1. Introduction

Drying is one of the oldest food processing methods. A solar dryer is a device that uses solar energy to extract moisture from various agricultural products to extend their shelf life [

1]. When compared to industrial dryers that use electricity or gas energy, solar dryers have a lower environmental impact [

2]. A few years ago, predicted equations and thin-layer models were used to calculate the performance of solar dryers [

3,

4]. However, some mobile applications and computer software have recently been developed to predict the behavior of the solar drying process using smartphone application [

5], numerical analyses with TRNSYS software [

6], and MATLAB and computational fluid dynamics (CFD) programs [

7].

A MATLAB/Simulink model was used in [

8] to predict drying performance under various weather conditions over a 10-year period. The simulated temperatures and moisture content were highly accurate when compared to those of the experimental data. However, because the drying process is a complex multi-physics and multiphase problem, a CFD model is critical for describing it. Furthermore, some CFD simulations for solar dryers have been completed [

9,

10,

11]. For instance, Sanghi et al. [

12] created a CFD model to simulate the corn drying process in a solar cabinet dryer. In [

12], the CFD model was used to simulate the dryer’s performance under overcast conditions with a lower incident solar irradiance, and the predicted removed moisture was 32% lower than in the fair-weather simulation. The predicted temperature and humidity distributions were similar to those of the experimental observations, though both temperature (8.5%) and humidity (21.4%) were overestimated. The model overpredicted the relative humidity due to the underprediction of the drying rate. Iranmanesh et al. [

13] investigated the solar CFD modeling of the system and a quality evaluation was used to investigate the performance of a solar cabinet drying system for dried apple slices. Amer and Albaloushi [

14] used a COMSOL CFD model to predict the trends of the air temperature, velocity, and performance of a solar dryer developed for drying cantaloupe.

Solar drying parameters such as drying temperature, air velocity, and other thermodynamic parameters for drying items all have an impact on the quality of fruits and vegetables. These parameters can be improved with CFD modeling and simulation techniques. It is critical to improve the efficiency of solar dryers and predict the performance of various types of solar dryers that preserve food quality [

15]. According to Amanlou and Zomorodian [

16], comparing the experimental results from the cabinet solar dryer and the predicted results from the CFD analysis’s data revealed very good correlation coefficients of 99.9% and 86.5% for the drying air temperature and air velocity in the drying chamber, respectively. Furthermore, Sonthikun et al. [

17] performed a CFD simulation for the air flow distribution inside a solar–biomass hybrid dryer to ensure the utility of air circulating fans. In terms of statistical parameters, the simulation results for temperature were found to be very close to the experimental values; the coefficient of determination and the root mean square of the percentage error varied from 0.98 to 0.99 and from 2.3% to 5.9%, respectively.

By measuring the temperature along the tunnel dryer, Hussain et al. [

18] validated the CFD model. The mean temperature difference between the experiment and the CFD simulation was found to be 1.5 °C, allowing for more qualitative insights into the temperature distribution within the collector and drying chamber. Benhamza et al. [

19] used CFD of indirect solar dryer results to determine the best configuration that ensures the most uniform drying. CFD and image processing demonstrated that a mass flow rate of 0.06 kg/s is the optimal operating condition for improving the drying uniformity and drying temperature. In [

20], Ansys Fluent software was used to visualize both the flow and thermal behavior inside a vertical hybrid photovoltaic/thermal (PV/T) solar dryer. The obtained results revealed that the deviation between the numerical and experimental findings ranged between 4.2 and 8.7%.

Recently, there has been growing interest in the impact of the PV/T collector’s design on both electrical and thermal performances. For instance, Touti et al. [

21] analyzed the geometry impact of a flat PV/T collector on its electrical and thermal performances. It has been observed that the system performance increases by increasing the number of air ducts in the PV/T collector. Recent developments of PV/T systems have heightened the need for compound parabolic concentrators (CPCs) and phase change materials (PCMs), as they are effective methods to promote both electrical and thermal performances [

22]. The integration of a CPC in a PV/T system enhances the thermal and electrical energy gain while the incorporation of PCMs boosts the cooling down of PV cells. A case study approach was adopted by Kong et al. [

22] to evaluate the effectiveness of a compound parabolic concentrating PV/T system integrated with PCMs (PV/T–CPCM). It was reported that the PV/T–CPCM system gained an important heat–electricity cogeneration performance with a maximum primary energy efficiency of 7.9%, approximately.

A 3D CFD simulation was used in [

23] to predict the flow and temperature distribution within a drying chamber. The maximum average temperature difference between the measurement and prediction by the CFD model was found to be 4.3 °C. A modeling process based on a CFD simulation was used in [

24] to diagnose the operation and determine the best solar drying operating parameters. The results of CFD combined with the experimental results gave the researchers a better understanding of the air distribution inside the dryer, which led to the avoidance of non-uniformity and the enhancement of the design. The CFD tool has also been shown to be an extremely powerful tool for the parametric study and optimization of a tray drying chamber design for use in batch-type tray dryers in leaf drying [

25].

Since the PV/T solar dryer is one of the most important types of solar dryers, some previous research has already been conducted [

4]. However, there are few research studies using CFD modeling to validate the performance of PV/T solar dryers [

2,

20] or to describe the solar drying process for tomato slices [

26]. Therefore, this paper can easily and clearly explain the performance of the solar PV/T dryer using a CFD simulation. Furthermore, we use the CFD model to simulate the air temperature and velocity distributions versus the experimental results when the drying chamber is empty (without tomato slices).

The purpose of this paper is to evaluate the performance of an indirect forced convection solar dryer equipped with a PV/T air collector. During our drying experiments of the tomato slices, the masses of the samples were instantaneously monitored together with the air temperature and relative humidity inside the PV/T collector and drying chamber. In addition, a 2D CFD model was carried out to simulate the airflow temperature and velocity inside the PV/T collector and drying chamber when the latter was empty, without the tomato slices. The CFD simulations were then compared with the experimental results.

2. Materials and Methods

2.1. PV/T Solar Dryer Setup

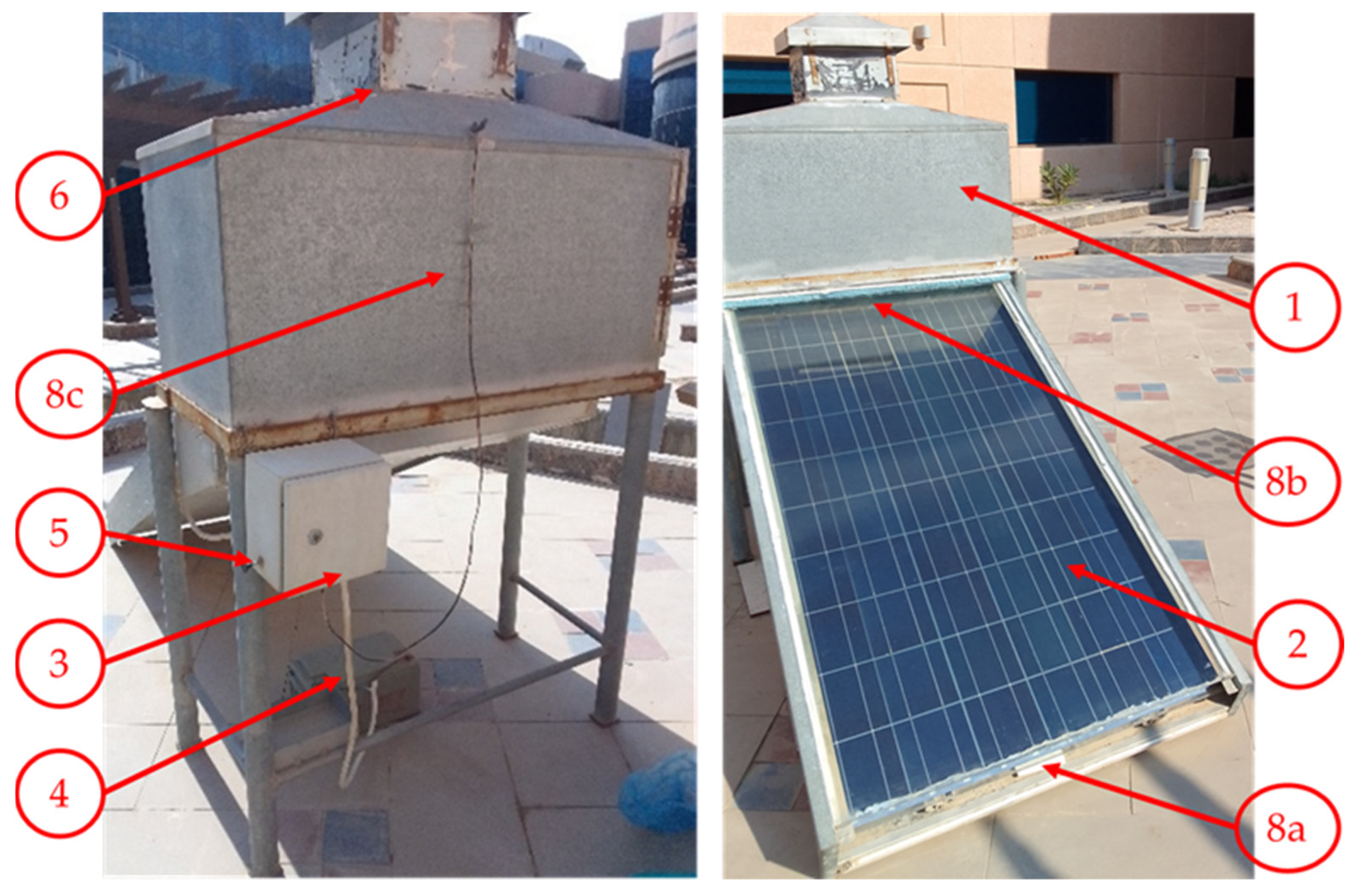

A solar dryer uses solar energy to dry agricultural products, which aids in their preservation. In this paper, the PV/T solar dryer shown in

Figure 1 and

Figure 2 is made up of the following components: (1) drying chamber, (2) PV/T solar collector, (3) solar charge controller, (4) battery, (5) PWM speed controller, (6) fan, (7) Arduino Mega, (8) DHT22 sensors, (9) load cells, and (10) SD card module.

Table 1 provides a brief description of components. The photovoltaic-thermal collector (PV/T) generates electricity as well as heated air for drying. A polycrystalline PV module generates the electricity, which is then stored in a gel battery. The stored energy is then used to power the fan, which ensures forced convection. The dryer is then filled with heated air to dry tomato slices. DHT22 sensors are installed inside the system and connected to Arduino Mega to measure the temperature and humidity. During the experiment, four load cells are used to measure the mass of tomatoes. The data collected are then saved to an SD card (

Figure 2).

2.2. Experimental Procedure

Experiments were carried out to test the solar dryer prototype, including open sun drying and forced convection drying. The experiments were performed in November till December 2022 at the College of Engineering at King Faisal University (25°20′08.4″ N Latitude, 49°35′52.9″ E Longitude), Al-Ahsa, Saudi Arabia, from 8:00 to 16:00 (roughly 8 h per day) and were stopped at night. Tomato slices were stored in plastic bags at night to prevent moisture buildup. Throughout these experiments, continuous readings for product mass as well as temperature and humidity inside the PV/T and dryer were recorded on an SD card. Two DHT22 sensors were installed in the inlet and outlet of the PV/T to measure temperature and humidity, while another one was installed inside the drying chamber above the product (

Figure 2).

Fresh tomatoes were sliced into samples with a thickness of around 5 mm (±0.2 mm) for all tomato slices. Fresh samples for open sun drying were left outside with an initial mass of 250 g (

Figure 3). In addition, fresh samples with an initial mass of 250 g were left inside the solar dryer (

Figure 4).

The fresh and dried moisture contents of tomato slices were measured by a moisture analyzer with a stainless steel platform (Model: Adam Equipment PMB 53). The tomato slices’ wet basis moisture content at any time (t

i) during drying process was determined using the following equation [

27]:

where W

d is the mass of the dried sample in (kg), and W

i is the mass of tomato slices at time t

i, in (kg). The tomato slices’ mass was determined by weighting the samples during the drying process.

Table 2 shows the air speed at the PV/T inlet, inside the dryer, and at the dryer outlet.

Uncertainty values are required for experimental work to evaluate various variables. Instruments, observation, calibration, reading, environment, and other factors all contribute to uncertainty. The temperature and relative humidity of the air at the inlet and outlet of the solar collector and inside the drying chamber, the mass of samples, and the air velocity were the independent parameters measured in the experiments.

Calculating uncertainty in experimental results for measuring different parameters is required to ensure that errors occur due to instrument selection. The uncertainty variables are Y

1, Y

2, … Y

n, and the independent variables for different parameters in the result Y

R are Z

1, Z

2, … Z

n. The estimation of the total uncertainty in the experimental process could be calculated as follows [

28,

29]:

Table 3 shows the uncertainty for various devices used in these experiments. Devices with an uncertainty of less than or equal to 5% are considered reasonable by standards.

According to Equation (2), the uncertainty of various parameters was calculated and is given in

Table 4.

2.3. Input Air Characteristics

The temperature in (°C), the relative humidity in (%), and the average velocity in (m/s) for ambient air as well as the solar irradiance in (W/m2) were measured by a local weather station in the Water Studies Center at King Faisal University (25°16′21.8″ N Latitude, 49°42′33.6″ E Longitude), Al Ahsa, Saudi Arabia.

The absolute humidity (AH) of air in (g/m

3) can be calculated using the following equation [

30]:

where T is the temperature expressed in (°C) and RH is the relative humidity expressed in (%).

2.4. Efficiency of the PV/T Solar Dryer

The following equations are used to assess the efficiency of the PV/T solar dryer: (1) the efficiency of the solar collector, (2) the efficiency of the drying chamber, and (3) the efficiency of the PV panel.

The solar collector efficiency η

C is given as [

31,

32]:

where the energy input to the solar air collector is as follows:

where I

c is the instantaneous inclined solar irradiance (W/m

2). The energy output from the solar air collector to the drying chamber is:

However, the output heat from the solar collector can be determined as follows [

33,

34]:

The drying chamber efficiency (η

d) is given as follows [

35]:

where the output heat from the solar collector equals the input heat to the drying chamber.

The total thermal energy by evaporation from the product is determined by [

5] as follows:

Since the outlet energy from the drying chamber is the energy needed to evaporate moisture from the product, it can be calculated from the following equations.

The sensible heat to raise tomatoes’ temperature (Q

s) can be estimated by the following:

The latent heat to evaporate moisture from tomato slices (Q

L) is computed by the following:

where m

t represents the rate of water removal from the product (kg

w/s), and λ

t represents the latent heat of water vaporization [

36] (2300 kJ/kg).

The moisture exchange between the product and the air inside the dryer follows a mass balance relationship in which moisture lost by the product is picked up by the air. The total mass of water to be removed from the total mass of the fresh product is given by the following [

5]:

The PV panel efficiency is expressed as [

1]:

2.5. Computational Fluid Dynamics (CFD) Simulation

A 2D CFD simulation was conducted using ANSYS Fluent 2023R1 for the solar dryer coupled to the photovoltaic/thermal collector (PV/T). The purpose of the simulation was to study the temperature and air velocity distribution inside the drying chamber when the latter is empty, without tomato slices.

Figure 5 depicts the geometry and dimensions of the PV/T solar dryer proposed as drawn in Ansys, while

Table 5 presents the dimensions of main parts of the PV/T solar dryer.

Figure 5 also shows the main dryer elements used in the CFD simulation. Several assumptions are adopted in this simulation: (1) there are no leaks in the dryer, (2) the system is fully isolated (except both the inlet and outlet), (3) the properties of the fluid are constant and uniform, and (4) the air flow inside the dryer is turbulent (Reynolds number Re > 4000). The properties of materials used in the ANSYS Fluent simulation are shown in

Table 6.

The fluid’s boundary conditions were as follows:

- (1)

For the air flow, the inlet boundary condition is specified as atmospheric pressure and the outlet boundary condition is specified as velocity outlet in the Y-axis direction, with the wall boundary conditions isolated and at no slip.

- (2)

For heat transfer, the PV panel and the glass cover have constant and uniform thermal energy, and heat transfer is accomplished through convection. The heat from the gap between the PV panel and the glass is transferred to the drying chamber by the air.

- (3)

The input parameters for CFD simulations are the collector’s inlet temperature (Tin), the dryer’s outlet air velocity (vout), the photovoltaic panel temperature (TPV), the glass cover temperature (Tg), the dryer’s outlet temperature (Tout), and the temperature of the dryer’s outside surface (TWall).

To conduct 2D CFD simulations in ANSYS, the standard k-epsilon turbulence model was selected to carry out computations in the steady-state phase, because it could produce satisfactory results for the current study. Moreover, this turbulence model has been widely used in practical engineering flow analyses since it was proposed by Launder and Spalding in 1972. The model’s robustness, economy, and reasonable accuracy have contributed to its popularity in industry for flow and heat transfer simulations [

37].

The standard k-epsilon turbulence model is presented by the following equations [

24]. The continuity equation can be written as follows:

The Reynolds-averaged Navier–Stokes (RANS) equations can be written as follows:

and

The turbulence kinetic energy (k) and its rate of dissipation (ε) are obtained from the following transport equations:

and

where the turbulent viscosity is:

and

Gk, which represents the generation of turbulence kinetic energy due to mean velocity gradients, is:

The model parameters are constant: C1ε = 1.44, C2ε = 1.92, Cµ = 0.09, σk = 1, and σε = 1.3.

Because the current study demonstrates CFD simulation for an empty solar dryer (without tomato slices), the input parameters required for simulation are measured then updated in the model before running calculations with ANSYS Fluent. The CFD simulation was carried out on 28 November 2022 at 13:00 when the drying chamber was empty. The input parameters for CFD model are given in

Table 7.

The PV panel temperature (T

PV) was calculated using the following equation [

38]:

where T

amb is the ambient temperature, I

c is the irradiance in W/m

2, and NOCT is the nominal operation cell temperature which ranged between 47 °C and 50 °C. In the current study, NOCT is assumed to be 47 °C since it is located on a south-oriented tilted surface [

38]. According to

Figure 6, the irradiance for the first day was 651 W/m

2 while it was 678 W/m

2 for the second day.

The glass cover temperature (T

g) can be calculated in Kelvin as follows [

39]:

where h

w is the wind heat transfer coefficient in (W/m

2 K) [

40]:

while ε

PV is the PV emittance (ε

PV = 0.92 [

41]) and v

w is the wind velocity, which was around 0.6 m/s on 28 November 2022 at 13:00.

The mesh is an essential component of the simulation process. It has an impact on the solution’s accuracy, convergence, and speed. The air inside the PV/T solar dryer was meshed using the meshing tool in Ansys Fluent 2023R1. The PV/T solar dryer mesh was created using quadrilateral elements whose edge lengths ranged from 0.9 mm to 2 mm. The mesh quality was assessed by ensuring that all elements’ skewness and quality fell within the optimal ranges (e.g., a target skewness of 0.9, a transition ratio of 0.272, a growth rate of 1.2, and a pinch tolerance of 0.081 mm).

A mesh independence study was carried out with five mesh refinements (mesh I—103199, mesh II—210064, mesh III—336529, mesh IV—408335, and mesh V—503925). Consequently, mesh IV was selected as a good compromise between accuracy and computation time. The selected mesh has 408,335 nodes and 403,771 elements, and it produced similar results to a mesh with more nodes. However, as the number of nodes decreased, the results change. Furthermore, the minimum orthogonal quality was 0.741 and the maximum aspect ratio was 3.078.

Figure 6 depicts the chosen mesh.

4. Discussion

Because the PV panel is located inside the solar collector, it is completely protected from inclement weather, so its efficiency is improved. However, because the fan is not operating at full capacity, the performance is evaluated under ambient conditions. The findings revealed that the PV power output and module temperature were proportional to solar irradiance and ambient temperature.

Since autumn is the rainy season in Al Ahsa, the ambient air humidity was excessively high in the morning and even during the day from November till December 2022. The air temperature was distributed in the opposite direction to the distribution of the air velocity inside the drying chamber. The air velocity inside the drying chamber may influence the air temperature. The efficiency of the PV/T solar dryer could be improved during the summer season due to an increase in solar irradiance.

The experimental results for drying the tomato slices inside the PV/T solar dryer (

Figure 8) show that the air temperature increased inside the solar collector, it was at its maximum value in the collector outlet, and then it decreased inside the drying chamber due to moisture extraction from the tomato slices. The inlet air temperature to the PV/T solar dryer (32.2 °C) increased slightly over the first day (29.8 °C). This could be attributed to a slight increase in solar irradiance (678 W/m

2) on the second day compared to that of the first day (651 W/m

2). This may also have an impact on the panel temperature, glass temperature, and outlet temperature.

According to our study of the air path for both the air temperature and velocity through the PV/T solar dryer on 28 November 2022 at 13:00 (with a solar irradiance of 682 W/m

2 when the drying chamber was empty (without any tomato slices)), the input parameters for the CFD model were equal to the data collected from the ambient air (

Table 7). The results show that the air temperature increased through the air path inside the solar collector, it was at its maximum value in the collector outlet, and then it decreased inside the drying chamber (

Figure 17). However, the air velocity increased from the inlet to the outlet of the solar collector, and it was at its maximum value in the outlet of the drying chamber (

Figure 18).

Table 9 depicts a comparison of the experimental and CFD simulation results for the output parameters on 28 November 2022 at 13:00 with a solar irradiance of 682 W/m

2 when the drying chamber was empty (without any tomato slices).

Table 9 also shows that the difference between the air outlet’s temperature for the CFD model and the experimental results for the solar collector and empty drying chamber was around 1 °C and 2 °C, respectively. As a result, the CFD model’s results were close to the experimental results and can accurately represent the performance of the solar dryer.

5. Conclusions

An indirect forced convection solar dryer prototype equipped with a PV/T air collector was used to conduct our experiment on the selected tomato slices. According to the thermal analysis of the solar drying system, we determined that its performance was good and that it saved energy.

CFD was found to be an important simulation tool for the design and development of the PV/T solar dryer. CFD can also be used to improve the design of solar dryers. This model enabled the visualization of air properties, such as temperature and velocity, within the solar dryer. The PV/T dryer’s air temperature and velocity were simulated and validated using experimental data when the drying chamber was empty (without any tomato slices); they showed good agreement. Our results present the advantages of collaboratively improving the PV/T solar dryer’s performance and help promote the application of PV/T systems for heat–electricity generation for developing environmentally sustainable equipment.

The possibility of rot was high in this version of the system due to the uncontrolled air temperature, which is the primary cause of rot, as well as the weather conditions. Therefore, this prototype needs to be modified to improve its performance. Furthermore, a 3D CFD study could be adopted to improve these results and to suggest new geometries for the PV/T collector. Mass transfer is not considered in this research study; it could be considered in further studies.