Prioritizing the Solutions to Overcome Lean Six Sigma 4.0 Challenges in SMEs: A Contemporary Research Framework to Enhance Business Operations

Abstract

:1. Introduction

- To explore the challenges of LSS 4.0 in Indian SMEs.

- To rank the solutions of LSS 4.0 that may be used as a benchmark for its effective implementation.

2. Literature Review

2.1. Lean Six Sigma

2.2. Industry 4.0

2.3. Integrating Lean Six Sigma and Industry 4.0

2.4. Research Gaps

- It is found through the scholarly literature that although a lot of literature is available in the context of lean, six sigma, lean six sigma, and Industry 4.0, literature in the context of Lean Six Sigma 4.0 needs to be explored.

- Moreover, the present research studies have yet to identify the solutions to overcome Lean Six Sigma 4.0 challenges.

- Prioritization of solutions to overcome the LSS 4.0 challenges is not available using any mathematical modeling approach.

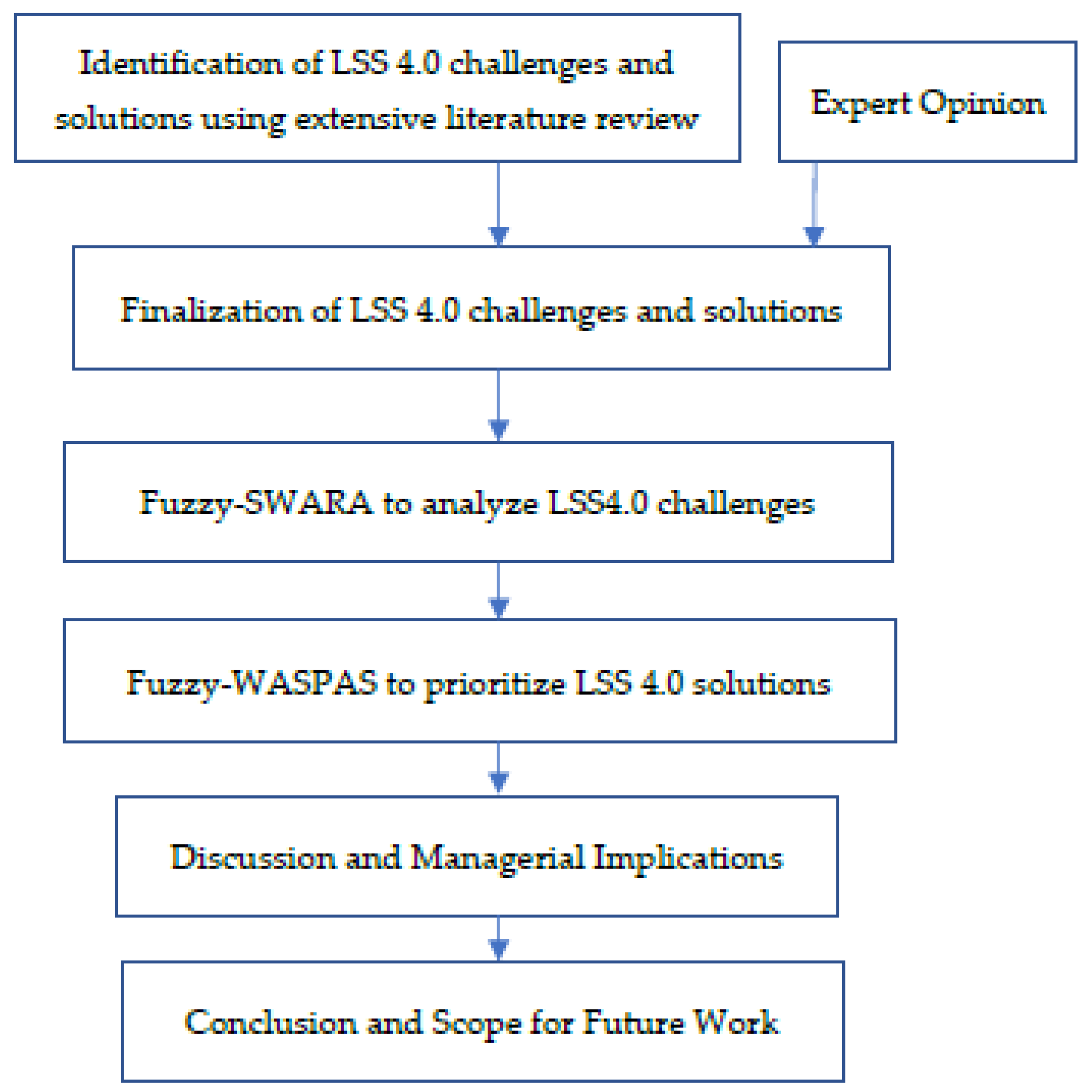

3. Research Methodology

- Phase 1: LSS 4.0 Challenges and Solutions were Identified

- Phase 2: Using fuzzy-SWARA to calculate the weight of LSS4.0 challenges

- Phase 3: Using fuzzy-WASPAS to rank the solutions for overcoming LSS4.0 challenges

3.1. Fuzzy-SWARA

3.2. Fuzzy-WASPAS

4. Case Illustration

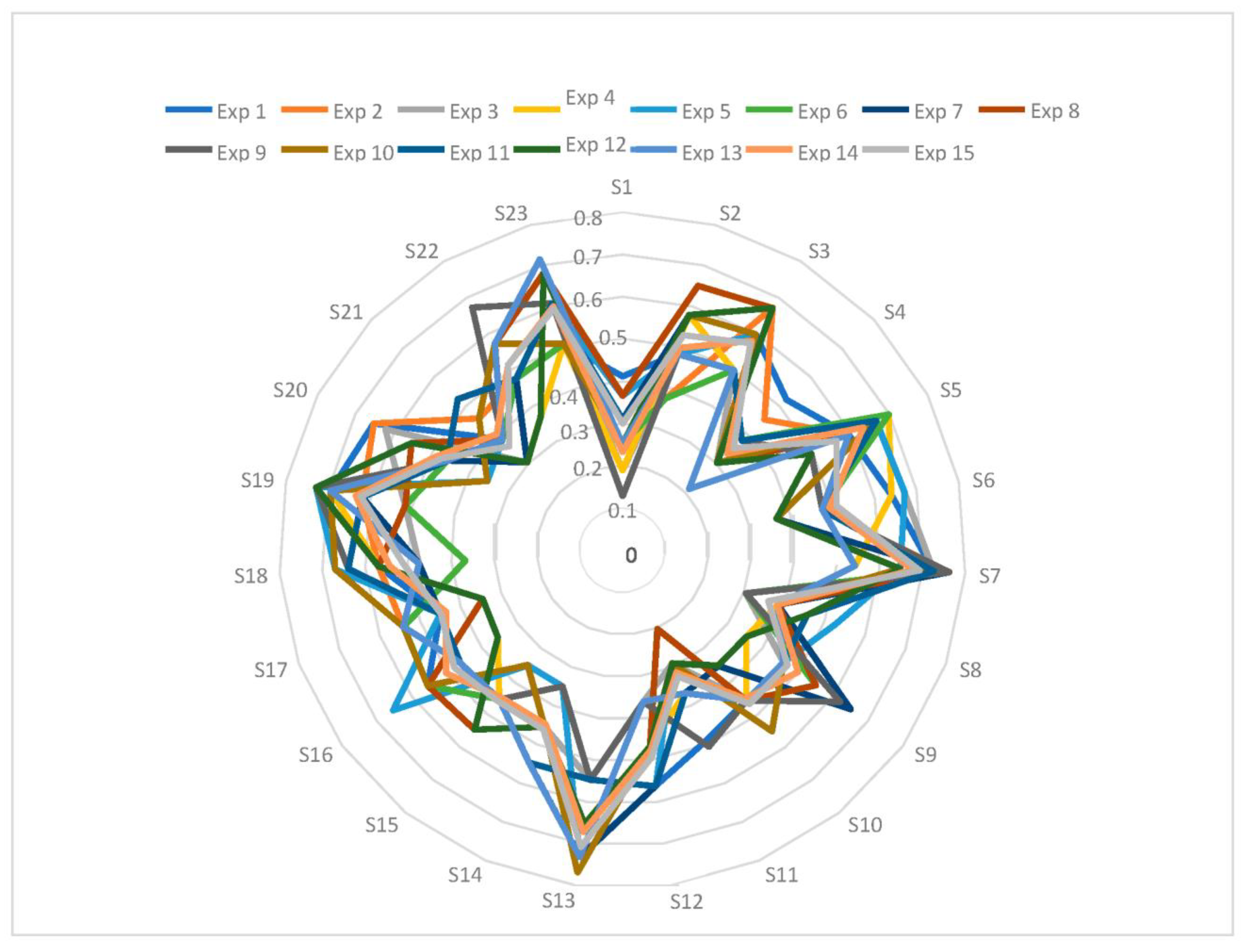

Sensitivity Analysis

5. Discussion

5.1. Theoretical Implications

5.2. Practical Implications

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Raghavan, V.A.; Yoon, S.; Srihari, K. Lean transformation in a high mix low volume electronics assembly environment. Int. J. Lean Six Sigma 2014, 5, 342–360. [Google Scholar] [CrossRef]

- Virmani, N.; Saha, R.; Sahai, R. Leagile manufacturing: A review paper. Int. J. Product. Qual. Manag. 2018, 23, 385–421. [Google Scholar] [CrossRef]

- Virmani, N.; Sharma, S.; Kumar, A.; Luthra, S. Adoption of industry 4.0 evidence in emerging economy: Behavioral reasoning theory perspective. Technol. Forecast. Soc. Chang. 2023, 188, 122317. [Google Scholar] [CrossRef]

- Virmani, N.; Saha, R.; Sahai, R. Understanding the barriers in implementing leagile manufacturing system. Int. J. Product. Qual. Manag. 2017, 22, 499–520. [Google Scholar] [CrossRef]

- Virmani, N.; Sharma, V. Prioritisation and assessment of leagile manufacturing enablers using interpretive structural modelling approach. Eur. J. Ind. Eng. 2019, 13, 701. [Google Scholar] [CrossRef]

- Virmani, N.; Salve, U.R. Significance of Human Factors and Ergonomics (HFE): Mediating Its Role Between Industry 4.0 Implementation and Operational Excellence. IEEE Trans. Eng. Manag. 2021, 1–14. [Google Scholar] [CrossRef]

- Samanta, M.; Virmani, N.; Singh, R.K.; Haque, S.N.; Jamshed, M. Analysis of critical success factors for successful integration of lean six sigma and Industry 4.0 for organizational excellence. TQM J. 2023; ahead of print. [Google Scholar] [CrossRef]

- Singh, B.; Garg, S.K.; Sharma, S.K. Lean can be a survival strategy during recessionary times. Int. J. Product. Perform. Manag. 2009, 58, 803–808. [Google Scholar] [CrossRef]

- Yadav, N.; Shankar, R.; Singh, S.P. Critical success factors for lean six sigma in quality 4.0. Int. J. Qual. Serv. Sci. 2021, 13, 123–156. [Google Scholar] [CrossRef]

- Ali, S.M.; Hossen, A.; Mahtab, Z.; Kabir, G.; Paul, S.K.; Adnan, Z.U.H. Barriers to lean six sigma implementation in the supply chain: An ISM model. Comput. Ind. Eng. 2020, 149, 106843. [Google Scholar] [CrossRef]

- Barclay, R.C.; Cudney, E.A.; Shetty, S.; Antony, J. Determining critical success factors for lean implementation. Total. Qual. Manag. Bus. Excel. 2021, 33, 818–832. [Google Scholar] [CrossRef]

- Kumar, M.; Rodrigues, V.S. Synergetic effect of lean and green on innovation: A resource-based perspective. Int. J. Prod. Econ. 2020, 219, 469–479. [Google Scholar] [CrossRef]

- Antony, J.; McDermott, O.; Powell, D.; Sony, M. The evolution and future of lean Six Sigma 4.0. TQM J. 2022; ahead of print. [Google Scholar] [CrossRef]

- Dora, M.K.; Van Goubergen, D.; Kumar, M.; Molnar, A.; Gellynck, X. Application of lean practices in small and medium-sized food enterprises. Br. Food J. 2014, 116, 125–141. [Google Scholar] [CrossRef]

- Yadav, G.; Desai, T.N. A fuzzy AHP approach to prioritize the barriers of integrated Lean Six Sigma. Int. J. Qual. Reliab. Manag. 2017, 34, 1167–1185. [Google Scholar] [CrossRef]

- Yadav, G.; Seth, D.; Desai, T.N. Application of hybrid framework to facilitate lean six sigma implementation: A manufacturing company case experience. Prod. Plan. Control. 2018, 29, 185–201. [Google Scholar] [CrossRef]

- Yadav, G.; Seth, D.; Desai, T.N. Prioritising solutions for Lean Six Sigma adoption barriers through fuzzy AHP-modified TOPSIS framework. Int. J. Lean Six Sigma 2018, 9, 270–300. [Google Scholar] [CrossRef]

- Sreedharan, V.R.; Sunder, M. V Critical success factors of TQM, Six Sigma, Lean and Lean Six Sigma: A literature review and key findings. Benchmarking Int. J. 2018, 25, 3479–3504. [Google Scholar] [CrossRef]

- Oliveira, G.A.; Tan, K.H.; Guedes, B. Lean and green approach: An evaluation tool for new product development focused on small and medium enterprises. Int. J. Prod. Econ. 2018, 205, 62–73. [Google Scholar] [CrossRef]

- Adikorley, R.D.; Rothenberg, L.; Guillory, A. Lean Six Sigma applications in the textile industry: A case study. Int. J. Lean Six Sigma 2017, 8, 210–224. [Google Scholar] [CrossRef]

- Antony, J.; Krishan, N.; Cullen, D.; Kumar, M. Lean Six Sigma for higher education institutions (HEIs): Challenges, barriers, success factors, tools/techniques. Int. J. Product. Perform. Manag. 2012, 61, 940–948. [Google Scholar] [CrossRef]

- Hilton, R.J.; Sohal, A. A conceptual model for the successful deployment of Lean Six Sigma. Int. J. Qual. Reliab. Manag. 2012, 29, 54–70. [Google Scholar] [CrossRef]

- Habidin, N.F.; Yusof, S.M. Critical success factors of Lean Six Sigma for the Malaysian automotive industry. Int. J. Lean Six Sigma 2013, 4, 60–82. [Google Scholar] [CrossRef]

- Gremyr, I.; Fouquet, J. Design for Six Sigma and lean product development. Int. J. Lean Six Sigma 2012, 3, 45–58. [Google Scholar] [CrossRef]

- Laureani, A.; Antony, J. Critical success factors for the effective implementation of Lean Sigma: Results from an empirical study and agenda for future research. Int. J. Lean Six Sigma 2012, 3, 274–283. [Google Scholar] [CrossRef]

- Kumar, S.; Luthra, S.; Govindan, K.; Kumar, N.; Haleem, A. Barriers in green lean six sigma product development process: An ISM approach. Prod. Plan. Control. 2016, 27, 604–620. [Google Scholar] [CrossRef]

- Orji, I. Examining barriers to organizational change for sustainability and drivers of sustainable performance in the metal manufacturing industry. Resour. Conserv. Recycl. 2019, 140, 102–114. [Google Scholar] [CrossRef]

- Mosterman, P.J.; Zander, J. Industry 4.0 as a Cyber-Physical System study. Softw. Syst. Model. 2016, 15, 17–29. [Google Scholar] [CrossRef]

- Hwang, G.; Lee, J.; Park, J.; Chang, T.-W. Developing performance measurement system for Internet of Things and smart factory environment. Int. J. Prod. Res. 2017, 55, 2590–2602. [Google Scholar] [CrossRef]

- Sung, T.K. Industry 4.0: A Korea Perspective. Technol. Forecast. Soc. Change 2018, 132, 40–45. [Google Scholar] [CrossRef]

- Dongfang, W.; Ponce, P.; Yu, Z.; Ponce, K.; Tanveer, M. The future of industry 4.0 and the circular economy in Chinese supply chain: In the Era of post-COVID-19 pandemic. Oper. Manag. Res. 2022, 15, 342–356. [Google Scholar] [CrossRef]

- Martín, J.M.M.; Martínez, S.C.; Martínez, J.M.G.; Soriano, D.E.R. Qualitative analysis on the driving force behind upcycling practices associated with mobile applications: Circular economy perspective. Oper. Manag. Res. 2022, 15, 647–661. [Google Scholar] [CrossRef]

- Xin, L.; Lang, S.; Mishra, A.R. Evaluate the challenges of sustainable supply chain 4.0 implementation under the circular economy concept using new decision making approach. Oper. Manag. Res. 2022, 15, 773–792. [Google Scholar] [CrossRef]

- Yin, Y.; Stecke, K.E.; Li, D. The evolution of production systems from Industry 2.0 through Industry 4.0. Int. J. Prod. Res. 2018, 56, 848–861. [Google Scholar] [CrossRef]

- Liao, Y.; Deschamps, F.; de Freitas Rocha Loures, E.; Ramos, L.F.P. Past, present and future of Industry 4.0-a systematic literature review and research agenda proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Agarwal, S.; Kant, R.; Shankar, R. Evaluating solutions to overcome humanitarian supply chain management barriers: A hybrid fuzzy SWARA—Fuzzy WASPAS approach. Int. J. Disaster Risk Reduct. 2020, 51, 101838. [Google Scholar] [CrossRef]

- Belhadi, A.; Touriki, F.E. Prioritizing the solutions of lean implementation in SMEs to overcome its barriers: An integrated fuzzy AHP-TOPSIS approach. J. Manuf. Technol. Manag. 2017, 28, 1115–1139. [Google Scholar] [CrossRef]

- Hill, J.; Thomas, A.J.; Mason-Jones, R.K.; El-Kateb, S. The implementation of a Lean Six Sigma framework to enhance operational performance in an MRO facility. Prod. Manuf. Res. 2018, 6, 26–48. [Google Scholar] [CrossRef]

- Sreedharan, V.R.; Raju, R. A systematic literature review of Lean Six Sigma in different industries. Int. J. Lean Six Sigma 2016, 7, 430–466. [Google Scholar] [CrossRef]

- Costa, L.B.M.; Godinho Filho, M.; Fredendall, L.D.; Ganga, G.M.D. Lean six sigma in the food industry: Construct development and measurement validation. Int. J. Prod. Econ. 2021, 231, 107843. [Google Scholar] [CrossRef]

- Gaikwad, S.K.; Paul, A.; Moktadir, A.; Paul, S.K.; Chowdhury, P. Analyzing barriers and strategies for implementing Lean Six Sigma in the context of Indian SMEs. Benchmarking: Int. J. 2020, 27, 2365–2399. [Google Scholar] [CrossRef]

- Vinodh, S.; Asokan, P. ISM and Fuzzy MICMAC application for analysis of Lean Six Sigma barriers with environmental considerations. Int. J. Lean Six Sigma 2018, 9, 64–90. [Google Scholar]

- Ahmad, R.; Amin, R.F.M.; Mustafa, S.A. Value stream mapping with lean thinking model for effective non-value added identification, evaluation and solution processes. Oper. Manag. Res. 2022, 15, 1490–1509. [Google Scholar] [CrossRef]

- Mishra, A.R.; Rani, P.; Pandey, K.; Mardani, A.; Streimikis, J.; Streimikiene, D.; Alrasheedi, M. Novel Multi-Criteria Intuitionistic Fuzzy SWARA–COPRAS Approach for Sustainability Evaluation of the Bioenergy Production Process. Sustainability 2020, 12, 4155. [Google Scholar] [CrossRef]

- Hettiarachchi, B.D.; Seuring, S.; Brandenburg, M. Industry 4.0-driven operations and supply chains for the circular economy: A bibliometric analysis. Oper. Manag. Res. 2022, 15, 858–878. [Google Scholar] [CrossRef]

- Jadhav, J.R.; Mantha, S.S.; Rane, S.B. Exploring barriers in lean implementation. Int. J. Lean Six Sigma 2014, 5, 122–148. [Google Scholar] [CrossRef]

- Keršulienė, V.; Zavadskas, E.K.; Turskis, Z. Selection of rational dispute resolution method by applying new step-wise weight assessment ratio analysis (SWARA). J. Bus. Econ. Manag. 2010, 11, 243–258. [Google Scholar] [CrossRef]

- Mardani, A.; Nilashi, M.; Zakuan, N.; Loganathan, N.; Soheilirad, S.; Saman, M.Z.M.; Ibrahim, O. A systematic review and meta-Analysis of SWARA and WASPAS methods: Theory and applications with recent fuzzy developments. Appl. Soft Comput. 2017, 57, 265–292. [Google Scholar] [CrossRef]

- Mishra, A.R.; Rani, P.; Pandey, K.; Mardani, A.; Streimikis, J.; Streimikiene, D.; Prajapati, H.; Kant, R.; Shankar, R. Prioritizing the solutions of reverse logistics implementation to mitigate its barriers: A hybrid modified SWARA and WASPAS approach. J. Clean. Prod. 2019, 240, 118219. [Google Scholar]

- Randhawa, J.S.; Ahuja, I.S. 5S—A quality improvement tool for sustainable performance: Literature review and directions. Int. J. Qual. Reliab. Manag. 2017, 34, 334–361. [Google Scholar] [CrossRef]

- Ruben, R.B.; Vinodh, S.; Asokan, P. Lean Six Sigma with environmental focus: Review and framework. Int. J. Adv. Manuf. Technol. 2018, 94, 4023–4037. [Google Scholar] [CrossRef]

- Salah, S.; Rahim, A. Implementing Lean Six Sigma in supply chain management. In An Integrated Company-Wide Management System; Springer: Cham, Switzerland, 2019; pp. 105–111. [Google Scholar]

- Shamsi, M.A.; Alam, A. Exploring Lean Six Sigma implementation barriers in Information Technology industry. Int. J. Lean Six Sigma 2018, 9, 523–542. [Google Scholar] [CrossRef]

- Singh, M.; Kumar, P.; Rathi, R. Modelling the barriers of Lean Six Sigma for Indian micro-small medium enterprises: An ISM and MICMAC approach. TQM J. 2019, 31, 673–695. [Google Scholar] [CrossRef]

- Sony, M.; Antony, J.; Park, S.; Mutingi, M. Key Criticisms of Six Sigma: A Systematic Literature Review. IEEE Trans. Eng. Manag. 2019, 67, 950–962. [Google Scholar] [CrossRef]

- Stankalla, R.; Koval, O.; Chromjakova, F. A review of critical success factors for the successful implementation of Lean Six Sigma and Six Sigma in manufacturing small and medium sized enterprises. Qual. Eng. 2018, 30, 453–468. [Google Scholar] [CrossRef]

- Trakulsunti, Y.; Antony, J.; Edgeman, R.; Cudney, B.; Dempsey, M.; Brennan, A. Reducing pharmacy medication errors using Lean Six Sigma: A Thai hospital case study. Total. Qual. Manag. Bus. Excel. 2022, 33, 664–682. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Turskis, Z.; Antucheviciene, J.; Zakarevicius, A. Optimization of weighted aggregated sum product assessment. Elektron. Elektrotech. 2012, 122, 3–6. [Google Scholar] [CrossRef]

| S. No. | Challenges in Implementation of Lean Six Sigma 4.0 | References |

|---|---|---|

| C1 | Lack of long-term strategic vision and mission | [26,27,28,29,30,31,32,33,34,35,36,37,38,39] |

| C2 | Lack of communication | [40,41,42] |

| C3 | Lack of training and educational programs | [37,38,39,43] |

| C4 | Lack of knowledge about benefits of LSS 4.0 | [2,10,44] |

| C5 | Cultural barriers | [22,39,45,46] |

| C6 | Employee resistance to adopting advanced technologies | [23,24] |

| C7 | Lack of top management and associated leadership skills | [26,37,47] |

| C8 | Lack of optimum utilization of resources | [35,37] |

| C9 | Lack of proper data collection strategies | [30,34] |

| C10 | Lack of IT infrastructure | [18,21,24] |

| C11 | Wrong tool selection for LSS strategies | [9,14,18] |

| C12 | Deficiency of collaboration among stakeholders | [10,14,18] |

| C13 | Lack of consultants in the field | [7,10,48] |

| C14 | Lack of motivation | [12,23] |

| C15 | Lack of empowerment and process thinking capabilities | [15,19,49] |

| C16 | Lack of estimation of execution cost | [18,22] |

| C17 | Ineffective roadmap for implementation | [25,37] |

| C18 | Lack of knowledge of LSS 4.0 tools | [23,29] |

| C19 | Poor organizational capabilities | [27,40,44] |

| C20 | Lack of performance measurement system | [50,51] |

| C21 | Conflicts among cross-functional teams | [47,52] |

| C22 | Wrong perception of LSS 4.0 as a technique, tool, or practice | [39,51,53] |

| C23 | High implementation cost | [40,54] |

| S.No. | Solutions to Overcome Lean Six Sigma Challenges | References |

|---|---|---|

| S1 | LSS 4.0 project tracking and assessment | [2,11] |

| S2 | Formation of team of experts with a project leader | [15,18,35] |

| S3 | Mutual knowledge sharing and continuous improvement culture | [30,32,39,55] |

| S4 | Developing strong project management skills | [1,19] |

| S5 | LSS 4.0 training and educational programs | [4,26,31,41] |

| S6 | Use of dedicated information technology facilities | [21,48] |

| S7 | Planning and long-term vision | [35,41,52] |

| S8 | Development of strong quality assurance system | [48,53] |

| S9 | Strong data analytics capabilities | [45,49] |

| S10 | Alignment of LSS 4.0 objectives with strategic goals | [28,38,46] |

| S11 | Create LSS4.0 dashboard | [19,24,38] |

| S12 | Providing sufficient time for transformation | [25,29,47] |

| S13 | Management participation in LSS 4.0 implementation | [17,20,29] |

| S14 | Strong communication network for change progress | [39,48] |

| S15 | Dedicated long-term planning of goals | [27,37,44] |

| S16 | Establishing supportive organizational culture | [28,41] |

| S17 | Applying change management strategies | [47,55] |

| S18 | Top management awareness regarding LSS 4.0 benefits | [37,56] |

| S19 | Optimum utilization of resources | [27,41,47] |

| S20 | Increase employee participation | [50,51,57] |

| S21 | Uniformity of work methods | [57,58] |

| S22 | Developing project management skills | [34,44,47] |

| S23 | Strong cooperation among stakeholders | [41,53] |

| Linguistic Term | Triangular Fuzzy Number |

|---|---|

| Very Less Important | (0, 0, 0.1) |

| Less Important | (0, 0.1, 0.3) |

| Not Important | (0.1, 0.3, 0.5) |

| Fairly Important | (0.3, 0.5, 0.7) |

| Important | (0.5, 0.7, 0.9) |

| High Important | (0.7, 0.9, 1) |

| Very High Important | (0.9, 1, 1) |

| Expert | Current Position | Years of Experience | Academia/Practitioner/Consultant |

|---|---|---|---|

| EX1 | CEO | 35 | Practitioner |

| EX2 | Head-CSR | 29 | Practitioner |

| EX3 | Project manager | 27 | Practitioner |

| EX4 | Director of quality management | 22 | Practitioner |

| EX5 | Lean six sigma projects leader | 16 | Practitioner |

| EX6 | Head-Quality Control | 23 | Practitioner |

| EX7 | Deputy General Manager | 29 | Practitioner |

| EX8 | Chief manufacturing executive | 22 | Practitioner |

| EX9 | Operations Head | 21 | Practitioner |

| EX10 | Assistant Project manager | 14 | Practitioner |

| EX11 | Design Head | 22 | Practitioner |

| EX12 | Executive Design Engineer | 13 | Consultant |

| EX13 | Production Manager | 21 | Consultant |

| EX14 | Executive Production Manager | 18 | Practitioner |

| EX15 | Senior Production Manager | 20 | Practitioner |

| Challenge | Comparative Importance | Coefficient Kj = Sj + 1 | Recalculated Fuzzy Weight | Relative Fuzzy Weight | Final Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C7 | 1 | 1 | 1 | 1 | 1 | 1 | 0.250 | 0.356 | 0.433 | 0.347 | |||

| C4 | 0.5 | 0.7 | 0.9 | 1.5 | 1.7 | 1.9 | 0.526 | 0.588 | 0.666 | 0.131 | 0.209 | 0.288 | 0.210 |

| C1 | 0.1 | 0.3 | 0.5 | 1.1 | 1.3 | 1.5 | 0.350 | 0.452 | 0.605 | 0.087 | 0.161 | 0.262 | 0.170 |

| C17 | 0.5 | 0.7 | 0.9 | 1.5 | 1.7 | 1.9 | 0.184 | 0.266 | 0.403 | 0.046 | 0.094 | 0.175 | 0.105 |

| C14 | 0.5 | 0.7 | 0.9 | 1.5 | 1.7 | 1.9 | 0.097 | 0.156 | 0.269 | 0.024 | 0.055 | 0.116 | 0.065 |

| C23 | 0.3 | 0.5 | 0.7 | 1.3 | 1.5 | 1.7 | 0.057 | 0.104 | 0.206 | 0.014 | 0.037 | 0.089 | 0.047 |

| C3 | 0.1 | 0.3 | 0.5 | 1.1 | 1.3 | 1.5 | 0.038 | 0.080 | 0.188 | 0.009 | 0.028 | 0.081 | 0.039 |

| C18 | 0.5 | 0.7 | 0.9 | 1.5 | 1.7 | 1.9 | 0.020 | 0.047 | 0.125 | 0.005 | 0.016 | 0.054 | 0.025 |

| C6 | 0.3 | 0.5 | 0.7 | 1.3 | 1.5 | 1.7 | 0.011 | 0.031 | 0.096 | 0.002 | 0.011 | 0.041 | 0.018 |

| C2 | 0.1 | 0.3 | 0.5 | 1.1 | 1.3 | 1.5 | 0.007 | 0.024 | 0.087 | 0.001 | 0.008 | 0.038 | 0.016 |

| C15 | 0.3 | 0.5 | 0.7 | 1.3 | 1.5 | 1.7 | 0.004 | 0.016 | 0.067 | 0.001 | 0.005 | 0.029 | 0.012 |

| C10 | 0.1 | 0.3 | 0.5 | 1.1 | 1.3 | 1.5 | 0.003 | 0.012 | 0.061 | 0.000 | 0.004 | 0.026 | 0.010 |

| C20 | 0.5 | 0.7 | 0.9 | 1.5 | 1.7 | 1.9 | 0.001 | 0.007 | 0.040 | 0.000 | 0.002 | 0.017 | 0.006 |

| C12 | 0.1 | 0.3 | 0.5 | 1.1 | 1.3 | 1.5 | 0.001 | 0.005 | 0.037 | 0.000 | 0.002 | 0.016 | 0.006 |

| C5 | 0.3 | 0.5 | 0.7 | 1.3 | 1.5 | 1.7 | 0.000 | 0.003 | 0.028 | 0.000 | 0.001 | 0.012 | 0.004 |

| C22 | 0.1 | 0.3 | 0.5 | 1.1 | 1.3 | 1.5 | 0.000 | 0.002 | 0.026 | 0.000 | 0.001 | 0.011 | 0.004 |

| C19 | 0.5 | 0.7 | 0.9 | 1.5 | 1.7 | 1.9 | 0.000 | 0.001 | 0.017 | 0.000 | 0.000 | 0.007 | 0.002 |

| C21 | 0.1 | 0.3 | 0.5 | 1.1 | 1.3 | 1.5 | 0.000 | 0.001 | 0.015 | 0.000 | 0.000 | 0.006 | 0.002 |

| C11 | 0.3 | 0.5 | 0.7 | 1.3 | 1.5 | 1.7 | 0.000 | 0.000 | 0.012 | 0.000 | 0.000 | 0.005 | 0.001 |

| C13 | 0.1 | 0.3 | 0.5 | 1.1 | 1.3 | 1.5 | 0.000 | 0.000 | 0.011 | 0.000 | 0.000 | 0.004 | 0.001 |

| C9 | 0.3 | 0.5 | 0.7 | 1.3 | 1.5 | 1.7 | 0.000 | 0.000 | 0.008 | 0.000 | 0.000 | 0.003 | 0.001 |

| C8 | 0.5 | 0.7 | 0.9 | 1.5 | 1.7 | 1.9 | 0.000 | 0.000 | 0.005 | 0.000 | 0.000 | 0.002 | 0.000 |

| C16 | 0.3 | 0.5 | 0.7 | 1.3 | 1.5 | 1.7 | 0.000 | 0.000 | 0.004 | 0.000 | 0.000 | 0.001 | 0.000 |

| 2.305 | 2.803 | 3.98524 | 0.499 | 0.888 | 1.55501 | 0.981 | |||||||

| C1 | C2 | …. | …. | C22 | C23 | |||||||||

| S1 | 0.9 | 1 | 1 | 0.1 | 0.3 | 0.5 | …. | …. | 0.9 | 1 | 1 | 0.9 | 1 | 1 |

| S2 | 0.3 | 0.5 | 0.7 | 0.1 | 0.3 | 0.5 | …. | …. | 0.1 | 0.3 | 0.5 | 0.3 | 0.5 | 0.7 |

| S3 | 0.5 | 0.7 | 0.9 | 0.7 | 0.9 | 1 | …. | …. | 0.3 | 0.5 | 0.7 | 0.3 | 0.5 | 0.7 |

| …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. |

| …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. |

| S21 | 0.3 | 0.5 | 0.7 | 0.5 | 0.7 | 0.9 | …. | …. | 0.3 | 0.5 | 0.7 | 0.1 | 0.3 | 0.5 |

| S22 | 0.5 | 0.7 | 0.9 | 0.3 | 0.5 | 0.7 | …. | …. | 0.3 | 0.5 | 0.7 | 0.5 | 0.7 | 0.9 |

| S23 | 0.3 | 0.5 | 0.7 | 0.3 | 0.5 | 0.7 | …. | …. | 0.3 | 0.5 | 0.7 | 0.3 | 0.5 | 0.7 |

| C1 | C2 | …. | …. | C22 | C23 | |||||||||

| S1 | 0.9 | 1 | 1 | 0.1 | 0.3 | 0.5 | …. | …. | 0.9 | 1 | 1 | 0.9 | 1 | 1 |

| S2 | 0.3 | 0.5 | 0.7 | 0.1 | 0.3 | 0.5 | …. | …. | 0.1 | 0.3 | 0.5 | 0.3 | 0.5 | 0.7 |

| S3 | 0.5 | 0.7 | 0.9 | 0.7 | 0.9 | 1 | …. | …. | 0.3 | 0.5 | 0.7 | 0.3 | 0.5 | 0.7 |

| …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. |

| …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. | …. |

| S21 | 0.3 | 0.5 | 0.7 | 0.5 | 0.7 | 0.9 | …. | …. | 0.3 | 0.5 | 0.7 | 0.1 | 0.3 | 0.5 |

| S22 | 0.5 | 0.7 | 0.9 | 0.3 | 0.5 | 0.7 | …. | …. | 0.3 | 0.5 | 0.7 | 0.5 | 0.7 | 0.9 |

| S23 | 0.3 | 0.5 | 0.7 | 0.3 | 0.5 | 0.7 | …. | …. | 0.3 | 0.5 | 0.7 | 0.3 | 0.5 | 0.7 |

| C1 | C2 | … | … | C22 | C23 | |||||||||

| S1 | 0.15 | 0.17 | 0.17 | 0.00 | 0.00 | 0.00 | … | … | 0.00 | 0.00 | 0.00 | 0.04 | 0.04 | 0.04 |

| S2 | 0.05 | 0.08 | 0.11 | 0.00 | 0.00 | 0.00 | … | … | 0.00 | 0.00 | 0.00 | 0.04 | 0.04 | 0.04 |

| S3 | 0.08 | 0.11 | 0.15 | 0.01 | 0.01 | 0.01 | … | … | 0.00 | 0.00 | 0.00 | 0.04 | 0.04 | 0.04 |

| …. | …. | …. | …. | …. | …. | …. | … | … | …. | …. | …. | …. | …. | …. |

| …. | …. | …. | …. | …. | …. | …. | … | … | …. | …. | …. | …. | …. | …. |

| S21 | 0.05 | 0.08 | 0.11 | 0.00 | 0.01 | 0.01 | … | … | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 | 0.02 |

| S22 | 0.08 | 0.11 | 0.15 | 0.00 | 0.00 | 0.01 | … | … | 0.00 | 0.00 | 0.00 | 0.02 | 0.03 | 0.04 |

| S23 | 0.05 | 0.08 | 0.11 | 0.00 | 0.00 | 0.01 | … | … | 0.00 | 0.00 | 0.00 | 0.01 | 0.02 | 0.03 |

| C1 | C2 | … | … | C22 | C23 | |||||||||

| S1 | 0.98 | 1.00 | 1.00 | 0.96 | 0.98 | 0.98 | … | … | 0.99 | 1.00 | 1.00 | 0.99 | 1.00 | 1.00 |

| S2 | 0.81 | 0.88 | 0.94 | 0.96 | 0.98 | 0.98 | … | … | 0.99 | 0.99 | 0.99 | 0.99 | 1.00 | 1.00 |

| S3 | 0.88 | 0.94 | 0.98 | 0.99 | 0.99 | 1.00 | … | … | 0.99 | 0.99 | 0.99 | 0.99 | 1.00 | 1.00 |

| …. | …. | …. | …. | …. | …. | …. | … | … | …. | …. | …. | …. | …. | …. |

| …. | …. | …. | …. | …. | …. | …. | … | … | …. | …. | …. | …. | …. | …. |

| S21 | 0.81 | 0.88 | 0.94 | 0.98 | 0.99 | 0.99 | … | … | 0.99 | 0.99 | 0.99 | 0.89 | 0.94 | 0.96 |

| S22 | 0.88 | 0.94 | 0.98 | 0.98 | 0.98 | 0.99 | … | … | 0.99 | 0.99 | 0.99 | 0.96 | 0.98 | 0.99 |

| S23 | 0.81 | 0.88 | 0.94 | 0.98 | 0.98 | 0.99 | … | … | 0.99 | 0.99 | 0.99 | 0.94 | 0.96 | 0.98 |

| Sol. | Aggregate Fuzzy Summation Value | 0.5 Qa, Sum | Aggregate Fuzzy Multiplication Value | 0.5 Qa, Mult | Qa | Rank | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 0.365 | 0.531 | 0.706 | 0.353 | 0.000 | 0.000 | 0.552 | 0.276 | 0.298 | 23 |

| S2 | 0.515 | 0.730 | 0.935 | 0.467 | 0.404 | 0.620 | 0.825 | 0.413 | 0.586 | 4 |

| S3 | 0.517 | 0.726 | 0.921 | 0.461 | 0.406 | 0.615 | 0.814 | 0.407 | 0.580 | 5 |

| S4 | 0.347 | 0.550 | 0.735 | 0.368 | 0.000 | 0.419 | 0.619 | 0.310 | 0.387 | 19 |

| S5 | 0.546 | 0.743 | 0.905 | 0.453 | 0.397 | 0.612 | 0.791 | 0.396 | 0.575 | 6 |

| S6 | 0.521 | 0.726 | 0.874 | 0.437 | 0.303 | 0.555 | 0.736 | 0.368 | 0.532 | 11 |

| S7 | 0.764 | 0.931 | 1.021 | 0.510 | 0.612 | 0.801 | 0.910 | 0.455 | 0.713 | 2 |

| S8 | 0.278 | 0.494 | 0.714 | 0.357 | 0.000 | 0.397 | 0.610 | 0.305 | 0.369 | 21 |

| S9 | 0.536 | 0.721 | 0.872 | 0.436 | 0.339 | 0.568 | 0.747 | 0.374 | 0.541 | 10 |

| S10 | 0.248 | 0.468 | 0.687 | 0.344 | 0.164 | 0.374 | 0.585 | 0.292 | 0.380 | 20 |

| S11 | 0.336 | 0.548 | 0.750 | 0.375 | 0.000 | 0.409 | 0.627 | 0.314 | 0.389 | 18 |

| S12 | 0.491 | 0.704 | 0.911 | 0.456 | 0.379 | 0.594 | 0.802 | 0.401 | 0.565 | 7 |

| S13 | 0.757 | 0.954 | 1.066 | 0.533 | 0.642 | 0.843 | 0.962 | 0.481 | 0.745 | 1 |

| S14 | 0.454 | 0.674 | 0.891 | 0.445 | 0.348 | 0.566 | 0.780 | 0.390 | 0.543 | 9 |

| S15 | 0.377 | 0.591 | 0.798 | 0.399 | 0.285 | 0.491 | 0.696 | 0.348 | 0.477 | 15 |

| S16 | 0.334 | 0.554 | 0.773 | 0.387 | 0.222 | 0.443 | 0.659 | 0.330 | 0.442 | 16 |

| S17 | 0.291 | 0.511 | 0.731 | 0.365 | 0.206 | 0.417 | 0.628 | 0.314 | 0.416 | 17 |

| S18 | 0.400 | 0.619 | 0.833 | 0.417 | 0.295 | 0.512 | 0.723 | 0.361 | 0.497 | 13 |

| S19 | 0.641 | 0.860 | 1.027 | 0.513 | 0.535 | 0.750 | 0.922 | 0.461 | 0.682 | 3 |

| S20 | 0.478 | 0.677 | 0.851 | 0.426 | 0.334 | 0.549 | 0.738 | 0.369 | 0.525 | 12 |

| S21 | 0.212 | 0.432 | 0.652 | 0.326 | 0.000 | 0.338 | 0.548 | 0.274 | 0.328 | 22 |

| S22 | 0.418 | 0.632 | 0.827 | 0.414 | 0.279 | 0.505 | 0.709 | 0.355 | 0.492 | 14 |

| S23 | 0.454 | 0.673 | 0.884 | 0.442 | 0.358 | 0.569 | 0.777 | 0.388 | 0.543 | 8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, P.K.; Maheswaran, R.; Virmani, N.; Raut, R.D.; Muduli, K. Prioritizing the Solutions to Overcome Lean Six Sigma 4.0 Challenges in SMEs: A Contemporary Research Framework to Enhance Business Operations. Sustainability 2023, 15, 3371. https://doi.org/10.3390/su15043371

Singh PK, Maheswaran R, Virmani N, Raut RD, Muduli K. Prioritizing the Solutions to Overcome Lean Six Sigma 4.0 Challenges in SMEs: A Contemporary Research Framework to Enhance Business Operations. Sustainability. 2023; 15(4):3371. https://doi.org/10.3390/su15043371

Chicago/Turabian StyleSingh, Priyanshu Kumar, R. Maheswaran, Naveen Virmani, Rakesh D. Raut, and Kamalakanta Muduli. 2023. "Prioritizing the Solutions to Overcome Lean Six Sigma 4.0 Challenges in SMEs: A Contemporary Research Framework to Enhance Business Operations" Sustainability 15, no. 4: 3371. https://doi.org/10.3390/su15043371

APA StyleSingh, P. K., Maheswaran, R., Virmani, N., Raut, R. D., & Muduli, K. (2023). Prioritizing the Solutions to Overcome Lean Six Sigma 4.0 Challenges in SMEs: A Contemporary Research Framework to Enhance Business Operations. Sustainability, 15(4), 3371. https://doi.org/10.3390/su15043371