Analytical and Finite-Element-Method-Based Analyses of Pile Shaft Capacity Subjected to Rainfall Infiltration

Abstract

:1. Introduction

2. Literature Review

3. Research Methodology

3.1. Mathematical Equations

3.2. Laboratory Experiment

3.3. Numerical Analysis

- Setting for a new model—10 nodded elements, full model type, units as meters, area of 12 × 12 square foot (sqf).

- Construction of the model geometry—creation of boreholes and indication of GWT depth.

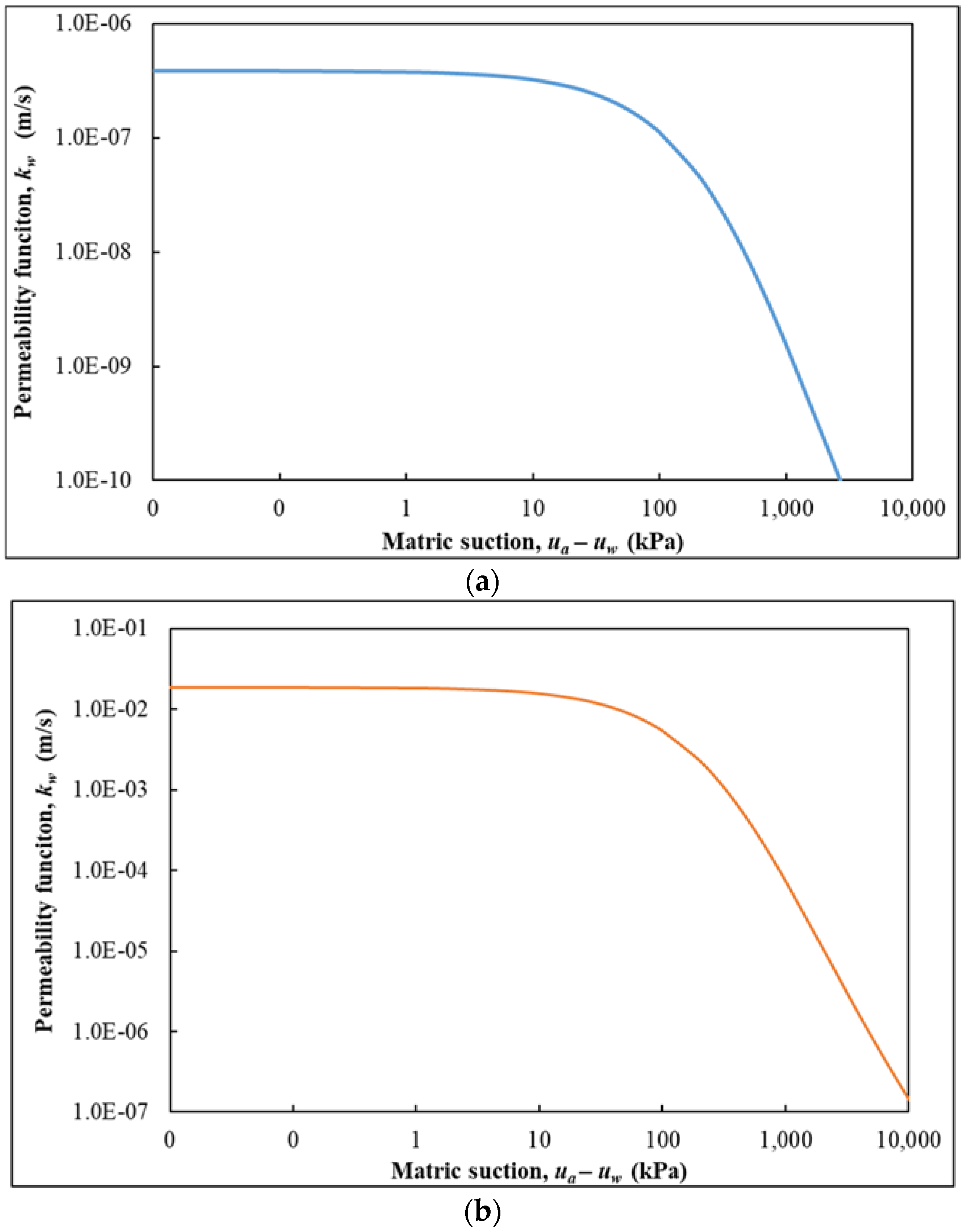

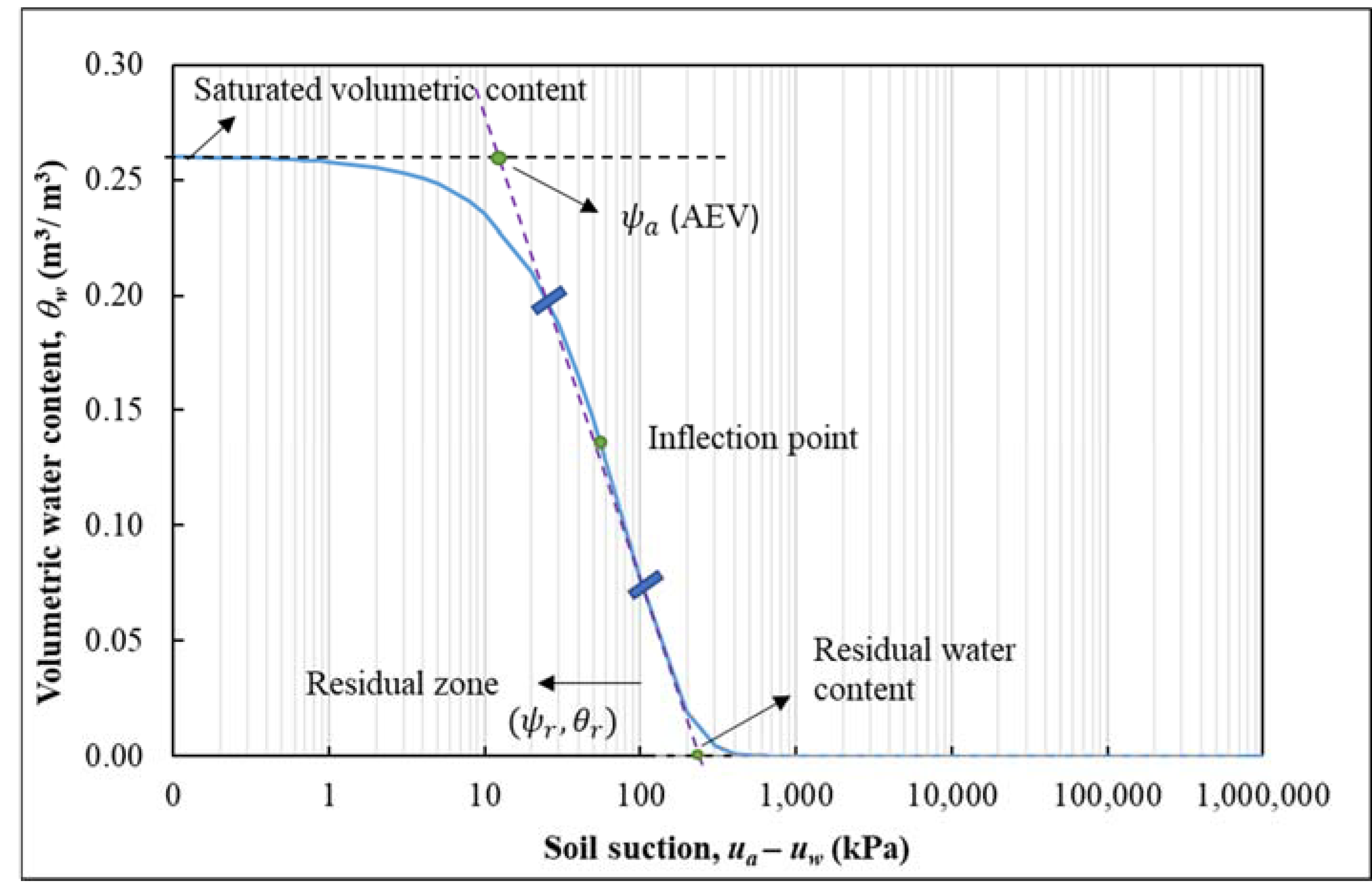

- Defining the unsaturated soil properties by entering the values for the matric suction, unsaturated permeability, and degree of saturation in the groundwater phase for each material using a user-defined method.

- Mesh properties where a fine mesh size for this modeling is chosen and the minimum element dimension of the mesh is 0.918 mm. This is to ensure that the calculation was accurate.

- The Mohr–Coulomb failure criterion was chosen for the soil, considered an isotropic and non-isolated material. Given the flexibility of the equation and the straightforward physical meanings of the material properties, this method is extensively utilized for stability analysis and critical stress prediction [41].

- The boundary conditions in this model are the pressure head (GWT depth) and the rainfall that was applied to the surface of the entire model. The assigned rainfall patterns were a 12-day rain period followed by a 12-day drying period. The most precipitation in Astana, Kazakhstan, in 12 days is 20 mm per day [42]. Using fully coupled analysis, the volume and cycle of rainfall were incorporated into the groundwater phase of simulation.

4. Results and Discussion

4.1. Analytical Calculations

4.1.1. β and Modified β Methods

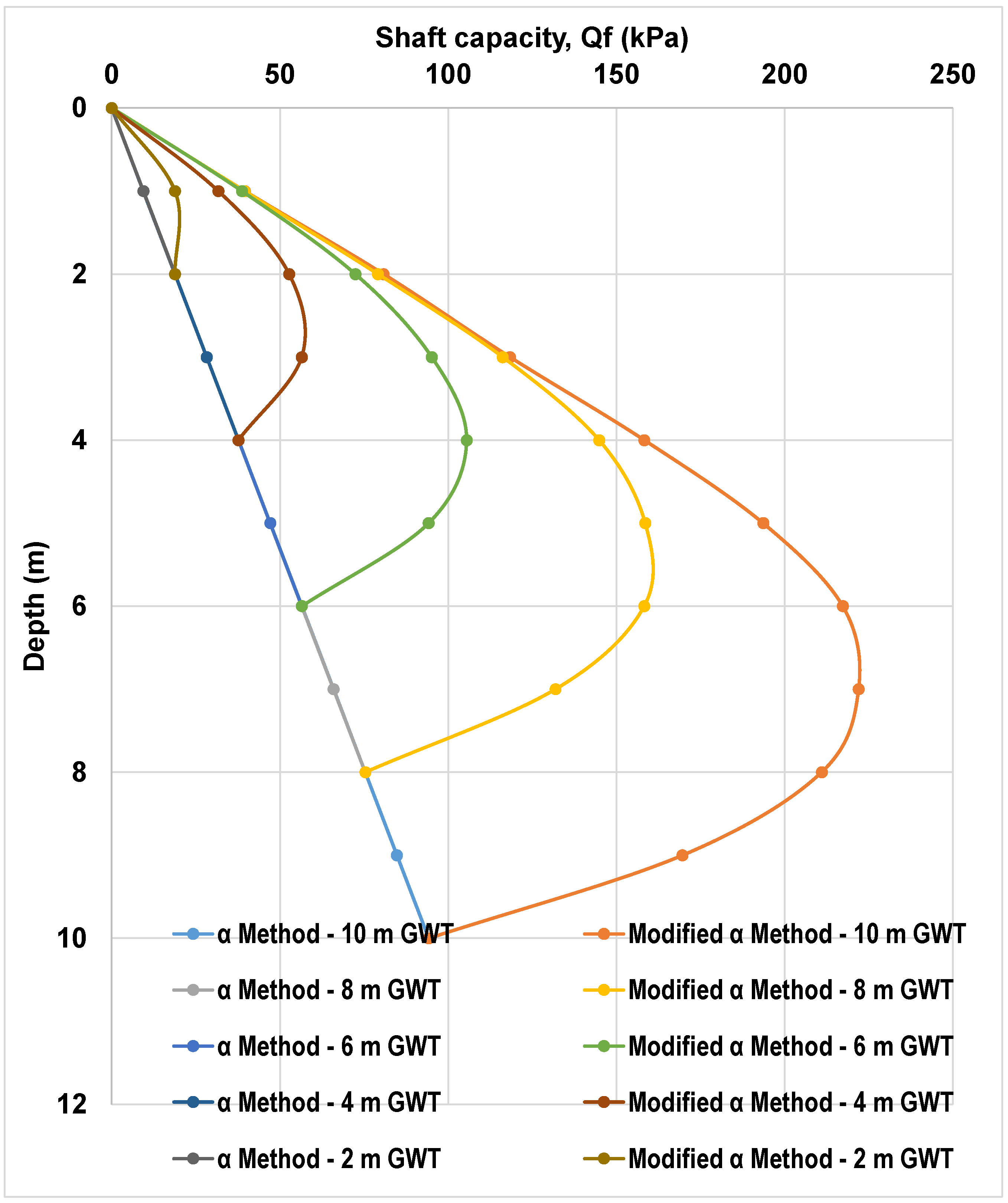

4.1.2. α and Modified α Methods

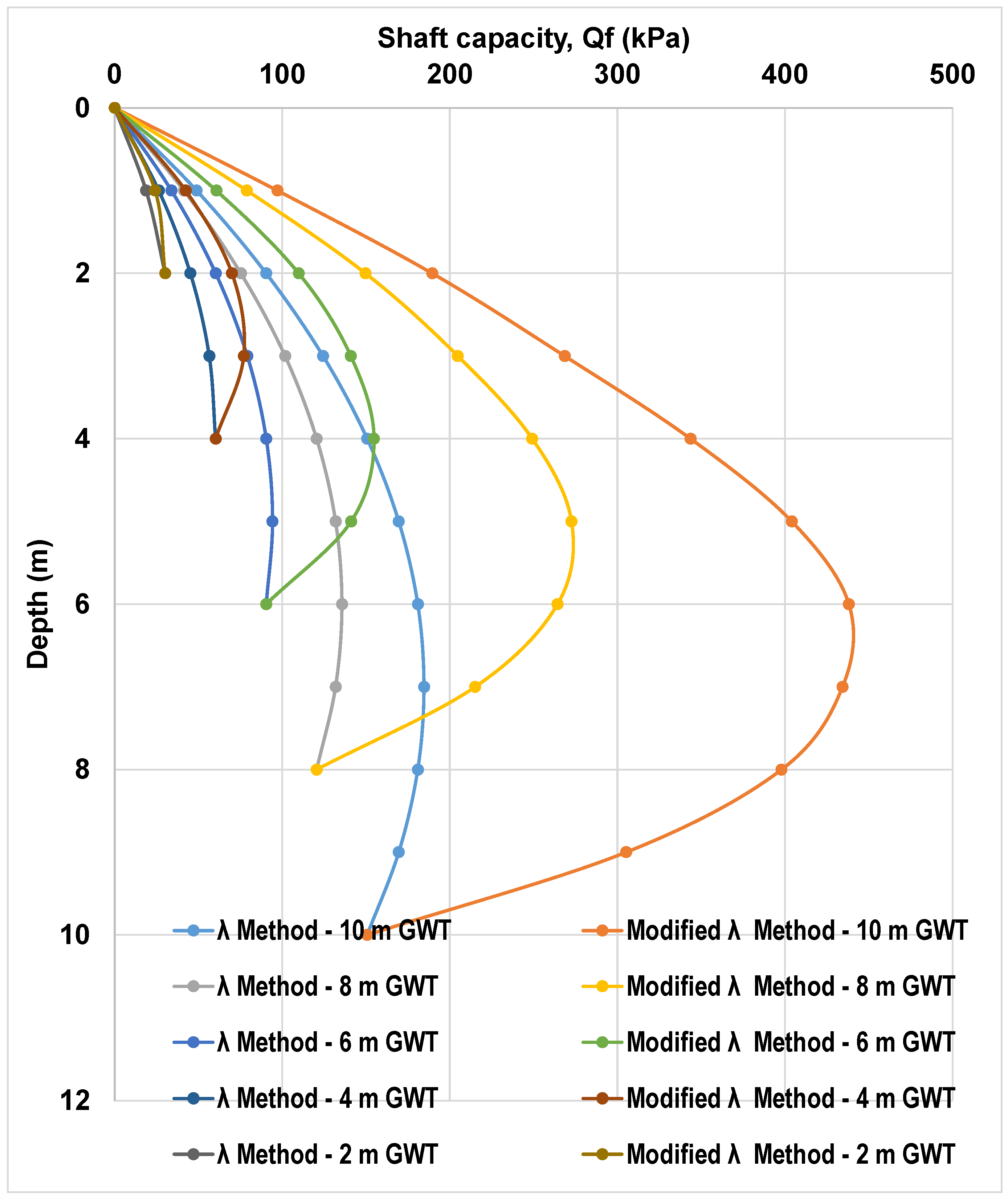

4.1.3. λ and Modified Methods

4.2. Numerical Analysis Using PLAXIS 3D (Version 22)

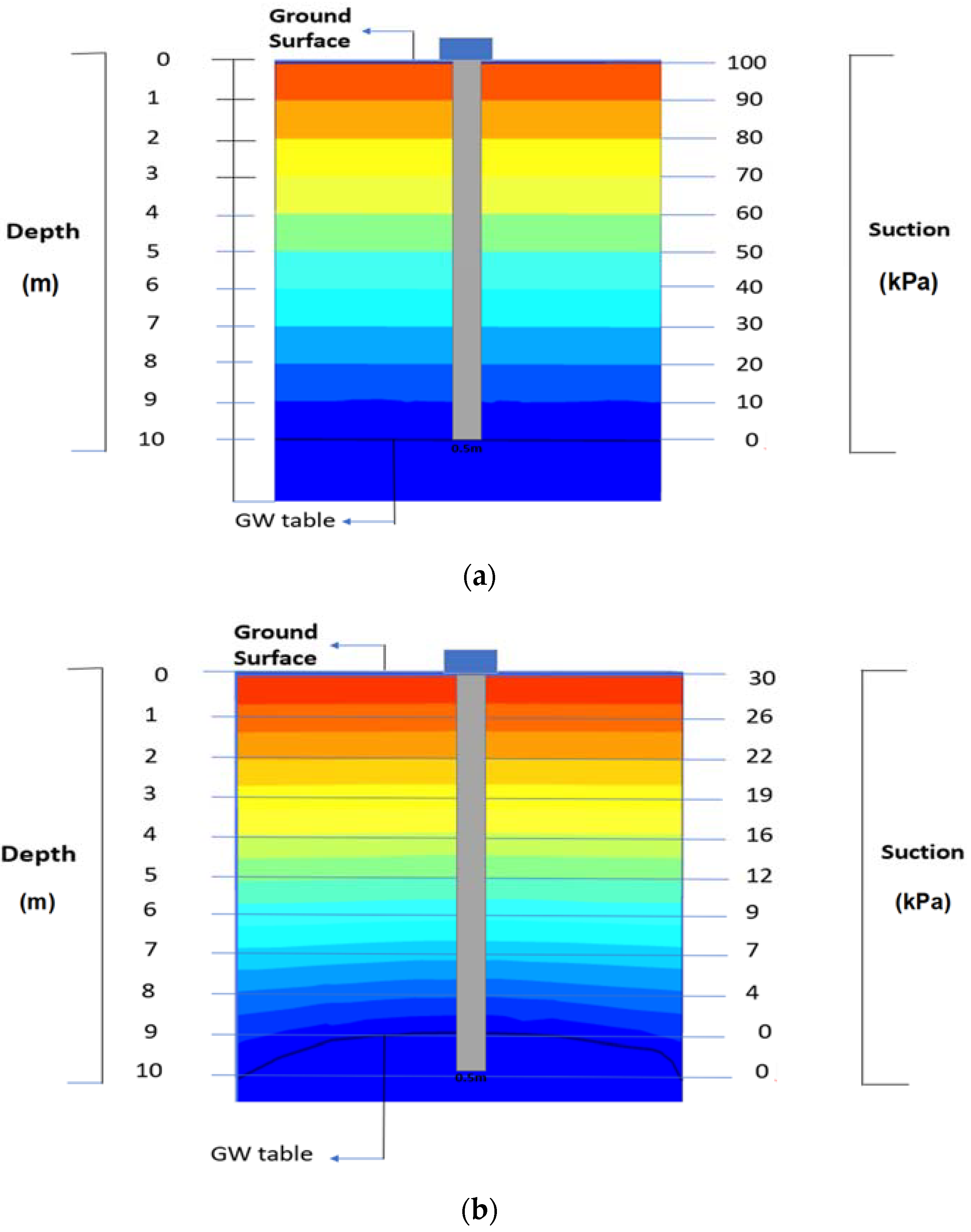

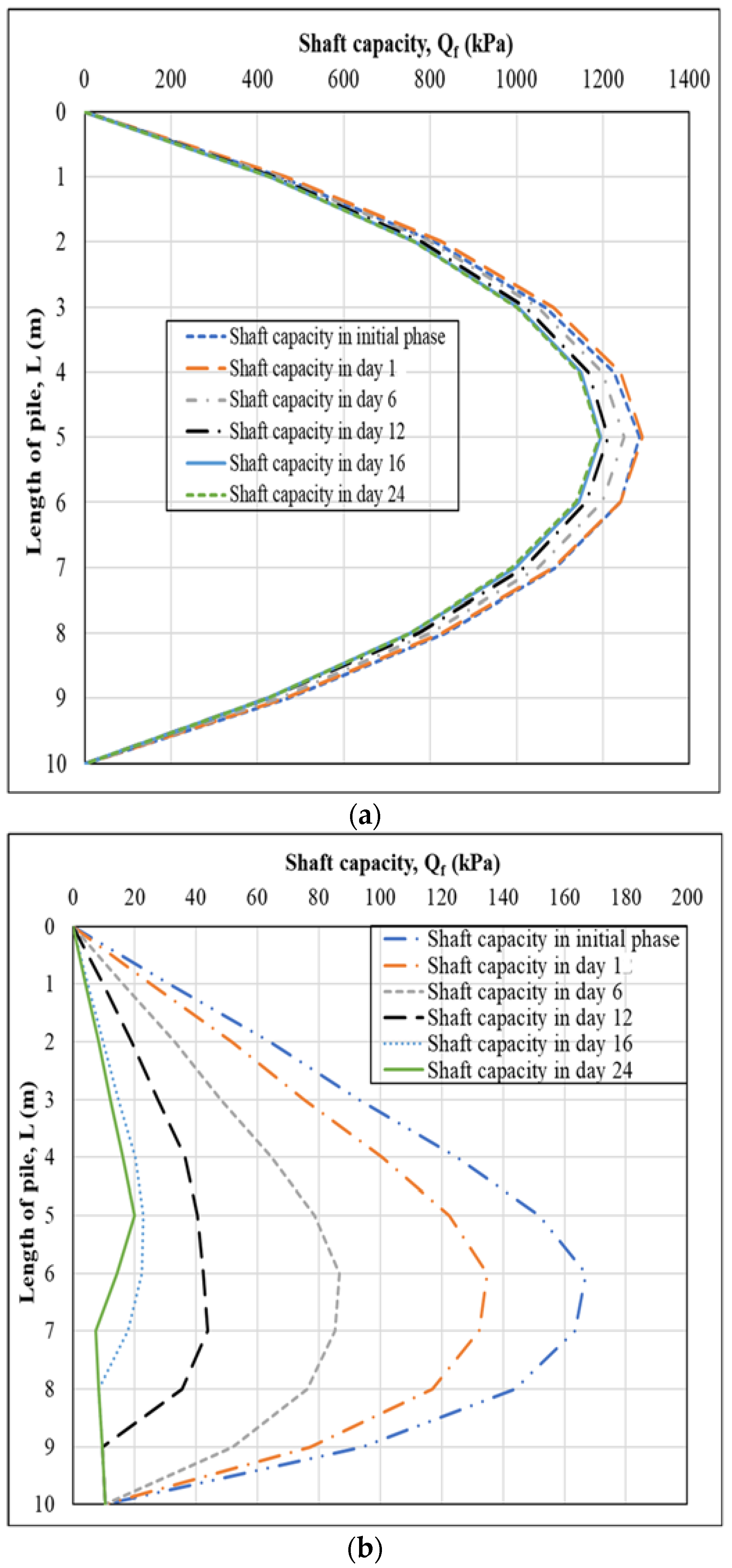

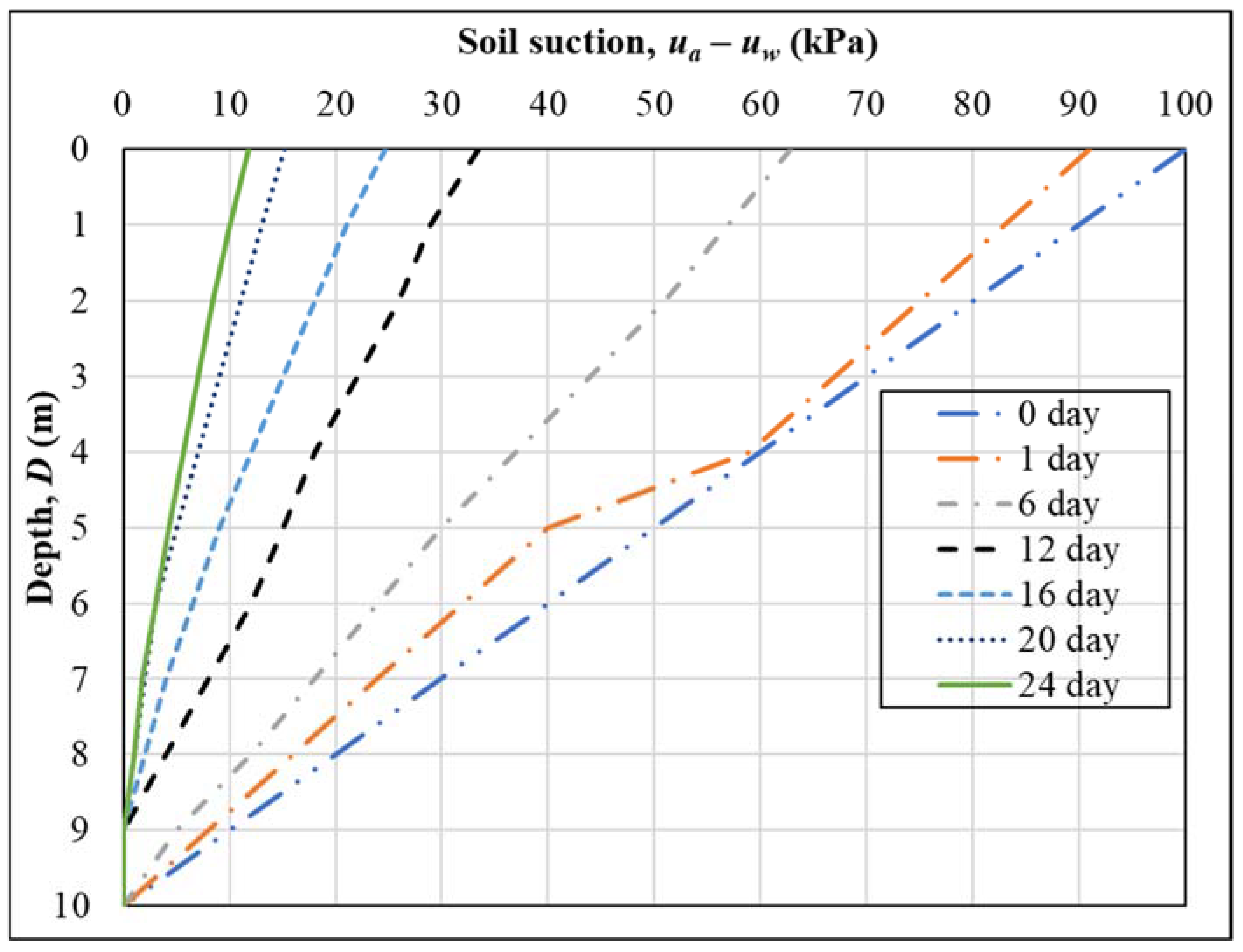

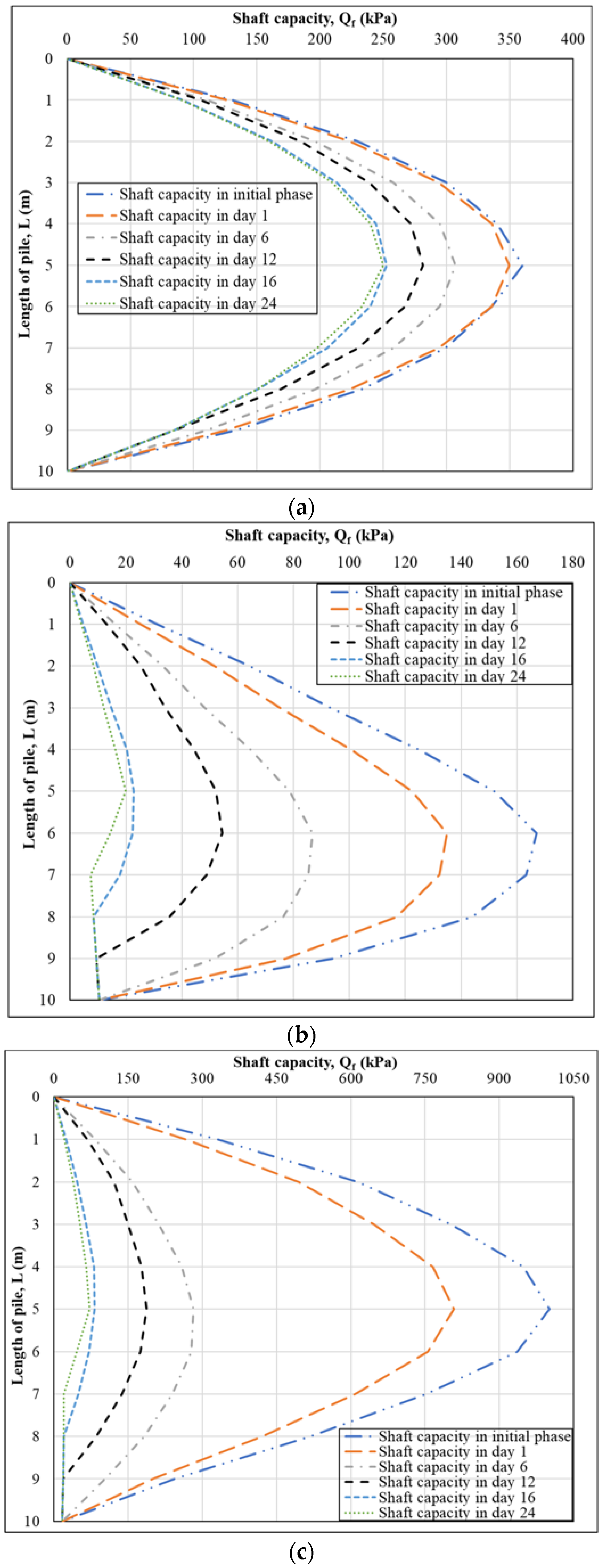

4.2.1. Results in Coarse-Grained Soil (Sand)

4.2.2. Results in Fine-Grained Soil (Kaolin)

5. Conclusions

- Rainfall has an effect on the rate of suction in the soil, which reduces even after the rain has stopped. This is due to water equalization in the surrounding environment, which is taken into consideration. Because there is no additional water seeping into the ground, the suction reduction rate tends to slow throughout the drying period.

- Analytical calculations incorporating negative pore water pressure indicated that the modified methods (β, α, and λ) consistently produced higher shaft capacities for pile foundations. The differences between the conventional and modified methods were significant, emphasizing the importance of considering negative pore water pressure. Unsurprisingly, the study recommended the use of unsaturated soil in the foundation design for a higher shaft capacity and pile optimization.

- The analytical calculation, incorporating PLAXIS 3D (Version 22) for the numerical study, showed a decline in the shaft capacity of piles with increasing soil suction. The study provided specific examples, indicating that coarse-grained soil generally has a higher shaft capacity compared to fine-grained soil.

- The modified β method was found to have a higher shaft capacity, attributed to the influence of effective stress. It was suggested that the modified β method is suitable for longer piles, while the modified α and λ methods are more sustainable for short piles.

- Sustainable pile design involves using resources efficiently and minimizing environmental impact. Understanding unsaturated soil mechanics can aid in optimizing the design to utilize local soil conditions effectively, reducing the need for excessive material use or environmental disruption.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fredlund, D.G.; Sheng, D.; Zhao, J. Estimation of soil suction from the soil-water characteristic curve. Can. Geotech. J. 2011, 48, 186–198. [Google Scholar] [CrossRef]

- Habasimbi, P.; Nishimura, T. Soil water characteristic curve of an unsaturated soil under low matric suction ranges and different stress conditions. Int. J. Geosci. 2019, 10, 39–56. [Google Scholar] [CrossRef]

- Kim, Y.; Satyanaga, A.; Rahardjo, H.; Park, H.; Sham, A.W.L. Estimation of effective cohesion using artificial neural networks based on index soil properties: A Singapore case. Eng. Geol. 2012, 289, 106163. [Google Scholar] [CrossRef]

- Vanapalli, S.K.; Garga, V.K.; Brisson, P. A modified permeameter for determination of unsaturated coefficient of permeability. Geotech. Geol. Eng. 2007, 25, 191–202. [Google Scholar] [CrossRef]

- Vanapalli, S.; Eigenbrod, K.; Taylan, Z.; Catana, C.; Oh, W.; Garven, E. A technique for estimating the shaft resistance of test piles in unsaturated soils. In Proceedings of the 5th International Conference Unsaturated Soils UNSAT, Barcelona, Spain, 6–8 September 2010. [Google Scholar]

- Vanapalli, S.K.; Lu, L.; Sedano, J.A.I.; Oh, W.T. Swelling Characteristics of Sand-Bentonite Mixtures. In Unsaturated Soils: Research and Applications; Springer: Berlin/Heidelberg, Germany, 2012; pp. 77–84. [Google Scholar]

- Ng, C.W.W.; Pang, Y.W. Influence of stress state on soil-water characteristics and slope stability. J. Geotech. Geoenviron. Eng. 2000, 126, 157–166. [Google Scholar] [CrossRef]

- Vanapalli, S.; Taylan, Z.N. Model piles behaviour in a compacted fine-grained unsaturated soil. In Proceedings of the 15th European Conference on Soil Mechanics and Geotechnical Engineering, Athens, Greece, 15 September 2011; IOS Press: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Sun, W.J.; Cui, Y.J. Investigating the microstructure changes for silty soil during drying. Geotechnique 2018, 68, 370–373. [Google Scholar] [CrossRef]

- Morris, P.H.; Graham, J.; Williams, D.J. Cracking in drying soils. Can. Geotech. J. 1992, 29, 263–277. [Google Scholar] [CrossRef]

- al-Omari, R.R.; Fattah, M.Y.; Kallawi, A.M. Bearing capacity of piles in unsaturated soil from theoretical and experimental approaches. In Proceedings of the 4th International Conference on Buildings, Construction and Environmental Engineering, Istanbul, Turkey, 7–9 October 2019; Volume 737, p. 012101. [Google Scholar]

- Thota, S.K.; Vahedifard, F. A model for ultimate bearing capacity of piles in unsaturated soils under elevated temperatures. In Proceedings of the 2nd International Conference on Energy Geotechnics (ICEGT 2020), San Diego, CA, USA, 20–23 September 2020; Volume 205, p. 05003. [Google Scholar]

- Santos, D.B.; Lemos, M.A.D.C.; Cavalcante, A.L.B. Transient unsaturated shaft resistance of a single pile during water flow. In Proceedings of the PanAm-UNSAT 2021: 3rd Pan-American Conference on Unsaturated Soils, Rio de Janeiro, Brazil, 26–28 July 2021; Volume 337, p. 03007. [Google Scholar]

- Liu, Y.; Vanapalli, S.K. Mechanical behavior of a floating model pile in unsaturated expansive soil associated with water infiltration: Laboratory investigations and numerical simulations. Soils Found. 2021, 61, 929–943. [Google Scholar] [CrossRef]

- Buranbayeva, A.; Zhussupbekov, A.Z.; Omarov, A. Numerical analysis and geomonitoring of behaviour of foundation of Abu-Dhabi Plaza in Nur-Sultan. In Proceedings of the Deep Foundations and Geotechnical Problems of Territories (DFGC 2021), Perm, Russian, 26–28 May 2021; IOP Publishing: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Nowamooz, H.; Masrouri, F. Suction variations and soil fabric of swelling compacted soils. J. Rock Mech. Geotech. Eng. 2010, 2, 129–134. [Google Scholar] [CrossRef]

- Rahardjo, H.; Satyanaga, A.; Leong, E.C. Effects of rainfall characteristics on the stability of tropical residual soil slope. In Proceedings of the 3rd European Conference on Unsaturated Soils E-UNSAT 2016, Paris, France, 12–14 September 2016; EDP Sciences: Paris, France, 2016. [Google Scholar]

- Vorwerk, S.; Cameron, D.; Keppel, G. Chapter 22—Clay Soil in Suburban Environments: Movement and Stabilization through Vegetation. In Ground Improvement Case Histories; Indraratna, B., Chu, J., Rujikiatkamjorn, C., Eds.; Butterworth-Heinemann: Oxford, UK, 2015; pp. 655–682. [Google Scholar]

- Vanapalli, S.K.; Fredlund, D.G.; Pufahl, D.E. The influence of soil structure and stress history on the soil–water characteristics of a compacted till. Geotechnique. 1999, 49, 143–159. [Google Scholar] [CrossRef]

- Tavakoli Dastjerdi, M.H.; Habibagahi, G.; Nikooee, E. Effect of confining stress on soil water retention curve and its impact on the shear strength of unsaturated soils. Vadose Zone J. 2014, 13, vzj2013.05.0094. [Google Scholar] [CrossRef]

- van Genuchten, M.T. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef]

- Yan, W.; Birle, E.; Cudmani, R. A new framework to determine general multimodal soil water characteristic curves. Acta Geotech. 2021, 16, 3187–3208. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, Q. Predicting bimodal soil–water characteristic curves. J. Geotech. Geoenviron. Eng. 2005, 131, 666–670. [Google Scholar] [CrossRef]

- Tinjum, J.M.; Benson, C.H.; Blotz, L.R. Soil-water characteristic curves for compacted clays. J. Geotech. Geoenviron. Eng. 1997, 123, 1060–1069. [Google Scholar] [CrossRef]

- Kocaman, K.; Ozocak, A.; Edil, T.B.; Bol, E.; Sert, S.; Onturk, K.; Ozsagir, M. Evaluation of Soil-Water Characteristic Curve and Pore-Size Distribution of Fine-Grained Soils. Water 2022, 14, 3445. [Google Scholar] [CrossRef]

- Tarantino, A. A water retention model for deformable soils. Geotechnique 2009, 59, 751–762. [Google Scholar] [CrossRef]

- Douthitt, B.; Houston, W.; Houston, S.; Walsh, K. Effect of wetting on pile friction. In Proceedings of the 2nd International Conference on Unsaturated Soils (UNSAT’98), Beijing, China, 27–30 August 1998. [Google Scholar]

- Costa, Y.D.; Cintra, J.C.; Zornberg, J.G. Influence of matric suction on the results of plate load tests performed on a lateritic soil deposit. Geotech. Test. J. 2003, 26, 219–227. [Google Scholar]

- Georgiadis, K.; Potts, D.; Zdravkovic, L. The influence of partial soil saturation on pile behaviour. Géotechnique 2003, 53, 11–25. [Google Scholar] [CrossRef]

- Lu, N. Unsaturated Soil Mechanics: Fundamental Challenges, Breakthroughs, and Opportunities. J. Geotech. Geoenviron. Eng. 2020, 146, 02520001. [Google Scholar] [CrossRef]

- Skempton, A. Cast in-situ bored piles in London clay. Geotechnique 1959, 9, 153–173. [Google Scholar] [CrossRef]

- Burland, J. Shaft Friction of Piles in Clay—A Simple Fundamental Approach; Ground Engineering: London, UK, 1973; Volume 6. [Google Scholar]

- Focht, J.A.; Vijayvergiya, V. A new way to predict capacity of piles in clay. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–3 May 1972; OTC: Richardson, TX, USA, 1972. [Google Scholar]

- Becker, D.E. Eighteenth Canadian Geotechnical Colloquium: Limit States Design For Foundations. Part I. An overview of the foundation design process. Can. Geotech. J. 1996, 33, 956–983. [Google Scholar] [CrossRef]

- Pachikin, K.; Erokhina, O.; Funakawa, S. Soils of Kazakhstan, their distribution and mapping. In Novel Measurement and Assessment Tools for Monitoring and Management of Land and Water Resources in Agricultural Landscapes of Central Asia; Springer: Cham, Switzerland, 2014; pp. 519–533. [Google Scholar]

- Fredlund, M.D.; Wilson, G.W.; Fredlund, D.G. Representation and estimation of the shrinkage curve. In Proceedings of the 3rd International Conference on Unsaturated Soils UNSAT’2002, Recife, Brazil, 10–13 March 2002; pp. 145–149. [Google Scholar]

- Hakro, M.R.; Kumar, A.; Almani, Z.; Ali, M.; Aslam, F.; Fediuk, R.; Klyuev, S.; Klyuev, A.; Sabitov, L. Numerical Analysis of Piled-Raft Foundations on Multi-Layer Soil Considering Settlement and Swelling. Buildings 2022, 12, 356. [Google Scholar] [CrossRef]

- Fredlund, D.G.; Xing, A. Equations for the soil-water characteristic curve. Can. Geotech. J. 1994, 31, 521–532. [Google Scholar] [CrossRef]

- Leong, E.C.; Rahardjo, H. Review of Soil-Water Characteristic Curve Equations. J. Geotech. Geoenviron. Eng. 1997, 123, 1106–1117. [Google Scholar] [CrossRef]

- Leong, E.C.; Rahardjo, H. Permeability functions for unsaturated soils. J. Geotech. Geoenviron. Eng. 1997, 123, 1118–1126. [Google Scholar] [CrossRef]

- Labuz, J.F.; Zang, A. Mohr–Coulomb Failure Criterion. Rock Mech. Rock Eng. 2012, 45, 975–979. [Google Scholar] [CrossRef]

- Zhussupbekov, A.; Shin, E.C.; Shakhmov, Z.; Tleulenova, G. Experimental study of model pile foundations in seasonally freezing soil ground. Geomate J. 2018, 15, 85–90. [Google Scholar] [CrossRef]

- Bentley. PLAXIS 3D Reference Manual. 2022. Available online: https://communities.bentley.com/cfs-file/__key/communityserver-wikis-components-files/00-00-00-05-58/PLAXIS_5F00_3D_5F00_CEV22.01_5F00_2_2D00_Reference.pdf (accessed on 30 November 2023).

- Dogan, A.; Motz, L.H. Saturated-Unsaturated 3D Groundwater Model. I: Development. J. Hydrol. Eng. 2005, 10, 492–504. [Google Scholar] [CrossRef]

- Satyanaga, A.; Rahardjo, H. Role of unsaturated soil properties in the development of slope susceptibility map. Proc. Inst. Civ. Eng. 2022, 175, 276–288. [Google Scholar] [CrossRef]

- Vanapalli, S.K.; Taylan, Z.N. Design of Single Piles Using the Mechanics of Unsaturated Soils. Geomate J. 2012, 2, 197–204. [Google Scholar]

| Index Property Tests | ASTM Code |

|---|---|

| Compaction standard proctor | D698-12 |

| Grain size distribution | |

| Sieve analysis | D6913-04 |

| Hydrometer analysis | D7928-21 |

| Atterberg limits | D4318-10 |

| Soil–water characteristic curve using HYPROP | D6836-92 |

| Permeability test using constant head | D2434-19 |

| Triaxial testing using consolidated undrained soil | D4767-11 |

| Soil | Cohesion, c′ (kPa) | Friction Angle, ϕ′ (°) | Unit Weight, γ (kN/m3) | Unsaturated Friction Angle, ϕb (°) |

|---|---|---|---|---|

| Kaolin | 18 | 23 | 14 | 11.5 |

| Sand | 0 | 45 | 15 | 22.5 |

| Soil type | Sand |

| Soil model | Mohr–Coulomb |

| Drainage type | Drained |

| Unsaturated unit weight, γunsat | 16 kN/m3 |

| Saturated unit weight, γsat | 20 kN/m3 |

| Void ratio, e | 0.71 |

| Modulus of elasticity, E | 430 kPa |

| Cohesion, c′ | 0 kPa |

| Friction angle, ϕ′ | 45° |

| Soil type | Kaolin |

| Soil model | Mohr–Coulomb |

| Drainage type | Drained |

| Unsaturated unit weight, γunsat | 18.3 kN/m3 |

| Saturated unit weight, γsat | 20.83 kN/m3 |

| Void ratio, e | 0.2 |

| Modulus of elasticity, E | 15.76 kPa |

| Cohesion, c′ | 18 kPa |

| Friction angle, ϕ′ | 14° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aventian, G.D.; Satyanaga, A.; Sagu, A.; Serikbek, B.; Pernebekova, G.; Aubakirova, B.; Zhai, Q.; Kim, J. Analytical and Finite-Element-Method-Based Analyses of Pile Shaft Capacity Subjected to Rainfall Infiltration. Sustainability 2024, 16, 313. https://doi.org/10.3390/su16010313

Aventian GD, Satyanaga A, Sagu A, Serikbek B, Pernebekova G, Aubakirova B, Zhai Q, Kim J. Analytical and Finite-Element-Method-Based Analyses of Pile Shaft Capacity Subjected to Rainfall Infiltration. Sustainability. 2024; 16(1):313. https://doi.org/10.3390/su16010313

Chicago/Turabian StyleAventian, Gerarldo Davin, Alfrendo Satyanaga, Aizhan Sagu, Bakytkul Serikbek, Gulnur Pernebekova, Bakhyt Aubakirova, Qian Zhai, and Jong Kim. 2024. "Analytical and Finite-Element-Method-Based Analyses of Pile Shaft Capacity Subjected to Rainfall Infiltration" Sustainability 16, no. 1: 313. https://doi.org/10.3390/su16010313

APA StyleAventian, G. D., Satyanaga, A., Sagu, A., Serikbek, B., Pernebekova, G., Aubakirova, B., Zhai, Q., & Kim, J. (2024). Analytical and Finite-Element-Method-Based Analyses of Pile Shaft Capacity Subjected to Rainfall Infiltration. Sustainability, 16(1), 313. https://doi.org/10.3390/su16010313