Difference in Energy Input and Output in Agricultural Production under Surface Irrigation and Water-Saving Irrigation: A Case Study of Kiwi Fruit in Shaanxi

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Acquisition

2.2. Feature Parameter Extraction

2.2.1. Quantification of Production and Investment Factor Indicators

2.2.2. Energy Characteristic Parameters

2.3. Evaluation of Energy Utilization Efficiency

2.4. Data Range Standardization

3. Results Analysis

3.1. Quantification of Production and Investment Factor Indicators

3.2. Energy Characteristic Parameters

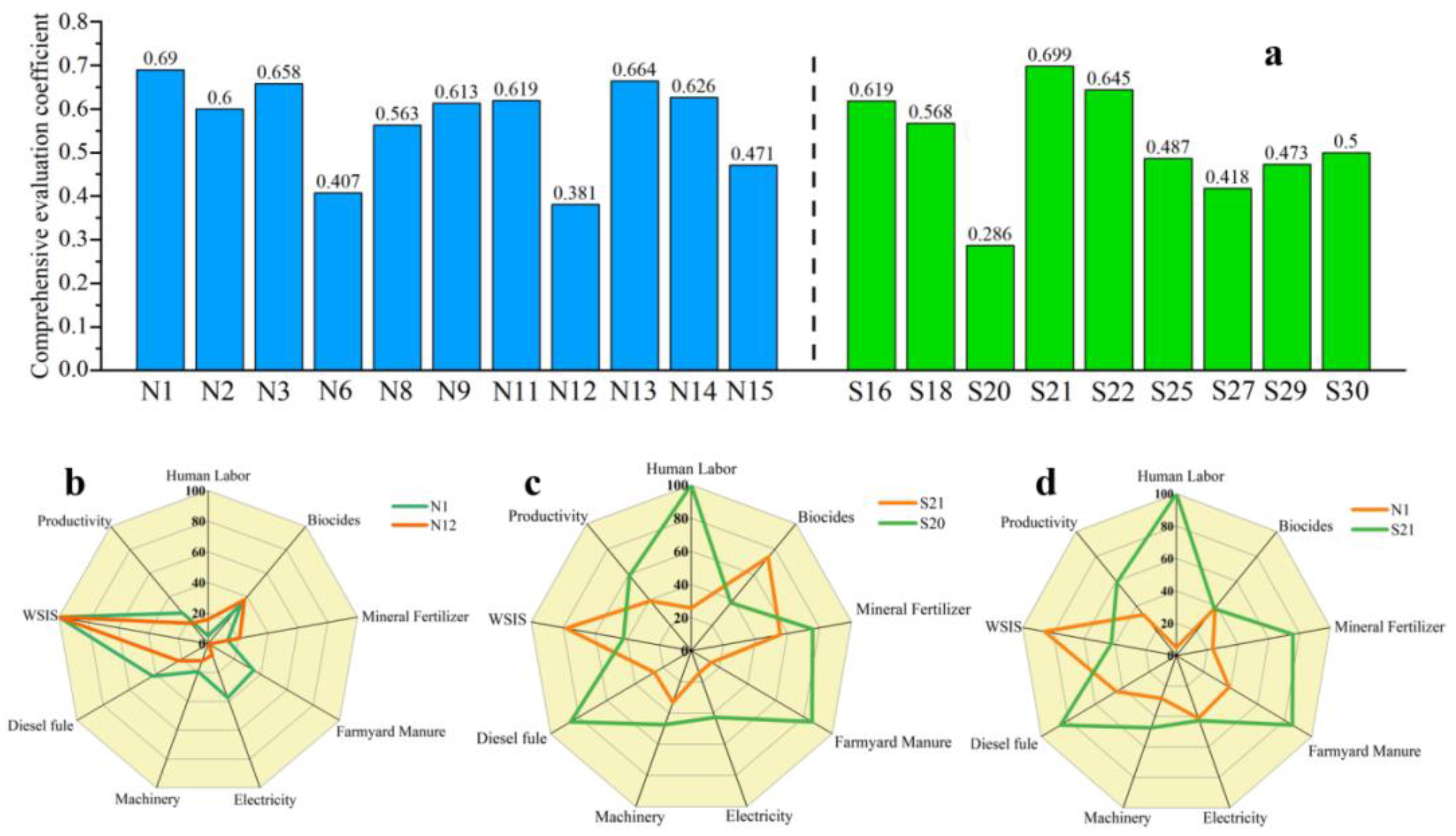

3.3. Evaluation of Energy Utilization Efficiency

3.3.1. Evaluation of the CCR-DEA Model

3.3.2. Evaluation of the ACE-DEA Model

4. Discussion

4.1. Huge Energy Saving Potential of Mineral Fertilizers

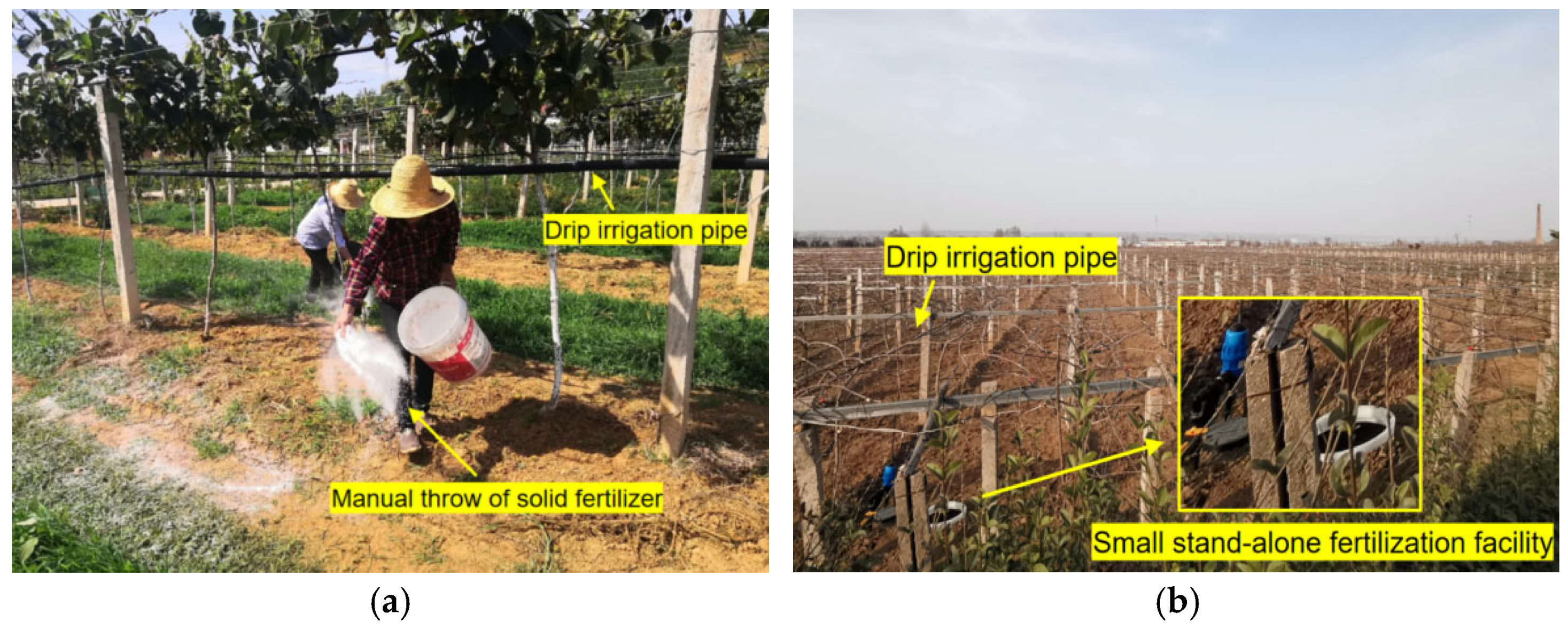

4.2. The Operation Quality of Water-Saving Irrigation Systems Needs to Be Improved Urgently

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- FAO. The 10 Elements of Agroecology: Guiding the Transition to Sustainable Food and Agricultural Systems; FAO: Rome, Italy, 2018. [Google Scholar]

- Barrios, E.; Gemmill-Herren, B.; Bicksler, A.; Siliprandi, E.; Brathwaite, R.; Moller, S.; Batello, C.; Tittonell, P. The 10 Elements of Agroecology: Enabling transitions towards sustainable agriculture and food systems through visual narratives. Ecosyst. People 2020, 16, 230–247. [Google Scholar] [CrossRef]

- Shaanxi Provincial Bureau of Statistics. 2018 Statistical Yearbook of Shaanxi Province; China Statistics Press: Beijing, China, 2018.

- Wang, Q. Research on the Cost and Benefit of Kiwifruit Growers in Shaanxi- Based on the Main Producing Areas. Ph.D. Thesis, Northwest A&F University, Xianyang, China, 2018. [Google Scholar]

- Shaanxi Provincial Bureau of Statistics. 2019 Statistical Yearbook of Shaanxi Province; China Statistics Press: Beijing, China, 2019.

- Shaanxi Provincial Bureau of Statistics. 2020 Statistical Yearbook of Shaanxi Province; China Statistics Press: Beijing, China, 2020.

- MWR (Ministry of Water Resources, PRC). China Water Statistical Yearbook 2015; China Water & Power Press: Beijing, China, 2015. (In Chinese)

- Tian, D.; Zhang, Y.; Mu, Y.; Zhou, Y.; Zhang, C.; Liu, J. The effect of drip irrigation and drip fertigation on N2O and NO emissions, water saving and grain yields in a maize field in the North China Plain. Sci. Total. Environ. 2017, 575, 1034–1040. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Zhuo, L.; Li, M.; Liu, Y.; Wu, P. The effect of development in water-saving irrigation techniques on spatial-temporal variations in crop water footprint and benchmarking. J. Hydrol. 2019, 577, 123916. [Google Scholar] [CrossRef]

- Darouich, H.M.; Pedras, C.M.; Gonçalves, J.M.; Pereira, L.S. Drip vs. surface irrigation: A comparison focusing on water saving and economic returns using multicriteria analysis applied to cotton. Biosyst. Eng. 2014, 122, 74–90. [Google Scholar] [CrossRef]

- Jacques, D.; Fox, G.; White, P. Farm level economic analysis of subsurface drip irrigation in Ontario corn production. Agric. Water Manag. 2018, 203, 333–343. [Google Scholar] [CrossRef]

- Jackson, T.M.; Khan, S.; Hafeez, M. A comparative analysis of water application and energy consumption at the irrigated field level. Agric. Water Manag. 2010, 97, 1477–1485. [Google Scholar] [CrossRef]

- Espinosa-Tasón, J.; Berbel, J.; Gutiérrez-Martín, C. Energized water: Evolution of water-energy nexus in the Spanish irrigated agriculture, 1950–2017. Agric. Water Manag. 2020, 233, 106073. [Google Scholar] [CrossRef]

- Yu, C. China’ s water crisis needs more than words. Nature 2011, 470, 307. [Google Scholar] [CrossRef]

- Burnham, M.; Ma, Z.; Zhu, D. The human dimensions of water saving irrigation: Lessons learned from Chinese smallholder farmers. Agric. Hum. Values 2015, 32, 347–360. [Google Scholar] [CrossRef]

- Yao, L.; Zhao, M.; Xu, T. China’s Water-Saving Irrigation Management System: Policy, Implementation, and Challenge. Sustainability 2017, 9, 2339. [Google Scholar] [CrossRef]

- Torki-Harchegani, M.; Ebrahimi, R.; Mahmoodi-Eshkaftaki, M. Almond production in Iran: An analysis of energy use efficiency (2008–2011). Renew. Sustain. Energy Rev. 2015, 41, 217–224. [Google Scholar] [CrossRef]

- Pellegrini, P.; Fernández, R.J. Crop intensification, land use, and on-farm energy-use efficiency during the worldwide spread of the green revolution. Proc. Natl. Acad. Sci. USA 2018, 115, 2335–2340. [Google Scholar] [CrossRef]

- Jat, S.L.; Parihar, C.M.; Singh, A.K.; Kumar, B.; Choudhary, M.; Nayak, H.S.; Parihar, M.D.; Parihar, N.; Meena, B.R. Energy auditing and carbon footprint under long-term conservation agriculture-based intensive maize systems with diverse inorganic nitrogen management options. Sci. Total Environ. 2019, 664, 659–668. [Google Scholar] [CrossRef]

- Ozkan, B.; Akcaoz, H.; Fert, C. Energy input–output analysis in Turkish agriculture. Renew. Energy 2004, 29, 39–51. [Google Scholar] [CrossRef]

- Tabar, I.B.; Keyhani, A.; Rafiee, S. Energy balance in Iran’s agronomy (1990–2006). Renew. Sustain. Energy Rev. 2010, 14, 849–855. [Google Scholar] [CrossRef]

- Hatirli, S.A.; Ozkan, B.; Fert, C. Energy inputs and crop yield relationship in greenhouse tomato production. Renew. Energy 2014, 31, 427–438. [Google Scholar] [CrossRef]

- Jones, M. Analysis of the use of energy in agriculture—Approaches and problems. Agric. Syst. 1989, 29, 339–355. [Google Scholar] [CrossRef]

- Singh, P.; Singh, G.; Sodhi, G. Applying DEA optimization approach for energy auditing in wheat cultivation under rice-wheat and cotton-wheat cropping systems in north-western India. Energy 2019, 181, 18–28. [Google Scholar] [CrossRef]

- Mousavi-Avval, S.H.; Rafiee, S.; Mohammadi, A. Optimization of energy consumption and input costs for apple production in Iran using data envelopment analysis. Energy 2011, 36, 909–916. [Google Scholar] [CrossRef]

- Muazu, A.; Yahya, A.; Ishak, W.; Khairunniza-Bejo, S. Yield Prediction Modeling Using Data Envelopment Analysis Methodology for Direct Seeding, Wetland Paddy Cultivation. Agric. Agric. Sci. Procedia 2014, 2, 181–190. [Google Scholar] [CrossRef]

- Mohseni, P.; Borghei, A.M.; Khanali, M. Coupled life cycle assessment and data envelopment analysis for mitigation of environmental impacts and enhancement of energy efficiency in grape production. J. Clean. Prod. 2018, 197, 937–947. [Google Scholar] [CrossRef]

- Elsoragaby, S.; Yahya, A.; Mahadi, M.R.; Nawi, N.M.; Mairghany, M. Energy utilization in major crop cultivation. Energy 2019, 173, 1285–1303. [Google Scholar] [CrossRef]

- Hosseini-Fashami, F.; Motevali, A.; Nabavi-Pelesaraei, A.; Hashemi, S.J.; Chau, K.W. Energy-Life cycle assessment on applying solar technologies for greenhouse strawberry production. Renew. Sustain. Energy Rev. 2019, 116, 109411. [Google Scholar] [CrossRef]

- Canakci, M.U.; Topakci, M.E.; Akinci, I.; Ozmerzi, A. Energy use pattern of some field crops and vegetable production: Case study for Antalya Region, Turkey. Energy Convers. Manag. 2005, 46, 655–666. [Google Scholar] [CrossRef]

- Rafiee, S.; Avval, S.H.M.; Mohammadi, A. Modeling and sensitivity analysis of energy inputs for apple production in Iran. Energy 2010, 35, 3301–3306. [Google Scholar] [CrossRef]

- Mobtaker, H.G.; Keyhani, A.; Mohammadi, A.; Rafiee, S.; Akram, A. Sensitivity analysis of energy inputs for barley production in Hamedan Province of Iran. Agric. Ecosyst. Environ. 2010, 137, 367–372. [Google Scholar] [CrossRef]

- Mobtaker, H.G.; Akram, A.; Keyhani, A. Energy use and sensitivity analysis of energy inputs for alfalfa production in Iran. Energy Sustain. Dev. 2012, 16, 84–89. [Google Scholar] [CrossRef]

- Mohammadi, A.; Omid, M. Economical analysis and relation between energy inputs and yield of greenhouse cucumber production in Iran. Appl. Energy 2010, 87, 191–196. [Google Scholar] [CrossRef]

- Nabavi-Pelesaraei, A.; Rafiee, S.; Hosseinzadeh-Bandbafha, H.; Shamshirband, S. Modeling energy consumption and greenhouse gas emissions for kiwifruit production using artificial neural networks. J. Clean. Prod. 2016, 133, 924–931. [Google Scholar] [CrossRef]

- Gopal, P.S.M.; Bhargavi, R. A novel approach for efficient crop yield prediction. Comput. Electron. Agric. 2019, 165, 104968. [Google Scholar] [CrossRef]

- Salehi, M.; Ebrahimi, R.; Maleki, A.; Mobtaker, H.G. An assessment of energy modeling and input costs for greenhouse button mushroom production in Iran. J. Clean. Prod. 2014, 64, 377–383. [Google Scholar] [CrossRef]

- Soltanali, H.; Nikkhah, A.; Rohani, A. Energy audit of Iranian kiwifruit production using intelligent systems. J. Energy. 2017, 139, 646–654. [Google Scholar] [CrossRef]

- Acheampong, A.O.; Boateng, E.B. Modelling carbon emission intensity: Application of artificial neural network. J. Clean. Prod. 2019, 225, 833–856. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Shariati, H.M.; Rafiee, S.; Mousazadeh, H. Comparison of energy consumption and GHG emissions of open field and green house strawberry production. Renew. Sustain. Energy Rev. 2014, 29, 316–324. [Google Scholar] [CrossRef]

- Chauhan, N.S.; Mohapatra, P.K.J.; Pandey, K.P. Improving energy productivity in paddy production through benchmarking—An application of data envelopment analysis. Energy Convers. Manag. 2006, 47, 1063–1085. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Rafiee, S.; Omid, M.; Mousazadeh, H. Applying data envelopment analysis approach to improve energy efficiency and reduce GHG (greenhouse gas) emission of wheat production. Energy 2013, 58, 588–593. [Google Scholar] [CrossRef]

- Singh, P.; Singh, G.; Sodhi, G.P.S. Energy auditing and optimization approach for improving energy efficiency of rice cultivation in south-western Punjab, India. Energy 2019, 174, 269–279. [Google Scholar] [CrossRef]

- Wang, R.C. Kiwifruit Quality Yield Anniversary Management Technology; China Agriculture Press: Beijing, China, 2000. [Google Scholar]

- Khoshroo, A.; Emrouznejad, A.; Ghaffarizadeh, A.; Kasraei, M.; Omid, M. Sensitivity analysis of energy inputs in crop production using artificial neural networks. J. Clean. Prod. 2018, 197, 992–998. [Google Scholar] [CrossRef]

- Singh, P.; Singh, G.; Sodhi, G. Energy and carbon footprints of wheat establishment following different rice residue management strategies vis-à-vis conventional tillage coupled with rice residue burning in north-western India. Energy 2020, 200, 117554. [Google Scholar] [CrossRef]

- De, D.; Singh, R.; Chandra, H. Technological impact on energy consumption in rainfed soybean cultivation in Madhya Pradesh. Appl. Energy 2001, 70, 193–213. [Google Scholar] [CrossRef]

- Pahlavan, R.; Omid, M.; Akram, A. Energy input–output analysis and application of artificial neural networks for predicting greenhouse basil production. Energy 2012, 37, 171–176. [Google Scholar] [CrossRef]

- Unakitan, G.; Hurma, H.; Yilmaz, F. An analysis of energy use efficiency of canola production in Turkey. Energy 2010, 35, 3623–3627. [Google Scholar] [CrossRef]

- Bartzas, G.; Komnitsas, K. Energy flow analysis in agriculture; the case of irrigated pistachio production in Greece. Sustain. Energy Technol. Assess. 2018, 28, 73–80. [Google Scholar] [CrossRef]

- Maestre-Valero, J.F.; Martin-Gorriz, B.; Nicolas, E.; Martinez-Mate, M.A.; Martinez-Alvarez, V. Deficit irrigation with reclaimed water in a citrus orchard. Energy and greenhouse-gas emissions analysis. Agric. Syst. 2018, 159, 93–102. [Google Scholar] [CrossRef]

- Helsel, Z.R. Energy and alternatives for fertilizer and pesticide use. In Energy in World Agriculture; Fluck, R.C., Ed.; Elsevier: Amsterdam, The Netherlands, 1992; Volume 6, pp. 177–201. [Google Scholar]

- Batty, J.C.; Keller, J. Energy Requirements for Irrigation. In Handbook of Energy Utilization in Agriculture; Pimentel, D., Ed.; CRC Press: Boca Raton, FL, USA, 1980; pp. 35–44. [Google Scholar]

- Demircan, V.; Ekinci, K.; Keener, H.M.; Akbolat, D.; Ekinci, C. Energy and economic analysis of sweet cherry production in Turkey: A case study from Isparta province. Energy Convers. Manag. 2006, 47, 1761–1769. [Google Scholar] [CrossRef]

- Singh, P.; Saini, S.P.; Sidhu, A.S. Effect evaluation of balanced fertilizer use in maize (Zea mayz L.) through yield attributes, crop efficiency and energy relationships in subtropical floodplain soils. Int. J. Agric. Sci. 2012, 8, 364–370. [Google Scholar]

- Tzanakakis, V.; Chatzakis, M.; Angelakis, A. Energetic environmental and economic assessment of three tree species and one herbaceous crop irrigated with primary treated sewage effluent. Biomass Bioenergy 2012, 47, 115–124. [Google Scholar] [CrossRef]

- Pervanchon, F.; Bockstaller, C.; Girardin, P. Assessment of energy use in arable farming systems by means of an agro-ecological indicator: The energy indicator. Agric. Syst. 2002, 72, 149–172. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Heidari, M.D.; Omid, M.; Mohammadi, A. Measuring productive efficiency of horticultural green houses in Iran: A data envelopment analysis approach. Expert Syst. Appl. 2012, 39, 1040–1045. [Google Scholar] [CrossRef]

- Cooper, W.W.; Pastor, J.T.; Aparicio, J.; Borras, F. Decomposing profit inefficiency in DEA through the weighted additive model. Eur. J. Oper. Res. 2011, 212, 411–416. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Rafiee, S.; Omid, M.; Mousazadeh, H. Reduction of CO2 emission by improving energy use efficiency of greenhouse cucumber production using DEA approach. Energy 2013, 55, 676–682. [Google Scholar] [CrossRef]

- Jamali, M.; Soufizadeh, S.; Yeganeh, B.; Emam, Y. A comparative study of irrigation techniques for energy flow and greenhouse gas (GHG) emissions in wheat agroecosystems under contrasting environments in south of Iran. Renew. Sustain. Energy Rev. 2021, 139, 110704. [Google Scholar] [CrossRef]

- Yousefi, M.; Damghani, A.M.; Khoramivafa, M. Energy consumption, greenhouse gas emissions and assessment of sustainability index in corn agroecosystems of Iran. Sci. Total. Environ. 2014, 493, 330–335. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, A.; Rafiee, S.; Mohtasebi, S.S.; Rafiee, H. Energy inputs—Yield relationship and cost analysis of kiwifruit production in Iran. Renew. Energy 2010, 35, 1071–1075. [Google Scholar] [CrossRef]

- Mardani, A.; Zavadskas, E.K.; Streimikiene, D.; Jusoh, A.; Khoshnoudi, M. A comprehensive review of data envelopment analysis (DEA) approach in energy efficiency. Renew. Sustain. Energy Rev. 2017, 70, 1298–1322. [Google Scholar] [CrossRef]

- Hu, F.; Shi, L.; Li, R.; Li, S.; Li, X.; Wang, X.; Tong, Y.A. Fertilization evaluation of kiwifruit in Guanzhong region of Shaanxi province. Soil Fertil. Sci. China 2017, 54, 44–49. [Google Scholar]

- Lu, Y.L.; Kang, T.T.; Zhang, X.J.; Gao, J.B.; Chen, Z.J.; Zhou, J.B. Evaluation of current fertilization status in kiwifruit orchards on the northern slope of Qinling Mountains: A case study of Yujiahe catchment, in Zhouzhi County. J. Plant Nutr. Fertil. 2016, 22, 380–387. [Google Scholar]

- Zhang, W.-F.; Yang, S.-Q.; Jin, Y.-H.; Liu, P.; Lou, S. The effects of straw mulching combined with nitrogen applications on the root distributions and nitrogen utilization efficiency of summer maize. Sci. Rep. 2020, 10, 21082. [Google Scholar] [CrossRef]

- IFA; IFADATA. International Fertilizer Industry Association. 2011. Available online: http://ifadata.fertilizer.org/ucSearch.aspx (accessed on 6 May 2021).

- Zhang, X.; Davidson, E.A.; Mauzerall, D.L.; Searchinger, T.D.; Dumas, P.; Shen, Y. Managing nitrogen for sustainable development. Nature 2015, 528, 51. [Google Scholar] [CrossRef]

- Guo, J.H.; Liu, X.J.; Zhang, Y.; Shen, J.L.; Han, W.X.; Zhang, W.F.; Christie, P.; Goulding, K.W.T.; Vitousek, P.M.; Zhang, F.S. Significant Acidification in Major Chinese Croplands. Science 2010, 327, 1008–1010. [Google Scholar] [CrossRef]

- Diaz, R.J.; Rosenberg, R. Spreading Dead Zones and Consequences for Marine Ecosystems. Science 2008, 321, 926–929. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Cao, G.; Li, X.; Zhang, H.; Wang, C.; Liu, Q.; Chen, X.; Cui, Z.; Shen, J.; Jiang, R.; et al. Closing yield gaps in China by empowering smallholder farmers. Nature 2016, 537, 671–674. [Google Scholar] [CrossRef] [PubMed]

- Yu, W.; Yue, Y.; Wang, F. The spatial-temporal coupling pattern of grain yield and fertilization in the North China plain. Agric. Syst. 2021, 196, 103330. [Google Scholar] [CrossRef]

- Li, H.; Mei, X.; Wang, J.; Huang, F.; Hao, W.; Li, B. Drip fertigation significantly increased crop yield, water productivity and nitrogen use efficiency with respect to traditional irrigation and fertilization practices: A meta-analysis in China. Agric. Water Manag. 2020, 244, 106534. [Google Scholar] [CrossRef]

- Cremades, R.; Wang, J.; Morris, J. Policies, economic incentives and the adoption of modern irrigation technology in China. Earth Syst. Dyn. 2015, 6, 399–410. [Google Scholar] [CrossRef]

- Huang, J.K.; Jin, S.Z. Who will farm in the future: From the perspective of intergenerational differences in the employment of rural households in China. J. Agrotech. Econ. 2015, 4–10. [Google Scholar]

- Alam, K. Farmers’ adaptation to water scarcity in drought-prone environments: A case study of Rajshahi District, Bangladesh. Agric. Water Manag. 2015, 148, 196–206. [Google Scholar] [CrossRef]

| Production Process | Unit | Energy Equivalents (MJ Unit−1) | References |

|---|---|---|---|

| A. Input | |||

| Human Labor | h | 1.96 | [34,47] |

| Machinery | h | 62.7 | [30] |

| Diesel fuel | L | 56.31 | [45] |

| Electricity | kW·h | 11.93 | [25,45,48] |

| Mineral fertilizer | |||

| (a) Nitrogen | kg | 66.14 | [25,34,35] |

| (b) Phosphate (P2O5) | kg | 12.44 | [31,34,35] |

| (c) Potassium (K2O) | kg | 11.15 | [34,35,49] |

| Farmyard Manure | kg | 0.3 | [34,35,50] |

| Biocides | |||

| (a) Fungicide | kg | 199 | [51,52] |

| (b) Insecticide | kg | 92 | [51,52] |

| WSIS | |||

| (a) Head system | kg | 148 | [51,53] |

| (b) Pipeline | kg | 112 | [51,53] |

| B. Output | |||

| Kiwifruit | kg | 1.9 | [20,34] |

| Energy Indices | Unit | Without WSIS | With WSIS | Guilan # | Mazandaran ## |

|---|---|---|---|---|---|

| Total energy input | MJha−1 | 85,444.07 | 72,268.24 | 104,156.03 | 30,285.62 |

| Total energy output | Mjha−1 | 59,660 | 62,341.2 | 49,512.14 | 46,639.85 |

| Energy ratio | — | 0.7 | 0.86 | 0.48 | 1.54 |

| Energy productivity | kgMJ−1 | 0.37 | 0.45 | 0.25 | 0.81 |

| Specific energy | MJkg−1 | 2.72 | 2.2 | 4.01 | 1.23 |

| Net energy | Mjha−1 | −25,784.07 | −9927.05 | −54,643.89 | 16,354.23 |

| Direct energy | Mjha−1 | 30,319.98 | 22,909.84 | 73,088.3 | 9110.45 |

| Indirect energy | Mjha−1 | 55,124.09 | 49,358.41 | 31,067.74 | 21,275.17 |

| Renewable energy | Mjha−1 | 12,624.18 | 6860.83 | 21,826.2 | 7713 |

| Non-renewable energy | Mjha−1 | 72,819.89 | 65,407.42 | 82,329.84 | 22,572.62 |

| DMU No. | CRSTE | DMU No. | CRSTE | DMU No. | CRSTE | DMU No. | CRSTE |

|---|---|---|---|---|---|---|---|

| N1 | 1.000 | N9 | 1.000 | S16 | 1.000 | S24 | 0.772 |

| N2 | 1.000 | N10 | 0.950 | S17 | 0.848 | S25 | 1.000 |

| N3 | 1.000 | N11 | 1.000 | S18 | 1.000 | S26 | 0.983 |

| N4 | 0.970 | N12 | 1.000 | S19 | 0.916 | S27 | 1.000 |

| N5 | 0.868 | N13 | 1.000 | S20 | 1.000 | S28 | 0.961 |

| N6 | 1.000 | N14 | 1.000 | S21 | 1.000 | S29 | 1.000 |

| N7 | 0.771 | N15 | 1.000 | S22 | 1.000 | S30 | 1.000 |

| N8 | 1.000 | S23 | 0.737 | S31 | 0.733 |

| Type | Particular | Average Energy Use | Average Energy Saving | % of Total Saving | % of Total Energy Used |

|---|---|---|---|---|---|

| MJ ha−1 | MJ ha−1 | ||||

| Without WSIS | Human labor | 11,507.1 | 1060.7 | 15.0 | 1.2 |

| Biocides | 6309.3 | 201.7 | 2.9 | 0.2 | |

| Mineral fertilizer | 39,253.3 | 425.0 | 6.0 | 0.5 | |

| Farmyard manure | 2921.0 | 0.0 | 0.0 | 0.0 | |

| Electricity | 12,827.7 | 3007.1 | 42.7 | 3.4 | |

| Machinery | 6168.0 | 1540.7 | 21.9 | 1.8 | |

| Diesel | 8498.0 | 815.4 | 11.6 | 0.9 | |

| WSIS | 0.0 | 0.0 | 0.0 | 0.0 | |

| Total | 87,484.4 | 7050.6 | 100.0 | 8.1 | |

| With WSIS | Human labor | 6538.6 | 529.9 | 3.74 | 0.7 |

| Biocides | 4292.2 | 300.6 | 2.12 | 0.4 | |

| Mineral fertilizer | 26,540.3 | 7913.3 | 55.83 | 10.7 | |

| Farmyard manure | 685.4 | 98.6 | 0.70 | 0.1 | |

| Electricity | 10,370.5 | 2326.0 | 16.41 | 3.2 | |

| Machinery | 6555.1 | 1577.7 | 11.13 | 2.1 | |

| Diesel | 7307.6 | 832.9 | 5.88 | 1.1 | |

| WSIS | 11,543.7 | 594.7 | 4.20 | 0.8 | |

| Total | 73,833.4 | 14,173.7 | 100.0 | 19.2 |

| Particular | Human Labor | Biocides | Mineral Fertilizer | Farmyard Manure | Electricity | Machinery | Diesel | WSIS |

|---|---|---|---|---|---|---|---|---|

| h/ha | kg/ha | kg/ha | kg/ha | kWh/ha | kg/ha | l/ha | kg | |

| Without WSIS | 5683.8 | 24.3 | 864.0 | 2495.99 | 620.00 | 113.13 | 115.37 | 0 |

| With WSIS | 1942.8 | 24.7 | 488.6 | 956.25 | 600.00 | 74.58 | 79.56 | 102.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Sun, H.; Ge, M.; Zhao, H.; Hu, Y.; Cui, C.; Wu, Z. Difference in Energy Input and Output in Agricultural Production under Surface Irrigation and Water-Saving Irrigation: A Case Study of Kiwi Fruit in Shaanxi. Sustainability 2023, 15, 3114. https://doi.org/10.3390/su15043114

Zhang Y, Sun H, Ge M, Zhao H, Hu Y, Cui C, Wu Z. Difference in Energy Input and Output in Agricultural Production under Surface Irrigation and Water-Saving Irrigation: A Case Study of Kiwi Fruit in Shaanxi. Sustainability. 2023; 15(4):3114. https://doi.org/10.3390/su15043114

Chicago/Turabian StyleZhang, Yongqiang, Hao Sun, Maosheng Ge, Hang Zhao, Yifan Hu, Changyue Cui, and Zhibin Wu. 2023. "Difference in Energy Input and Output in Agricultural Production under Surface Irrigation and Water-Saving Irrigation: A Case Study of Kiwi Fruit in Shaanxi" Sustainability 15, no. 4: 3114. https://doi.org/10.3390/su15043114

APA StyleZhang, Y., Sun, H., Ge, M., Zhao, H., Hu, Y., Cui, C., & Wu, Z. (2023). Difference in Energy Input and Output in Agricultural Production under Surface Irrigation and Water-Saving Irrigation: A Case Study of Kiwi Fruit in Shaanxi. Sustainability, 15(4), 3114. https://doi.org/10.3390/su15043114