Digital Quantitative Study on Fracture Gas Storage Space for a Three-Layer Composite Residual Mining Area

Abstract

1. Introduction

2. Engineering Situations

3. Similarity Simulation Experiment Scheme and Digital Analysis Method

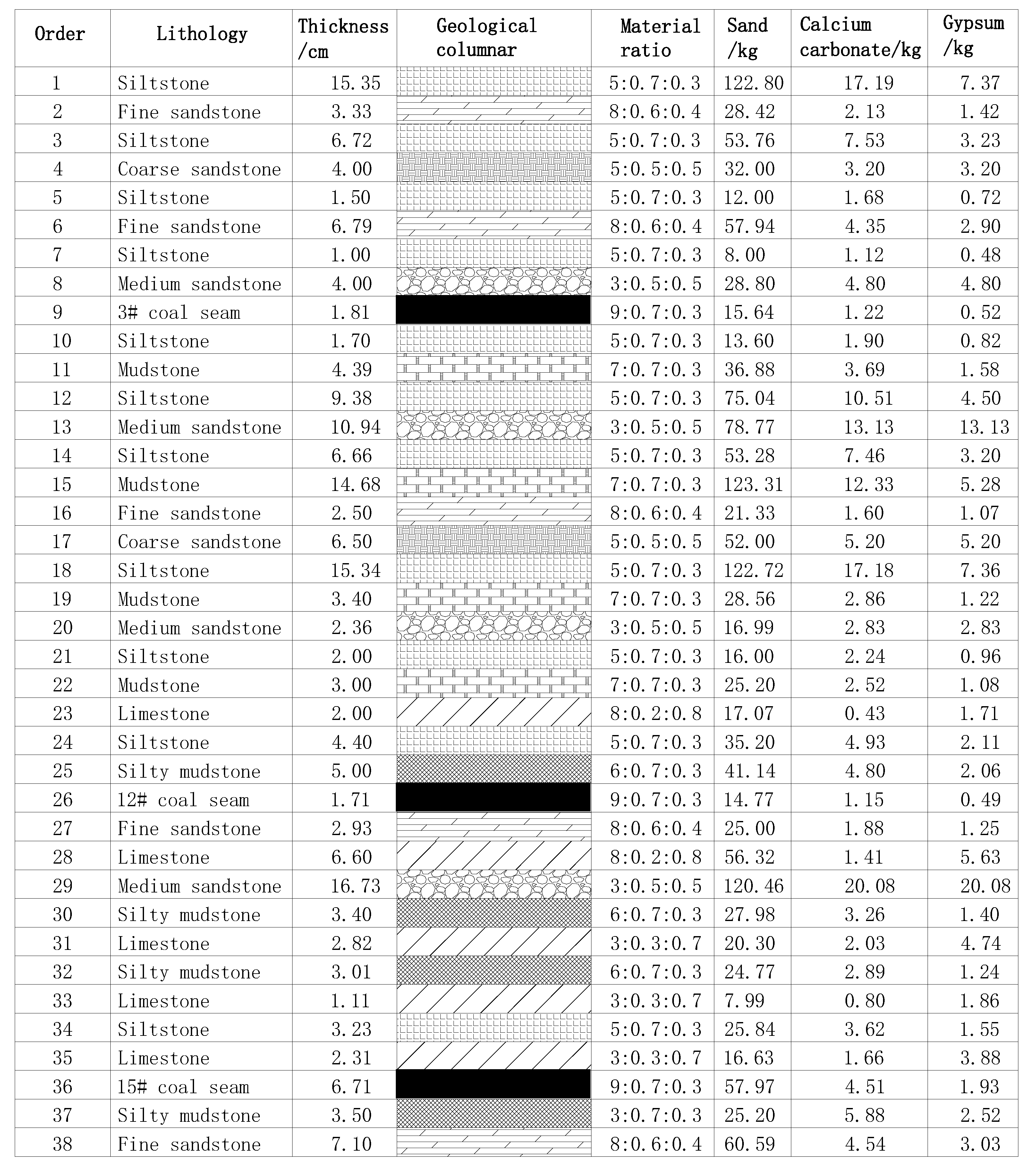

3.1. Design of a Similar Model

3.2. DIC Full-Field Strain Measurement System

3.3. Experimental Process and Digital Processing Method

3.3.1. Similarity Simulation Experimental Process and Monitoring Method

- Model laying includes installing the template, batching, stirring, and molding. To prevent too much material from adhering to the inside of the mixer, a manual mixing method is adopted to accurately match the material.

- The main experimental steps in the excavation process are as follows:

- (1)

- Before preparing for excavation, open the control software of the XTDIC equipment and record 20 initial displacement photos.

- (2)

- The simulation time similarity ratio is Ct = 10. The actual working face advance is 3 m/d. According to the actual working face ‘38′ operation system, the model simulation time for each shift Tm is 0.8 h. That is, in the simulation, 0.8 h (48 min) is equal to 8 h in the actual working face. Every 48 min will excavate 10 cm in length.

- (3)

- After each 10 cm excavation, a set of data is recorded with the XTDIC. At the same time, a high-definition camera is used to take photos in a fixed position. The XTDIC photography time is set to record once for 3 s. Therefore, each set of data contains 20 photos in one minute. After recording a series of data, the excavation and data recording are continued until the end of the working face.

3.3.2. Digital Processing Method of Fracture Distribution

4. Results Analysis and Discussion

4.1. Evolution of Rock Strata Displacement in Composite RMA

4.2. Digital Analysis of Fracture Development in Composite RMA

4.2.1. Quantitative Analysis of Fracture Field Image

- (1)

- The fractures across the partition are counted using the principle of cutting the fractures at the partition line when counting the number of fractures in each partition of the whole composite RMA (when the same fracture spans two zones, the number of fractures is counted in each zone without affecting each other).

- (2)

- The longitudinal and horizontal fractures in the same partition are counted according to the principle of cutting the intersection of the two. Fractures with continuous characteristics are regarded as single fractures.

- (3)

- If the inclination angle is greater than 45°, it is regarded as a longitudinal fracture.

4.2.2. Division of Three-Layer Composite Fracture Field Area

5. Conclusions

- (1)

- During the evolution from single to three-layer composite RMA, the displacement region of rock layers larger than 3.5 mm has changed from an isosceles trapezoid with a narrow top and a wide bottom to a two-layer stacked trapezoid. Finally, it evolved into a huge, inverted trapezoid with a wide top and a narrow bottom and shows an upward extension trend. As the number of RMAs below increases, the angle and range of the displacement area of rock strata in the whole composite RMA increase radially.

- (2)

- The fracture rate of the same area in a composite RMA is greater than that of a single one. When the single RMA evolves into a two-layer and three-layer composite RMA, the uppermost RMA overall average fracture rate increases by 28.29% and 64.26%, respectively. Compared with the vertical distance between the RMAs, mining thickness is the main factor affecting the growth of fractures in a composite RMA.

- (3)

- In the long-distance composite RMA, the overburden fracture rate shows an approximately exponential growth trend from top to bottom. The fracture rate shows a parabolic trend distribution in the horizontal partition, showing a concave shape with highs on both sides and a low in the middle. The overall fracture rate of the close-distance composite RMA increases more sharply, the average fracture rate in the concentrated growth area is 12.65%, which reached the highest value in the three-layer RMA. The number of longitudinal fractures on both sides of the composite RMA accounts for more than 60% of total fractures, which indicates that the cross-layer fracture area is the main migration channel for CBM.

- (4)

- The mining disturbance of the cross-layer fracture area near the open-cut is greater than that on the other side, so the occupied area and its average fracture rate are greater than those on the stopping side. In engineering applications, the cross-layer fracture connected area on the side of the open-cut is a favorable extraction location for surface drilling in the composite RMA, which can effectively control and extract the CBM in the composite RMA.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- McGlade, C.; Speirs, J.; Sorrell, S. Unconventional gas—A review of regional and global resource estimates. J. Energy 2013, 55, 571–584. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Feng, G.R.; Zhang, M.; Ren, H.R.; Bai, J.W.; Guo, Y.X.; Jiang, H.N.; Kang, L.X. Residual coal exploitation and its impact on sustainable development of the coal industry in China. J. Energy Policy 2016, 96, 534–541. [Google Scholar] [CrossRef]

- Feng, G.R.; Zhang, Y.J.; Qi, T.Y.; Kang, L.X. Status and research progress for residual coal mining in China. J. China Coal Soc. 2020, 45, 151–159. [Google Scholar]

- Karacan, C.O.; Ruiz, F.A.; Cote, M.; Phipps, S. Coal mine methane: A review of capture and utilization practices with benefits to mining safety and to greenhouse gas reduction. Int. J. Coal Geol. 2011, 86, 121–156. [Google Scholar] [CrossRef]

- Black, D.J.; Aziz, N.I. Developments in coal mine methane drainage and utilisation in Australia. In Proceedings of the Ninth International Mine Ventilation Congress, New Delhi, India, 10–13 November 2009. [Google Scholar]

- Feng, G.R.; Zhao, J.P.; Wang, H.W.; Li, Z.; Fang, Z.L.; Fan, W.C.; Yang, P.; Yang, X.J. Study of the internal re-breaking characteristics of broken limestone during compression. J. Powder Technol. 2022, 396, 449–455. [Google Scholar] [CrossRef]

- Kirchgessner, D.A.; Piccot, S.D.; Masemore, S.S. An improved inventory of methane emissions from coal mining in the United States. J. Air Waste Manag. Assoc. 2000, 50, 1904–1919. [Google Scholar] [CrossRef] [PubMed]

- Warmuzinski, K. Harnessing methane emissions from coal mining. Process Saf. Environ. Prot. 2008, 86, 315–320. [Google Scholar] [CrossRef]

- Pach, G.; Zenon, R.; Wrona, P. Developments in coal mine methane drainage and utilisation of The Upper Silesia. 2014. [Google Scholar]

- Karacan, C.O.; Warwick, P.D. Assessment of coal mine methane (CMM) and abandoned mine methane (AMM) resource potential of longwall mine panels: Example from Northern Appalachian Basin, USA. Int. J. Coal Geol. 2019, 208, 37–53. [Google Scholar] [CrossRef]

- Shimada, H.; Chen, Y.L.; Hamanaka, A.; Sasaoka, T.; Shimada, H.; Matsui, K. Application of Highwall Mining System to Recover Residual Coal in End-walls. In Proceedings of the Procedia Earth and Planetary Science, International Symposium on Earth Science and Technology, Bandung, Indonesia, 18–19 September 2012. [Google Scholar]

- Mazzotti, M.; Pini, R.; Storti, G. Enhanced coalbed methane recovery. J. Supercrit. Fluids 2009, 47, 619–627. [Google Scholar] [CrossRef]

- Creedy, D.P.; Garne, R.K.; Holloway, S.; Ren, T.X. A Review of the Worldwide Status of Coalbed Methane Extraction and Utilisation; Wardell Armstrong, British Geological Survey, University of Nottingham: Nottingham, UK, 2001; pp. 28–34. [Google Scholar]

- Tao, S.; Pan, Z.J.; Tang, S.L.; Chen, S.D. Current status and geological conditions for the applicability of CBM drilling technologies in China: A review. Int. J. Coal Geol. 2019, 202, 95–108. [Google Scholar] [CrossRef]

- Karmis, M.; Triplett, T.; Haycocks, C.; Goodman, G. Mining subsidence and its prediction in Appalachian coalfield. In Proceedings of the Proceedings—Symposium on Rock Mechanics, College Station, Texas, 20–23 June 1983; pp. 665–675. [Google Scholar]

- Peng, S.S. Longwall Mining; Society for Mining Metallurgy and Exploration: Englewood, CO, USA, 1984. [Google Scholar]

- Li, Z.; Feng, G.R.; Jiang, H.N.; Hu, S.Y.; Cui, J.Q.; Song, C.; Gao, Q.; Qi, T.Y.; Guo, X.Q.; Li, C.; et al. The correlation between crushed coal porosity and permeability under various methane pressure gradients: A case study using Jincheng anthracite. Greenh. Gases Sci. Technol. 2018, 8, 493–509. [Google Scholar] [CrossRef]

- Lin, T.Q. Influence of Mining activities on mine rock mass and control engineering. J. China Coal Soc. 1995, 20, 1–5. [Google Scholar]

- Qian, M.G.; Xu, J.L. Study on the “O-SHAPE” circle distribution characteristics of mining-induced fractures in the overlaying strata. J. China Coal Soc. 1998, 23, 466–469. [Google Scholar]

- Li, S.G.; Lin, H.F.; Zhao, P.X.; Xiao, P.; Pan, H.Y. Dynamic evolution of mining fissure elliptic paraboloid zone and extraction coal and gas. J. China Coal Soc. 2014, 39, 1455–1462. [Google Scholar]

- Qin, W.; Xu, J.L. Horizontal Subzone Characteristics and Methane Seepage Properties of the Gas Flowing Fracture Zone above the Gob. Adv. Civ. Eng. 2018, 2018, 9071578. [Google Scholar] [CrossRef]

- Xie, G.X.; Yang, K. Study of macro stress shell evolving characteristics of rock surrounding face. Chin. J. Rock Mech. Eng. 2010, 29, 2676–2680. [Google Scholar]

- Xu, J.L.; Qian, M.G.; Jin, H.W. Study on “coal and coal-bed methane simultaneous extraction” technique on the basis of strata movement. J. China Coal Soc. 2004, 29, 129–132. [Google Scholar]

- Karacan, C.; Goodman, G. Hydraulic conductivity changes and influencing factors in longwall overburden determined by slug tests in gob gas ventholes. Int. J. Rock Mech. Min. Sci. 2009, 46, 1162–1174. [Google Scholar] [CrossRef]

- Liu, X.Y. Experimental Study of Dynamic Development and Fractal law of Mining Rock Fracture. Appl. Mech. Mater. 2011, 71–78, 3428–3432. [Google Scholar] [CrossRef]

- Xu, P.; Li, S.; Lin, H.; Ding, Y.; Shuang, H.; Liu, S.; Tian, Y. Fractal Characterization of Pressure-Relief Gas Permeability Evolution in a Mining Fracture Network. Energies 2021, 14, 7031. [Google Scholar] [CrossRef]

- Majdi, A.; Hassani, F.; Nasiri, M. Prediction of the height of destressed zone above the mined panel roof in longwall coal mining. Int. J. Coal Geol. 2012, 98, 62–72. [Google Scholar] [CrossRef]

- Poulsen, B.A.; Adhikary, D.; Guo, H. Simulating mining-induced strata permeability changes. Eng. Geol. 2018, 237, 208–216. [Google Scholar] [CrossRef]

- Li, Z. Research on the Deformation and Seepage Characteristics of Crushed Coal and Rock and Its Application in Abandoned Coal Mine Gob Methane Extraction; D. Taiyuan University of Technology: Taiyuan, China, 2018. [Google Scholar]

- Xu, Y.Y. Coal Mining; M. China University of Mining and Technology Press: Xuzhou, China, 1999. [Google Scholar]

- Liu, H.Y.; Cheng, Y.P.; Zhou, H.X.; Wang, H.F.; Yu, Q.X. Study on the Influence of Mining-induced Fracture Development of Super-long Distance Protected Layer on Pressure Relief Gas Extraction. In Proceedings of the 2007 China (Huainan) International Conference on Coal Mine Gas Control Technology, China; 2007; pp. 140–147. [Google Scholar]

- Li, S.Q.; He, X.Q.; Li, S.Q.; Zhang, S.J.; Yan, Z.; Xie, Q.X.; Ding, Y. Experimental research on strata movement and fracture dynamic evolution of double pressure-relief mining in coal seams group. J. China Coal Soc. 2013, 38, 2146–2152. [Google Scholar]

- Ma, H.F.; Cheng, Z.H.; Liu, W. Evolution characteristics of mining stress and overlying strata displacement field under superimposed mining in close distance coal seam group. J. Saf. Sci. Technol. 2017, 13, 28–33. [Google Scholar]

- Karacan, C.O.; Esterhuizen, G.S.; Schatzel, S.J.; Diamond, W.P. Reservoir simulation-based modeling for characterizing longwall methane emissions and gob gas venthole production. Int. J. Coal Geol. 2007, 71, 225–245. [Google Scholar] [CrossRef]

- Hu, Y.Z.; Liu, C.Q.; Liu, C.Y.; Xhen, B.B. Development regularity of mining-induced fractures in mixed mining of coal seam group. J. Min. Saf. Eng. 2015, 32, 396–400. [Google Scholar]

- Si, G.; Jamnikar, S.; Lazar, J.; Shi, J.Q.; Durucan, S.; Korre, A.; Zavsek, S. Monitoring and modelling of gas dynamics in multi-level longwall top coal caving of ultra-thick coal seams, part I: Borehole measurements and a conceptual model for gas emission zones. Int. J. Coal Geol. 2015, 144, 98–110. [Google Scholar] [CrossRef]

- Qin, W.; Xu, J.L.; Peng, X.Y.; Hu, G.Z. Optimal layout of surface borehole network for gas drainage from abandoned gob. J. Min. Saf. Eng. 2013, 30, 289–295. [Google Scholar]

- Qin, W.; Xu, J.L.; Hu, G.Z. Optimization of abandoned gob methane drainage through well placement selection. J. Nat. Gas Sci. Eng. 2015, 25, 148–158. [Google Scholar] [CrossRef]

- Zhuo, H.; Qin, B.T.; Shi, Q.L.; Li, L. Development law of air leakage fractures in shallow coal seams: A case study in the Shendong Coalfield of China. Environ. Earth Sci. 2018, 77, 772. [Google Scholar] [CrossRef]

- Huang, Q.X.; Du, J.W.; Hou, E.K.; Yang, F. Research on overburden and ground surface cracks distribution and formation mechanism in shallow coal seams group mining. J. Min. Saf. Eng. 2019, 36, 7. [Google Scholar]

- Tian, C.L.; Liu, Y.B.; Yang, X.L.; Hu, Q.T.; Wang, B.; Yang, H.M. Development characteristics and field detection of overburden fracture zone in multiseam mining: A case study. Energy Sci. Eng. 2020, 8, 602–615. [Google Scholar] [CrossRef]

- Liu, Y.B.; Cheng, J.L.; Jiao, J.J.; Meng, X.X. Feasibility study on multi-seam upward mining of multi-layer soft-hard alternate complex roof. Environ. Earth Sci. 2022, 81, 424. [Google Scholar] [CrossRef]

- Wu, Q.Y.; Guo, Z.W.; Zhai, H.L.; Wang, J.W.; Zhang, M.J.; Chi, B.S.; Wang, E.Y.; Guo, S.Q. Physical simulation on spatial distribution of void fraction in overburden due to repeated mining in North Shaanxi Mining Area. Coal Sci. Technol. 2022, 50, 105–111. [Google Scholar]

- Riley, P.; Crowe, P. Airborne and Terrestrial Laser Scanning-Applications for Illawarra Coal. In Coal Operators’ Conference; Aziz, N., Ed.; University of Wollongong & the Australasian Institute of Mining and Metallurgy: Wollongong, NSW, Australia, 2006; pp. 266–275. [Google Scholar]

- Berkovic, G.; Shafir, E. Optical methods for distance and displacement measurements. Adv. Opt. Photon. 2012, 4, 441–471. [Google Scholar] [CrossRef]

- Kashfuddoja, M.; Prasath, R.G.R.; Ramji, M. Study on experimental characterization of carbon fiber reinforced polymer panel using digital image correlation: A sensitivity analysis. Opt. Lasers Eng. 2014, 62, 17–30. [Google Scholar] [CrossRef]

- Zhou, Y.; Sun, C.; Song, Y.; Chen, J. Image pre-filtering for measurement error reduction in digital image correlation. Opt. Lasers Eng. 2015, 65, 46–56. [Google Scholar] [CrossRef]

- Palamara, D.R.; Nicholson, M.; Flentje, P.; Baafi, E.; Brassington, G.M. An evaluation of airborne laser scan data for coalmine subsidence mapping. Int. J. Remote Sens. 2007, 28, 3181–3203. [Google Scholar] [CrossRef]

- Feng, F.; Chen, S.J.; Wang, Y.J.; Huang, W.P.; Han, Z.Y. Cracking mechanism and strength criteria evaluation of granite affected by intermediate principal stresses subjected to unloading stress state. Int. J. Rock Mech. Min. Sci. 2021, 143, 10473. [Google Scholar] [CrossRef]

- Chen, S.J.; Feng, F.; Wang, Y.J.; Li, D.Y.; Huang, W.P.; Zhao, X.D.; Jiang, N. Tunnel failure in hard rock with multiple weak planes due to excavation unloading of in-situ stress. J. Cent. South Univ. 2020, 27, 2864–2882. [Google Scholar] [CrossRef]

- Feng, F.; Xie, Z.W.; Xue, T.X.; Wang, E.Y.; Huang, R.F.; Li, X.L.; Gao, S.X. Application of a combined FEM/DEM approach for teaching a deep rock mass mechanics course. Sustainability 2023, 15, 937. [Google Scholar] [CrossRef]

- Smith, J.; Ghabraie, B.; Ren, G.; Holden, L. Application of 3D laser scanner, optical transducers and digital image processing techniques in physical modelling of mining-related strata movement. Int. J. Rock Mech. Min. Sci. 2015, 100, 219–230. [Google Scholar]

- Hu, L.Q. The Evolution Law of the Dominant Channel of Pressure Relief Gas in the Overburden Cracks in the Mining Area; D. Taiyuan University of Technology: Taiyuan, China, 2021. [Google Scholar]

- Feng, G.R.; Li, Z.; Hu, S.Y.; Zhng, Y.T.; Zhang, A.; Gao, Q.; Jiang, H.N.; Guo, X.Q.; Li, C.; Cui, J.Q. Distribution of gob empty space for methane drainage during the longwall mining: A case study. J. Nat. Gas Sci. Eng. 2018, 60, 112–124. [Google Scholar] [CrossRef]

- Zhang, C.W. Formation Mechanism and Multi-Scale Seepage Characteristics of Overburden Fracture in Abandoned Coal Mine; D. Taiyuan University of Technology: Taiyuan, China, 2021. [Google Scholar]

- Wang, H.W.; Zhou, H.W.; Zuo, J.P. Application of optical measurement method in strata movement simulation experiment. J. China Coal Soc. 2006, 31, 278–281. [Google Scholar]

- Chew, K.S.; Zarrabi, K. Non-contact displacements measurement using an improved particle swarm optimization based digital speckle correlation method. In Proceedings of the International Conference on Pattern Analysis and Intelligent Robotics ICPAIR 2011, Kuala Lumpur, Malaysia, 28–29 June 2011. [Google Scholar]

- Xiao, X.C.; Pan, Y.S.; Lv, X.F. Experimental study of deep depth tunnel surrounding rock burst proneness with equivalent material simulating method based on digital speckle correlation technique. J. China Coal Soc. 2011, 36, 1629–1635. [Google Scholar]

- Yuan, C.F.; Yuan, Z.J.; Wang, Y.T.; Li, C.M. Analysis of the diffusion process of mining overburden separation strata based on the digital speckle correlation coefficient field. Int. J. Rock Mech. Min. Sci. 2019, 119, 13–21. [Google Scholar] [CrossRef]

- Zhang, L.F.; Chen, Z.H.; Nian, G.Q.; Bao, M.; Zhou, Z.H. Base friction testing methodology for the deformation of rock masses caused by mining in an open-pit slope. Measurement 2023, 206, 112–235. [Google Scholar] [CrossRef]

- Ren, W.Z.; Guo, C.M.; Peng, Z.Q.; Wang, Y.G. Model experimental research on deformation and subsidence characteristics of ground and wall rock due to mining under thick overlying terrane. Int. J. Rock Mech. Min. Sci. 2010, 47, 614–624. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, G.; Fan, W.; Li, Z.; Wang, Z.; Zhang, Y.; Yang, Y.; Yang, X.; Zhang, X.; Feng, G. Digital Quantitative Study on Fracture Gas Storage Space for a Three-Layer Composite Residual Mining Area. Sustainability 2023, 15, 6348. https://doi.org/10.3390/su15086348

Feng G, Fan W, Li Z, Wang Z, Zhang Y, Yang Y, Yang X, Zhang X, Feng G. Digital Quantitative Study on Fracture Gas Storage Space for a Three-Layer Composite Residual Mining Area. Sustainability. 2023; 15(8):6348. https://doi.org/10.3390/su15086348

Chicago/Turabian StyleFeng, Guorui, Weichao Fan, Zhen Li, Zhiwei Wang, Yidie Zhang, Yanqun Yang, Xiaohong Yang, Xiangming Zhang, and Gan Feng. 2023. "Digital Quantitative Study on Fracture Gas Storage Space for a Three-Layer Composite Residual Mining Area" Sustainability 15, no. 8: 6348. https://doi.org/10.3390/su15086348

APA StyleFeng, G., Fan, W., Li, Z., Wang, Z., Zhang, Y., Yang, Y., Yang, X., Zhang, X., & Feng, G. (2023). Digital Quantitative Study on Fracture Gas Storage Space for a Three-Layer Composite Residual Mining Area. Sustainability, 15(8), 6348. https://doi.org/10.3390/su15086348