Impact of Copper Stabilizer Thickness on SFCL Performance with PV-Based DC Systems Using a Multilayer Thermoelectric Model

Abstract

:1. Introduction

1.1. Background and Motivation

1.2. Literature Review

1.3. Contribution

1.4. Organization

2. System Description

3. DC System Fault Analysis

4. Numerical Model

5. Simulation Results and Discussion

5.1. Case Studies

5.1.1. Case Study 1 (80 µm Copper Stabilizer)

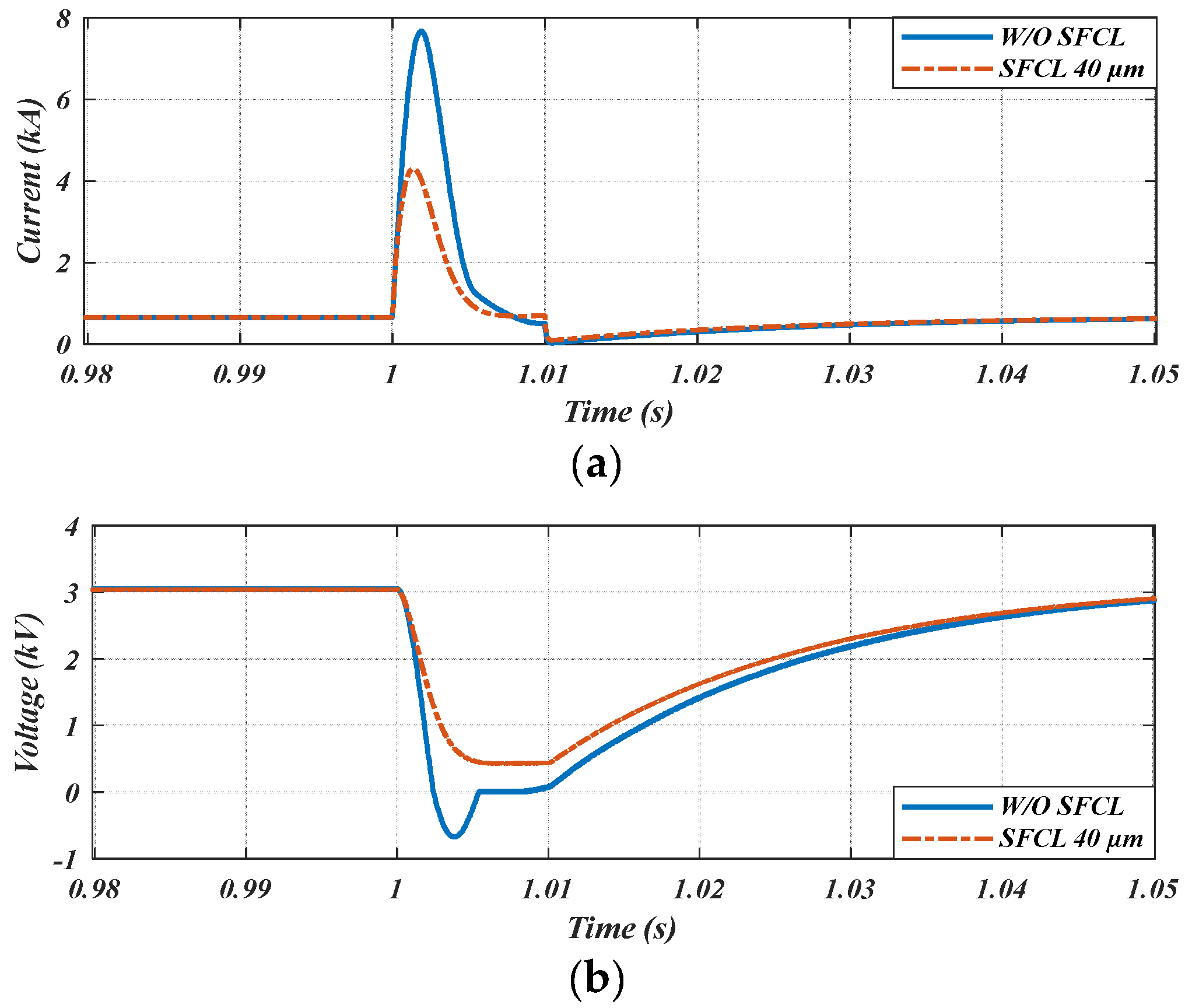

5.1.2. Case Study 2 (40 µm Copper Stabilizer)

5.1.3. Case Study 3 (20 µm Copper Stabilizer)

5.1.4. Case Study 4 (10 µm Copper Stabilizer)

5.2. Discussion and Comparison

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Iqbal, N.; Abbasi, K.R.; Shinwari, R.; Guangcai, W.; Ahmad, M.; Tang, K. Does exports diversification and environmental innovation achieve carbon neutrality target of OECD economies? J. Environ. Manag. 2021, 291, 112648. [Google Scholar] [CrossRef] [PubMed]

- European Commission. A European Green Deal. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en (accessed on 24 February 2023).

- European Commission. 2050 Long-Term Strategy. Available online: https://ec.europa.eu/clima/eu-action/climate-strategies-targets/2050-long-term-strategy_en (accessed on 24 February 2023).

- Kato, E.; Kurosawa, A. Role of negative emissions technologies (NETs) and innovative technologies in transition of Japan’s energy systems toward net-zero CO2 emissions. Sustain. Sci. 2021, 16, 463–475. [Google Scholar] [CrossRef]

- Government of Saudi Arabia. Vision 2030 Kingdom of Saudi Arabia. 2020; pp. 1–85. Available online: https://vision2030.gov.sa/download/file/fid/417 (accessed on 24 February 2023).

- Kingdom of Saudi Arabia Renewable Energy Project Development Office. Saudi Arabia National Renewable Energy Program. 2019. Available online: https://www.ief.org/_resources/files/events/third-ief-eu-energy-day/turki-al-shehri-24.02-repdo---ief_riyadh_v2-2.pdf (accessed on 24 February 2023).

- Saudi Green Initiative. 2021. Available online: https://saudigreeninitiative.org/ (accessed on 24 February 2023).

- Saudi Arabia Commits to Net Zero Emissions by 2060. 2021. Available online: https://www.bbc.com/news/world-middle-east-58955584#:~:text=The world’s biggest oil exporter,130bn) to Reach the Goal (accessed on 24 February 2023).

- Andersen, A.D. No transition without transmission: HVDC electricity infrastructure as an enabler for renewable energy? Environ. Innov. Soc. Transit. 2014, 13, 75–95. [Google Scholar] [CrossRef]

- Ryndzionek, R.; Sienkiewicz, Ł. Evolution of the HVDC link connecting offshore wind farms to onshore power systems. Energies 2020, 13, 1914. [Google Scholar] [CrossRef]

- Zhuo, Z.; Zhang, N.; Yang, J.; Kang, C.; Smith, C.; O’Malley, M.J.; Kroposki, B. Transmission Expansion Planning Test System for AC/DC Hybrid Grid with High Variable Renewable Energy Penetration. IEEE Trans. Power Syst. 2020, 35, 2597–2608. [Google Scholar] [CrossRef]

- Ludin, G.A.; Nakadomari, A.; Yona, A.; Mikkili, S.; Rangarajan, S.S.; Collins, E.R.; Senjyu, T. Technical and Economic Analysis of an HVDC Transmission System for Renewable Energy Connection in Afghanistan. Sustainability 2022, 14, 1468. [Google Scholar] [CrossRef]

- Liang, X.; Abbasipour, M. HVDC Transmission and its Potential Application in Remote Communities: Current Practice and Future Trend. IEEE Trans. Ind. Appl. 2022, 58, 1706–1719. [Google Scholar] [CrossRef]

- Beheshtaein, S.; Cuzner, R.M.; Forouzesh, M.; Savaghebi, M.; Guerrero, J.M. DC Microgrid Protection: A Comprehensive Review. IEEE J. Emerg. Sel. Top. Power Electron. 2019; early access. [Google Scholar] [CrossRef]

- Alafnan, H. Turboelectric Aircraft DC Network Fault Analysis and Protection Solution Using Superconducting Fault Current Limiters. Ph.D. Thesis, University of Bath, Bath, UK, 2021. [Google Scholar]

- Nahas, E.W.; Abd el-Ghany, H.A.; Mansour, D.E.A.; Eissa, M.M. Extensive analysis of fault response and extracting fault features for DC microgrids. Alexandria Eng. J. 2021, 60, 2405–2420. [Google Scholar] [CrossRef]

- Tan, C.; Teng, X.; Ding, Q.; Xiao, X.; Lan, Q.; Cao, R.; Chang, L. Synergistic balancing control for low-inertia power systems with high PV penetration: Tibet as a case study. Energy Rep. 2022, 8, 2924–2935. [Google Scholar] [CrossRef]

- Pei, X.; Smith, A.C.; Cwikowski, O.; Barnes, M. Hybrid DC circuit breaker with coupled inductor for automatic current commutation. Int. J. Electr. Power Energy Syst. 2020, 120, 106004. [Google Scholar] [CrossRef]

- Alafnan, H.; Elshiekh, M.; Pei, X.; Altouq, S.; Fazeli, S.M.; Sun, Q.; Zhang, M.; Yuan, W. Application of SMES-FCL in Electric Aircraft for Stability Improvement. IEEE Trans. Appl. Supercond. 2019, 29, 5000906. [Google Scholar] [CrossRef]

- Alafnan, H.; Zeng, X.; Pei, X.; Khedr, M.; Zhang, M.; Yuan, W. Analysing Faults and SFCL Response in Electric Aircraft. J. Phys. Conf. Ser. 2020, 1559, 012103. [Google Scholar] [CrossRef]

- Mansour, D.E.A.; Yehia, D.M. Analysis of 3-phase superconducting fault current limiters in power systems with inhomogeneous quenching. IEEE Trans. Appl. Supercond. 2013, 23, 5602605. [Google Scholar] [CrossRef]

- Yehia, D.M.; Taha, I.B.M. Application of Superconducting Fault Current Limiter as a Virtual Inertia for DC Distribution Systems. IEEE Access 2021, 9, 135384–135391. [Google Scholar] [CrossRef]

- Elshiekh, M.; Elwakeel, A.; Venuturumilli, S.; Alafnan, H.; Pei, X.; Zhang, M.; Yuan, W. Utilising SMES-FCL to improve the transient behaviour of a doubly fed induction generator DC wind system. Int. J. Electr. Power Energy Syst. 2021, 131, 107099. [Google Scholar] [CrossRef]

- NASA. The Causes of Climate Change. 2021. Available online: https://climate.nasa.gov/causes/ (accessed on 24 February 2023).

- Al-Ghussain, L. Global warming: Review on driving forces and mitigation. Environ. Prog. Sustain. Energy 2019, 38, 13–21. [Google Scholar] [CrossRef]

- Hoegh-Guldberg, O.; Jacob, D.; Bindi, M.; Brown, S.; Camilloni, I.; Diedhiou, A.; Djalante, R.; Ebi, K.; Engelbrecht, F.; Guiot, J.; et al. Chapter 3: Impacts of 1.5 °C global warming on natural and human systems. In Global Warming of 1.5 °C; IPCC Secretariat: Geneva, Switzerland, 2018; pp. 175–311. [Google Scholar]

- Delbeke, J.; Runge-Metzger, A.; Slingenberg, Y.; Werksman, J. The paris agreement. In Towards a Climate-Neutral Europe; Routledge: Abington, UK, 2019; pp. 24–45. [Google Scholar] [CrossRef]

- Hansen, K.; Breyer, C.; Lund, H. Status and perspectives on 100% renewable energy systems. Energy 2019, 175, 471–480. [Google Scholar] [CrossRef]

- Nwaigwe, K.N.; Mutabilwa, P.; Dintwa, E. An overview of solar power (PV systems) integration into electricity grids. Mater. Sci. Energy Technol. 2019, 2, 629–633. [Google Scholar] [CrossRef]

- Ramachandran, T.; Mourad, A.H.I.; Hamed, F. A Review on Solar Energy Utilization and Projects: Development in and around the UAE. Energies 2022, 15, 3754. [Google Scholar] [CrossRef]

- Song, D.; Pei, H.; Liu, Y.; Wei, H.; Yang, S.; Hu, S. Review on Legislative System of Photovoltaic Industry Development in China. Energies 2022, 15, 306. [Google Scholar] [CrossRef]

- AEO. U.S. Electricity Generation and Shares from Selected Fuels and Renewable Sources; AEO: Brussels, Belgium, 2021; Volume 2021. [Google Scholar]

- General, Assembly. United Nations Transforming our World: The 2030 Agenda for Sustainable Development; Division for Sustainable Development Goals: New York, NY, USA, 2015. [Google Scholar]

- Marques Lameirinhas, R.A.; Torres, J.P.N.; de Melo Cunha, J. A Photovoltaic Technology Review: History, Fundamentals and Applications. Energies 2022, 15, 1823. [Google Scholar] [CrossRef]

- Sakkas, S. Control of a DC Microgrid. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2018. [Google Scholar]

- Rodriguez-Diaz, E.; Vasquez, J.C.; Guerrero, J.M. Intelligent DC Homes in Future Sustainable Energy Systems: When efficiency and intelligence work together. IEEE Consum. Electron. Mag. 2016, 5, 74–80. [Google Scholar] [CrossRef]

- Cuzner, R.M.; Venkataramanan, G. The status of DC micro-grid protection. In Proceedings of the 2008 IEEE Industry Applications Society Annual Meeting, Edmonton, AB, Canada, 5–9 October 2008; pp. 1–8. [Google Scholar] [CrossRef]

- Van Delft, D.; Kes, P. The discovery of superconductivity. Phys. Today 2010, 63, 38–43. [Google Scholar] [CrossRef]

- Weng, F.; Zhang, M.; Elwakeel, A.; Lan, T.; McNeill, N.; Yuan, W. Transient Test and AC Loss Study of a Cryogenic Propulsion Unit for All Electric Aircraft. IEEE Access 2021, 9, 59628–59636. [Google Scholar] [CrossRef]

- Yazdani-Asrami, M.; Zhang, M.; Yuan, W. Challenges for developing high temperature superconducting ring magnets for rotating electric machine applications in future electric aircrafts. J. Magn. Magn. Mater. 2021, 522, 167543. [Google Scholar] [CrossRef]

- Alafnan, H.; Pei, X.; Khedr, M.; Alsaleh, I.; Albaker, A.; Alturki, M.; Mansour, D.-E.A. The Possibility of Using Superconducting Magnetic Energy Storage/Battery Hybrid Energy Storage Systems Instead of Generators as Backup Power Sources for Electric Aircraft. Sustainability 2023, 15, 1806. [Google Scholar] [CrossRef]

- Elshiekh, M. Increasing Wind Energy Integration into Power Grids Using Multifunctional Superconducting Devices Design. Ph.D. Thesis, University of Bath, Bath, UK, 2020. [Google Scholar]

- Pei, X.; Smith, A.C.; Barnes, M. Superconducting Fault Current Limiters for HVDC Systems; Elsevier: Amsterdam, The Netherlands, 2015; Volume 80. [Google Scholar]

- Xiang, B.; Junaid, M.; Gao, L.; Liu, Z.; Geng, Y.; Wang, J.; Yanabu, S. Influencing Factors on Quench and Recovery of YBCO Tapes for DC Superconducting Fault Current Limiter. IEEE Trans. Appl. Supercond. 2019, 29, 5600806. [Google Scholar] [CrossRef]

- Superpower Inc. 2G HTS Wire Specification. Available online: https://www.superpower-inc.com/specification.aspx (accessed on 24 February 2023).

- Xiang, B.; Wang, W.; Li, H.; Gao, L.; Liu, Z.; Geng, Y.; Wang, J.; Tu, Y. Study on the influencing factors to reduce the recovery time of superconducting tapes and coils for the DC superconducting fault current limiter applications. High Volt. 2022, 7, 483–495. [Google Scholar] [CrossRef]

- Song, W.; Pei, X.; Alafnan, H.; Xi, J.; Zeng, X.; Yazdani-Asrami, M.; Xiang, B.; Liu, Z. Experimental and Simulation Study of Resistive Helical HTS Fault Current Limiters: Quench and Recovery Characteristics. IEEE Trans. Appl. Supercond. 2021, 31, 5–10. [Google Scholar] [CrossRef]

- Chang, B. DC Protection of Multi-Terminal VSC-HVDC Systems. Ph.D. Thesis, University of Manchester, Manchester, UK, 2016. [Google Scholar]

- Jones, C.E.; Norman, P.J.; Sztykiel, M.; Pena Alzola, R.; Burt, G.M.; Galloway, S.J.; Kawashita, L.F.; Hallett, S.R. Electrical and Thermal Effects of Fault Currents in Aircraft Electrical Power Systems with Composite Aerostructures. IEEE Trans. Transp. Electrif. 2018, 4, 660–670. [Google Scholar] [CrossRef]

- Li, X.; Song, Q.; Liu, W.; Rao, H.; Xu, S.; Li, L. Protection of nonpermanent faults on DC overhead lines in MMC-based HVDC systems. IEEE Trans. Power Deliv. 2013, 28, 483–490. [Google Scholar] [CrossRef]

- Monadi, M.; Zamani, M.A.; Candela, J.I.; Luna, A.; Rodriguez, P. Protection of AC and DC distribution systems Embedding distributed energy resources: A comparative review and analysis. Renew. Sustain. Energy Rev. 2015, 51, 1578–1593. [Google Scholar] [CrossRef]

- Alafnan, H. Fault Analysis and Protection Solution for DC Transmission Lines of Solar Farms Using Superconducting Fault Current Limiters. In Proceedings of the 2022 5th International Conference on Power Electronics and Their Applications (ICPEA), Hail, Saudi Arabia, 29–31 March 2022; p. 5. [Google Scholar]

- De Sousa, W.T.B.; Dias, R.; Da Silva, F.A.; Polasek, A.; De Andrade, R. Comparison between the fault current limiting performance of Bi-2212 bifilar components and 2G YBCO coils. IEEE Trans. Appl. Supercond. 2013, 23, 2–6. [Google Scholar] [CrossRef]

- Naderi, S.; Davari, P.; Zhou, D.; Negnevitsky, M.; Blaabjerg, F. A Review on Fault Current Limiting Devices to Enhance the Fault Ride-Through Capability of the Doubly-Fed Induction Generator Based Wind Turbine. Appl. Sci. 2018, 8, 2059. [Google Scholar] [CrossRef]

- Elshiekh, M.E.; Mansour, D.-E.A.; Azmy, A.M. Improving Fault Ride-Through Capability of DFIGBased Wind Turbine Using Superconducting Fault Current Limiter. IEEE Trans. Appl. Supercond. 2012, 23, 5601204. [Google Scholar] [CrossRef]

- Xiang, B.; Gao, L.; Liu, Z.; Geng, Y.; Wang, J. Short-circuit fault current-limiting characteristics of a resistive-type superconducting fault current limiter in DC grids. Supercond. Sci. Technol. 2020, 33, 024005. [Google Scholar] [CrossRef]

- Bock, J.; Hobl, A.; Schramm, J.; Kramer, S.; Janke, C. Resistive superconducting fault current limiters are becoming a mature technology. IEEE Trans. Appl. Supercond. 2015, 25, 5600604. [Google Scholar] [CrossRef]

- Nam, K.; Lee, C.; Park, D.K.; Ko, T.K.; Seok, B.Y. Thermal and electrical analysis of coated conductor under AC over-current. IEEE Trans. Appl. Supercond. 2007, 17, 1923–1926. [Google Scholar] [CrossRef]

- Elshiekh, M.; Zhang, M.; Ravindra, H.; Chen, X.; Venuturumilli, S.; Huang, X.; Schoder, K.; Steurer, M.; Yuan, W. Effectiveness of Superconducting Fault Current Limiting Transformers in Power Systems. IEEE Trans. Appl. Supercond. 2018, 28, 5601607. [Google Scholar] [CrossRef]

- Pérez-Chávez, J.J.; Trillaud, F.; Castro, L.M.; Quéval, L.; Polasek, A.; De Andrade Junior, R. Generic Model of Three-Phase (RE)BCO Resistive Superconducting Fault Current Limiters for Transient Analysis of Power Systems. IEEE Trans. Appl. Supercond. 2019, 29, 5601811. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Critical current (A, single tape) | 300 |

| Total thickness (μm) | 140/100/80/70 |

| YBCO layer thickness (μm) | 1 |

| Silver layer thickness (μm) | 3.8 |

| Hastelloy stabilizer thickness (μm) | 50 |

| Copper stabilizer thickness (μm) | 80/40/20/10 |

| Width (mm) | 12 |

| Length of tape (m) | 300 |

| Rated voltage (kV) | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alafnan, H.; Pei, X.; Mansour, D.-E.A.; Khedr, M.; Song, W.; Alsaleh, I.; Albaker, A.; Alturki, M.; Zeng, X. Impact of Copper Stabilizer Thickness on SFCL Performance with PV-Based DC Systems Using a Multilayer Thermoelectric Model. Sustainability 2023, 15, 7372. https://doi.org/10.3390/su15097372

Alafnan H, Pei X, Mansour D-EA, Khedr M, Song W, Alsaleh I, Albaker A, Alturki M, Zeng X. Impact of Copper Stabilizer Thickness on SFCL Performance with PV-Based DC Systems Using a Multilayer Thermoelectric Model. Sustainability. 2023; 15(9):7372. https://doi.org/10.3390/su15097372

Chicago/Turabian StyleAlafnan, Hamoud, Xiaoze Pei, Diaa-Eldin A. Mansour, Moanis Khedr, Wenjuan Song, Ibrahim Alsaleh, Abdullah Albaker, Mansoor Alturki, and Xianwu Zeng. 2023. "Impact of Copper Stabilizer Thickness on SFCL Performance with PV-Based DC Systems Using a Multilayer Thermoelectric Model" Sustainability 15, no. 9: 7372. https://doi.org/10.3390/su15097372