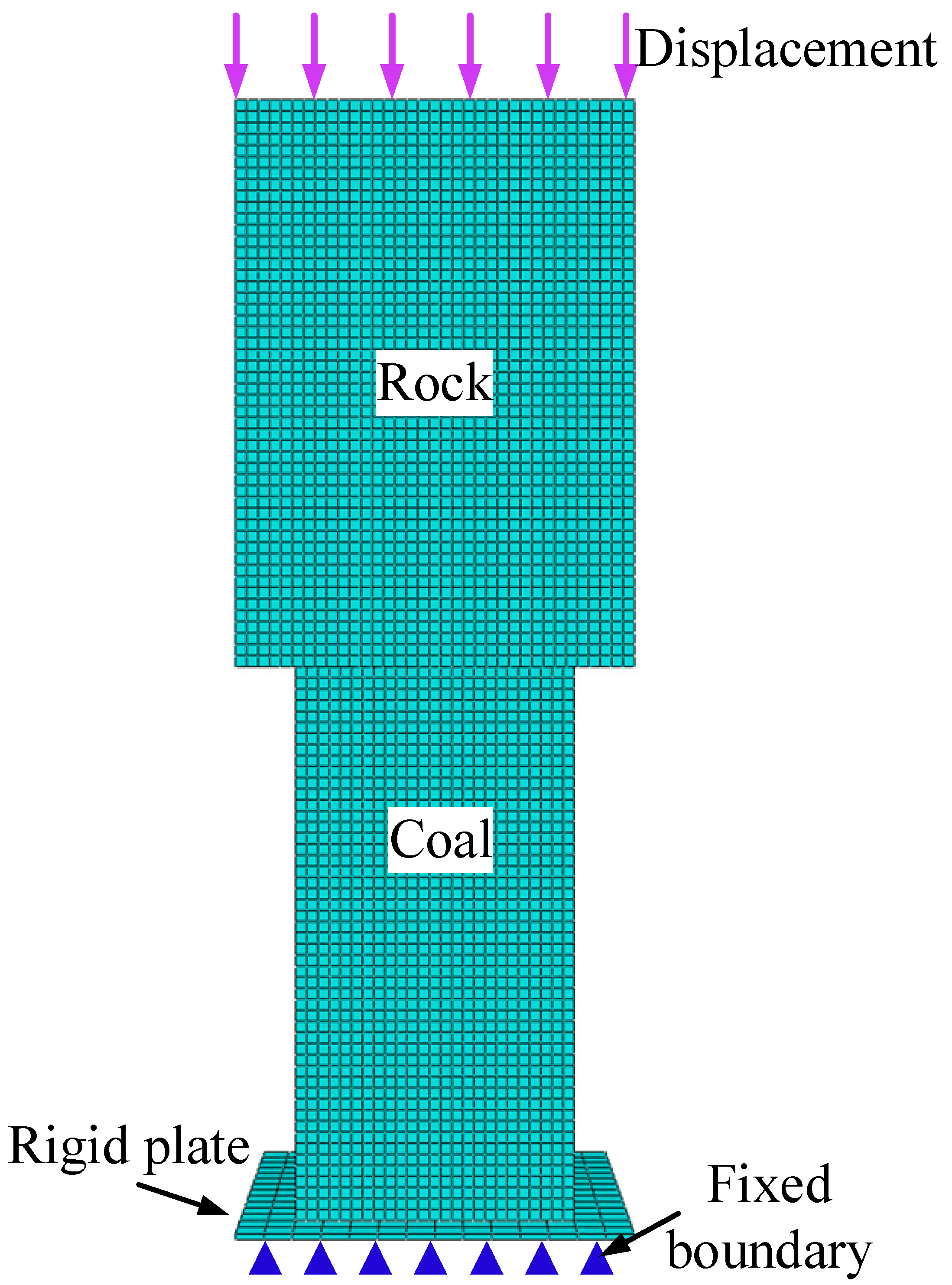

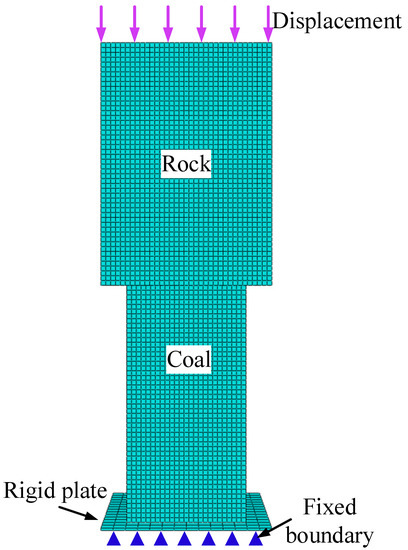

The instability and failure of rock–coal system were simulated by Abaqus software. The numerical model of rock–coal system is shown in Figure 3. The lower part of the model is the sidewall coal, which is a rectangular standard specimen with a size of 50 mm × 50 mm × 100 mm. Drucker–Prager failure criterion and shear damage model were selected to simulate the damage and failure process of the coal [27]. The parameters were determined by comparing the stress–strain curve of the coal model with the laboratory test by using trial-and-error method [28]. The specific parameters are listed in Table 1. The stiffness of the coal specimen is 42.5 MN/m.

Figure 3.

Numerical model of the rock–coal system.

Table 1.

Parameters of the coal.

The roof rock is above the coal, which is a rectangular specimen with a size of 70 mm × 70 mm × 100 mm. In a roadway coal burst, coal sidewall is the main burst body, and the roof rock is the main loading body [29,30]. The strength of rock is greater than that of the coal, and the rock remains in the pre-peak stage when the coal is fractured. Therefore, in the simulation process, the failure of rock was not considered, and the elastic property was applied to the rock with a density of 2000 kg/m3 and a Poisson’s ratio of 0.25 [31]. This paper focuses on the energy evolution law of rock–coal system under different stiffness ratios kr/kc of rock to coal, and performs loading tests for different stiffness ratios by changing the elastic modulus of rock. The stiffness ratios kr/kc of rock to coal designed in the simulation are 0.5, 1.0, 2.0, and 3.0.

Between the rock and coal, the tangential behavior and normal behavior of the contact surface are defined in the simulation. In order to eliminate the influence of end-face friction on the test results [32], the friction coefficient in the tangential direction is set at zero. In the normal direction, it is set as the “Hard” contact to ensure that there is no model penetration when the rock model and the coal model are in contact with each other.

C3D8R eight-node linear hexahedral element was selected as the finite element mesh type of the model, and Abaqus dynamic display solver was used for calculation. Vertical downward axial displacement was applied to the top of the model for loading, and the rigid plate under the model is fixed. The total axial deformation u of the rock–coal system was recorded.

3.2. Energy Monitoring

The energy involved in the whole process of rock–coal system failure includes: elastic strain energy Wcs; dissipation energy Wcd and kinetic energy Wck of coal; and elastic strain energy Wrs and kinetic energy Wrk of rock. According to theoretical analysis, the increase in strain energy Wcs of coal and elastic strain energy Wrs of rock aggravates the dynamic damage degree of the coal [33], while the increase in dissipation energy Wcd of coal weakens its dynamic damage degree. The magnitude of kinetic energy Wck of coal is directly related to its dynamic damage degree. Elastic strain energy Wcs of coal and elastic strain energy Wrs of rock are superposed and transformed into dissipation energy Wcd and kinetic energy Wck of coal and kinetic energy Wrk of rock. Therefore, the simulation mainly monitors the energy parameters, such as elastic strain energy Wcs, dissipation energy Wcd and kinetic energy Wck of coal, and elastic strain energy Wrs and kinetic energy Wrk of rock. The supply energy Wr-c of rock to coal can be calculated by the following formula:

Wr-c = Wcd + Wck − Wcs

In Abaqus, various energy output quantities are provided, such as recoverable strain energy (ALLSE), as well as energy dissipated by rate-independent and rate-dependent plastic deformation (ALLPD) and kinetic energy (ALLKE). In these energy output quantities, ALLSE is the elastic strain of coal or rock, ALLPD is the dissipation energy of coal, and ALLKE is the kinetic energy of coal or rock.

4. Results and Analysis

4.1. Failure Mode

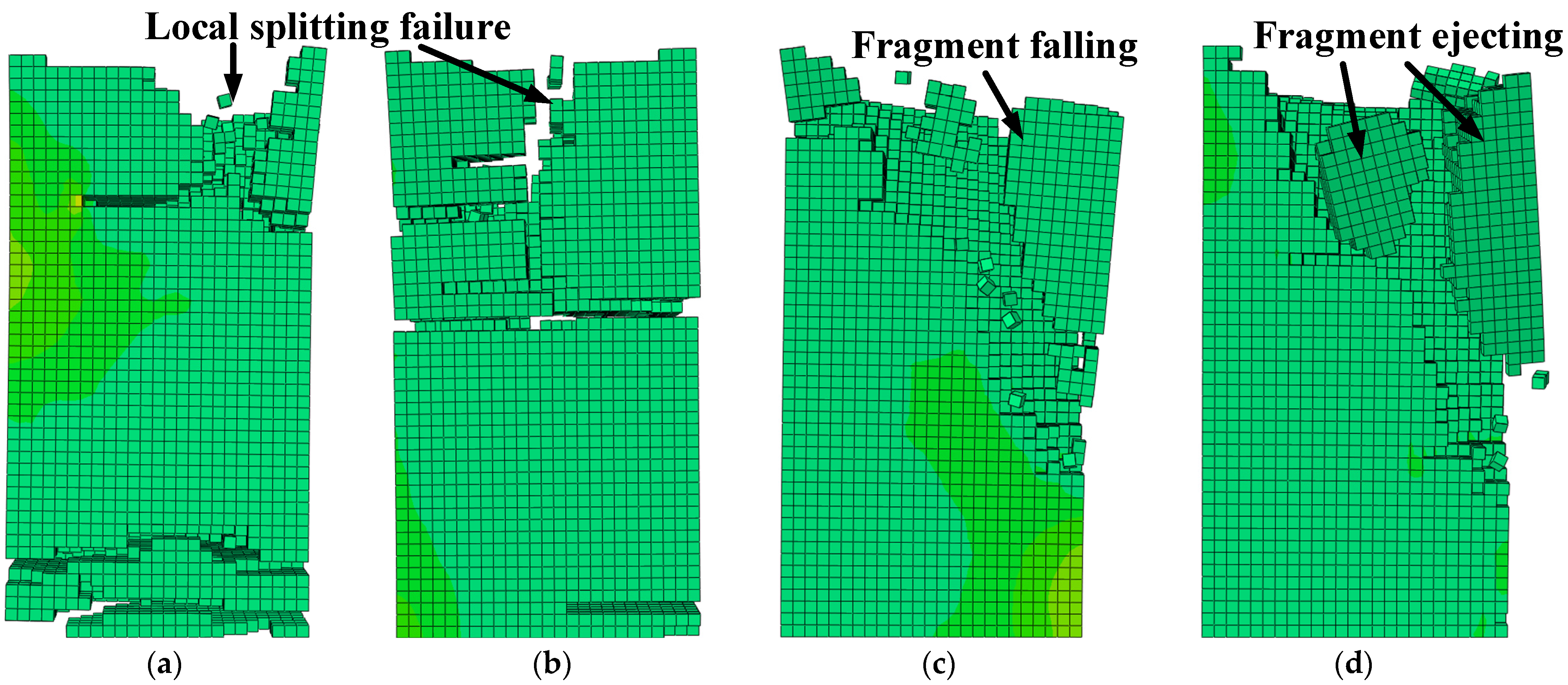

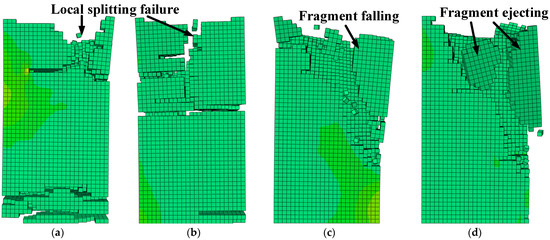

The failure modes of the coal specimens under different stiffness ratios kr/kc are shown in Figure 4. When the stiffness ratio kr/kc is 0.5, the fragments falling from the specimen are ejected quickly and show obvious burst characteristics. When the stiffness ratio kr/kc increases to 1.0, the ejecting velocity of the fragments obviously decreases. When the stiffness ratio kr/kc is 3.0 or 2.0, cracks on the post-peak coal specimen are generated slowly, the progressive stripping of the fragments occurs locally in the model, and the failure process is stable. The failure mode and variation law of coal under different loading stiffnesses are similar to those of laboratory testing results [30].

Figure 4.

Failure mode of coal specimen under the stiffness ratios of (a) 3.0, (b) 2.0, (c) 1.0, and (d) 0.5.

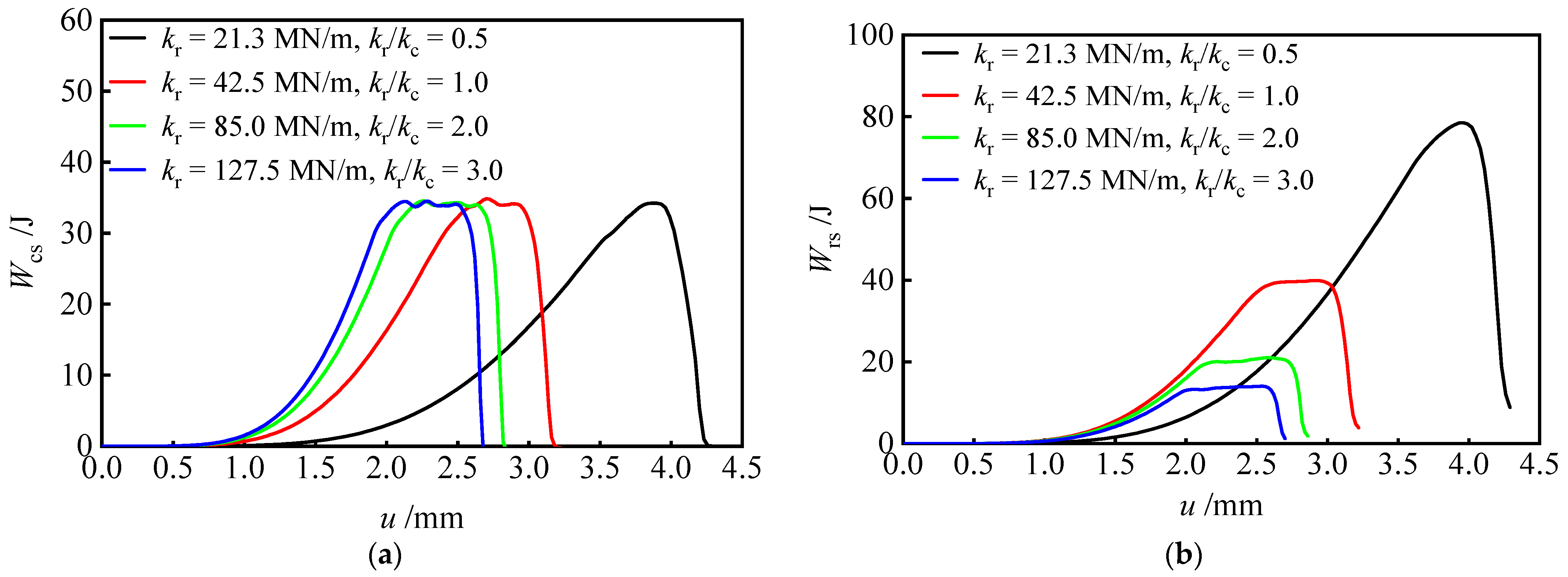

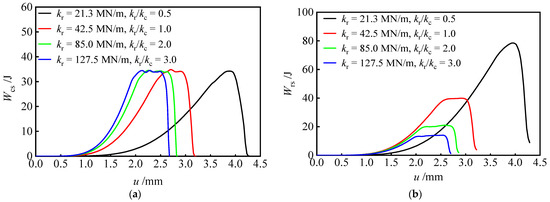

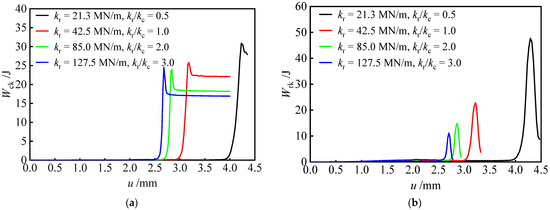

4.2. Strain Energy of Coal and Rock

The evolution curves of the elastic strain energy of coal under different stiffness ratios kr/kc are shown in Figure 5a. Under different stiffness ratios kr/kc, the extreme value of the elastic strain energy Wcs of coal is between 34.2 J and 34.6 J, with little change. When the rock stiffness kr changes, the extreme value of the elastic strain energy Wcs of coal will not change, and the rock stiffness kr has little effect on the energy storage property of the coal itself. When the elastic strain energy Wcs of the coal reaches the extreme value of energy storage, the elastic strain energy curve tends to flatten. At this time, the plastic deformation of the coal occurs and the elastic strain energy Wcs does not increase. Under the constant displacement loading speed, when the stiffness ratio kr/kc decreases, the duration of the flattened section of the elastic strain energy Wcs is shortened. For example, when the stiffness ratio kr/kc is 3, the flattened section of the elastic strain energy Wcs needs to be continuously loaded by 0.5 mm, and when the stiffness ratio kr/kc is 0.5, it is reduced to 0.1 mm.

Figure 5.

Elastic strain energy evolution curves of (a) coal and (b) rock.

The elastic strain energy evolution curves of rock are shown in Figure 5b. Combined with the analysis of the elastic strain energy evolution law of coal, when the coal is fractured and its internal elastic strain energy Wcs is released, the elastic strain energy Wrs of the rock is also released; that is, the deformation rebound phenomenon of the rock occurs [19]. There is an obvious difference between the elastic strain energy Wrs of rocks under different stiffness ratios kr/kc. When the stiffness ratio kr/kc is 0.5, the extreme value of the rock elastic strain energy Wrs is about 80 J. When the stiffness ratio kr/kc increases to 3.0, the extreme value of the rock elastic strain energy Wrs decreases to 13 J. There are also obvious changes in the release rate of rock elastic strain energy. When the stiffness ratio kr/kc is 3.0, the release rate of rock elastic strain energy is 11.7 J/s, and when the stiffness ratio kr/kc is 0.5, it increases to 21.5 J/s. Compared with rock with high stiffness, rock with low stiffness can accumulate more elastic strain energy, and its energy release rate is faster. According to the stiffness theory, in a rock–coal system, low-stiffness rock will generate a stronger energy supply. The higher elastic strain energy and faster energy release rate of low-stiffness rock are the manifestations of this energy supply.

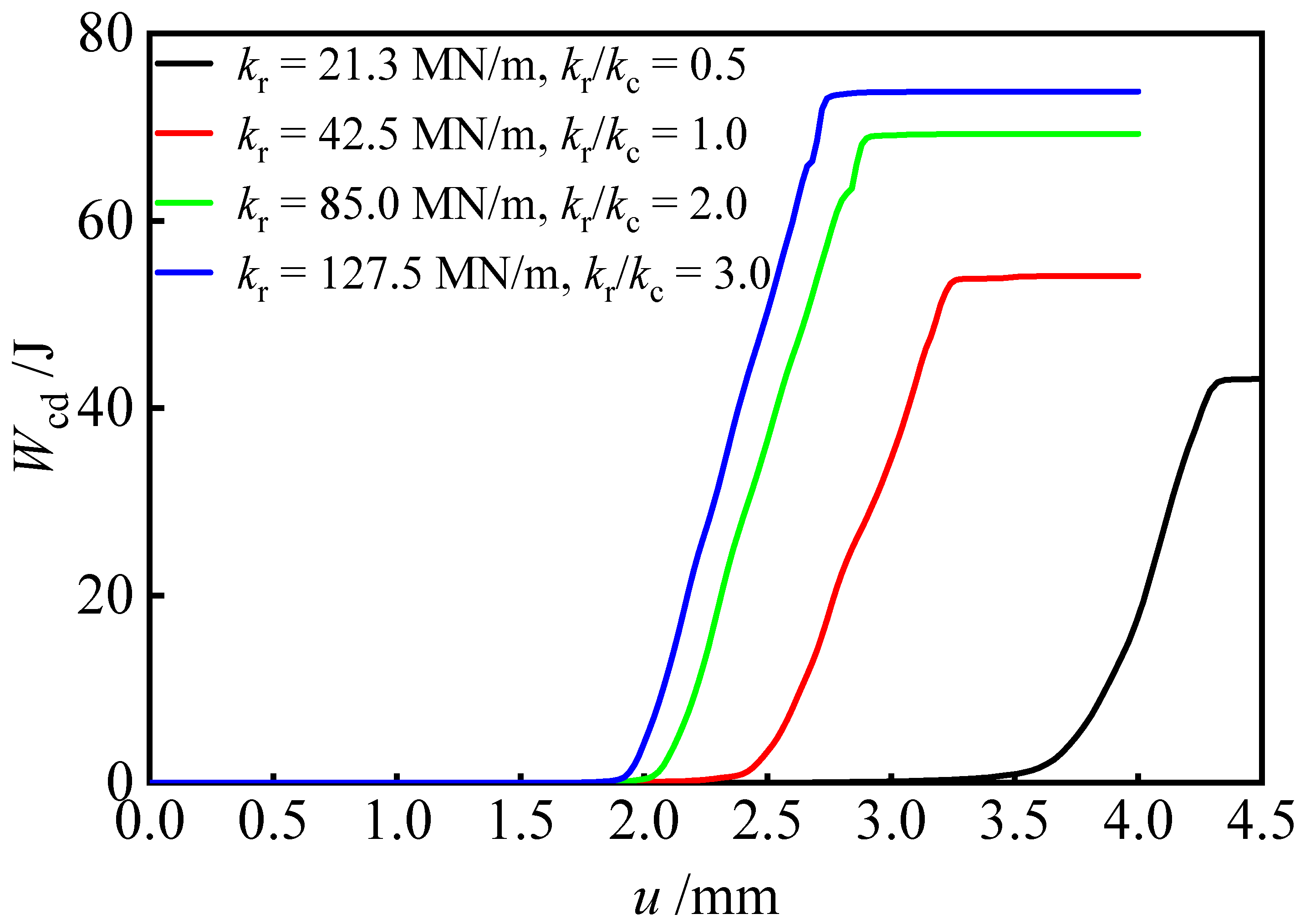

4.3. Dissipation Energy of Coal

The evolution curves of dissipation energy of coal are shown in Figure 6. Compared with the evolution of coal elastic strain energy in Figure 5a, the dissipation energy Wcd starts to increase before the coal elastic strain energy Wcs reaches the extreme value, indicating that there are micro-cracks generating in the coal before its failure, and some energy is dissipated. When the elastic strain energy Wcs of the coal is fully released and is reduced to 0, the dissipation energy Wcd reaches the maximum value, and the coal is completely fractured. With the decrease in the stiffness ratio kr/kc, the increasing rate of the dissipation energy Wcd of the coal changes little, but the total dissipation energy Wcd decreases gradually. When the stiffness ratio kr/kc is 3.0, the dissipation energy Wcd of coal is 73.8 J, and when the stiffness ratio kr/kc is 0.5, the dissipation energy Wcd is reduced to 43.3 J. When the roof stiffness kr decreases, the dissipation energy Wcd of coal decreases, which indicates that the rapid rebound of the roof rock leads to a decrease in the coal’s plasticity and an increase in brittleness.

Figure 6.

Dissipation energy evolution curves of coal.

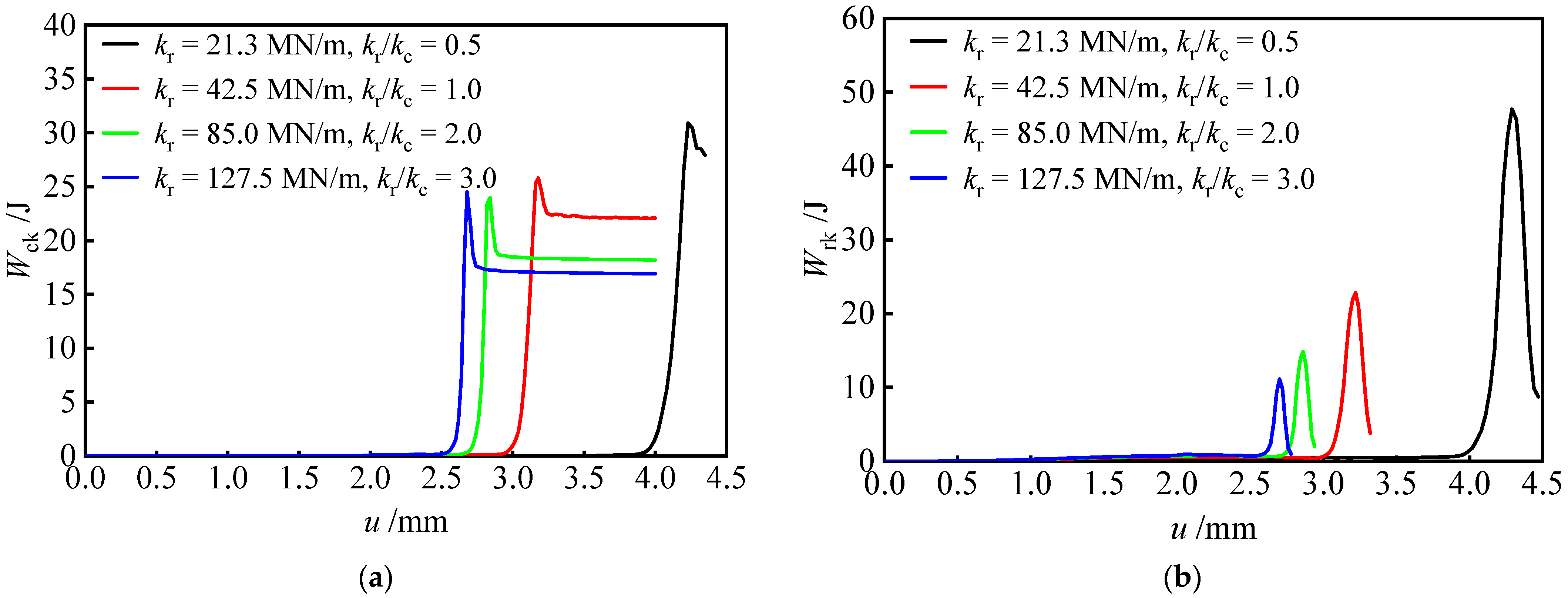

4.4. Kinetic Energy of Coal and Rock

The kinetic energy evolution curves of coal and rock are shown in Figure 7. The laboratory tests show that [19,30] the deformation rebound phenomenon obviously occurs when the specimen is fractured, and the rebound speed is negatively correlated with the stiffness of the testing machine; that is, the smaller the stiffness of the testing machine, the faster the deformation rebound speed of the testing machine. For a rock–coal system, the rock is equivalent to a testing machine, and the coal is equivalent to a specimen. When the coal is fractured, the elastic strain energy Wrs of the rock is released, and its deformation rebounds. Part of the elastic strain energy Wrs is converted into its kinetic energy Wrk, and the other part of the elastic strain energy Wrs is supplied to the coal specimen and converted into the kinetic energy Wck of the coal. With the decrease in the rock stiffness kr, the elastic strain energy Wrs released by the rock increases when it rebounds, and its kinetic energy Wrk increases. The kinetic energy Wck of the coal increases too. When the stiffness ratio kr/kc is 3.0, the kinetic energy Wrk of the rock is about 11.11 J, and the kinetic energy Wck of the coal is 24.52 J. When the stiffness ratio kr/kc is 0.5, the kinetic energy Wrk of the rock is 47.69 J and the kinetic energy Wck of the coal is 30.90 J. There is an obvious difference in the energy supply of the rock to coal under the loading of the two kinds of rock stiffnesses. The increase in the kinetic energy Wrk of the rock indicates that the rebound speed of the rock is accelerated when the coal is fractured, the loading speed of the deformation rebound of the rock to the coal is faster, and the energy supply is stronger. After the rock stiffness kr decreases, the dissipation energy Wcd of the coal decreases and the kinetic energy Wck increases, indicating that the energy dissipated by the coal decreases under the condition of low-stiffness loading, and more energy is converted into its own kinetic energy Wck. The kinetic energy Wck is a manifestation of the ejecting velocity of coal fragments. The greater kinetic energy Wck of the coal, the faster the ejecting speed of the fragments. The coal shows stronger burst failure characteristics.

Figure 7.

Kinetic energy evolution curves of (a) coal and (b) rock.

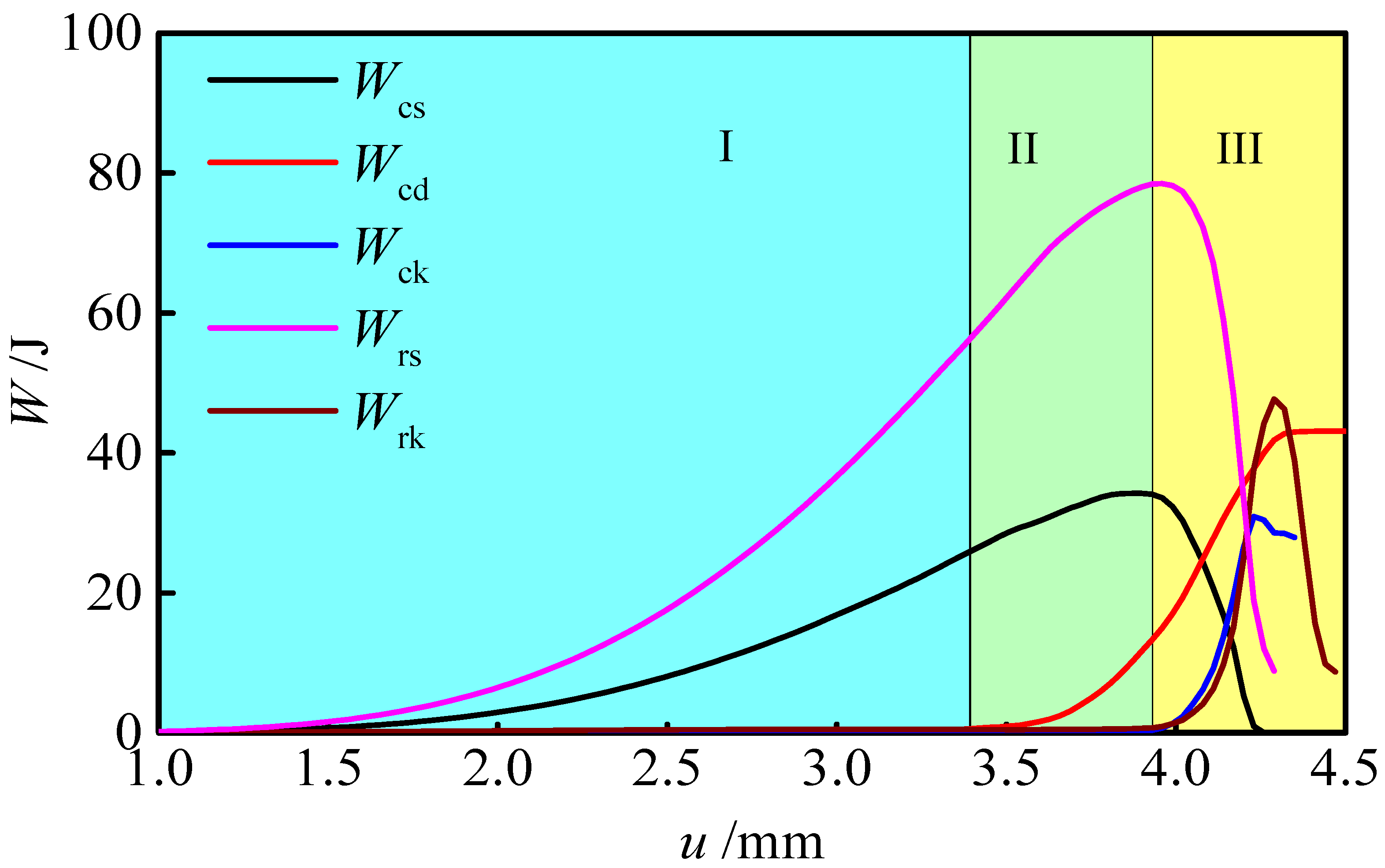

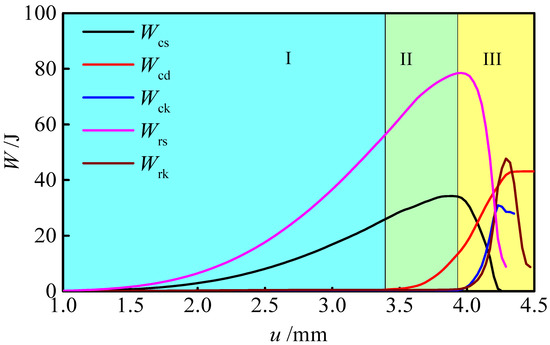

4.5. Energy Evolution Law of Rock–Coal System

When the stiffness ratio kr/kc is 0.5, the energy evolution curves of the coal and rock are shown in Figure 8. The energy evolution process can be divided into three stages. In the stage I, the coal and rock bear the load together, and their strain energy gradually increases, converting the external input energy into internal elastic strain energy. The dissipation energy Wcd of the coal is zero. In the stage II, before the internal elastic strain energy Wcs of the coal reaches its storage limit, the coal will undergo plastic deformation, and part of the external input energy will be dissipated in the form of plastic deformation energy. At this time, the internal elastic strain energy of the coal and rock will continue to increase. In the stage III, the internal elastic strain energy Wcs of the coal reaches its energy storage limit and begins to decrease (i.e., energy release). The internal elastic strain energy of the coal and the rock is released synchronously. Part of the elastic strain energy Wrs of the rock is converted into its own kinetic energy Wrk, and the other part is supplied to the coal. The elastic strain energy Wcs of the coal is released in the form of kinetic energy Wck and dissipation energy Wcd until the elastic strain energy Wcs drops to zero and the coal is completely fractured.

Figure 8.

Energy evolution curves of coal and rock.

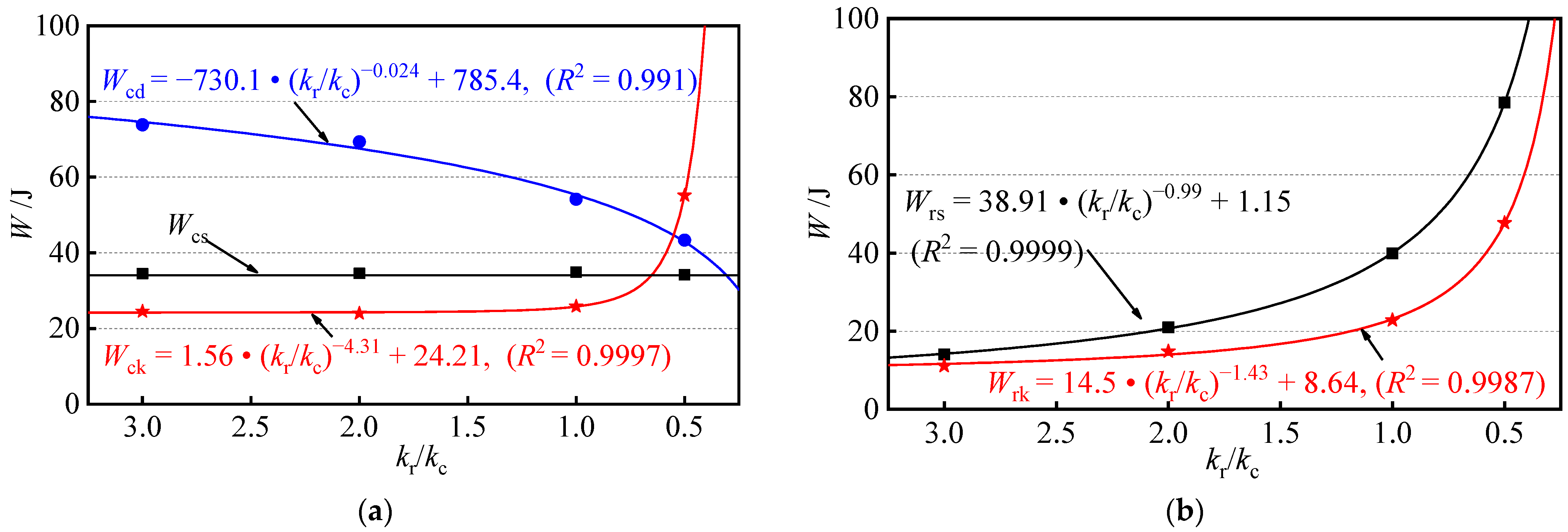

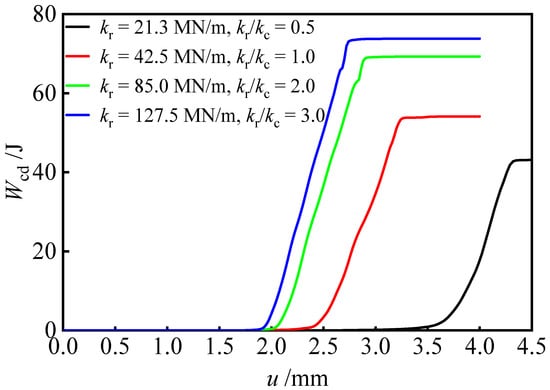

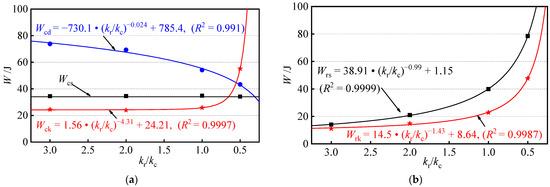

The relationship between the energy and stiffness ratio is shown in Figure 9. It should be noted that, in order to visually show the changing law of energy parameters of the rock–coal system when the stiffness ratio kr/kc is decreased, the stiffness ratio kr/kc decreases along the x-axis.

Figure 9.

The energy of (a) coal and (b) rock changing curves with stiffness ratio.

The change in the rock stiffness kr mainly affects the dissipation energy Wcd and kinetic energy Wck of the coal as well as the elastic strain energy Wrs and kinetic energy Wrk of the rock, and has little effect on the elastic strain energy Wcs of the coal. With the decrease in the stiffness ratio kr/kc, the dissipation energy Wcd of the coal decreases gradually, while the kinetic energy Wck of the coal, the elastic strain energy Wrs, and the kinetic energy Wrk of the rock increase gradually, all of which have power function relationships with the stiffness ratio kr/kc. Compared with other energy, the kinetic energy Wck of coal is more sensitive to the change in the stiffness ratio kr/kc. When the stiffness ratio kr/kc is greater than one, the kinetic energy Wck of the coal changes slowly, and the influence of the stiffness change on the failure form of the coal is weak. When the stiffness ratio kr/kc is less than one, the kinetic energy Wck of the coal increases sharply with the decrease in the stiffness ratio kr/kc. When the rock stiffness kr is less than the coal stiffness kc, the rock deformation rebound speed is faster and more energy is released, resulting in the accelerated failure speed of the coal after the peak point. The micro-cracks in the coal rapidly expand into the fracture zone in a very short time. The energy dissipated by the coal is reduced, and its kinetic energy Wck is increased.

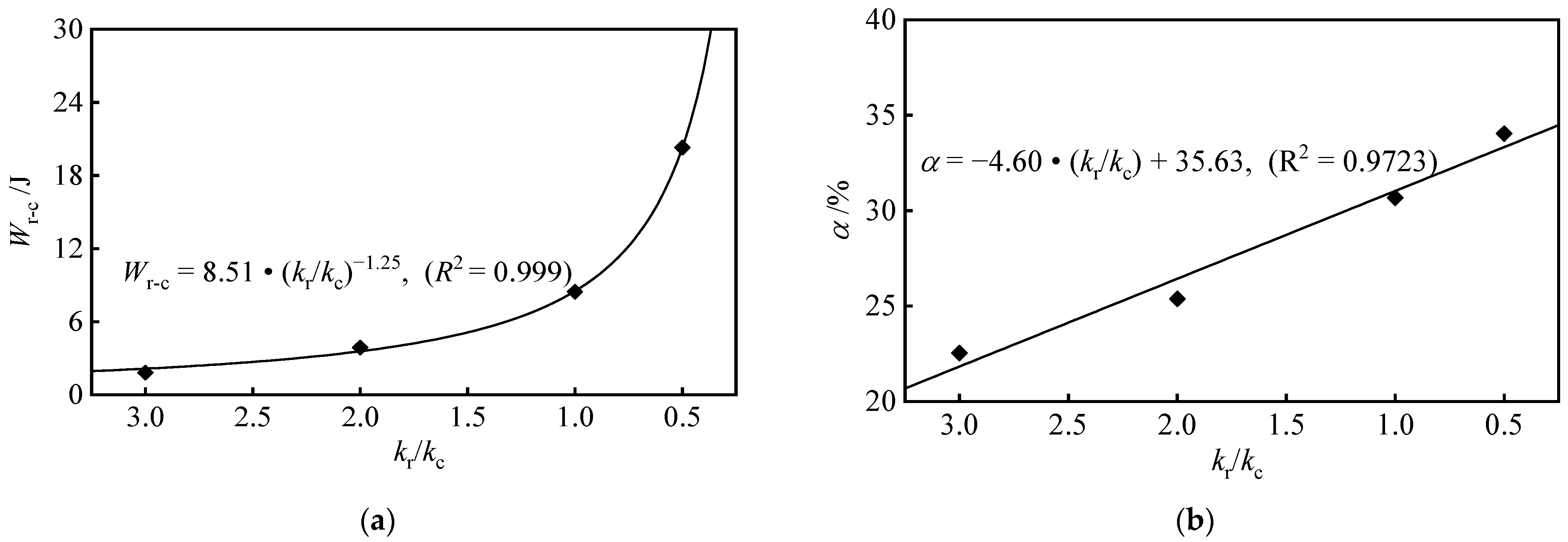

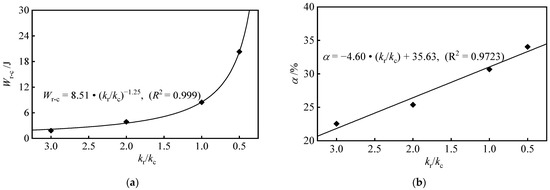

With the decrease in the stiffness ratio kr/kc, the difference between the elastic strain energy Wrs and kinetic energy Wrk of the rock increases, and more energy is supplied to the coal. The changing curves of the supplied energy Wr-c and energy supply rate α are shown in Figure 10. The supplied energy Wr-c and energy supply rate α increase with the decrease in the stiffness ratio kr/kc. The supplied energy Wr-c and the stiffness ratio kr/kc have a power function relationship, and the energy supply rate α and the stiffness ratio kr/kc have a linear relationship. The lower the rock stiffness kr, the more energy supply to the coal [19,30].

Figure 10.

Changing curves of (a) supplied energy and (b) energy supply rate.

5. Discussion

In the previous research on the energy mechanism of coal bursts, the strain energy release of coal is the main energy resource. The effect of the surrounding rocks on the coal is mainly reflected in the kinetic energy of the fractured overburdened rock. The commonly used energy criterion is [4]:

where Wk is the kinetic energy of the fractured overburdened rock.

Wcs + Wk > Wcd

Based on the stiffness theory and the simulation research above, the roof’s energy supply plays an important role in coal bursts. When the stiffness ratio kr/kc is 3.0, 2.0, 1.0, and 0.5, the roof’s energy supply Wr-c is 1.822 J, 3.871 J, 8.459 J, and 20.293 J. The ratios of the supplied energy Wr-c to the coal elastic strain Wcs are 5.30%, 11.25%, 24.59%, and 58.9%, respectively. When the stiffness ratio kr/kc is less than the critical value, the roof’s energy supply is the key energy source affecting the coal failure mode. Therefore, in the coal burst mechanism, the roof stiffness and energy supply should be considered. Based on Equation (6) and Figure 10b, the coal burst energy criterion can be modified as:

kr/kc ≤ λ, (1 + a·kc/kr)Wcs + Wk > Wcd

kc/kr > λ, Wcs + Wk > Wcd

The above criterion comprehensively takes into account the stiffness theory and energy theory, and is suitable for coal burst risk assessments of roadways.

6. Conclusions

According to the stiffness theory, one coal burst energy model of a rock–coal system is established, and the numerical simulation method is used to quantitatively reveal the energy supply mechanism of the roof to the sidewall under different stiffness ratios. The main conclusions are as follows:

- (1)

- The stiffness ratio of rock to coal has little effect on the extreme value of the elastic strain energy of the coal, and mainly affects its dissipation energy and kinetic energy. With the decrease in the stiffness ratio, the dissipation energy of the coal after the peak point decreases in a power function, the plasticity decreases, and the brittleness increases. The kinetic energy of coal is negatively correlated with the stiffness ratio in a power function. When the stiffness ratio is less than one, the sensitivity of the kinetic energy of coal to the change in the stiffness ratio increases sharply.

- (2)

- When the coal is fractured, the low-stiffness roof instantaneously generates deformation rebound and kinetic energy, which applies the dynamic load and energy supply behavior to the coal. With the decrease in the stiffness ratio, the release amount and release rate of the rock elastic strain energy gradually increase. The rock elastic strain energy and kinetic energy have power function relations with the stiffness ratio, respectively.

- (3)

- When a rock–coal system burst failure occurs, the kinetic energy of the coal comes from the release of the elastic strain energy of the coal and the energy supply from the rock. The supplied energy and energy supply rate of the rock to the coal increase with the decrease in the stiffness ratio. The supplied energy and the stiffness ratio have a power function relationship. The energy supply rate and the stiffness ratio have a linear relationship.

Author Contributions

Conceptualization, Y.Y., Z.L. and W.Z.; Data curation, X.T. and Z.L.; Software, X.T. and Q.M.; Writing—original draft, Y.Y. and W.Z.; Writing—review and editing, Q.M. All authors have read and agreed to the published version of the manuscript.

Funding

The study was financially supported by Major Program of Shandong Provincial Natural Science Foundation (NO. ZR2019ZD13), National Natural Science Foundation of China (NO. 52074167), and China Postdoctoral Science Foundation (NO. 2019M660024).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wu, Y.Z.; Gao, F.Q.; Chen, J.Y.; He, J. Experimental study on the performance of rock bolts in coal burst-prone mines. Rock Mech. Rock Eng. 2019, 52, 3959–3970. [Google Scholar] [CrossRef]

- Mottahedi, A.; Ataei, M. Fuzzy fault tree analysis for coal burst occurrence probability in underground coal mining. Tunn. Undergr. Space Technol. 2019, 83, 165–174. [Google Scholar] [CrossRef]

- Yang, X.H.; Ren, T.; Tan, L.H.; Remennikov, A.; He, X.Q. Developing coal burst propensity index method for Austrialian coal mines. Int. J. Min. Sci. Technol. 2018, 28, 783–790. [Google Scholar] [CrossRef]

- Pan, J.F.; Liu, S.H.; Wang, S.W.; Xia, Y.X. A new theoretical view of rockburst and its engineering application. Adv. Civ. Eng. 2018, 2018, 4683457. [Google Scholar] [CrossRef]

- Li, Z.L.; Dou, L.M.; Wang, G.F.; Cai, W.; He, J.; Ding, Y.L. Risk evaluation of rock burst through theory of static and dynamic stresses superposition. J. Cent. South Univ. 2015, 22, 676–683. [Google Scholar] [CrossRef]

- Zhao, T.B.; Guo, W.Y.; Tan, Y.L.; Yin, Y.C.; Cai, L.S.; Pan, J.F. Case studies of rock bursts under complicated geological conditions during multi-seam mining at a depth of 800 m. Rock Mech. Rock Eng. 2018, 51, 153–1564. [Google Scholar] [CrossRef]

- He, M.C.; Ren, F.Q.; Cheng, C. Experimental and numerical analyses on the effect of stiffness on bedded sandstone strain burst with varying dip angle. Bull. Eng. Geol. Environ. 2019, 78, 3593–3610. [Google Scholar] [CrossRef]

- Akdag, S.; Karakus, M.; Taheri, A.; Nguyen, G.; He, M.C. Effects of thermal damage on strain burst mechanism for brittle rocks under true-triaxial loading conditions. Rock Mech. Rock Eng. 2018, 51, 1675–1682. [Google Scholar] [CrossRef]

- Gong, F.Q.; Wang, Y.L.; Wang, Z.G.; Pan, J.F.; Luo, S. A new criterion of coal burst proneness based on the residual elastic energy index. Int. J. Min. Sci. Technol. 2021, 31, 553–563. [Google Scholar] [CrossRef]

- Gong, F.Q.; Si, X.F.; Li, X.B.; Wang, S.Y. Experimental investigation of strain rockburst in circular caverns under deep three-dimensional high-stress conditions. Rock Mech. Rock Eng. 2019, 52, 1459–1474. [Google Scholar] [CrossRef]

- Cook, N.G.W. The failure of rock. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1965, 2, 389–403. [Google Scholar] [CrossRef]

- Khosravi, A.; Simon, R. Verification of the CSDS model in estimating the postpeak behavior of hard rocks. Int. J. Geomech. 2018, 18, 04017166.1–04017166.15. [Google Scholar] [CrossRef]

- Qin, S.Q.; Jiao, J.J.; Tang, C.A.; Li, Z.G. Instability leading to coal bumps and nonlinear evolutionary mechanisms for a coal-pillar-and-roof system. Int. J. Solids Struct. 2006, 43, 7407–7423. [Google Scholar] [CrossRef]

- Zhang, D.X.; Guo, W.Y.; Zhang, C.W.; Gong, X.F.; Li, Z.H.; Qiu, Y.; Chen, W.G. A new burst evaluation index of coal-rock combination specimen considering rebound and damage effects of rock. Geomat. Nat. Hazards Risk 2020, 11, 984–999. [Google Scholar] [CrossRef]

- Li, C.C.; Zhao, T.B.; Zhang, Y.B.; Wan, W.K. A study on the energy sources and the role of the surrounding rock mass in strain burst. Int. J. Rock Mech. Min. Sci. 2021, 147, 104921. [Google Scholar] [CrossRef]

- Cai, M.; Hou, P.Y.; Zhang, X.W.; Feng, X.T. Post-peak stress-strain curves of brittle hard rocks under axial-strain-controlled loading. Int. J. Rock Mech. Min. Sci. 2019, 52, 3959–3970. [Google Scholar] [CrossRef]

- Xu, Y.H.; Cai, M. Influence of loading system stiffness on post-peak stress-strain curve of stable rock failures. Rock Mech. Rock Eng. 2017, 50, 2255–2275. [Google Scholar] [CrossRef]

- Hou, P.Y.; Cai, M. Post-peak stress-strain curves of brittle hard rocks under different loading environment system stiffness. Rock Mech. Rock Eng. 2022, 55, 3837–3857. [Google Scholar] [CrossRef]

- Zhao, T.B.; Yin, Y.C.; Tan, Y.L.; Xing, M.L.; Tang, X.X.; Li, C.C. Development of a rock testing system with changeable stiffness and its application in the study on the rock failure mechanical behavior. Chin. J. Rock Mech. Eng. 2022, 41, 1846–1857. [Google Scholar]

- Xu, Y.H.; Cai, M. Influence of strain energy released from a testing machine on rock failure process. Can. Geotech. J. 2018, 55, 777–791. [Google Scholar] [CrossRef]

- Wang, X.Y.; Yin, Y.C.; Xing, M.L.; Zhang, D.D.; Chen, Y.; Wang, E.C. Microsimulation study on energy release and rock block ejection force of granite under different unloading conditions. Front. Earth Sci. 2022, 10, 909371. [Google Scholar] [CrossRef]

- Feng, X.J.; Zhang, Q.M.; Ali, M. 3D modelling of the strength effect of backfill-rocks on controlling rockburst risk: A case study. Arab. J. Geosci. 2020, 13, 128. [Google Scholar] [CrossRef]

- Feng, X.J.; Ding, Z.; Ju, Y.Q.; Zhang, Q.M.; Ali, M. “Double peak” of dynamic strengths and acoustic emission responses of coal masses under dynamic loading. Nat. Resour. Res. 2022, 31, 1705–1720. [Google Scholar] [CrossRef]

- Hudson, J.A.; Crouch, S.L.; Fairhurst, C. Soft, stiff and servo-controlled testing machines: A review with reference to rock failure. Eng. Geol. 1972, 6, 155–189. [Google Scholar] [CrossRef]

- Lu, J.; Yin, G.Z.; Deng, B.Z.; Zhang, W.Z.; Li, M.H.; Chai, X.W.; Liu, C.; Liu, Y.B. Permeability characteristics of layered composited coal-rock under true triaxial stress conditions. J. Nat. Gas Sci. Eng. 2019, 66, 60–76. [Google Scholar] [CrossRef]

- Ma, Q.; Tan, Y.L.; Liu, X.S.; Zhao, Z.H.; Fan, D.Y.; Purev, L. Experimental and numerical simulation of loading rate effects on failure and strain energy characteristics of coal-rock composite samples. J. Cent. South Univ. 2021, 28, 3207–3222. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, J.; Meng, Q.G.; Yu, M.L.; Zhang, Z.J.; Guo, Z.G. Coal rock breaking simulation and cutting performance analysis of disc cutters. Teh. Vjesn.-Tech. Gaz. 2021, 28, 1755–1761. [Google Scholar]

- Han, W.; Jiang, Y.J.; Luan, H.J.; Du, Y.T.; Zhu, Y.G.; Liu, J.K. Numerical investigation on the shear behavior of rock-like materials containing fissure-holes with FEM-CZM method. Comput. Geotech. 2020, 125, 103670. [Google Scholar] [CrossRef]

- Tan, Y.L.; Liu, X.S.; Shen, B.T.; Ning, J.G.; Gu, Q.H. New approaches to testing and evaluating the impact capability of coal seam with hard roof and/or floor in coal mines. Geomech. Eng. 2018, 14, 367–376. [Google Scholar]

- Yin, Y.C.; Zheng, W.W.; Tang, X.X.; Xing, M.L.; Zhang, Y.B.; Zhu, Y.H. Test study on failure and energy supply characteristics of rock under different loading stiffness. Eng. Fail. Anal. 2022, 142, 106796. [Google Scholar] [CrossRef]

- Gercek, H. Poisson’s ratio values for rocks. Int. J. Rock Mech. Min. Sci. 2007, 44, 1–13. [Google Scholar] [CrossRef]

- Chen, J.C.; Chemenda, A.I. Numerical simulation of true 3D rock tests with classical and new three-invariant constitutive models focusing on the end effects. Arab. J. Sci. Eng. 2020, 45, 9367–9378. [Google Scholar] [CrossRef]

- Carpinteri, A.; Lacidogna, G.; Corrado, M.; Di Battista, E. Cracking and crackling in concrete-like materials: A dynamic energy balance. Eng. Fract. Mech. 2016, 155, 130–144. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).