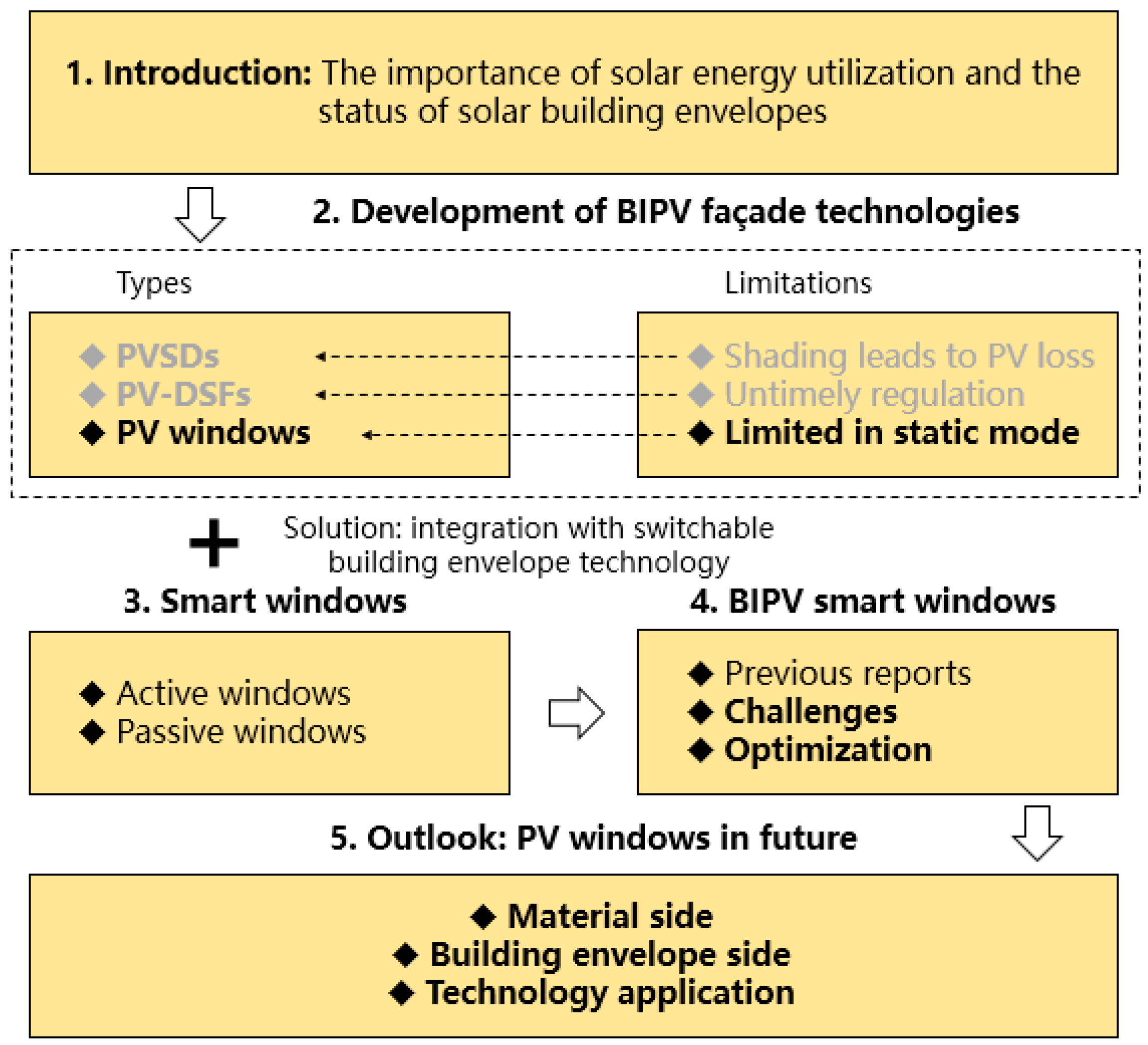

Challenges and Optimization of Building-Integrated Photovoltaics (BIPV) Windows: A Review

Abstract

:1. Introduction

2. Development of BIPV Façade Technologies

2.1. Energy Properties of Different BIPV Façades

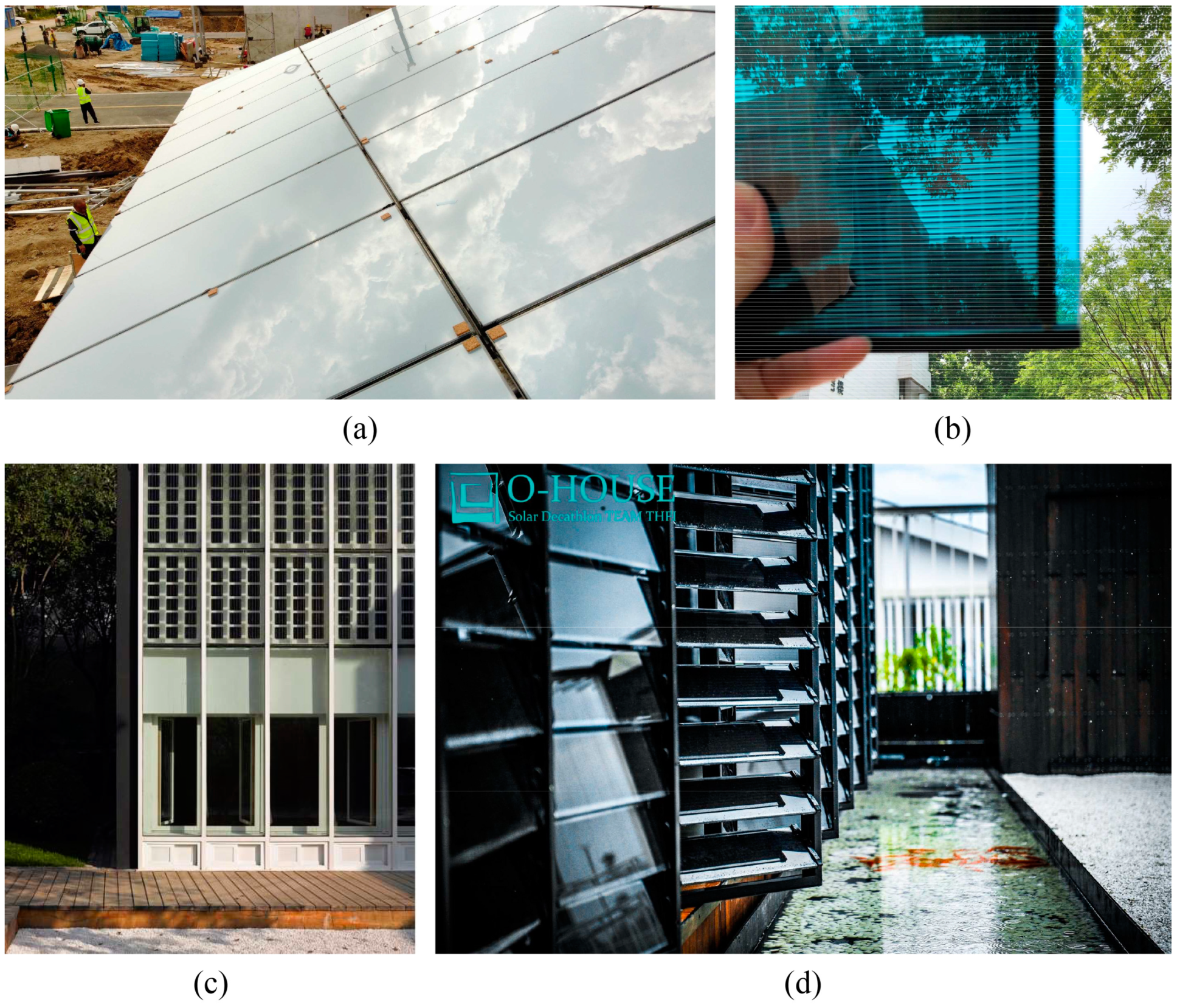

2.2. Photovoltaic Integrated Shading Devices (PVSDs)

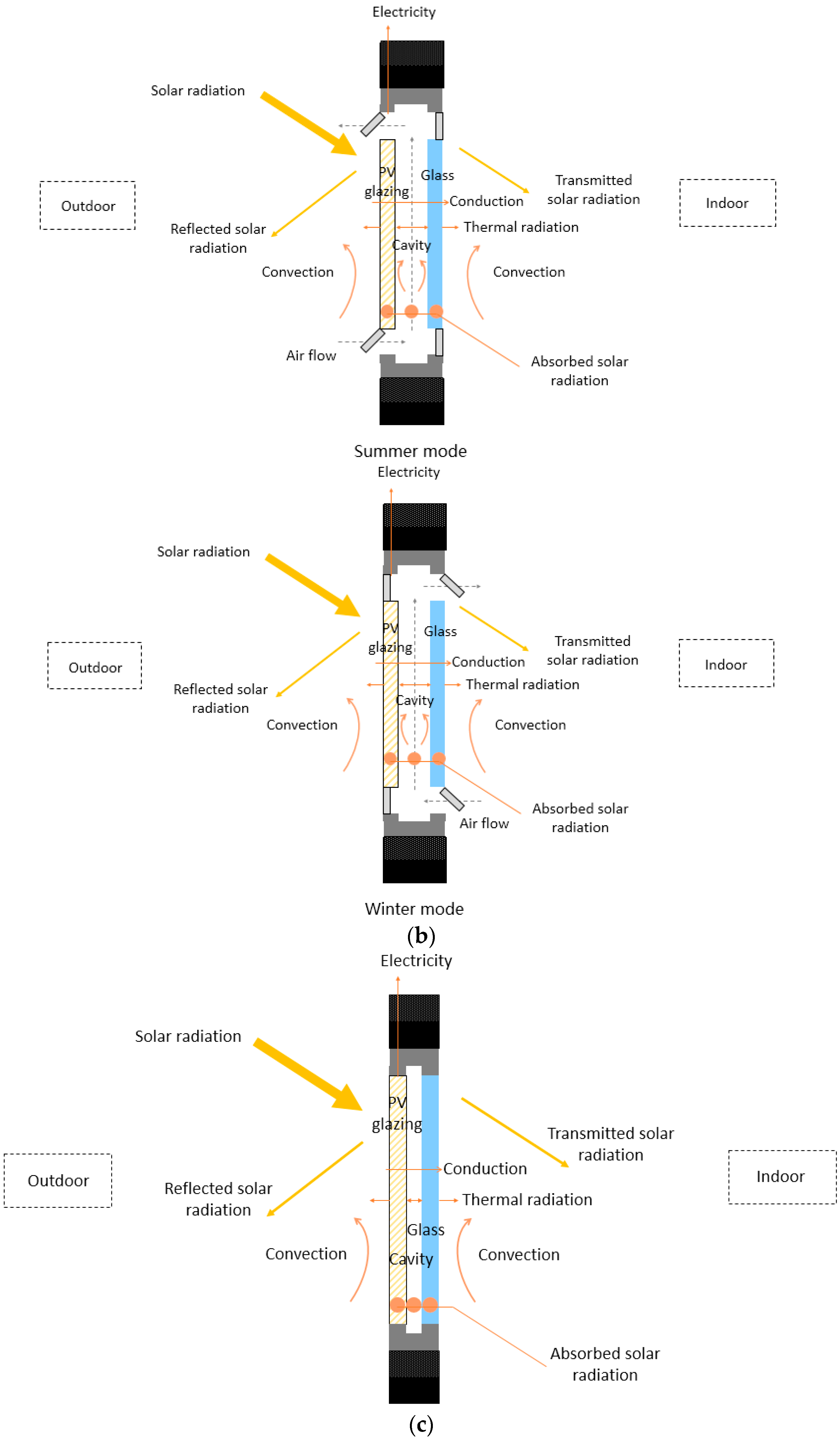

2.3. Photovoltaic Double-Skin Façades (PV-DSFs)

2.4. Photovoltaic Windows

2.5. Summary: Limitations and Solutions of BIPV Façades

3. Smart Window for Energy Savings

3.1. Active Smart Windows

3.2. Passive Smart Windows

3.3. Combining Smart Windows with PV Glazing: A Discussion

4. BIPV Smart Windows

4.1. BIPV Smart Windows Reported in the Previous Literature

4.1.1. Radiation-Regulated Switchable PV Windows

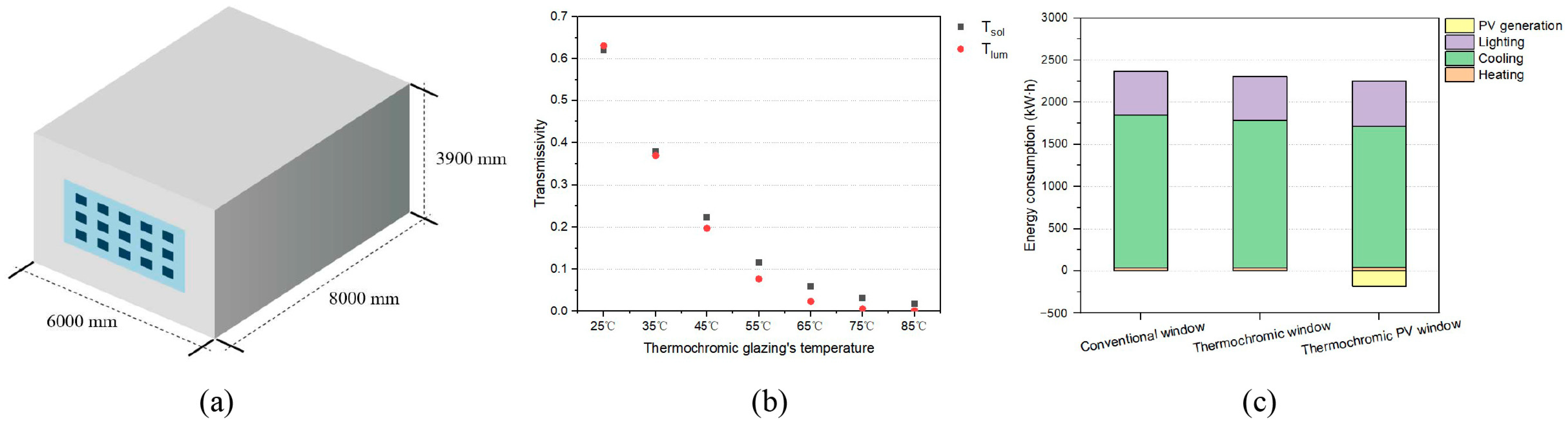

4.1.2. Thermal Conduction-Regulated Switchable PV Windows

4.2. Challenges

4.2.1. Energy Conversion Efficiency and Temperature Coefficient of PV Materials

4.2.2. Building Façades Receive Little Solar Radiation

4.2.3. Suitable Building Energy-Saving Scenarios

4.2.4. Color Quality of Transmitted Light

4.2.5. Robustness of Novel PV Modules

4.2.6. Economics

4.2.7. Effects of Application in Full-Scale Buildings

4.3. Optimization

4.3.1. Materials

- Photovoltaic materials

- Optical/thermal regulation materials

4.3.2. Building Envelopes

- From static to switchable building envelopes

- A discussion on achieving performance optimization of PV windows

5. Outlook

- From the material point of view, the development of new PV materials and optical/thermal regulation materials is an important contribution to the optimization of the energy-saving performance of PV windows. However, the development of new ideal PV window materials should have smaller temperature coefficients, lower costs, higher robustness and no significant change in the color quality of the transmitted light into the interior (avoiding unreasonable color rendering indexes for transmitted light, i.e., Ra ≤ 80).

- From the perspective of the building envelope, the application of PV windows needs to focus on the comprehensive energy-saving scenarios to be achieved by the building. There are differences in daylighting, heat transfer, and power generation differences between buildings in various climate zones, seasons and hours of the day and night. PV smart windows that satisfy the switchable scenarios of insulation and heat gain have more potential for energy saving. A passive switchable building envelope does not require a control strategy and has the advantage of an automatic response. Active switchable envelopes are more capable of regulation but may be characterized by system complexity or additional energy consumption. In addition, PV windows of façades may have the limitation of receiving less radiation, which can be increased by tilting the window when ventilating, which thus increases the PV production capacity.

- From the perspective of building applications, short-term or long-term experimental research on full-scale smart PV windows should be carried out in the future. The actual energy-saving effects of theoretical studies need to be verified by long-term data monitoring, and the assessment of indoor people’s acceptance should be introduced [134]. It is since some new models of windows, although they have good energy-saving potential, may affect the sight of windows or the subjective acceptance of people.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jakučionytė-Skodienė, M.; Krikštolaitis, R.; Liobikienė, G. The Contribution of Changes in Climate-Friendly Behaviour, Climate Change Concern and Personal Responsibility to Household Greenhouse Gas Emissions: Heating/Cooling and Transport Activities in the European Union. Energy 2022, 246, 123387. [Google Scholar] [CrossRef]

- Yang, T.; Athienitis, A.K. A Review of Research and Developments of Building-Integrated Photovoltaic/Thermal (BIPV/T) Systems. Renew. Sustain. Energy Rev. 2016, 66, 886–912. [Google Scholar] [CrossRef]

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A Review on Buildings Energy Consumption Information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Hao, D.; Qi, L.; Tairab, A.M.; Ahmed, A.; Azam, A.; Luo, D.; Pan, Y.; Zhang, Z.; Yan, J. Solar Energy Harvesting Technologies for PV Self-Powered Applications: A Comprehensive Review. Renew. Energy 2022, 188, 678–697. [Google Scholar] [CrossRef]

- Xu, L.; Dai, L.; Yin, L.; Sun, X.; Xu, W.; Yang, R.; Wang, X.; Zhang, Y. Research on the Climate Response of Variable Thermo-Physical Property Building Envelopes: A Literature Review. Energy Build. 2020, 226, 110398. [Google Scholar] [CrossRef]

- Kou, F.; Shi, S.; Zhu, N.; Song, Y.; Zou, Y.; Mo, J.; Wang, X. Improving the Indoor Thermal Environment in Lightweight Buildings in Winter by Passive Solar Heating: An Experimental Study. Indoor Built Environ. 2022, 31, 2257–2273. [Google Scholar] [CrossRef]

- Levinson, R.; Akbari, H.; Reilly, J.C. Cooler Tile-Roofed Buildings with near-Infrared-Reflective Non-White Coatings. Build. Environ. 2007, 42, 2591–2605. [Google Scholar] [CrossRef]

- Kolokotroni, M.; Gowreesunker, B.L.; Giridharan, R. Cool Roof Technology in London: An Experimental and Modelling Study. Energy Build. 2013, 67, 658–667. [Google Scholar] [CrossRef]

- Zhai, Y.; Ma, Y.; David, S.N.; Zhao, D.; Lou, R.; Tan, G.; Yang, R.; Yin, X. Scalable-Manufactured Randomized Glass-Polymer Hybrid Metamaterial for Daytime Radiative Cooling. Science 2017, 355, 1062–1066. [Google Scholar] [CrossRef]

- Piffer, Y.; Jonsson, J.C.; Güths, S.; Machado, R.M.S.; Lamberts, R. Development and Validation of an Optical Model for Water-Based Windows with Clear Glazing: A Parametric Performance Assessment. Build. Environ. 2022, 209, 108635. [Google Scholar] [CrossRef]

- Nicoletti, F.; Kaliakatsos, D.; Ferraro, V.; Cucumo, M.A. Analysis of the Energy and Visual Performance of a Building with Photochromic Windows for a Location in Southern Italy. Build. Environ. 2022, 224, 109570. [Google Scholar] [CrossRef]

- Aburas, M.; Ebendorff-Heidepriem, H.; Lei, L.; Li, M.; Zhao, J.; Williamson, T.; Wu, Y.; Soebarto, V. Smart Windows–Transmittance Tuned Thermochromic Coatings for Dynamic Control of Building Performance. Energy Build. 2021, 235, 110717. [Google Scholar] [CrossRef]

- Goia, F.; Perino, M.; Serra, V. Experimental Analysis of the Energy Performance of a Full-Scale PCM Glazing Prototype. Sol. Energy 2014, 100, 217–233. [Google Scholar] [CrossRef]

- Sung, D. A New Look at Building Facades as Infrastructure. Engineering 2016, 2, 63–68. [Google Scholar] [CrossRef]

- Krzaczek, M.; Kowalczuk, Z. Thermal Barrier as a Technique of Indirect Heating and Cooling for Residential Buildings. Energy Build. 2011, 43, 823–837. [Google Scholar] [CrossRef]

- Dussault, J.-M.; Gosselin, L. Office Buildings with Electrochromic Windows: A Sensitivity Analysis of Design Parameters on Energy Performance, and Thermal and Visual Comfort. Energy Build. 2017, 153, 50–62. [Google Scholar] [CrossRef]

- Wijeratne, W.; Samarasinghalage, T.I.; Yang, R.J.; Wakefield, R. Multi-Objective Optimisation for Building Integrated Photovoltaics (BIPV) Roof Projects in Early Design Phase. Appl. Energy 2022, 309, 118476. [Google Scholar] [CrossRef]

- Chapin, D.M.; Fuller, C.S.; Pearson, G.L. A New Silicon P-n Junction Photocell for Converting Solar Radiation into Electrical Power. J. Appl. Phys. 1954, 25, 676–677. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sudhakar, K.; Baredar, P. A Comprehensive Review on Design of Building Integrated Photovoltaic System. Energy Build. 2016, 128, 99–110. [Google Scholar] [CrossRef]

- Chen, X.; Huang, J.; Yang, H. Multi-Criterion Optimization of Integrated Photovoltaic Facade with Inter-Building Effects in Diverse Neighborhood Densities. J. Clean. Prod. 2020, 248, 119269. [Google Scholar] [CrossRef]

- Tarantini, M.; Loprieno, A.D.; Porta, P.L. A Life Cycle Approach to Green Public Procurement of Building Materials and Elements: A Case Study on Windows. Energy 2011, 36, 2473–2482. [Google Scholar] [CrossRef]

- Shi, S.; Liu, Z.; Liu, S.; Zhu, N.; Song, Y.; Zhang, H. Sustainable Architectural Education of Practice Technological Innovation and Talent Training in Solar Decathlon China. Archit. J. 2022, 24–30. [Google Scholar]

- Shi, S.; Zhu, N.; Song, Y. Parameter Design and Experimental Evaluation of the Optical Performance of Colored Semi-Transparent PV Modules. In Proceedings of the 15th Building Physics Conference of China, Shanghai, China, 10–12 March 2023. [Google Scholar]

- Shi, S.; Chu, Y.; Gao, W.; Song, Y. BIPV Technology Application for Architectural Facade. World Archit. Rev. 2022, 37, 35–38. [Google Scholar]

- Mandalaki, M.; Papantoniou, S.; Tsoutsos, T. Assessment of Energy Production from Photovoltaic Modules Integrated in Typical Shading Devices. Sustain. Cities Soc. 2014, 10, 222–231. [Google Scholar] [CrossRef]

- Mandalaki, M.; Zervas, K.; Tsoutsos, T.; Vazakas, A. Assessment of Fixed Shading Devices with Integrated PV for Efficient Energy Use. Sol. Energy 2012, 86, 2561–2575. [Google Scholar] [CrossRef]

- Zhang, W.L.; Lu, L.; Peng, J.Q. Evaluation of Potential Benefits of Solar Photovoltaic Shadings in Hong Kong. Energy 2017, 137, 1152–1158. [Google Scholar] [CrossRef]

- Taveres-Cachat, E.; Lobaccaro, G.; Goia, F.; Chaudhary, G. A Methodology to Improve the Performance of PV Integrated Shading Devices Using Multi-Objective Optimization. Appl. Energy 2019, 247, 731–744. [Google Scholar] [CrossRef]

- Nagy, Z.; Svetozarevic, B.; Jayathissa, P.; Begle, M.; Hofer, J.; Lydon, G.; Willmann, A.; Schlueter, A. The Adaptive Solar Facade: From Concept to Prototypes. Front. Archit. Res. 2016, 5, 143–156. [Google Scholar] [CrossRef]

- Jayathissa, P.; Luzzatto, M.; Schmidli, J.; Hofer, J.; Nagy, Z.; Schlueter, A. Optimising Building Net Energy Demand with Dynamic BIPV Shading. Appl. Energy 2017, 202, 726–735. [Google Scholar] [CrossRef]

- Jayathissa, P.; Jansen, M.; Heeren, N.; Nagy, Z.; Schlueter, A. Life Cycle Assessment of Dynamic Building Integrated Photovoltaics. Life Cycle Environ. Ecol. Impact Anal. Sol. Technol. 2016, 156, 75–82. [Google Scholar] [CrossRef]

- Li, X.; Peng, J.; Li, N.; Wu, Y.; Fang, Y.; Li, T.; Wang, M.; Wang, C. Optimal Design of Photovoltaic Shading Systems for Multi-Story Buildings. J. Clean. Prod. 2019, 220, 1024–1038. [Google Scholar] [CrossRef]

- Shi, S.; Sun, J.; Liu, M.; Chen, X.; Gao, W.; Song, Y. Energy-Saving Potential Comparison of Different Photovoltaic Integrated Shading Devices (PVSDs) for Single-Story and Multi-Story Buildings. Energies 2022, 15, 9196. [Google Scholar] [CrossRef]

- Yang, S.L.; Cannavale, A.; Prasad, D.; Sproul, A.; Fiorito, F. Numerical Simulation Study of BIPV/T Double-Skin Facade for Various Climate Zones in Australia: Effects on Indoor Thermal Comfort. Build. Simul. 2019, 12, 51–67. [Google Scholar] [CrossRef]

- Yang, S.; Cannavale, A.; Di Carlo, A.; Prasad, D.; Sproul, A.; Fiorito, F. Performance Assessment of BIPV/T Double-Skin Façade for Various Climate Zones in Australia: Effects on Energy Consumption. Sol. Energy 2020, 199, 377–399. [Google Scholar] [CrossRef]

- Zhu, L.; Zhang, J.; Li, Q.; Shao, Z.; Chen, M.; Yang, Y.; Sun, Y. Comprehensive Analysis of Heat Transfer of Double-Skin Facades Integrated High Concentration Photovoltaic (CPV-DSF). Renew. Energy 2020, 161, 635–649. [Google Scholar] [CrossRef]

- Peng, J.; Lu, L.; Yang, H.; Ma, T. Comparative Study of the Thermal and Power Performances of a Semi-Transparent Photovoltaic Façade under Different Ventilation Modes. Appl. Energy 2015, 138, 572–583. [Google Scholar] [CrossRef]

- Peng, J.; Lu, L.; Yang, H. An Experimental Study of the Thermal Performance of a Novel Photovoltaic Double-Skin Facade in Hong Kong. Sol. Energy 2013, 97, 293–304. [Google Scholar] [CrossRef]

- Peng, J.Q.; Curcija, D.C.; Lu, L.; Selkowitz, S.E.; Yang, H.X.; Zhang, W.L. Numerical Investigation of the Energy Saving Potential of a Semi-Transparent Photovoltaic Double-Skin Facade in a Cool-Summer Mediterranean Climate. Appl. Energy 2016, 165, 345–356. [Google Scholar] [CrossRef]

- Liu, X.; Shen, C.; Wang, J.; Zhang, C.; Shuai, Y. Static and Dynamic Regulations of Photovoltaic Double Skin Facades towards Building Sustainability: A Review. Renew. Sustain. Energy Rev. 2023, 183, 113458. [Google Scholar] [CrossRef]

- He, W.; Zhang, Y.X.; Sun, W.; Hou, J.X.; Jiang, Q.Y.; Ji, J. Experimental and Numerical Investigation on the Performance of Amorphous Silicon Photovoltaics Window in East China. Build. Environ. 2011, 46, 363–369. [Google Scholar] [CrossRef]

- Wang, C.; Ji, J.; Uddin, M.M.; Yu, B.; Song, Z. The Study of a Double-Skin Ventilated Window Integrated with CdTe Cells in a Rural Building. Energy 2021, 215, 119043. [Google Scholar] [CrossRef]

- Wang, C.Y.; Ji, J.; Yu, B.D.; Zhang, C.Y.; Ke, W.; Wang, J. Comprehensive Investigation on the Luminous and Energy-Saving Performance of the Double-Skin Ventilated Window Integrated with CdTe Cells. Energy 2022, 238, 19. [Google Scholar] [CrossRef]

- Lee, H.M.; Yoon, J.H. Power Performance Analysis of a Transparent DSSC BIPV Window Based on 2 Year Measurement Data in a Full-Scale Mock-Up. Appl. Energy 2018, 225, 1013–1021. [Google Scholar] [CrossRef]

- Yu, J.C.; Sun, J.; Chandrasekaran, N.; Dunn, C.J.; Chesman, A.S.R.; Jasieniak, J.J. Semi-Transparent Perovskite Solar Cells with a Cross-Linked Hole Transport Layer. Nano Energy 2020, 71, 104635. [Google Scholar] [CrossRef]

- Aste, N.; Leonforte, F.; Piccolo, A. Color Rendering Performance of Smart Glazings for Building Applications. Sol. Energy 2018, 176, 51–61. [Google Scholar] [CrossRef]

- Park, K.E.; Kang, G.H.; Kim, H.I.; Yu, G.J.; Kim, J.T. Analysis of Thermal and Electrical Performance of Semi-Transparent Photovoltaic (PV) Module. Energy 2010, 35, 2681–2687. [Google Scholar] [CrossRef]

- Liao, W.; Xu, S. Energy Performance Comparison among See-through Amorphous-Silicon PV (Photovoltaic) Glazings and Traditional Glazings under Different Architectural Conditions in China. Energy 2015, 83, 267–275. [Google Scholar] [CrossRef]

- Aste, N.; Buzzetti, M.; Del Pero, C.; Fusco, R.; Testa, D.; Leonforte, F. Visual Performance of Yellow, Orange and Red LSCs Integrated in a Smart Window. Energy Proc. 2017, 105, 967–972. [Google Scholar] [CrossRef]

- Yan, F.; Noble, J.; Peltola, J.; Wicks, S.; Balasubramanian, S. Semitransparent OPV Modules Pass Environmental Chamber Test Requirements. Sol. Energy Mater. Sol. Cells 2013, 114, 214–218. [Google Scholar] [CrossRef]

- Sellami, N.; Mallick, T.K.; McNeil, D.A. Optical Characterisation of 3-D Static Solar Concentrator. Energy Convers. Manag. 2012, 64, 579–586. [Google Scholar] [CrossRef]

- Lin, J.; Lai, M.; Dou, L.; Kley, C.S.; Chen, H.; Peng, F.; Sun, J.; Lu, D.; Hawks, S.A.; Xie, C.; et al. Thermochromic Halide Perovskite Solar Cells. Nat. Mater. 2018, 17, 261–267. [Google Scholar] [CrossRef] [PubMed]

- Roberts, F.; Yang, S.; Du, H.; Yang, R. Effect of Semi-Transparent a-Si PV Glazing within Double-Skin Façades on Visual and Energy Performances under the UK Climate Condition. Renew. Energy 2023, 207, 601–610. [Google Scholar] [CrossRef]

- Jhumka, H.; Yang, S.; Gorse, C.; Wilkinson, S.; Yang, R.; He, B.-J.; Prasad, D.; Fiorito, F. Assessing Heat Transfer Characteristics of Building Envelope Deployed BIPV and Resultant Building Energy Consumption in a Tropical Climate. Energy Build. 2023, 298, 113540. [Google Scholar] [CrossRef]

- Sun, Y.; Shanks, K.; Baig, H.; Zhang, W.; Hao, X.; Li, Y.; He, B.; Wilson, R.; Liu, H.; Sundaram, S.; et al. Integrated Semi-Transparent Cadmium Telluride Photovoltaic Glazing into Windows: Energy and Daylight Performance for Different Architecture Designs. Appl. Energy 2018, 231, 972–984. [Google Scholar] [CrossRef]

- Zhang, W.; Lu, L.; Peng, J.; Song, A. Comparison of the Overall Energy Performance of Semi-Transparent Photovoltaic Windows and Common Energy-Efficient Windows in Hong Kong. Energy Build. 2016, 128, 511–518. [Google Scholar] [CrossRef]

- Skandalos, N.; Karamanis, D. An Optimization Approach to Photovoltaic Building Integration towards Low Energy Buildings in Different Climate Zones. Appl. Energy 2021, 295, 24. [Google Scholar] [CrossRef]

- Yang, R.J.; Zou, P.X. Building Integrated Photovoltaics (BIPV): Costs, Benefits, Risks, Barriers and Improvement Strategy. Int. J. Constr. Manag. 2016, 16, 39–53. [Google Scholar] [CrossRef]

- Liu, S.; Kwok, Y.T.; Lau, K.K.-L.; Chan, P.W.; Ng, E. Investigating the Energy Saving Potential of Applying Shading Panels on Opaque Façades: A Case Study for Residential Buildings in Hong Kong. Energy Build. 2019, 193, 78–91. [Google Scholar] [CrossRef]

- Castillo, M.S.; Liu, X.; Abd-AlHamid, F.; Connelly, K.; Wu, Y. Intelligent Windows for Electricity Generation: A Technologies Review. Build. Simul. 2022, 15, 1747–1773. [Google Scholar] [CrossRef]

- Xu, Y.; Yan, C.; Yan, S.; Liu, H.; Pan, Y.; Zhu, F.; Jiang, Y. A Multi-Objective Optimization Method Based on an Adaptive Meta-Model for Classroom Design with Smart Electrochromic Windows. Energy 2022, 243, 122777. [Google Scholar] [CrossRef]

- Zhang, L.; Du, Y.; Xia, F.; Gao, Y. Two Birds with One Stone: A Novel Thermochromic Cellulose Hydrogel as Electrolyte for Fabricating Electric-/Thermal-Dual-Responsive Smart Windows. Chem. Eng. J. 2022, 455, 140849. [Google Scholar] [CrossRef]

- Li, C.; Tang, H. Evaluation on Year-Round Performance of Double-Circulation Water-Flow Window. Renew. Energy 2020, 150, 176–190. [Google Scholar] [CrossRef]

- Yamaç, H.İ.; Koca, A. Experimental Investigation of Water Flow Window System and Numerical Modeling of Solar Thermal Energy Storage with Phase Change Materials on the Way of Nearly Zero Energy Buildings. J. Energy Storage 2021, 43, 103118. [Google Scholar] [CrossRef]

- Wu, S.; Sun, H.; Duan, M.; Mao, H.; Wu, Y.; Zhao, H.; Lin, B. Applications of Thermochromic and Electrochromic Smart Windows: Materials to Buildings. Cell Rep. Phys. Sci. 2023, 4, 101370. [Google Scholar] [CrossRef]

- Zhou, X.; Meng, Y.; Vu, T.D.; Gu, D.; Jiang, Y.; Mu, Q.; Li, Y.; Yao, B.; Dong, Z.; Liu, Q.; et al. A New Strategy of Nanocompositing Vanadium Dioxide with Excellent Durability. J. Mater. Chem. A 2021, 9, 15618–15628. [Google Scholar] [CrossRef]

- Wang, Y.; Bai, S.; Wei, L.; Niu, X.; Wang, S.; Niu, M.; Li, L.; Guo, X.; Gao, Y. Mineralized Supramolecular Hydrogel as Thermo-Responsive Smart Window. J. Mater. Sci. 2021, 56, 6955–6965. [Google Scholar] [CrossRef]

- Zhang, C.; Shen, C.; Zhang, Y.; Zheng, K.; Pu, J.; Zhao, X.; Ma, X. Experimental Study of Indoor Light/Thermal Environment with Spectrally Selective Windows Using ATO Nanofluids in Winter. Energy Build. 2023, 278, 112597. [Google Scholar] [CrossRef]

- Zheng, J.; Bao, S.; Jin, P. TiO2 (R)/VO2 (M)/TiO2 (A) Multilayer Film as Smart Window: Combination of Energy-Saving, Antifogging and Self-Cleaning Functions. Nano Energy 2015, 11, 136–145. [Google Scholar] [CrossRef]

- Zäll, E.; Karlsson, S.; Järn, M.; Segervald, J.; Lundberg, P.; Wågberg, T. Durability of Antireflective SiO2 Coatings with Closed Pore Structure. Sol. Energy Mater. Sol. Cells 2023, 261, 112521. [Google Scholar] [CrossRef]

- Priya, A.V.; Shaik, S. Crystal Mud Transparent Slime as a Glazing Material for Net-Zero Energy Buildings: Enhanced Energy Savings, Diurnal Lighting, and CO2 Mitigation. Energy Sustain. Dev. 2022, 71, 151–166. [Google Scholar] [CrossRef]

- Liu, C.; Wu, Y.; Zhu, Y.; Li, D.; Ma, L. Experimental Investigation of Optical and Thermal Performance of a PCM-Glazed Unit for Building Applications. Energy Build. 2018, 158, 794–800. [Google Scholar] [CrossRef]

- Wang, M.; Liu, Y.; Qi, B.; Li, D.; Wang, W. BSE-Based Dispersion Quantification of Carbon Fibres in Cementitious Composite through FCM-CA Approach. Constr. Build. Mater. 2020, 260, 119789. [Google Scholar] [CrossRef]

- Liu, C.; Wu, Y.; Li, D.; Zhou, Y.; Wang, Z.; Liu, X. Effect of PCM Thickness and Melting Temperature on Thermal Performance of Double Glazing Units. J. Build. Eng. 2017, 11, 87–95. [Google Scholar] [CrossRef]

- Liu, X.; Wu, Y. A Review of Advanced Architectural Glazing Technologies for Solar Energy Conversion and Intelligent Daylighting Control. Archit. Intell. 2022, 1, 10. [Google Scholar] [CrossRef]

- Malara, F.; Cannavale, A.; Carallo, S.; Gigli, G. Smart Windows for Building Integration: A New Architecture for Photovoltachromic Devices. ACS Appl. Mater. Interfaces 2014, 6, 9290–9297. [Google Scholar] [CrossRef] [PubMed]

- Huaulmé, Q.; Mwalukuku, V.M.; Joly, D.; Liotier, J.; Kervella, Y.; Maldivi, P.; Narbey, S.; Oswald, F.; Riquelme, A.J.; Anta, J.A. Photochromic Dye-Sensitized Solar Cells with Light-Driven Adjustable Optical Transmission and Power Conversion Efficiency. Nat. Energy 2020, 5, 468–477. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Wu, Y. Design, Development and Characterisation of a Building Integrated Concentrating Photovoltaic (BICPV) Smart Window System. Sol. Energy 2021, 220, 722–734. [Google Scholar] [CrossRef]

- Connelly, K.; Wu, Y.; Chen, J.; Lei, Y. Design and Development of a Reflective Membrane for a Novel Building Integrated Concentrating Photovoltaic (BICPV) ‘Smart Window’ System. Appl. Energy 2016, 182, 331–339. [Google Scholar] [CrossRef]

- Liu, X.; Wu, Y. Experimental Characterisation of a Smart Glazing with Tuneable Transparency, Light Scattering Ability and Electricity Generation Function. Appl. Energy 2021, 303, 117521. [Google Scholar] [CrossRef]

- Liu, X.; Wu, Y. Monte-Carlo Optical Model Coupled with Inverse Adding-Doubling for Building Integrated Photovoltaic Smart Window Design and Characterisation. Sol. Energy Mater. Sol. Cells 2021, 223, 110972. [Google Scholar] [CrossRef]

- Nie, Y.; He, W.; Liu, X.; Hu, Z.; Yu, H.; Liu, H. Smart Luminescent Solar Concentrator as a BICPV Window; Springer: Berlin/Heidelberg, Germany, 2022; pp. 1–10. [Google Scholar]

- Liu, S.; Du, Y.W.; Tso, C.Y.; Lee, H.H.; Cheng, R.; Feng, S.-P.; Yu, K.M. Organic Hybrid Perovskite (MAPbI3− xClx) for Thermochromic Smart Window with Strong Optical Regulation Ability, Low Transition Temperature, and Narrow Hysteresis Width. Adv. Funct. Mater. 2021, 31, 2010426. [Google Scholar] [CrossRef]

- Götz-Köhler, M.; Banik, U.; Meddeb, H.; Neugebohrn, N.; Berends, D.; Gehrke, K.; Vehse, M.; Agert, C. Switchable Photovoltaic Window for On-Demand Shading and Electricity Generation. Sol. Energy 2022, 232, 433–443. [Google Scholar] [CrossRef]

- Wu, Y.; Zhao, H.; Sun, H.; Duan, M.; Lin, B.; Wu, S. A Review of the Application of Radiative Sky Cooling in Buildings: Challenges and Optimization. Energy Convers. Manag. 2022, 265, 115768. [Google Scholar] [CrossRef]

- Tang, H.; Wu, J.; Li, C. Experimental and Numerical Study of a Reversible Radiative Sky Cooling PV Window. Sol. Energy 2022, 247, 441–452. [Google Scholar] [CrossRef]

- Ahmed, S.; Li, S.; Li, Z.; Xiao, G.; Ma, T. Enhanced Radiative Cooling of Solar Cells by Integration with Heat Pipe. Appl. Energy 2022, 308, 118363. [Google Scholar] [CrossRef]

- Zou, H.; Wang, C.; Yu, J.; Huang, D.; Yang, R.; Wang, R. Eliminating Greenhouse Heat Stress with Transparent Radiative Cooling Film. Cell Rep. Phys. Sci. 2023, 4, 101539. [Google Scholar] [CrossRef]

- Zhao, X.; Aili, A.; Zhao, D.; Xu, D.; Yin, X.; Yang, R. Dynamic Glazing with Switchable Solar Reflectance for Radiative Cooling and Solar Heating. Cell Rep. Phys. Sci. 2022, 3, 100853. [Google Scholar] [CrossRef]

- Liu, D.; Yang, C.; Lunt, R.R. Halide Perovskites for Selective Ultraviolet-Harvesting Transparent Photovoltaics. Joule 2018, 2, 1827–1837. [Google Scholar] [CrossRef]

- Wang, P.; Liu, Z.; Zhang, X.; Hu, M.; Zhang, L.; Fan, J. Adaptive Dynamic Building Envelope Integrated with Phase Change Material to Enhance the Heat Storage and Release Efficiency: A State-of-the-Art Review. Energy Build. 2023, 286, 112928. [Google Scholar] [CrossRef]

- Elarga, H.; Goia, F.; Zarrella, A.; Dal Monte, A.; Benini, E. Thermal and Electrical Performance of an Integrated PV-PCM System in Double Skin Façades: A Numerical Study. Sol. Energy 2016, 136, 112–124. [Google Scholar] [CrossRef]

- Elarga, H.; Dal Monte, A.; Andersen, R.K.; Benini, E. PV-PCM Integration in Glazed Building. Co-Simulation and Genetic Optimization Study. Build. Environ. 2017, 126, 161–175. [Google Scholar] [CrossRef]

- Elarga, H.; Goia, F.; Benini, E. PV-PCM Integration in Glazed Buildings. Numerical Study through MATLAB/TRNSYS Linked Model; Free University of Bozen Bolzano: Bolzano, Italy, 2017; Volume 3, p. 8. [Google Scholar]

- Ke, W.; Ji, J.; Wang, C.; Zhang, C.; Xie, H.; Tang, Y.; Lin, Y. Comparative Analysis on the Electrical and Thermal Performance of Two CdTe Multi-Layer Ventilated Windows with and without a Middle PCM Layer: A Preliminary Numerical Study. Renew. Energy 2022, 189, 1306–1323. [Google Scholar] [CrossRef]

- Ballif, C.; Haug, F.-J.; Boccard, M.; Verlinden, P.J.; Hahn, G. Status and Perspectives of Crystalline Silicon Photovoltaics in Research and Industry. Nat. Rev. Mater. 2022, 7, 597–616. [Google Scholar] [CrossRef]

- Rosa-Clot, M.; Rosa-Clot, P.; Tina, G.M.; Scandura, P.F. Submerged Photovoltaic Solar Panel: SP2. Renew. Energy 2010, 35, 1862–1865. [Google Scholar] [CrossRef]

- Uddin, M.M.; Wang, C.; Zhang, C.; Ji, J. Investigating the Energy-Saving Performance of a CdTe-Based Semi-Transparent Photovoltaic Combined Hybrid Vacuum Glazing Window System. Energy 2022, 253, 124019. [Google Scholar] [CrossRef]

- Tian, X.; Wang, J.; Yuan, S.; Ji, J.; Ke, W.; Wang, C. Investigation on the Electrical Performance of a Curved PV Roof Integrated with CIGS Cells for Traditional Chinese Houses. Energy 2023, 263, 125911. [Google Scholar] [CrossRef]

- Paudyal, B.R.; Imenes, A.G. Investigation of Temperature Coefficients of PV Modules through Field Measured Data. Sol. Energy 2021, 224, 425–439. [Google Scholar] [CrossRef]

- Adeeb, J.; Farhan, A.; Al-Salaymeh, A. Temperature Effect on Performance of Different Solar Cell Technologies. J. Ecol. Eng. 2019, 20, 249–254. [Google Scholar] [CrossRef]

- Li, J.; Li, Z.; Wang, Y.; Zhang, H. Energy Utilization and Carbon Reduction Potential of Solar Energy in Residential Blocks: A Case Study on a Tropical High-Density City in China. Sustainability 2023, 15, 12975. [Google Scholar] [CrossRef]

- Liu, D.; Sun, Y.; Wilson, R.; Wu, Y. Comprehensive Evaluation of Window-Integrated Semi-Transparent PV for Building Daylight Performance. Renew. Energy 2020, 145, 1399–1411. [Google Scholar] [CrossRef]

- Luo, W.; Kramer, R.; Kompier, M.; Smolders, K.; de Kort, Y.; van Marken Lichtenbelt, W. Effects of Correlated Color Temperature of Light on Thermal Comfort, Thermophysiology and Cognitive Performance. Build. Environ. 2023, 231, 109944. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, X.; Du, J. Glazing Type (Colour and Transmittance), Daylighting, and Human Performances at a Workspace: A Full-Scale Experiment in Beijing. Build. Environ. 2019, 153, 168–185. [Google Scholar] [CrossRef]

- Hu, Y.; Xue, Q.; Wang, H.; Zou, P.; Yang, J.; Chen, S.; Cheng, Y. Experimental Investigation on Indoor Daylight Environment of Building with Cadmium Telluride Photovoltaic Window. Energy Built Environ. 2023, 5, 404–413. [Google Scholar] [CrossRef]

- Meechoowas, E.; Poosrisoma, S.; Jampeerung, P.; Jitwatcharakomol, T. The Effect of Heat Treatment on Fe2+/Fe3+ Ratio in Soda-Lime Silicate Glass. Key Eng. Mater. 2015, 659, 194–198. [Google Scholar] [CrossRef]

- Tranell, G.; Ostrovski, O.; Jahanshahi, S. The Equilibrium Partitioning of Titanium between Ti3+ and Ti4+ Valency States in CaO-SiO2-TiOxslags. Metall. Mater. Trans. B 2002, 33, 61–67. [Google Scholar] [CrossRef]

- Fan, S.; Wang, Y.; Cao, S.; Sun, T.; Liu, P. A Novel Method for Analyzing the Effect of Dust Accumulation on Energy Efficiency Loss in Photovoltaic (PV) System. Energy 2021, 234, 121112. [Google Scholar] [CrossRef]

- Parida, B.; Iniyan, S.; Goic, R. A Review of Solar Photovoltaic Technologies. Renew. Sustain. Energy Rev. 2011, 15, 1625–1636. [Google Scholar] [CrossRef]

- Kayes, B.M.; Nie, H.; Twist, R.; Spruytte, S.G.; Reinhardt, F.; Kizilyalli, I.C.; Higashi, G.S. Higashi 27.6% Conversion Efficiency, a New Record for Single-Junction Solar Cells under 1 Sun Illumination. In Proceedings of the 2011 37th IEEE Photovoltaic Specialists Conference, Seattle, WA, USA, 19–24 June 2011; pp. 4–8. [Google Scholar]

- Aste, N.; Tagliabue, L.C.; Palladino, P.; Testa, D. Integration of a Luminescent Solar Concentrator: Effects on Daylight, Correlated Color Temperature, Illuminance Level and Color Rendering Index. Sol. Energy 2015, 114, 174–182. [Google Scholar] [CrossRef]

- Wang, H.; Lin, C.; Hu, Y.; Zhang, X.; Han, J.; Cheng, Y. Study on Indoor Adaptive Thermal Comfort Evaluation Method for Buildings Integrated with Semi-Transparent Photovoltaic Window. Build. Environ. 2023, 228, 109834. [Google Scholar] [CrossRef]

- Shi, S.; Yan, X.; Song, Y. Spatial Design Strategies for Lightweight Roofing Buildings Driven by Rain Noise Reduction; Casini, M., Ed.; Springer Nature: Singapore, 2023; pp. 383–392. [Google Scholar]

- Micheli, L.; Caballero, J.A.; Fernandez, E.F.; Smestad, G.P.; Nofuentes, G.; Mallick, T.K.; Almonacid, F. Correlating Photovoltaic Soiling Losses to Waveband and Single-Value Transmittance Measurements. Energy 2019, 180, 376–386. [Google Scholar] [CrossRef]

- Wang, J.; Tan, G.; Yang, R.; Zhao, D. Materials, Structures, and Devices for Dynamic Radiative Cooling. Cell Rep. Phys. Sci. 2022, 3, 101198. [Google Scholar] [CrossRef]

- Guo, B.; Chen, L.; Shi, S.; Ishaq, A.; Wan, D.; Chen, Z.; Zhang, L.; Luo, H.; Gao, Y. Low Temperature Fabrication of Thermochromic VO2 Thin Films by Low-Pressure Chemical Vapor Deposition. RSC Adv. 2017, 7, 10798–10805. [Google Scholar] [CrossRef]

- Li, D.; Li, Z.; Zheng, Y.; Liu, C.; Hussein, A.K.; Liu, X. Thermal Performance of a PCM-Filled Double-Glazing Unit with Different Thermophysical Parameters of PCM. Sol. Energy 2016, 133, 207–220. [Google Scholar] [CrossRef]

- Wang, S.; Zhou, Y.; Jiang, T.; Yang, R.; Tan, G.; Long, Y. Thermochromic Smart Windows with Highly Regulated Radiative Cooling and Solar Transmission. Nano Energy 2021, 89, 106440. [Google Scholar] [CrossRef]

- Kondrashov, V.I.; Polkan, G.A.; Gorina, I.N.; Bondareva, L.N.; Zverev, Y.V. Heat-Absorbing Glass: Directions of Synthesis. Glass Ceram. 2000, 57, 75–77. [Google Scholar] [CrossRef]

- Surekha, K.; Sundararajan, S. Self-Cleaning Glass. In Anti-Abrasive Nanocoatings; Elsevier: Amsterdam, The Netherlands, 2015; pp. 81–103. [Google Scholar]

- Midtdal, K.; Jelle, B.P. Self-Cleaning Glazing Products: A State-of-the-Art Review and Future Research Pathways. Sol. Energy Mater. Sol. Cells 2013, 109, 126–141. [Google Scholar] [CrossRef]

- Yang, J.; Wu, H.; Xu, X.; Huang, G.; Cen, J.; Liang, Y. Regional Climate Effects on the Optimal Thermal Resistance and Capacitance of Residential Building Walls. Energy Build. 2021, 244, 111030. [Google Scholar] [CrossRef]

- Freewan, A.A.Y. Impact of External Shading Devices on Thermal and Daylighting Performance of Offices in Hot Climate Regions. Sol. Energy 2014, 102, 14–30. [Google Scholar] [CrossRef]

- Rodriguez-Ake, A.; Xamán, J.; Hernández-López, I.; Sauceda, D.; Carranza-Chávez, F.J.; Zavala-Guillén, I. Numerical Study and Thermal Evaluation of a Triple Glass Window under Mexican Warm Climate Conditions. Energy 2022, 239, 122075. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, H.; Wang, Y.; Shi, X. Adaptive Façades: Review of Designs, Performance Evaluation, and Control Systems. Buildings 2022, 12, 2112. [Google Scholar] [CrossRef]

- Formentini, M.; Lenci, S. An Innovative Building Envelope (Kinetic Façade) with Shape Memory Alloys Used as Actuators and Sensors. Autom. Constr. 2018, 85, 220–231. [Google Scholar] [CrossRef]

- Boreyko, J.B.; Zhao, Y.; Chen, C.-H. Planar Jumping-Drop Thermal Diodes. Appl. Phys. Lett. 2011, 99, 234105. [Google Scholar] [CrossRef]

- Tang, K.; Dong, K.; Li, J.; Gordon, M.P.; Reichertz, F.G.; Kim, H.; Rho, Y.; Wang, Q.; Lin, C.-Y.; Grigoropoulos, C.P. Temperature-Adaptive Radiative Coating for All-Season Household Thermal Regulation. Science 2021, 374, 1504–1509. [Google Scholar] [CrossRef] [PubMed]

- Geng, Y.; Zhang, Z.; Yu, J.; Chen, H.; Zhou, H.; Lin, B.; Zhuang, W. An Intelligent IEQ Monitoring and Feedback System: Development and Applications. Engineering 2022, 18, 218–231. [Google Scholar] [CrossRef]

- Dai, L.; Chen, S.; Liu, J.; Gao, Y.; Zhou, J.; Chen, Z.; Cao, C.; Luo, H.; Kanehira, M. F-Doped VO 2 Nanoparticles for Thermochromic Energy-Saving Foils with Modified Color and Enhanced Solar-Heat Shielding Ability. Phys. Chem. Chem. Phys. 2013, 15, 11723–11729. [Google Scholar] [CrossRef]

- Warwick, M.E.A.; Ridley, I.; Binions, R. The Effect of Variation in the Transition Hysteresis Width and Gradient in Thermochromic Glazing Systems. Sol. Energy Mater. Sol. Cells 2015, 140, 253–265. [Google Scholar] [CrossRef]

- Kou, F.; Gong, Q.; Zou, Y.; Mo, J.; Wang, X. Solar Application Potential and Thermal Property Optimization of a Novel Zero-Carbon Heating Building. Energy Build. 2023, 279, 112688. [Google Scholar] [CrossRef]

- Vossen, F.M.; Aarts, M.P.; Debije, M.G. Debije Visual Performance of Red Luminescent Solar Concentrating Windows in an Office Environment. Energy Build. 2016, 113, 123–132. [Google Scholar] [CrossRef]

| PV Window Types | Diagram | Economics and Performance Aspects of the Application Analysis |

|---|---|---|

| Transparent CdTe PV glazing [43] |  | PV coverage rates requiring parametric design optimization, especially in different climate zones where the potential for energy savings needs to be evaluated before application; less material consumption and lower cost |

| Semi-transparent perovskite PV modules [45] |  | Available with different visible light transmittances; transmitted light color quality evaluations required |

| Spaced type PV glazing [47] |  | PV cells possibly affect the visibility of people indoors |

| See-through a-Si PV glazing [48] |  | Light transmission design optimization is necessary; transmitted light color quality evaluations are required |

| Luminescent solar concentrator (LSC) [49] |  | Collection of both diffuse and direct light; transmitted light color quality evaluations required |

| Semi-transparent organic PV glazing (OPV) [50] |  | Available in designed colors; low production costs; already available in both flexible and rigid applications; long-term stability as the key to its commercial expansion |

| Three-dimensional static solar concentrator [51] |  | Direct and diffused light can be utilized throughout the day; lower costs (smaller area of PV materials) |

| Thermochromic halide perovskite solar cells [52] |  | The transmittance of modules varies at different temperatures, which has the effect of preventing overheating; color change temperature requiring design; transmitted light color quality evaluations required |

| Facade Types | Refs. | Year | PV Materials | Variable Performance | Energy-Saving Effects |

|---|---|---|---|---|---|

| PVSDs | Mandalaki et al. [25,26] | 2012, 2014 | Monocrystalline silicon | - | Surrounding shading PVSDs have the maximum power generation, and brise soleil semifaçade louvers PVSDs have the minimum power generation; the more PV panel area used does not necessarily mean that more power is generated |

| Zhang et al. [27] | 2017 | Polycrystalline silicon | - | In the case of Hong Kong, the southern elevation is best tilted at 30° to maximize power generation, and the southern elevation is best tilted at 20° to maximize the potential for comprehensive energy-saving | |

| Taveres-Cachat et al. [28] | 2019 | Copper indium gallium selenide (CIGS) | - | With the Pareto-optimal solution, energy savings of approximately 19 kW·h/m2 can be realized | |

| Nagy et al. [29,30,31] | 2016, 2017 | Copper indium gallium selenide (CIGS) | Heat convection, thermal radiation, | A 20~80% net energy saving compared to static PV shading devices | |

| Li et al. [32] | 2019 | Polycrystalline silicon | - | The optimal tilt angles for installing PVSDs in Harbin, Beijing, Changsha, Kunming, and Guangzhou are 55°, 50°, 40°, 40°, and 30°, respectively, and the optimal PV panel width is 1.156 m | |

| Shi et al. [33] | 2022 | Monocrystalline silicon | - | The average comprehensive energy savings of different PVSDs ranged from 16.12% to 51.95% | |

| BIPV double-skin façades | Yang et al. [34,35] | 2019, 2020 | Amorphous silicon PV, dye-sensitized solar cell (DSSC), and perovskite solar cells | Heat convection | Building energy savings of up to 106% based on the set parameters in the study |

| Zhu et al. [36] | 2020 | GaAs | Heat convection | The comprehensive heat transfer coefficient is 1.179 W/(m2·K) with an exhaust heat of 143.70 W | |

| Peng et al. [37,38] | 2013, 2015 | Amorphous silicon | Heat convection | Ventilated BIPV façades can reduce indoor heat gain and increase power generation by 3% | |

| Peng et al. [39] | 2016 | Amorphous silicon | Heat convection | Electricity production of 65 kW·h per unit area per year; net electricity consumption can be reduced by about 50% | |

| BIPV windows | He et al. [41] | 2011 | Amorphous silicon | Heat convection | 46.5% reduction in indoor radiant heat gain in summer; lower inner glass surface temperature |

| Wang et al. [42] | 2021 | CdTe | Heat convection | Seasonal regulation; heat transfer energy savings of 205.76 kW·h and 333.09 kW·h in winter and summer, respectively | |

| Wang et al. [43] | 2022 | CdTe | Heat convection | Winter and summer window SHGCs are 0.28 and 0.11, respectively | |

| Lee et al. [44] | 2018 | Dye-sensitized solar cell (DSSC) | - | Photovoltaic window power generation efficiency of 2.64~4.14% | |

| Yu et al. [45] | 2020 | Perovskite | - | A power conversion efficiency of 16.7%; average visible light transmittance of 10~30% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, S.; Zhu, N. Challenges and Optimization of Building-Integrated Photovoltaics (BIPV) Windows: A Review. Sustainability 2023, 15, 15876. https://doi.org/10.3390/su152215876

Shi S, Zhu N. Challenges and Optimization of Building-Integrated Photovoltaics (BIPV) Windows: A Review. Sustainability. 2023; 15(22):15876. https://doi.org/10.3390/su152215876

Chicago/Turabian StyleShi, Shaohang, and Ning Zhu. 2023. "Challenges and Optimization of Building-Integrated Photovoltaics (BIPV) Windows: A Review" Sustainability 15, no. 22: 15876. https://doi.org/10.3390/su152215876