Experimental Study of the Effect of Tack Coats on Interlayer Bond Strength of Pavement

Abstract

:1. Introduction

2. Raw Materials

2.1. Aggregate

2.2. Asphalt Cement

2.3. Mineral Filler

2.4. Tack Coat Materials

- RC-70 cut back to asphalt.

- RC-250 cut back to asphalt.

- CSS-1h emulsified asphalt.

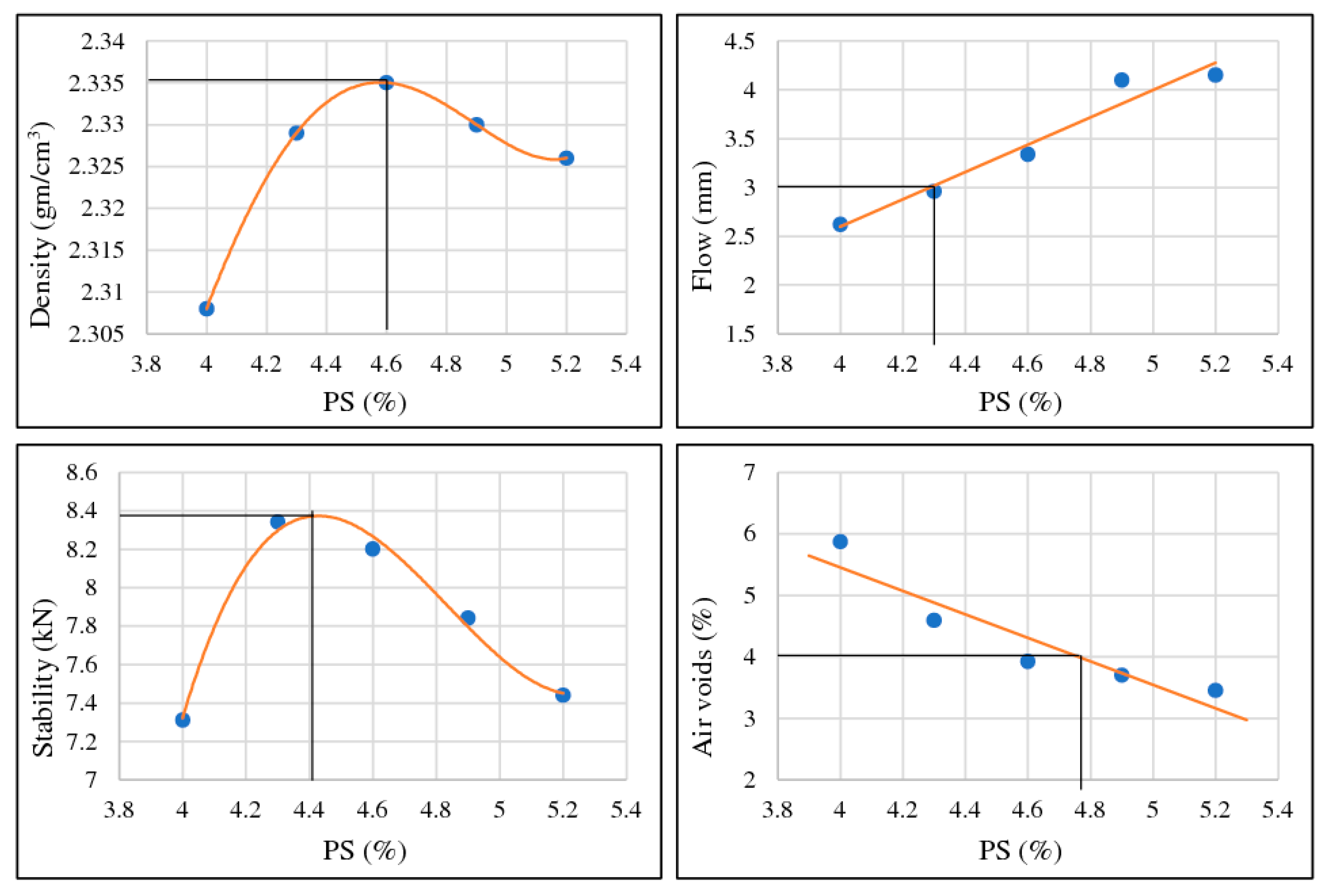

3. Mix Design and Production

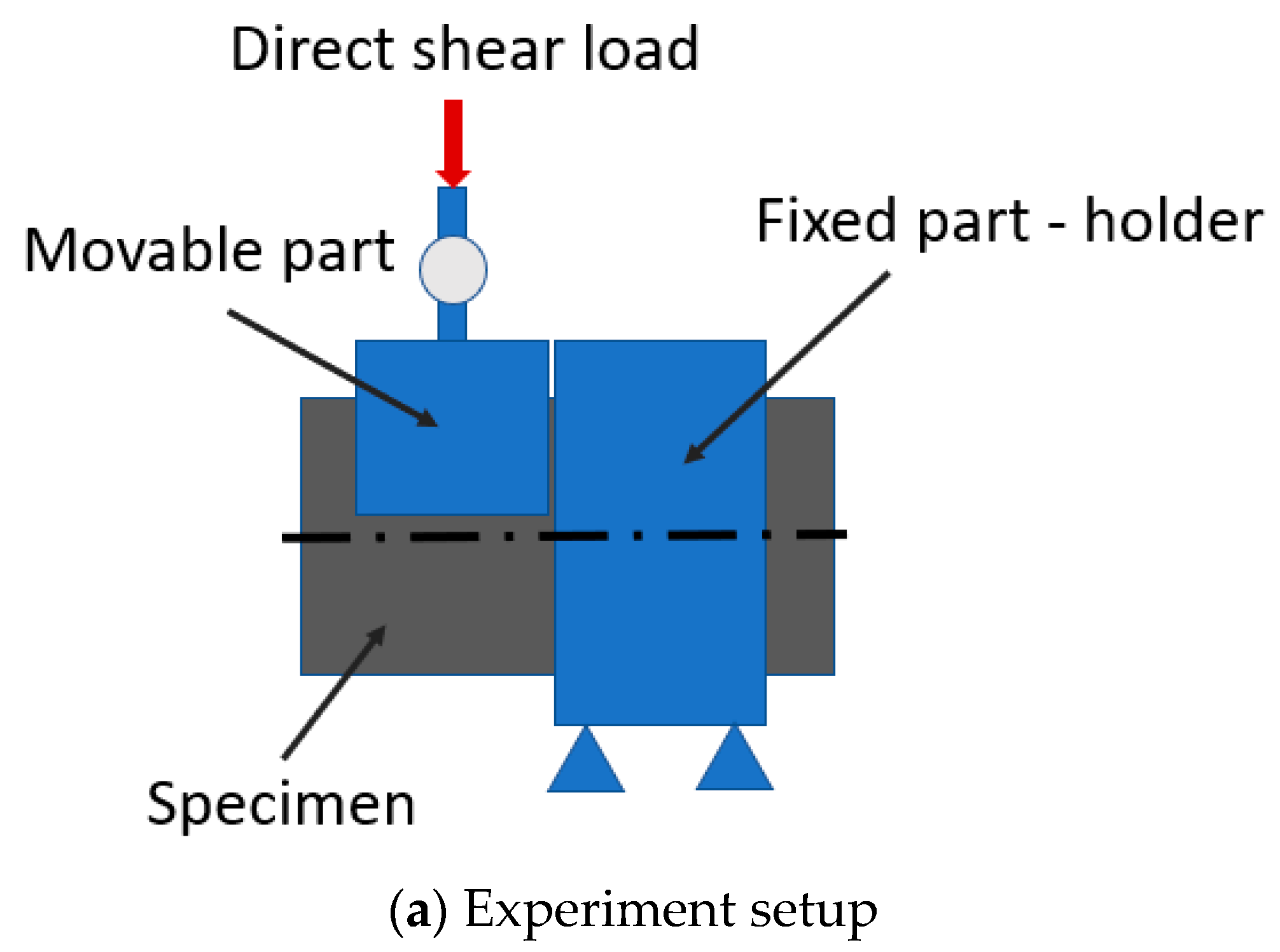

4. Laboratory Test

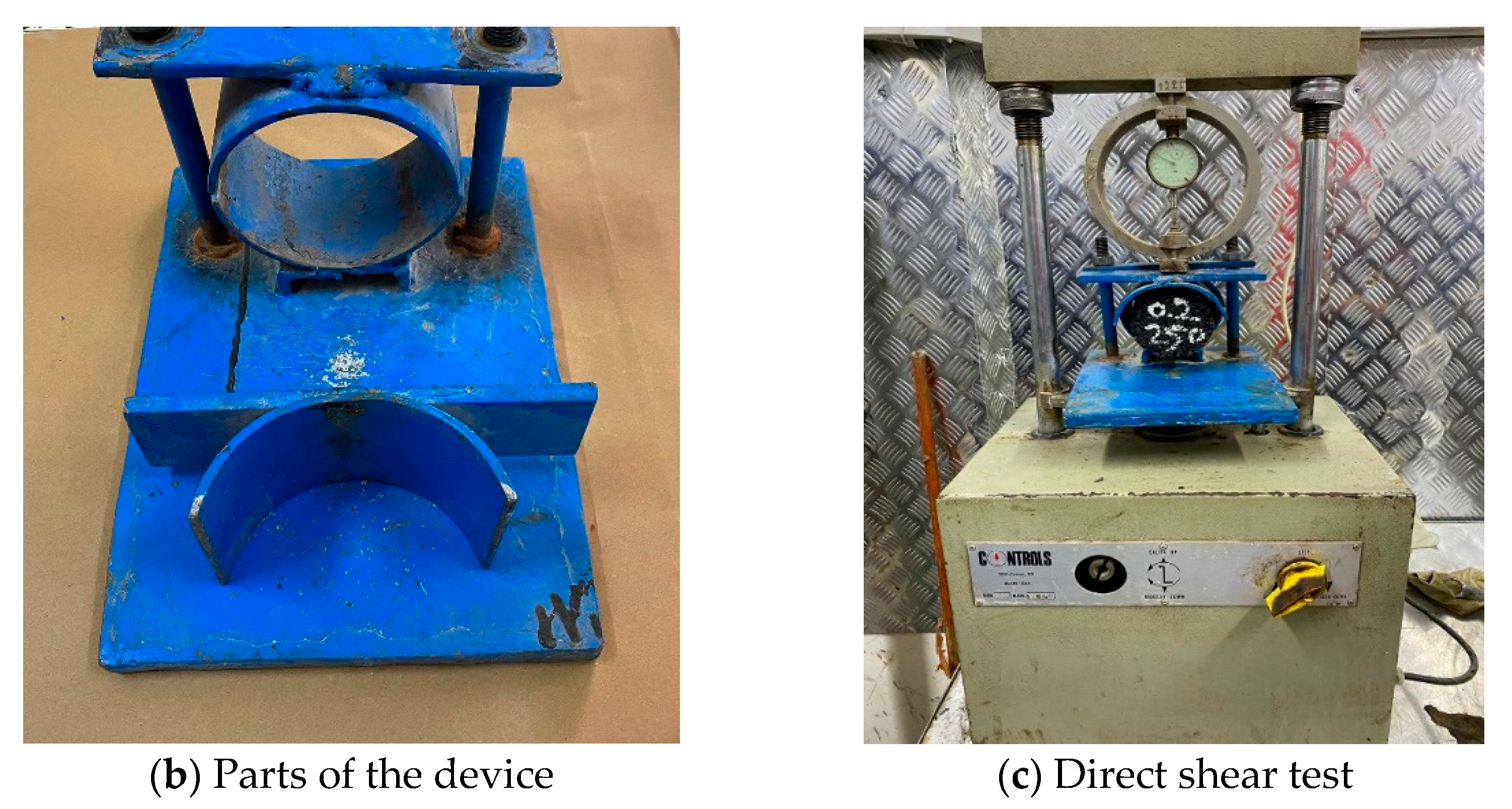

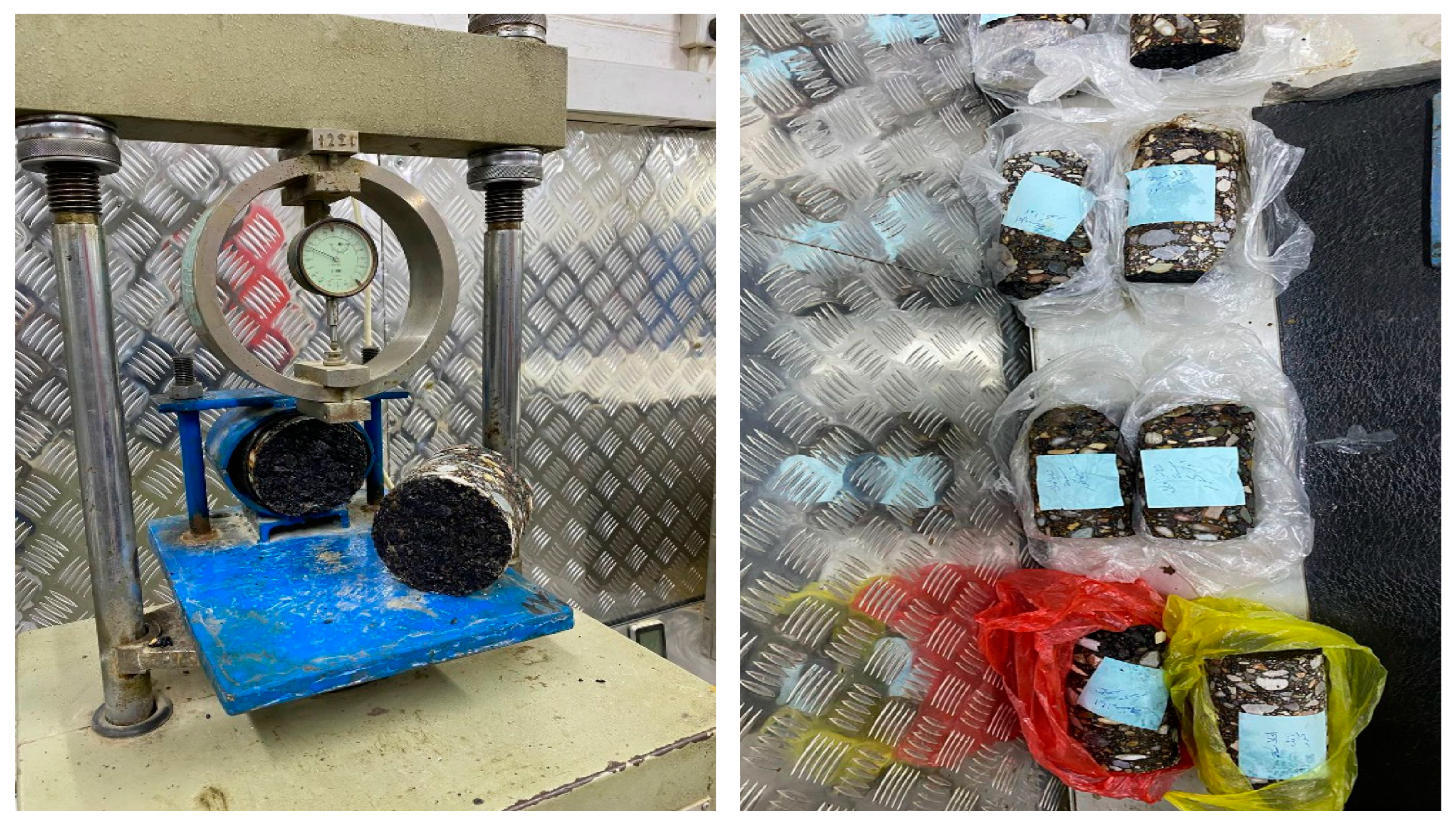

4.1. Specimens Preparation

4.2. The Bond Strength Evaluation

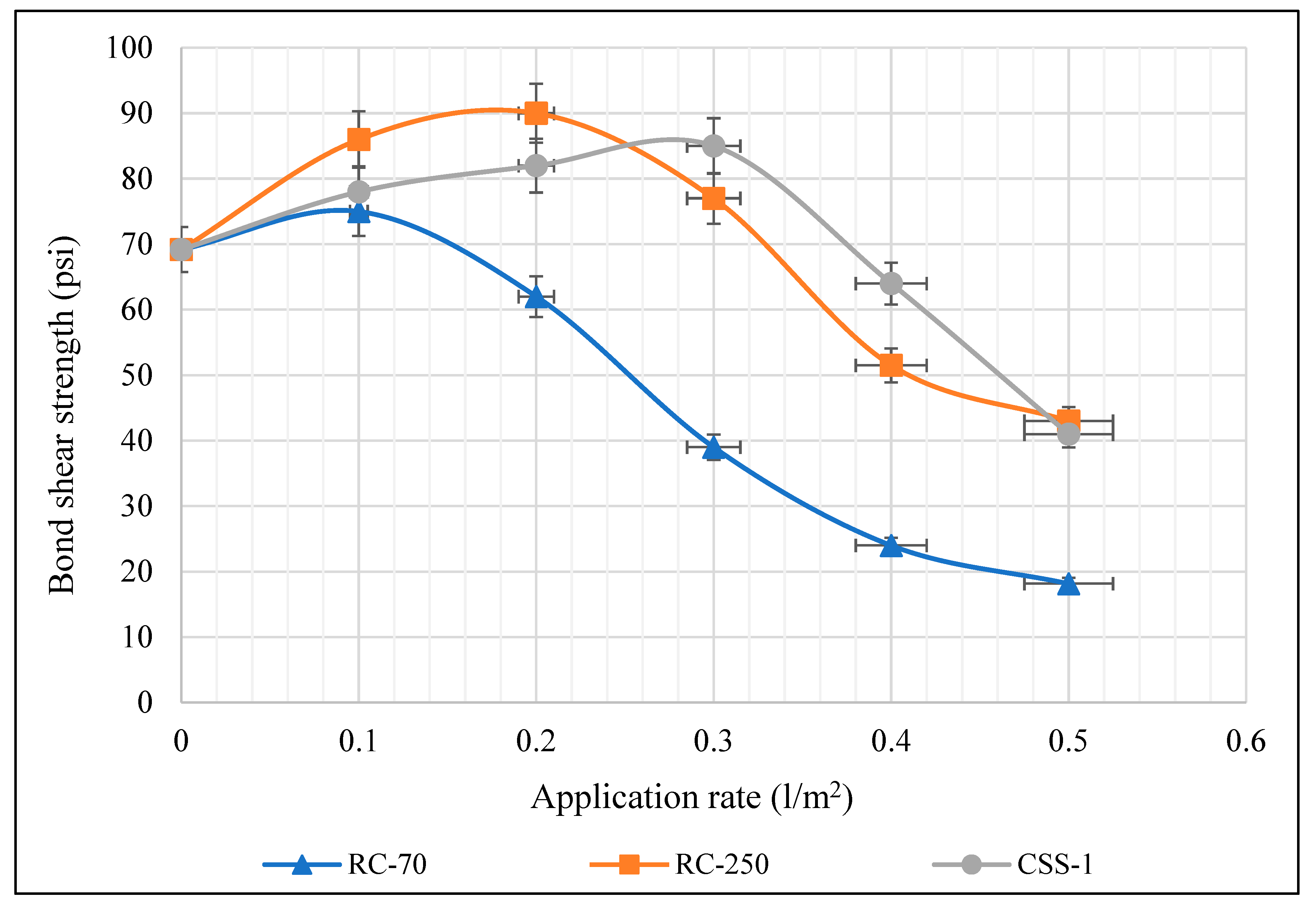

4.3. Test Results

5. Field Test

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sarsam, S.I.; Nuaimi, S.A.A. Assessing the deformation at interfaces of flexible pavement under cyclic shear stresses. Indian J. Eng. 2020, 17, 271–281. [Google Scholar]

- Gao, J.; Yao, Y.; Yang, J.; Song, L.; Xu, J.; He, L.; Tao, W. Migration behavior of reclaimed asphalt pavement mastic during hot mixing. J. Clean. Prod. 2022, 376, 134123. [Google Scholar] [CrossRef]

- Yao, Y.; Yang, J.; Gao, J.; Zheng, M.; Xu, J.; Zhang, W.; Song, L. Strategy for improving the effect of hot in-place recycling of asphalt pavement. Constr. Build. Mater. 2023, 366, 130054. [Google Scholar] [CrossRef]

- Yang, K.; Li, R.; Yu, Y.; Pei, J.; Liu, T. Evaluation of interlayer stability in asphalt pavements based on shear fatigue property. Constr. Build. Mater. 2020, 258, 119628. [Google Scholar] [CrossRef]

- Bahia, H.U.; Sufian, A.; Swiertz, D.; Mohammad, L.N.; Akentuna, M.; Bitumix Solutions, L.L.C. Investigation of Tack Coat Materials Tracking Performance; No. 0092-17-06; Wisconsin Department of Transportation Research & Library Unit: Madison, MI, USA, 2019.

- Alnuami, S.A.; Sarsam, S.I. Assessing the Influence of Moisture Damage under Repeated Load on Multilayer Interface Bond Strength of Asphalt Concrete. J. Eng. 2020, 26, 21–42. [Google Scholar] [CrossRef]

- Saba, R.; Hovin, W.; Jorgensen, T. An investigation into the effects of tack coat application rate on interlayer shear bond strength. In Proceedings of the 6th Eurasphalt & Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016. [Google Scholar] [CrossRef]

- Hou, X.; Xiao, F.; Guo, R.; Xiang, Q.; Wang, T.; Wang, J. Application of spectrophotometry on detecting asphalt content of emulsified asphalt. J. Clean. Prod. 2019, 215, 626–633. [Google Scholar] [CrossRef]

- Zhang, W. Effect of tack coat application on interlayer shear strength of asphalt pavement: A state-of-the-art review based on application in the United States. Int. J. Pavement Res. Technol. 2017, 10, 434–445. [Google Scholar] [CrossRef]

- West, R.C.; Zhang, J.; Moore, J. Evaluation of Bond Strength between Pavement Layers; NCAT Report 05-08; National Center for Asphalt Technology: Auburn, AL, USA, 2005; p. 4. [Google Scholar]

- Al-Bayati, A. Permanent Deformation Prediction of Asphalt Concrete under Repeated Loading. Ph.D. Thesis, Civil Engineering Department, University of Baghdad, Baghdad, Iraq, 2006. [Google Scholar]

- Mohammad, L.N.; Hassan, M.; Patel, N. Effects of Shear Bond Characteristics of Tack Coats on Pavement Performance at the Interface. Transp. Res. Rec. 2011, 2209, 6–8. [Google Scholar] [CrossRef]

- Albayati, A.H. Performance evaluation of plant produced warm mix asphalt. J. Eng. 2018, 24, 145–164. [Google Scholar] [CrossRef]

- Le, M.T.; Nguyen, Q.H.; Nguyen, M.L. Numerical and experimental investigations of asphalt pavement behaviour, taking into account interface bonding conditions. Infrastructures 2020, 5, 21. [Google Scholar] [CrossRef] [Green Version]

- Mohammad, L.N.; Mostafa, A.E.; Bae, A.; Patel, N.; Button, J.; Scherocman, J.A. Optimization of Tack Coat for HMA Placement; NCHRP Report 712; Transportation Research Board: Washington, DC, USA, 2012. [Google Scholar]

- Joni, T. Studying the Effect of Different Types of Emulsified Materials on Interface Bond Strength between Pavement Layers. Assoc. Arab. Univ. J. Eng. Sci. 2018, 25, 45–63. [Google Scholar]

- Ghabchi, R.; Dharmarathna, C.P. Effect of tack coat emulsion type, application rate, and surface type and texture on early-age interlayer shear strength of pavements in cold regions. Int. J. Pavement Eng. 2020, 23, 1881–1896. [Google Scholar] [CrossRef]

- Wei, F.; Cao, J.; Zhao, H.; Han, B. Laboratory investigation on the interface bonding between Portland cement concrete pavement and asphalt overlay. Math. Probl. Eng. 2021, 2021, 8831287. [Google Scholar] [CrossRef]

- SCRB/R9; General Specification for Roads and Bridges, Section R/9, Hot-Mix Asphalt Concrete Pavement, Revised Edition. State Corporation of Roads and Bridges, Ministry of Housing and Construction: Baghdad, Iraq, 2003.

- Alani, A.F. Evaluating The Performance of Asphalt Concrete Mixes by Utilizing Carbon Black as Asphalt Modifier. J. Univ. Babylon Eng. Sci. 2018, 26, 222–236. [Google Scholar]

- Albayati, A.; Wang, Y.; Haynes, J. Size effect of hydrated lime on the mechanical performance of asphalt concrete. Materials 2022, 15, 3715. [Google Scholar] [CrossRef] [PubMed]

- Al-Tameemi, A.F.; Wang, Y.; Albayati, A.; Haynes, J. Moisture susceptibility and fatigue performance of hydrated lime–modified asphalt concrete: Experiment and design application case study. J. Mater. Civ. Eng. 2019, 31, 04019019. [Google Scholar] [CrossRef] [Green Version]

- ASTM D6927; Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures. ASTM International: West Conshohocken, PA, USA, 2015; Volume I, pp. 1–7. [CrossRef]

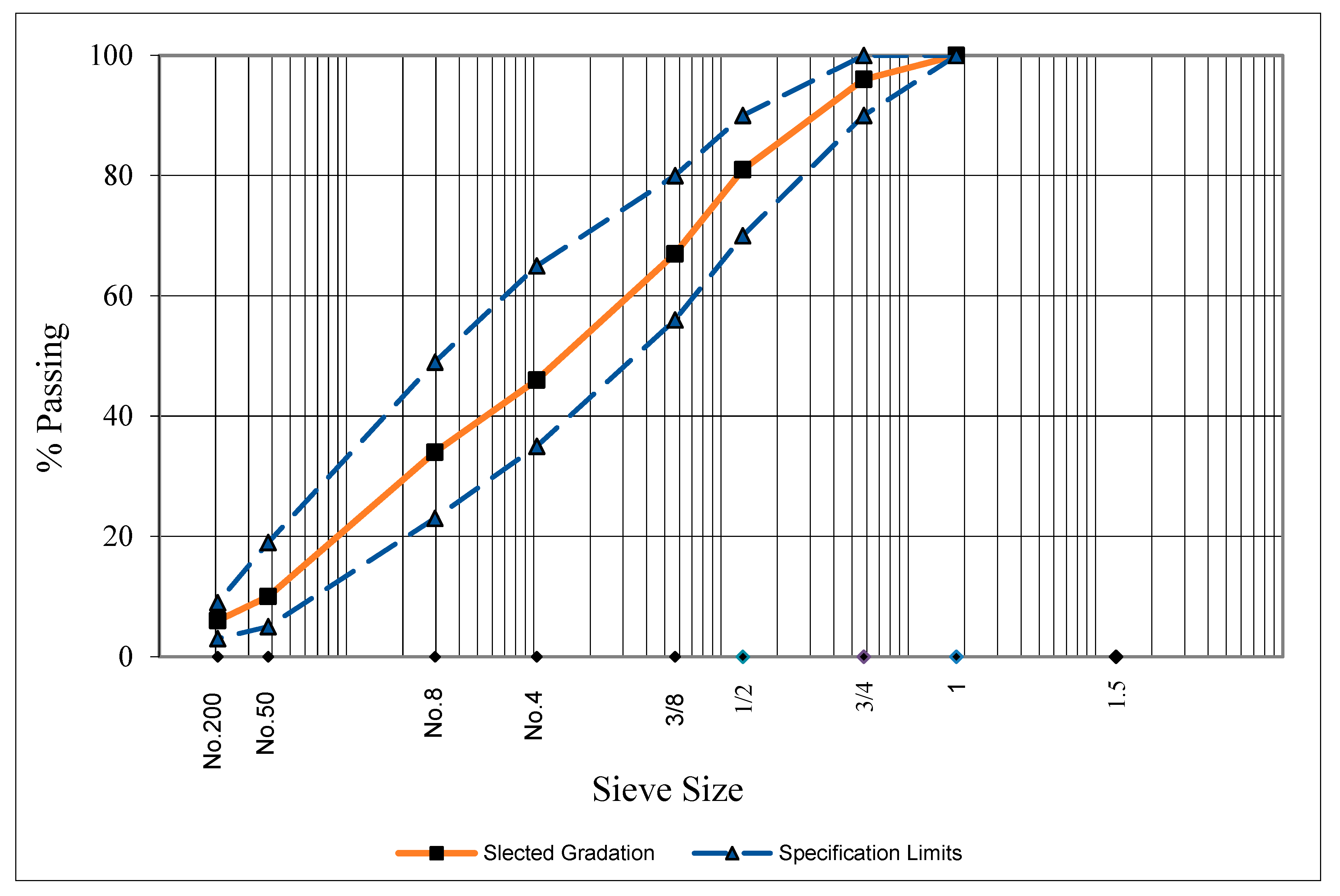

| Percent Passing | |||||||

|---|---|---|---|---|---|---|---|

| Sieve Size, mm (inch) | The Gradation of Aggregate Samples | Final Gradation | SCRB Specification Requirements | ||||

| Coarse Agg. (25–4.75 mm) | Midsize Agg. (12.5–2.36 mm) | Crusher Sand | Natural Sand | Filler | |||

| 25 (1) | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| 19 (3/4) | 88 | 100 | 100 | 100 | 100 | 96 | 90–100 |

| 12.5 (1/2) | 46 | 100 | 100 | 100 | 100 | 81 | 70–90 |

| 9.5 (3/8) | 9 | 92 | 100 | 100 | 100 | 67 | 56–80 |

| 4.75 (No. 4) | 0 | 10 | 85 | 97 | 100 | 46 | 35–65 |

| 2.36 (No. 8) | 0 | 0 | 60 | 83 | 100 | 34 | 23–49 |

| 0.30 (No. 50) | 0 | 0 | 3 | 51 | 100 | 10 | 5–19 |

| 0.075 (No. 200) | 0 | 0 | 1 | 6 | 95 | 6 | 3–9 |

| Mixing Ratio | 35% | 15% | 37% | 8% | 5% | ||

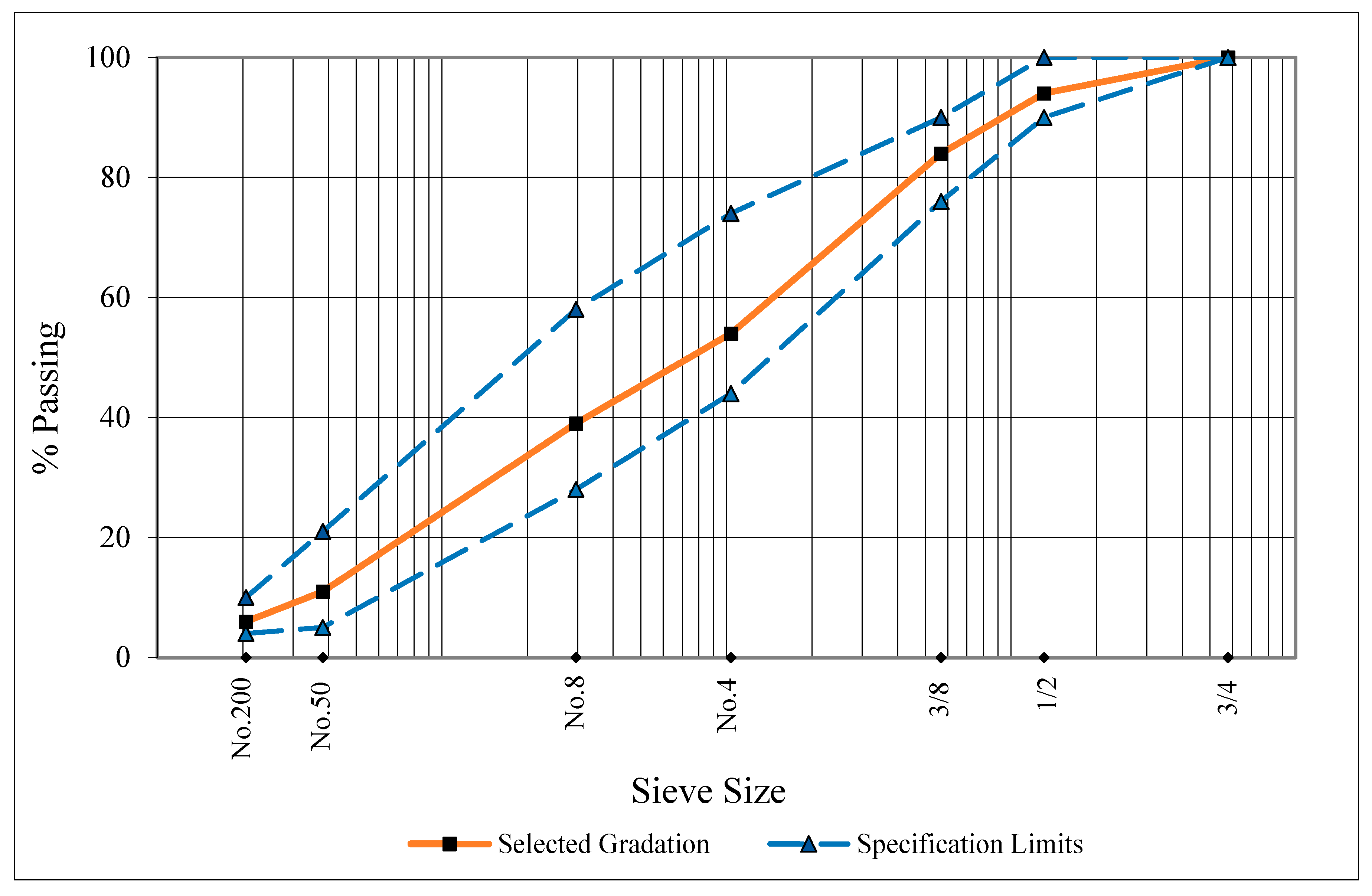

| Percent Passing | |||||||

|---|---|---|---|---|---|---|---|

| The Gradation of Aggregate Samples | Final Gradation | SCRB Specification Requirements | |||||

| Sieve Size, mm (inch) | Coarse Agg. (19–4.75 mm) | Midsize Agg. (12.5–2.36 mm) | Crusher Sand | Natural Sand | Filler | ||

| 19 (3/4) | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| 12.5 (1/2) | 60 | 100 | 100 | 100 | 100 | 94 | 90–100 |

| 9.5 (3/8) | 10 | 92 | 100 | 100 | 100 | 84 | 76–90 |

| 4.75 (No. 4) | 0 | 10 | 85 | 97 | 100 | 54 | 44–74 |

| 2.36 (No. 8) | 0 | 0 | 60 | 83 | 100 | 39 | 28–58 |

| 0.30 (No. 50) | 0 | 0 | 3 | 51 | 100 | 11 | 5–21 |

| 0.075 (No. 200) | 0 | 0 | 1 | 6 | 95 | 6 | 4–10 |

| Mixing Ratio | 15% | 27% | 43% | 10% | 5% | ||

| Property | ASTM Designation | Test Results | Specification Requirements |

|---|---|---|---|

| Bulk Specific Gravity | ASTM C-127 | 2.564 | …. |

| Apparent Specific Gravity | ASTM C-127 | 2.656 | …. |

| Percent Water Absorption | ASTM C-127 | 0.424 | …. |

| Percent Wear, Los Angles Abrasion | ASTM C-131 | 18 | Max. 35, Binder |

| Flat and Elongated Ratio (5:1) | ASTM D-4791 | 4 | Max. 10 |

| Percent Fractured Pieces | ASTM D-5821 | 94 | Min. 90 |

| Soundness, 5 cycles, MgSO4 | ASTM C-88 | 3.83 | Max. 18% |

| Property | ASTM Designation | Test Results | Specification Requirements |

|---|---|---|---|

| Bulk Specific Gravity | ASTM C-127 | 2.593 | …. |

| Apparent Specific Gravity | ASTM C-127 | 2.679 | …. |

| Percent Water Absorption | ASTM C-127 | 0.396 | …. |

| Percent Wear, Los Angles Abrasion | ASTM C-131 | 18 | Max. 30, Wearing |

| Flat and Elongated Ratio (5:1) | ASTM D-4791 | 3 | Max. 10 |

| Percent Fractured Pieces | ASTM D-5821 | 96 | Min. 90 |

| Soundness, 5 cycles, MgSO4 | ASTM C-88 | 3.83 | Max. 18% |

| Property | ASTM Designation | Test Results | Specification Requirements | |

|---|---|---|---|---|

| Bulk Specific Gravity | ASTM C-128 | 2.684 | …. | |

| Apparent Specific Gravity | ASTM C-128 | 2.727 | …. | |

| Percent Water Absorption | ASTM C-128 | 0.706 | …. | |

| Plasticity Index | AASHTO T89 | NP | Max. 4% | |

| Percent Deleterious material | AASHTO T112 | 0.63 | Max. 3% | |

| Sand Equivalent | AASHTO T176 | natural | 58 | Min. 45 |

| crusher | 72 | |||

| Property | ASTM Designation | Test Result | SCRB Specification |

|---|---|---|---|

| Penetration at 25 °C, 100 g, 5 s (0.1 mm) | ASTM D-5 | 47 | (40–50) |

| Ductility at 25 °C, 5 cm/min. (cm) | ASTM D-113 | 145 | >100 |

| Flashpoint (Cleveland open cup), (°C) | ASTM D-92 | 321 | Min. 232 |

| The softening point, (°C) | ASTM D-36 | 56 | ------------ |

| Viscosity @ 135 °C, cP | ASTM D-4402 | 650 | Min. 400 |

| Viscosity @ 165 °C, cP | ASTM D-4402 | 145 | --------- |

| Specific gravity at 25 °C | ASTM D-70 | 1.03 | --------- |

| Property | Result |

|---|---|

| Bulk specific gravity | 3.15 |

| Passing Sieve No. 200 (0.075 mm) | 95% |

| Property | Test Results | Specification Limits | |||

|---|---|---|---|---|---|

| RC-70 | RC-250 | RC-70 | RC-250 | ||

| Kinematic Viscosity at 60 °C (CSt) | 102 | 458 | 70–140 | 250–500 | |

| Test on residue from the distillation | Viscosity at 60 °C (poise) | 72 | 94 | 60–240 | 60–240 |

| Ductility at 25 °C (cm) | 110 | 110 | Min 100 | Min 100 | |

| Residue from distillation to 360 °C (%) | 57 | 66 | Min 55 | Min 65 | |

| Flash point (tag open cup), (°C) | 62 | 68 | - | Min 27 | |

| Water (%) | Nil | Nil | Max. 0.2 | Max. 0.2 | |

| Residue solubility in trichloroethylene (%) | 99.3 | 99.3 | Min 99.0 | Min 99.0 | |

| Property | Test result | Specification Limits | |

|---|---|---|---|

| Min. | Max. | ||

| Viscosity, Saybolt-Furol at 25 °C | 26 | 20 | 100 |

| Residue by distillation (%) | 58.3 | 57 | - |

| Residue by evaporation | 54.9 | 50 | - |

| Sieve test, (%) | 0.02 | - | 0.0 |

| Cement mixing test,% | 0.732 | - | 2.0 |

| Settlement test, 5-day,% | 0.1 | 0 | 1 |

| One-day storage stability test,% | 0.04 | 0 | 1 |

| Penetration, 25 °C, 100 g, 5 s | 133 | 100 | 250 |

| Ductility, 25 °C cm/min | 185 | 40 | - |

| Solubility in trichloroethylene,% | 99 | 97.5 | - |

| Specific gravity at 25 °C | 1.02 | - | - |

| Application Rate, L/m2 | 0 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 |

|---|---|---|---|---|---|---|

| Tack Coat Type | Bond Strength at Various Application Rates (psi) | |||||

| RC-70 | 69.2 | 75 | 62 | 39 | 24 | 18.16 |

| RC-250 | 69.2 | 86 | 90 | 77 | 51.5 | 43 |

| CSS-1 | 69.2 | 78 | 82 | 85 | 64 | 41 |

| Application Rate, L/m2 | 0 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 |

|---|---|---|---|---|---|---|

| Tack Coat Type | Bond Shear Strength at Various Application Rates (psi) | |||||

| RC-250 | 61 | 69 | 74 | 59 | 44 | 37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, M.H.; Khalil, A.H.; Wang, Y. Experimental Study of the Effect of Tack Coats on Interlayer Bond Strength of Pavement. Sustainability 2023, 15, 6600. https://doi.org/10.3390/su15086600

Ali MH, Khalil AH, Wang Y. Experimental Study of the Effect of Tack Coats on Interlayer Bond Strength of Pavement. Sustainability. 2023; 15(8):6600. https://doi.org/10.3390/su15086600

Chicago/Turabian StyleAli, Mohammed H., Amjad H. Khalil, and Yu Wang. 2023. "Experimental Study of the Effect of Tack Coats on Interlayer Bond Strength of Pavement" Sustainability 15, no. 8: 6600. https://doi.org/10.3390/su15086600

APA StyleAli, M. H., Khalil, A. H., & Wang, Y. (2023). Experimental Study of the Effect of Tack Coats on Interlayer Bond Strength of Pavement. Sustainability, 15(8), 6600. https://doi.org/10.3390/su15086600