Shattering Effect Study of Aramid–Steel Composite Target Plates under Localized Blast Loading

Abstract

:1. Introduction

2. Test Description

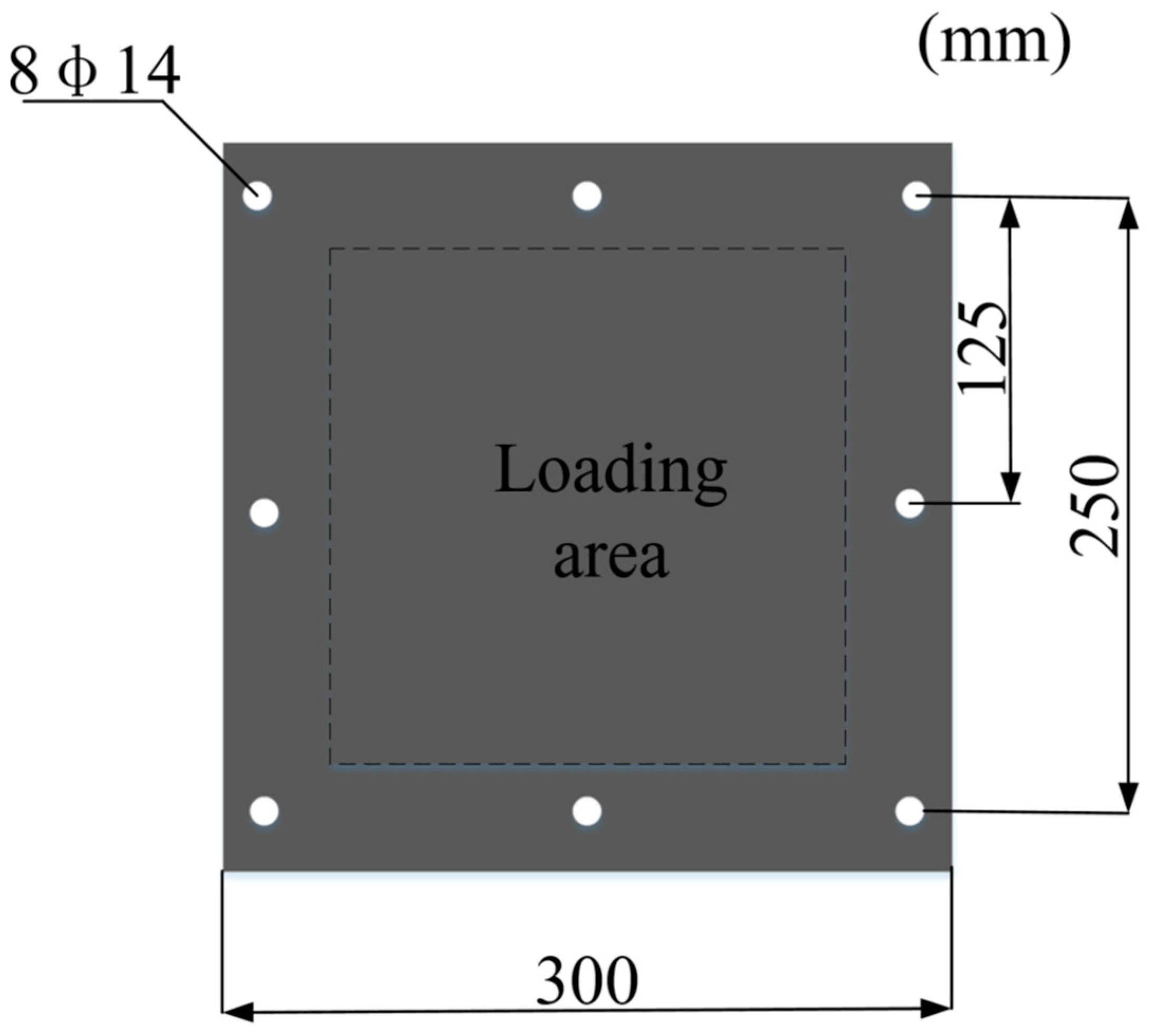

2.1. Specimen Design

2.2. Test Device

2.3. Test Result

2.3.1. Single-Layer Steel (S-1) Plate

2.3.2. Single-Layer Steel (S-2) Plate

2.3.3. Back Burst Side Stuck ASCT (SA) Plates

2.3.4. Blast Side Stuck ASCT (AS) Plates

2.3.5. Aramid Sandwich ASCT (SAS) Plates

3. Numerical Model

3.1. Finite Element Model

3.2. Material Model

3.2.1. Steel Plate

3.2.2. Adhesive

3.2.3. Aramid Fiber Composite

3.2.4. Air and Explosives

3.3. Comparison between Test Results and Numerical Results

3.3.1. Single-Layer Steel (S-1) Plate

3.3.2. Single-Layer Steel (S-2) Plate

3.3.3. Back Burst Side Sticked ASCT (SA) Plates

3.3.4. Blast Side Sticked ASCT (AS) Plates

3.3.5. Aramid Sandwich ASCT (SAS) Plates

3.4. Anti-Explosion Performance Analysis of Single-Layer Steel Plate and ASCT Plates with Different Configurations

4. Analysis of the Energy Dissipation Mechanism of the Aramid Layer in ASCT (SA) Plate

5. Failure Mode and Dimensionless Analysis of ASCT (SA) Plate

5.1. Failure Mode Analysis

5.2. Dimensionless Analysis

- Physical parameters of cylindrical TNT, including TNT charge Q, charge density ρe, and internal energy Ee released by unit mass explosive.

- Relevant physical parameters of steel plate, including density ρs, elastic modulus Es, yield strength σs, thickness D, and the side length of steel plate l.

- Physical parameters of aramid laminates, including density ρa, elastic modulus Ea, tensile strength σa, thickness d, and dimension la.

- Adhesion between steel plate and aramid laminate, including tensile failure stress σ and shear failure stress τ.

- Burst center distance parameter: the vertical distance h from the center of the cylindrical charge to the target plate surface.

5.2.1. Effect of Bursting Distance on the Deflection of the Center of an ASCT (SA) Plate

5.2.2. Effect of TNT Charge on the Deflection of the Center of the ASCT (SA) Plate

5.2.3. Effect of Aramid Layer Thickness on the Central Deflection of ASCT (SA) Plates

5.2.4. Empirical Formula of Central Deflection

6. Conclusions

- The structural configuration of the explosion-proof surface of the steel plate stuck aramid laminate can effectively improve anti-explosion performance. The test phenomena of the single-layer steel plate and ASCT plate under local explosive load are better consistent with the numerical simulation results. Through a series of different structural configurations of the explosion-resistant properties of ASCT plates, it was observed that the aramid laminate pasted on the back explosion surface of the steel plate effectively shortened the diameter of the explosion pit and reduced the center displacement deflection. The critical destructive TNT doses of single-layer steel plates and ASCT plates with different structural configurations were obtained through numerical simulation, which determined the best explosion resistance of the ASCT (SA) plate structure configuration.

- The anti-explosion mechanism of ASCT (SA) plate was analyzed from the perspective of stress wave propagation and energy absorption. The shock wave fabricated by the explosion generates reflection and transmission at the interface between the steel and aramid layer. Changing the propagation direction of the stress wave, the aramid layer reduces the strength of the reflected tensile stress wave. Aramid fiber possesses a large elastic modulus and elongation, which can absorb the energy generated by explosions and provide deformation resistance for steel plates.

- The failure modes of the ASCT (SA) plate under different TNT charge, explosive center distance, and aramid laminate thickness were analyzed by experiment and numerical calculation, and the corresponding empirical formulas were given. The results show that the central displacement deflection of the ASCT (SA) plate has an exponential relationship with TNT charge and detonation center distance. The thickness of the aramid laminate on the back surface of the steel plate has a linear relationship with the center displacement deflection of the ASCT (SA) plate, and the center displacement deflection decreases linearly with the increase in the thickness of the adhesive layer. The obtained empirical formula of central deflection can accurately predict the central deflection of the aramid–steel composite target plate under local explosion.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| ρs | Mass density of steel |

| ρa | Mass density of aramid board |

| hts | hta Thickness of steel and aramid layer |

| σ | S Stress and strength value |

| n,S | Normal and shear direction |

| T | Transmission coefficient |

| c | Wave velocity |

| ρ | Material density |

| σT | Transmission stress of steel |

| σI | Transmission stress of aramid layer |

References

- Zhongxian, L.; Du Hao, B.C. A Review of Current Researches on Blast Load Effects on Building Structures in China. Trans. Tianjin Univ. 2006, 12, 35–41. [Google Scholar]

- Wang, W.; Yang, G.; Yang, J.; Wang, J.; Wang, X. Experimental and numerical research on reinforced concrete slabs strengthened with POZD coated corrugated steel under contact explosive load. Int. J. Impact Eng. 2022, 166, 104256. [Google Scholar] [CrossRef]

- Lan, S.R.; Lok, T.S.; Heng, L. Composite structural panels subjected to explosive loading. Constr. Build. Mater. 2005, 19, 387–395. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, D.; Lu, F.; Wang, S.-C.; Tang, F. Experimental study on scaling the explosion resistance of a one-way square reinforced concrete slab under a close-in blast loading. Int. J. Impact Eng. 2012, 49, 158–164. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, D.; Lu, F.; Wang, S.-C.; Tang, F. Experimental study and numerical simulation of the damage mode of a square reinforced concrete slab under close-in explosion. Eng. Fail. Anal. 2013, 27, 41–51. [Google Scholar] [CrossRef]

- Nurick, G.N.; Gelman, M.E.; Marshall, N.S. Tearing of blast loaded plates with clamped boundary conditions. Int. J. Impact Eng. 1996, 18, 803–827. [Google Scholar] [CrossRef]

- Nurick, G.N.; Martin, J.B. Deformation of thin plates subjected to impulsive loading—A review: Part I: Theoretical considerations. Int. J. Impact Eng. 1989, 8, 159–170. [Google Scholar] [CrossRef]

- Nurick, G.N.; Martin, J.B. deformation of thin plates subjected to impulsive loading—A review part ii: Experimental studies. Int. J. Impact Eng. 1989, 8, 171–186. [Google Scholar] [CrossRef]

- Olson, M.D.; Nurick, G.N.; Fagnan, J.R. Deformation and rupture of blast loaded square plates—Predictions and experiments. Int. J. Impact Eng. 1993, 13, 279–291. [Google Scholar] [CrossRef]

- Ramajeyathilagam, K.; Vendhan, C.P. Deformation and rupture of thin rectangular plates subjected to underwater shock. Int. J. Impact Eng. 2004, 30, 699–719. [Google Scholar] [CrossRef]

- Rudrapatna, N.S.; Vaziri, R.; Olson, M.D. Deformation and failure of blast-loaded square plates. Int. J. Impact Eng. 1999, 22, 449–467. [Google Scholar] [CrossRef]

- Wen, H.M. Deformation and tearing of clamped circular work-hardening plates under impulsive loading. Int. J. Press. Vessel. Pip. 1998, 75, 67–73. [Google Scholar] [CrossRef]

- Dm, A.; Plnf, B.; Dw, C.; Ar, D. Evaluation of effectiveness of polymer coatings in reducing blast-induced deformation of steel plates. Def. Technol. 2021, 17, 1895–1904. [Google Scholar]

- Hou, H.; Chen, C.; Cheng, Y.; Zhang, P.; Wang, J. Effect of structural configuration on air blast resistance of polyurea-coated composite steel plates: Experimental studies. Mater. Des. 2019, 182, 108049. [Google Scholar] [CrossRef]

- Mkar, A.; Sm, B.; Hp, C.; Ammi, D.; Msa, E.; Ahe, F. Investigation of mechanical properties of dual-fiber reinforcement in polymer composite. J. Mater. Res. Technol. 2022, 18, 3908–3915. [Google Scholar]

- Rangasamy, G.; Mani, S.; Kolandavelu, S.K.S.; Alsoufi, M.S.; Ibrahim, A.M.M.; Muthusamy, S.; Panchal, H.; Sadasivuni, K.K.; Elsheikh, A.H. An extensive analysis of mechanical, thermal and physical properties of jute fiber composites with different fiber orientations—ScienceDirect. Case Stud. Therm. Eng. 2021, 28, 101612. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Panchal, H.; Shanmugan, S.; Muthuramalingam, T.; El-Kassas, A.M.; Ramesh, B. Recent progresses in wood-plastic composites: Pre-processing treatments, manufacturing techniques, recyclability and eco-friendly assessment. Clean. Eng. Technol. 2022, 8, 100450. [Google Scholar] [CrossRef]

- Elsheikh, A. Bistable Morphing Composites for Energy-Harvesting Applications. Polymers 2022, 14, 1893. [Google Scholar] [CrossRef]

- Wang, X.Y. Mechanical Analysis and Design of Composite Materials; National University of Defense Technology Press: Changsha, China, 1999; pp. 137–141. [Google Scholar]

- Nilakantan, G.; Merrill, R.L.; Keefe, M.; Jr, J.; Wetzel, E.D. Experimental investigation of the role of frictional yarn pull-out and windowing on the probabilistic impact response of kevlar fabrics. Compos. Part B 2015, 68, 215–229. [Google Scholar] [CrossRef]

- Ambrosetti, S.; Bozzolo, A.; Dotoli, R.; Bardaro, D.; Fay, S. Textile-Based Luggage Containers for Onboard Blast Protection. SAE Int. J. Aerosp. 2011, 4, 690–698. [Google Scholar]

- Vannucci Paolo Masi Filippo Mariano Maria, P. Blast actions in aircrafts: An integrated methodology for designing protection devices. Eng. Struct. 2018, 175, 895–911. [Google Scholar]

- Mayo, J.B.; Wetzel, E.D.; Hosur, M.V.; Jeelani, S. Stab and puncture characterization of thermoplastic-impregnated aramid fabrics. Int. J. Impact Eng. 2009, 36, 1095–1105. [Google Scholar] [CrossRef]

- Tabiei, A.; Nilakantan, G. Ballistic impact of dry woven fabric composites: A review. Appl. Mech. Rev. 2008, 61, 010801. [Google Scholar] [CrossRef]

- Palta, E.; Gutowski, M.; Fang, H. A numerical study of steel and hybrid armor plates under ballistic impacts. Int. J. Solids Struct. 2018, 136–137, 279–294. [Google Scholar] [CrossRef]

- Ramadhan, A.A.; Abu Talib, A.R.; Mohd Rafie, A.S.; Zahari, R. High velocity impact response of Kevlar-29/epoxy and 6061-T6 aluminum laminated panels. Mater. Des. 2013, 43, 307–321. [Google Scholar] [CrossRef]

- Majzoobi, G.H.; Morshedi, H.; Farhadi, K. The effect of aluminum and titanium sequence on ballistic limit of bi-metal 2/1 FMLs. Thin-Walled Struct. 2018, 122, 1–7. [Google Scholar] [CrossRef]

- Langdon, G.S.; Lemanski, S.L.; Nurick, G.N.; Simmons, M.C.; Cantwell, W.J.; Schleyer, G.K. Behaviour of fibre-metal laminates subjected to localised blast loading: Part I—Experimental observations. Int. J. Impact Eng. 2007, 34, 1202–1222. [Google Scholar] [CrossRef]

- Lemanski, S.L.; Nurick, G.N.; Langdon, G.S.; Simmons, M.C.; Cantwell, W.J.; Schleyer, G.K. Behaviour of fibre metal laminates subjected to localised blast loading—Part II: Quantitative analysis. Int. J. Impact Eng. 2007, 34, 1223–1245. [Google Scholar] [CrossRef]

- Jena, P.K.; Ramanjeneyulu, K.; Siva Kumar, K.; Balakrishna Bhat, T. Ballistic studies on layered structures. Mater. Des. 2009, 30, 1922–1929. [Google Scholar] [CrossRef]

- Qun, Z.M.; Jin, Z.M.; Chi, H.T. Study on explosion-proof detonation wave performance of armor steel/aramid composite material. Appl. Eng. Plast. 2006, 16–18. [Google Scholar]

- Dong, Y.; Yang, L.; Jin, Z.; Wu, L. Experimental and numerical analysis of ballistic impact response of fiber-reinforced composite/metal composite target. Compos. Struct. 2022, 294, 115776. [Google Scholar] [CrossRef]

- Pang, Y.; Yan, X.; Qu, J.; Wu, L. Dynamic response of polyurethane foam and fiber orthogonal corrugated sandwich structure subjected to low-velocity impact. Compos. Struct. 2022, 282, 114994. [Google Scholar] [CrossRef]

- Loikkanen, M.; Powell, D. Simulation of ballistic impact on composite panels. Mech. Eng. 2008, 1–12. [Google Scholar]

- Park, Y.; Kim, Y.H.; Baluch, A.H.; Kim, C.G. Numerical simulation and empirical comparison of the high velocity impact of STF impregnated Kevlar fabric using friction effects. Compos. Struct. 2015, 125, 520–529. [Google Scholar] [CrossRef]

- Johnson, R.; Cook, W.K. A constitutive model and data for metals subjected to large strains high strain rates and high temperatures. Eng. Fract. Mech. 1983, 21, 541–548. [Google Scholar]

- Yun, T.; Kong, X.Y.; Wu, W.G. Numerical analysis of explosion response of steel plate/Kevlar laminated structure. Chin. Ship Res. 2016, 11, 84–90. [Google Scholar]

- Navarro, P.C. Modelling of the adhesive layer in mixed ceramic/metal armours subjected to impact. Compos. Part A Appl. Sci. Manuf. 2000, 31, 823–833. [Google Scholar]

- Dogan, F.; Hadavinia, H.; Donchev, T.; Bhonge, P.S. Delamination of impacted composite structures by cohesive zone interface elements and tiebreak contact. Cent. Eur. J. Eng. 2012, 2, 612–626. [Google Scholar] [CrossRef] [Green Version]

- Chang, F.K.; Chang, K.Y. A Progressive Damage Model for Laminated Composites Containing Stress Concentrations. J. Compos. Mater. 1987, 21, 834–855. [Google Scholar] [CrossRef]

- Wang, Y.B. Study on Elastic Resistance and Failure Mechanism of Fiber Reinforced Laminated Materials; University of Science and Technology of China: Hefei, China, 2006. [Google Scholar]

- Nianming, H.U.; Chen, C.; Hou, H.; Zhu, X. Simulation on damage characteristic of composite laminates under high-velocity projectile impact. Ordnance Mater. Sci. Eng. 2017, 40, 66–70. [Google Scholar]

- Zheng, K.; Xu, X. Experimental and Numerical Study on the Mechanical Behavior of Composite Steel Structure under Explosion Load. Materials 2021, 14, 246. [Google Scholar] [CrossRef]

- Curry, R.J.; Langdon, G.S. Transient response of steel plates subjected to close proximity explosive detonations in air. Int. J. Impact Eng. 2016, 102, 102–116. [Google Scholar] [CrossRef]

- Song, B.; Hun, S.S.; Wang, L.L. Effect of Different Order of Layered Materials on the Intensity of Transmission Shock Wave. Acta Armamentarii 2000, 21, 272–274. [Google Scholar]

- Tedesco, J.W.; Landis, D.W. Wave propagation through layered systems. Comput. Struct. 1989, 32, 625–638. [Google Scholar] [CrossRef]

- Ngnra, M. Deformation and tearing of clamped circular plates subjected to localised central blast loads. In Recent Developments in Computational and Applied Mechanics; CIMNE: Barcelona, Spain, 1997; pp. 277–301. [Google Scholar]

- Jacob, N.; Yuen, S.; Nurick, G.N.; Bonorchis, D.; Desai, S.A.; Tait, D. Scaling aspects of quadrangular plates subjected to localised blast loads—Experiments and predictions. Int. J. Impact Eng. 2004, 30, 1179–1208. [Google Scholar] [CrossRef]

- Cloete, T.J.; Nurick, G.N.; Palmer, R.N. The deformation and shear failure of peripherally clamped centrally supported blast loaded circular plates. Int. J. Impact Eng. 2005, 32, 92–117. [Google Scholar] [CrossRef]

| Configuration | Geometry | Aramid Layer Position | Area Density (kg/m2) | Total Mass(kg) |

|---|---|---|---|---|

| S |  | - | 31.20 | 4.99 |

| SA |  | Rear side | 30.88 | 4.94 |

| AS |  | Front side | 30.88 | 4.94 |

| SAS |  | Sandwiched | 30.88 | 4.94 |

—Steel plate layer (marked as S)

—Steel plate layer (marked as S)  —Aramid layer (marked as A).

—Aramid layer (marked as A).| Test Piece | Steel Plate Thickness (mm) | Aramid Layer Thickness (mm) | Area Density (kg/m2) | Blasting Distance (mm) | TNT (g) |

|---|---|---|---|---|---|

| S-1 | 4.0 | - | 31.20 | 50 | 75 |

| SA | 3.6 | 2 | 30.88 | 50 | 75 |

| AS | 3.6 | 2 | 30.88 | 50 | 75 |

| ASA | 1.8 + 1.8 | 2 | 30.88 | 50 | 75 |

| S-2 | 3.6 | - | 28.08 | 50 | 75 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| ρ (kg/m3) | 7800 | m | 1.762 |

| E (GPa) | 200 | Cp | 469 |

| A (MPa) | 293.8 | D1 | 0.472 |

| B (MPa) | 230.2 | D2 | 18.728 |

| N | 0.578 | D3 | −7.805 |

| C | 0.0652 | D4 | −0.0193 |

| M | 1.762 | D5 | 13.017 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| c/s−1 | 4000 | p | 0.189 |

| E (GPa) | 2 | σ0 (GPa) | 1.3 |

| β Ep (GPa) | 0.016 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| ρ (kg/m3) | 1440 | V23 | 0.14 |

| E1 (GPa) | 21 | G12 (Gpa) | 1.3 |

| E2 (Gpa) | 21 | G23 (Gpa) | 1.3 |

| E3 (Gpa) | 4.6 | G31 (Gpa) | 1.3 |

| V12 | 0.31 | Kfail (Gpa) | 2 |

| V13 | 0.14 | AOPT | - |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| ρ (kg/m3) | 163 | B (GPa) | 3.231 |

| D (m/s) | 693 | R1 | 4.15 |

| PCJ (GPa) | 21 | R2 | 0.95 |

| A (GPa) | 37.12 | ω | 0.35 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| ρ (kg/m3) | 1.2 | C4, C5 | 0.4 |

| C0, C1, C2, C3, C6 | 0 | E (J/kg) | 2.5 |

| Test Piece No | The Total Thickness of the Plate (mm) | Center Displacement (mm) | Hole Size (mm) | Simulation Error (%) | ||

|---|---|---|---|---|---|---|

| Test Result | Simulation Results | Test Result | Simulation Results | |||

| S-1 | 4 | 28.09 | 28.05 | - | - | 0.1 |

| SA | 3.8 | 24.70 | 26.48 | - | - | 1.9 |

| AS | 3.8 | - | - | 26.08 | 24.00 | 8 |

| SAS | 3.8 | - | - | 35.00 | 34.50 | 1.43 |

| S-2 | 3.6 | 30.10 | 30.57 | - | - | 1.63 |

| Dimensionless Blast Center Distance/x1 | Dimensionless Dosage/x2 | Dimensionless Aramid Thickness/x3 | Central Deflection/y |

|---|---|---|---|

| 13.889 | 1.022 | 0.556 | 2.718 |

| 13.889 | 1.111 | 0.556 | 4.071 |

| 13.889 | 1.189 | 0.556 | 5.063 |

| 13.889 | 1.256 | 0.556 | 6.186 |

| 13.889 | 1.318 | 0.556 | 7.355 |

| 13.889 | 1.374 | 0.556 | 8.561 |

| 13.889 | 1.426 | 0.556 | 9.559 |

| 13.889 | 1.474 | 0.556 | 10.439 |

| 13.889 | 1.519 | 0.556 | 11.668 |

| 13.889 | 1.603 | 0.556 | 13.896 |

| 13.889 | 1.641 | 0.556 | 15.198 |

| 11.111 | 1.318 | 0.556 | 10.534 |

| 13.889 | 1.318 | 0.556 | 7.355 |

| 16.667 | 1.318 | 0.556 | 5.241 |

| 19.444 | 1.318 | 0.556 | 3.881 |

| 22.222 | 1.318 | 0.556 | 2.920 |

| 25.000 | 1.318 | 0.556 | 2.562 |

| 27.778 | 1.318 | 0.556 | 2.275 |

| 30.556 | 1.318 | 0.556 | 2.076 |

| 13.889 | 1.318 | 0.278 | 7.500 |

| 13.889 | 1.318 | 0.556 | 7.355 |

| 13.889 | 1.318 | 0.833 | 6.729 |

| 13.889 | 1.318 | 1.111 | 6.122 |

| 13.889 | 1.318 | 1.389 | 5.678 |

| 13.889 | 1.318 | 1.667 | 5.240 |

| 13.889 | 1.318 | 1.944 | 4.769 |

| 13.889 | 1.318 | 2.222 | 4.457 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Z.; Chen, Y.; Wang, Z.; Li, S.; Wei, W.; Chen, J. Shattering Effect Study of Aramid–Steel Composite Target Plates under Localized Blast Loading. Sustainability 2023, 15, 4160. https://doi.org/10.3390/su15054160

Gao Z, Chen Y, Wang Z, Li S, Wei W, Chen J. Shattering Effect Study of Aramid–Steel Composite Target Plates under Localized Blast Loading. Sustainability. 2023; 15(5):4160. https://doi.org/10.3390/su15054160

Chicago/Turabian StyleGao, Zhen, Yeqing Chen, Zhenqing Wang, Shutao Li, Wanli Wei, and Jialin Chen. 2023. "Shattering Effect Study of Aramid–Steel Composite Target Plates under Localized Blast Loading" Sustainability 15, no. 5: 4160. https://doi.org/10.3390/su15054160

APA StyleGao, Z., Chen, Y., Wang, Z., Li, S., Wei, W., & Chen, J. (2023). Shattering Effect Study of Aramid–Steel Composite Target Plates under Localized Blast Loading. Sustainability, 15(5), 4160. https://doi.org/10.3390/su15054160