Insight into the Evolutionary Mechanism of the Rear Fissure of Landslides That Conform to the Three-Section Mechanism

Abstract

:1. Introduction

2. Rear Fissure in a Typical Landslide

3. Base Friction Testing for Landslide Fissure Extension

3.1. Sample Preparation

3.2. Testing Scheme

- (I)

- According to the material ratio listed in Table 1, two different materials were determined and stirred evenly;

- (II)

- The testing model slope was constructed on the belt of the base friction tester according to the schematic design of the base friction model shown in Figure 2; then, preconsolidation was completed;

- (III)

- After the reasonable arrangement of the light supplement equipment, the PIV high-speed camera (Figure 2c,d) was arranged at a suitable height above the slope model and connected to the computer control system. The camera was configured with a sample interval of 30 frames per second;

- (IV)

- The conveyor belt began to rotate to render model deformation stable for more than 1 min, along with PIV measurement;

- (V)

- Belt rotation was suspended to excavate the first section of the top fissure (Section I in Figure 2b, labeled by a red dashed line), with a length of 20 mm and a width of about 1.5 mm, and the conveyor belt began to rotate to render model deformation stable for more than 1 min, along with PIV measurement;

- (VI)

- In order to create a fissure with a total depth of 60 mm and a width of roughly 1.5 mm, conveyor belt rotation was stopped in order to excavate the second section of the fissure (Section II in Figure 2b, labeled by a red dashed line). After that, the belt resumed rotating to make the model deformation stable for more than a minute, accompanied by PIV measurements;

- (VII)

- Repeating the operations outlined in steps (V) and (VI), the slope models with a fissure with a total depth of 100/140/180/220 mm were loaded and measured on the conveyor belt of the base friction tester. It is noted that visible damage on both sides of the fissure was prohibited during fissure excavation; thus, a thin and pointed tool, e.g., a toothpick, was recommended in the experiment.

3.3. Experimental Results

- (1)

- Evolution of the displacement field

- (2)

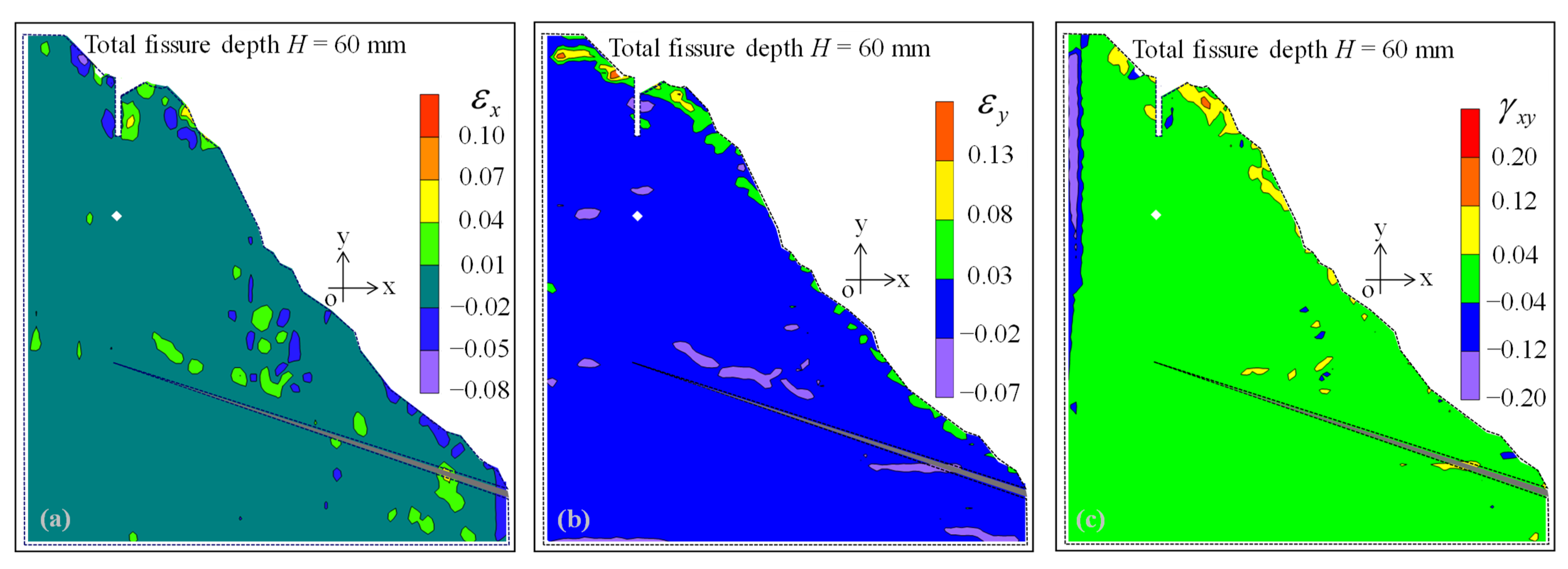

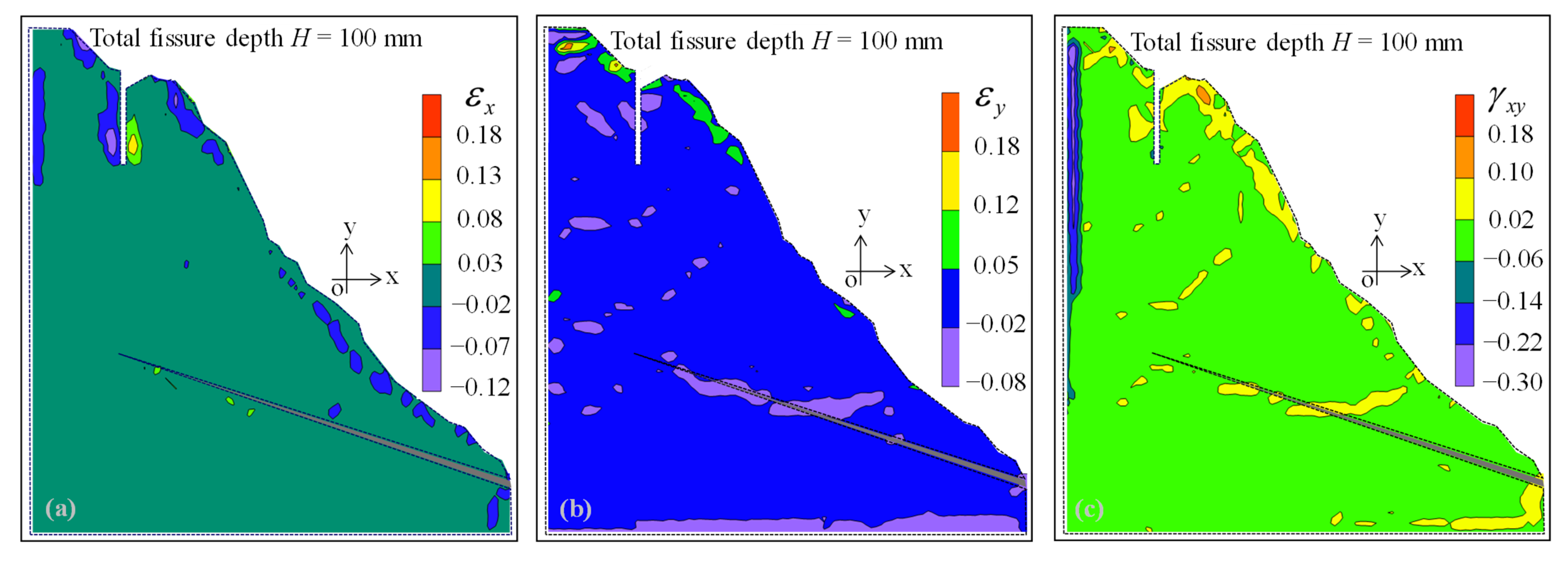

- Evolution of strain fields

4. Evolutionary Mechanism of the Rear Fissure

- Without the rear tension fissure, controlled by the specially sloped structure with a weak interlayer in front, it is inevitable that the rear fissure will initiate in the special position according to displacement differentiation and strain concentration;

- For the rear tension fissure propagation from zero to approximately 0.5 Hcr, with the creep active zone of the front weak interlayer migrating from outside to inside, the traction action, especially for the fissure tip, is gradually increased to accelerate rear tension fissure extension, accompanying significant strain concentrations at the tension fissure tip;

- For the rear tension fissure propagation from approximately 0.5 Hcr to nearly Hcr, with an increasing trend of the rear fissure closure, the strain concentration cores, mainly at the half-depth of the tension fissure, gradually diverge from the tension fissure tip, resulting in a reduction in the propagation drive of the rear tension fissure;

- With a tension fissure of nearly Hcr and a rotation trend of the slope body, the rear tension fissure tip is dominated by compression–shear stresses, portending the upcoming shear failure of the locking section along a circular-arc fracture path.

5. Discussion

6. Conclusions

- (1)

- Through displacement differentiation and strain concentration controlled by the front weak interlayer, the rear tension fissure is inevitable; therefore, we recommend consideration of in the stability evaluation of landslides that conform to the three-section mechanism;

- (2)

- For the rear tension fissure propagation from zero to nearly Hcr, controlled by the migration of displacement differentiation and strain concentration, the driving effect undergoes acceleration, then deceleration, roughly bounded by the half critical tension fissure at the slope rear;

- (3)

- The trend of rear tension fissure closure may originate from a tension fissure depth of approximately Hcr/2, which is not a sufficient condition for landslide occurrence, which may result in misreporting of precursor information with respect to early warning of locked landslides that conform to the three-section mechanism.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tao, Z.G.; Geng, Q.; Zhu, C.; He, M.; Cai, H.; Pang, S.; Meng, X. The mechanical mechanism of large-scale toppling failure for counter-inclined rock slopes. J. Geophys. Eng. 2019, 16, 541–558. [Google Scholar] [CrossRef]

- Huang, R.Q.; Chen, G.Q.; Guo, F.; Zhang, G.; Zhang, Y. Experimental study on the brittle failure of the locking section in a large-scale rock slide. Landslides 2016, 13, 583–588. [Google Scholar] [CrossRef]

- Huang, R.Q. Mechanisms of large-scale landslides in China. B Eng. Geol. Environ. 2012, 71, 161–170. [Google Scholar] [CrossRef]

- Chen, G.Q.; Tang, P.; Huang, R.Q.; Wang, D.; Lin, Z.; Huang, D. Critical tension crack depth in rockslides that conform to the three-section mechanism. Landslides 2021, 18, 79–88. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Liu, H.C. Key Engineering Geology Problem and Research on Longyangxia Hydropower Station of Huanghe River; University of Technology Press: Chengdu, China, 1990. [Google Scholar]

- Li, X.S.; Li, Q.; Wang, Y.M.; Liu, W.; Hou, D.; Zheng, W.; Zhang, X. Experimental study on instability mechanism and critical intensity of variation rainfall of high-steep rock slopes under unsaturated conditions. Int. J. Min. Sci. Technol. 2023, 33, 1243–1260. [Google Scholar] [CrossRef]

- Yin, Y.; Deng, Q.; Li, W.; He, K.; Wang, Z.; Li, H.; An, P.; Fang, K. Insight into the crack characteristics and mechanisms of retrogressive slope failures: A large-scale model test. Eng. Geol. 2023, 327, 107360. [Google Scholar] [CrossRef]

- Wu, X.Y.; Niu, F.J.; Liang, Q.G.; Li, G. Study on tensile strength and tensile-shear coupling mechanism of loess around Lanzhou and Yanan city in China by unconfined penetration test. Ksce J. Civ. Eng. 2019, 23, 2471–2482. [Google Scholar] [CrossRef]

- Lu, Y.; Chen, X.; Wang, L. Research on Fracture Mechanism and Stability of Slope with Tensile Cracks. Appl. Sci. 2022, 12, 12687. [Google Scholar] [CrossRef]

- Zhu, C.; He, M.; Karakus, M.; Cui, X.; Tao, Z. Investigating toppling failure mechanism of anti-dip layered slope due to excavation by physical modelling. Rock Mech. Rock Eng. 2020, 53, 5029–5050. [Google Scholar] [CrossRef]

- Wang, C.; Wang, H.; Qin, W.; Wei, S.; Tian, H.; Fang, K. Behaviour of pile-anchor reinforced landslides under varying water level, rainfall, and thrust load: Insight from physical modelling. Eng. Geol. 2023, 325, 107293. [Google Scholar] [CrossRef]

- Tao, Z.G.; Zhu, C.; He, M.C.; Liu, K. Research on the safe mining depth of anti-dip bedding slope in Changshanhao Mine. Geomech. Geophys. Geo. 2020, 6, 36. [Google Scholar]

- Ren, F.Q.; Zhu, C.; He, M.C. Moment tensor analysis of acoustic emissions for cracking mechanisms during schist strain burst. Rock Mech. Rock Eng. 2020, 53, 153–170. [Google Scholar] [CrossRef]

- Dong, M.; Zhang, F.; Lv, J.; Hu, M.; Li, Z. Study on Deformation and Failure Law of Soft-hard rock interbedding Toppling slope Base on Similar Test. Bull. Eng. Geol. Environ. 2020, 79, 4625–4637. [Google Scholar] [CrossRef]

- Dong, M.; Zhang, F.; Hu, M.; Liu, C. Study on the Influence of Anchorage Angle on the Anchorage Effect of Soft-hard Inter-bedded Toppling Deformed Rock Mass. Ksce J. Civ. Eng. 2020, 24, 2382–2392. [Google Scholar] [CrossRef]

- Zhang, D.-B.; Zhang, Y.; Cheng, T.; Meng, Y.; Fang, K.; Garg, A.; Garg, A. Measurement of displacement for open pit to underground mining transition using digital photogrammetry. Measurement 2017, 109, 187–199. [Google Scholar] [CrossRef]

- Beng, X.T.; Zhang, G.C.; Yang, Y.C.; Zhu, C.; Karakus, M.; Wang, D. Flexural toppling characteristics of anti-dip soft rock slope with base friction test. B Eng. Geol. Environ. 2023, 82, 21. [Google Scholar] [CrossRef]

- Tu, G.; Deng, H.; Li, M. Development and evolution of deep-seated toppling landslide by rapid river downcutting. Bull. Eng. Geol. Environ. 2023, 82, 185. [Google Scholar] [CrossRef]

- Bray, J.W.; Goodman, R.E. The Theory of Base Friction Models. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1981, 18, 453–468. [Google Scholar] [CrossRef]

- Wang, Y.K.; Sun, S.W.; Pang, B.; Liu, L. Base friction test on unloading deformation mechanism of soft foundation waste dump under gravity. Measurement 2020, 163, 108054. [Google Scholar] [CrossRef]

- Zhang, S.; Shi, W.; Yang, C.; Wang, Y.; Yu, X. Experimental evaluation of gentle anti-dip slope deformation and fracture network under the action of underground mining. Landslides 2022, 20, 381–408. [Google Scholar] [CrossRef]

- Fang, K.; Zhang, J.; Tang, H.; Hu, X.; Yuan, H.; Wang, X.; An, P.; Ding, B. A quick and low-cost smartphone photogrammetry method for obtaining 3D particle size and shape. Eng. Geol. 2023, 322, 107170. [Google Scholar] [CrossRef]

- Zhu, C.; He, M.C.; Karakus, M.; Zhang, X.; Tao, Z. Numerical simulations of the failure process of an aclinal slope physical model and control mechanism of negative Poisson’s ratios cable. B Eng. Geol. Environ. 2021, 80, 3365–3380. [Google Scholar] [CrossRef]

- Bao, M.; Chen, Z.H.; Zhang, L.F.; Nian, G.; Zhu, T.; Hao, J. Experimental study on the sliding instability mechanism of slopes with weak layers under creeping action. Measurement 2023, 212, 112690. [Google Scholar] [CrossRef]

- Zhou, Z.H.; Chen, Z.H.; Shen, Y.; Bao, M.; Nian, G.; Zhang, L.; Liu, Y. Failure of rock slopes with intermittent joints: Failure process and stability calculation models. Lithosphere 2022, 2021, 8923718. [Google Scholar] [CrossRef]

- Huang, R.Q. Some catastrophic landslides since the twentieth century in the southwest of China. Landslides 2009, 6, 69–81. [Google Scholar]

- Huang, R.Q.; Xu, Q. Typical Catastrophic Landslides in China; Science Press: Beijing, China, 2008. [Google Scholar]

- Huang, R.Q.; Zhang, Z.Y.; Wang, S.T. Systematic Engineering Geology Studying of the Stability of High Slope; Chengdu University of Technology Press: Chengdu, China, 1991. [Google Scholar]

- Tao, Z.G.; Zhu, C.; He, M.C.; Karakus, M. A physical modeling-based study on the control mechanisms of Negative Poisson’s ratio anchor cable on the stratified toppling deformation of anti-inclined slopes. Int. J. Rock Mech. Min. 2021, 138, 104632. [Google Scholar] [CrossRef]

- Zhang, L.F.; Chen, Z.H.; Nian, G.Q.; Bao, M.; Zhou, Z. Base friction testing methodology for the deformation of rock masses caused by mining in an open-pit slope. Measurement 2023, 206, 112235. [Google Scholar] [CrossRef]

- Fang, K.; Tang, H.M.; Li, C.D.; Su, X.; An, P.; Sun, S. Centrifuge modelling of landslides and landslide hazard mitigation: A review. Geosci. Front. 2023, 14, 101493. [Google Scholar] [CrossRef]

- Ning, Y.B.; Tang, H.; Zhang, G.; Smith, J.V.; Zhang, B.; Shen, P.; Chen, H. A complex rockslide developed from a deep-seated toppling failure in the upper Lancang River, Southwest China. Eng. Geol. 2021, 293, 106329. [Google Scholar] [CrossRef]

- Fang, K.; Dong, A.; Tang, H.; An, P.; Zhang, B.; Miao, M.; Ding, B.; Hu, X. Comprehensive assessment of the performance of a multismartphone measurement system for landslide model test. Landslides 2022, 20, 845–864. [Google Scholar] [CrossRef]

- Ge, X.R. Deformation control law of rock fatigue failure, real-time X-ray CT scan of geotechnical testing and new method of stability analysis of slopes and dam foundations. Chin. J. Geotech. Eng. 2008, 30, 1–20.w. [Google Scholar]

| Slope Part | Material Ratio (Mass Ratio) | γ (kN/m3) | c (kPa) | φ (°) |

|---|---|---|---|---|

| Main mass | Barite:quartz sand:paraffin oil = 32:16:7 | 24.0 | 29.2 | 33.9 |

| Weak interlayer | Bentonite:barite:quartz sand:water = 10:3:2:5 | 18.0 | 0.76 | 18.6 |

| Test Aim | Exploring the Evolutionary Mechanism of the Rear Fissure in a Kind of Landslide | ||||

|---|---|---|---|---|---|

| Basic | Triggers | Gravity-like force | Container | Model type | Two-dimensional |

| Force action | Base friction | Model size | Length: 543 mm; width: 520 mm; thickness: 5 mm | ||

| Landslide Classification | Potential Rockslide | Preparation | Compaction | ||

| Slope model | Tension fissure | Man-made | Monitor tool | PIV system | Displacements of various marker points dispersed automatically |

| Material (Main mass) | 58% barite, 29% quartz sand, 13% paraffin oil. | Test | Prototype | Potential landslide named deformation body II | |

| Material (Weak interlayer) | 50% bentonite, 15% barite, 10% quartz sand, 25% water. | Condition | Test variable | Different fissure length | |

| Important results | |||||

| ① | The rear tension fissure has an inevitability to initiate controlled by the specially slope structures and the three-section mechanism of potential landslides. | ||||

| ② | For the rear tension fissure propagation from zero to nearly Hcr, the driving effect of tension fissure propagation undergoes a process from accelerating to then decelerating, roughly bounded by the half critical tension fissure at the slope rear. | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, P.; Chen, G.; Qin, S. Insight into the Evolutionary Mechanism of the Rear Fissure of Landslides That Conform to the Three-Section Mechanism. Sustainability 2024, 16, 17. https://doi.org/10.3390/su16010017

Tang P, Chen G, Qin S. Insight into the Evolutionary Mechanism of the Rear Fissure of Landslides That Conform to the Three-Section Mechanism. Sustainability. 2024; 16(1):17. https://doi.org/10.3390/su16010017

Chicago/Turabian StyleTang, Peng, Guoqing Chen, and Siqing Qin. 2024. "Insight into the Evolutionary Mechanism of the Rear Fissure of Landslides That Conform to the Three-Section Mechanism" Sustainability 16, no. 1: 17. https://doi.org/10.3390/su16010017