Development of Lignocellulosic-Based Insulation Materials from Agave fourcroydes and Washingtonia filifera for Use in Sustainable Buildings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

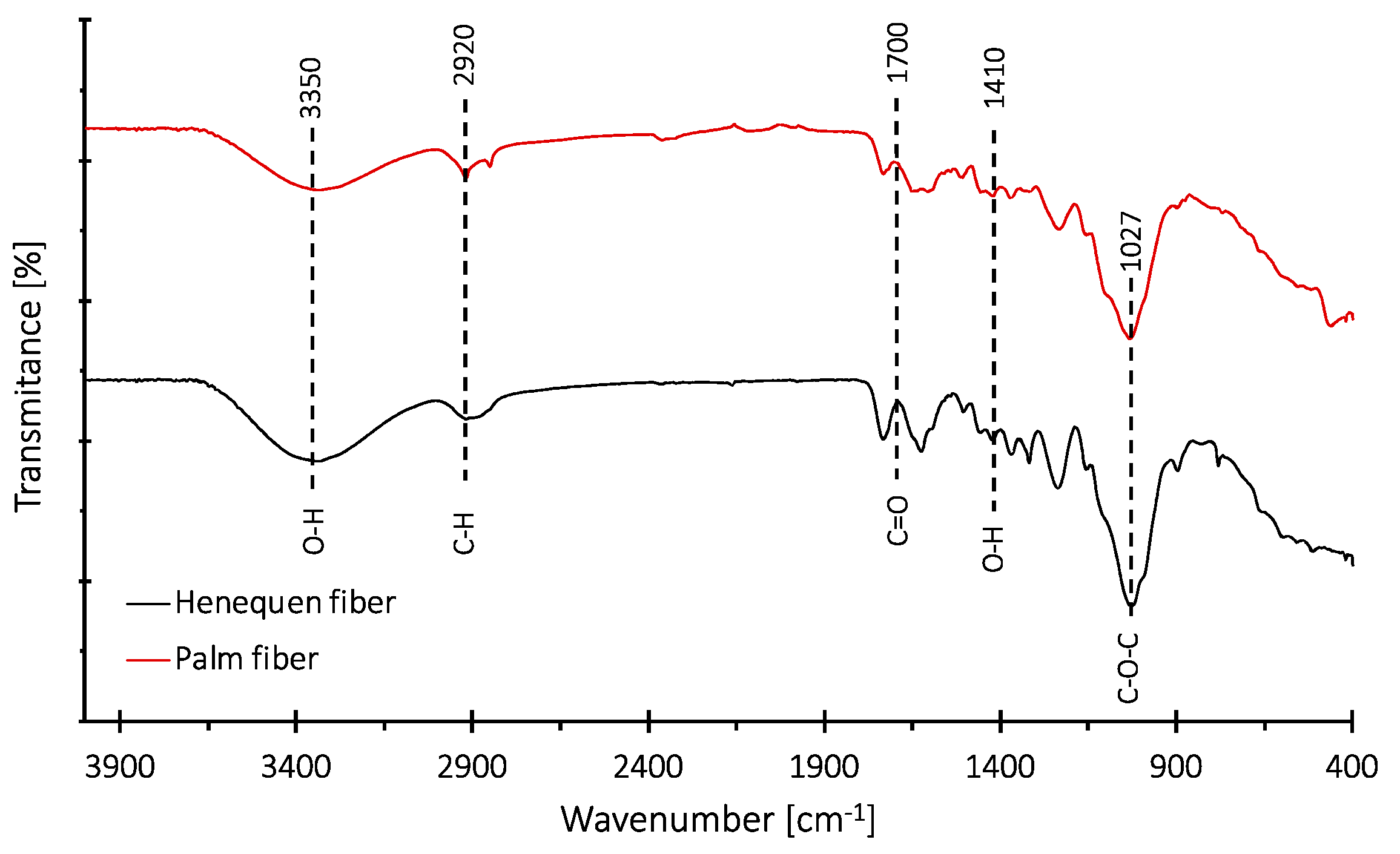

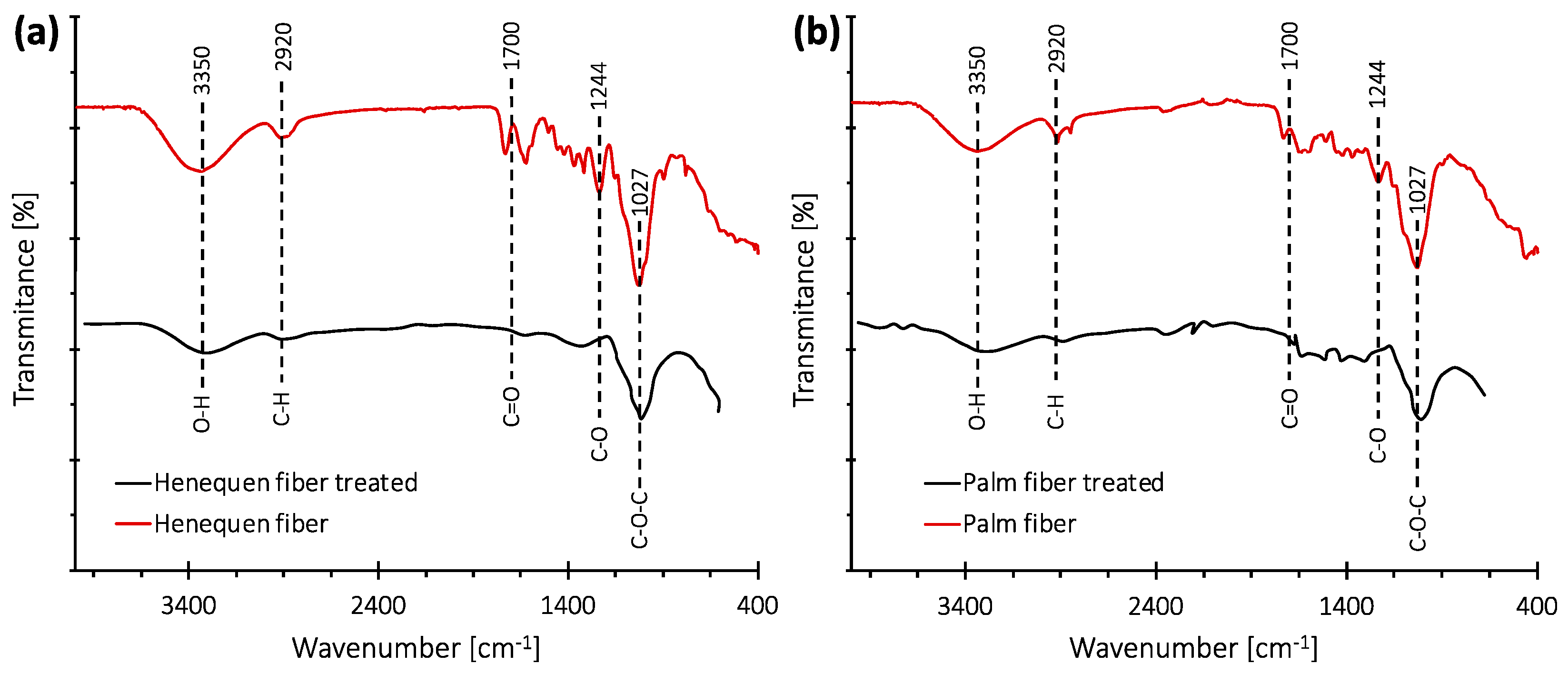

2.1.1. Chemical Characterization

2.1.2. Physical Characterization

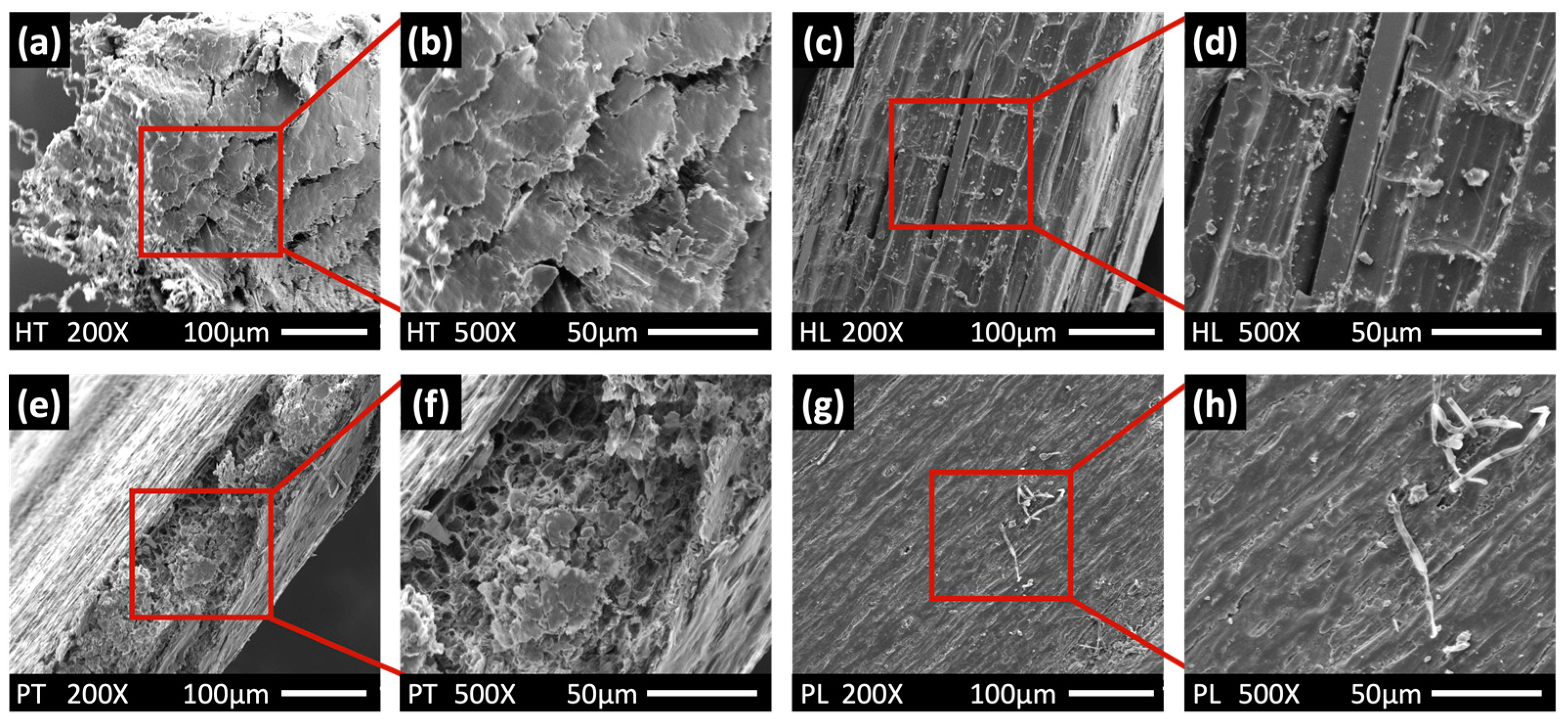

2.1.3. Microstructural Characterization

2.2. Experimental Design

2.2.1. Experimental Matrix

2.2.2. Prototype Manufacturing

2.3. Response Variables

2.3.1. Density and Porosity

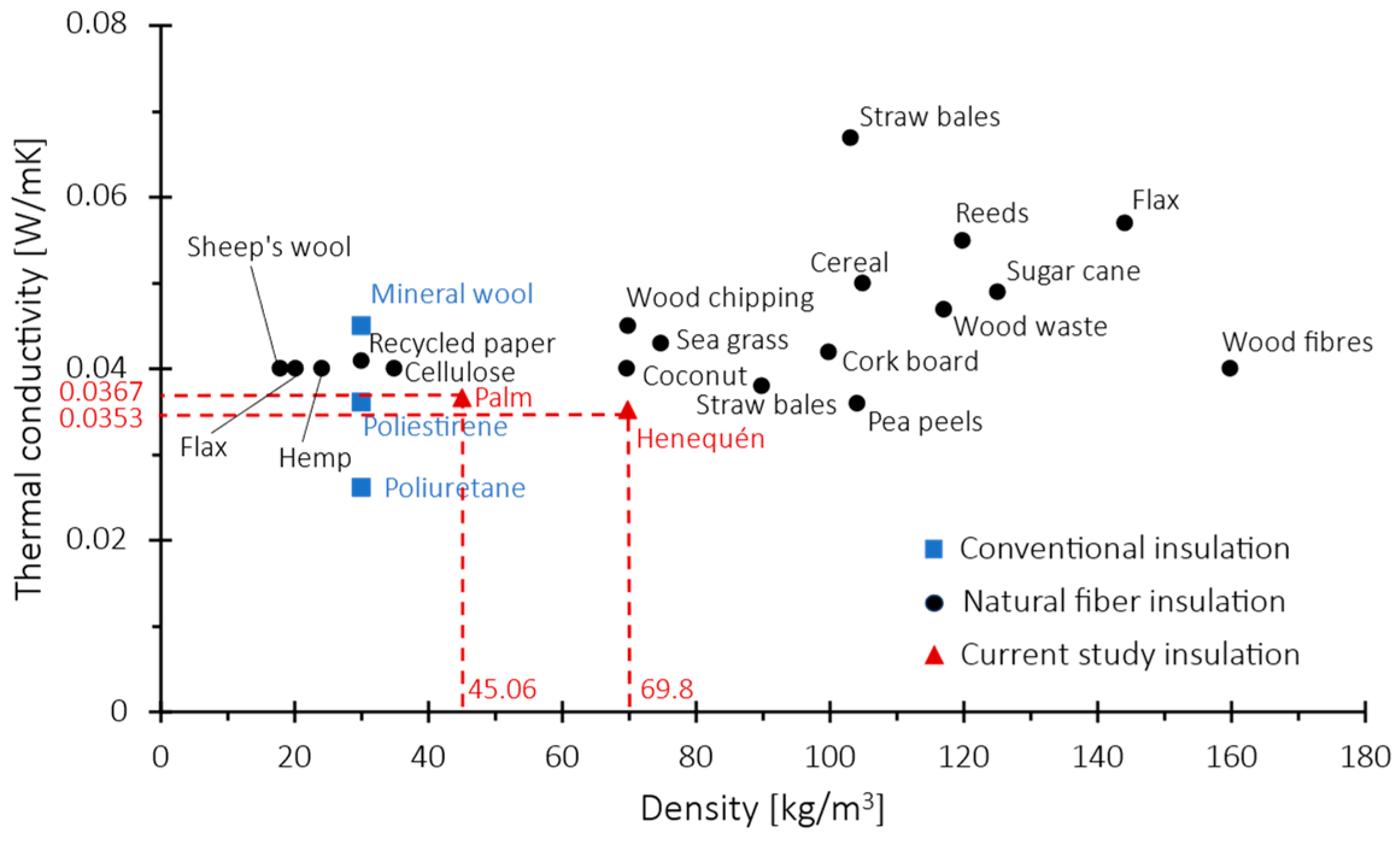

2.3.2. Thermal Conductivity

2.3.3. Flexural Strength

3. Results and Discussion

3.1. Raw Materials

3.2. Experimental Design

3.2.1. Orthogonal Array

3.2.2. Density, Porosity, and Thermal Conductivity

3.2.3. Flexural Strength

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alvarez García, G. Energía en Edificaciones. Rev. Mex. Física 2013, 59, 44–51. [Google Scholar]

- De Rosa, M.; Bianco, V.; Scarpa, F.; Tagliafico, L.A. Heating and cooling building energy demand evaluation; A simplified model and a modified degree days approach. Appl. Energy 2014, 128, 217–229. [Google Scholar] [CrossRef]

- Calderón, R.; Arredondo, J.A.; Gallegos, R.; Mayagoitia, F. Electrical consumption and CO2 reduction using saving systems and thermal insulation applied to dwellings in arid lands of Mexico. Inf. Tecnol. 2011, 22, 69–78. [Google Scholar] [CrossRef]

- Filippín, C.; Flores Larsen, S. Analysis of energy consumption patterns in multi-family housing in a moderate cold climate. Energy Policy 2009, 37, 3489–3501. [Google Scholar] [CrossRef]

- Cetiner, I.; Shea, A.D. Wood waste as an alternative thermal insulation for buildings. Energy Build. 2018, 168, 374–384. [Google Scholar] [CrossRef]

- Bozsaky, D. The historical development of thermal insulation materials. Period. Polytech. Archit. 2010, 41, 49. [Google Scholar] [CrossRef]

- Abd Rashid, A.F.; Yusoff, S. A review of life cycle assessment method for building industry. Renew. Sustain. Energy Rev. 2015, 45, 244–248. [Google Scholar] [CrossRef]

- Hancevic, P.; Navajas, F. Consumo residencial de electricidad y eficiencia energética: Un enfoque de regresión cuantílica. Trimest. Econ. 2015, 82, 897–927. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Grande-Acosta, G.K.; Islas-Samperio, J.M. Boosting Energy Efficiency and Solar Energy inside the Residential, Commercial, and Public Services Sectors in Mexico. Energies 2020, 13, 5601. [Google Scholar] [CrossRef]

- Lucero-álvarez, J.; Rodríguez-Muñoz, N.A.; Martín-Domínguez, I.R. The effects of roof and wall insulation on the energy costs of low income housing in Mexico. Sustainability 2016, 8, 590. [Google Scholar] [CrossRef]

- Liu, L.; Li, H.; Lazzaretto, A.; Manente, G.; Tong, C.; Liu, Q.; Li, N. The development history and prospects of biomass-based insulation materials for buildings. Renew. Sustain. Energy Rev. 2017, 69, 912–932. [Google Scholar] [CrossRef]

- Sangmesh, B.; Patil, N.; Jaiswal, K.K.; Gowrishankar, T.P.; Selvakumar, K.K.; Jyothi, M.S.; Jyothilakshmi, R.; Kumar, S. Development of sustainable alternative materials for the construction of green buildings using agricultural residues: A review. Constr. Build. Mater. 2023, 368, 130457. [Google Scholar] [CrossRef]

- Mati-Baouche, N.; De Baynast, H.; Lebert, A.; Sun, S.; Lopez-Mingo, C.J.S.; Leclaire, P.; Michaud, P. Mechanical, thermal and acoustical characterizations of an insulating bio-based composite made from sunflower stalks particles and chitosan. Ind. Crops Prod. 2014, 58, 244–250. [Google Scholar] [CrossRef]

- Arevalo-Gallegos, A.; Ahmad, Z.; Asgher, M.; Parra-Saldivar, R.; Iqbal, H.M.N. Lignocellulose: A sustainable material to produce value-added products with a zero waste approach—A review. Int. J. Biol. Macromol. 2017, 99, 308–318. [Google Scholar] [CrossRef] [PubMed]

- Juárez Alvarado, C.A. Concretos Base Cemento Portland Reforzados con Fibras Naturales (Agave lechuguilla), Como Materiales para Construcción en México; Universidad Autonoma de Nuevo Leon: San Nicolás de los Garza, Mexico, 2002. [Google Scholar]

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.-M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef] [PubMed]

- Chikhi, M.; Agoudjil, B.; Boudenne, A.; Gherabli, A. Experimental investigation of new biocomposite with low cost for thermal insulation. Energy Build. 2013, 66, 267–273. [Google Scholar] [CrossRef]

- Salleh, S.Z.; Awang Kechik, A.; Yusoff, A.H.; Taib, M.A.A.; Mohamad Nor, M.; Mohamad, M.; Tan, T.G.; Ali, A.; Masri, M.N.; Mohamed, J.J.; et al. Recycling food, agricultural, and industrial wastes as pore-forming agents for sustainable porous ceramic production: A review. J. Clean. Prod. 2021, 306, 127264. [Google Scholar] [CrossRef]

- Petrella, A.; De Gisi, S.; Di Clemente, M.E.; Todaro, F.; Ayr, U.; Liuzzi, S.; Dobiszewska, M.; Notarnicola, M. Experimental Investigation on Environmentally Sustainable Cement Composites Based on Wheat Straw and Perlite. Materials 2022, 15, 453. [Google Scholar] [CrossRef]

- Cury, R.K.; Aguas, M.Y.; Martinez, M.A.; Olivero, V.R.; Chams, C.L. Residuos agroindustriales su impacto, manejo y aprovechamiento. Rev. Colomb. Cienc. Anim.-RECIA 2017, 9, 122–132. [Google Scholar] [CrossRef]

- Saval, S. Aprovechamiento de Residuos Agroindustriales: Pasado, Presente y Futuro. BioTecnologia 2012, 16, 14–46. [Google Scholar]

- Sanjay, M.R.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Pruncu, C.I.; Khan, A. A comprehensive review of techniques for natural fibers as reinforcement in composites: Preparation, processing and characterization. Carbohydr. Polym. 2019, 207, 108–121. [Google Scholar] [CrossRef]

- Rodrigues, I.; Mata, T.M.; Martins, A.A. Environmental analysis of a bio-based coating material for automobile interiors. J. Clean. Prod. 2022, 367, 133011. [Google Scholar] [CrossRef]

- Savic, A.; Antonijevic, D.; Jelic, I.; Zakic, D. Thermomechanical behavior of bio-fiber composite thermal insulation panels. Energy Build. 2020, 229, 110511. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and Properties of Natural Fiber Polymer Composites: A Comprehensive Review; Elsevier: Amsterdam, The Netherlands, 2018; Volume 172, ISBN 9198944711. [Google Scholar]

- Clemons, C.M. Natural Fibers. In Functional Fillers for Plastics; Xanthos, M., Ed.; John Wiley & Sons, Inc.: Weinbeim, Germany, 2010; pp. 213–223. ISBN 9783527323616. [Google Scholar]

- Zach, J.; Hroudová, J.; Brožovský, J.; Krejza, Z.; Gailius, A. Development of Thermal Insulating Materials on Natural Base for Thermal Insulation Systems. Procedia Eng. 2013, 57, 1288–1294. [Google Scholar] [CrossRef]

- Zach, J.; Slávik, R.; Novák, V. Investigation of the Process of Heat Transfer in the Structure of Thermal Insulation Materials Based on Natural Fibres. Procedia Eng. 2016, 151, 352–359. [Google Scholar] [CrossRef]

- Locane, J.J. Fundamentos: Material lignocelulosico. In Miradas Locales en Tiempos Globales; Iberoamericana Vervuert: Madrid, Spain, 2019; pp. 23–96. [Google Scholar]

- Kremensas, A.; Stapulioniene, R.; Vaitkus, S.; Kairyte, A. Investigations on Physical-mechanical Properties of Effective Thermal Insulation Materials from Fibrous Hemp. Procedia Eng. 2017, 172, 586–594. [Google Scholar] [CrossRef]

- Reif, M.; Zach, J.; Hroudová, J. Studying the Properties of Particulate Insulating Materials on Natural Basis. Procedia Eng. 2016, 151, 368–374. [Google Scholar] [CrossRef]

- Park, J.H.; Kang, Y.; Lee, J.; Chang, S.J.; Wi, S.; Kim, S. Development of wood-lime boards as building materials improving thermal and moisture performance based on hygrothermal behavior evaluation. Constr. Build. Mater. 2019, 204, 576–585. [Google Scholar] [CrossRef]

- Tangjuank, S. Thermal insulation and physical properties of particleboards from pineapple leaves. Int. J. Phys. Sci. 2011, 6, 4528–4532. [Google Scholar] [CrossRef]

- Annie Paul, S.; Boudenne, A.; Ibos, L.; Candau, Y.; Joseph, K.; Thomas, S. Effect of fiber loading and chemical treatments on thermophysical properties of banana fiber/polypropylene commingled composite materials. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1582–1588. [Google Scholar] [CrossRef]

- Ali, M.E.; Alabdulkarem, A. On thermal characteristics and microstructure of a new insulation material extracted from date palm trees surface fibers. Constr. Build. Mater. 2017, 138, 276–284. [Google Scholar] [CrossRef]

- Vaitkus, S.; Karpaviciute, R.; Vejelis, S.; Lekunaite, L. Development and research of thermal insulation materials from natural fibres. Key Eng. Mater. 2014, 604, 285–288. [Google Scholar] [CrossRef]

- SIAP. Henequén: El “Oro Verde” Yucateco; SIAP: Chiba, Japan, 2018. [Google Scholar]

- Rojas Herrera, C.; Cea Lemus, M.; Rosas Diaz, F.E.; Cardenas Ramirez, J.P. Physical, Chemical and Mechanical Characterization of a Prototype Insulating Material Based on Eucalyptus Bark Fiber. IEEE Lat. Am. Trans. 2018, 16, 2441–2446. [Google Scholar] [CrossRef]

- Rosas-Díaz, F.; García-Hernández, D.G.; Mendoza-Rangel, J.M.; Terán-Torres, B.T.; Galindo-Rodríguez, S.A.; Juárez-Alvarado, C.A. Development of a Portland Cement-Based Material with Agave salmiana Leaves Bioaggregate. Materials 2022, 15, 6000. [Google Scholar] [CrossRef]

- Technical Association of Pulp an Paper Industry. T 257 cm-02 Sampling and Preparing WOOD for analysis; Technical Association of Pulp an Paper Industry: Atlanta, GA, USA, 2012. [Google Scholar]

- Technical Association of Pulp an Paper Industry. T 211 om-02 Ash in Wood, Pulp, Paper and Paperboard: Combustion at 525 °C; Technical Association of Pulp an Paper Industry: Atlanta, GA, USA, 2007. [Google Scholar]

- Technical Association of Pulp an Paper Industry. T 204 cm-97—Solvent Extractives of Wood and Pulp; Technical Association of Pulp an Paper Industry: Atlanta, GA, USA, 2007. [Google Scholar]

- Technical Association of Pulp an Paper Industry. T 222 om-02—Acid-Insoluble Lignin in Wood and Pulp; Technical Association of Pulp an Paper Industry: Atlanta, GA, USA, 2011. [Google Scholar]

- Wise, L.; Murphy, M.; D’Addieco, A. Chlorite holocellulose, its fractionation and bearing on summative wood analysis and studies on the hemicelluloses. Paptrade Enterp. 1946, 122, 35–43. [Google Scholar]

- Rowell, R. The chemistry of solid wood. In Handbook of Wood Chemistry and Wood Composites; CRC Press: Boca Raton, FL, USA, 1983; Volume 19, pp. 17–18. [Google Scholar]

- IEEE 442-2017; Guide for Thermal Resistivity Measurements of Soils and Backfill Materials. IEEE Standards Association: Piscataway, NJ, USA, 2018.

- D5334-00; Standard Test Method for Determination of Thermal Conductivity of Soil and Soft Rock by Thermal Needle Probe Procedure. American Society for Testing and Materials: West Conshohocken, PA, USA, 2000.

- Juárez-Alvarado, C.A.; Magniont, C.; Escadeillas, G.; Terán-Torres, B.T.; Rosas-Diaz, F.; Valdez-Tamez, P.L. Sustainable Proposal for Plant-Based Cementitious Composites, Evaluation of Their Mechanical, Durability and Comfort Properties. Sustainability 2022, 14, 14397. [Google Scholar] [CrossRef]

- Albitar, M.; Mohamed Ali, M.S.; Visintin, P.; Drechsler, M. Durability evaluation of geopolymer and conventional concretes. Constr. Build. Mater. 2017, 136, 374–385. [Google Scholar] [CrossRef]

- Alawar, A.; Hamed, A.M.; Al-Kaabi, K. Characterization of treated date palm tree fiber as composite reinforcement. Compos. Part B Eng. 2009, 40, 601–606. [Google Scholar] [CrossRef]

- Kestur, G.S.; Flores-Sahagun, T.H.S.; Dos Santos, L.P.; Dos Santos, J.; Mazzaro, I.; Mikowski, A. Characterization of blue agave bagasse fibers of Mexico. Compos. Part A Appl. Sci. Manuf. 2013, 45, 153–161. [Google Scholar] [CrossRef]

- Poletanovic, B.; Janotka, I.; Janek, M.; Bacuvcik, M.; Merta, I. Influence of the NaOH-treated hemp fibres on the properties of fly-ash based alkali-activated mortars prior and after wet/dry cycles. Constr. Build. Mater. 2021, 309, 125072. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2019. [Google Scholar]

- Groemping, U. Relative Importance for Linear Regression in R: The Package relaimpo. J. Stat. Softw. 2006, 17, 1–27. [Google Scholar]

- EN 1602:2013; Thermal Insulating Products for Building Applications—Determination of the Apparent Density. European Standard: Brussels, Belgium, 2013.

- EN 823:2013; Thermal Insulating Products for Building Applications—Determination of Thickness. European Standard: Brussels, Belgium, 2013.

- C578-19; Standard Specification for Rigid, Cellular Polystyrene Thermal Insulation. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- Castillo, A.; Castillo, A.A.; Delgado, R.S.; Hernández, E.G.; Domínguez, M.M.; Baeza, J.M.G.; Cruz, A.A.; García, R.C.; Morales, A.; Franco, P.J.H.; et al. Aprovechamiento integral de los materiales lignocelulósicos. Mater. Lignocelulósicos 2012, 13, 140–150. [Google Scholar]

- Li, Z.; Du, G.; Yang, H.; Liu, T.; Yuan, J.; Liu, C.; Li, J.; Ran, X.; Gao, W.; Yang, L. Construction of a cellulose-based high-performance adhesive with a crosslinking structure bridged by Schiff base and ureido groups. Int. J. Biol. Macromol. 2022, 223, 971–979. [Google Scholar] [CrossRef] [PubMed]

- Velásquez Restrepo, S.M.; Pelaéz Arroyave, G.J.; Giraldo Vásquez, D.H. Uso de fibras vegetales en materiales compuestos de matriz polimérica: Una revisión con miras a su aplicación en el diseño de nuevos productos Use of vegetable fibers in polymer matrix composites: A review. Inf. Técnico 2016, 80, 77–86. [Google Scholar] [CrossRef]

- Amziane, S.; Collet, F.; Report, S.; Committee, R.T. Bio-aggregates Based Building Materials; Amziane, S., Collet, F., Eds.; Springer Dordrecht: Paris, France, 2017; Volume 23, ISBN 978-94-024-1031-0. [Google Scholar]

- Nozahic, V.; Amziane, S.; Torrent, G.; Saïdi, K.; De Baynast, H. Design of green concrete made of plant-derived aggregates and a pumice-lime binder. Cem. Concr. Compos. 2012, 34, 231–241. [Google Scholar] [CrossRef]

- Agopyan, V.; Savastano, H.; John, V.M.; Cincotto, M.A. Developments on vegetable fibre–cement based materials in São Paulo, Brazil: An overview. Cem. Concr. Compos. 2005, 27, 527–536. [Google Scholar] [CrossRef]

- Amziane, S.; Sonebi, M. Overview on Biobased Building Material made with plant aggregate. RILEM Tech. Lett. 2016, 1, 31–38. [Google Scholar] [CrossRef]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Adi, D.S.; Ismadi; Damayanti, R.; Subiyanto, B.; Fatriasari, W.; Fudholi, A. A review on natural fibers for development of eco-friendly bio-composite: Characteristics, and utilizations. J. Mater. Res. Technol. 2021, 13, 2442–2458. [Google Scholar] [CrossRef]

- Piñeros-Castro, Y. Aprovechamiento de Biomasa Lignocelulósica, Algunas Experiencias de Investigación en Colombia; Universidad de Bogotá Jorge Tadeo Lozano: Bogotá, Colombia, 2016; ISBN 9789587251524. [Google Scholar]

- Carmona, J.E.; Mussatto, S.I.; Castillo-Quiroz, D.; Morales-Martínez, T.K.; Ríos-González, L.J. Propiedades químicas, estructurales y funcionales de la lechuguilla (Agave lechuguilla Torr.). Rev. Mex. Cienc. For. 2018, 8, 100–122. [Google Scholar] [CrossRef]

- Castillo Quiroz, D.; Trinidad Sáenz Reyes, J.; Narcia Velasco, M.; Antonio Vázquez Ramos, J. Propiedades fisico-mecanicas de la fibra de Agave lechuguilla Torr. de cinco procedencias bajo plantaciones. Rev. Mex. Ciencias For. 2013, 4, 78–91. [Google Scholar]

- Chabannes, M.; Nozahic, V.; Amziane, S. Design and multi-physical properties of a new insulating concrete using sunflower stem aggregates and eco-friendly binders. Mater. Struct. 2015, 48, 1815–1829. [Google Scholar] [CrossRef]

- Magniont, C.; Escadeillas, G.; Coutand, M.; Oms-Multon, C. Use of plant aggregates in building ecomaterials. Eur. J. Environ. Civ. Eng. 2012, 16, s17–s33. [Google Scholar] [CrossRef]

- Anggraini, V.; Asadi, A.; Huat, B.B.K.; Nahazanan, H. Effects of coir fibers on tensile and compressive strength of lime treated soft soil. Measurement 2015, 59, 372–381. [Google Scholar] [CrossRef]

- D’Alessandro, A.; Fabiani, C.; Pisello, A.L.; Ubertini, F.; Luigi Materazzi, A.; Cotana, F. Innovative concretes for low-carbon constructions: A review. Int. J. Low-Carbon Technol. 2017, 12, 289–309. [Google Scholar] [CrossRef]

- Benfratello, S.; Capitano, C.; Peri, G.; Rizzo, G.; Scaccianoce, G.; Sorrentino, G. Thermal and structural properties of a hemp–lime biocomposite. Constr. Build. Mater. 2013, 48, 745–754. [Google Scholar] [CrossRef]

- Sabathier, V.; Magniont, C.; Escadeillas, G.; Juarez, C.A. Flax and hemp fibre reinforced pozzolanic matrix: Evaluation of impact of time and natural weathering. Eur. J. Environ. Civ. Eng. 2017, 21, 1403–1417. [Google Scholar] [CrossRef]

- Badagliacco, D.; Sanfilippo, C.; Megna, B.; La Mantia, T.; Valenza, A. Mechanical and Thermal Properties of Insulating Sustainable Mortars with Ampelodesmos mauritanicus and Pennisetum setaceum Plants as Aggregates. Appl. Sci. 2021, 11, 5910. [Google Scholar] [CrossRef]

- Zavala-Arceo, A.; Cruz-Argüello, J.C.; Figueroa-Torres, M.Z.; Yeladaqui-Tello, A. Determinación de las propiedades térmicas de un mortero modificado con sargazo como material alternativo en construcción. Rev. Ing. Civ. 2019, 3, 1–9. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; García-Hortal, J.A.; Barra, M. Fiber-matrix interactions in cement mortar composites reinforced with cellulosic fibers. Cellulose 2011, 18, 281–289. [Google Scholar] [CrossRef]

- López-Sosa, L.B.; Alvarado-Flores, J.J.; Corral-Huacuz, J.C.; Aguilera-Mandujano, A.; Rodríguez-Martínez, R.E.; Guevara-Martínez, S.J.; Alcaraz-Vera, J.V.; Rutiaga-Quiñones, J.G.; Zárate-Medina, J.; Ávalos-Rodríguez, M.L.; et al. A Prospective Study of the Exploitation of Pelagic Sargassum spp. as a Solid Biofuel Energy Source. Appl. Sci. 2020, 10, 8706. [Google Scholar] [CrossRef]

- Ore, B.Y.; Pichilingue, L.E.R.; Valderrama Negrón, A.C. Extracción y caracterización del alginato de sodio de la macroalga Macrocystis pyrifera. Rev. Soc. Química Perú 2020, 86, 276–287. [Google Scholar] [CrossRef]

- Benchouia, H.E.; Guerira, B.; Chikhi, M.; Boussehel, H.; Tedeschi, C. An experimental evaluation of a new eco-friendly insulating material based on date palm fibers and polystyrene. J. Build. Eng. 2023, 65, 105751. [Google Scholar] [CrossRef]

- Moradkhani, G.; Profili, J.; Robert, M.; Laroche, G.; Elkoun, S. Effects of Wet and Dry Treatments on Surface Functional Groups and Mechanical Properties of Flax Fiber Composites. Coatings 2023, 13, 1036. [Google Scholar] [CrossRef]

- Kumar Rout, A.; Kar, J.; Kumar Jesthi, D.; Kumar Sutar, A. Effect of Surface Treatment on the Physical, Chemical, and Mechanical Properties of Palm Tree Leaf Stalk Fibers. BioResources 2016, 11, 4432–4445. [Google Scholar]

- Canché-Escamilla, G.; De los Santos-Hernández, J.M.; Andrade-Canto, S.; Gómez-Cruz, R. Obtención de Celulosa a Partir de los Desechos Agrícolas del Banano. Inf. Tecnol. 2005, 16, 83–88. [Google Scholar] [CrossRef]

- Romero Viloria, P.; Marfisi, S.; Rondón, P.O.; Rojas De Gáscue, B.; Peña, G. Obtención de celulosa microcristalina a partir de desechos agrícolas del cambur (Musa sapientum). Rev. Iberoam. Polímeros 2014, 15, 286–300. [Google Scholar]

- Obi Reddy, K.; Uma Maheswari, C.; Shukla, M.; Song, J.I.; Varada Rajulu, A. Tensile and structural characterization of alkali treated Borassus fruit fine fibers. Compos. Part B Eng. 2013, 44, 433–438. [Google Scholar] [CrossRef]

- NCh853:2021; Componentes y Elementos para Edificación—Resistencia Térmica y Transmitancia Térmica—Métodos de Cálculo. Instituto Nacional de Normalización: Santiago, Chile, 2021.

- Lian, X.; Tian, L.; Li, Z.; Zhao, X. Thermal conductivity analysis of natural fiber-derived porous thermal insulation materials. Int. J. Heat Mass Transf. 2024, 220, 124941. [Google Scholar] [CrossRef]

| Variables | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| Fiber length [cm] | 3 | 6 | 9 |

| Boiling time [min] | 30 | 45 | 60 |

| NaOH concentration [%] | 0.5 | 1 | 1.5 |

| Blending time [s] | 3 | 6 | 10 |

| Test | Agave fourcroydes | Washingtonia filifera |

|---|---|---|

| Moisture analysis | 2.7461 ± 3.3908% | 9.7856 ± 2.7482% |

| Ash analysis | 3.7284 ± 0.5952% | 18.8786 ± 2.8753% |

| Ethanol−Toluene extractables | 7.5916 ± 0.8028% | 13.3333 ± 0.7217% |

| Acid insoluble lignin | 12.1453 ± 2.5991% | 31.8416 ± 1.7471% |

| Holocellulose content | 18.1001 ± 3.6485% | 36.0441 ± 2.6094% |

| α -cellulose content | 33.6363 ± 2.3945% | 46.4297 ± 1.6553% |

| Hemicellulose content | 15.5362 ± 1.4369% | 10.3856 ± 4.1917% |

| Species | Cellulose [%] | Hemicellulose [%] | Lignin [%] | Source |

|---|---|---|---|---|

| Sugar cane bagasse | 57 | 20 | 19 | [67] |

| Pine | 84.9 | 15.3 | ND | [67] |

| Eucalyptus | 79–89 | 21 | 0.5 | [64,67] |

| Hemp | 35–52 | 9–27 | 17–28 | [62,63] |

| Flax | 43–47 | 24–26 | 21–23 | [65,66] |

| Sunflower | 42.1 | 29.7 | 13.4 | [63,65] |

| Wheat | 44.5 | 33.2 | 22.3 | [63] |

| Oats | 31–37 | 27–38 | 16–19 | [30] |

| Coconut | 35–60 | 15–28 | 20–48 | [64] |

| Sisal | 43–88 | 9–27 | 3.8–9.9 | [30,64] |

| Blue agave | 73.6 | ND | 21.1 | [52] |

| Agave lechuguilla | 17.72 | 17.15 | 7.32 | [68,69] |

| Henequen | 77.6 | 8–20 | 77.8 | [30] |

| Fiber | SO3 | Cl | K2O | CaO | Fe2O3 | SiO2 | Al2O3 |

|---|---|---|---|---|---|---|---|

| Henequen | 4.300% | 0.188% | 8.768% | 83.227% | 1.738% | ND | ND |

| Palm | 13.817% | 0.433% | 4.425% | 15.814% | 1.240% | 59.623% | 0.622% |

| Variable | Fiber Length | Boiling Time | NaOH Concentration | Blending Time |

|---|---|---|---|---|

| Optimum value | 3 cm | 60 min | 1.5% | 10 s |

| Variable | Sum Sq | Mean Sq | F Value | Pr (>F) | Contribution [%] |

|---|---|---|---|---|---|

| (a) Palm Fiber Insulation Density | |||||

| Fiber length | 0.00022119 | 2.21 × 10−4 | 6.2333 | 0.01806 * | 1.54 |

| Boiling time | 0.00000517 | 5.17 × 10−6 | 0.1457 | 0.70527 | 3.59 |

| NaOH concentration | 0.00000006 | 5.90 × 10−8 | 0.0017 | 0.96774 | 4.1 |

| Blending time | 0.00011095 | 1.11 × 10−4 | 3.1266 | 0.08687 | 7.71 |

| (b) Palm fiber insulation thermal conductivity | |||||

| Fiber length | 4.59 × 10−5 | 4.59 × 10−5 | 24.9000 | 0.00002193 *** | 24.65 |

| Boiling time | 1.58 × 10−5 | 1.58 × 10−5 | 8.5993 | 0.0062713 ** | 8.5 |

| NaOH concentration | 2.50 × 10−5 | 2.50 × 10−5 | 13.5746 | 0.0008708 *** | 13.42 |

| Blending time | 4.24 × 10−5 | 4.24 × 10−5 | 22.9875 | 0.00003867 *** | 22.73 |

| (c) Henequen fiber density | |||||

| Fiber length | 1.87 × 10−3 | 0.0018727 | 19.0840 | 0.0001299 *** | 14.32 |

| Boiling time | 3.16 × 10−3 | 0.0031648 | 32.3000 | 0.000003067 *** | 24.21 |

| NaOH concentration | 2.56 × 10−3 | 0.0025627 | 26.1150 | 0.00001566 *** | 19.6 |

| Blending time | 2.43 × 10−3 | 0.0024296 | 24.7590 | 0.00002302 *** | 18.58 |

| (d) Henequen fiber thermal conductivity | |||||

| Fiber length | 3.58 × 10−5 | 3.58 × 10−5 | 3.9100 | 0.05695 | 9.99 |

| Boiling time | 1.44 × 10−5 | 1.44 × 10−5 | 1.5702 | 0.21955 | 4.01 |

| NaOH concentration | 1.41 × 10−5 | 1.41 × 10−5 | 1.5400 | 0.22444 | 3.92 |

| Blending time | 9.98 × 10−6 | 9.98 × 10−6 | 1.0900 | 0.30477 | 2.78 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosas-Díaz, F.; García-Hernández, D.G.; Juárez-Alvarado, C.A. Development of Lignocellulosic-Based Insulation Materials from Agave fourcroydes and Washingtonia filifera for Use in Sustainable Buildings. Sustainability 2024, 16, 5455. https://doi.org/10.3390/su16135455

Rosas-Díaz F, García-Hernández DG, Juárez-Alvarado CA. Development of Lignocellulosic-Based Insulation Materials from Agave fourcroydes and Washingtonia filifera for Use in Sustainable Buildings. Sustainability. 2024; 16(13):5455. https://doi.org/10.3390/su16135455

Chicago/Turabian StyleRosas-Díaz, Felipe, David Gilberto García-Hernández, and Cesar A. Juárez-Alvarado. 2024. "Development of Lignocellulosic-Based Insulation Materials from Agave fourcroydes and Washingtonia filifera for Use in Sustainable Buildings" Sustainability 16, no. 13: 5455. https://doi.org/10.3390/su16135455

APA StyleRosas-Díaz, F., García-Hernández, D. G., & Juárez-Alvarado, C. A. (2024). Development of Lignocellulosic-Based Insulation Materials from Agave fourcroydes and Washingtonia filifera for Use in Sustainable Buildings. Sustainability, 16(13), 5455. https://doi.org/10.3390/su16135455