1. Introduction

It is evident that increasing the visibility of road signs can help to improve road safety. Some studies on lighting and road safety show that 90% of the information that a driver needs is acquired by sight and at night the eye suffers from a significant deficit of information [

1,

2,

3]. There are a number of factors associated with traffic accidents at night, such as fatigue and increased speed, but visibility also plays an important role [

4,

5]. The driver’s visual capacity is reduced to 20% with respect to daytime driving, and his or her ability to perceive distances and fields of vision is also reduced [

6].

The severity of traffic accidents is usually higher during night-time driving than during daytime driving, as stated by Regev et al. [

7]. In the specific case of Spain, the figures collected by Spain’s Directorate General of Traffic indicate that the highest percentage of accidents does not occur during night-time driving, but it is when the highest percentage of fatal accidents occur. The accident fatality rate (the ratio between the number of deaths and accident victims) in Spain was 1.2 in 2019; however, in the case of night-time accidents (including dusk and dawn), this ratio reaches 1.69, which is 40% higher [

8]. Studies from other countries have also shown that the accident and fatality rate in night-time driving can be as high as 1.6 times the daytime accident rate [

9,

10].

Guidelines for the design and implementation of horizontal road signage usually explain the daytime and night-time visibility characteristics of road markings. According to night-time visibility, these guides classify the markings into non-retroreflective and retroreflective markings [

11]. Retroreflection is defined as the capacity that some surfaces have to reflect light in the direction of the emitting source, which allows road markings to be visible to drivers during the night when the vehicle’s headlights are incident on the markings [

12].

The materials used in these markings are considered as the “base”, such as paints and thermoplastics, and the “post-mixing” materials include glass beads and non-slip aggregates [

12]. The glass beads provide road markings with retroreflection, which is calculated as the ratio between the luminance of a marked area of road in one given direction and the illuminance of that area [

13].

For its part, luminance can be defined as the brightness intensity of a material and is the result of dividing the luminous intensity of a surface by its area of incidence in a given direction [

14]. The signage guide explains that the luminances from a vehicle’s headlights are generally small and states a normal range between 0.001 cd/m

2 and 0.100 cd/m

2. To increase the retroreflection of road markings, glass beads are usually used that intensify the visual stimulus so that relatively small objects can be seen [

15].

An alternative base material to those commonly used, which would provide a greater degree of visibility for road users, including both drivers and pedestrians, is a material that is photoluminescent. Photoluminescent materials emit light as a result of the release of energy due to the absorption of photons [

16,

17,

18,

19,

20]. During stimulation (exposure to the sun), the absorbed energy stimulates electronic transitions to higher energy states (excited state). When the stimulation ends, the electron falls from the excited state to a lower energy state, releasing the energy in the form of light. Depending on the lifetime of the emitted luminescence, photoluminescent materials can be classified as fluorescent (average life < 10 ms) or phosphorescent (average life ≥ 0.1 s) [

21]. The design of materials with photoluminescent properties for use in pavements has focused on phosphorescent-type materials; that is, those that emit light once the excitation has ceased.

In the 1990s, materials called “long-lasting phosphors” were discovered and products with high emission power and long decay times were obtained, such as strontium aluminate, which is a yellow, odourless, and non-flammable monoclinic crystalline powder [

22]. This heavier-than-water compound is chemically and biologically inert. When activated with the appropriate dopant, it behaves as a photoluminescent phosphor. Currently, the most commonly found phosphorescent materials are strontium aluminates europium and dysprosium doped (SrAl

2O

4:Eu

2+,Dy

3+), which emits in green, and calcium aluminates europium and neodymium doped (CaAl

2O

4:Eu

2+,Nd

3+), which emits in blue. Currently, these are used in exit signs, road signage, and other safety-related signs. Thus, photoluminescent signage must comply with standard UNE 23035-1.

The use of materials with photoluminescent properties on the surface course of road pavements or bicycle lanes is a very attractive idea as they are capable of absorbing solar energy during the day in order to emit it during the night.

Luminance is a key factor in these types of materials, which depends on the type of surface and illumination source, and the unit of measurement is the candela per square metre (cd/m

2). For its part, illuminance refers to the light intensity that is incident on a surface, measured in lux. According to Andre and Owens [

23], the minimum night-time visibility in many road safety applications is 3.3 lx, while the illuminance in many indoor illumination applications is normally around 300 lx.

As Bachanek et al. reported, global consumption of electricity is reaching considerable sums and increases by around 3% every year [

24]. Outdoor illumination is responsible for 15–19% of this consumption and illumination represents 2.4% of humanity’s annual energy resources, and is responsible for 5–6% of the total greenhouse gas emissions to the atmosphere [

25,

26].

Sadeghian et al. reviewed the energy-saving options in the electrical distribution grid for buildings and public lighting systems [

27]. They analysed the energy and emissions savings potential of a series of prior studies with different alternatives, concluding that there are potential solutions for reducing energy consumption.

Recently, Belloni et al. developed an intelligent illumination system based on blue diode laser technology combined with photoluminescent pavements to obtain a self-illuminating surface [

28]. Even though this application is still a prototype, the results indicate promising benefits in terms of electricity saving and uniformity of luminance.

Many cities and municipalities throughout the world are starting to explore intelligent city options for the illumination of public spaces. Notable among the most innovative are those that study the possibility of replacing or supporting artificial street lighting by means of bioluminescence, with transgenic bioluminescent plants [

29] and marine bacteria [

30].

Studies relating to photoluminescence on road pavements have focused on a photoluminescent coating on the top layer of the bituminous mix. Praticò et al. studied the photoluminescence phenomenon in terms of loading and unloading according to the type of pavement (dense or gap-graded bituminous mixes), and the paint treatment by applying a coating with photoluminescent properties on the top layer of the pavement [

31]. Gutiérrez and Colorado developed a photoluminescent coating made from strontium aluminate and expanded polyethylene waste for use in asphalt pavements and obtained acceptable mechanical properties [

32].

Giulinai and Auteliano analysed the use of photoluminescent pigments for thin surface courses based on zinc sulphide (ZnS:Cu) and on strontium aluminate (SrAl

2O

4:Eu

2+,Dy

3+) under different experimental conditions [

33]. They concluded that the selection of photoluminescent pigments should favour materials capable of absorbing radiation from sunlight and re-radiating it at wavelengths visible to the human eye for appreciable periods of time.

Chiatti et al. published a study in which they researched innovative solutions for achieving luminescent and reflective results at the same time [

34]. They used paints with different coloured pigments from the strontium aluminate, calcium aluminate and silicate family, all doped with europium, in order to obtain different colours. They statistically verified that the attenuation of the luminance varied with the chemical composition of each pigment. The results indicated that the europium-doped strontium aluminate reached much higher radiance and luminance values than the other two compounds.

The application of photoluminescent elements on Portland cement for pavement concretes has also been studied, as in the works of Sanjuán and Argiz or Rosas-Casares et al., for example [

35,

36].

Similarly, the aim of this study is to analyse the effectiveness of different applications for pavement surfaces from the luminance point of view, including bituminous mixes as well as bituminous mortars and paints, and to compare the results obtained.

4. Conclusions

This study analyses the feasibility of using photoluminescent materials to partially or totally replace artificial illumination as a sustainable alternative to reduce the consumption of electrical energy and decarbonise outdoor urban environments, at the same time as improving road safety.

The results obtained allow the following conclusions to be made:

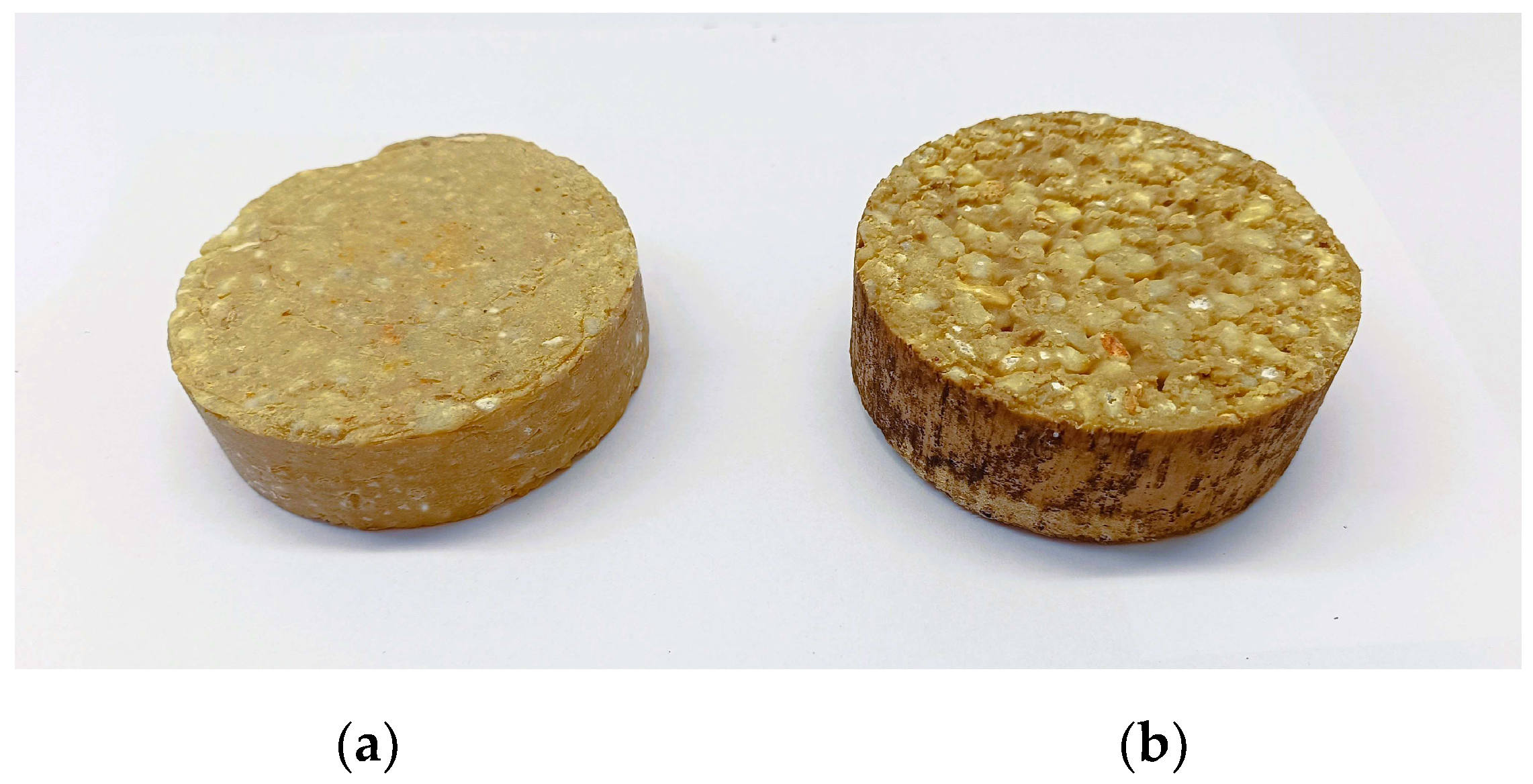

For the bituminous mixes, texture is a key factor in the luminance value obtained. It was observed that most closed surfaces can achieve double the initial luminance value for the same content of aluminate and glass beads.

The bituminous mortars show that the higher the aluminate and glass beads content, the higher the luminance, although the colour of the base also has an influence with clear bases having higher luminance.

It was observed that the effect of the base surface colour is more significant for the paints than for the mortars, and higher luminance values were obtained for the light bases. For the same base, in general, the luminances increase with the aluminate and glass bead content, except for very high bead values combined with very high aluminate values, in which case the luminance value starts to decay. Paint 60-6 W has the dosage that allows the highest luminance values to be obtained.

Finally, it has been shown that the luminescent paints applied on light surfaces can reach luminance values higher than those obtained by means of bituminous mixes and mortars, making it possible to achieve a good photoluminescent level while economising on the amount of materials necessary.

Photoluminescent mixes can be considered the new materials of the future due to their numerous benefits for society. Not only do they improve night-time visibility, but they also save energy because public lighting in city streets can be reduced, thus contributing to the mitigation of the urban heat island effect, considered a key issue for sustainable development.