The Effect of Size on the Mechanical Properties of 3D-Printed Polymers

Abstract

:1. Introduction

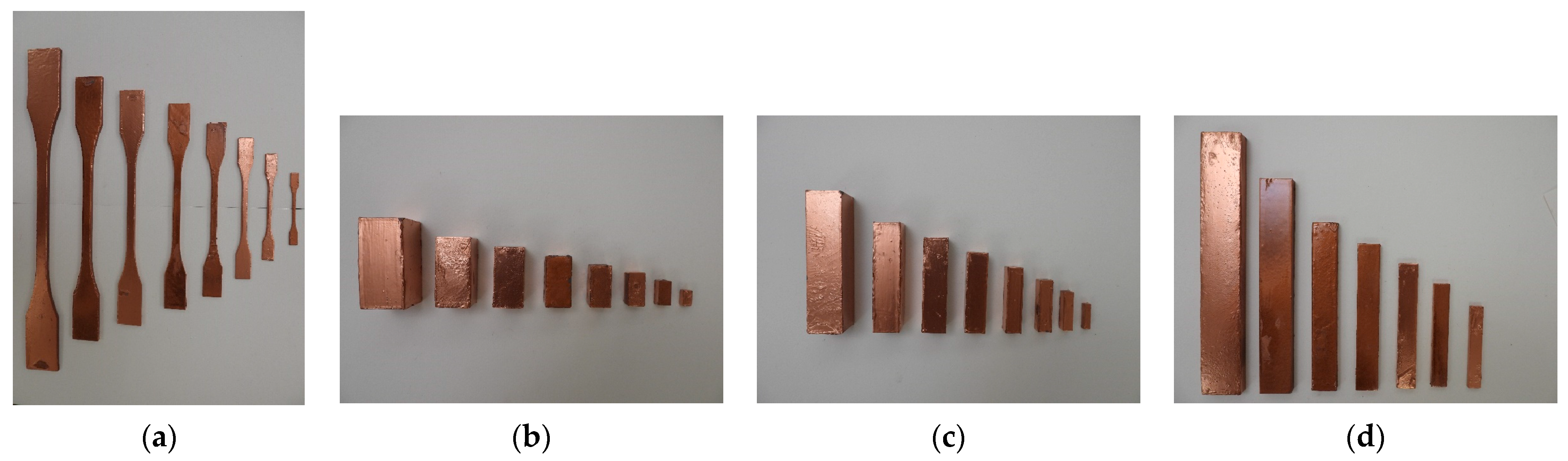

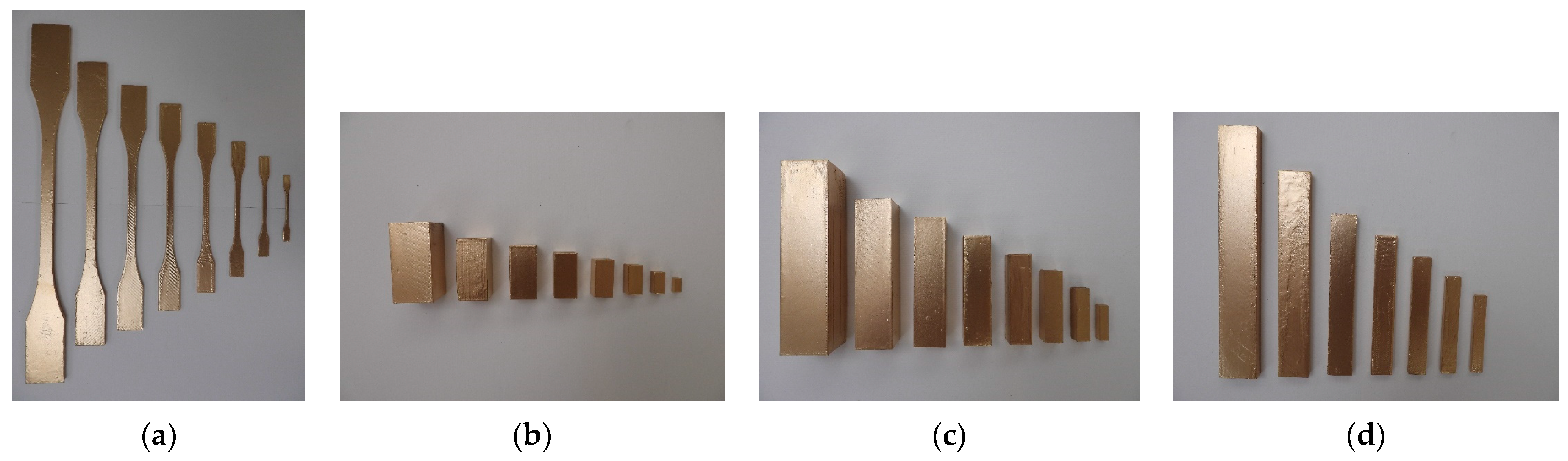

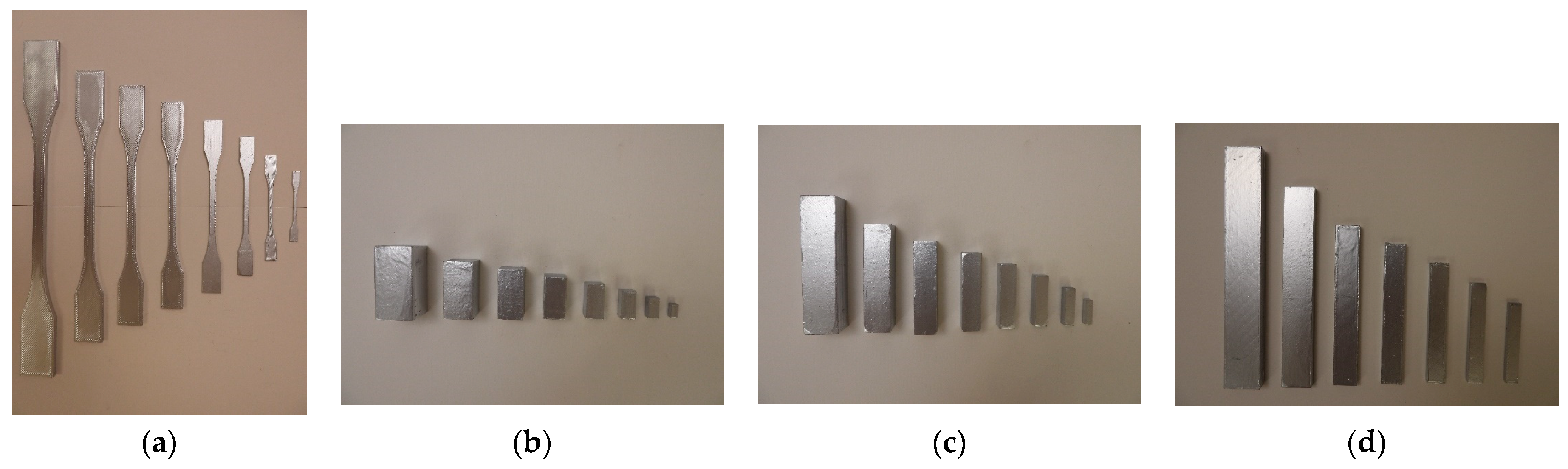

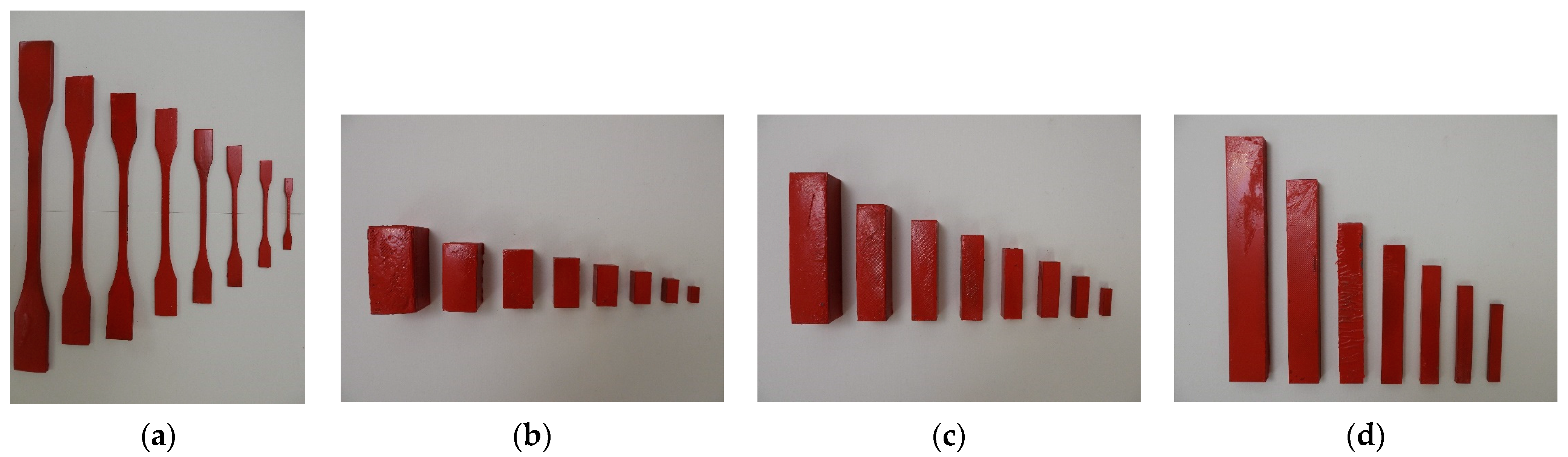

2. Materials and Methods

- -

- PC/ABS filament was from the Polymaker brand with a density of 1.1 g/cm3, tensile strength of 39.9 1 MPa in the X-Y plane, and Charpy impact strength of 25.8 1.3 kJ/m2 in the X-Y plane.

- -

- ASA filament was from the PM brand with a density of 1.07 g/cm3, flexural strength of 1800 MPa, and impact strength of 12 kJ/m2.

- -

- PLA filament was from the 3DJacke brand with a density of 1.24 g/cm3 and a tensile strength of 70 MPa.

- -

- Nylon filament was from the FIBERLOGY brand with a density of 1.01 g/cm3, tensile strength of 51 MPa, and IZOD impact strength of 12 kJ/m2.

3. Results and Discussion

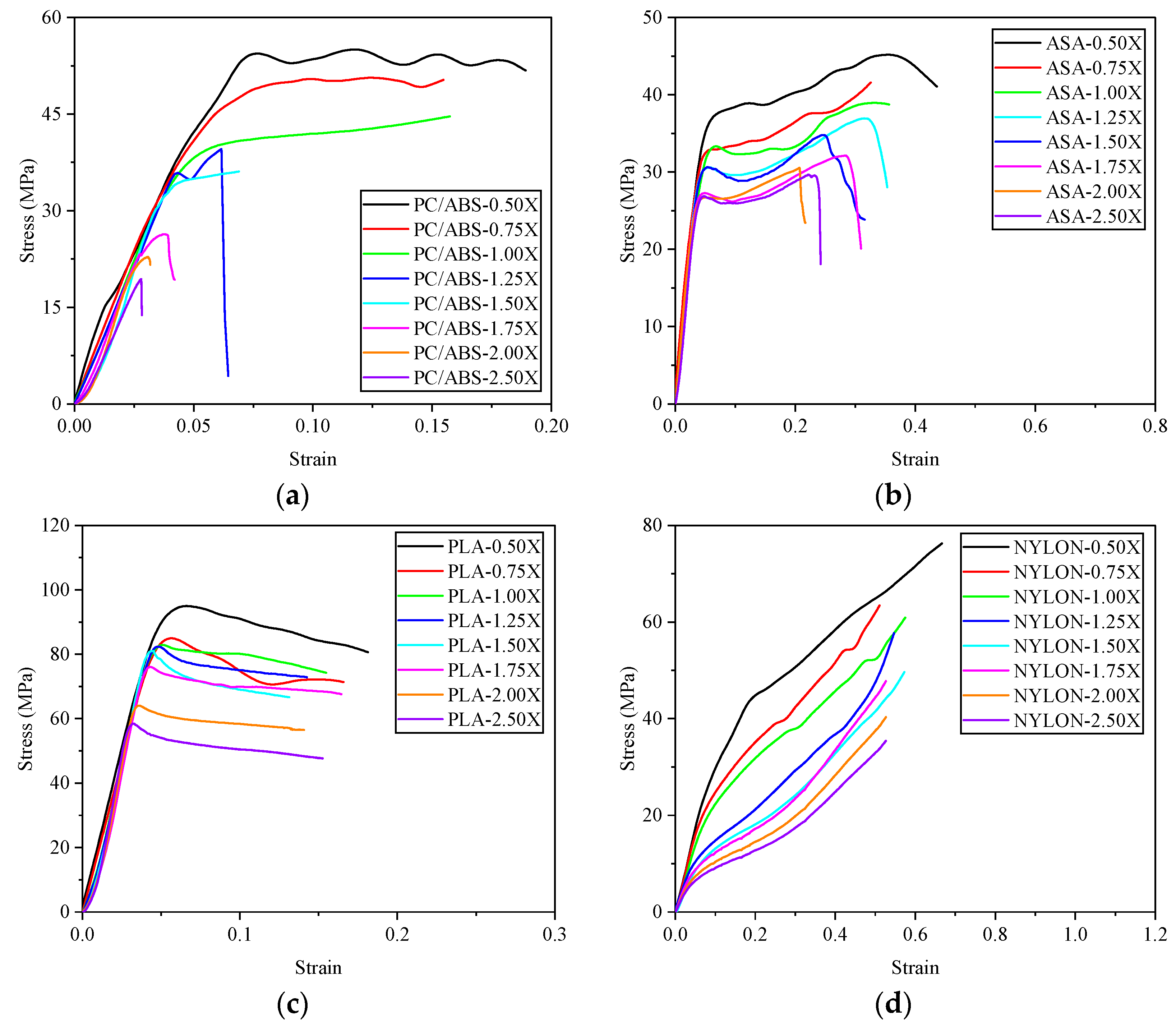

3.1. Tension Results

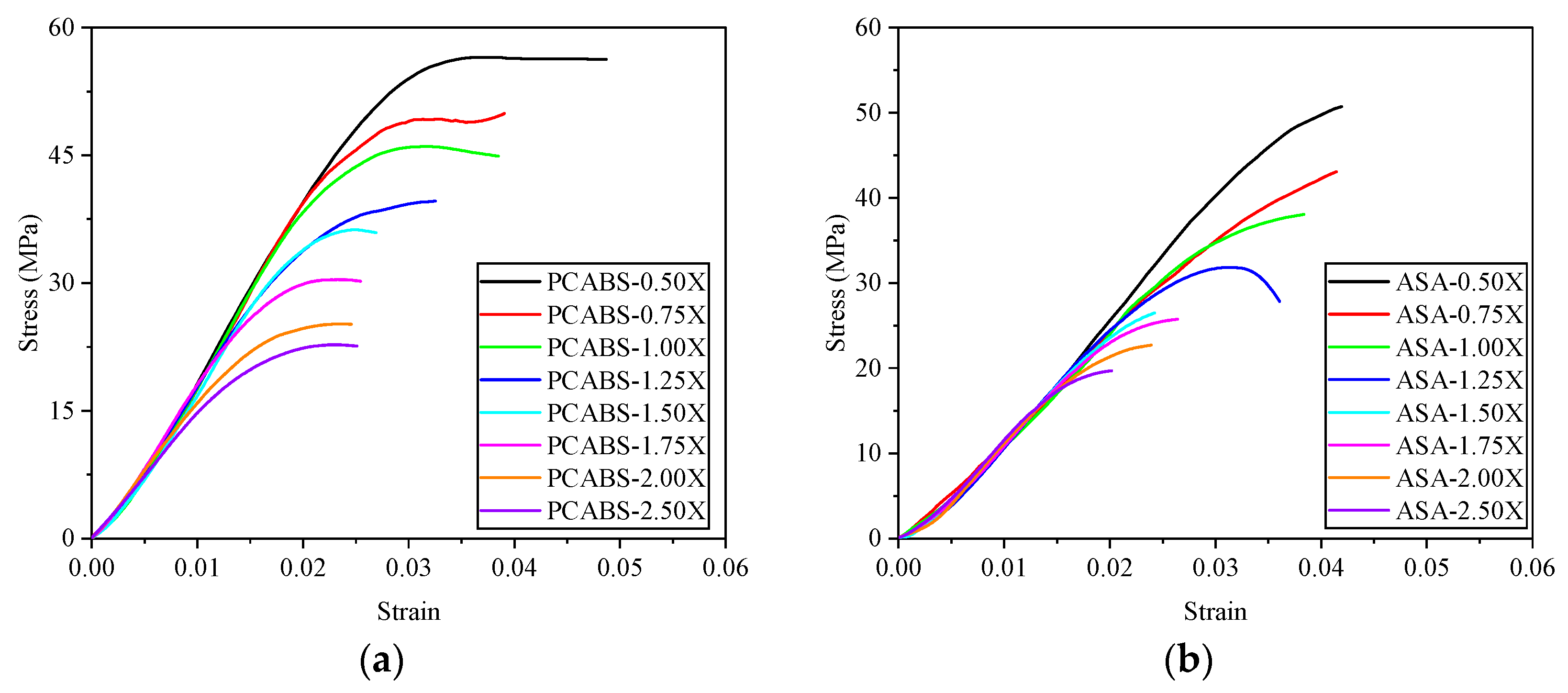

3.2. Compression Results

3.3. Elastic Modulus Results

3.4. Flexure Results

4. Concluding Remarks

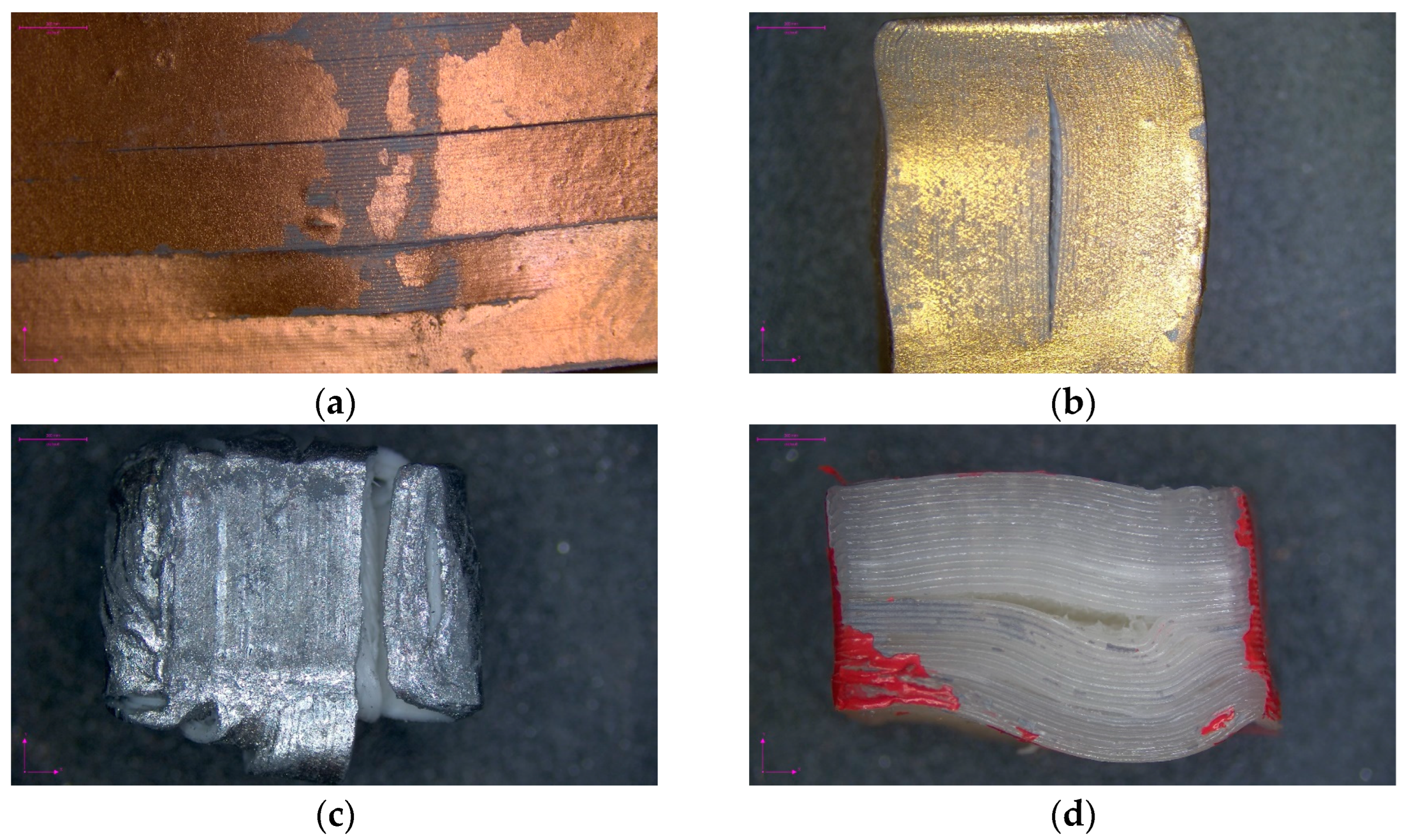

- The abrupt and brittle nature of specimen failure was a common thread across all tested materials, except nylon. This deviation highlights the exceptional ductility of nylon, which is particularly evident in its response to applied stress during testing.

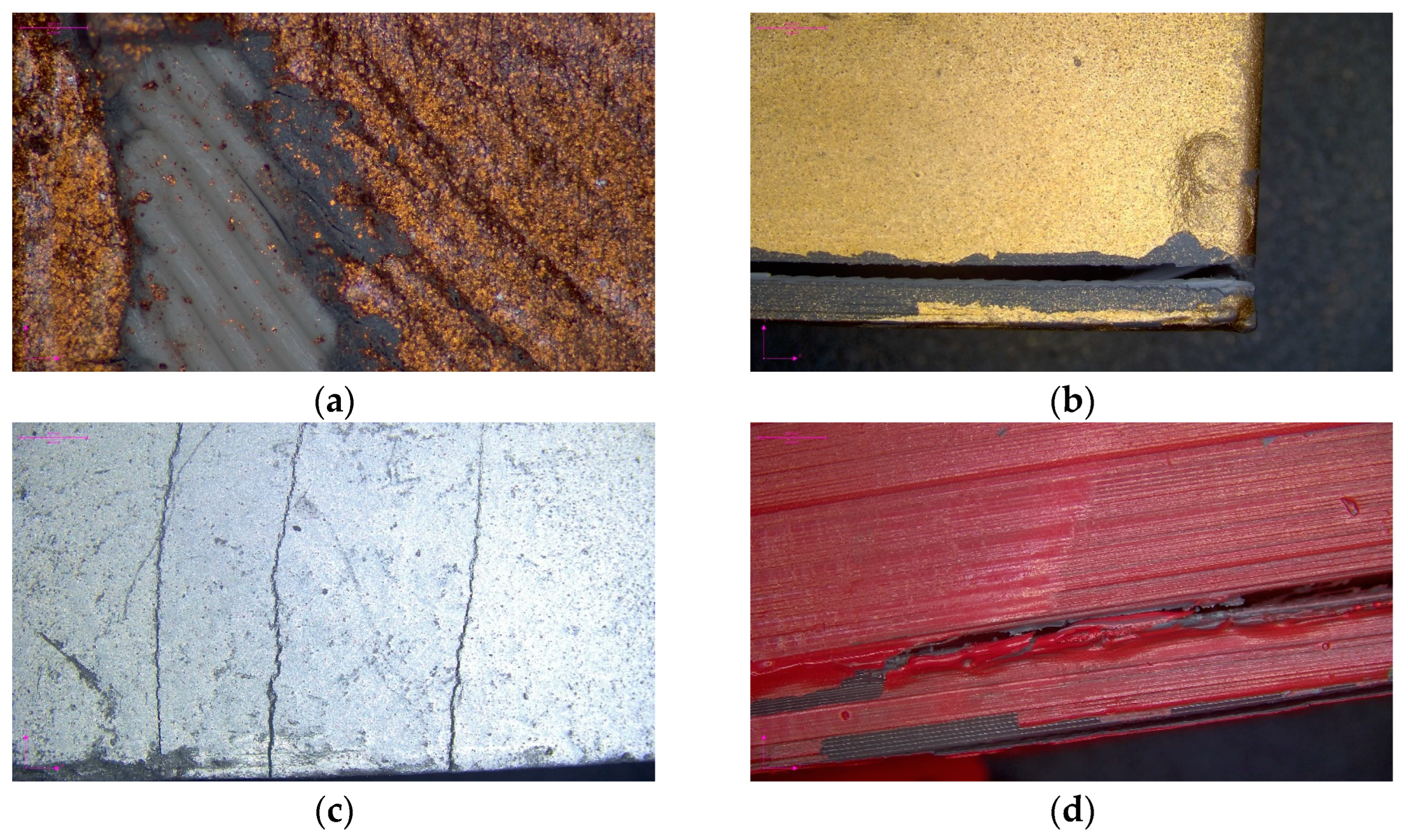

- Anisotropy emerged as a significant characteristic, particularly conspicuous in compression and elastic modulus tests, with PC/ABS and nylon showcasing notable tendencies in this regard.

- Examining the mechanical performance in detail, a discernible pattern emerges. PLA, PC/ABS, and ASA displayed a linear ascending branch followed by a sudden brittle failure. This contrasts starkly with the behavior of nylon, which exhibited a distinct response pattern.

- The superior strength exhibited by PLA specimens relative to their counterparts is a noteworthy revelation, underlining the exceptional performance potential of this material. This could be attributed to its higher tensile strength in comparison to other materials.

- Delving into the realm of tensile loading, an intriguing dual behavior emerged. While the ascending branch displayed isotropic characteristics, the strength values themselves exhibited a size-dependent tendency, revealing a nuanced interplay between material properties and loading conditions. As the specimens increase in size, the performance is influenced more by the overall integrity of the specimen rather than localized bonding deficiencies, resulting in lower standard deviation (SD) values. Put differently, the results obtained for larger specimens are more dependable. Additionally, the absorbed energy demonstrates a declining trend as the specimen size increases.

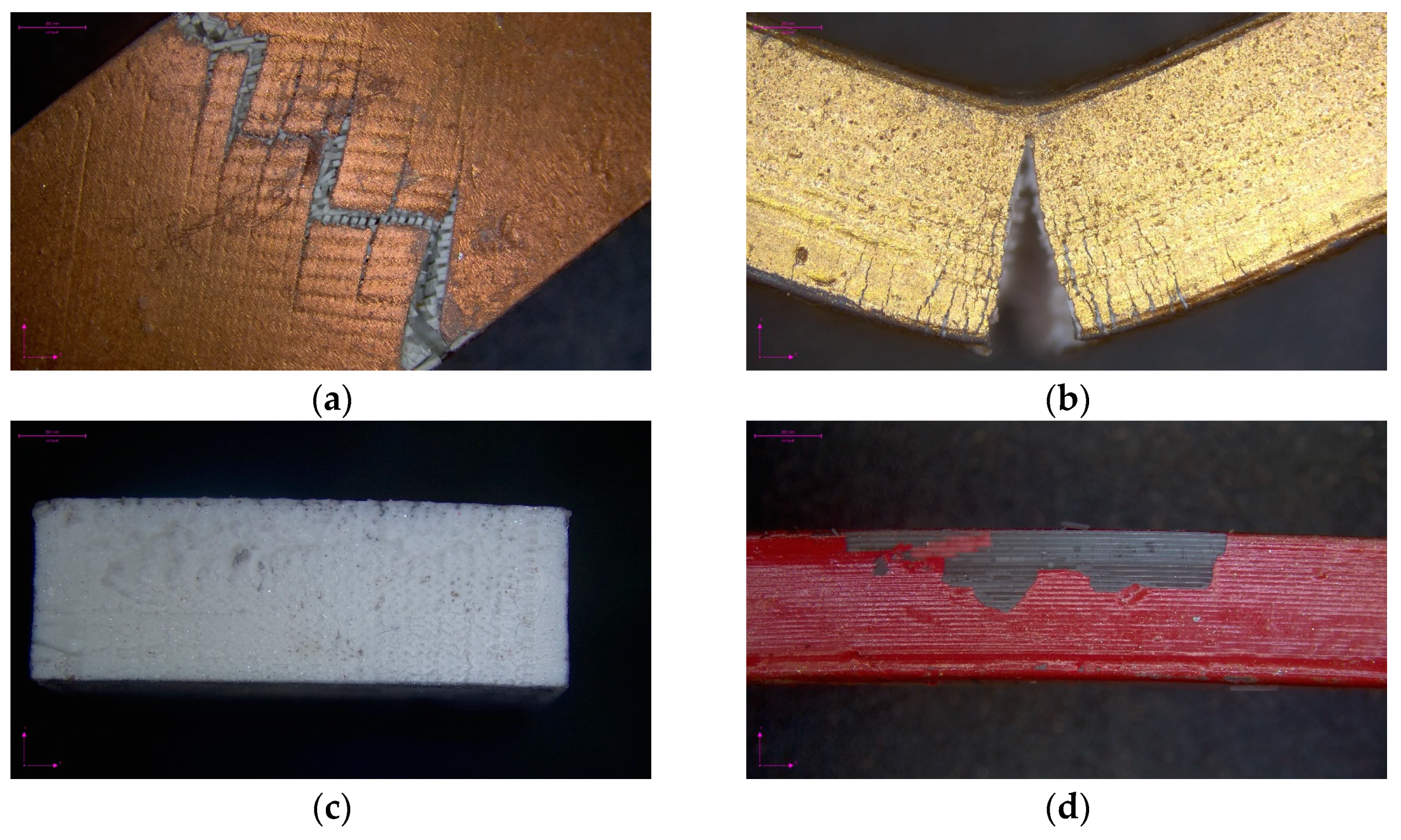

- An intriguing facet of the failure mode was identified. Failures predominantly initiated in between layers, specifically at the interfaces, rather than within the layers themselves. This observation speaks volumes about the inherent strength of the filament relative to the interlayer bonds, shedding light on a crucial aspect of material behavior under stress.

- It is hypothesized that during compression, smaller specimens with a reduced surface area allocate larger portions of their area to the load-bearing capacity, resulting in greater strain values. Essentially, more material is involved in supporting the load compared to larger specimens, where higher strains are concentrated. In this context, the fracture process zone (FPZ) introduced by Bažant and Kazemi [53] is relevant for explaining the size effect phenomenon, as the strength depends on the size ratio of the FPZ relative to the overall specimen size. This ratio is expected to be higher in smaller specimens, explaining their increased energy absorption and higher strength.

- The modulus of elasticity was less affected by size variations.

- Notably, the most pronounced size effect was observed in flexural tests. The examination unveiled a nonmonotonic association between strength and size, characterized by a local extremum. PC/ABS, PLA, and ASA demonstrated a pronounced dependence on size, in contrast to the ductile nature of nylon, where variations in size effects were negligible. These results imply that designers working on 3D-printed structures can enhance strength by integrating a defined size constraint into the component design process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Villarreal, G.P.U.; Pereira, A.D.E.S.; de Freitas, R.R.M.; Moraes, M.C.B.; Sepulveda, A.F.; de Araujo, D.R.; Fraceto, L.F. Zein-based nanoformulations with encapsulated methyl salicylate incorporated in 3D printing biopolymer devices targeting potential uses in pest management. Colloids Surf. A Physicochem. Eng. Asp. 2023, 670, 131511. [Google Scholar] [CrossRef]

- Englezos, K.; Wang, L.; Tan, E.C.; Kang, L. 3D printing for personalised medicines: Implications for policy and practice. Int. J. Pharm. 2023, 635, 122785. [Google Scholar] [CrossRef]

- Bazli, M.; Ashrafi, H.; Rajabipour, A.; Kutay, C. 3D printing for remote housing: Benefits and challenges. Autom. Constr. 2023, 148, 104772. [Google Scholar] [CrossRef]

- Beetz, D.I.F.S. 3D Printing in the Automotive Industry. In Inkjet Printing in Industry: Materials, Technologies, Systems, and Applications; Wiley: Hoboken, NY, USA, 2022; Volume 3, pp. 1427–1460. [Google Scholar]

- Lau, I.; Sun, Z. The role of 3D printed heart models in immediate and long-term knowledge acquisition in medical education. Rev. Cardiovasc. Med. 2022, 23, 22. [Google Scholar] [CrossRef]

- Dobroś, K.; Hajto-Bryk, J.; Zarzecka, J. Application of 3D-printed teeth models in teaching dentistry students: A scoping review. Eur. J. Dent. Educ. 2023, 27, 126–134. [Google Scholar] [CrossRef]

- Fallacara, G.; Parisi, N. Additive manufacturing in architecture: 3D printing solutions for vaulted spaces. In Proceedings of the 75th RILEM Annual Week 2021: Advances in Sustainable Construction Materials and Structures, Merida, Mexico, 29 August—September 2021; Volume 40, p. 407. [Google Scholar]

- Yoha, K.S.; Moses, J.A. 3D Printing approach to valorization of agri-food processing waste streams. Foods 2023, 12, 212. [Google Scholar] [CrossRef]

- Košir, T.; Slavič, J. Modeling of single-process 3D-printed piezoelectric sensors with resistive electrodes: The low-pass filtering effect. Polymers 2023, 15, 158. [Google Scholar] [CrossRef]

- Singh, S.; Mali, H.S. 3D printed orthotic insoles for foot rehabilitation. In 3D Printing in Podiatric Medicine; Academic Press: Cambridge, MA, USA, 2023; pp. 211–219. [Google Scholar]

- Flauder, S.; Bombarda, I.; D’Ambrosio, R.; Langhof, N.; Lazzeri, A.; Krenkel, W.; Schafföner, S. Size effect of carbon fiber-reinforced silicon carbide composites (C/C-SiC): Part 2-tensile testing with alignment device. J. Eur. Ceramic Soc. 2022, 42, 1227–1237. [Google Scholar] [CrossRef]

- Ji, S.; Di, S.; Long, X. DEM Simulation of uniaxial compressive and flexural strength of sea ice: Parametric study. J. Eng. Mech. 2017, 143, C40160. [Google Scholar] [CrossRef]

- Dalli, D.; Varandas, L.; Scalici, T.; Arteiro, A.; Catalanotti, G. Exploiting intrinsic size effect to overcome specimen scaling limitations in fracture toughness characterisation of composite materials. Eng. Fract. Mech. 2023, 277, 108951. [Google Scholar] [CrossRef]

- Zhang, L.; Harrison, W.; Mehraban, S.; Brown, S.G.R.; Lavery, N.P. Size Effect on the post-necking behaviour of dual-phase 800 steel: Modelling and experiment. Materials 2023, 16, 1458. [Google Scholar] [CrossRef] [PubMed]

- Rahimidehgolan, F.; Altenhof, W. Compressive behavior and deformation mechanisms of rigid polymeric foams: A review. Compos. Part B Eng. 2023, 253, 110513. [Google Scholar] [CrossRef]

- Pathirage, M.; Tong, D.; Thierry, F.; Cusatis, G.; Grégoire, D.; Pijaudier-Cabot, G. Discrete modeling of concrete failure and size-effect. Theor. Appl. Fract. Mech. 2023, 124, 103738. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Zhang, W.; Ma, G. Size effect of fractured rock mass based on 3D printed model testing. Rock Mech. Rock Eng. 2022, 55, 7005–7020. [Google Scholar] [CrossRef]

- Albayati, A.; Wang, Y.; Haynes, J. Size effect of hydrated lime on the mechanical performance of asphalt concrete. Materials 2022, 15, 3715. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Najafi, F.; Ho, K.; Hamidinejad, M.; Cui, T.; Walker, G.C.; Singh, C.V.; Filleter, T. Mechanical size effect of free-standing nanoconfined polymer films. Macromolecules 2022, 55, 1248–1259. [Google Scholar] [CrossRef]

- Ziaee, M.; Crane, N.B. Binder jetting: A review of process, materials, and methods. Addit. Manuf. 2019, 28, 781–801. [Google Scholar] [CrossRef]

- Hamidi, F.; Aslani, F. Additive manufacturing of cementitious composites: Materials, methods, potentials, and challenges. Constr. Build. Mater. 2019, 218, 582–609. [Google Scholar] [CrossRef]

- Dunn, M.; Wheel, M. Size effect anomalies in the behaviour of loaded 3D mechanical metamaterials. Philos. Mag. 2020, 100, 139–156. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Kua, H.W.; Na Yu, L.; Chung, J.K.H. Fresh properties of cementitious materials containing rice husk ash for construction 3D printing. J. Mater. Civ. Eng. 2020, 32, 04020195. [Google Scholar] [CrossRef]

- Ma, S.; Kawashima, S. Investigating the working mechanisms of viscosity-modifying admixtures through rheological and water transport properties. J. Mater. Civ. Eng. 2020, 32, 04020195. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Grafe, J.; Nerella, V.N.; Spaniol, E.; Hertel, M.; Füssel, U. 3D-printed steel reinforcement for digital concrete construction–Manufacture, mechanical properties and bond behaviour. Constr. Build. Mater. 2018, 179, 125–137. [Google Scholar] [CrossRef]

- Bell, D.; Siegmund, T. 3D-printed polymers exhibit a strength size effect. Addit. Manuf. 2018, 21, 658–665. [Google Scholar] [CrossRef]

- Wu, C.; Chen, C.; Cheeseman, C. Size effects on the mechanical properties of 3D printed plaster and PLA parts. J. Mater. Civ. Eng. 2021, 33, 04021152. [Google Scholar] [CrossRef]

- Elmrabet, N.; Siegkas, P. Dimensional considerations on the mechanical properties of 3D printed polymer parts. Polym. Test. 2020, 90, 106656. [Google Scholar] [CrossRef]

- ISO 527-1; Plastics—Determination of Tensile Properties—Part 1: General Principles. 3rd Edition, Technical Committee: ISO/TC 61/SC 2 Mechanical Behavior, ICS: 83.080.01 Plastics in General. International Organization for Standardization: Geneva, Switzerland, 2019. Available online: www.iso.org (accessed on 17 October 2023).

- ISO 37; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties, Technical Committee: ISO/TC 45/SC 2 Testing and Analysis, ICS: 83.060 Rubber. International Organization for Standardization: Geneva, Switzerland, 2017. Available online: www.iso.org (accessed on 17 October 2023).

- Nurizada, A.; Kirane, K. Induced anisotropy in the fracturing behavior of 3D printed parts analyzed by the size effect method. Eng. Fract. Mech. 2020, 239, 107304. [Google Scholar] [CrossRef]

- Yao, T.; Deng, Z.; Zhang, K.; Li, S. A method to predict the ultimate tensile strength of 3D printing polylactic acid (PLA) materials with different printing orientations. Compos. Part B Eng. 2019, 163, 393–402. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H.; Hassana, O.B. Anisotropic damage inferred to 3D printed polymers using fused dep-osition modelling and subject to severe compression. Eur. Polym. J. 2016, 85, 324–340. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, Q.; Ni, Y.; Liu, P.; Liu, F.; Leguillon, D.; Xu, L.R. A systematic investigation on the minimum tensile strengths and size effects of 3D printing polymers. Polym. Test. 2023, 117, 107845. [Google Scholar] [CrossRef]

- Ng, F.L.; Tran, T.Q.; Liu, T. A methodology to develop part acceptance criteria model using non-destructive inspection technique for FDM printed part. Mater. Today Proc. 2022, 70, 310–316. [Google Scholar] [CrossRef]

- Naughton, P.; Rudert, K. Improved car seats by blow-moulded plastic seat-back design. ATZ Worldw. 2006, 108, 9. [Google Scholar] [CrossRef]

- Meng, Z.H.; Guo, W.; Wei, X.B. Comparative analysis of automotive interior trim materials based on moldflow. Appl. Mech. Mater. 2012, 117–119, 1496–1500. [Google Scholar] [CrossRef]

- Govindaraj, K.; Balaji, K.V.; Vimalathithan, M.; Samir, G.; Rajesh, L. Mold in Color Diamond White ASA Material for Automotive Exterior Application (No. 2019-28-2562); SAE Technical Paper: Brisbane, Australia, 2019. [Google Scholar]

- Mubaraki, M.; Ali, S.I.A.; Ismail, A.; Yusoff, N.I.M. Rheological evaluation of asphalt cements modified with ASA polymer and Al2O3 nanoparticles. Procedia Eng. 2016, 143, 1276–1284. [Google Scholar] [CrossRef]

- Is Recycling PLA Really Better than Composting? Online News Post. Available online: https://3dprintingindustry.com/news/is-recycling-pla-really-better-than-composting-49679 (accessed on 17 October 2023).

- Vink, E.T.H.; Rábago, K.R.; Glassner, D.A.; Gruber, P.R. Applications of life cycle assessment to NatureWork polylactide (PLA) production. Polym. Degrad. Stab. 2003, 80, 403–419. [Google Scholar] [CrossRef]

- Skoratko, A.; Katzer, J. Harnessing 3D printing of plastics in construction—Opportunities and limitations. Materials 2021, 14, 4547. [Google Scholar] [CrossRef] [PubMed]

- Murad, Y.; Alseid, B. Poly-lactic acid and carbon fibers 3D printed bars for seismic retrofitting RC beam-to-column joints subjected to elevated temperature. Structures 2022, 43, 1530–1547. [Google Scholar] [CrossRef]

- Garrido, R.; Cabeza, L.F.; Falguera, V.; Navarro, O.P. Potential Use of Cow Manure for Poly(Lactic Acid) Production. Sustainability 2022, 14, 16753. [Google Scholar] [CrossRef]

- Mecheter, A.; Tarlochan, F. Fused Filament Fabrication Three-Dimensional Printing: Assessing the Influence of Geometric Complexity and Process Parameters on Energy and the Environment. Sustainability 2023, 15, 12319. [Google Scholar] [CrossRef]

- Fonseca, A.; Ramalho, E.; Gouveia, A.; Figueiredo, F.; Nunes, J. Life Cycle Assessment of PLA Products: A Systematic Literature Review. Sustainability 2023, 15, 12470. [Google Scholar] [CrossRef]

- Mak, S.L.; Wu, M.Y.T.; Chak, W.Y.; Kwong, W.K.; Tang, W.F.; Li, C.H.; Lee, C.C.; Li, C.Y. A Review of the Feasibility of Producing Polylactic Acid (PLA) Polymers Using Spent Coffee Ground. Sustainability 2023, 15, 13498. [Google Scholar] [CrossRef]

- Amel, H.; Rongong, J.; Moztarzadeh, H.; Hopkinson, N. Effect of section thickness on fatigue performance of laser sintered nylon 12. Polym. Test. 2016, 53, 204–210. [Google Scholar] [CrossRef]

- Letzelter, E.; Guingand, M.; De Vaujany, J.P.; Schlosser, P. A new experimental approach for measuring thermal behaviour in the case of nylon 6/6 cylindrical gears. Polym. Test. 2010, 29, 1041–1051. [Google Scholar] [CrossRef]

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. Book of Standards Volume: 08.01; Developed by Sub-Committee: D20.10; ICS Code: 83.080.01. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D695; Standard Test Method for Compressive Properties of Rigid Plastics Book of Standards Volume: 08.01; Developed by Subcommittee: D20.10; ICS Code: 83.080.01. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D6272; Standard Test Method for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials by Four-Point Bending. Book of Standards Volume: 08.03; Developed by Subcommittee: D20.10; ICS Code: 29.035.20; 83.080.01. ASTM International: West Conshohocken, PA, USA, 2017.

- Bažant, Z.P.; Kazemi, M.T. Determination of fracture energy, process zone longth and brittleness number from size effect, with application to rock and conerete. Int. J. Fract. 1990, 44, 111–131. [Google Scholar] [CrossRef]

| Material | Density (g/cm3) | Nozzle Temperature (°C) | Bed Temperature (°C) |

|---|---|---|---|

| PC/ABS | 1.10 | 260 | 105 |

| ASA | 1.07 | 260 | 100 |

| PLA | 1.24 | 215 | 60 |

| Polyamide (nylon) | 1.01 | 255 | 100 |

| Test | Size (mm) | Specimen Sizes |

|---|---|---|

| Tensile—ASTM D638-22 [50] | Specimen Type II (l: 183) | 0.5–0.75–12.5 |

| Compression—ASTM D695-15 [51] | W × d × l: 12.7 × 12.7 × 25.4 | 0.52.5 |

| Elastic modulus—ASTM D695-15 [51] | W × d × l: 12.7 × 12.7 × 50.8 | 0.52.5 |

| Flexure—ASTM D6272-17 [52] | W × d × l: 12 × 4 × 80, : 64 | 3 |

| Specimen ID | Tension | ||

|---|---|---|---|

| Peak Strain | Peak Stress SD (MPa) | ||

| PC/ABS-0.5X | 0.0778 | 55.2120 2.71 | 2.5131 |

| PC/ABS-0.75X | 0.0803 | 50.5110 2.43 | 2.38108 |

| PC/ABS-1X | 0.0828 | 48.3519 2.04 | 2.37244 |

| PC/ABS-1.25X | 0.0824 | 46.9998 1.87 | 2.39724 |

| PC/ABS-1.5X | 0.1044 | 45.5095 1.64 | 3.11441 |

| PC/ABS-1.75X | 0.0922 | 43.4549 1.05 | 2.5588 |

| PC/ABS-2X | 0.0883 | 41.9903 0.75 | 2.37539 |

| PC/ABS-2.5X | 0.0826 | 38.1276 0.54 | 2.01147 |

| ASA-0.5X | 0.0448 | 43.3089 2.02 | 1.00589 |

| ASA-0.75X | 0.0465 | 40.7120 2.01 | 1.03037 |

| ASA-1X | 0.0426 | 35.8206 1.88 | 0.83513 |

| ASA-1.25X | 0.0410 | 33.4997 1.74 | 0.76811 |

| ASA-1.5X | 0.0363 | 31.2675 1.32 | 0.63481 |

| ASA-1.75X | 0.0407 | 30.1234 1.21 | 0.71767 |

| ASA-2X | 0.0451 | 29.7052 0.98 | 0.78457 |

| ASA-2.5X | 0.0431 | 25.7492 0.76 | 0.69454 |

| PLA-0.5X | 0.0517 | 61.0224 3.01 | 1.54912 |

| PLA-0.75X | 0.0507 | 53.9398 2.28 | 1.41441 |

| PLA-1X | 0.0487 | 51.8098 2.11 | 1.31708 |

| PLA-1.25X | 0.0495 | 49.6304 1.88 | 1.38744 |

| PLA-1.5X | 0.0530 | 48.7510 1.34 | 1.41017 |

| PLA-1.75X | 0.0592 | 46.1234 1.12 | 1.607 |

| PLA-2X | 0.0538 | 44.8028 0.94 | 1.3569 |

| PLA-2.5X | 0.0581 | 40.6771 0.53 | 1.36561 |

| NYLON-0.5X | 4.1320 | 43.9991 2.10 | 143.10031 |

| NYLON-0.75X | 3.8008 | 38.6681 1.89 | 121.80686 |

| NYLON-1X | 3.6909 | 36.9330 1.75 | 100.49585 |

| NYLON-1.25X | 2.9158 | 32.4276 1.32 | 71.81942 |

| NYLON-1.5X | 3.3459 | 30.8783 1.21 | 74.9468 |

| NYLON-1.75X | 2.1091 | 27.4480 0.98 | 42.67815 |

| NYLON-2X | 1.8455 | 25.4888 0.76 | 34.678 |

| NYLON-2.5X | 1.4764 | 23.2169 0.49 | 25.26962 |

| Specimen ID | Compression | |

|---|---|---|

| Peak Strain | Peak Stress SD (MPa) | |

| PC/ABS-0.5X | 0.1169 | 55.0104 1.70 |

| PC/ABS-0.75X | 0.1245 | 50.6436 1.54 |

| PC/ABS-1X | 0.1574 | 44.6432 1.23 |

| PC/ABS-1.25X | 0.0616 | 39.5815 1.12 |

| PC/ABS-1.5X | 0.0689 | 36.0704 0.78 |

| PC/ABS-1.75X | 0.0370 | 26.3288 0.50 |

| PC/ABS-2X | 0.0309 | 22.8352 0.32 |

| PC/ABS-2.5X | 0.0281 | 19.3911 0.12 |

| ASA-0.5X | 0.3548 | 45.1741 1.61 |

| ASA-0.75X | 0.3257 | 41.5776 1.43 |

| ASA-1X | 0.3321 | 38.9494 1.21 |

| ASA-1.25X | 0.3163 | 36.9471 0.98 |

| ASA-1.5X | 0.2447 | 34.7739 0.54 |

| ASA-1.75X | 0.2847 | 32.1476 0.32 |

| ASA-2X | 0.2071 | 30.5418 0.28 |

| ASA-2.5X | 0.2218 | 29.6770 0.14 |

| PLA-0.5X | 0.0657 | 94.9714 4.02 |

| PLA-0.75X | 0.0563 | 84.9381 3.98 |

| PLA-1X | 0.0510 | 82.8473 3.21 |

| PLA-1.25X | 0.0471 | 82.3288 3.11 |

| PLA-1.5X | 0.0437 | 80.9809 3.01 |

| PLA-1.75X | 0.0430 | 76.0557 2.78 |

| PLA-2X | 0.0357 | 64.0457 2.52 |

| PLA-2.5X | 0.0326 | 58.5110 2.43 |

| NYLON-0.5X | 0.6668 | 76.2642 2.12 |

| NYLON-0.75X | 0.5109 | 63.4428 2.01 |

| NYLON-1X | 0.5747 | 60.8946 1.98 |

| NYLON-1.25X | 0.5470 | 57.7265 1.54 |

| NYLON-1.5X | 0.5727 | 49.6329 1.21 |

| NYLON-1.75X | 0.5267 | 47.7792 1.04 |

| NYLON-2X | 0.5267 | 40.3372 0.98 |

| NYLON-2.5X | 0.5267 | 35.4255 0.65 |

| Specimen ID | a | = | |

|---|---|---|---|

| PC/ABS-0.5X | −1.7745 | 2.0381 | 0.9979 |

| PC/ABS-0.75X | −2.3974 | 2.0680 | 0.9947 |

| PC/ABS-1X | −2.3290 | 2.0512 | 0.9966 |

| PC/ABS-1.25X | −0.7327 | 1.8121 | 0.9968 |

| PC/ABS-1.5X | −1.6758 | 1.8575 | 0.9963 |

| PC/ABS-1.75X | −0.1634 | 1.7315 | 0.9932 |

| PC/ABS-2X | 0.2115 | 1.5240 | 0.9959 |

| PC/ABS-2.5X | 0.3440 | 1.3850 | 0.9949 |

| ASA-0.5X | −2.2848 | 1.3978 | 0.9971 |

| ASA-0.75X | −0.7138 | 1.2163 | 0.9983 |

| ASA-1X | −1.2141 | 1.2406 | 0.9973 |

| ASA-1.25X | −1.8107 | 1.2871 | 0.9951 |

| ASA-1.5X | −1.5037 | 1.2709 | 0.9975 |

| ASA-1.75X | −1.3770 | 1.2447 | 0.9958 |

| ASA-2X | −1.5498 | 1.2573 | 0.9902 |

| ASA-2.5X | −1.0753 | 1.2443 | 0.9956 |

| PLA-0.5X | −2.8610 | 2.5564 | 0.9977 |

| PLA-0.75X | −6.0186 | 2.5779 | 0.9929 |

| PLA-1X | −4.9147 | 2.5313 | 0.9981 |

| PLA-1.25X | −8.5565 | 2.6429 | 0.9906 |

| PLA-1.5X | −7.3615 | 2.6363 | 0.9942 |

| PLA-1.75X | −8.7725 | 2.5337 | 0.9925 |

| PLA-2X | −7.0675 | 2.5595 | 0.9933 |

| PLA-2.5X | −7.4474 | 2.3881 | 0.9861 |

| NYLON-0.5X | 0.7116 | 1.3090 | 0.9988 |

| NYLON-0.75X | −0.06277 | 1.3233 | 0.9998 |

| NYLON-1X | 2.6880 | 1.1136 | 0.9911 |

| NYLON-1.25X | −2.0692 | 1.3950 | 0.9983 |

| NYLON-1.5X | −0.0601 | 1.3193 | 0.9978 |

| NYLON-1.75X | 0.6576 | 1.2433 | 0.9929 |

| NYLON-2X | −0.4243 | 1.3310 | 0.9992 |

| NYLON-2.5X | −1.5034 | 1.4536 | 0.9982 |

| Specimen ID | Flexural Strength SD (MPa) |

|---|---|

| PC/ABS-1X | 59.8800 2.81 |

| PC/ABS-1.25X | 55.6096 2.33 |

| PC/ABS-1.5X | 79.2864 3.65 |

| PC/ABS-1.75X | 53.5673 2.12 |

| PC/ABS-2X | 55.8600 2.34 |

| PC/ABS-2.5X | 39.7608 1.75 |

| PC/ABS-3X | 41.6425 1.21 |

| ASA-1X | 59.5050 2.54 |

| ASA-1.25X | 68.0704 3.01 |

| ASA-1.5X | 56.9556 2.01 |

| ASA-1.75X | 39.3796 1.88 |

| ASA-2X | 47.1610 1.43 |

| ASA-2.5X | 59.4080 2.21 |

| ASA-3X | 47.4764 2.01 |

| PLA-1X | 89.9360 2.20 |

| PLA-1.25X | 107.8720 2.01 |

| PLA-1.5X | 109.6378 1.87 |

| PLA-1.75X | 108.2857 1.75 |

| PLA-2X | 85.9800 1.35 |

| PLA-2.5X | 114.5382 0.95 |

| PLA-3X | 96.8945 0.66 |

| NYLON-1X | 35.0450 1.51 |

| NYLON-1.25X | 22.3520 1.01 |

| NYLON-1.5X | 19.8511 0.98 |

| NYLON-1.75X | 19.5086 0.88 |

| NYLON-2X | 17.2500 0.76 |

| NYLON-2.5X | 15.5384 0.43 |

| NYLON-3X | 19.4093 0.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadaghian, H.; Dadmand, B.; Pourbaba, M.; Jabbari, S.; Yeon, J.H. The Effect of Size on the Mechanical Properties of 3D-Printed Polymers. Sustainability 2024, 16, 356. https://doi.org/10.3390/su16010356

Sadaghian H, Dadmand B, Pourbaba M, Jabbari S, Yeon JH. The Effect of Size on the Mechanical Properties of 3D-Printed Polymers. Sustainability. 2024; 16(1):356. https://doi.org/10.3390/su16010356

Chicago/Turabian StyleSadaghian, Hamed, Behrooz Dadmand, Majid Pourbaba, Soheil Jabbari, and Jung Heum Yeon. 2024. "The Effect of Size on the Mechanical Properties of 3D-Printed Polymers" Sustainability 16, no. 1: 356. https://doi.org/10.3390/su16010356

APA StyleSadaghian, H., Dadmand, B., Pourbaba, M., Jabbari, S., & Yeon, J. H. (2024). The Effect of Size on the Mechanical Properties of 3D-Printed Polymers. Sustainability, 16(1), 356. https://doi.org/10.3390/su16010356