Abstract

Green mining is an effective way to achieve sustainable development in the coal industry. Preventing coal and gas outburst dynamic disasters are essential for ensuring sustainable and safe mining. The numerous microscopic pores within the coal serve as the primary storage space for gas, making it critical to explore the structural distribution and seepage characteristics to reveal the disaster mechanism. Under mining stress, gas within the micropores of the coal migrates outward through cracks, with these cracks exerting a significant control effect on gas migration. Therefore, this study focuses on utilizing natural fractured coal bodies as research objects, employing a micro-CT imaging system to conduct scanning tests and digital core technology to reconstruct sample pore and fracture structures in three dimensions, and characterizing the pores, cracks, skeleton structure, and connectivity. A representative elementary volume (REV) containing macro cracks was selected to establish an equivalent model of the pore network, and a seepage simulation analysis was performed using the visualization software. Revealing the seepage characteristics of fractured coal mass from a microscopic perspective. The research results can provide guidance for gas drainage and dynamic disaster early warning in deep coal mines, thus facilitating the sustainable development of coal mining enterprises.

1. Introduction

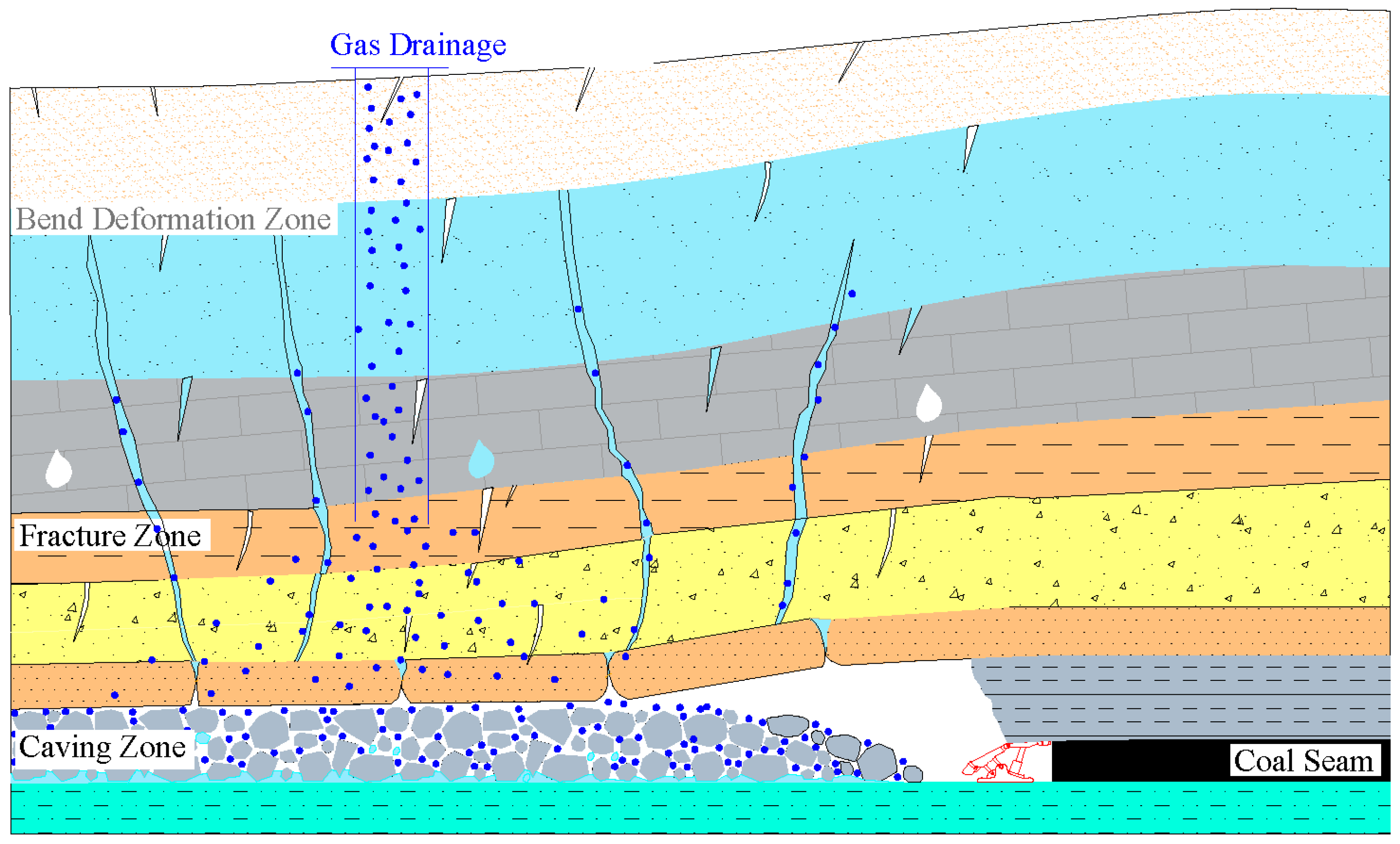

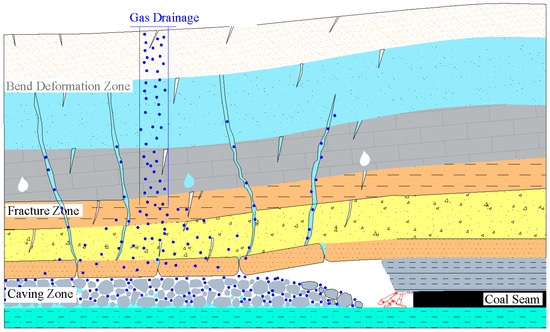

In recent decades, in order to maintain the sustainable development of the coal economy, the coal industry in China has shifted from traditional extensive exploiting to green and low-carbon development. With the increasing depth of coal mining, coal mines are facing more and more risks associated with disasters. Among them, preventing coal and gas outbursts and dynamic disasters is essential for ensuring sustainable and safe mining [1,2,3,4]. Deep high-gas coal reservoirs generally have the characteristics of high adsorption and low permeability. The coal mining activities disrupted the original state of the coal reservoir, thus damaging its integrity and further developing internal fractures. The gas primarily originates from the coal–rock bodies scattered at the bottom and the residual coal pillars on both sides of the abandoned mine voids [5,6,7]. The gas migration in the coal mining goaf is depicted in Figure 1; the gas exists in two states (free or adsorbed) within the fractured coal bodies. Under the effect of mining-induced pressure relief, the desorbed gas diffuses into microscopic pores and eventually gushes out from the fractured coal rock bodies through macroscopic cracks [8,9,10]. The pore–fracture structure within the coal rock bodies is a key indicator for evaluating reservoir information. The interconnected pore–fractures not only serve as the natural storage space for gas but also act as the main channels for fluid migration [11,12]. The characteristics of the pore–fracture spatial structure and its microscale seepage properties within the coal rock bodies are closely related to the extraction of gas. Therefore, to explore the evolution mechanism of coal and gas outbursts during coal mining, it is necessary to analyze the characteristics of the pore–fracture spatial structure and its microscale seepage properties in the fractured coal. The findings of this study will significantly contribute to enhancing coal mine safety production and promoting the sustainable development of the coal industry.

Figure 1.

The gas migration in the coal mining goaf.

Scholars have conducted numerous studies on the comprehensive characterization of the microscopic pore and fissure structure of coal and its microscopic seepage characteristics. Li et al. [13] analyzed the three-dimensional pore–fracture network structure of bituminous coal and anthracite using scanning electron microscopy and tomography techniques. Wang et al. [14] combined micro-CT scanning and visualization techniques to quantitatively characterize the pore–fracture structure in coal. Wang et al. [15] utilized X-ray CT scanning technology to analyze the geometric features of pore fractures in coal at nano, micro, and macro scales. Zhao et al. [16] performed a detailed visualization of the grain size distribution and pore structures and noted that there are significant differences in the pore connectivity of different physical reservoirs. Wang et al. [17] utilized CT scan reconstruction, nuclear magnetic resonance (NMR), and magnetic resonance imaging (MRI) to analyze the pore size distribution, connectivity, and seepage characteristics of coal samples. In terms of macroscopic fracture characterization and connectivity of fractured coal rock mass, Zhang et al. [18] utilized a pore network model to analyze the spatial distribution and connectivity of fractures, thereby indicating that the number and size of equivalent pores in the sample significantly increased after fracturing and that the relatively large penetrating fractures exerted a decisive role in coal permeability. Zhang et al. [19] conducted CT scanning experiments on coal samples under three different mining methods, thus quantitatively analyzing the size and spatial distribution characteristics of micro-cracks in the coal body. Xie et al. [20] conducted a quantitative analysis of the fracture network in the coal body after fracturing through industrial CT, thus defining an index to describe the complexity of the fracture network, and the permeability of the fractured coal sample exhibited a power function growth with the complexity increase.

Numerous scholars have researched the microscopic seepage characteristics of coal masses. Jing et al. [21] utilized X-ray microtomography to obtain the internal microstructure of heterogeneous fractured coal bodies, including the coal matrix, mineral composition, and cleats, and conducted statistical analysis on the geometric characteristics such as direction, length, and thickness. Ni et al. [22] based on CT scanning technology to simulate the flow process of coalbed methane in large pores. Cheng et al. [23] analyzed the microstructural characteristics of different rocks, analyzed the influence of pore microstructural characteristics on rock mechanical properties, and noted that rock deformation is related to porosity, pore size, and pore morphology. Yang et al. [24] developed a novel pore network model, which was utilized to analyze the impact of different organic matter contents on oil-shale permeability, thus revealing that the permeability is mainly dependent on the slip and adsorption conditions in organic and inorganic matter. Lv et al. [25] obtained a 3D digital core model that can reflect the characteristics of fractured reservoirs, added a discrete fracture network to the existing digital core model, and proved (through simulation) that the permeability of fractured rock increases exponentially with pore size. Yang et al. [26] reconstructed the micromodel of tight sandstone based on CT scanning technology and intuitively displayed the micro seepage characteristics. Shi et al. [27] utilized nano-tomography and nano-CT to perform 3D characterization of the micro-fracture structure of low-rank bituminous coal and used Avizo software 9.1 to simulate the seepage of single-phase fluid in the micro-fracture network, thus indicating that the pore–fracture structure exhibits apparent heterogeneity and micro-fractures exert a strong control effect on seepage. Wang et al. [28] established a structural model of different pore sizes and connectivity and noted that the change in pore size not only affects the seepage characteristics in the pores but also affects the stable seepage speed in the fractures. Zhu et al. [29] extracted the pore network from the segmented three-dimensional digital coal core, identified the fluid migration channels controlled by organic matter pores, and noted that gas slippage and formation initial pressure were the main factors affecting methane flow.

The aforementioned study reveals that digital core technology can be utilized to characterize the pore and fissure structure of fractured coal bodies in reservoirs, in which pore size distribution, pore throat characteristics, and connectivity exert a certain impact on fluid migration. Since the perspective accuracy is related to the specimen size, previous researchers have analyzed the pore and fracture characteristics of reservoirs at different scales. Most of the research objects were intact coal and rock bodies with small sizes, and there was a lack of analysis of natural fractured coal bodies containing macroscopic fractures. According to the phenomenon of gas escaping from the fractured coal in the goaf’s storage space, the analysis of the pore and fissure structure and seepage characteristics of the macro-cracked coal mass can provide a basis for exploring the gas flow in the goaf. The research results can guide gas drainage and early warning of dynamic disasters in deep coal mining.

2. Experimental Materials and Equipment

2.1. Specimens Preparation

The large-sized coal blocks from the mining goaf were transported to the laboratory for processing. It is worth mentioning that the specimens utilized in the test were obtained from the 8119 working face and of No. 3–5 Coal seam in Tashan Coal Mine in Datong City, Shanxi Province, which belongs to the carboniferous coal seam. Due to their substantial size, nearly half a cubic meter in volume, these blocks were secured onto the base platform of a drilling rig. A water drill was employed to core these blocks, maintaining a steady drilling speed to minimize damage to the specimens. The process was illustrated in Figure 2. During the process of drilling and coring a large coal block, a specimen containing natural cracks was accidentally discovered. It can be observed that the two ends of the specimen are complete, and there is a natural macrocrack in the middle. The diameter of the specimen is 50 mm, and the length is approximately 200 mm. The cracks are distributed in a curved shape along the specimen length, with a maximum length and width of 105 mm and 0.5 mm, respectively. Notably, obtaining such a specimen with a natural fracture is exceedingly valuable. Such a specimen is a rare find compared to the millimeter-sized specimens commonly produced in laboratories; this specimen is significantly larger and contains a natural macroscopic fracture that is distinctly different from the fractures in damaged specimens and artificially pre-made fractures. It can more accurately reflect the reservoir information of the fractured coal body in the mined-out area.

Figure 2.

The collection process of naturally fractured coal specimen.

Due to its ability to reproduce the internal mineral structure and pore–fracture distribution of the tested object without causing any damage, CT scanning technology is being widely utilized in related research in the geotechnical field. The technology is crucial for investigating the micro-damage issues of materials such as coal and rock. The imaging principle is as follows: X-rays penetrate the object to be tested and undergo a certain degree of attenuation as per the sample’s density distribution. The attenuation coefficient is directly proportional to the sample density. The transmitted rays are captured by the detector behind them, and the signals are transferred into the computer system and converted into a data body. After reconstructing the data body according to a certain algorithm, a three-dimensional model of the sample is obtained. The internal structure of the model is presented in different grayscale values, ranging from 0 to 255. The higher the sample density, the higher the grayscale value presented, and vice versa. In the three-dimensional visualization and reconstruction analysis software, the grayscale range is threshold-segmented to extract and distinguish the pores, fractures, and mineral components in the model. This visually presents the location, size, and spatial distribution of the model’s internal pores and fractures. Select the representative elementary volume (REV) containing fractures, and utilize the built-in seepage calculation module to simulate seepage and calculate the absolute permeability of the rock core in the direction of the fracture.

To reflect the spatial structure characteristics of pores and fissures inside the aforementioned natural fissure coal body, X-ray computed tomography (CT) was utilized to conduct the test. The equipment is illustrated in Figure 3. The high-penetration CT system equipment is the NanoVoxel-4000 switch reflection type of Sanying Precision Company (Tianjin, China), which is equipped with a 190 kV voltage and 140 uA current microfocus ray source, a working turret, and a flat-panel detector; has both high resolution and high penetration capability; and can ensure penetration of large-size samples. Meanwhile, high precision is ensured. The exposure time is 0.6 s, and the number of acquisition frames is 5400. The spiral scanning mode is utilized to quickly scan the specimen. The number of turns is 5, and the pitch is 106. The number of scanned cross-sectional images is 4226, and the number of longitudinal images is 4226. The number of cross-sectional images is 1764, and the spatial voxel is 29.15 um. After the scanning is completed, the 8-bit data volume is imported into the three-dimensional visualization software Avizo 9.1 to construct a three-dimensional digital core.

Figure 3.

NanoVoxel 4000 series of an X-ray three-dimensional micro-CT system.

To obtain the distribution of pores and fissures within the natural fissure coal samples, the scanning test was performed using the aforementioned equipment, which can realize the scanning of standard-size specimens to meet the requirements of the preceding natural fissure coal specimens. The detailed process for the scanning test is as follows:

- (1)

- Place the natural fissure specimen on the working turntable, and use sealing mud and tape to firmly fix the bottom of the specimen; thus, the longitudinal axis of the cylindrical specimen is kept perpendicular to the rays, and the specimen is prevented from being deflected during the rotation process. Furthermore, ensure that the relative positions of the samples will not be changed during the rotation process.

- (2)

- After the specimen is installed, close the window where the specimen is placed; turn on the X-ray power supply; move the sample to the vicinity of the ray focal point; adjust the height of the sample stage to make it match with the ray transmitting end; ensure that the natural fissure specimen is in the scanning window; set parameters such as the voltage, current, number of laps, and pitch; and start to scan the specimen by spiral scanning after the setting is completed.

- (3)

- After the scanning is completed, turn off the X-ray power supply, check the quality of the scanning through the three-way slice data, and confirm the completion of the samples from the worktable; CT slice data will be imported into the three-dimensional visualization software for further analysis of the pore and fissure structure.

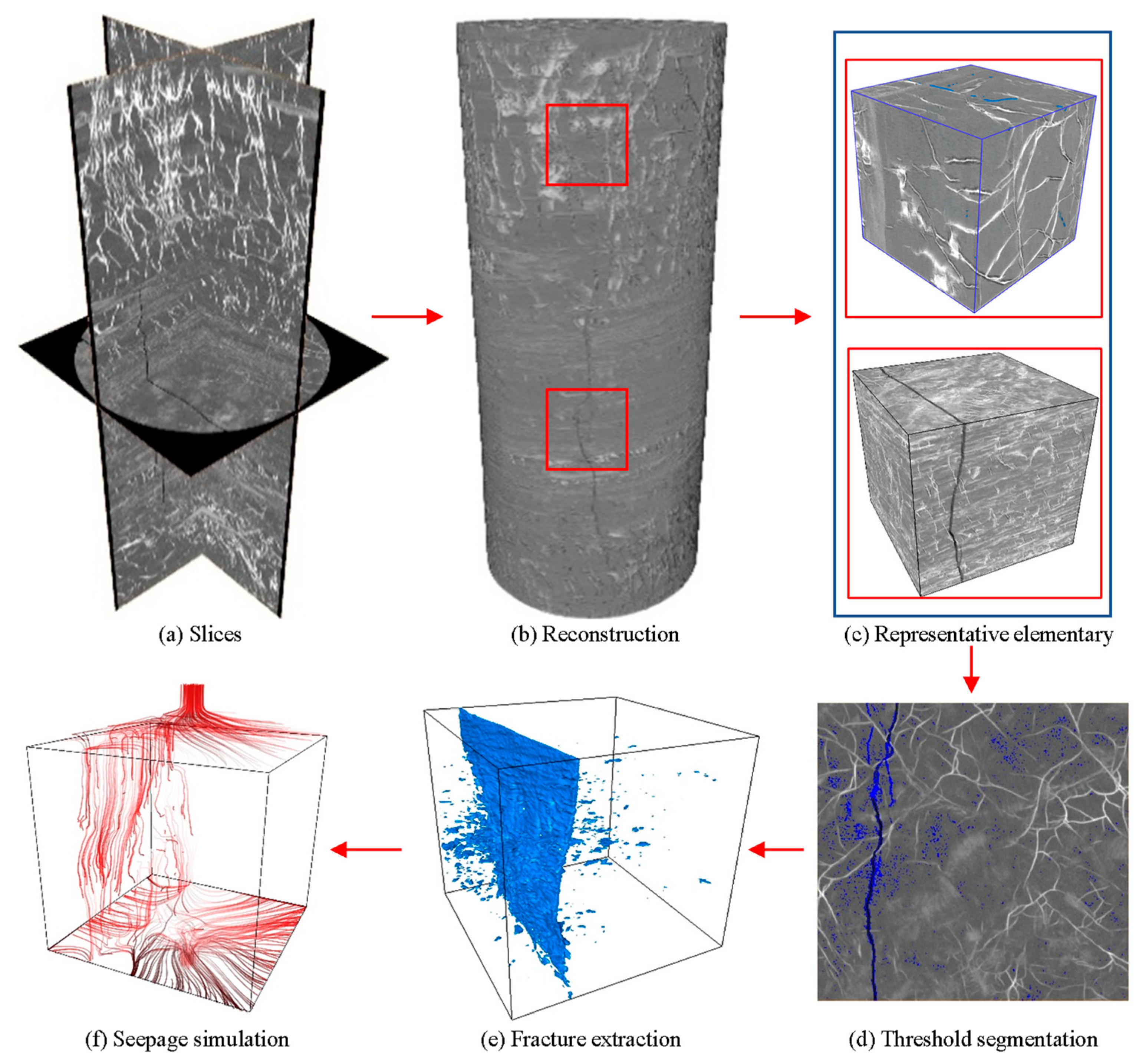

2.2. Reconstruction Processes

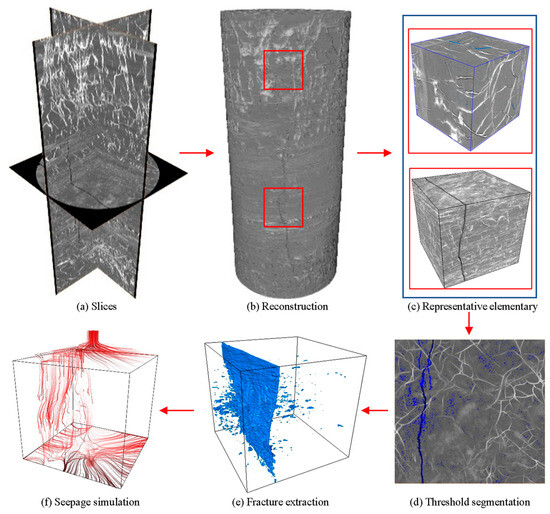

The reconstruction processes of the naturally fractured coal samples are depicted in Figure 4. To more effectively illustrate the characteristics of pores and fissures within the natural fissure coal body, a three-dimensional reconstruction of the scanned two-dimensional image is required, which primarily involves several steps [30,31,32,33]. Initially, the two-dimensional slice image undergoes preprocessing, filtering, and noise reduction to eliminate any artifacts or noise induced by scanning equipment or human errors, which enhances the clarity of the structure in the image while preserving its integrity. Subsequently, the two-dimensional slice data are imported into the three-dimensional visualization software, Avizo. Based on the distinct gray values exhibited by different substances, appropriate threshold intervals are set to extract components such as pores, cracks, and various mineral matrices, which enables the separate presentation of connected pores and isolated cavities, and the calculation of the radius, surface area, pore throat, and coordination number of each hole in the model for quantitative analysis. However, due to the limited memory space of laptop computers, there can be issues with insufficient memory when analyzing and calculating the entire specimen. Therefore, the representative elementary volume (REV) is chosen to accurately represent the material properties for further analysis of the pores–cracks characteristics. The seepage module is subsequently employed to simulate the pressure applied to the upper and lower parts, respectively. The seepage path is visualized through streamline distribution, and the distribution of permeability, flow velocity, and pressure can be simultaneously displayed.

Figure 4.

Schematic diagram of the reconstruction process.

Three distinct materials can be identified in the two-dimensional slices through grayscale distribution: dark black structures of pores and fissures, white minerals, and a gray coal matrix. These materials are easily distinguishable in most slices. However, a few slice images exhibit blurred artifacts at the boundary contours, thus necessitating the use of median filtering to reduce noise. After preprocessing, the images are imported into the Avizo three-dimensional visualization software. Using the Volume Rendering command, a three-dimensional model of the entire specimen is reconstructed. This approach immensely enhances the analysis of the macroscopic mechanical properties of coal samples. However, it also significantly increases the storage and operational demands on the computer. During computation, issues of insufficient memory may arise, thereby necessitating the selection of a representative elementary volume by cutting the cylinder. After several trials, a unit body size of 11.66 × 11.66 × 11.66 mm3 was chosen. This size not only reflects the characteristics of pores and cracks in the cracked coal sample but also considers the computer’s data processing capabilities. The selected unit body contains longitudinal natural cracks. Threshold segmentation is subsequently performed based on the grayscale distribution map. By adjusting the range of the threshold interval, the distribution of cracks can be visualized. The watershed algorithm is utilized for segmentation, and the Separate Objects command in the software is utilized to extract the pores and cracks in the unit body. The Volume Fraction command enables the analysis of the distribution characteristics of porosity. Finally, the absolute permeability experiment simulation algorithm, a built-in module of the software, is utilized to simulate the seepage of the representative elementary volume. The connectivity is subsequently analyzed based on the characteristics of the streamline distribution.

3. Digital Core Reconstruction Processes

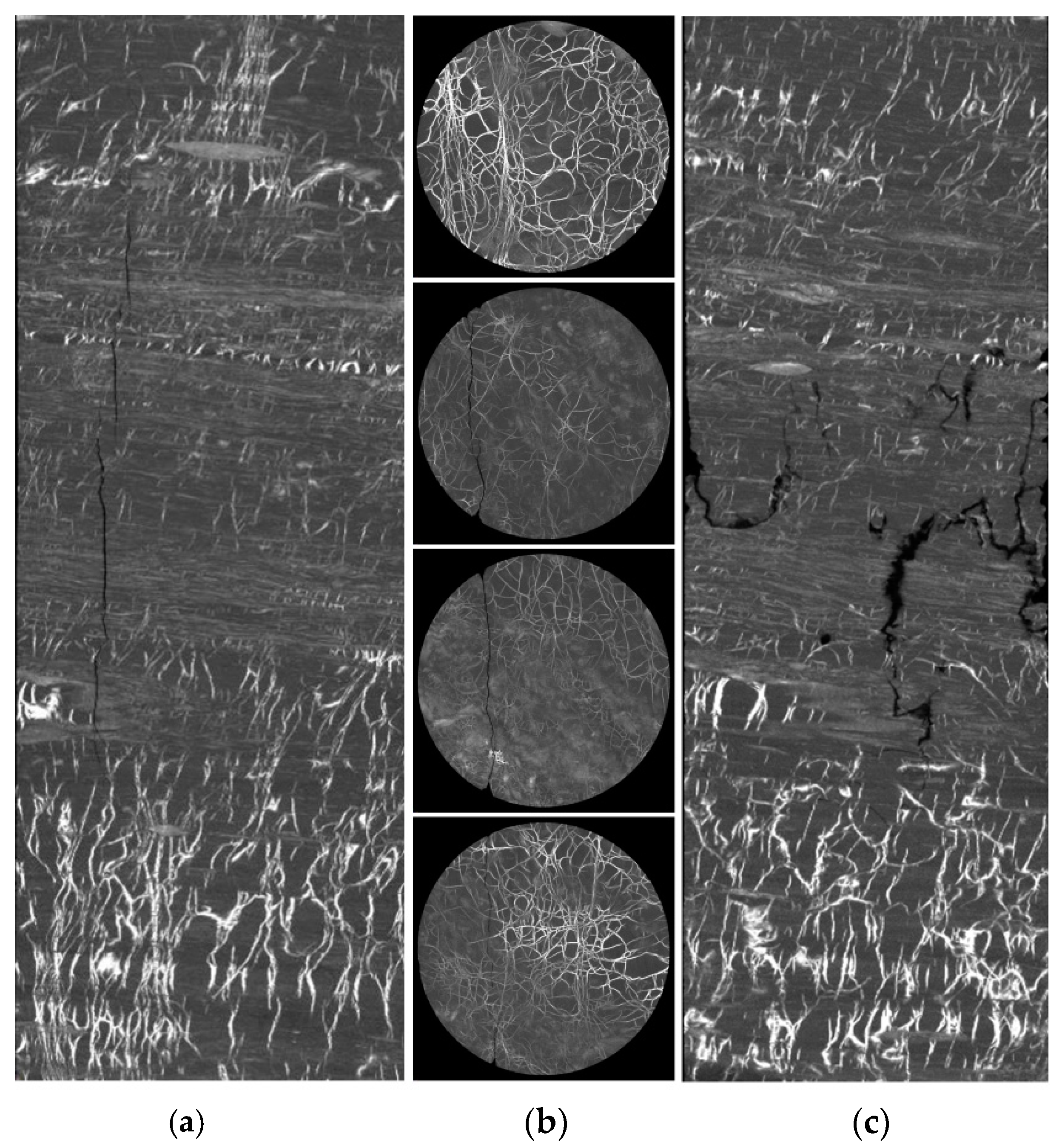

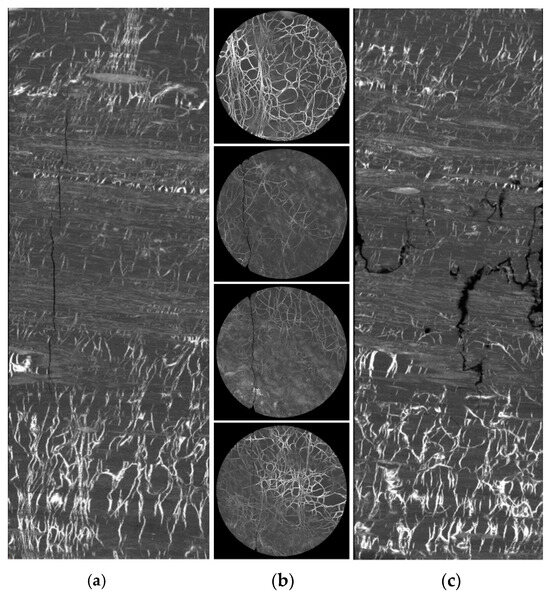

3.1. Slice Analysis

Based on the aforementioned operation process, we delve into the distribution of the pore–fissure structure in coal samples, utilizing the two-dimensional slice diagrams that we have acquired. It is crucial to highlight that this study chose a handful of representative CT slices from a series of natural fissure coal sample CT slices for further analysis. As illustrated in Figure 5, we present the slice diagrams of fractured coal samples. Upon examination, the surface of the original sample is speckled with black and white spots, which is indicative of various minerals. The predominant shades of gray and black represent the natural carbon element. Concurrently, a minor presence of white spots signifies a small quantity of clay minerals, and the intersecting white lines observed are kerogen. In addition, it can also be observed that there is an apparent macrocrack inside the sample, which is distributed at the left edge. From the image, it is apparent that the internal structure of the cracked coal sample is relatively dense and that this internal structure is modified as the number of layers changes; moreover, the morphological characteristics of the cracks will also change accordingly. Combining the longitudinal slices in the XZ direction and YZ direction below, it can be observed that the height of the sample is 150 mm, and the upper and lower ends of the sample are relatively complete without apparent macro cracks. The cracks are mainly distributed in the middle layer of the sample and at the upper end. The change from top to bottom is also a gradual process. The cracks are mainly distributed on the left side of the specimen. From top to bottom, the openings of the original cracks at both ends are smaller. From top to bottom, the process is from small to large and then to small. Cracks initiate and gradually expand along the weaker areas of the specimen edge.

Figure 5.

Section diagram of fractured coal scanned by CT. (a) XZ Direction (b) XY Direction (c) YZ Direction.

In addition, there are vacancies in some internal crack areas. It can be observed that the damage illustrated in the slice diagrams of different layers is also different. In addition, it should be noted that the coal samples with natural cracks are more realistic than the artificial cracks created in the process. Meanwhile, this large-sized fractured coal body can more truly reflect the characteristics of the fractured coal reservoir, which is immensely significant for analyzing fracture seepage.

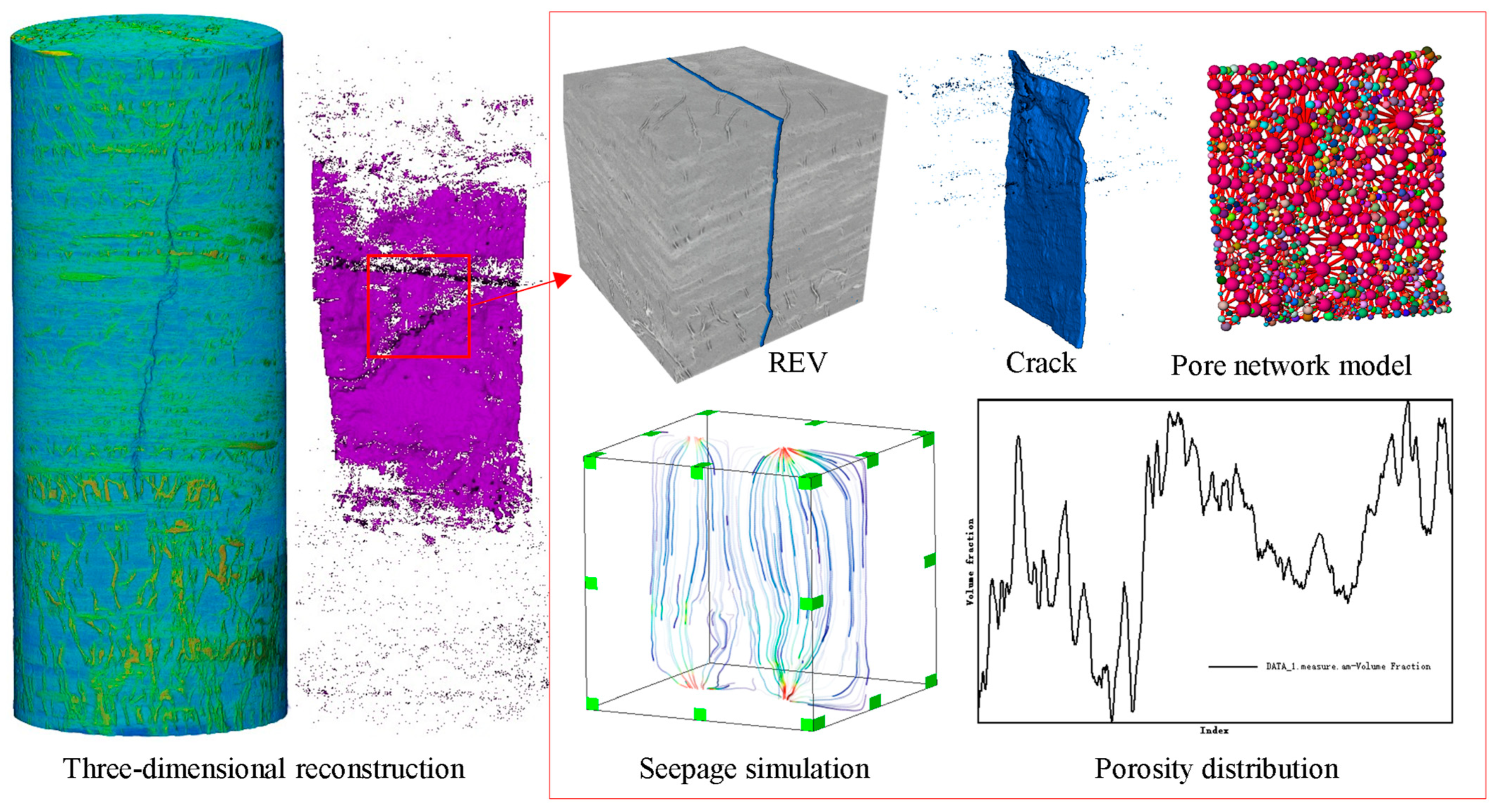

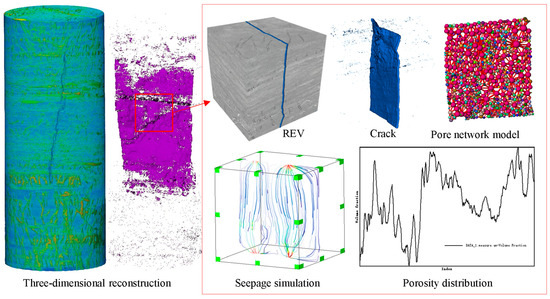

3.2. Digital Core Reconstruction

Import the two-dimensional CT slices into the Avizo software for visual representation. After three-dimensional reconstruction, the overall digital core model is obtained, as depicted in Figure 6. It is rendered in color and allocated different color displays according to changes in grayscale values. The red color represents the mineral components in the model, and the blue zone is the coal matrix. Subsequently, the coal matrix, pore fissures, and mineral components are extracted, respectively, by adjusting the threshold interval. It can be observed that the model as a whole is consistent with the composition of the original fractured coal sample and that it more realistically restores the characteristics of the original fractured coal specimen. The two ends of the specimen are relatively complete, with more mineral components distributed on the surface, and there is an apparent macroscopic crack in the middle. By observing the separated parts, it can be observed that the coal matrix and mineral components account for the main part. The coal matrix is the main body, and the white minerals are crisscrossed, similar to vines. The macroscopic cracks occupy a small volume and are apparently continuous. The thickness gradually increases from both ends to the middle, with a maximum value of approximately 2 mm. There are some fillers, such as debris, mixed in the cracks, and some isolated pores are randomly distributed on both sides and ends of the specimen. These macroscopic, large cracks and tiny pores coexist, and the connectivity between them must exert an impact on gas migration in fractured coal bodies.

Figure 6.

The analysis process of digital core reconstruction.

This study focuses on the cracks and pore structures. When performing the separation operation on the macro cracks and isolated pores obtained above, due to the large number of calculations, the computer has limitations of insufficient memory and can extract only six representative elementary volumes (REV) from the entire model. We utilize the processing process of one of the representative elementary volumes as an illustration. Use the Extract Subvolume command in the software to extract the unit body containing cracks and perform threshold segmentation on it to obtain the distribution of pores and cracks; subsequently, combine the macro cracks and isolated pores, which are separated separately. It can be observed that isolated pores present scattered distribution characteristics and occupy a small volume. In comparison, the volume of macroscopic cracks is much larger than that of pores. For connected cracks, the maximum sphere algorithm can be utilized to generate a pore network model that is connected through balls and sticks of different diameters. The diameter of the ball represents the size, and the thickness of the stick represents connectivity. Based on this model, the permeability can be calculated, which immensely saves calculation time. After many attempts, it was found that the applicability of the model containing macroscopic large fractures is poor, and the absolute permeability experiment simulation module in the software can more truly reflect the absolute permeability characteristics containing macroscopic fractures. In addition, by calculating the ratio pertaining to the volume of pore cracks to the total volume, the porosity distribution curve of each layer in the unit body along the Z-axis direction can be calculated.

4. Experimental and Result Analysis

4.1. Pore and Fracture Structure Characteristics

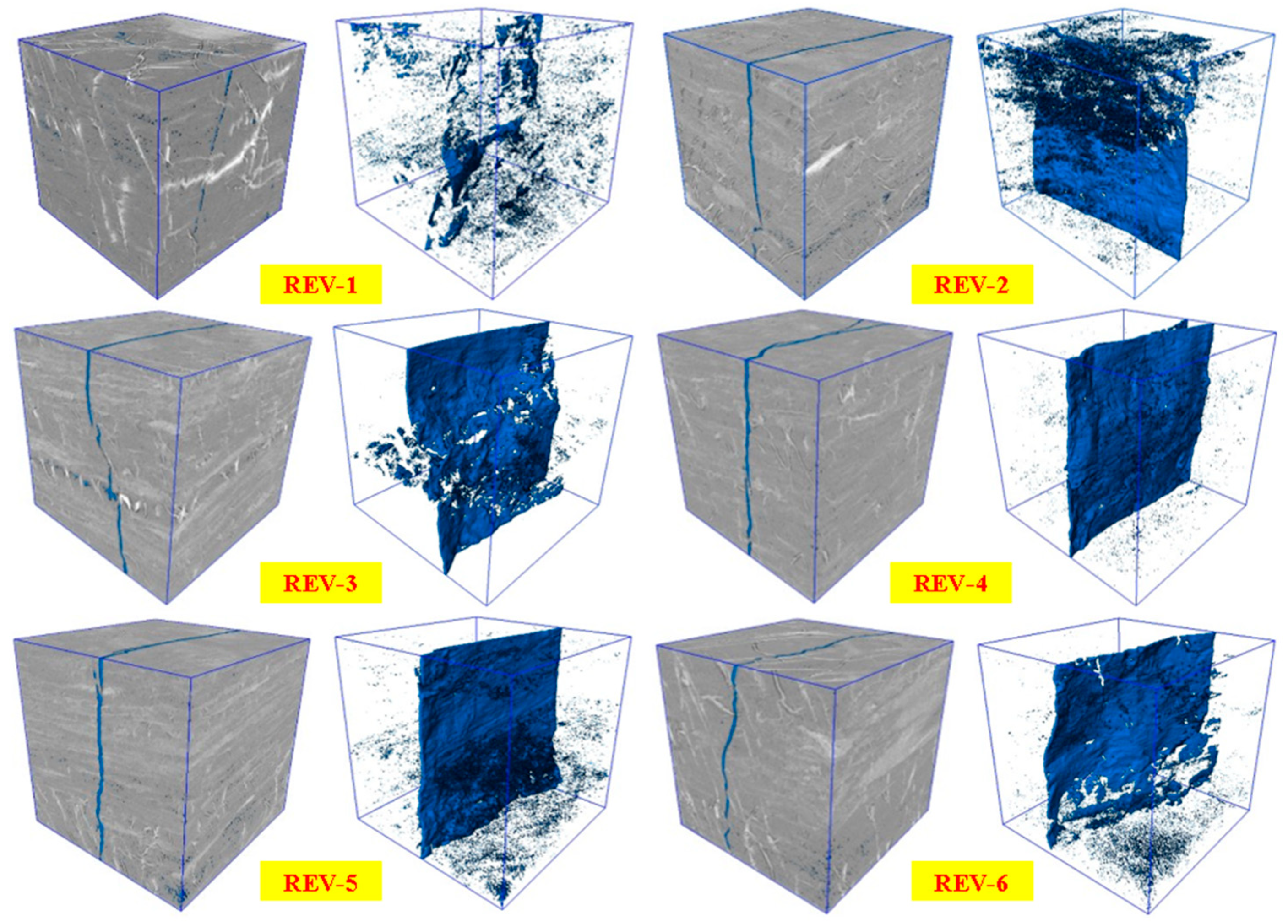

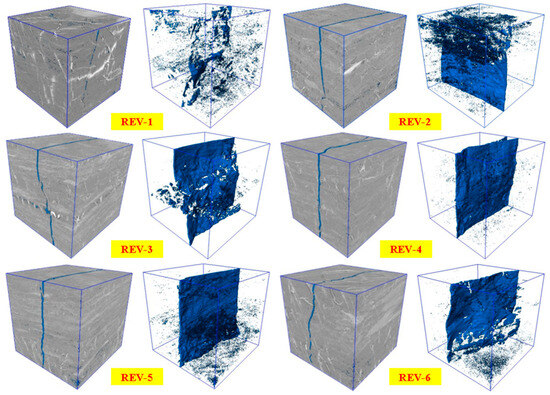

To more vividly characterize the pore and fissure structure characteristics of coal samples, Avizo software was utilized to separate the pore and fissure structure in the previous section and to present the pore and fissure morphology and distribution characteristics from a three-dimensional perspective. Figure 7 illustrates the evolution diagram of the three-dimensional pore and crack structure of the representative elementary volume (REV) at different positions along the natural fissure coal. It can be observed that there are certain differences between the three-dimensional models at different parts along the cracks. Although their main structures are coal matrices and contain some mineral components, there are apparent differences between the various components. The mineral composition in the REV-1 unit body is apparently higher than that in other specimens. Each unit body contains a longitudinal macroscopic crack, accompanied by some pores. By comparing the macroscopic cracks and pores, it can be found that the pore distribution reveals that the non-uniformity and distribution are relatively dispersed. Although most secondary cracks and pores exist in an isolated state, in comparison, the existing longitudinal macrocrack exhibits satisfactory connectivity.

Figure 7.

Three-dimensional pore and fissure distribution of REV.

By comparing the distribution pattern of pore cracks in each unit body, it can be observed that macroscopic cracks and pore cracks coexist in the unit body, and pore crack structures of different sizes and shapes are formed in the interior of the fractured coal body. The REV-1 unit body exhibits inconspicuous penetrating cracks; the distribution of pore cracks in the piece is the least; the macroscopic cracks are apparently different from other units; and their connectivity and width are apparently smaller than other units. Moreover, there are some sporadic isolated pores randomly distributed around the distribution in the unit, and their number and volume are less; REV-2 bottom macroscopic cracks are developing, and there are some sporadic distributed pores at the top; and the crack opening gradually increases from the top to the bottom. REV-3 and REV-4 units are more similar: they are all penetrated by a macroscopic longitudinal crack, which presents a near-vertical shape with a certain width. A large number of pores are distributed around the macrocracks, and some pores are connected to the cracks. The REV-5 and REV-6-unit bodies are more similar; in addition to the existence of a longitudinal crack in the middle, the unit body is filled with pores of different sizes, and the difference with the other specimens is that the pore–crack structure in the cell body significantly increased. Generally, the large number of pore clusters provides a satisfactory storage space for the gas in the coal reservoir. It can also be observed that there is an apparent through-fracture surface in the longitudinal direction in each model, which provides a favorable channel for the diffusion and seepage of gas in the coal for the transportation of fluids in the fractured coal reservoir.

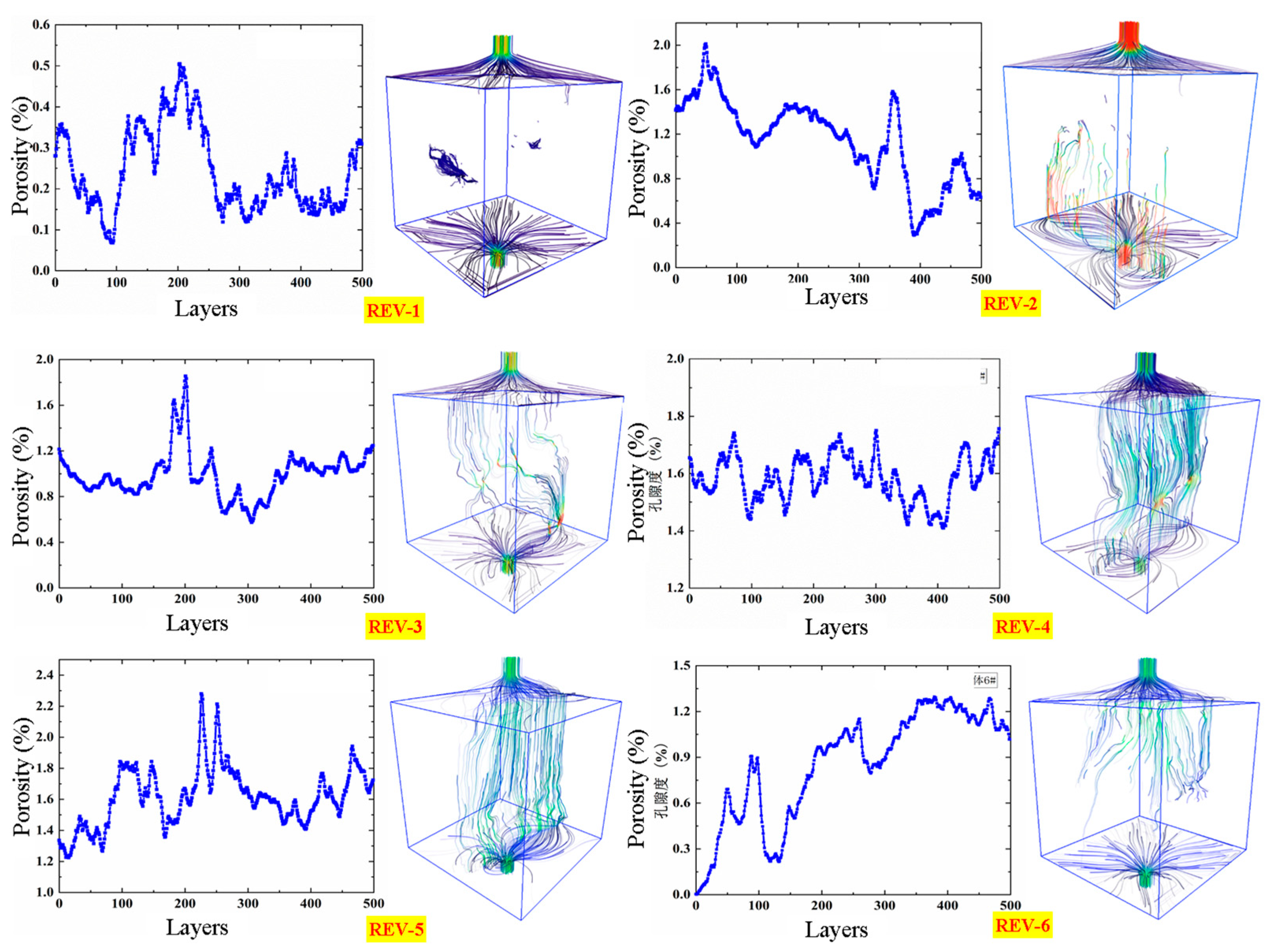

4.2. Microscopic Seepage Simulation Analysis

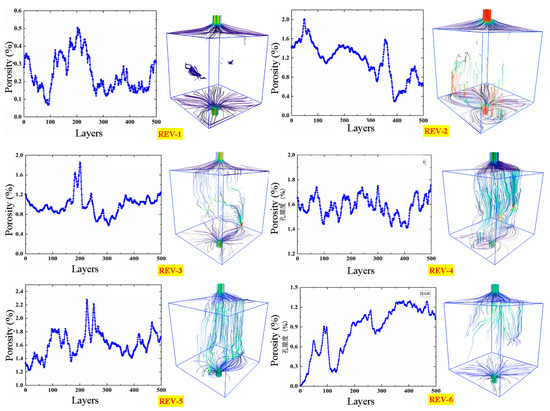

To quantitatively analyze the pores and cracks in the characterizing unit body, the volume fraction command is utilized to statistically analyze the pore and crack volume in each unit body, calculate the porosity size of each layer along the Z-axis, and conduct seepage of the characterizing unit body. Simulating the seepage characteristics of the pore–fracture dual medium structure from the microscopic level, the model assumes that single-phase fluid migrates from the top to the bottom along the through-fracture and applies pressures on the top and bottom of the model, respectively, with magnitudes of 2 MPa and 0.1 MPa. To analyze the dominant role of cracks in the crack unit body, the fluid flows along the crack surface. The Z-axis direction of the specimen is utilized as the plane of flow field inflow and outflow, and the streamline distribution is observed. To analyze connectivity, the built-in algorithm obtains the absolute permeability of the model based on Darcy’s law. Figure 8 below depicts the porosity and seepage simulation results of each unit body.

Figure 8.

The porosity distribution and seepage simulation results.

It can be observed that the porosity in each unit body fluctuates up and down along the layers, and the regularity of each curve is not apparent. The amplitude of fluctuations is related to the distribution of pores and cracks. The density of isolated pores and changes in the opening of penetrating cracks can affect it. However, in general, their porosity gradually increases with the increase in height, and the maximum porosity that appears at the minimum porosity size is 2.3% in REV-5 and 0.0004% in REV-6, which is consistent with the aforementioned distribution characteristics of pores and cracks presented. The distribution of these porosities is related to the migration of fluid.

In addition, from the distribution of flow lines in the fracture-containing units, it can be observed that the seepage in the fractured coal body is largely dependent on the penetrating macroscopic fractures, and it can be observed that there is almost no flow line through in unit REV-1, and there are flow lines in units REV-2 and REV-6; however, there are interruptions in the flow lines due to the discontinuity of the macroscopic fracture in the specimen. The flow lines in REV-3, REV-4, and REV-5 are increasing in number, which indicates good connectivity. The pressure difference between the upper and lower surfaces of the model drives fluid transportation, and the permeability pressure gradually decreases along the direction of fluid transportation; moreover, the flow velocity in each part of the unit cell exhibits apparent differences, and the flow velocity in the crack is apparently larger than that in other parts. Generally, the number of internal flow lines increases with the increasing degree of pore and fracture development in the unit body, thus indicating that the connectivity along the natural fissure coal body is increasingly enhanced from top to bottom, and the dominance of the fissures becomes increasingly apparent in the seepage process.

5. Discussion

Deep coal seams contain abundant coalbed methane resources, as shallow resources are depleted, coal mining has shifted to deeper levels [34,35,36]. However, the low porosity and permeability of deep coal rock make it susceptible to coal and gas outburst accidents. As an associated product in the coal-forming process, gas was the main component in coal seams and coal-measure strata [37,38,39]. Its properties are different from those of traditional sandstone and shale petroleum reservoirs. It exists in pores, joints, and fissures in the form of free, adsorption, and solid solution states, respectively, under different formation pressures. The pore and fracture system not only affects the macroscopic physical and mechanical parameters of the coal body (density and strength), but also influences the physical properties of the coal body (porosity and permeability). Therefore, it is necessary to conduct an in-depth discussion on the pore structure and seepage characteristics of natural fractured coal bodies.

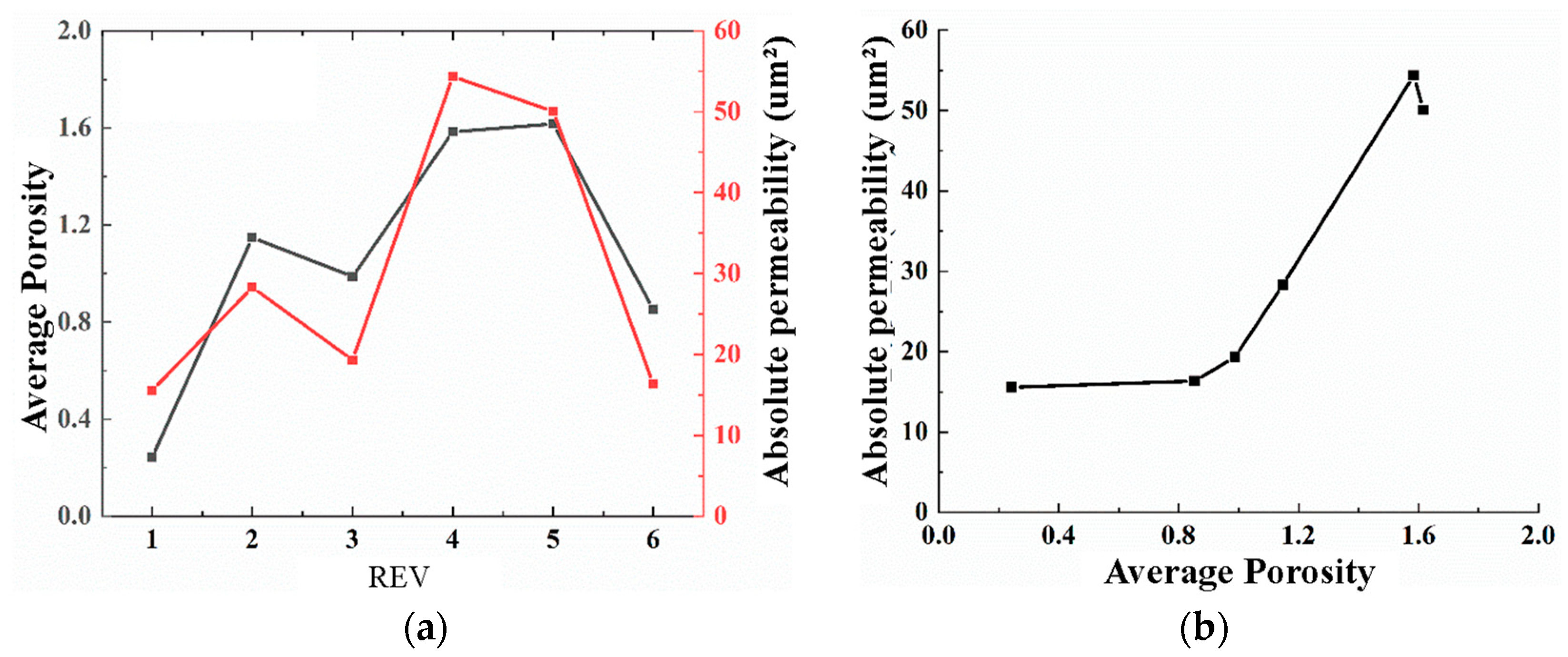

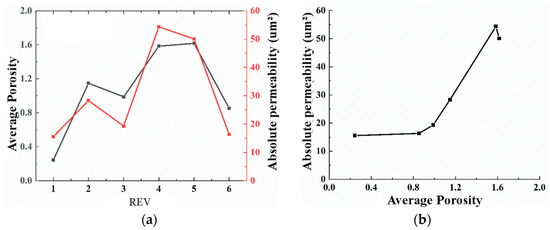

By analyzing the test results, it can be seen that there was an obvious positive correlation between the average porosity and absolute permeability of the specimen. The storage space was mainly composed of connected cracks and pores, and cracks are the main seepage channels. As the number of different layers increases, there are an increasing number of connected cracks and seepage streamlines inside the sample, and the degree of internal connectivity is immensely increased, thus forming a satisfactory seepage channel. It is apparent that the sample is mainly along the crack surface and that it forms the migration fracture channels. Based on the average porosity distribution of each unit body and comparing it with the calculated absolute permeability, the average porosity and absolute permeability change curves are obtained, as illustrated in Figure 9. The permeability and porosity change curves of fractured coal samples at different positions in Figure 9a indicate that the changes in porosity and permeability are generally consistent. As the interception locations continue to increase, the porosity and absolute permeability of the sample increase. The rate generally exhibits a trend of first increasing and subsequently decreasing, which is consistent with the change rules affecting the aforementioned distribution of pore cracks and seepage streamlines. Since the initial state of the coal sample contains cracks in the middle, the permeability exhibits an increasing trend as the cracks expand during the seepage process. In addition, the change curve of absolute permeability with porosity in Figure 9b reveals that the absolute permeability exhibits a gradually increasing trend as the average porosity increases.

Figure 9.

The average porosity and absolute permeability change curve. (a) porosity and permeability (b) absolute permeability with porosity.

Combined with the three-dimensional pore and fracture reconstruction model of natural fractured coal bodies, it can be observed that as the model size increases, the shape of natural fractures also becomes more complex, the length of the fractures increases, and the shape appears curved. Since the original cracks in the sample already exist and are distributed in a discontinuous state, during the seepage simulation process, the seepage streamlines are also intermittent. The opening of the cracks is a major factor affecting seepage. Due to the selection of the sample, different locations result in different seepage channels. The larger the channels inside the sample, the more apparent the fluid passing through the interior becomes in the process of flowing. When the connectivity of the coal body is optimal, the gas migration process in the coal body becomes smoother. Contrastingly, in areas without crack channels, due to the effect of pressure, new pores and cracks will be generated and continue to flow. If there are no pores and cracks, gas accumulates in the original channels, and the gas pressure gradually increases. During the coal mining process, cracks are generated due to pressure relief, and gas escapes from the pores and converges into the original cracks.

Porosity and permeability are important parameters that reflect the characteristics of coal seam reservoirs. During coal seam excavation, coal seam gas is discharged due to stress release and further development of pore fissures under the action of unloading. The research results of this article can not only effectively extract coal seam gas, reduce coal mine gas dynamic disasters, and ensure safe and efficient production of mines, but also achieve multiple effects such as clean energy supply and atmospheric environmental protection, accelerating the promotion of “carbon peaking and carbon neutrality”.

6. Conclusions

Herein, the CT scanning test technology was utilized on natural fractured coal bodies to obtain the internal pore and fracture structural characteristics of fractured coal masses. Avizo software 9.1 is utilized to extract representation units for fractured coal masses, and a three-dimensional reconstruction of the pore and fracture model is performed. Thus, a seepage simulation was conducted on REV and the main conclusions obtained are as follows:

- (1)

- According to the CT scanning results, it can be observed that there is an apparent macrocrack inside the natural fissure coal body, and secondary cracks and pores are distributed around it. The pores are contiguously distributed in local areas, and there are some isolated pores. It can also be observed that the size of macroscopic fractures is significantly larger than the pores. The establishment of a pore network model more intuitively reproduces the distribution of macroscopic fractures, pores, and channels, and the structure of the natural fractured coal reservoir has been characterized in a relatively fine manner.

- (2)

- By analyzing the seepage simulation results of the fractured coal body surface certificate, it can be observed that the permeability of the original coal body without cracks is low, and there is almost no internal streamlined distribution in the simulation results, whereas the simulation results with cracks indicate that the fluid flows along the main While the fractures migrate downward, they also migrate into the surrounding connected secondary fractures and pores, thus forming good seepage channels, which leads to an increase in the permeability of the fractured coal body.

- (3)

- The seepage of fluid in fractured coal is a complex process that is affected by fluid properties, in situ stress distribution, and pore and fracture structure. Combining CT scanning technology with computational fluid dynamics can enable researchers to deeply understand multi-phase flow at different scales, which bears immense significance for the development of unconventional resources.

- (4)

- Through comparative analysis, it is evident that there exists a clear positive correlation between the evolution of permeability and porosity in fractured coal mass. In the practice of coal seam gas extraction, the development of reservoir fractures can be promoted by means of drilling pressure relief and presplitting blasting. Which will promote gas extraction and provide support for the sustainable development of coal mining enterprises.

Author Contributions

Writing-original draft, C.Z.; Investigation, Z.J.; Methodology, G.F.; Software, L.Z. and R.G.; Supervision, C.L. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the National Natural Science Foundation of China (No. 52304149, No. 52274135), Supported by Fundamental Research Program of Shanxi Province (No. 202103021223093), the Key Project of National Natural Science Foundation of China (No. 51925402). The New Cornerstone Science Foundation through the XPLORER PRIZE, the China Postdoctoral Science Foundation (No. 2022M722346), the Natural Science Foundation of Shanxi Province (No. 202303021212073), Basic Research Program of Shanxi Province (Grant No. 202203021212268).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no competing interests.

References

- Si, X.; Luo, Y.; Luo, S. Influence of lithology and bedding orientation on failure behavior of “D” shaped tunnel. Theor. Appl. Fract. Mech. 2024, 129, 104219. [Google Scholar] [CrossRef]

- Ma, Q.; Liu, X.; Tan, Y.; Elsworth, D.; Shang, J.; Song, D.; Liu, X.; Yan, F. Numerical study of mechanical properties and microcrack evolution of double-layer composite rock specimens with fissures under uniaxial compression. Eng. Fract. Mech. 2023, 289, 109403. [Google Scholar] [CrossRef]

- Wang, X.; Li, J.; Zhao, X.; Liang, Y. Propagation characteristics and prediction of blast-induced vibration on closely spaced rock tunnels. Tunn. Undergr. Space Technol. 2022, 123, 104416. [Google Scholar] [CrossRef]

- Teng, T.; Xue, Y.; Zhang, C. Modeling and simulation on heat-injection enhanced coal seam gas recovery with experimentally validated non-Darcy gas flow. J. Pet. Sci. Eng. 2019, 177, 734–744. [Google Scholar] [CrossRef]

- Chen, S.; Dou, L.; Cai, W.; Zhang, L.; Tian, M.; Han, Z. Evolution of coal microfracture by cyclic fracturing of liquid nitrogen based on μCT and convolutional neural networks. Rock Mech. Rock Eng. 2024, 57, 2103–2124. [Google Scholar] [CrossRef]

- Liu, Q.; Fu, Q.; Yang, K.; Wei, Q.; Liu, H.; Wu, H. Geomechanical Modeling and Inversion Analysis of the in-situ Stress Field in Deep Marine Shale Formations: A Case Study of the Longmaxi Formation, Dingshan Area, China. Front. Earth Sci. 2022, 9, 808535. [Google Scholar] [CrossRef]

- Zhang, W.; Guo, W.-Y.; Wang, Z.-Q. Influence of lateral pressure on mechanical behavior of different rock types under biaxial compression. J. Central South Univ. 2022, 29, 3695–3705. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Cui, B.; Feng, G.; Zhang, S.; Zhang, C.; Zhang, Z. A Disturbed Voussoir Beam Structure Mechanical Model and Its Application in Feasibility Determination of Upward Mining. Energies 2023, 16, 7190. [Google Scholar] [CrossRef]

- Yu, Y.; Qiu, Z.; Cheng, W.; Yang, Q.; Cui, W.; Rong, K.; Li, Y. Fracture and porosity evolution of coal under uniaxial compression: An in-situ X-ray tomography study. Geomech. Energy Environ. 2023, 36, 100499. [Google Scholar] [CrossRef]

- Feng, C.; Li, X.; Xu, E.; Sui, H.; Xue, F.; Xie, H. Microstructure characteristics of tectonic coal and natural coal: A case study of Guizhou, China. Nat. Resour. Res. 2023, 32, 2901–2926. [Google Scholar] [CrossRef]

- Wang, J.; Huang, X.; Xu, J.; Zhang, Z.; Wang, S.; Li, Y. Network analysis of pore structure of coral reef limestone and its implications for seepage flow. Eng. Geol. 2023, 318, 107103. [Google Scholar] [CrossRef]

- Zhao, J.; Li, J.; Wang, H.; Braithwaite, C.; Zhang, Q. Fracturing and AE characteristics of matrix-inclusion rock types under dynamic Brazilian testing. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 2022, 157, 105164. [Google Scholar] [CrossRef]

- Li, Z.; Liu, D.; Cai, Y.; Ranjith, P.G.; Yao, Y. Multi-scale quantitative characterization of 3-D pore-fracture networks in bituminous and anthracite coals using FIB-SEM tomography and X-ray μ-CT. Fuel 2017, 209, 43–53. [Google Scholar] [CrossRef]

- Wang, G.; Shen, J.N.; Chu, X.Y.; Cao, C.; Jiang, C.; Zhou, X. Characterization and analysis of pores and fissures of high-rank coal based on CT three-dimensional reconstruction. J. China Coal Soc. 2017, 42, 2074–2080. [Google Scholar]

- Wang, X.; Pan, J.; Wang, K.; Ge, T.; Wei, J.; Wu, W. Characterizing the shape size and distribution heterogeneity of pore-fractures in high rank coal based on X-ray CT image analysis and mercury intrusion porosimetry. Fuel 2020, 282, 118754. [Google Scholar] [CrossRef]

- Zhao, J.; Cui, L.; Chen, H.; Li, N.; Wang, Z.; Ma, Y.; Du, G. Quantitative characterization of rock microstructure of digitalcore based on CT scanning. Geoscienence 2020, 34, 1206–1212. [Google Scholar]

- Wang, G.; Han, D.; Qin, X.; Liu, Z.; Liu, J. A comprehensive method for studying pore structure and seepage characteristics of coal mass based on 3D CT reconstruction and NMR. Fuel 2020, 281, 118735. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, S.; Zhang, C.; Fang, X.; Li, S. The characterization of bituminous coal microstructure and permeability by liquid nitrogen fracturing based on μCT technology. Fuel 2019, 262, 116635. [Google Scholar] [CrossRef]

- Zhang, Z.; Xie, H.; Zhang, R.; Gao, M.; Ai, T.; Zha, E. Size and spatial fractal distributions of coal fracture networks under different mining-induced stress conditions. Int. J. Rock Mech. Min. Sci. 2020, 132, 104364. [Google Scholar] [CrossRef]

- Xie, J.; Gao, M.; Zhang, R.; Ren, L.; Peng, G.; Ai, T.; Yang, B. Experimental investigation on the gas flow characteristics of coal samples with different fracture network complexities. J. Nat. Gas Sci. Eng. 2020, 82, 103487. [Google Scholar] [CrossRef]

- Jing, Y.; Armstrong, R.T.; Mostaghimi, P. Image-based fracture pipe network modelling for prediction of coal permeability. Fuel 2020, 270, 117447. [Google Scholar] [CrossRef]

- Ni, X.; Jie, M.; Lv, R.; Lin, X. Quantitative 3D spatial characterization and flow simulation of coal macropores based on μCT technology. Fuel 2017, 200, 199–207. [Google Scholar] [CrossRef]

- Cheng, Z.L.; Sui, W.B.; Ning, Z.F.; Gao, Y.; Hou, Y.; Chang, C.; Li, J. Microstructure characteristics and its effects on mechanical properties of digital core. Chin. J. Rock Mechnics Eng. 2018, 37, 449–460. [Google Scholar]

- Yang, Y.; Wang, K.; Zhang, L.; Sun, H.; Zhang, K.; Ma, J. Pore-scale simulation of shale oil flow based on pore network model. Fuel 2019, 251, 683–692. [Google Scholar] [CrossRef]

- Lv, W.; Yan, G.; Liu, Y.; Liu, X.; Du, D.; Wang, R. Effect of fractal fractures on permeability in three-dimensional digital rocks. Fractals 2019, 27, 1940015. [Google Scholar] [CrossRef]

- Yang, F.; Wang, H.; Huang, B. Study on the stress sensitivity and seepage characteristics of tight sandstone based on CT scanning. J. Geomech. 2019, 25, 475–482. [Google Scholar]

- Shi, X.; Pan, J.; Pang, L.; Wang, R.; Li, G.; Tian, J.; Wang, H. 3D microfracture network and seepage characteristics of low-volatility bituminous coal based on nano-CT. J. Nat. Gas Sci. Eng. 2020, 83, 103556. [Google Scholar] [CrossRef]

- Wang, G.; Han, D.; Jiang, C.; Zhang, Z. Seepage characteristics of fracture and dead-end pore structure in coal at micro-and meso-scales. Fuel 2020, 266, 117058. [Google Scholar] [CrossRef]

- Zhu, Q.; Song, W.; Yang, Y.; Lu, X.; Liu, L.; Zhang, Y.; Sun, H.; Yao, J. An advection-diffusion-mechanical deformation integral model to predict coal matrix methane permeability combining digital rock physics with laboratory measurements. Appl. Geochem. 2021, 126, 104861. [Google Scholar] [CrossRef]

- Zhang, C.; Jia, S.; Huang, X.; Shi, X.; Zhang, T.; Zhang, L.; Wang, F. Accurate characterization method of pores and various minerals in coal based on CT scanning. Fuel 2024, 358, 130128. [Google Scholar] [CrossRef]

- Liu, P.; Nie, B.; Zhao, Z.; Zhao, Y.; Li, Q. Characterization of ultrasonic induced damage on multi-scale pore/fracture in coal using gas sorption and μ-CT 3D reconstruction. Fuel 2023, 332, 126178. [Google Scholar] [CrossRef]

- Fan, N.; Wang, J.; Deng, C.; Fan, Y.; Wang, T.; Guo, X. Quantitative characterization of coal microstructure and visualization seepage of macropores using CT-based 3D reconstruction. J. Nat. Gas Sci. Eng. 2020, 81, 103384. [Google Scholar] [CrossRef]

- Yin, S.; Li, Z.; Wang, E.; Niu, Y.; Tian, H.; Li, X.; Li, H.; Yang, C. The infrared thermal effect of coal failure with different impact types and its relationship with bursting liability. Infrared Phys. Technol. 2024, 138, 105263. [Google Scholar] [CrossRef]

- Xiao, W.; Xuepeng, Z.; Wenxin, L.; Yujing, J.; Zhengliang, L.; Chunguang, W. Analytical theoretical study on ultra-low friction characteristics of coal rock interfaces under tress wave action. J. China Coal Soc. 2024, 1–13. [Google Scholar] [CrossRef]

- Du, Z.; Sheng, S.; Guo, J. Effect of composite activators on mechanical properties, hydration activity and microstructure of red mud-based geopolymer. J. Mater. Res. Technol. 2023, 24, 8077–8085. [Google Scholar] [CrossRef]

- Liu, J.; He, X.; Huang, H.; Yang, J.; Dai, J.; Shi, X.; Xue, F.; Rabczuk, T. Predicting gas flow rate in fractured shale reservoirs using discrete fracture model and GA-BP neural network method. Eng. Anal. Bound. Elem. 2024, 159, 315–330. [Google Scholar] [CrossRef]

- Zhang, Y.; Cui, B.; Wang, Y.; Zhang, S.; Feng, G.; Zhang, Z. Evolution Law of Shallow Water in Multi-Face Mining Based on Partition Characteristics of Catastrophe Theory. Fractal Fract. 2023, 7, 779. [Google Scholar] [CrossRef]

- Zhao, C.; Liu, J.; Dai, H.; Huang, H.; Shi, X. Frictional evolution process and stability properties of Longmaxi shale under fluid injection. Energy 2024, 294, 130910. [Google Scholar] [CrossRef]

- Tu, W.; Li, L.; Zhou, Z.; Shang, C. Thickness Calculation of Accumulative Damaged Zone by Rock Mass Blasting Based on Hoek–Brown Failure Criterion. Int. J. Geomech. 2022, 22, 04021273. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).