Fruit Phantoms for Robotic Harvesting Trials—Mango Example

Abstract

:1. Introduction

1.1. Requirement

1.2. Fruit Phantoms

1.3. Fruit Stalk Phantoms

1.4. Aim

2. Materials and Methods

2.1. Mango Fruit

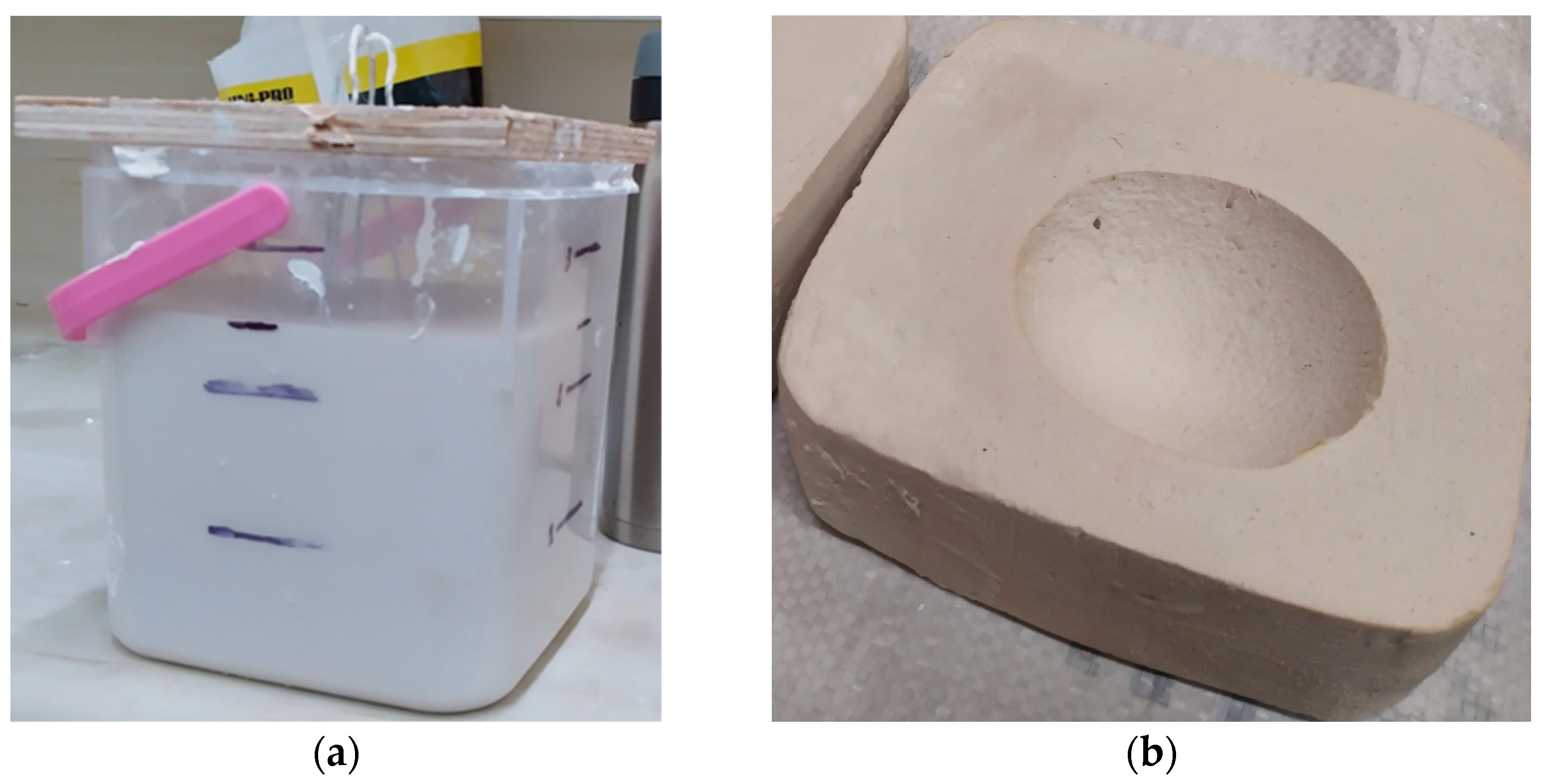

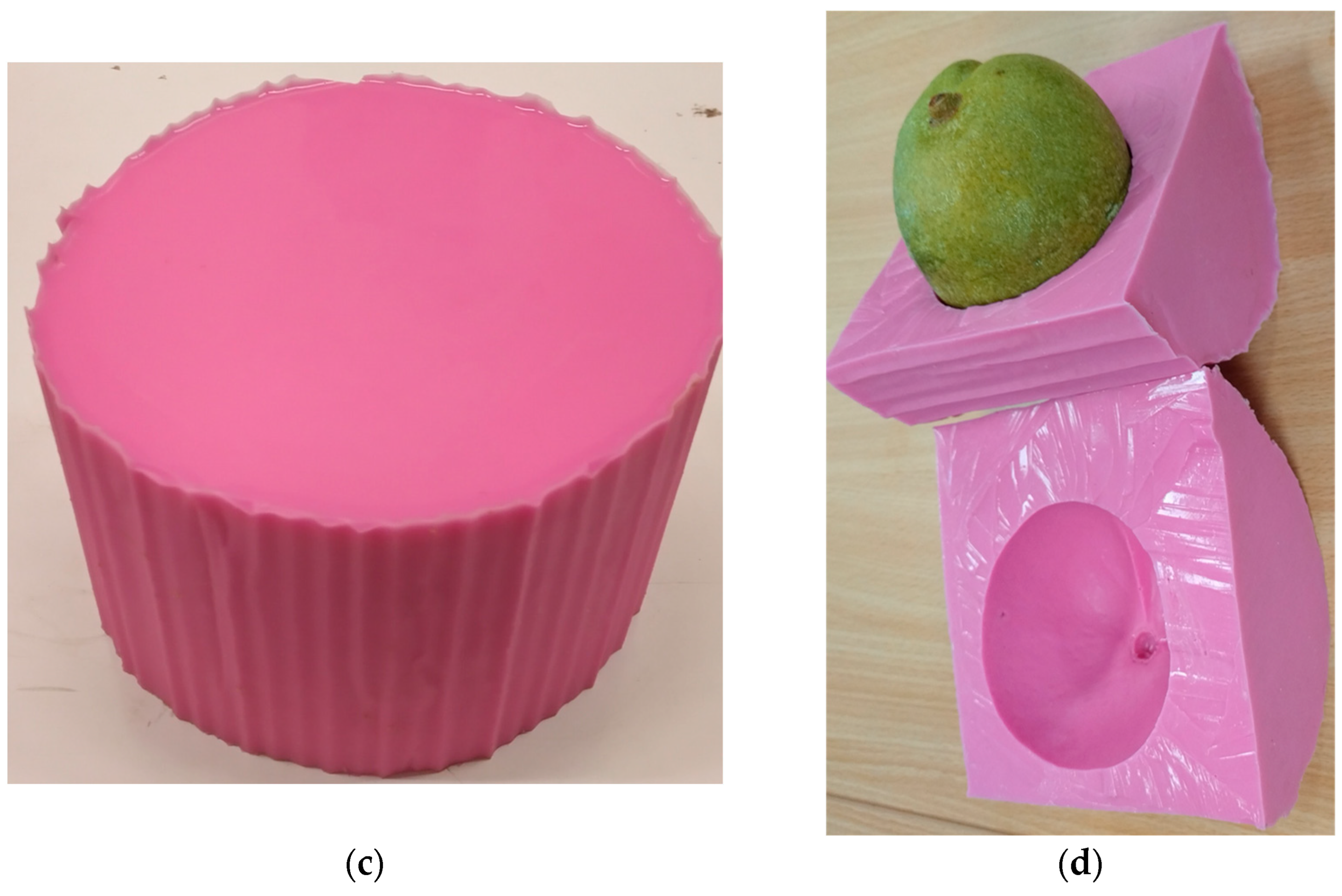

2.2. Fruit Moulds

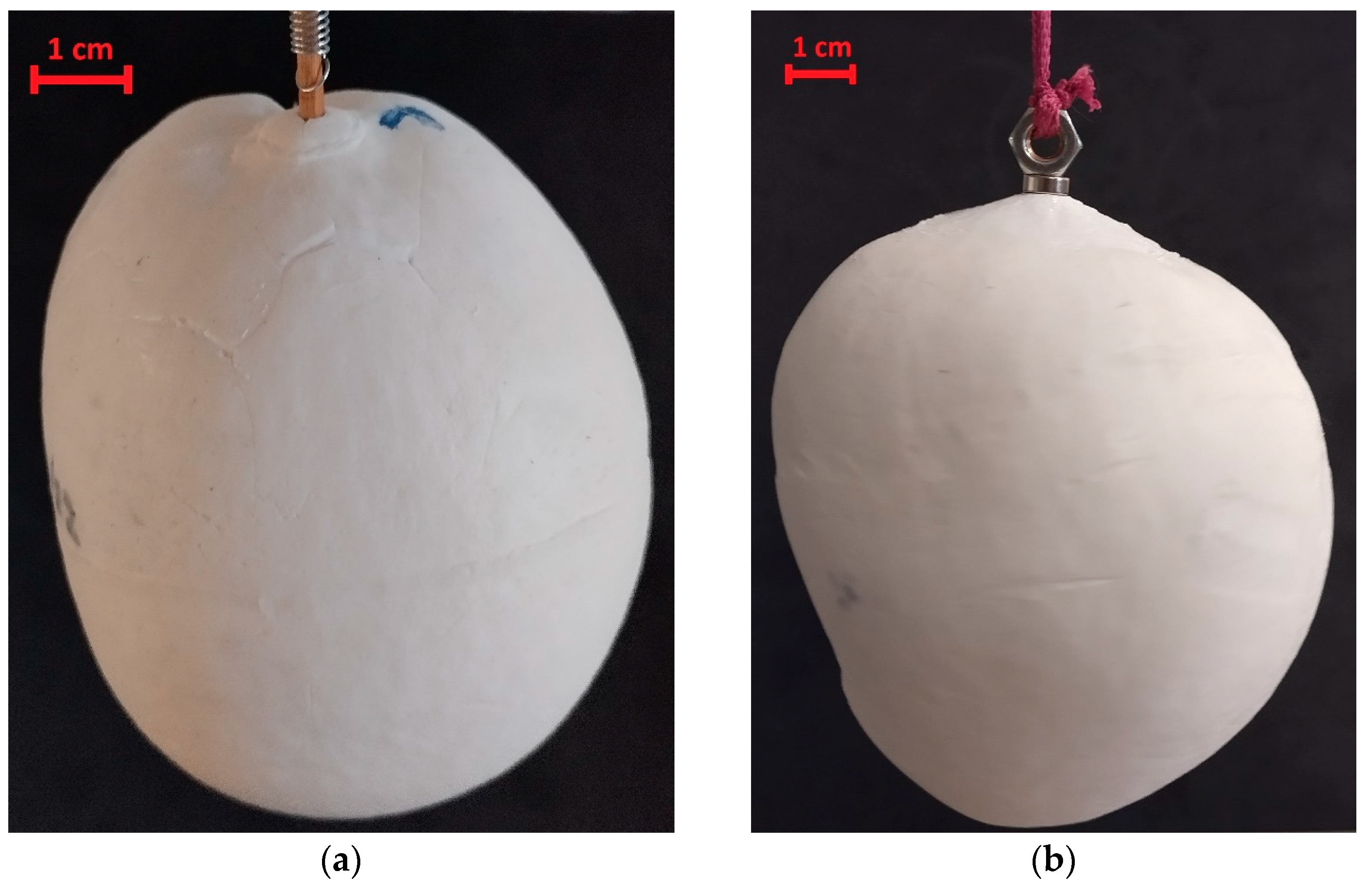

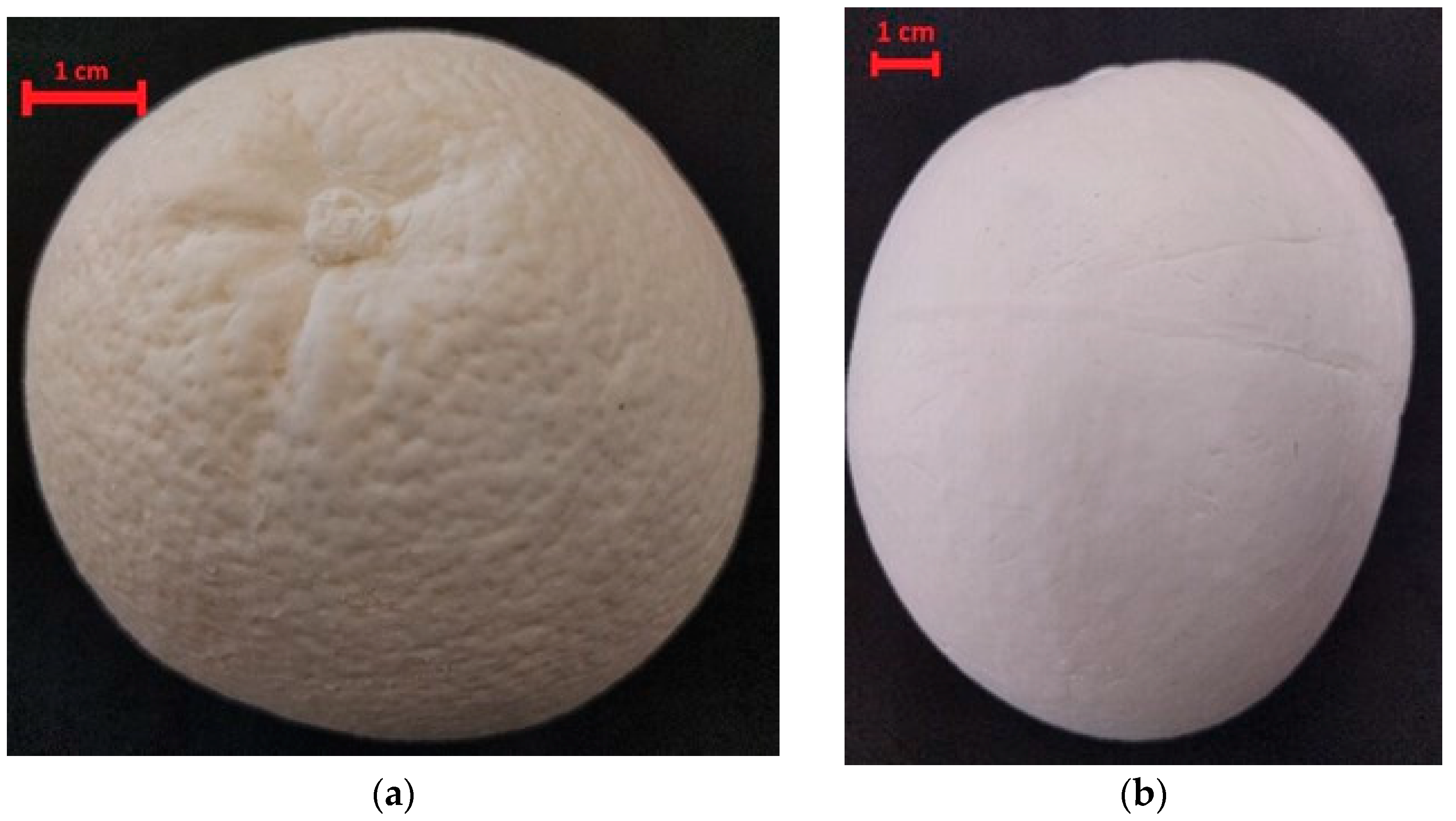

2.3. Fruit Phantoms

2.4. Fruit Peduncles (Stalk)

3. Results and Discussion

3.1. Fuit Moulds

3.2. Fruit Phantom

3.3. Fruit Model Stalk

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Original Fruit | Phantom Mass as % of Fruit Mass | |||||

|---|---|---|---|---|---|---|

| ID # | Mass (g) | Day 0 | Day 100 | Day 150 | Day 220 | Day 320 |

| A | 339 | 112 | 111 | 111 | 111 | 110 |

| B | 457 | 111 | 111 | 111 | 110 | 110 |

| C | 500 | 111 | 111 | 110 | 110 | 110 |

| D | 556 | 113 | 113 | 113 | 112 | 112 |

| E | 583 | 107 | 107 | 106 | 106 | 106 |

| F | 748 | 111 | 111 | 111 | 111 | 111 |

References

- Dale-Hallett, L.; Carlang, R. Fruit Collection in Museums Victoria. Available online: https://collections.museumsvictoria.com.au/articles/1187 (accessed on 15 August 2022).

- Supplies, C.L.a.E. Teaching Model, Fruit Model. Available online: http://www.canfortlab.com/Teaching-Model-Fruits-Model-p405.html (accessed on 1 November 2022).

- Etsy. Whole Pear Silicone Mold. Large 3D Fruit Silicone Mold for Soap. Available online: https://www.etsy.com/au/listing/917166596/whole-pear-silicone-mold-large-3d-fruit (accessed on 1 November 2022).

- Sketchfab. Fruits 3D Models. Available online: https://sketchfab.com/tags/fruits (accessed on 1 November 2022).

- Turbosquid. Professional Fruit 3D Models. Available online: https://www.turbosquid.com/3d-model/fruit (accessed on 1 November 2022).

- Defraeye, T.; Wu, W.; Prawiranto, K.; Fortunato, G.; Kemp, S.; Hartmann, S.; Cronje, P.; Verboven, P.; Nicolai, B. Artificial fruit for monitoring the thermal history of horticultural produce in the cold chain. J. Food Eng. 2017, 215, 51–60. [Google Scholar] [CrossRef]

- de Mello Vasconcelos, O.C.; de Campos Ferreira, G.J.B.; de Castro Silva, J.; Mederos, B.J.T.; de Freitas, S.T. Development of an artificial fruit prototype for monitoring mango skin and flesh temperatures during storage and transportation. Postharvest Biol. Technol. 2019, 158, 110956. [Google Scholar] [CrossRef] [Green Version]

- Drouzas, A.; Tsami, E.; Saravacos, G. Microwave/vacuum drying of model fruit gels. J. Food Eng. 1999, 39, 117–122. [Google Scholar] [CrossRef]

- Birla, S.L.; Wang, S.; Tang, J. Computer simulation of radio frequency heating of model fruit immersed in water. J. Food Eng. 2008, 84, 270–280. [Google Scholar] [CrossRef] [Green Version]

- Aweta. Produce-Mango. Available online: https://www.aweta.com/en/produce/mango (accessed on 2 November 2022).

- Lishman, M. ImpacTrack. Available online: https://martinlishman.com/impactrack/ (accessed on 2 November 2022).

- Shanker, T.; Downey, G.; Chabot, E.; Sun, Y. A Silicone human head model for testing acoustic properties of the upper airway. In Proceedings of the 2013 39th Annual Northeast Bioengineering Conference, Syracuse, NY, USA, 5–7 April 2013; pp. 247–248. [Google Scholar]

- Izdihar, K.; Abdul Razak, H.R.; Supion, N.; Karim, M.K.A.; Osman, N.H.; Norkhairunnisa, M. Structural, mechanical, and dielectric properties of polydimethylsiloxane and silicone elastomer for the fabrication of clinical-grade kidney phantom. Appl. Sci. 2021, 11, 1172. [Google Scholar] [CrossRef]

- Polymerdatabase. Poly(dimethylsiloxane). Available online: https://polymerdatabase.com/polymers/Polydimethylsiloxane.html (accessed on 2 November 2022).

- ACS. Molecule of the Week Archive-Polydimethylsiloxane. Available online: https://www.acs.org/content/acs/en/molecule-of-the-week/archive/p/polydimethylsiloxane.html (accessed on 15 August 2022).

- Ceseracciu, L.; Heredia-Guerrero, J.A.; Dante, S.; Athanassiou, A.; Bayer, I.S. Robust and biodegradable elastomers based on corn starch and polydimethylsiloxane (PDMS). ACS Appl. Mater. Interfaces 2015, 7, 3742–3753. [Google Scholar] [CrossRef] [PubMed]

- Hao, L.; Shi, Z.; Zhao, X. Mechanical behavior of starch/silicone oil/silicone rubber hybrid electric elastomer. React. Funct. Polym. 2009, 69, 165–169. [Google Scholar] [CrossRef]

- Atwood, R.C.; Lin, C.-S.; Lucas, G.M. Room Temperature Curable Silicone Sealant. U.S. Patent 6,451,440 B2, 17 September 2002. [Google Scholar]

- Wang, A. How to Make Rubber with Cornstarch & Silicon. Available online: https://www.ehow.com/how_12118905_make-rubber-cornstarch-silicon.html (accessed on 7 November 2022).

- Torregrosa, A.; Albert, F.; Aleixos, N.; Ortiz, C.; Blasco, J. Analysis of the detachment of citrus fruits by vibration using artificial vision. Biosyst. Eng. 2014, 119, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Bu, L.; Chen, C.; Hu, G.; Zhou, J.; Sugirbay, A.; Chen, J. Investigating the dynamic behavior of an apple branch-stem-fruit model using experimental and simulation analysis. Comput. Electron. Agric. 2021, 186, 106224. [Google Scholar] [CrossRef]

- Assirelli, A.; Caracciolo, G.; Cacchi, M.; Sirri, S.; Pallottino, F.; Costa, C. Evaluation of the detachment force needed for mechanical thinning of green peach fruits. Sustainability 2018, 10, 2291. [Google Scholar] [CrossRef]

- Polat, R.; Acar, I.; Bilim, C.H.; Sağlam, R.; Erol, B.A. Determination of spring rigidity and fruit detachment force with respect to harvesting technique in pistachio nut trees. Afr. J. Agric. Res. 2011, 6, 532–537. [Google Scholar]

| Process | Duration (h) |

|---|---|

| Creation of the cardboard container | 2 |

| Pinkysil™ addition to the container | 0.75 |

| Curing at room temperature | 4 |

| Curing at at 10 °C | 24 |

| Removal of mango from mould | 0.5 |

| Material | n | Density (g/cc) | Firmness (HA, Type A) | Brittleness | Surface Detail | Ease of Working |

|---|---|---|---|---|---|---|

| Fruit–Honey Gold (harvest stage) | 3 | 0.94 (0.01) | 73.7 (0.8) | n/a | n/a | n/a |

| –Kensington Pride (harvest stage) | 4 | 0.93 (0.02) | 73.1 (0.4) | n/a | n/a | n/a |

| –Keitt (harvest stage) | 2 | 0.94 (0.01) | 73.9 (0.4) | n/a | n/a | n/a |

| –R2E2 (harvest stage) | 9 | 0.98 (0.01) | 80.6 (1.2) | n/a | n/a | n/a |

| –R2E2 (eating stage) | 3 | 0.95 (0.01) | 43.9 (1.7) | n/a | n/a | n/a |

| Aweta reference ball 1 | 1 | 0.98 | 26.5 | medium | n/a | n/a |

| Aweta reference ball 2 | 1 | 0.98 | 11 | medium | n/a | a/a |

| Protite embedding acrylic resin | 1 | 1.23 | 100 | high | good | low |

| PinkySil PDMS | 3 | 1.10 | 15.0 (0.5) | low | excellent | medium |

| Sealant + Corn Starch (3:2 ratio) | 4 | 1.14 (0.01) | 28.8 (1.3) | low | good | high |

| Sealant + Corn Starch (1:1 ratio) | 1 | 1.14 | 31.0 (1.0) | low | good | high |

| Sealant + Wheat Starch (1:1 ratio) | 1 | 1.14 | 33.2 (0.6) | low | good | high |

| Material | Detachment Force (kgf) |

|---|---|

| Pre-harvest fruit | 6.5 (1.0) |

| Phantom–wooden dowel | 6.1 (0.6) |

| Phantom–magnet 1.5 kg | 1.3 (0.1) |

| Phantom–magnet 10 kg | 6.9 (1.4) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goulart, R.; Jarvis, D.; Walsh, K.B. Fruit Phantoms for Robotic Harvesting Trials—Mango Example. Sustainability 2023, 15, 1789. https://doi.org/10.3390/su15031789

Goulart R, Jarvis D, Walsh KB. Fruit Phantoms for Robotic Harvesting Trials—Mango Example. Sustainability. 2023; 15(3):1789. https://doi.org/10.3390/su15031789

Chicago/Turabian StyleGoulart, Rafael, Dennis Jarvis, and Kerry B. Walsh. 2023. "Fruit Phantoms for Robotic Harvesting Trials—Mango Example" Sustainability 15, no. 3: 1789. https://doi.org/10.3390/su15031789