Implementing Cool Roof and Bio-PCM in Portable Cabins to Create Low-Energy Buildings Suitable for Different Climates

Abstract

:1. Introduction

1.1. Cool Roof Techniques

1.2. Phase Change Materials (PCMs)

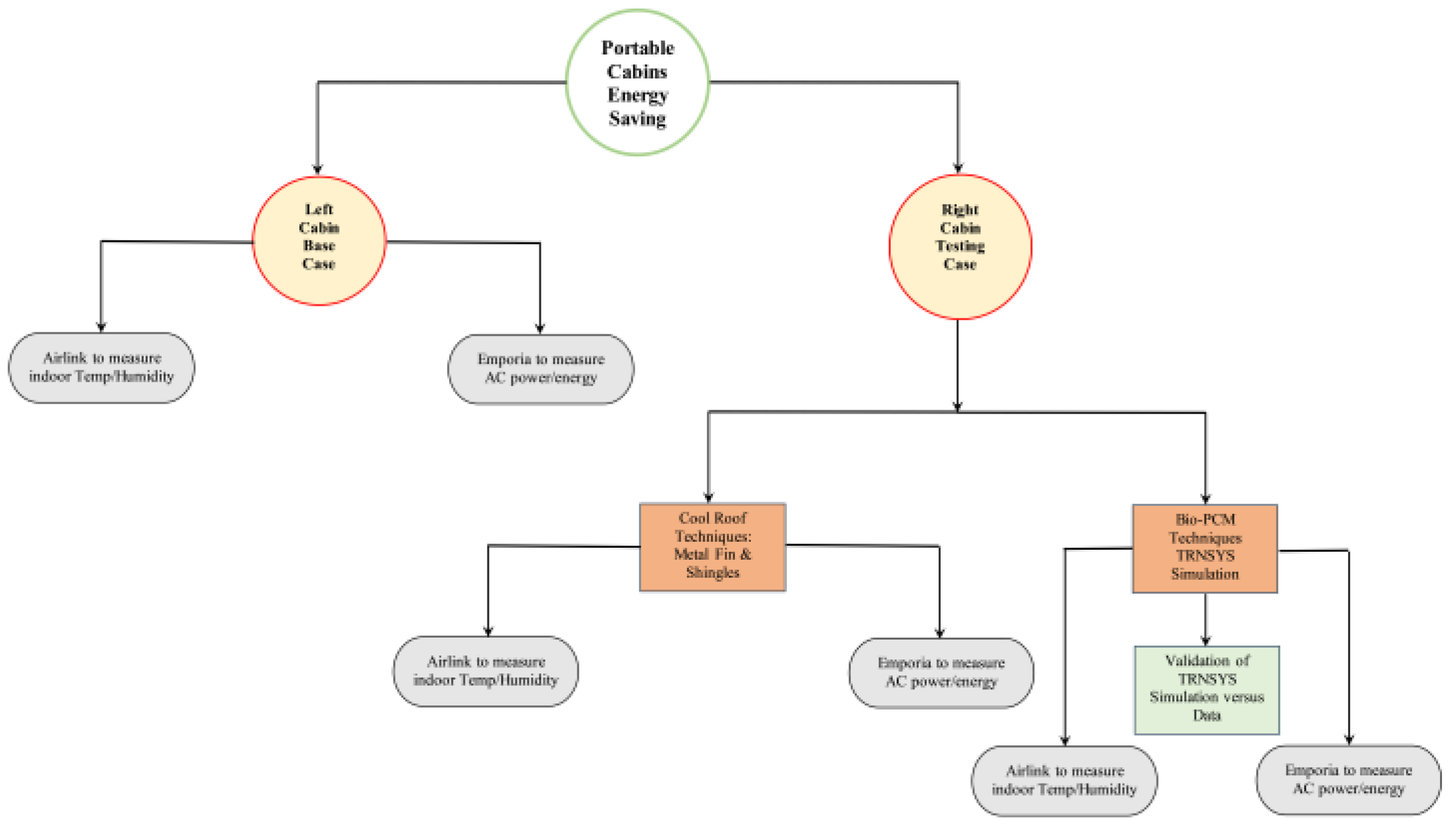

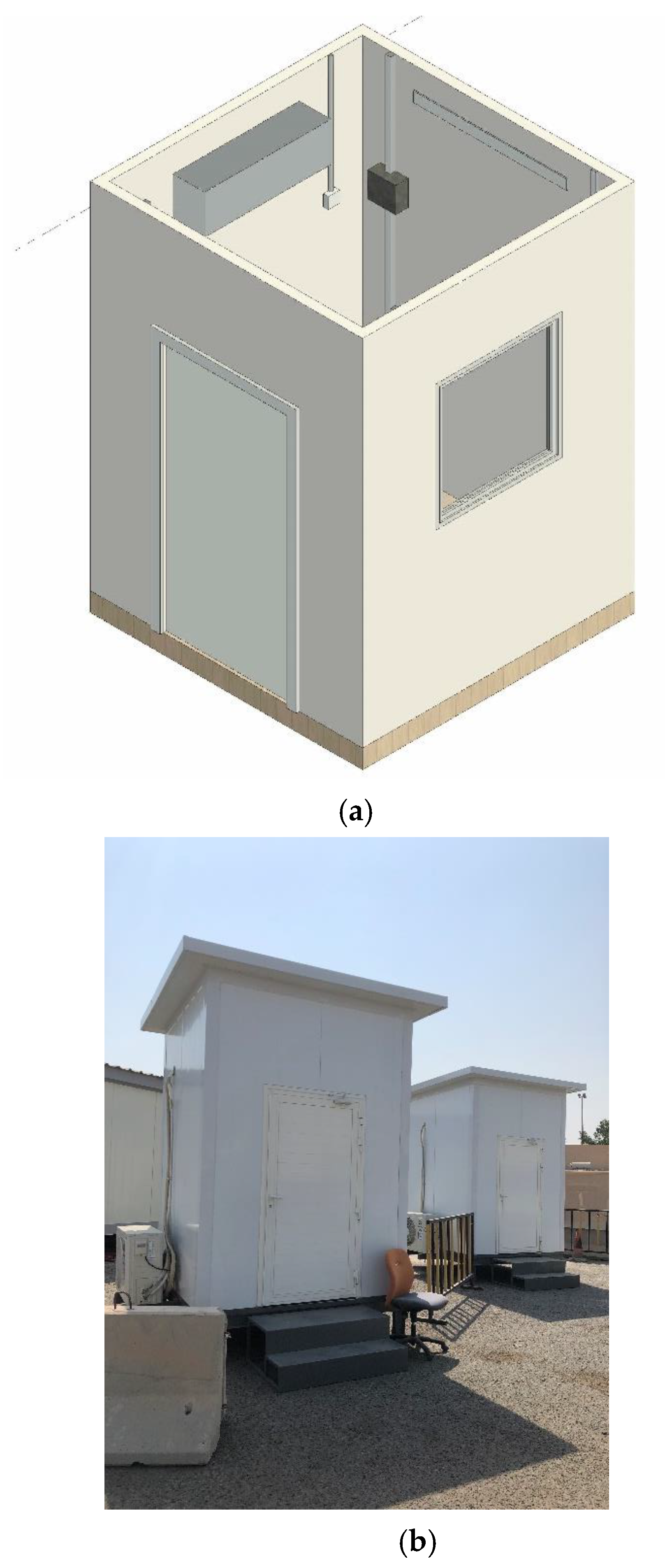

2. Materials and Methods

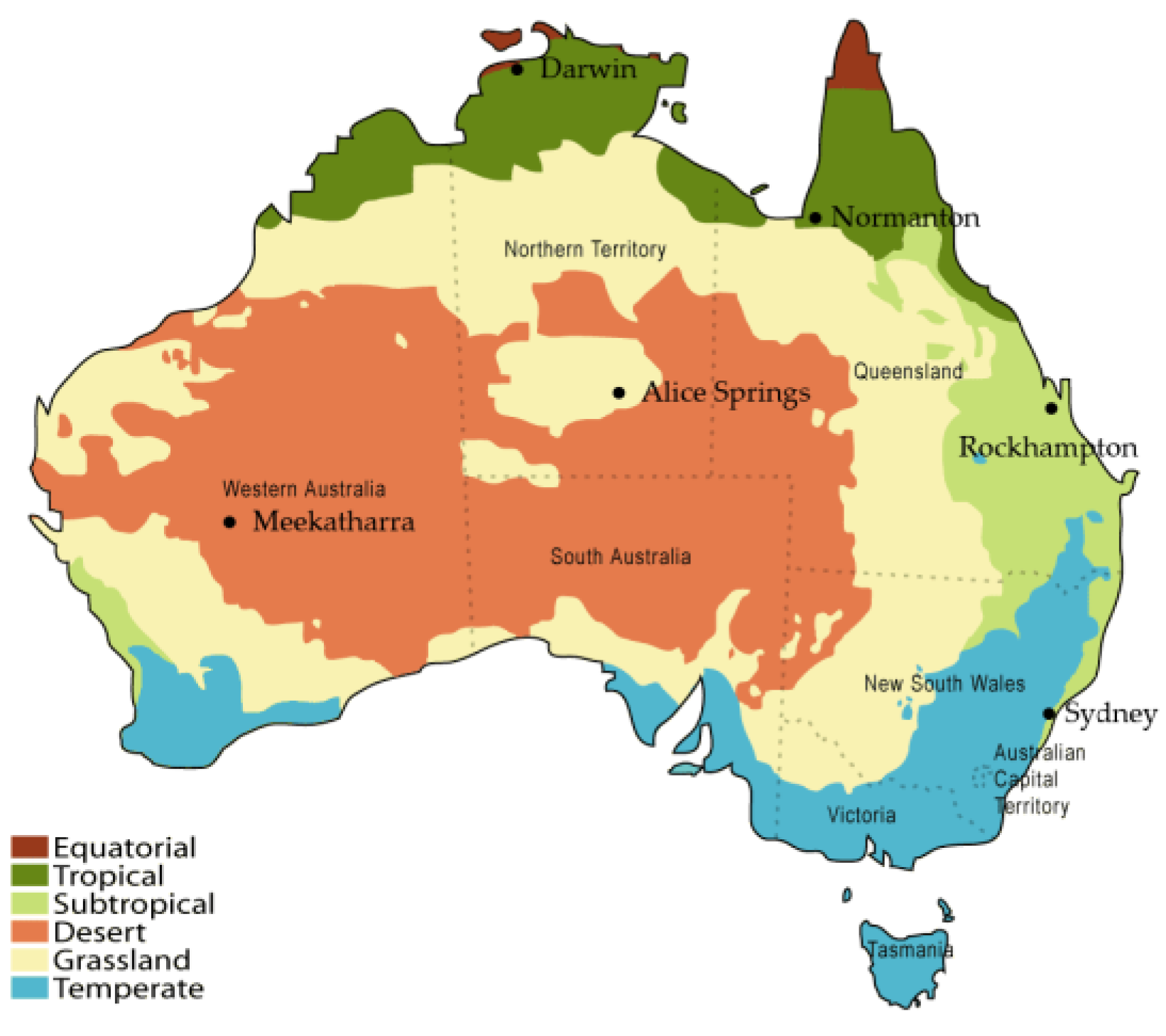

2.1. Studied Climates

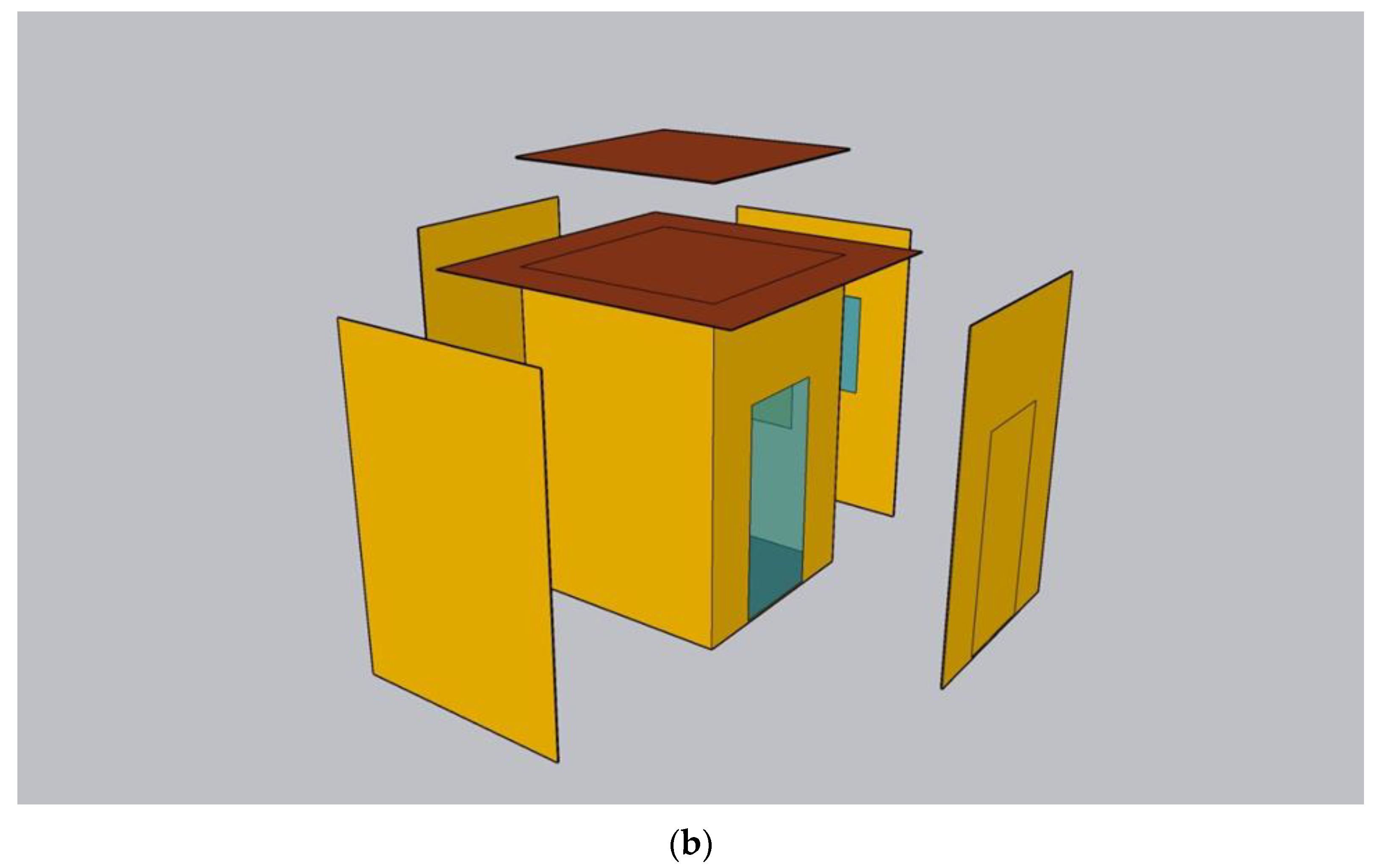

2.2. Experimental Equipment

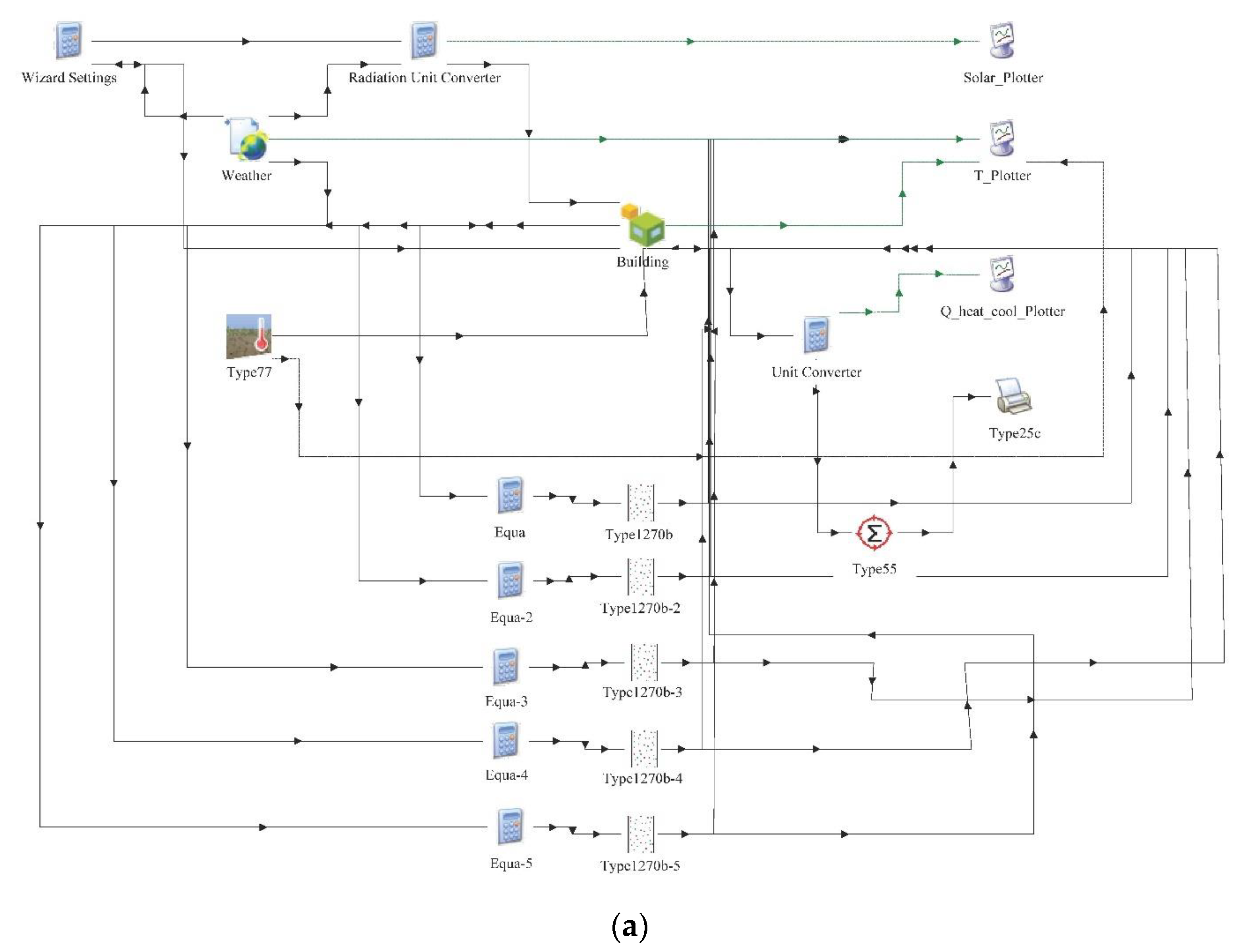

2.3. Simulation Technique

- The specific heats of the Bio-PCM are constants but with different values for liquid and solid phases.

- The contact resistance between the PCM layer and the adjacent wall layers is neglected.

- The melting and solidification are constant temperature processes.

3. Experimental Results and Discussions

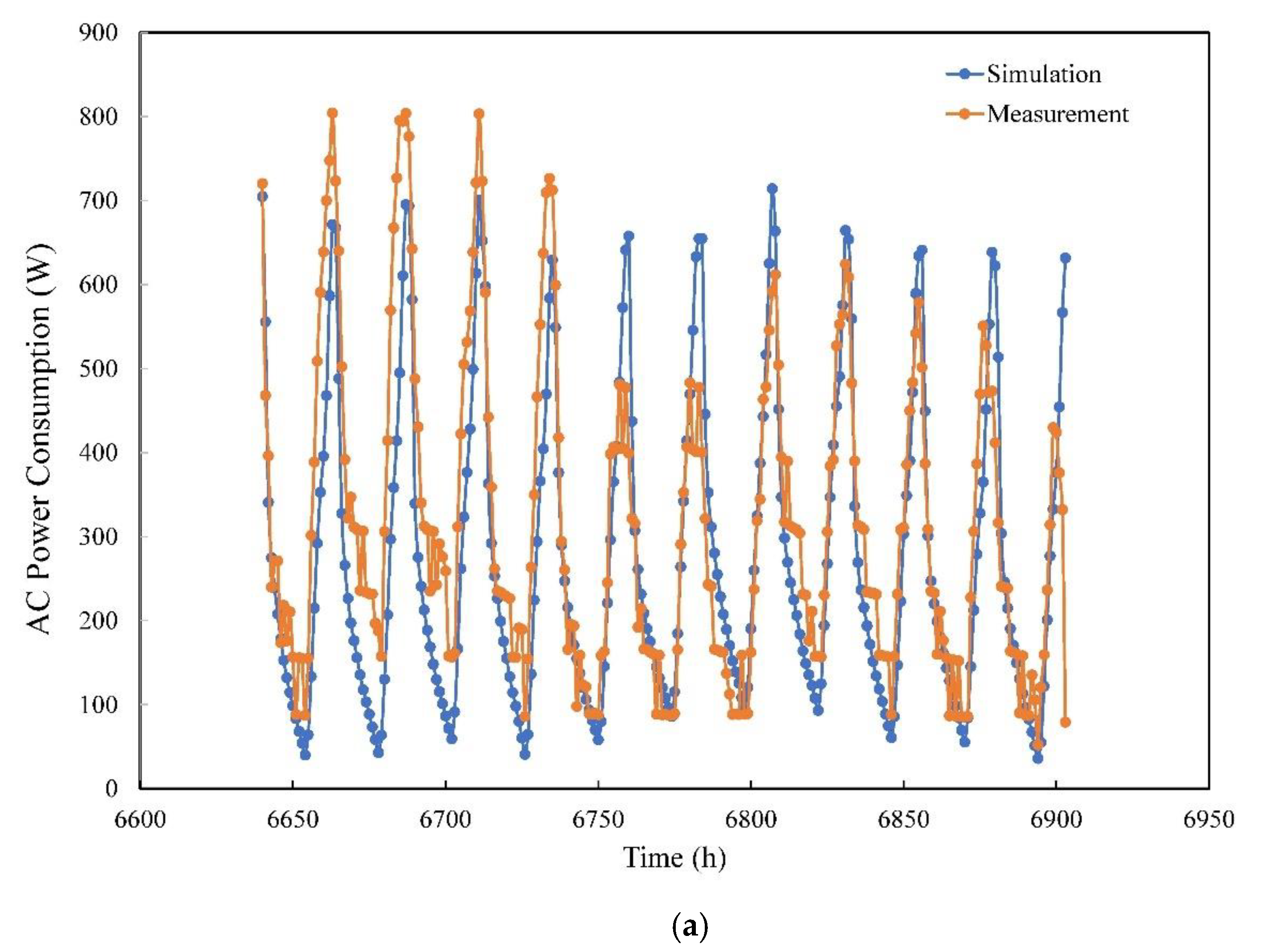

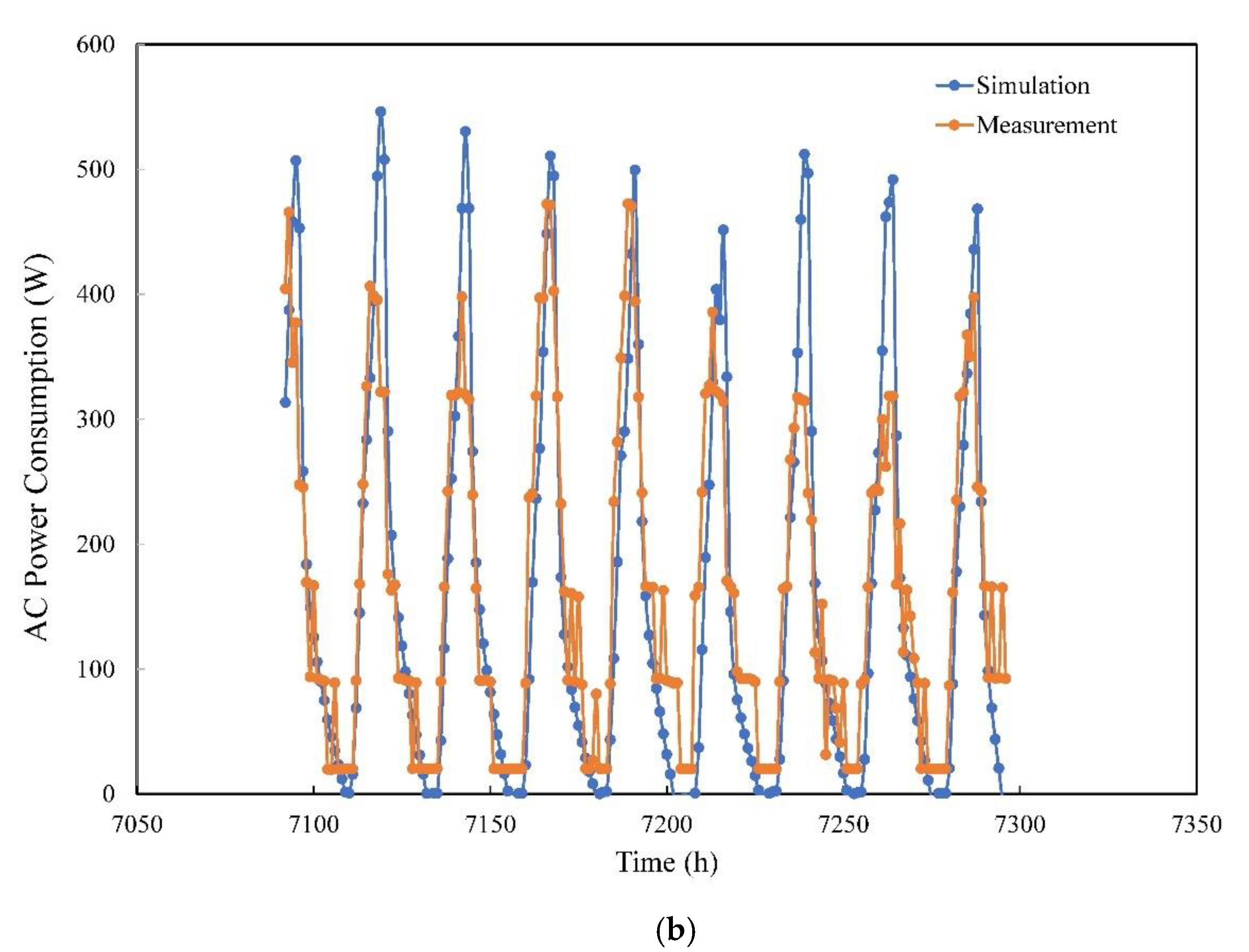

3.1. Similarity Checks

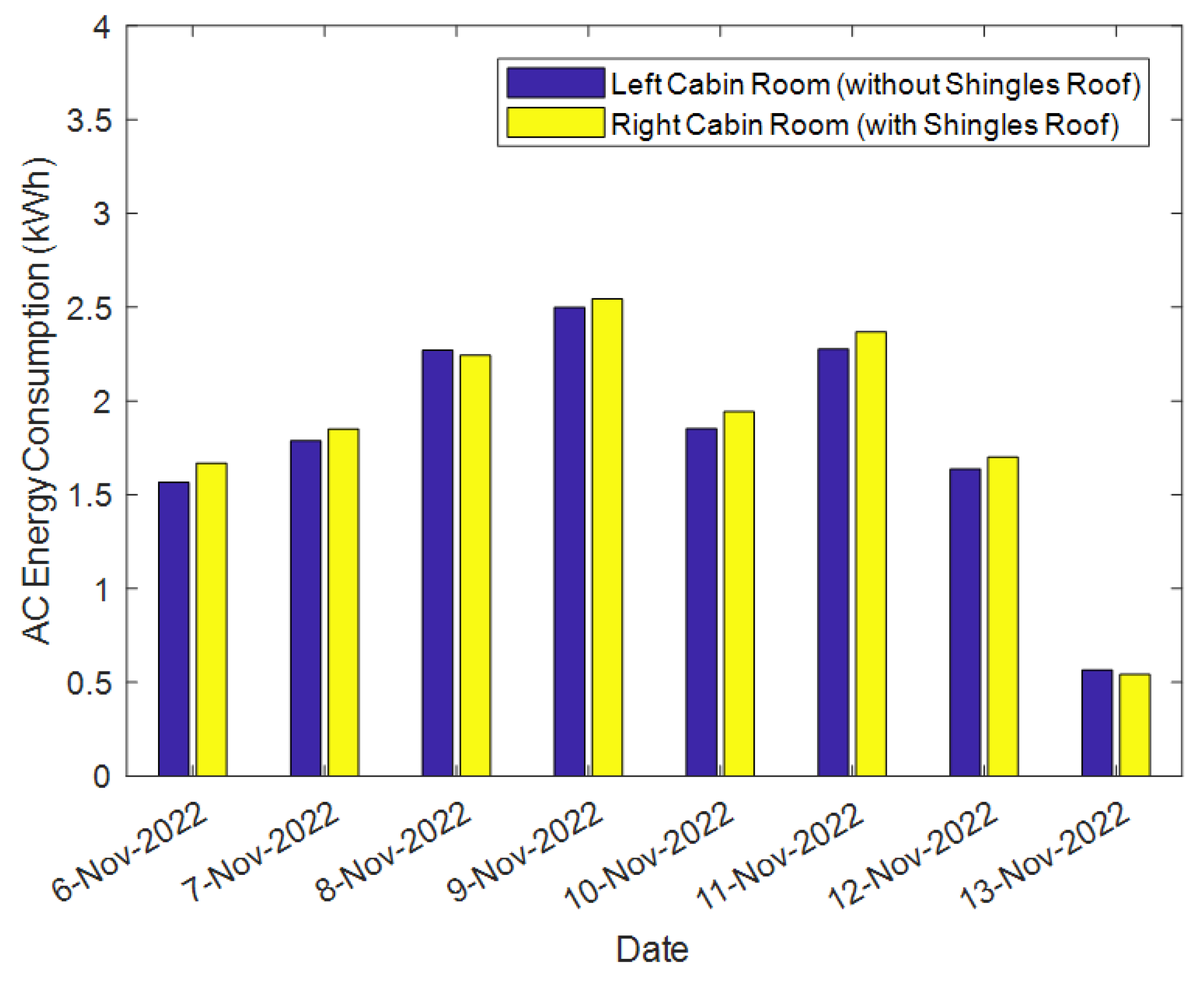

3.2. Application of Shingles as a Cool Roof

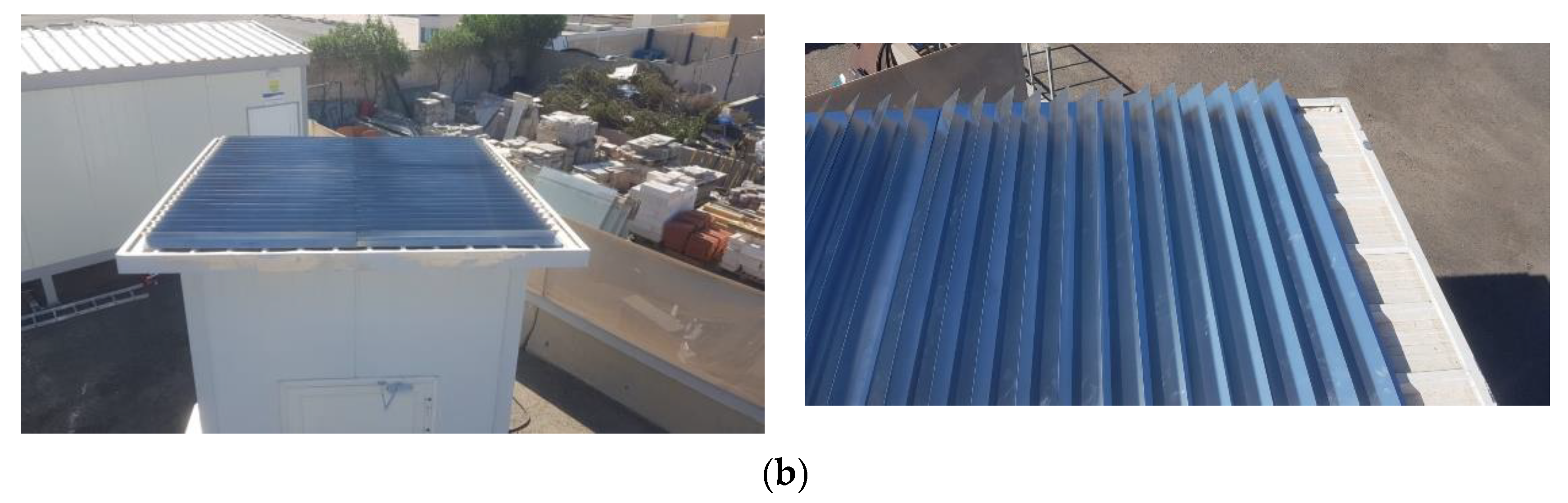

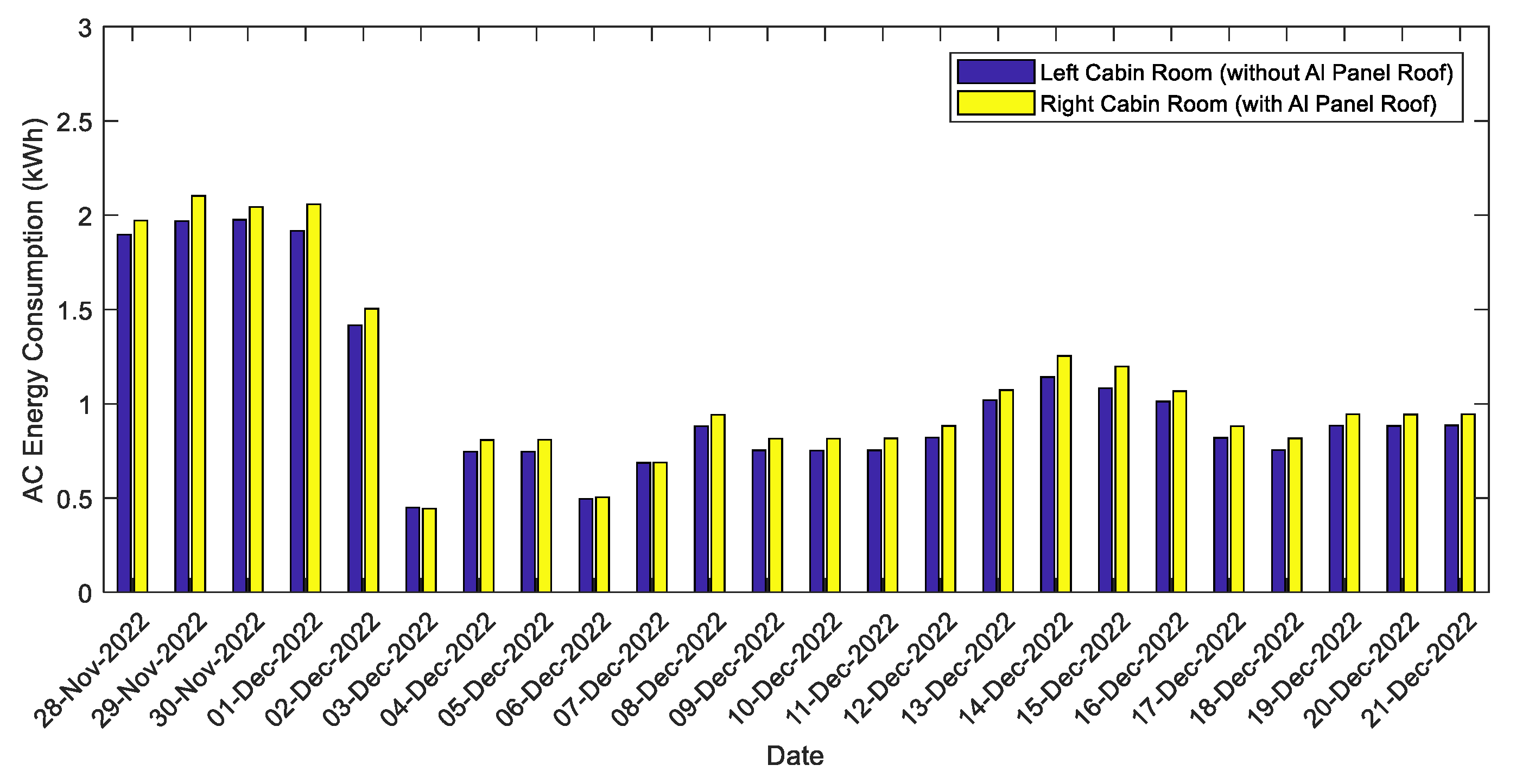

3.3. Application of a Finned Metal Cool Roof

4. Simulation Results and Discussions

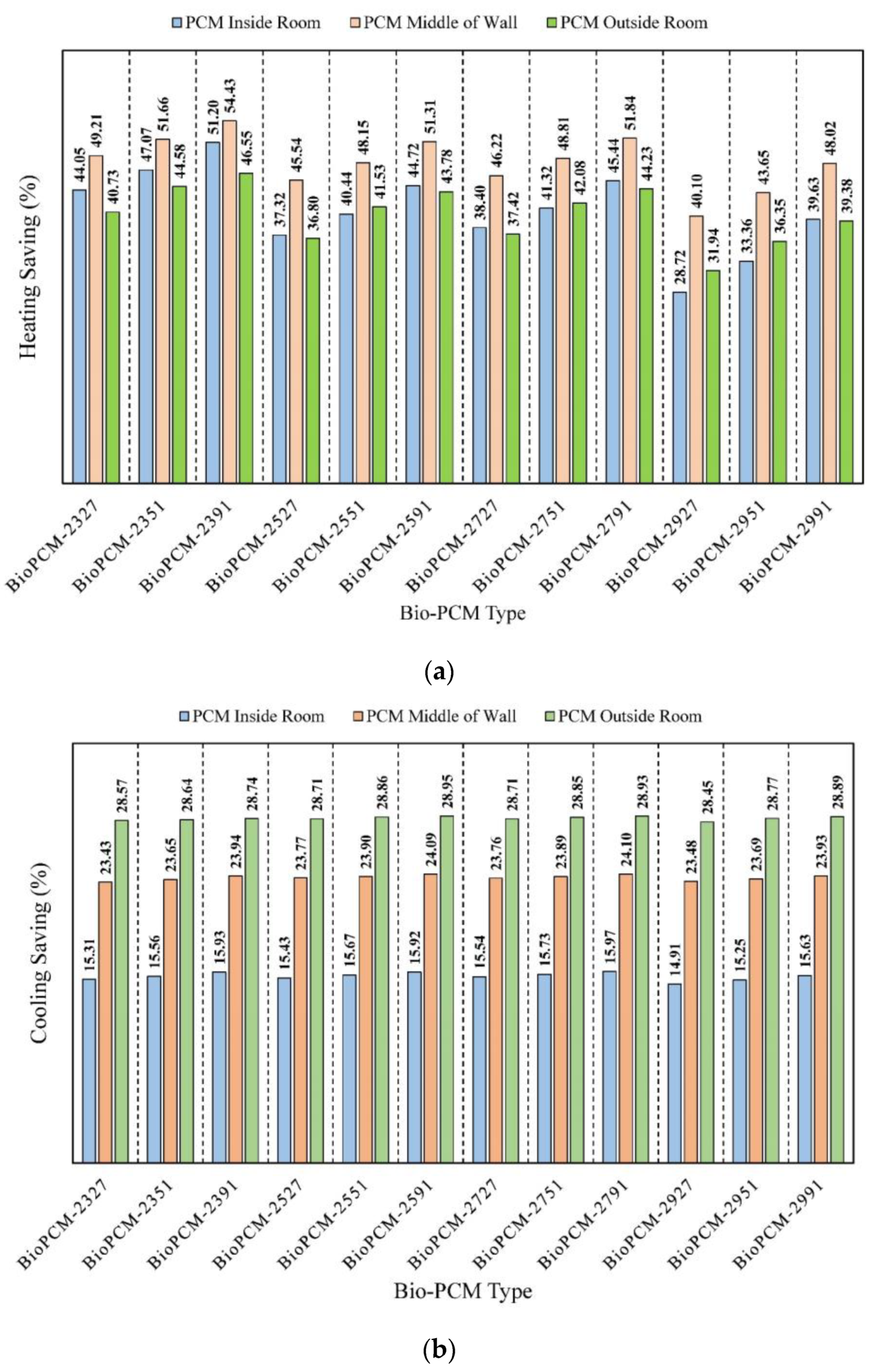

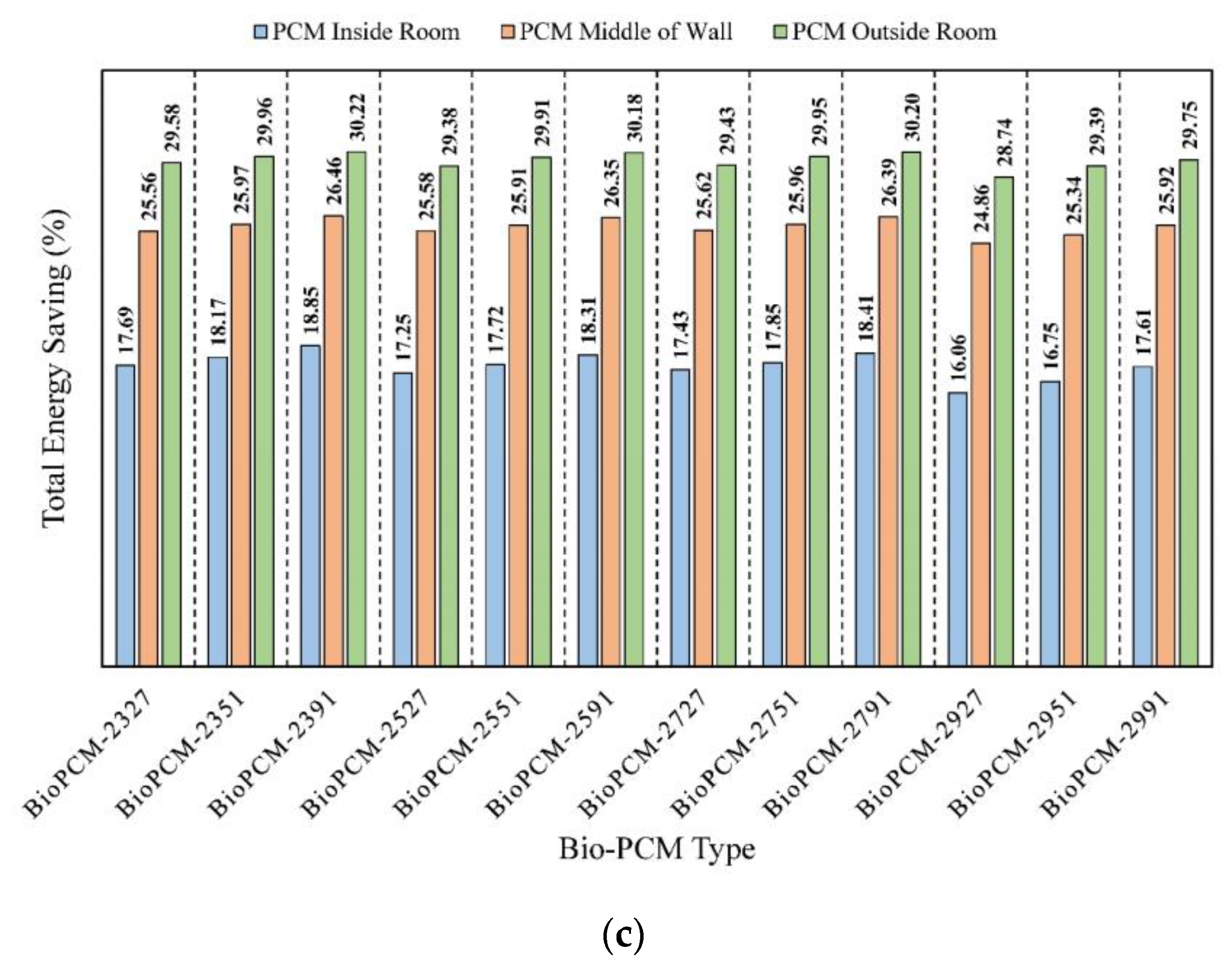

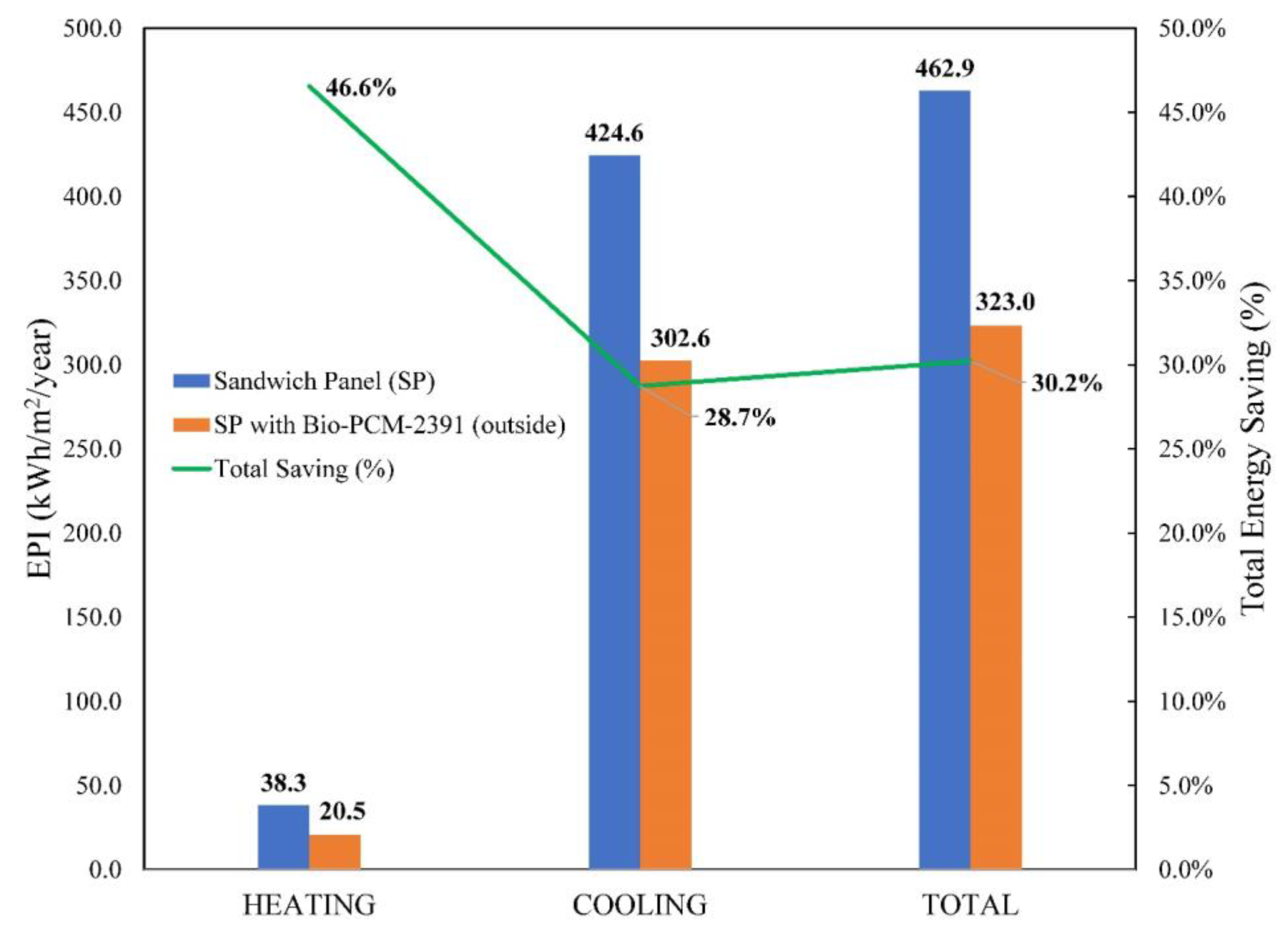

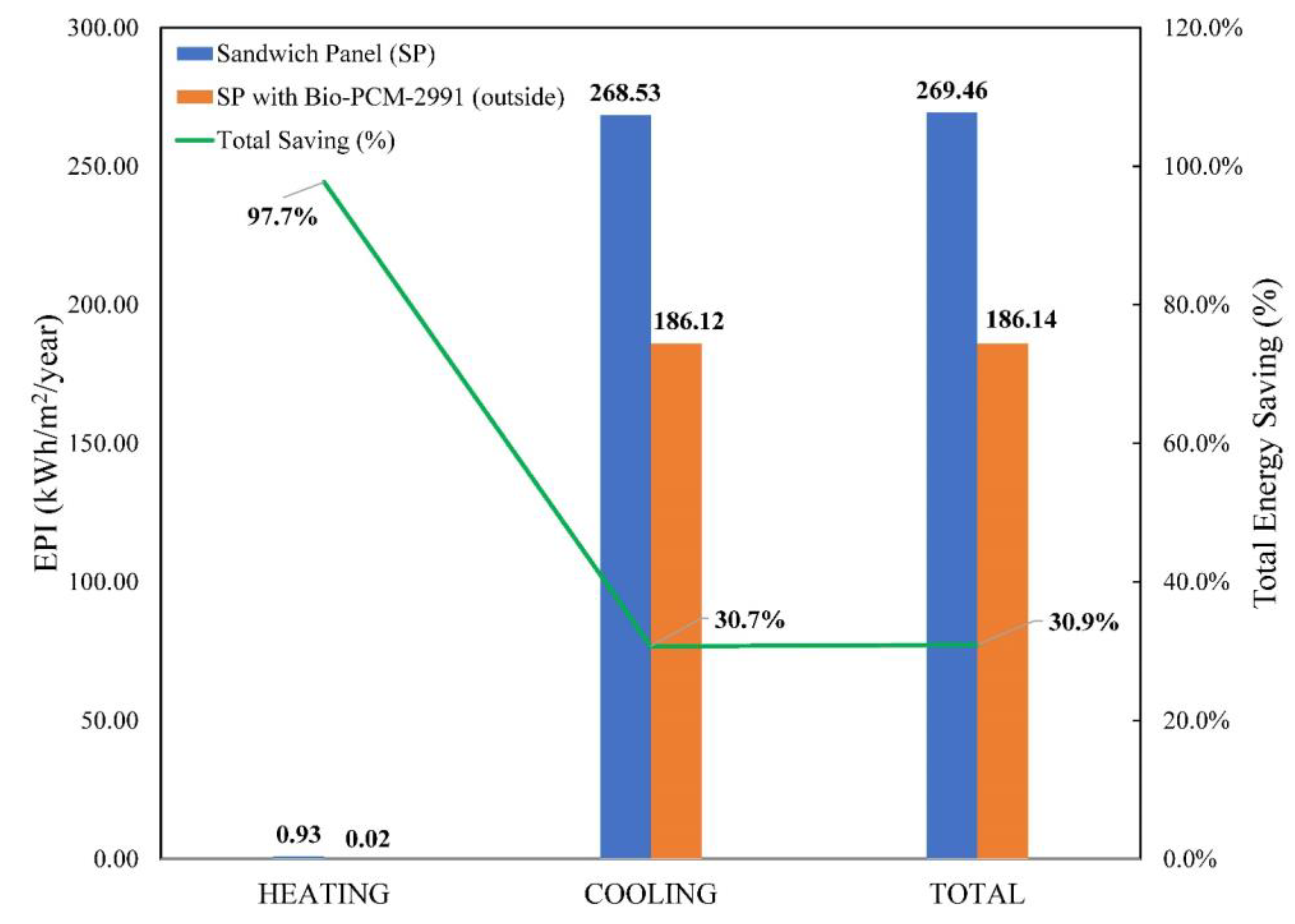

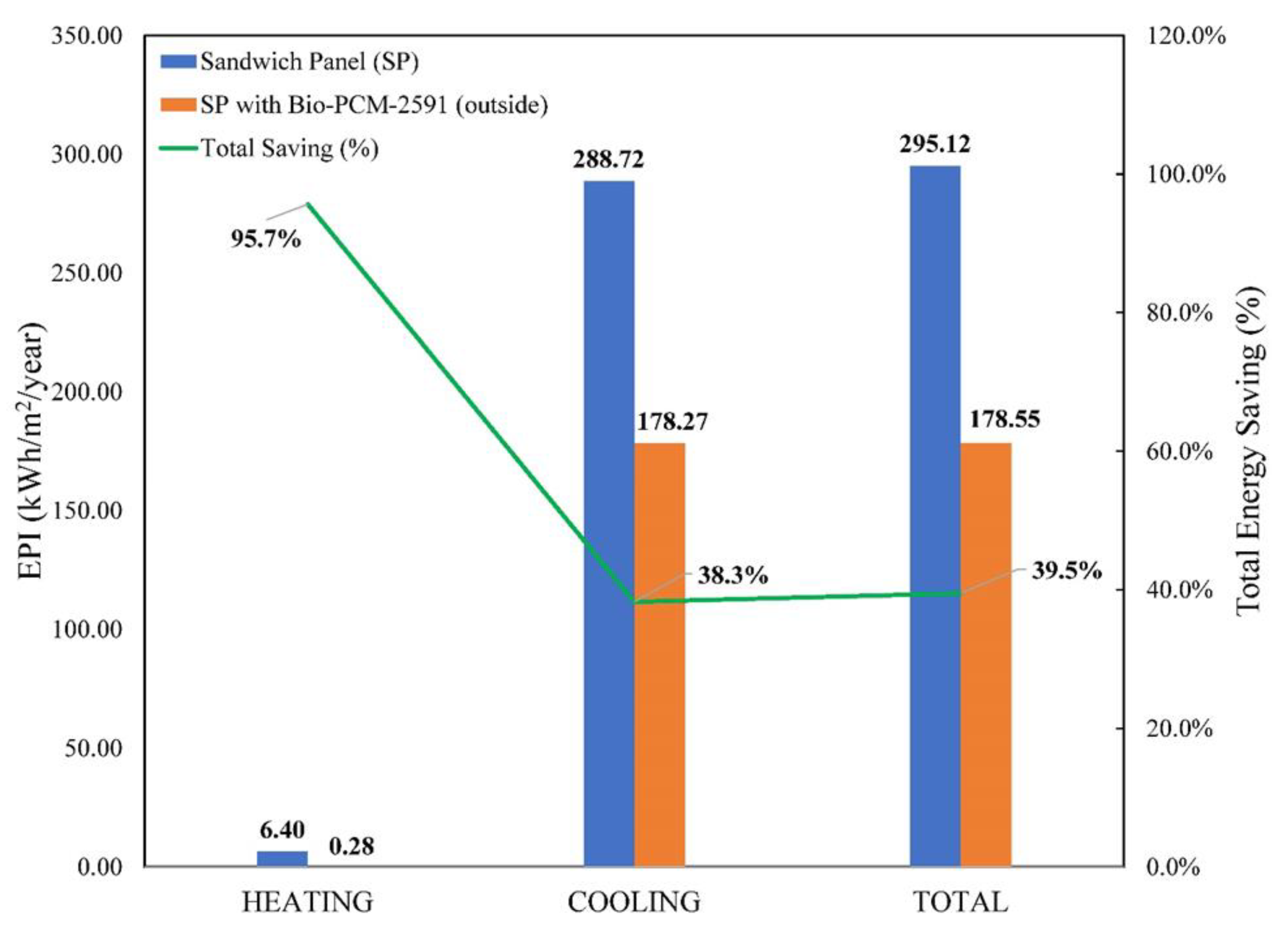

4.1. Energy Saving of Bio-PCMs in Kuwait

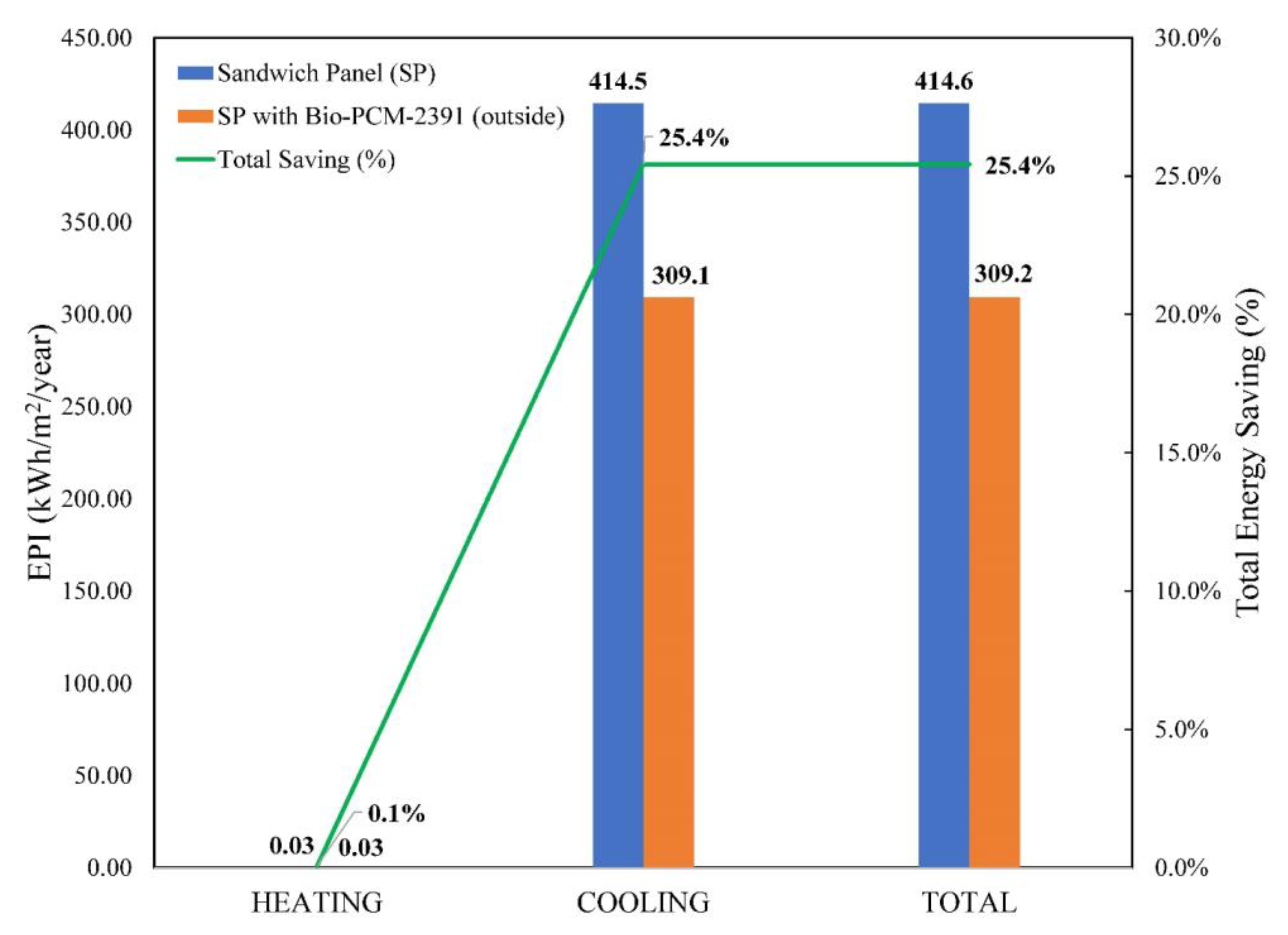

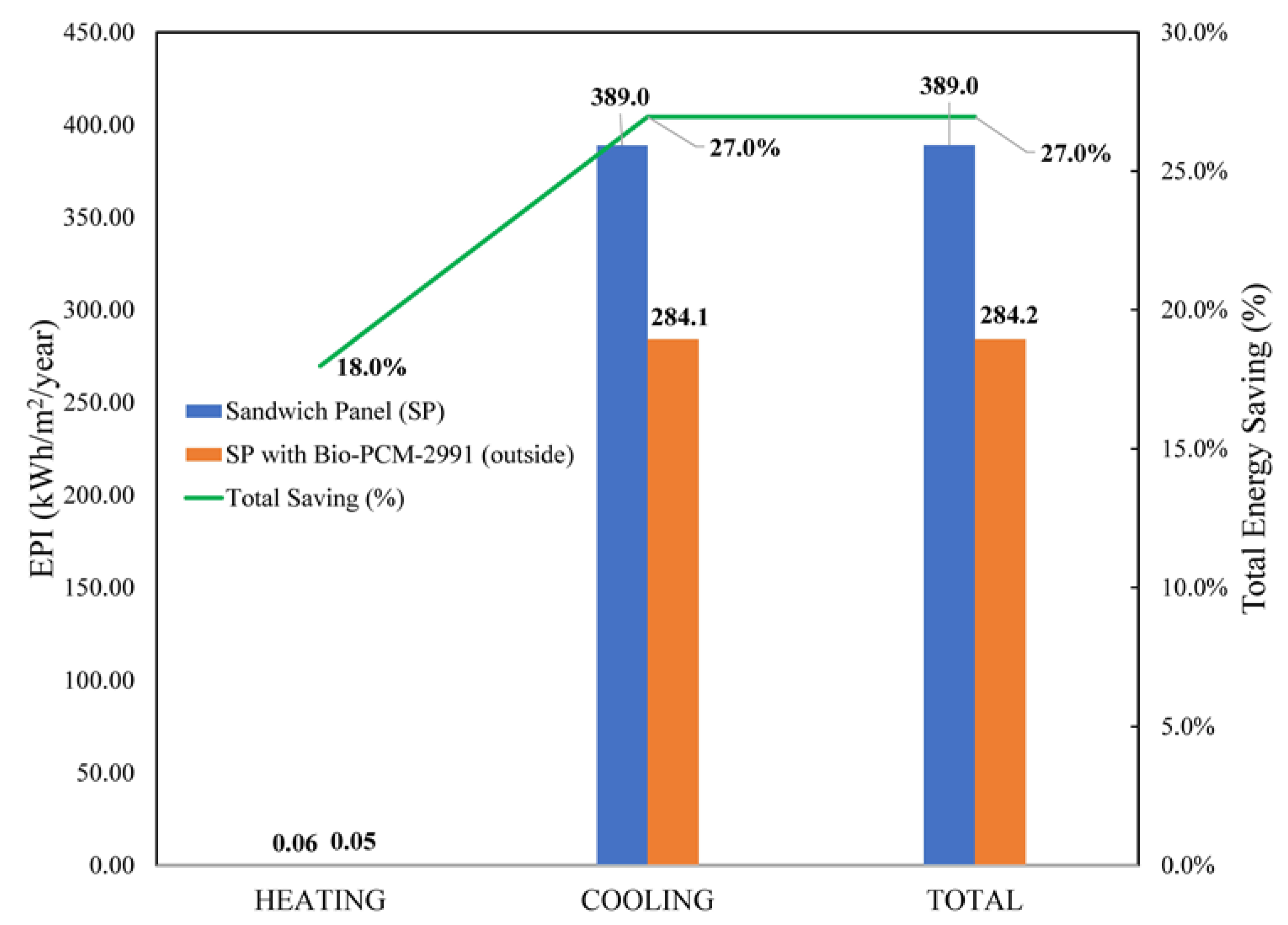

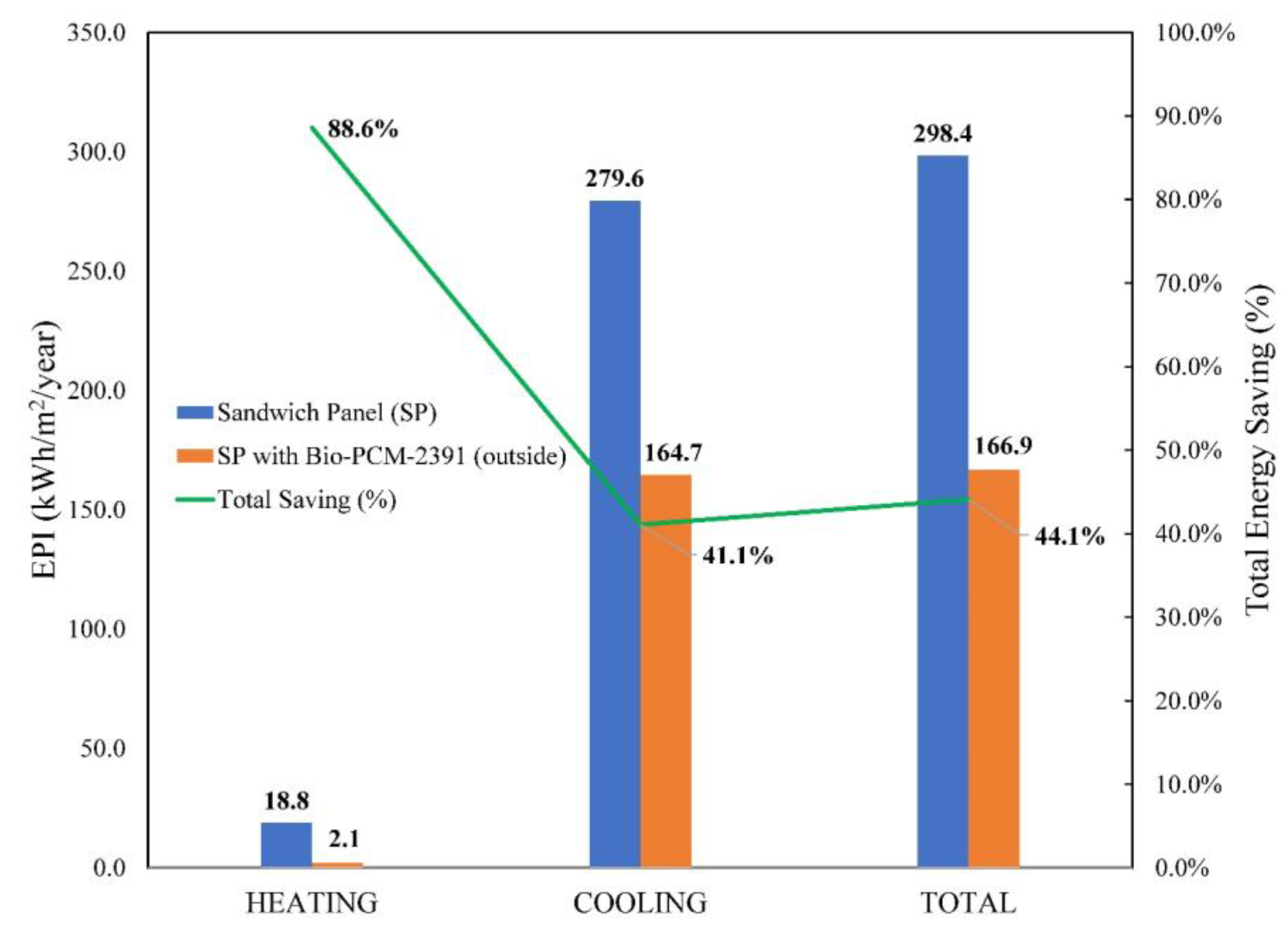

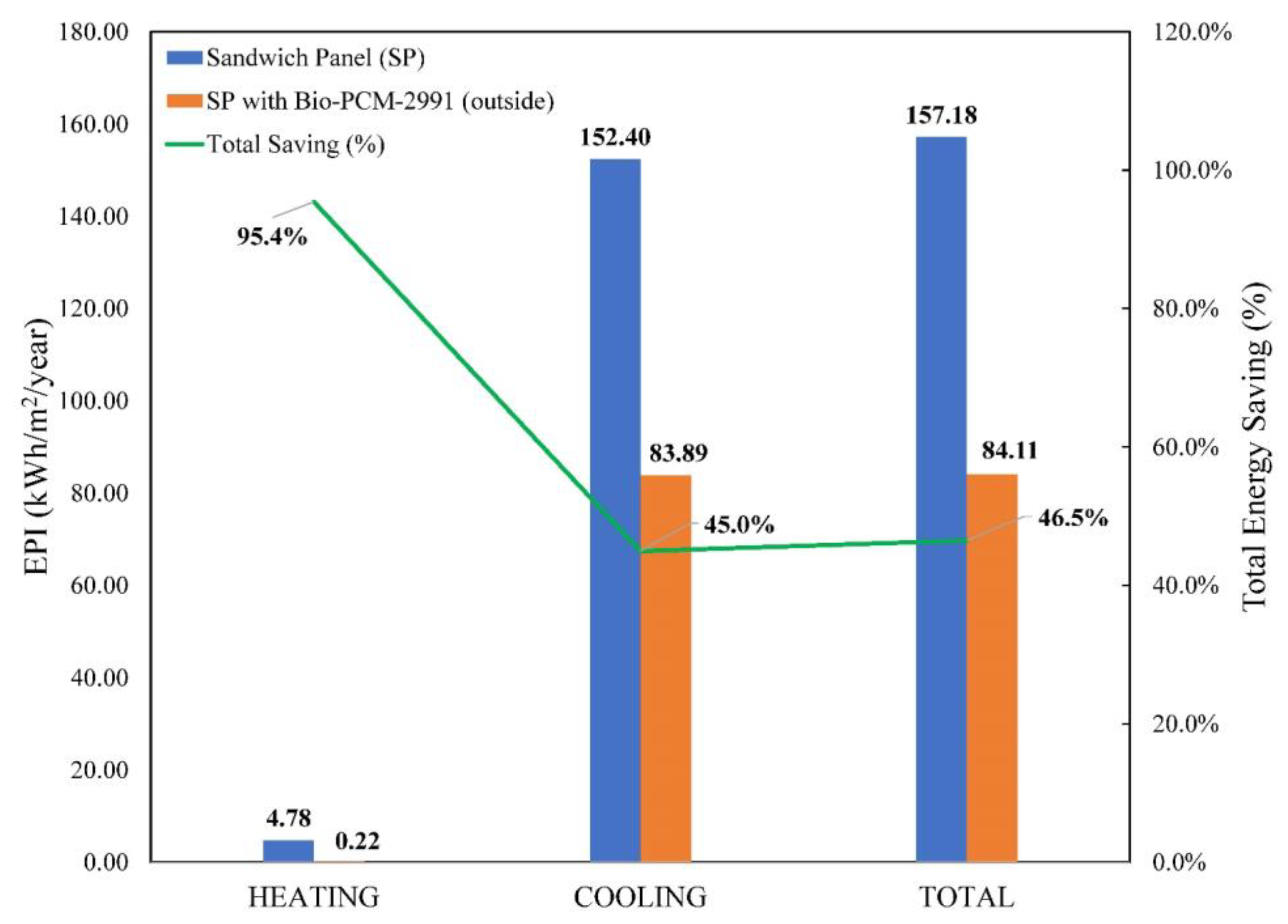

4.2. Energy Saving of Bio-PCMs in Australia

5. Conclusions

- The experimental results show that the use of sustainable cool roofs has altered the thermal characteristics of the cabin, with the cabin fitted with these cool roofs being cooler than the base cabin, although shingles increased AC energy consumption by 2.8%, and the finned metal roof raised it by 6.4%.

- The TRNSYS model was validated against AC power measurements in the portable cabin with a cumulative error value of only 0.37%.

- The study assesses the desert climate of Kuwait and six different climate regions in Australia for utilizing sustainable Bio-PCMs. By placing the Bio-PCM layer outside the cabin walls, 30% of the total (heating/cooling) energy can be saved in Kuwait.

- In Australia, the sustainable city of Sydney, with a temperate climate, can save 46.5% as the highest total energy saving, while the sustainable city of Darwin, with an equatorial climate, can save 25.4% as the lowest total energy saving.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Maylshev, T.; Al-Abdullah, Y.; Sreekanth, K. Kuwait Energy Outlook 2019. Kuwait Institute for Scientific Research [Online]. 2019. Available online: http://www.kisr.edu.kw/en/facilities/energy-building (accessed on 10 January 2023).

- Krarti, M.; Hajiah, A. Analysis of impact of daylight time savings on energy use of buildings in Kuwait. Energy Policy 2011, 39, 2319–2329. [Google Scholar] [CrossRef]

- Saber, H.H.; Maref, W. Energy performance of cool roofs followed by development of practical design tool. Front. Energy Res. 2019, 7, 122. [Google Scholar] [CrossRef]

- Aldawi, F.; Alam, F.; Date, A.; Alghamdi, M.; Aldhawi, F. A new house wall system for residential buildings. Energy Build. 2013, 67, 403–418. [Google Scholar] [CrossRef]

- Howard, B.; Parshall, L.; Thompson, J.; Hammer, S.; Dickinson, J.; Modi, V. Spatial distribution of urban building energy consumption by end use. Energy Build. 2012, 45, 141–151. [Google Scholar] [CrossRef]

- Zhao, H.-x.; Magoulès, F. A review on the prediction of building energy consumption. Renew. Sustain. Energy Rev. 2012, 16, 3586–3592. [Google Scholar] [CrossRef]

- Kyogoku, S.; Takebayashi, H. Effects of Upward Reflective Film Applied to Window Glass on Indoor and Outdoor Thermal Environments in a Mid-Latitude City. Sustainability 2023, 15, 3848. [Google Scholar] [CrossRef]

- Amirkhani, S.; Bahadori-Jahromi, A.; Mylona, A.; Godfrey, P.; Cook, D. Impact of Low-E Window Films on Energy Consumption and CO2 Emissions of an Existing UK Hotel Building. Sustainability 2019, 11, 4265. [Google Scholar] [CrossRef]

- Bahadori-Jahromi, A.; Rotimi, A.; Mylona, A.; Godfrey, P.; Cook, D. Impact of Window Films on the Overall Energy Consumption of Existing UK Hotel Buildings. Sustainability 2017, 9, 731. [Google Scholar] [CrossRef]

- Sedaghat, A.; Abbas Oloomi, S.A.; Malayer, M.A.; Alkhatib, F.; Sabri, F.; Sabati, M.; Salem, H.; Zafar, W.J.; Mostafaeipour, A.; Issakhov, A.; et al. Effects of window films in thermo-solar properties of office buildings in hot-arid climates. Front. Energy Res. 2021, 9, 665978. [Google Scholar] [CrossRef]

- Rasul, M.G.; Ashfaque Ahmed, M.A.; Chowdhury, A.A.; Khan, M.M.K.; Narayanan, R.; Sabati, M.; Sedaghat, A. Building thermal performance analysis with an extensive green roof and bio-phase change materials in the Australian sub-tropical climate. In Proceedings of the 7th International Conference on Renewable Energy and Conservation, ICREC 2022, Paris, France, 18–20 November 2022. [Google Scholar]

- Sabati, M.; Rasul, M.G.; Anwar, M.; Khan, M.M.; Chowdhury, A.A.; Sedaghat, A. An experimental rooftop greenery setup in a subtropical/hot-humid climate for sustainable development and mitigation of climate change. In Proceedings of the 2020 Fifteenth International Conference on Ecological Vehicles and Renewable Energies (EVER) 2020, Monte-Carlo, Monaco, 10–12 September 2020; IEEE: Piscataway, NJ, USA; pp. 1–6. [Google Scholar]

- Elie Tawil, P. Guidelines for Selecting Cool Roofs. 2010. Available online: https://www.cedengineering.com/userfiles/M02-042%20-%20Guidelines%20for%20Selecting%20Cool%20Roofs%20-%20US.pdf (accessed on 10 January 2023).

- Rawat, M.; Singh, R.N. A study on the comparative review of cool roof thermal performance in various regions. Energy Built Environ. 2022, 3, 327–347. [Google Scholar] [CrossRef]

- US Green Building Council (USGBC). Leadership in Energy and Environmental Design. Available online: https://www.usgbc.org/leed (accessed on 10 January 2023).

- Aditya, L.; Mahlia, T.M.I.; Rismanchi, B.; Ng, H.M.; Hasan, M.H.; Metselaar, H.S.C.; Muraza, O.; Aditiya, H.B. A review on insulation materials for energy conservation in buildings. Renew. Sustain. Energy Rev. 2017, 73, 1352–1365. [Google Scholar] [CrossRef]

- A Virtual Tour of an Energy Efficient House. 2023. Available online: https://www.energy.gov/energysaver/energy-saver (accessed on 10 January 2023).

- Energy Star: Recommended Home Insulation R–Values. 2023. Available online: https://www.energystar.gov/campaign/seal_insulate/identify_problems_you_want_fix/diy_checks_inspections/insulation_r_values (accessed on 10 January 2023).

- Seifhashemi, M.; Capra, B.R.; Milller, W.; Bell, J. The potential for cool roofs to improve the energy efficiency of single storey warehouse-type retail buildings in Australia: A simulation case study. Energy Build. 2018, 158, 1393–1403. [Google Scholar] [CrossRef]

- Antonaia, A.; Ascione, F.; Castaldo, A.; D’Angelo, A.; De Masi, R.F.; Ferrara, M.; Vanoli, G.P.; Vitiello, G. Cool materials for reducing summer energy consumptions in Mediterranean climate: In-lab experiments and numerical analysis of a new coating based on acrylic paint. Appl. Therm. Eng. 2016, 102, 91–107. [Google Scholar] [CrossRef]

- Bozonnet, E.; Doya, M.; Allard, F. Cool roofs impact on building thermal response: A French case study. Energy Build. 2011, 43, 3006–3012. [Google Scholar] [CrossRef]

- De Masi, R.F.; Ruggiero, S.; Vanoli, G.P. Acrylic white paint of industrial sector for cool roofing application: Experimental investigation of summer behavior and aging problem under Mediterranean climate. Sol. Energy 2018, 169, 468–487. [Google Scholar] [CrossRef]

- Kolokotroni, M.; Gowreesunker, B.; Giridharan, R. Cool roof technology in London: An experimental and modelling study. Energy Build. 2013, 67, 658–667. [Google Scholar] [CrossRef]

- Romeo, C.; Zinzi, M. Impact of a cool roof application on the energy and comfort performance in an existing non-residential building. A Sicilian case study. Energy Build. 2013, 67, 647–657. [Google Scholar] [CrossRef]

- Shittu, E.; Stojceska, V.; Gratton, P.; Kolokotroni, M. Environmental impact of cool roof paint: Case-study of house retrofit in two hot islands. Energy Build. 2020, 217, 110007. [Google Scholar] [CrossRef]

- Yew, M.C.; Yew, M.K.; Saw, L.H.; Ng, T.C.; Chen, K.P.; Rajkumar, D.; Beh, J.H. Experimental analysis on the active and passive cool roof systems for industrial buildings in Malaysia. J. Build. Eng. 2018, 19, 134–141. [Google Scholar] [CrossRef]

- Zingre, K.T.; Wan, M.P.; Wong, S.K.; Toh, W.B.T.; Lee, I.Y.L. Modelling of cool roof performance for double-skin roofs in tropical climate. Energy 2015, 82, 813–826. [Google Scholar] [CrossRef]

- Costanzo, V.; Evola, G.; Gagliano, A.; Marletta, L.; Nocera, F. Study on the application of cool paintings for the passive cooling of existing buildings in Mediterranean climates. Adv. Mech. Eng. 2013, 5, 413675. [Google Scholar] [CrossRef]

- Sahoo, S.R. Measured temperature reductions and improved thermal comfort from application of cool roof paint on an economical weaker section houses in India. Int. J. Adv. Arts Sci. Eng. 2015, 3, 2320–6144. [Google Scholar]

- Roman, K.K.; O'Brien, T.; Alvey, J.B.; Woo, O. Simulating the effects of cool roof and PCM (phase change materials) based roof to mitigate UHI (urban heat island) in prominent US cities. Energy 2016, 96, 103–117. [Google Scholar] [CrossRef]

- Stavrakakis, G.; Androutsopoulos, A.; Vyörykkä, J. Experimental and numerical assessment of cool-roof impact on thermal and energy performance of a school building in Greece. Energy Build. 2016, 130, 64–84. [Google Scholar] [CrossRef]

- Kim, G.A.; Song, B.G.; and Park, K.H. Long-term monitoring for comparison of seasonal effects on cool roofs in humid subtropical climates. Energy Build. 2020, 206, 109572. [Google Scholar] [CrossRef]

- He, Y.; Yu, H.; Ozaki, A.; Dong, N. Thermal and energy performance of green roof and cool roof: A comparison study in Shanghai area. J. Clean. Prod. 2020, 267, 122205. [Google Scholar] [CrossRef]

- Chen, J.; Lu, L. Comprehensive evaluation of thermal and energy performance of radiative roof cooling in buildings. J. Build. Eng. 2021, 33, 101631. [Google Scholar] [CrossRef]

- Androutsopoulos, A.; Stavrakakis, G.; Damasiotis, M. Cool roof impacts on a school-building thermal and energy performance in Athens, Greece. Procedia Environ. Sci. 2017, 38, 178–186. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, Y.; Chi, Y.; Hong, Y.; Yin, J. Shape-morphing materials and structures for energy-efficient building envelopes. Mater. Today Energy 2021, 22, 100874. [Google Scholar] [CrossRef]

- Habibi, S.; Obonyo, E.A.; Memari, A.M. Design and development of energy efficient re-roofing solutions. Renew. Energy 2020, 151, 1209–1219. [Google Scholar] [CrossRef]

- CREST Contracting. 2023. Available online: https://www.tucsonroofing.com/residential-roofing-services/built-up-roofing/ (accessed on 10 January 2023).

- Wikipedia. Roof Shingles. 2023. Available online: https://en.wikipedia.org/wiki/Roof_shingle (accessed on 10 January 2023).

- Alchapar, N.L.; Correa, E.N. Aging of roof coatings. Solar reflectance stability according to their morphological characteristics. Constr. Build. Mater. 2016, 102, 297–305. [Google Scholar] [CrossRef]

- Blueprint Roofing and Construction. 2023. Available online: https://www.roofnola.com/new-orleans-roofing/roof-types/metal-roofing (accessed on 10 January 2023).

- Panayiotou, G.; Kalogirou, S.A.; Tassou, S.A. Evaluation of the application of Phase Change Materials (PCM) on the envelope of a typical dwelling in the Mediterranean region. Renew. Energy 2016, 97, 24–32. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Soibam, J. Numerical Investigation of a Heat Exchanger Using Phase Change Materials (PCMs) for Small-Scale Combustion Appliances. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2018. [Google Scholar]

- Bruno, F.; Tay, N.H.S.; Belusko, M. Minimising energy usage for domestic cooling with off-peak PCM storage. Energy Build. 2014, 76, 347–353. [Google Scholar] [CrossRef]

- de Gracia, A. Dynamic building envelope with PCM for cooling purposes–Proof of concept. Appl. Energy 2019, 235, 1245–1253. [Google Scholar] [CrossRef]

- Roach, P.; Bruno, F.; Belusko, M. Modelling the cooling energy of night ventilation and economiser strategies on façade selection of commercial buildings. Energy Build. 2013, 66, 562–570. [Google Scholar] [CrossRef]

- Xie, J.; Wang, W.; Liu, J.; Pan, S. Thermal performance analysis of PCM wallboards for building application based on numerical simulation. Sol. Energy 2018, 162, 533–540. [Google Scholar] [CrossRef]

- Muruganantham, K. Applications of Phase Change Materials in Buildings; Arizona State University: Tempe, AZ, USA, 2010. [Google Scholar]

- Phase Change Solutions. 2022. Available online: https://phasechange.com/ (accessed on 10 January 2023).

- Sedaghat, A.; Salem, H.; Hussam, W.K.; Mahdizadeh, A.; Al-Khiami, M.I.; Malayer, M.A.; Soleimani, S.M.; Sabati, M.; Narayanan, R.; Rasul, M.; et al. Second Annual Report on Development of a Novel Low-Energy Building: Utilization of Phase Change Materials, Cool Roofs, and Solar-Assisted Air Conditioning. KFAS Internal Report, Kuwait, 2023.

- Environment Public Authority Kuwait. Kuwait’s Initial National Communications under the United Nations Framework Convention on Climate Change. 2012. Available online: https://unfccc.int/resource/docs/natc/kwtnc1.pdf (accessed on 10 January 2023).

- Stern, H.; De Hoedt, G.; Ernst, J. Objective classification of Australian climates. Aust. Meteorol. Mag. 2000, 49, 87–96. [Google Scholar]

- Wikipedia. A Climate Map of Australia. 2023. Available online: https://en.m.wikipedia.org/wiki/File:Australia-climate-map_MJC01_1.svg (accessed on 10 January 2023).

- Khechiba, A.; Djaghrouri, D.; Benabbas, M.; Leccese, F.; Rocca, M.; Salvadori, G. Balancing Thermal Comfort and Energy Consumption in Residential Buildings of Desert Areas: Impact of Passive Strategies. Sustainability 2023, 15, 8383. [Google Scholar] [CrossRef]

- Davis Air Quality Monitors for Home and Business. 2023. Available online: https://cdn.shopify.com/s/files/1/0515/5992/3873/files/AirLInk_Pillar_Page_PDF_v3.pdf?v=1639701418 (accessed on 10 January 2023).

- Emporia. Emporia Gen 2 Vue Energy Monitor. 2023. Available online: https://www.emporiaenergy.com/ (accessed on 10 January 2023).

- Sedaghat, A.; Soleimani, S.M.; Al-Khiami, M.I.; Sabati, M.; Rasul, M.; Narayanan, R.; Khan, M.M. Development of a Novel Low-Energy Building: Effects of Room Orientation and Wall Materials. Key Eng. Mater. 2023, 945, 101–108. [Google Scholar] [CrossRef]

- Sedaghat, A.; Salem, H.; Hussam, W.K.; Mahdizadeh, A.; Al-Khiami, M.I.; Malayer, M.A.; Soleimani, S.M.; Sabati, M.; Narayanan, R.; Rasul, M.; et al. Exploring energy-efficient building solutions in hot regions: A study on bio-phase change materials and cool roof coatings. J. Build. Eng. 2023, 76, 107258. [Google Scholar] [CrossRef]

- Politi, C.; Peppas, A.; Taxiarchou, M. Data-Driven Integrated Decision Model for Analysing Energetic Behaviour of Innovative Construction Materials Capable of Hybrid Energy Storage. Sustainability 2023, 15, 12863. [Google Scholar] [CrossRef]

- Asustral Plywoods. 2023. Available online: https://www.australply.com.au/technical/thermal-properties (accessed on 10 January 2023).

- Manzello, S.L.; Park, S.H.; Mizukami, T.E.N.S.E.I.; Bentz, D.P. Measurement of thermal properties of gypsum board at elevated temperatures. In Proceedings of the 5th International Conference on Structures in Fire, Nanyang Technological University, Singapore, 28–30 May 2008; pp. 28–30. [Google Scholar]

| Particulate matters | |

| Particle range of measurements | 0.3–1 µm; 1–2.5 µm; 2.5–10 µm |

| Particle resolution | 1 µg/m3 |

| Accuracy | ±10 µg/m3 |

| Update interval | 1 min |

| Indoor/outdoor relative humidity | |

| Resolution and unit | 0.1% |

| Range | 0.1% to 100% RH |

| Accuracy | ±2% |

| Update interval | 1 min |

| Indoor/outdoor temperature | |

| Resolution and unit | Current data: 0.1 °C |

| Range | −40 °C to +60 °C |

| Accuracy | ± 0.3 °C (typical) |

| Update interval | 1 min |

| Details | Values |

|---|---|

| Frequency | 50–60 Hz |

| Max Current | 50 A |

| Output | 0.0–0.333 V (Measuring 0–50 A) |

| Accuracy | ±2% |

| Dimensions | 1.6″ × 0.9″ × 1″ (41 mm × 23 mm × 26 mm) |

| Window Diameter | 0.39″ (10 mm) |

| Cable Length | 39″ (1 m) |

| Connector | 2.5 mm right-angled two-pole audio connector |

| Materials | U-Value (W/m2K) | ρ (kg/m3) | k (kJ/hmK) | Cp (kJ/kgK) |

|---|---|---|---|---|

| Sandwich Roof | 0.218 | |||

| Plywood [60]: Floor | 2.064 | |||

| Sandwich Panels (75 mm): Walls | 0.2534 | 47.18 | 0.07236 | 0.8 |

| Gypsum Board [62] | 752 | 0.077 | 1.017 |

| Phase Change Material ID | TRNSYS Parameter Value |

|---|---|

| 901.23QFGM27 | 901.2327 |

| 901.23QFGM51 | 901.2351 |

| 901.23QFGM91 | 901.2391 |

| 901.25QFGM27 | 901.2527 |

| 901.25QFGM51 | 901.2551 |

| 901.25QFGM91 | 901.2591 |

| 901.27QFGM27 | 901.2727 |

| 901.27QFGM51 | 901.2751 |

| 901.27QFGM91 | 901.2791 |

| 901.29QFGM27 | 901.2927 |

| 901.29QFGM51 | 901.2951 |

| 901.29QFGM91 | 901.2991 |

| Melting Point (°C) | Latent Heat (J/g) | Energy Storage Capacity (kJ/m2) | Specific Heat (J/gK) | Thermal Conductivity (W/mK) | Relative Density (g/mL) | Phase State |

|---|---|---|---|---|---|---|

| 23, 25, 27, 29 | 210–250 | 400–1250 | 2.2–4.5 | 0.15–2.5 | 0.85–1.4 | Liquid, viscous gel, solid-solid gel |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sedaghat, A.; Mahdizadeh, A.; Narayanan, R.; Salem, H.; Hussam, W.K.; Al-Khiami, M.I.; Malayer, M.A.; Soleimani, S.M.; Sabati, M.; Rasul, M.; et al. Implementing Cool Roof and Bio-PCM in Portable Cabins to Create Low-Energy Buildings Suitable for Different Climates. Sustainability 2023, 15, 14700. https://doi.org/10.3390/su152014700

Sedaghat A, Mahdizadeh A, Narayanan R, Salem H, Hussam WK, Al-Khiami MI, Malayer MA, Soleimani SM, Sabati M, Rasul M, et al. Implementing Cool Roof and Bio-PCM in Portable Cabins to Create Low-Energy Buildings Suitable for Different Climates. Sustainability. 2023; 15(20):14700. https://doi.org/10.3390/su152014700

Chicago/Turabian StyleSedaghat, Ahmad, Arash Mahdizadeh, Ramadas Narayanan, Hayder Salem, Wisam K. Hussam, Mohamad Iyad Al-Khiami, Mahdi Ashtian Malayer, Sayed M. Soleimani, Mohammad Sabati, Mohammad Rasul, and et al. 2023. "Implementing Cool Roof and Bio-PCM in Portable Cabins to Create Low-Energy Buildings Suitable for Different Climates" Sustainability 15, no. 20: 14700. https://doi.org/10.3390/su152014700

APA StyleSedaghat, A., Mahdizadeh, A., Narayanan, R., Salem, H., Hussam, W. K., Al-Khiami, M. I., Malayer, M. A., Soleimani, S. M., Sabati, M., Rasul, M., & Kamal Khan, M. M. (2023). Implementing Cool Roof and Bio-PCM in Portable Cabins to Create Low-Energy Buildings Suitable for Different Climates. Sustainability, 15(20), 14700. https://doi.org/10.3390/su152014700