Production Cost of Biocarbon and Biocomposite, and Their Prospects in Sustainable Biobased Industries

Abstract

1. Introduction

2. Materials and Methods

2.1. Biocarbon Production (Chipping, Transportation, and Pyrolysis)

| Parameters | Chipper | Excavator | Source |

|---|---|---|---|

| Equipment price, $ | 350,000 | 300,000 | [53] |

| Life span, years | 5 | 5 * | [54,55,56] * Assumed |

| Capacity, ton/h (green wood chips) | 10 | - | [53] |

| Interest rate, % | 8 | 8 | [51], |

| Salvage value, % | 20 | 20 * | [55,56]; * Assumed |

| Operation and maintenance cost/year, % | 5 | 5 | [53] |

| Insurance & registration, $/year | 2500 | 2500 | Assumed |

| Operation, h/day | 9 | 4 | [53] |

| Labor cost, $/h | 20 | 20 | [51] |

| Fuel consumption, L/day | 209 | 74 | Estimated |

| Fuel cost (diesel), $/L | 1 | 1 | Assumed |

| Parameters | Truck | Containers/Bins | Source |

|---|---|---|---|

| Equipment cost, $ | 150,000 | 100,000 | [53] |

| Life span, years | 10 * | 10 | * [51] |

| Trips/day | 5 | 5 | [53] |

| Interest rate, % | 8 | 8 | [51] |

| Salvage value, % | 15 | 15 | [51] |

| Maintenance cost, % | 5 | 5 | [53] |

| Insurance cost, % | 2.5 | 2.5 | [51] |

| Registration, $/year | 2500 | 2500 | [51] |

| Fuel consumption, L/day | 536 | - | Estimated |

| Fuel cost (diesel), $/L | 1 | 1 | Assumed |

| Parameters | Data | Source |

|---|---|---|

| Loan, $ | 4,365,000 | Estimated |

| Shelter & storage tank, $ | 500,000 | [53] |

| Price of the pyrolysis unit, $ | 3,500,000 | [53] |

| Interest rate, % | 8 | [51] |

| Salvage value, % | 12 | [51] |

| Operation and maintenance cost, % | 5 | [53] |

| Insurance & registration, $/year | 5000 | Assumed |

| Labor cost, $/year | 360,000 | Assumed |

| Corporate tax (Small business), % | 15 | [57] |

2.2. Composite Manufacturing (Compounding and Molding) Plant

| Parameters | Data | Source |

|---|---|---|

| Loan, $ | 4,514,882 | Estimated |

| Shelter & storage, $ | 500,000 | Assumed |

| * Compounding/extrusion machine, $ | 2,929,591 | Author-defined |

| * Molding machine, $ | 720,291 | Author-defined |

| Interest rate, % | 8 | [51] |

| Salvage value, % | 12 | [51] |

| Maintenance cost, % | 1 | Assumed (BDDC, University of Guelph) |

| Insurance & registration, $/year | 5000 | Assumed |

| Labor cost, $/year | 360,000 | Assumed |

| Corporate tax (Small business), % | 15 | [57] |

2.3. Life Cycle Costing of Biocarbon and Net Present Value (NPV) of Biocarbon Plant

2.4. Life Cycle Costing (LCC) of Biocomposite and Net Present Value (NPV) of a Biocomposite Manufacturing Plant

3. Results and Discussion

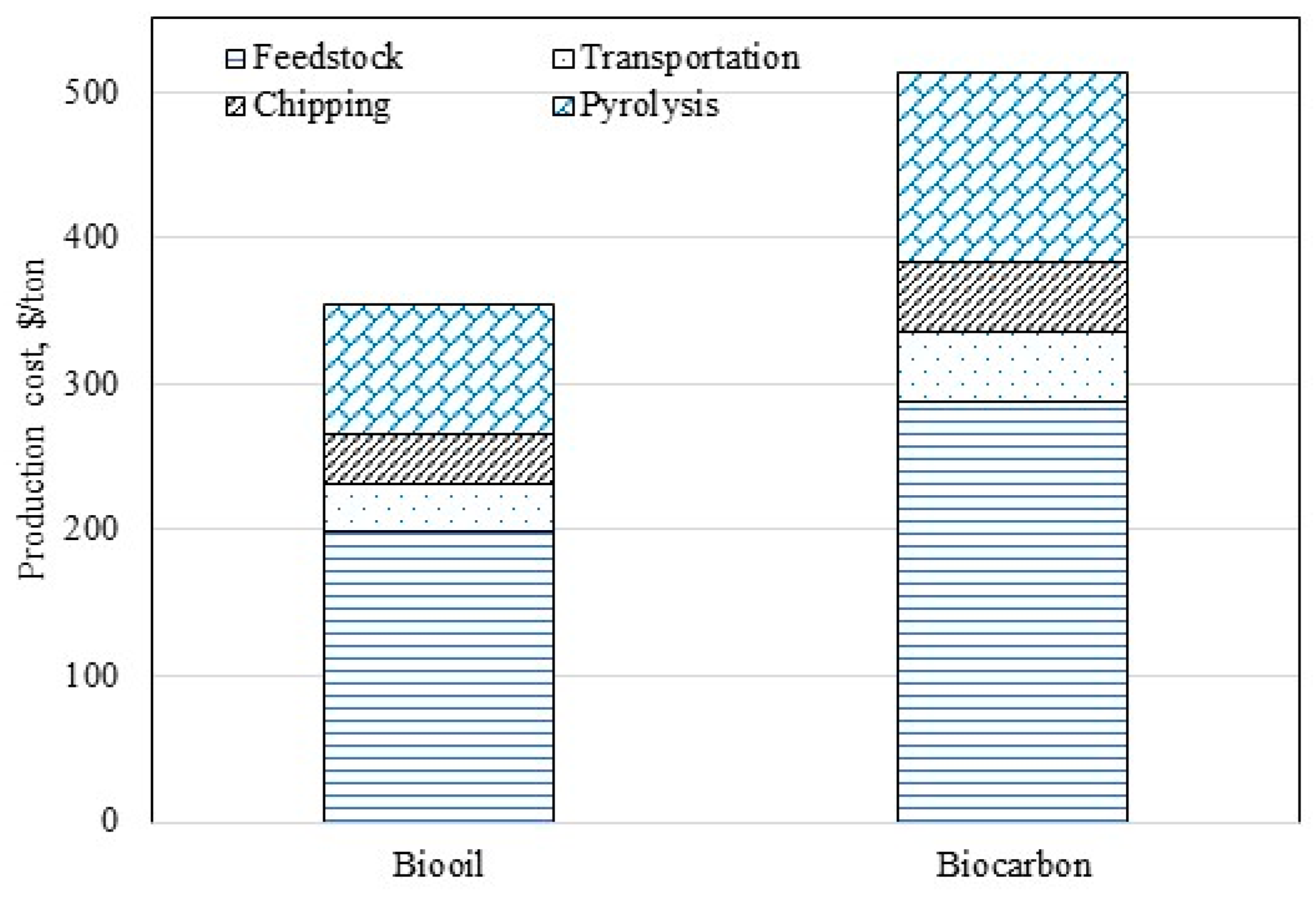

3.1. Life Cycle Cost (LCC) of Biocarbon and Bio-Oil

3.2. Net Present Value (NPV) of a Biocarbon Plant

3.3. Life Cycle Costing (LCC) of Biocomposite and Automotive Components, and NPV of Biocomposite Plant

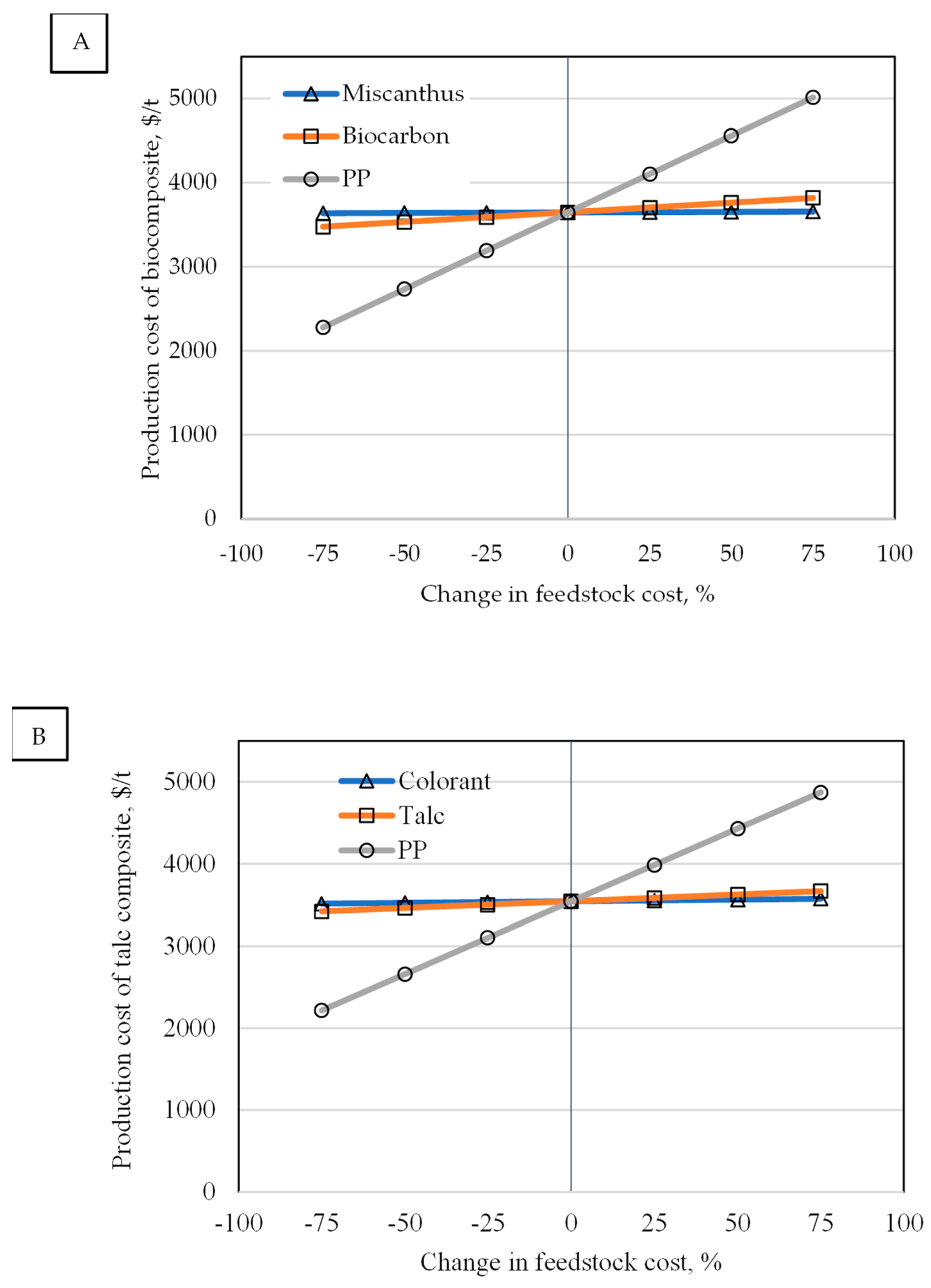

3.4. Sensitivity Analysis

3.4.1. Effect of Miscanthus Price on the Life Cycle Costing of Biocarbon and Composite Manufacturing Plants

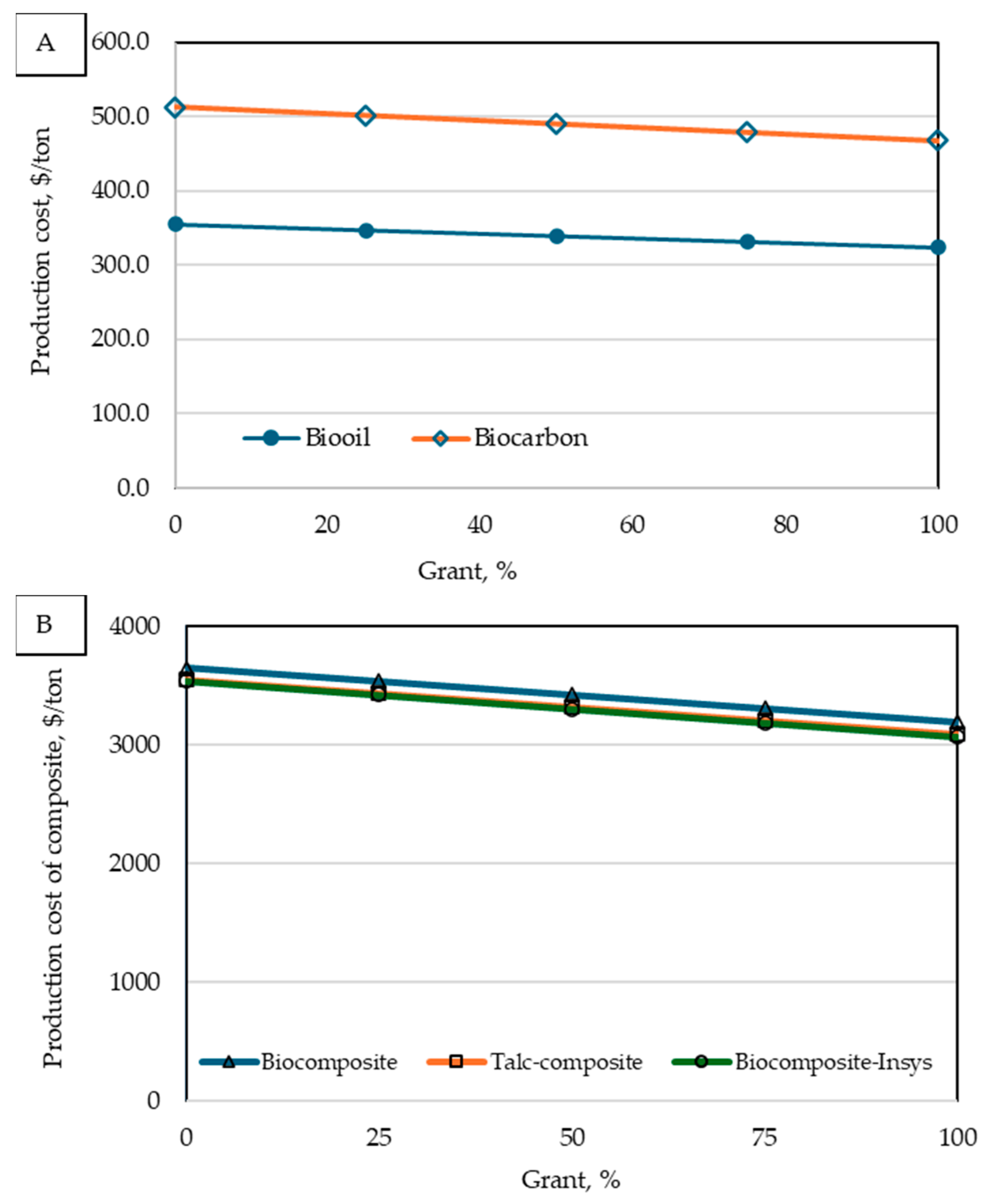

3.4.2. Effect of Grant for Biocarbon and Composite Manufacturing Plants

3.4.3. Contribution of Biocarbon and Biocomposite Plants to the Bioeconomy

4. Discussion and Implications

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, T.; Rodriguez-Uribe, A.; Misra, M.; Mohanty, A.K. Sustainable Carbonaceous Biofiller from Miscanthus: Size Reduction, Characterization, and Potential Bio-Composites Applications. BioResources 2018, 13, 3720–3739. [Google Scholar] [CrossRef]

- Behazin, E.; Misra, M.; Mohanty, A.K. Sustainable Biocarbon from Pyrolyzed Perennial Grasses and Their Effects on Impact Modified Polypropylene Biocomposites. Compos. Part B Eng. 2017, 118, 116–124. [Google Scholar] [CrossRef]

- Civancik-Uslu, D.; Ferrer, L.; Puig, R.; Fullana-i-Palmer, P. Are Functional Fillers Improving Environmental Behavior of Plastics? A Review on LCA Studies. Sci. Total Environ. 2018, 626, 927–940. [Google Scholar] [CrossRef]

- Penciuc, D.; Le Duigou, J.; Daaboul, J.; Vallet, F.; Eynard, B. Product Life Cycle Management Approach for Integration of Engineering Design and Life Cycle Engineering. AI EDAM 2016, 30, 379–389. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; ElayaPerumal, A.; Alavudeen, A.; Thiruchitrambalam, M. Mechanical and Water Absorption Behaviour of Banana/Sisal Reinforced Hybrid Composites. Mater. Des. 2011, 32, 4017–4021. [Google Scholar] [CrossRef]

- Lehto, J.; Oasmaa, A.; Solantausta, Y.; Kytö, M.; Chiaramonti, D. Review of Fuel Oil Quality and Combustion of Fast Pyrolysis Bio-Oils from Lignocellulosic Biomass. Appl. Energy 2014, 116, 178–190. [Google Scholar] [CrossRef]

- Biederman, L.A.; Stanley Harpole, W. Biochar and Its Effects on Plant Productivity and Nutrient Cycling: A Meta-Analysis. GCB Bioenergy 2013, 5, 202–214. [Google Scholar] [CrossRef]

- Kern, J.; Tammeorg, P.; Shanskiy, M.; Sakrabani, R.; Knicker, H.; Kammann, C.; Tuhkanen, E.-M.; Smidt, G.; Prasad, M.; Tiilikkala, K. Synergistic Use of Peat and Charred Material in Growing Media–an Option to Reduce the Pressure on Peatlands? J. Environ. Eng. Landsc. Manag. 2017, 25, 160–174. [Google Scholar] [CrossRef]

- Homagain, K.; Shahi, C.; Luckai, N.; Sharma, M. Biochar-Based Bioenergy and Its Environmental Impact in Northwestern Ontario Canada: A Review. J. For. Res. 2014, 25, 737–748. [Google Scholar] [CrossRef]

- Downie, A.; Munroe, P.; Cowie, A.; Van Zwieten, L.; Lau, D.M.S. Biochar as a Geoengineering Climate Solution: Hazard Identification and Risk Management. Crit. Rev. Environ. Sci. Technol. 2012, 42, 225–250. [Google Scholar] [CrossRef]

- Ogunsona, E.O.; Misra, M.; Mohanty, A.K. Sustainable Biocomposites from Biobased Polyamide 6,10 and Biocarbon from Pyrolyzed Miscanthus Fibers. J. Appl. Polym. Sci. 2017, 134, 1–11. [Google Scholar] [CrossRef]

- Chang, B.P.; Rodriguez-Uribe, A.; Mohanty, A.K.; Misra, M. A Comprehensive Review of Renewable and Sustainable Biosourced Carbon through Pyrolysis in Biocomposites Uses: Current Development and Future Opportunity. Renew. Sustain. Energy Rev. 2021, 152, 111666. [Google Scholar] [CrossRef]

- Boland, C.S.; De Kleine, R.; Keoleian, G.A.; Lee, E.C.; Kim, H.C.; Wallington, T.J. Life Cycle Impacts of Natural Fiber Composites for Automotive Applications: Effects of Renewable Energy Content and Lightweighting. J. Ind. Ecol. 2016, 20, 179–189. [Google Scholar] [CrossRef]

- Akhshik, M.; Panthapulakkal, S.; Tjong, J.; Sain, M. Life Cycle Assessment and Cost Analysis of Hybrid Fiber-Reinforced Engine Beauty Cover in Comparison with Glass Fiber-Reinforced Counterpart. Environ. Impact Assess. Rev. 2017, 65, 111–117. [Google Scholar] [CrossRef]

- AAFC. Investing in Canada’s Bioeconomy to Help Provide Opportunities for Farmers and Grow the Clean Economy. Agriculture and Agri-Food Canada. Available online: https://www.canada.ca/en/agriculture-agri-food/news/2019/04/investing-in-canadas-bioeconomy-to-help-provide-opportunities-for-farmers-and-grow-the-clean-economy.html (accessed on 27 April 2019).

- Kim, H.C.; Wallington, T.J. Life-Cycle Energy and Greenhouse Gas Emission Benefits of Lightweighting in Automobiles: Review and Harmonization. Environ. Sci. Technol. 2013, 47, 6089–6097. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, S.; Wang, C.; Mu, C.; Huang, X. High-Strength Charcoal Briquette Preparation from Hydrothermal Pretreated Biomass Wastes. Fuel Process. Technol. 2018, 171, 293–300. [Google Scholar] [CrossRef]

- Hesser, F. Environmental Advantage by Choice: Ex-Ante LCA for a New Kraft Pulp Fibre Reinforced Polypropylene Composite in Comparison to Reference Materials. Compos. Part B Eng. 2015, 79, 197–203. [Google Scholar] [CrossRef]

- Ten, E.; Vermerris, W. Recent Developments in Polymers Derived from Industrial Lignin. J. Appl. Polym. Sci. 2015, 132, 1–13. [Google Scholar] [CrossRef]

- Roy, P.; Tadele, D.; Defersha, F.; Misra, M.; Mohanty, A.K. Environmental and Economic Prospects of Biomaterials in the Automotive Industry. Clean Technol. Environ. Policy 2019, 21, 1535–1548. [Google Scholar] [CrossRef]

- Fogorasi, M.; Barbu, I. The Potential of Natural Fibres for Automotive Sector—Review. IOP Conf. Ser. Mater. Sci. Eng. 2017, 252, 012044. [Google Scholar] [CrossRef]

- Väisänen, T.; Das, O.; Tomppo, L. A Review on New Bio-Based Constituents for Natural Fiber-Polymer Composites. J. Clean. Prod. 2017, 149, 582–596. [Google Scholar] [CrossRef]

- Akampumuza, O.; Wambua, P.M.; Ahmed, A.; Li, W.; Qin, X.H. Review of the Applications of Biocomposites in the Automotive Industry. Polym. Compos. 2017, 38, 2553–2569. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. A Sustainable and Resilient Approach through Biochar Addition in Wood Polymer Composites. Sci. Total Environ. 2015, 512–513, 326–336. [Google Scholar] [CrossRef]

- Brown, D.; Rowe, A.; Wild, P. A Techno-Economic Analysis of Using Mobile Distributed Pyrolysis Facilities to Deliver a Forest Residue Resource. Bioresour. Technol. 2013, 150, 367–376. [Google Scholar] [CrossRef]

- Kludze, H.; Deen, B.; Weersink, A.; van Acker, R.; Janovicek, K.; De Laporte, A. Assessment of the Availability of Agricultural Biomass for Heat and Energy Production in Ontario; Ontario Ministry of Agriculture, Food and Rural Affairs: Toronto, ON, Canada, 2010; pp. 1–125. [Google Scholar]

- Allison, G.G.; Morris, C.; Clifton-brown, J.; Lister, S.J.; Donnison, I.S. Genotypic Variation in Cell Wall Composition in a Diverse Set of 244 Accessions of Miscanthus. Biomass Bioenergy 2011, 35, 4740–4747. [Google Scholar] [CrossRef]

- Clifton-brown, J.; Hastings, A.; Mos, M.; Jon, P.; Ashman, C.; Awty-carroll, D.; Cerazy, J.; Chiang, Y.; Cosentino, S.; Cracroft-eley, W.; et al. Progress in Upscaling Miscanthus Biomass Production for the European Bio-Economy with Seed-Based Hybrids. Glob. Change Biol. Bioenergy 2017, 9, 6–17. [Google Scholar] [CrossRef]

- Cuthbertson, D.M. The Production of Pyrolytic Biochar for Addition in Value-Added Composite Material. Master’s Thesis, The University of Western Ontario, London, ON, Canada, 2018. [Google Scholar]

- Lu, H.R.; El Hanandeh, A. Life Cycle Perspective of Bio-Oil and Biochar Production from Hardwood Biomass; What Is the Optimum Mix and What to Do with It? J. Clean. Prod. 2019, 212, 173–189. [Google Scholar] [CrossRef]

- Dang, Q.; Hu, W.; Rover, M.; Brown, R.C.; Wright, M.M. Economics of Biofuels and Bioproducts from an Integrated Pyrolysis Biorefinery. Biofuels Bioprod. Biorefining 2016, 10, 790–803. [Google Scholar] [CrossRef]

- Hu, W.; Dang, Q.; Rover, M.; Brown, R.C.; Wright, M.M. Comparative Techno-Economic Analysis of Advanced Biofuels, Biochemicals, and Hydrocarbon Chemicals via the Fast Pyrolysis Platform. Biofuels 2016, 7, 57–67. [Google Scholar] [CrossRef]

- Homagain, K.; Shahi, C.; Luckai, N.; Sharma, M. Life Cycle Cost and Economic Assessment of Biochar-Based Bioenergy Production and Biochar Land Application in Northwestern Ontario, Canada. For. Ecosyst. 2016, 3, 21. [Google Scholar] [CrossRef]

- Bergman, R.; Sahoo, K.; Englund, K.; Mousavi-Avval, S.H. Lifecycle Assessment and Techno-Economic Analysis of Biochar Pellet Production from Forest Residues and Field Application. Energies 2022, 15, 1559. [Google Scholar] [CrossRef]

- Jin, Q.; O’Keefe, S.F.; Stewart, A.C.; Neilson, A.P.; Kim, Y.-T.; Huang, H. Techno-Economic Analysis of a Grape Pomace Biorefinery: Production of Seed Oil, Polyphenols, and Biochar. Food Bioprod. Process. 2021, 127, 139–151. [Google Scholar] [CrossRef]

- Indra Reddy, M.; Anil Kumar, M.; Rama Bhadri Raju, C. Tensile and Flexural Properties of Jute, Pineapple Leaf and Glass Fiber Reinforced Polymer Matrix Hybrid Composites. Mater. Today Proc. 2018, 5, 458–462. [Google Scholar] [CrossRef]

- Snowdon, M.R.; Mohanty, A.K.; Misra, M. Miscibility and Performance Evaluation of Biocomposites Made from Polypropylene/Poly(Lactic Acid)/Poly(Hydroxybutyrate-Co-hydroxyvalerate) with a Sustainable Biocarbon Filler. ACS Omega 2017, 2, 6446–6454. [Google Scholar] [CrossRef]

- Hassan, A.; Ding, W.; Aslam, M.A.; Bian, Y.; Liu, Q.; Sheng, Z. Microwave Absorption Property of Coffee Waste Bio-Carbon Modified by Industrial Waste MnFe2O4 Particles. J. Mater. Res. Technol. 2020, 9, 12869–12879. [Google Scholar] [CrossRef]

- Guo, Z.; Ren, P.; Zhang, Z.; Dai, Z.; Lu, Z.; Jin, Y.; Ren, F. Fabrication of Carbonized Spent Coffee Grounds/Graphene Nanoplates/Cyanate Ester Composites for Superior and Highly Absorbed Electromagnetic Interference Shielding Performance. J. Mater. Sci. Technol. 2022, 102, 123–131. [Google Scholar] [CrossRef]

- Beigbeder, J.; Soccalingame, L.; Perrin, D.; Bénézet, J.-C.; Bergeret, A. How to Manage Biocomposites Wastes End of Life? A Life Cycle Assessment Approach (LCA) Focused on Polypropylene (PP)/Wood Flour and Polylactic Acid (PLA)/Flax Fibres Biocomposites. Waste Manag. 2019, 83, 184–193. [Google Scholar] [CrossRef]

- Akhshik, M.; Panthapulakkal, S.; Tjong, J.; Sain, M. The Effect of Lightweighting on Greenhouse Gas Emissions and Life Cycle Energy for Automotive Composite Parts. Clean Technol. Environ. Policy 2019, 21, 625–636. [Google Scholar] [CrossRef]

- Akhshik, M.; Panthapulakkal, S.; Tjong, J.; Sain, M. A Comparative Life Cycle Assessment Based Evaluation of Greenhouse Gas Emission and Social Study: Natural Fibre versus Glass Fibre Reinforced Plastic Automotive Parts. Int. J. Glob. Warm. 2018, 15, 350–369. [Google Scholar] [CrossRef]

- Boland, C.; Dekleine, R.; Moorthy, A.; Keoleian, G.; Kim, H.C.; Lee, E.; Wallington, T.J.; Co, F.M. A Life Cycle Assessment of Natural Fiber Reinforced Composites in Automotive Applications. SAE Tech. Pap. 2014, 1959. [Google Scholar] [CrossRef]

- Delogu, M.; Zanchi, L.; Dattilo, C.A.; Pierini, M. Innovative Composites and Hybrid Materials for Electric Vehicles Lightweight Design in a Sustainability Perspective. Mater. Today Commun. 2017, 13, 192–209. [Google Scholar] [CrossRef]

- Sahoo, K.; Upadhyay, A.; Runge, T.; Bergman, R.; Puettmann, M.; Bilek, E. Life-Cycle Assessment and Techno-Economic Analysis of Biochar Produced from Forest Residues Using Portable Systems. Int. J. Life Cycle Assess. 2021, 26, 189–213. [Google Scholar] [CrossRef]

- Tadele, D.; Roy, P.; Defersha, F.; Misra, M.; Mohanty, A.K. A Comparative Life-Cycle Assessment of Talc-and Biochar-Reinforced Composites for Lightweight Automotive Parts. Clean Technol. Environ. Policy 2020, 22, 639–649. [Google Scholar] [CrossRef]

- Roy, P.; Defersha, F.; Rodriguez-Uribe, A.; Misra, M.; Mohanty, A.K. Evaluation of the Life Cycle of an Automotive Component Produced from Biocomposite. J. Clean. Prod. 2020, 273, 123051. [Google Scholar] [CrossRef]

- Venkatesan, R.; Sana, S.S.; Ramkumar, V.; Alagumalai, K.; Kim, S.C. Development and characterization of poly (butylene adipate-co-terephthalate)(PBAT) composites with N, P-doped carbons for food packaging. Carbon Lett. 2023, 33, 1679–1687. [Google Scholar] [CrossRef]

- Venkatesan, R.; Rajeswari, N. TiO2 nanoparticles/poly (butylene adipate-co-terephthalate) bionanocomposite films for packaging applications. Polym. Adv. Technol. 2017, 28, 1699–1706. [Google Scholar] [CrossRef]

- Chen, W.; Oldfield, T.L.; Cinelli, P.; Righetti, M.C.; Holden, N.M. Hybrid Life Cycle Assessment of Potato Pulp Valorisation in Biocomposite Production. J. Clean. Prod. 2020, 269, 122366. [Google Scholar] [CrossRef]

- Cleary, J.; Wolf, D.P.; Caspersen, J.P. Comparing the Life Cycle Costs of Using Harvest Residue as Feedstock for Small-and Large-Scale Bioenergy Systems (Part II). Energy 2015, 86, 539–547. [Google Scholar] [CrossRef]

- Jahirul, M.I.; Rasul, M.G.; Chowdhury, A.A.; Ashwath, N. Biofuels Production through Biomass Pyrolysis—A Technological Review. Energies 2012, 5, 4952–5001. [Google Scholar] [CrossRef]

- Fransham, P.; (Abri-Tech Inc., Namur, QC, Canada). Personal Communication, 2016.

- Morey, R.V.; Kaliyan, N.; Schmidt, D.R.; Tiffany, D.G. A Biomass Supply Logistics System. In 2009 Reno, NV, USA, 21–24 June 2009; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2009; p. 1. [Google Scholar]

- Thakur, A. Power Generation from Forest Residues. Master’s Thesis, University of Alberta, Edmonton, AB, Canada, 2011. [Google Scholar]

- Westbrook, M.D., Jr.; Dale Greene, W.; Izlar, R.L. Utilizing Forest Biomass by Adding a Small Chipper to a Tree-Length Southern Pine Harvesting Operation. South J. Appl. For. 2007, 31, 165–169. [Google Scholar] [CrossRef]

- Canada-Revenue-Agency. Corporation Tax Rates. Available online: https://www.canada.ca/en/revenue-agency/services/tax/businesses/topics/corporations/corporation-tax-rates.html (accessed on 16 April 2019).

- KPMG, L.L.P. Wood Pellet Plant Cost Study for the Algoma and Martel Forests in the Western Portion of the Great Lakes/St. Lawrence Forest; Bay Adeland Centre: Toronto, ON, Canada, 2008. [Google Scholar]

- Statistics Canada. Consumer Price Index, Historical Summary (1996 to 2015). Statistics Canada. Available online: http://www.statcan.gc.ca/tables-tableaux/sum-som/l01/cst01/econ46a-eng.htm (accessed on 15 September 2016).

- Aden, A.; Ruth, M.; Ibsen, K.; Jechura, J.; Neeves, K.; Sheehan, J.; Wallace, B.; Montague, L.; Slayton, A.; Lukas, J. Lignocellulosic Biomass to Ethanol Process Design and Economics Utilizing Co-Current Dilute Acid Prehydrolysis and Enzymatic Hydrolysis for Corn Stover; National Renewable Energy Lab.: Golden, CO, USA, 2002. [Google Scholar]

- Stephenson, A.L.; Dupree, P.; Scott, S.A.; Dennis, J.S. The Environmental and Economic Sustainability of Potential Bioethanol from Willow in the UK. Bioresour. Technol. 2010, 101, 9612–9623. [Google Scholar] [CrossRef]

- New Energy Farms; Miscanthus Production Cost; (Leamington, Essex County, ON, Canada). Personal Communication, 2020.

- Bali, A.; (Competitive Green Technologies, Leamington, ON, Canada). Personal Communication, 2020.

- Nematian, M.; Keske, C.; Ng’ombe, J.N. A Techno-Economic Analysis of Biochar Production and the Bioeconomy for Orchard Biomass. Waste Manag. 2021, 135, 467–477. [Google Scholar] [CrossRef]

- Kim, D.; Anderson, N.M.; Chung, W. Financial Performance of a Mobile Pyrolysis System Used to Produce Biochar from Sawmill Residues. For. Prod. J. 2015, 65, 189–197. [Google Scholar] [CrossRef]

- International-Biochar-Innitiative. State of the Biochar Industry 2013. 2013. Available online: https://biochar-international.org/resources/state-of-the-biochar-industry/ (accessed on 13 June 2024).

- Canola-Council-Canada. Historic Canola Oi, Meal and Seed Prices. 2016. Available online: https://www.canolacouncil.org/markets-stats/exports/ (accessed on 21 January 2023).

- Palma, M.A.; Richardson, J.W.; Roberson, B.E.; Ribera, L.A.; Outlaw, J.L.; Munster, C. Economic Feasibility of a Mobile Fast Pyrolysis System for Sustainable Bio-Crude Oil Production. Int. Food Agribus. Manag. Rev. 2011, 14, 1–16. [Google Scholar]

- TPE. Industry News. The Plastic Exchange: Commodity Plastic Resin. Available online: http://www.theplasticsexchange.com/ (accessed on 7 January 2023).

- MRNFP. Exploring for Talc in Quebec. Available online: https://mern.gouv.qc.ca/english/publications/mines/minerals/talc.pdf (accessed on 7 January 2023).

- AAFC. The Canadian Bioeconomy. Available online: http://publications.gc.ca/collections/collection_2016/aac-aafc/A22-12322-2015-eng.pdf (accessed on 10 September 2016).

- BIC. BIC’s BioProducts Agriculture Science Cluster Gets $7.1 Million Support from AAFC. Available online: https://docs.wixstatic.com/ugd/b22338_398bebcbe31b493ca57042af3f25ffd5.pdf (accessed on 5 April 2019).

- Li, W.; Ciais, P.; Stehfest, E.; Van Vuuren, D.; Popp, A.; Arneth, A.; Di Fulvio, F.; Doelman, J.; Humpenöder, F.; Harper, A.B.; et al. Mapping the Yields of Lignocellulosic Bioenergy Crops from Observations at the Global Scale. Earth Syst. Sci. Data 2020, 12, 789–804. [Google Scholar]

- Li, W.; Ciais, P.; Han, M.; Zhao, Q.; Chang, J.; Goll, D.S.; Zhu, L.; Wang, J. Bioenergy Crops for Low Warming Targets Require Half of the Present Agricultural Fertilizer Use. Environ. Sci. Technol. 2021, 55, 10654–10661. [Google Scholar]

- Cheng, Y.; Huang, M.; Lawrence, D.M.; Calvin, K.; Lombardozzi, D.L.; Sinha, E.; Pan, M.; He, X. Future Bioenergy Expansion Could Alter Carbon Sequestration Potential and Exacerbate Water Stress in the United States. Sci. Adv. 2022, 8, eabm8237. [Google Scholar] [CrossRef]

- Stenzel, F.; Greve, P.; Lucht, W.; Tramberend, S.; Wada, Y.; Gerten, D. Irrigation of Biomass Plantations May Globally Increase Water Stress More than Climate Change. Nat. Commun. 2021, 12, 1512. [Google Scholar] [CrossRef]

- Suopajärvi, H.; Fabritius, T. Towards More Sustainable Ironmaking—An Analysis of Energy Wood Availability in Finland and the Economics of Charcoal Production. Sustainability 2013, 5, 1188–1207. [Google Scholar] [CrossRef]

- Meyer, S.; Glaser, B.; Quicker, P. Technical, Economical, and Climate-Related Aspects of Biochar Production Technologies: A Literature Review. Environ. Sci. Technol. 2011, 45, 9473–9483. [Google Scholar] [CrossRef]

- Ahmed, M.B.; Zhou, J.L.; Ngo, H.H.; Guo, W. Insight into Biochar Properties and Its Cost Analysis. Biomass Bioenergy 2016, 84, 76–86. [Google Scholar] [CrossRef]

- Fornes, F.; Belda, R.M.; Lidón, A. Analysis of Two Biochars and One Hydrochar from Different Feedstock: Focus Set on Environmental, Nutritional and Horticultural Considerations. J. Clean. Prod. 2015, 86, 40–48. [Google Scholar] [CrossRef]

- McCarl, B.A.; Peacocke, C.; Chrisman, R.; Kung, C.-C.; Sands, R.D. Economics of Biochar Production, Utilization and Greenhouse Gas Offsets. In Biochar for Environmental Management: Science and Technology; Routledge: London, UK, 2009; pp. 341–358. [Google Scholar]

- Kludze, H.; Deen, B.; Weersink, A.; van Acker, R.; Janovicek, K.; De Laporte, A. Impact of Land Classification on Potential Warm Season Grass Biomass Production in Ontario, Canada. Can. J. Plant Sci. 2013, 93, 249–260. [Google Scholar] [CrossRef]

- Liu, T.; Ma, Z.; McConkey, B.; Kulshreshtha, S.; Huffman, T.; Green, M.; Liu, J.; Du, Y.; Shang, J. Bioenergy Production Potential on Marginal Land in Canada. In Proceedings of the 2012 First International Conference on Agro-Geoinformatics (Agro-Geoinformatics), Shanghai, China, 2–4 August 2012. [Google Scholar] [CrossRef]

- EDC (Exploring Canada’s Cleantech). Exploring Canada’s Cleantech Sector. 2023. Available online: https://www.edc.ca/en/guide/edc-explore-canada-cleantech-sector.html (accessed on 27 March 2024).

- OFA. Assessment of Hay Crop Acreage and Pasture Land for Biomass Production in Ontario. Ontario Federation of Agriculture. Available online: www.ofa.on.ca/uploads/userfiles/files/haycropreport-final.pdf (accessed on 14 March 2017).

- Rancourt, Y.; Neumeyer, C.; Zou, N. Results from the 2015 Bioproducts Production and Development Survey; Statistics Canada: Ottawa, ON, Canada, 2017. [Google Scholar]

- NRCAN (Natural Resources Canada). A Forest Bioeconomy Framework for Canada [WWW Document]. Natural Resources Canada. 2017. Available online: https://cfs.nrcan.gc.ca/pubwarehouse/pdfs/39162.pdf (accessed on 26 July 2022).

- BioTalent. Close-Up on the Bio-Economy: Labor Market Intelligence [WWW Document]. BioTalent Canada. 2021. Available online: https://www.biotalent.ca/wp-content/uploads/BioTalent-Canada-LMI-DemandandSupply-13OCT2021-1.pdf (accessed on 26 July 2022).

- Roy, P.; Dias, G. Prospects for Pyrolysis Technologies in the Bioenergy Sector: A Review. Renew. Sustain. Energy Rev. 2017, 77, 59–69. [Google Scholar] [CrossRef]

- Hitzl, M.; Corma, A.; Pomares, F.; Renz, M. The Hydrothermal Carbonization (HTC) Plant as a Decentral Biorefinery for Wet Biomass. Catal. Today 2015, 257, 154–159. [Google Scholar] [CrossRef]

- Fang, J.; Zhan, L.; Sik Ok, Y.; Gao, B. Minireview of Potential Applications of Hydrochar Derived from Hydrothermal Carbonization of Biomass. J. Ind. Eng. Chem. 2018, 57, 15–21. [Google Scholar] [CrossRef]

- Takaya, C.A.; Fletcher, L.A.; Singh, S.; Anyikude, K.U.; Ross, A.B. Phosphate and Ammonium Sorption Capacity of Biochar and Hydrochar from Different Wastes. Chemosphere 2016, 145, 518–527. [Google Scholar] [CrossRef]

- Behazin, E.; Misra, M.; Mohanty, A.K. Compatibilization of Toughened Polypropylene/Biocarbon Biocomposites: A Full Factorial Design Optimization of Mechanical Properties. Polym. Test. 2017, 61, 364–372. [Google Scholar] [CrossRef]

- Behazin, E.; Mohanty, A.K.; Misra, M. Sustainable Lightweight Biocomposite from Toughenned Polypropylene and Biocarbon for Automobile Applications. In Proceedings of the 21st International Conference on Composite Materials, Xi’an, China, 20–25 August 2017; pp. 20–25. [Google Scholar]

- Kludze, H.; Deen, B.; Dutta, A. Impact of agronomic treatments on fuel characteristics of herbaceous biomass for combustion. Fuel Process. Technol. 2013, 109, 96–102. [Google Scholar] [CrossRef]

- OMAFRA. Classifying Prime and Marginal Agricultural Soils and Landscapes: Guidelines for Application of the Canada Land Inventory in Ontario. Ontario’s Ministry of Agriculture, Food and Rural Affairs, 2015. Available online: https://www.ontario.ca/page/government-ontario (accessed on 13 June 2024).

- StatCan. Land Area by Province and Territory. Stat. Canada. 2015. Available online: http://www.statcan.gc.ca (accessed on 13 June 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roy, P.; Rodriguez-Uribe, A.; Mohanty, A.K.; Pujari, D.; Tiessen, M.; Bali, A.; Misra, M. Production Cost of Biocarbon and Biocomposite, and Their Prospects in Sustainable Biobased Industries. Sustainability 2024, 16, 5633. https://doi.org/10.3390/su16135633

Roy P, Rodriguez-Uribe A, Mohanty AK, Pujari D, Tiessen M, Bali A, Misra M. Production Cost of Biocarbon and Biocomposite, and Their Prospects in Sustainable Biobased Industries. Sustainability. 2024; 16(13):5633. https://doi.org/10.3390/su16135633

Chicago/Turabian StyleRoy, Poritosh, Arturo Rodriguez-Uribe, Amar K. Mohanty, Devashish Pujari, Mike Tiessen, Atul Bali, and Manjusri Misra. 2024. "Production Cost of Biocarbon and Biocomposite, and Their Prospects in Sustainable Biobased Industries" Sustainability 16, no. 13: 5633. https://doi.org/10.3390/su16135633

APA StyleRoy, P., Rodriguez-Uribe, A., Mohanty, A. K., Pujari, D., Tiessen, M., Bali, A., & Misra, M. (2024). Production Cost of Biocarbon and Biocomposite, and Their Prospects in Sustainable Biobased Industries. Sustainability, 16(13), 5633. https://doi.org/10.3390/su16135633