The Interplay between Digital Technologies, Supply Chain Resilience, Robustness and Sustainable Environmental Performance: Does Supply Chain Complexity Matter?

Abstract

:1. Introduction

2. Theoretical Framework

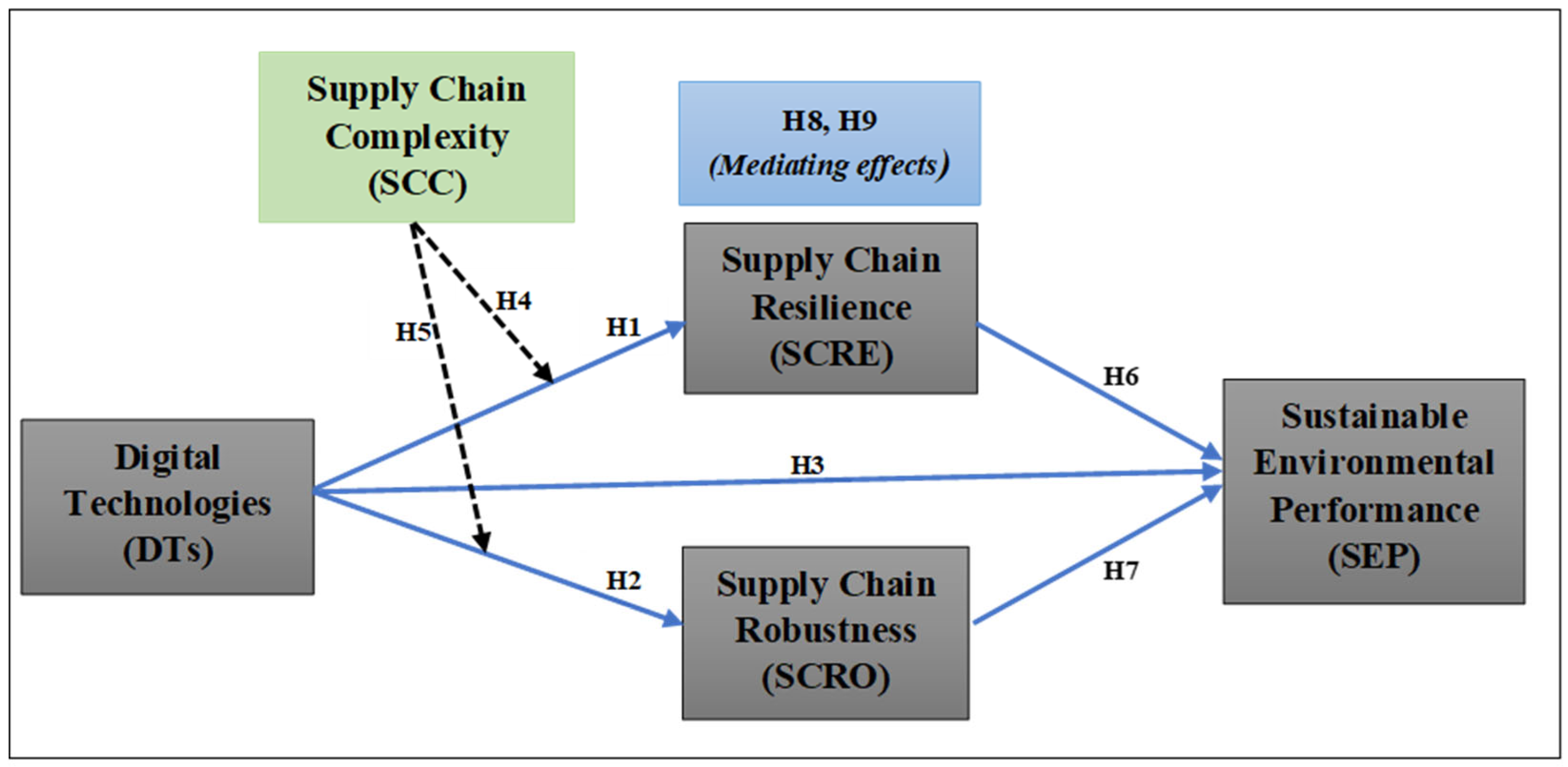

3. Review of Literature and Hypothesis Formulation

3.1. Digital Technologies Impact on Supply Chain Resilience and Robustness

3.2. Digital Technologies and Sustainable Environmental Performance

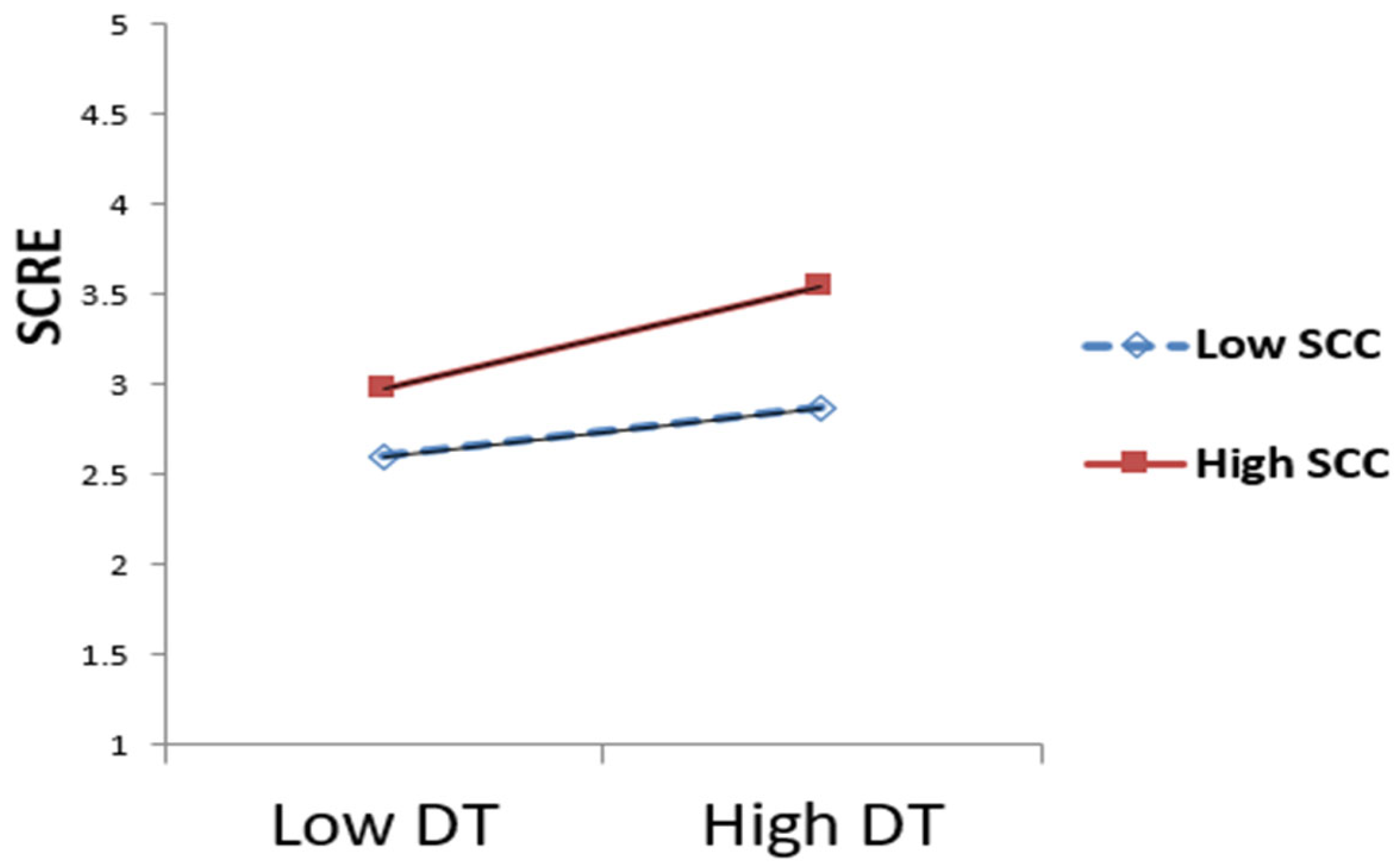

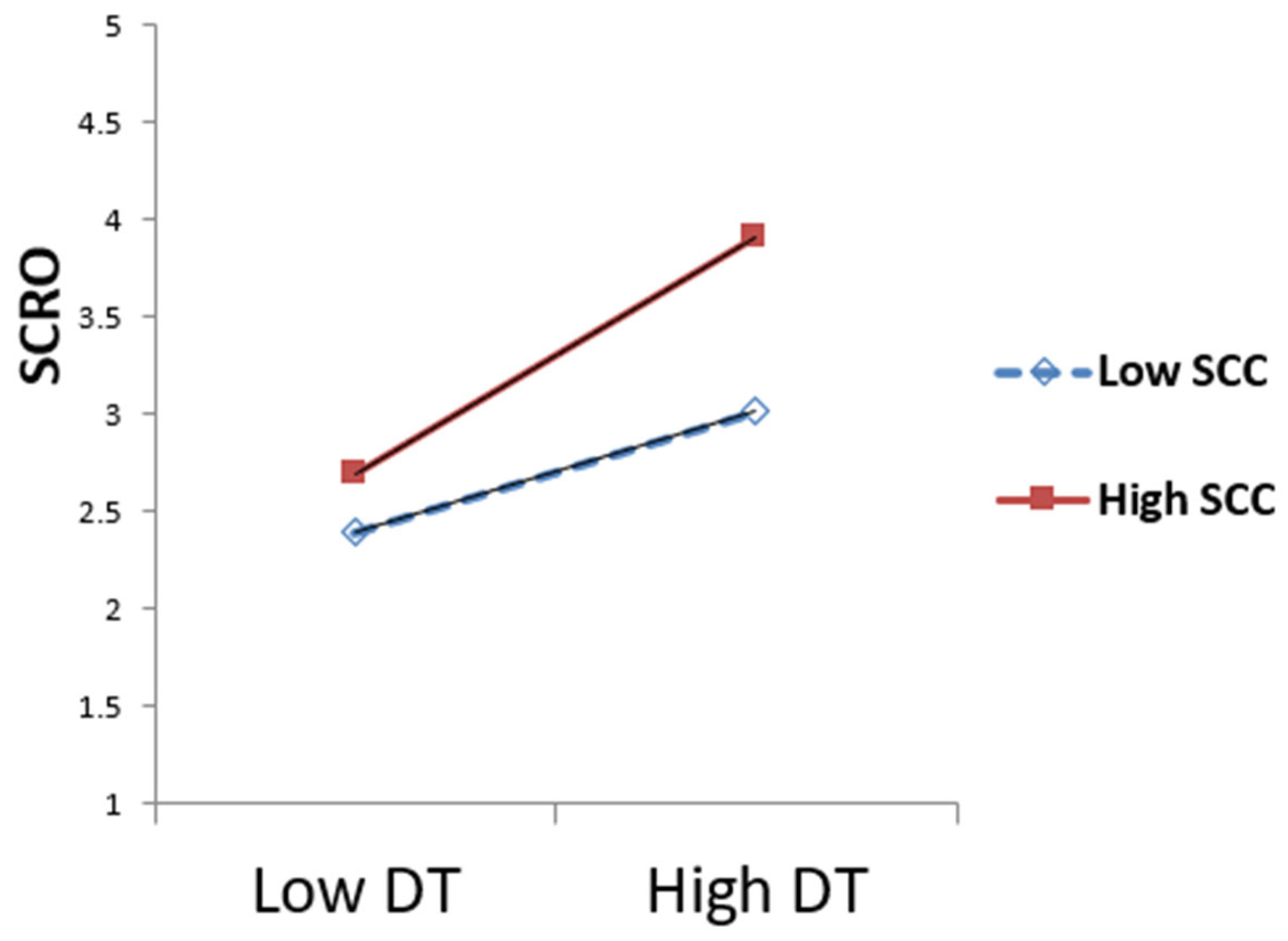

3.3. The Impact of Supply Chain Complexity: SCC’s Moderating Role

3.4. The Mediating Role of Supply Chain Resilience and Robustness

4. Methodology

4.1. Data Collection and Sample Description

4.2. Scale Development and Metrics

4.3. Methods for Data Analysis

5. Results

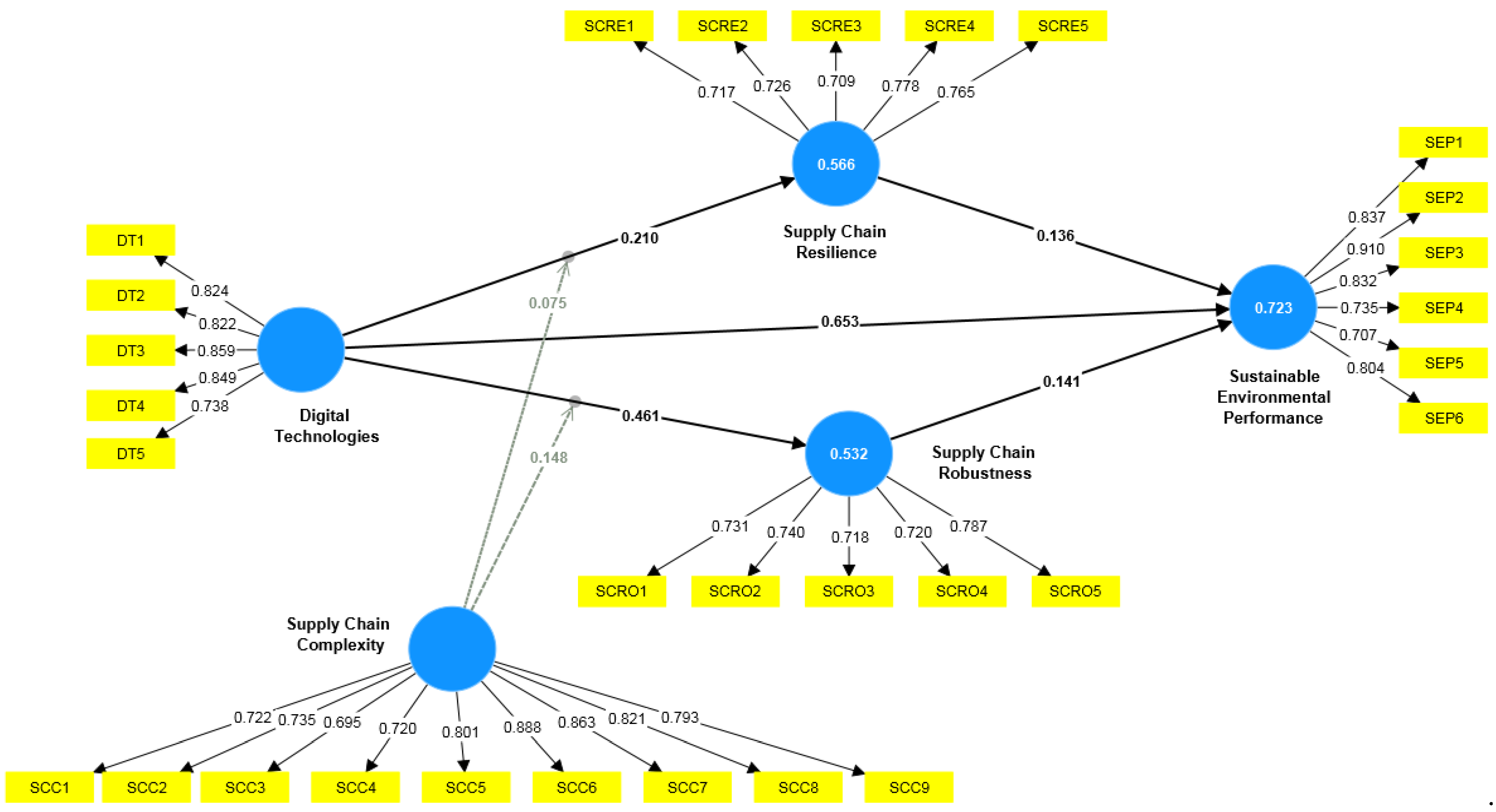

5.1. Measurement Model Assessment

5.2. Hypotheses Testing

6. Discussion and Conclusions

7. Implications, Limitations, and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Joshi, S.; Sharma, M. Impact of sustainable supply chain management on performance of SMEs amidst COVID-19 pandemic: An Indian perspective. Int. J. Logist. Econ. Glob. 2022, 9, 248–276. [Google Scholar] [CrossRef]

- Mohamed, M. Green Intellectual Capital and Business Sustainability in the Egyptian Industrial Companies: The Mediating Role of Green Innovation. Sci. J. Financ. Commer. Stud. Res. (SJFCSR) 2023, 4, 1059–1096. [Google Scholar] [CrossRef]

- Al-Khatib, A.W.; Shuhaiber, A. Green Intellectual Capital and Green Supply Chain Performance: Does Big Data Analytics Capabilities Matter? Sustainability 2022, 14, 10054. [Google Scholar] [CrossRef]

- Alnaim, M.; Metwally, A.B.M. Institutional Pressures and Environmental Management Accounting Adoption: Do Environmental Strategy Matter? Sustainability 2024, 16, 3020. [Google Scholar] [CrossRef]

- Ahmed, N.M.M. The Moderating Effect of Environmental Management Accounting Practices on the Relationship Between Green Supply Chain Management Practices and Corporate Performance of Egyptian Manufacturing Firms. Sci. J. Financ. Commer. Stud. Res. (SJFCSR) 2022, 3, 475–507. [Google Scholar] [CrossRef]

- Naseeb, H.; Metwally, A. Outsourcing insurance in the time of COVID-19: The cyber risk dilemma. J. Risk Manag. Financ. Inst. 2022, 15, 155–160. [Google Scholar]

- Gregurec, I.; Tomičić Furjan, M.; Tomičić-Pupek, K. The Impact of COVID-19 on Sustainable Business Models in SMEs. Sustainability 2021, 13, 1098. [Google Scholar] [CrossRef]

- Metwally, A.B.M.; Diab, A.; Mohamed, M.K. Telework operationalization through internal CSR, governmentality and accountability during the COVID-19: Evidence from a developing country. Int. J. Organ. Anal. 2022, 30, 1441–1464. [Google Scholar] [CrossRef]

- Kwok, A.O.J.; Koh, S.G.M. COVID-19 and Extended Reality (XR). Curr. Issues Tour. 2021, 24, 1935–1940. [Google Scholar] [CrossRef]

- Sharma, H.B.; Vanapalli, K.R.; Cheela, V.R.S.; Ranjan, V.P.; Jaglan, A.K.; Dubey, B.; Goel, S.; Bhattacharya, J. Challenges, opportunities, and innovations for effective solid waste management during and post COVID-19 pandemic. Resour. Conserv. Recycl. 2020, 162, 105052. [Google Scholar] [CrossRef]

- Metwally, A.B.M.; Ali, S.A.M.; Mohamed, A.T.I. Resilience and Agility as Indispensable Conditions for Sustaining Viable Supply Chain During Pandemics: The Case of Bahrain. In Proceedings of the 2020 International Conference on Data Analytics for Business and Industry: Way Towards a Sustainable Economy (ICDABI), Sakheer, Bahrain, 26–27 October 2020; pp. 1–5. [Google Scholar]

- Hohenstein, N.-O. Supply chain risk management in the COVID-19 pandemic: Strategies and empirical lessons for improving global logistics service providers’ performance. Int. J. Logist. Manag. 2022, 33, 1336–1365. [Google Scholar] [CrossRef]

- Buhaya, M.I.; Metwally, A.B.M. Green intellectual capital and green supply chain performance: Do external pressures matter? Cogent Bus. Manag. 2024, 11, 2349276. [Google Scholar] [CrossRef]

- Pujawan, I.N.; Bah, A.U. Supply chains under COVID-19 disruptions: Literature review and research agenda. Supply Chain Forum Int. J. 2022, 23, 81–95. [Google Scholar] [CrossRef]

- Alva Ferrari, A.; Bogner, K.; Palacio, V.; Crisostomo, D.; Seeber, N.; Ebersberger, B. The COVID-19 pandemic as a window of opportunity for more sustainable and circular supply chains. Clean. Logist. Supply Chain 2023, 7, 100101. [Google Scholar] [CrossRef]

- Naseeb, H.; Diab, A.A.; Metwally, A. The impact of the COVID-19 pandemic on medical and travel insurance pricing and fraud risks: An exploratory study. J. Risk Manag. Financ. Inst. 2020, 14, 59–71. [Google Scholar]

- Metwally, A.B.M.; Diab, A. An institutional analysis of the risk management process during the COVID-19 pandemic: Evidence from an emerging market. J. Account. Organ. Chang. 2023, 19, 40–62. [Google Scholar] [CrossRef]

- Muhammad, N.; Upadhyay, A.; Kumar, A.; Gilani, H. Achieving operational excellence through the lens of lean and Six Sigma during the COVID-19 pandemic. Int. J. Logist. Manag. 2022, 33, 818–835. [Google Scholar] [CrossRef]

- Metwally, A.B.M.; Ali, H.; Diab, A.A.; Hussainey, K. The hype of risk-based management control: A phronetic approach. Risk Gov. Control Financ. Mark. Inst. 2019, 9, 18–33. [Google Scholar] [CrossRef]

- Frare, A.B.; Beuren, I.M. The role of green process innovation translating green entrepreneurial orientation and proactive sustainability strategy into environmental performance. J. Small Bus. Enterp. Dev. 2022, 29, 789–806. [Google Scholar] [CrossRef]

- Lone, S.A.; Ahmad, A. COVID-19 pandemic—An African perspective. Emerg. Microbes Infect. 2020, 9, 1300–1308. [Google Scholar] [CrossRef]

- Zaazou, Z.A.; Salman Abdou, D. Egyptian small and medium sized enterprises’ battle against COVID-19 pandemic: March–July 2020. J. Humanit. Appl. Soc. Sci. 2022, 4, 94–112. [Google Scholar] [CrossRef]

- Abu Hatab, A.; Lagerkvist, C.-J.; Esmat, A. Risk perception and determinants in small- and medium-sized agri-food enterprises amidst the COVID-19 pandemic: Evidence from Egypt. Agribusiness 2021, 37, 187–212. [Google Scholar] [CrossRef]

- Khalifa, N.; Abd Elghany, M.; Abd Elghany, M. Exploratory research on digitalization transformation practices within supply chain management context in developing countries specifically Egypt in the MENA region. Cogent Bus. Manag. 2021, 8, 1965459. [Google Scholar] [CrossRef]

- Hamdy, A. Supply chain capabilities matter: Digital transformation and green supply chain management in post-pandemic emerging economies: A case from Egypt. Oper. Manag. Res. 2024, 1–19. [Google Scholar] [CrossRef]

- Ardolino, M.; Rapaccini, M.; Saccani, N.; Gaiardelli, P.; Crespi, G.; Ruggeri, C. The role of digital technologies for the service transformation of industrial companies. Int. J. Prod. Res. 2018, 56, 2116–2132. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Parekh, H.; Mani, V.; Belhadi, A.; Sharma, R. Digital twin for sustainable manufacturing supply chains: Current trends, future perspectives, and an implementation framework. Technol. Forecast. Soc. Chang. 2022, 176, 121448. [Google Scholar] [CrossRef]

- Alvarenga, M.Z.; Oliveira, M.P.V.d.; Oliveira, T.A.G.F.d. The impact of using digital technologies on supply chain resilience and robustness: The role of memory under the COVID-19 outbreak. Supply Chain Manag. Int. J. 2023, 28, 825–842. [Google Scholar] [CrossRef]

- Li, Y.; Dai, J.; Cui, L. The impact of digital technologies on economic and environmental performance in the context of industry 4.0: A moderated mediation model. Int. J. Prod. Econ. 2020, 229, 107777. [Google Scholar] [CrossRef]

- Singh, G.; Singh, S.; Daultani, Y.; Chouhan, M. Measuring the influence of digital twins on the sustainability of manufacturing supply chain: A mediating role of supply chain resilience and performance. Comput. Ind. Eng. 2023, 186, 109711. [Google Scholar] [CrossRef]

- Atieh Ali, A.A.; Sharabati, A.-A.A.; Allahham, M.; Nasereddin, A.Y. The Relationship between Supply Chain Resilience and Digital Supply Chain and the Impact on Sustainability: Supply Chain Dynamism as a Moderator. Sustainability 2024, 16, 3082. [Google Scholar] [CrossRef]

- Ben Abdelaziz, F.; Chen, Y.-T.; Dey, P.K. Supply chain resilience, organizational well-being, and sustainable performance: A comparison between the UK and France. J. Clean. Prod. 2024, 444, 141215. [Google Scholar] [CrossRef]

- Sharma, M.; Antony, R.; Sharma, A.; Daim, T. Can smart supply chain bring agility and resilience for enhanced sustainable business performance? Int. J. Logist. Manag. 2024. ahead-of-print. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Papadopoulos, T.; Luo, Z.; Wamba, S.F.; Roubaud, D. Can big data and predictive analytics improve social and environmental sustainability? Technol. Forecast. Soc. Chang. 2019, 144, 534–545. [Google Scholar] [CrossRef]

- Kiel, D.; MÜLler, J.M.; Arnold, C.; Voigt, K.-I. Sustainable industrial value creation: Benefits and challenges of industry 4.0. Int. J. Innov. Manag. 2017, 21, 1740015. [Google Scholar] [CrossRef]

- Negri, M.; Cagno, E.; Colicchia, C. Building sustainable and resilient supply chains: A framework and empirical evidence on trade-offs and synergies in implementation of practices. Prod. Plan. Control 2024, 35, 90–113. [Google Scholar] [CrossRef]

- Bevilacqua, M.; Ciarapica, F.E.; Marcucci, G. Supply Chain Resilience research trends: A literature overview. IFAC-PapersOnLine 2019, 52, 2821–2826. [Google Scholar] [CrossRef]

- Wong, C.W.Y.; Lirn, T.-C.; Yang, C.-C.; Shang, K.-C. Supply chain and external conditions under which supply chain resilience pays: An organizational information processing theorization. Int. J. Prod. Econ. 2020, 226, 107610. [Google Scholar] [CrossRef]

- Iftikhar, A.; Ali, I.; Stevenson, M. The silver lining of supply chain complexity: Building supply chain resilience and robustness through exploitation and exploration. Supply Chain Manag. Int. J. 2024, 29, 244–259. [Google Scholar] [CrossRef]

- Brandon-Jones, E.; Squire, B.; Autry, C.W.; Petersen, K.J. A Contingent Resource-Based Perspective of Supply Chain Resilience and Robustness. J. Supply Chain Manag. 2014, 50, 55–73. [Google Scholar] [CrossRef]

- El Baz, J.; Ruel, S. Can supply chain risk management practices mitigate the disruption impacts on supply chains’ resilience and robustness? Evidence from an empirical survey in a COVID-19 outbreak era. Int. J. Prod. Econ. 2021, 233, 107972. [Google Scholar] [CrossRef] [PubMed]

- Kwak, D.-W.; Seo, Y.-J.; Mason, R. Investigating the relationship between supply chain innovation, risk management capabilities and competitive advantage in global supply chains. Int. J. Oper. Prod. Manag. 2018, 38, 2–21. [Google Scholar] [CrossRef]

- Walker, B. Resilience: What it is and is not. Ecol. Soc. 2020, 25, 11. [Google Scholar] [CrossRef]

- Klibi, W.; Martel, A.; Guitouni, A. The design of robust value-creating supply chain networks: A critical review. Eur. J. Oper. Res. 2010, 203, 283–293. [Google Scholar] [CrossRef]

- Chowdhury, M.M.H.; Quaddus, M.A. Supply chain sustainability practices and governance for mitigating sustainability risk and improving market performance: A dynamic capability perspective. J. Clean. Prod. 2021, 278, 123521. [Google Scholar] [CrossRef]

- Nguyen, T.; Zhou, L.; Spiegler, V.; Ieromonachou, P.; Lin, Y. Big data analytics in supply chain management: A state-of-the-art literature review. Comput. Oper. Res. 2018, 98, 254–264. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Papadopoulos, T.; Dubey, R.; Wamba, S.F.; Childe, S.J.; Hazen, B.; Akter, S. Big data and predictive analytics for supply chain and organizational performance. J. Bus. Res. 2017, 70, 308–317. [Google Scholar] [CrossRef]

- Wamba, S.F.; Gunasekaran, A.; Akter, S.; Ren, S.J.-F.; Dubey, R.; Childe, S.J. Big data analytics and firm performance: Effects of dynamic capabilities. J. Bus. Res. 2017, 70, 356–365. [Google Scholar] [CrossRef]

- Galbraith, J. Designing Complex Organizations; Addison-Wesley Longman Publishing Co., Inc.: Boston, MA, USA, 1973. [Google Scholar]

- Premkumar, G.; Ramamurthy, K.; Saunders, C.S. Information Processing View of Organizations: An Exploratory Examination of Fit in the Context of Interorganizational Relationships. J. Manag. Inf. Syst. 2005, 22, 257–294. [Google Scholar] [CrossRef]

- Yan, F.; Chen, L.; Jia, F.; Liu, Y. Building supply chain resilience through collaborative innovation: An information processing theory perspective. J. Digit. Econ. 2023, 2, 233–243. [Google Scholar] [CrossRef]

- Lawrence, P.R.; Lorsch, J.W. Organization and Environment: Managing Differentiation and Integration; Harvard University Press: Cambridge, MA, USA, 1967. [Google Scholar]

- Fan, H.; Li, G.; Sun, H.; Cheng, T.C.E. An information processing perspective on supply chain risk management: Antecedents, mechanism, and consequences. Int. J. Prod. Econ. 2017, 185, 63–75. [Google Scholar] [CrossRef]

- Aslam, J.; Saleem, A.; Kim, Y.B. Blockchain-enabled supply chain management: Integrated impact on firm performance and robustness capabilities. Bus. Process Manag. J. 2023, 29, 1680–1705. [Google Scholar] [CrossRef]

- Busse, C.; Meinlschmidt, J.; Foerstl, K. Managing Information Processing Needs in Global Supply Chains: A Prerequisite to Sustainable Supply Chain Management. J. Supply Chain Manag. 2017, 53, 87–113. [Google Scholar] [CrossRef]

- Zhu, S.; Song, J.; Hazen, B.T.; Lee, K.; Cegielski, C. How supply chain analytics enables operational supply chain transparency. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 47–68. [Google Scholar] [CrossRef]

- Lu, Q.; Jiang, Y.; Wang, Y. Improving supply chain resilience from the perspective of information processing theory. J. Enterp. Inf. Manag. 2024, 37, 721–744. [Google Scholar] [CrossRef]

- Jia, F.; Zhang, T.; Chen, L. Sustainable supply chain Finance:Towards a research agenda. J. Clean. Prod. 2020, 243, 118680. [Google Scholar] [CrossRef]

- Hussain, G.; Nazir, M.S.; Rashid, M.A.; Sattar, M.A. From supply chain resilience to supply chain disruption orientation: The moderating role of supply chain complexity. J. Enterp. Inf. Manag. 2023, 36, 70–90. [Google Scholar] [CrossRef]

- Pandey, S.; Singh, R.K.; Gunasekaran, A.; Kaushik, A. Cyber security risks in globalized supply chains: Conceptual framework. J. Glob. Oper. Strateg. Sourc. 2020, 13, 103–128. [Google Scholar] [CrossRef]

- Cheung, K.-F.; Bell, M.G.H.; Bhattacharjya, J. Cybersecurity in logistics and supply chain management: An overview and future research directions. Transp. Res. Part E Logist. Transp. Rev. 2021, 146, 102217. [Google Scholar] [CrossRef]

- Möller, D.P.F. Cybersecurity in Digital Transformation. In Guide to Cybersecurity in Digital Transformation: Trends, Methods, Technologies, Applications and Best Practices; Möller, D.P.F., Ed.; Springer Nature Switzerland: Cham, Switzerland, 2023; pp. 1–70. [Google Scholar]

- Saeed, S.; Altamimi, S.A.; Alkayyal, N.A.; Alshehri, E.; Alabbad, D.A. Digital Transformation and Cybersecurity Challenges for Businesses Resilience: Issues and Recommendations. Sensors 2023, 23, 6666. [Google Scholar] [CrossRef]

- Metwally, A.B.M.; Ali, S.A.M.; Mohamed, A.T.I. Thinking Responsibly About Responsible AI in Risk Management: The Darkside of AI in RM. In Proceedings of the 2024 ASU International Conference in Emerging Technologies for Sustainability and Intelligent Systems (ICETSIS), Manama, Bahrain, 28–29 January 2024; pp. 1–5. [Google Scholar]

- Min, H. Blockchain technology for enhancing supply chain resilience. Bus. Horiz. 2019, 62, 35–45. [Google Scholar] [CrossRef]

- Ivanov, D.; Das, A. Coronavirus (COVID-19/SARS-CoV-2) and supply chain resilience: A research note. Int. J. Integr. Supply Manag. 2020, 13, 90–102. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Bryde, D.J.; Dwivedi, Y.K.; Papadopoulos, T. Blockchain technology for enhancing swift-trust, collaboration and resilience within a humanitarian supply chain setting. Int. J. Prod. Res. 2020, 58, 3381–3398. [Google Scholar] [CrossRef]

- Manupati, V.K.; Schoenherr, T.; Ramkumar, M.; Panigrahi, S.; Sharma, Y.; Mishra, P. Recovery strategies for a disrupted supply chain network: Leveraging blockchain technology in pre- and post-disruption scenarios. Int. J. Prod. Econ. 2022, 245, 108389. [Google Scholar] [CrossRef]

- Ben-Daya, M.; Hassini, E.; Bahroun, Z. Internet of things and supply chain management: A literature review. Int. J. Prod. Res. 2019, 57, 4719–4742. [Google Scholar] [CrossRef]

- Al-Talib, M.; Melhem, W.Y.; Anosike, A.I.; Garza Reyes, J.A.; Nadeem, S.P.; Kumar, A. Achieving resilience in the supply chain by applying IoT technology. Procedia CIRP 2020, 91, 752–757. [Google Scholar] [CrossRef]

- Birkel, H.S.; Hartmann, E. Internet of Things—The future of managing supply chain risks. Supply Chain Manag. Int. J. 2020, 25, 535–548. [Google Scholar] [CrossRef]

- Kassa, A.; Kitaw, D.; Stache, U.; Beshah, B.; Degefu, G. Artificial intelligence techniques for enhancing supply chain resilience: A systematic literature review, holistic framework, and future research. Comput. Ind. Eng. 2023, 186, 109714. [Google Scholar] [CrossRef]

- Kassa, M.K.; Wube, H.D. Benefits and Challenges of Industry 4.0 in African Emerging Economies. In Pan-African Conference on Artificial Intelligence; Springer Nature Switzerland: Cham, Switzerland, 2023; pp. 261–276. [Google Scholar]

- Lai, K.-h.; Wong, C.W.Y.; Lam, J.S.L. Sharing environmental management information with supply chain partners and the performance contingencies on environmental munificence. Int. J. Prod. Econ. 2015, 164, 445–453. [Google Scholar] [CrossRef]

- Addo-Tenkorang, R.; Helo, P.T. Big data applications in operations/supply-chain management: A literature review. Comput. Ind. Eng. 2016, 101, 528–543. [Google Scholar] [CrossRef]

- Cao, G.; Duan, Y.; Cadden, T. The link between information processing capability and competitive advantage mediated through decision-making effectiveness. Int. J. Inf. Manag. 2019, 44, 121–131. [Google Scholar] [CrossRef]

- Joshi, A.D.; Gupta, S.M. Evaluation of design alternatives of End-Of-Life products using internet of things. Int. J. Prod. Econ. 2019, 208, 281–293. [Google Scholar] [CrossRef]

- Vern, P.; Miftah, N.; Panghal, A. Digital Technology: Implementation Challenges and Strategies in Agri-Food Supply Chain. In Agri-Food 4.0; Mor, R.S., Kumar, D., Singh, A., Eds.; Advanced Series in Management; Emerald Publishing Limited: Bingley, UK, 2022; Volume 27, pp. 17–30. [Google Scholar]

- Benevento, E.; Stefanini, A.; Aloini, D.; Dulmin, R.; Mininno, V. Beyond Digital Technologies: Investigating the Barriers to Supply Chain Integration of Healthcare Organizations. In IEEE Transactions on Engineering Management; IEEE: New York, NY, USA, 2023; pp. 1–13. [Google Scholar] [CrossRef]

- Oh, I.; Kim, J. Frontiers and laggards: Which firms benefit from adopting advanced digital technologies? Manag. Decis. Econ. 2023, 44, 753–766. [Google Scholar] [CrossRef]

- Curran, R.; Gomis, G.; Castagne, S.; Butterfield, J.; Edgar, T.; Higgins, C.; McKeever, C. Integrated digital design for manufacture for reduced life cycle cost. Int. J. Prod. Econ. 2007, 109, 27–40. [Google Scholar] [CrossRef]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Fosso Wamba, S.; Akter, S.; Edwards, A.; Chopin, G.; Gnanzou, D. How ‘big data’ can make big impact: Findings from a systematic review and a longitudinal case study. Int. J. Prod. Econ. 2015, 165, 234–246. [Google Scholar] [CrossRef]

- Schniederjans, D.G.; Hales, D.N. Cloud computing and its impact on economic and environmental performance: A transaction cost economics perspective. Decis. Support Syst. 2016, 86, 73–82. [Google Scholar] [CrossRef]

- Wiedmer, R.; Griffis, S.E. Structural characteristics of complex supply chain networks. J. Bus. Logist. 2021, 42, 264–290. [Google Scholar] [CrossRef]

- Ateş, M.A.; Memiş, H. Embracing supply base complexity: The contingency role of strategic purchasing. Int. J. Oper. Prod. Manag. 2021, 41, 830–859. [Google Scholar] [CrossRef]

- Giannoccaro, I.; Nair, A.; Choi, T. The Impact of Control and Complexity on Supply Network Performance: An Empirically Informed Investigation Using NK Simulation Analysis. Decis. Sci. 2018, 49, 625–659. [Google Scholar] [CrossRef]

- Bozarth, C.C.; Warsing, D.P.; Flynn, B.B.; Flynn, E.J. The impact of supply chain complexity on manufacturing plant performance. J. Oper. Manag. 2009, 27, 78–93. [Google Scholar] [CrossRef]

- Bode, C.; Wagner, S.M. Structural drivers of upstream supply chain complexity and the frequency of supply chain disruptions. J. Oper. Manag. 2015, 36, 215–228. [Google Scholar] [CrossRef]

- Akın Ateş, M.; Suurmond, R.; Luzzini, D.; Krause, D. Order from chaos: A meta-analysis of supply chain complexity and firm performance. J. Supply Chain Manag. 2022, 58, 3–30. [Google Scholar] [CrossRef]

- Diab, A.; Metwally, A.B.M. Institutional complexity and CSR practices: Evidence from a developing country. J. Account. Emerg. Econ. 2020, 10, 655–680. [Google Scholar] [CrossRef]

- Aitken, J.; Esain, A.E.; Williams, S. Management of complexity in the care ecosystem. Supply Chain Manag. Int. J. 2021, 26, 481–494. [Google Scholar] [CrossRef]

- Birkie, S.E.; Trucco, P.; Fernandez Campos, P. Effectiveness of resilience capabilities in mitigating disruptions: Leveraging on supply chain structural complexity. Supply Chain Manag. Int. J. 2017, 22, 506–521. [Google Scholar] [CrossRef]

- Birkie, S.E.; Trucco, P. Do not expect others do what you should! Supply chain complexity and mitigation of the ripple effect of disruptions. Int. J. Logist. Manag. 2020, 31, 123–144. [Google Scholar] [CrossRef]

- ElMaraghy, H.; AlGeddawy, T.; Samy, S.N.; Espinoza, V. A model for assessing the layout structural complexity of manufacturing systems. J. Manuf. Syst. 2014, 33, 51–64. [Google Scholar] [CrossRef]

- Cheng, C.-Y.; Chen, T.-L.; Chen, Y.-Y. An analysis of the structural complexity of supply chain networks. Appl. Math. Model. 2014, 38, 2328–2344. [Google Scholar] [CrossRef]

- De Biagi, V.; Chiaia, B. Complexity and robustness of frame structures. Int. J. Solids Struct. 2013, 50, 3723–3741. [Google Scholar] [CrossRef]

- Monostori, J. Robustness- and Complexity-oriented Characterization of Supply Networks’ Structures. Procedia CIRP 2016, 57, 67–72. [Google Scholar] [CrossRef]

- Olivares Aguila, J.; ElMaraghy, W. Structural complexity and robustness of supply chain networks based on product architecture. Int. J. Prod. Res. 2018, 56, 6701–6718. [Google Scholar] [CrossRef]

- Tang, C.S. Robust strategies for mitigating supply chain disruptions. Int. J. Logist. Res. Appl. 2006, 9, 33–45. [Google Scholar] [CrossRef]

- Morais-Storz, M.; Nguyen, N. The role of unlearning in metamorphosis and strategic resilience. Learn. Organ. 2017, 24, 93–106. [Google Scholar] [CrossRef]

- Piprani, A.Z.; Mohezar, S.; Jaafar, N.I. Supply chain integration and supply chain performance: The mediating role of supply chain resilience. Int. J. Supply Chain Manag. 2020, 9, 58–73. [Google Scholar]

- Morgan, G. National business systems research: Progress and prospects. Scand. J. Manag. 2007, 23, 127–145. [Google Scholar] [CrossRef]

- Flynn, B.B.; Huo, B.; Zhao, X. The impact of supply chain integration on performance: A contingency and configuration approach. J. Oper. Manag. 2010, 28, 58–71. [Google Scholar] [CrossRef]

- Rizzi, F.; Gigliotti, M.; Annunziata, E. Exploring the nexus between GSCM and organisational culture: Insights on the role of supply chain integration. Supply Chain Manag. Int. J. 2023, 28, 300–323. [Google Scholar] [CrossRef]

- Wang, J.; Feng, T. Supply chain ethical leadership and green supply chain integration: A moderated mediation analysis. Int. J. Logist. Res. Appl. 2023, 26, 1145–1171. [Google Scholar] [CrossRef]

- Tarifa-Fernandez, J.; De Burgos-Jiménez, J. Supply chain integration and performance relationship: A moderating effects review. Int. J. Logist. Manag. 2017, 28, 1243–1271. [Google Scholar] [CrossRef]

- Manik, D.; Sinulingga, S.; Ishak, A. Impact of supply chain integration on business performance: A review. J. Sist. Tek. Ind. 2022, 24, 85–106. [Google Scholar] [CrossRef]

- Ambulkar, S.; Blackhurst, J.; Grawe, S. Firm’s resilience to supply chain disruptions: Scale development and empirical examination. J. Oper. Manag. 2015, 33–34, 111–122. [Google Scholar] [CrossRef]

- Chowdhury, M.M.H.; Quaddus, M.; Agarwal, R. Supply chain resilience for performance: Role of relational practices and network complexities. Supply Chain Manag. Int. J. 2019, 24, 659–676. [Google Scholar] [CrossRef]

- Russell, D.M.; Saldanha, J.P. Five Tenets of Security-Aware Logistics and Supply Chain Operation. Transp. J. 2003, 42, 44–54. [Google Scholar]

- Shukla, A.; Agarwal Lalit, V.; Venkatasubramanian, V. Optimizing efficiency-robustness trade-offs in supply chain design under uncertainty due to disruptions. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 623–647. [Google Scholar] [CrossRef]

- Wieland, A.; Durach, C.F. Two perspectives on supply chain resilience. J. Bus. Logist. 2021, 42, 315–322. [Google Scholar] [CrossRef]

- Chen, C.; Wang, J.; Qiu, F.; Zhao, D. Resilient Distribution System by Microgrids Formation after Natural Disasters. IEEE Trans. Smart Grid 2016, 7, 958–966. [Google Scholar] [CrossRef]

- Wieland, A.; Wallenburg, C.M. Dealing with supply chain risks. Int. J. Phys. Distrib. Logist. Manag. 2012, 42, 887–905. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, H. Empirical research on associations among information technology, supply chain robustness and supply chain performance. Int. J. Bus. Manag. 2011, 6, 231. [Google Scholar] [CrossRef]

- Jun, W.; Rowley, C. Change and continuity in management systems and corporate performance: Human resource management, corporate culture, risk management and corporate strategy in South Korea. Bus. Hist. 2014, 56, 485–508. [Google Scholar] [CrossRef]

- Gölgeci, I.; Kuivalainen, O. Does social capital matter for supply chain resilience? The role of absorptive capacity and marketing-supply chain management alignment. Ind. Mark. Manag. 2020, 84, 63–74. [Google Scholar] [CrossRef]

- Zaid, A.A.; Jaaron, A.A.M.; Talib Bon, A. The impact of green human resource management and green supply chain management practices on sustainable performance: An empirical study. J. Clean. Prod. 2018, 204, 965–979. [Google Scholar] [CrossRef]

- Junaid, M.; Zhang, Q.; Cao, M.; Luqman, A. Nexus between technology enabled supply chain dynamic capabilities, integration, resilience, and sustainable performance: An empirical examination of healthcare organizations. Technol. Forecast. Soc. Chang. 2023, 196, 122828. [Google Scholar] [CrossRef]

- Hair Jr, J.; Black, W.; Babin, B. Multivariate Data Analysis; Pearson Education Ltd.: Prentice Hall, NY, USA, 2009. [Google Scholar]

- Hair, J.F.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to use and how to report the results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A new criterion for assessing discriminant validity in variance-based structural equation modeling. J. Acad. Mark. Sci. 2015, 43, 115–135. [Google Scholar] [CrossRef]

- Hair, J.; Hair, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM); Sage Publications: Thousand Oaks, CA, USA, 2021. [Google Scholar]

- Bruque Cámara, S.; Moyano Fuentes, J.; Maqueira Marín, J.M. Cloud computing, Web 2.0, and operational performance. Int. J. Logist. Manag. 2015, 26, 426–458. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, Y.; Xu, L.D.; Zhang, L.; Li, B.H. CCIoT-CMfg: Cloud Computing and Internet of Things-Based Cloud Manufacturing Service System. IEEE Trans. Ind. Inform. 2014, 10, 1435–1442. [Google Scholar] [CrossRef]

| Freq. | % | ||

|---|---|---|---|

| Gender | Male | 237 | 81.2 |

| Female | 55 | 18.8 | |

| Experience | 1–5 years | 30 | 10.2 |

| 6–10 years | 76 | 26 | |

| 11–15 years | 88 | 30 | |

| More than 15 years | 98 | 33.8 | |

| Industry | Food and Beverages | 69 | 23.6 |

| Textiles and Durables | 36 | 12.3 | |

| Industrial Goods, Services and Automobiles | 44 | 15.1 | |

| Energy and Support Services | 14 | 4.8 | |

| Paper and Packaging | 28 | 9.6 | |

| Basic Resources | 57 | 19.5 | |

| IT and Electronics | 14 | 4.8 | |

| Healthcare and Pharmaceuticals | 30 | 10.3 | |

| Total | 292 | 100 | |

| Scale Variables and Items | Outer Loading | Alpha | CR | AVE |

|---|---|---|---|---|

| Digital Technologies (DTs) | 0.877 | 0.881 | 0.672 | |

| DT-1: Internet of Things | 0.824 | |||

| DT-2: Digital twins | 0.822 | |||

| DT-3: Cloud computing | 0.859 | |||

| DT-4: Big data analytics | 0.849 | |||

| DT-5: Blockchain | 0.738 | |||

| Supply Chain Resilience (SCRE) | 0.810 | 0.831 | 0.547 | |

| SCRE-1: We can successfully respond to unanticipated disturbances by swiftly resuming the flow of our product. | 0.717 | |||

| SCRE-2: We’re ready to face the financial fallout from any disruptions in the supply chain. | 0.726 | |||

| SCRE-3: We are able to respond promptly in the event that the supply chain is interrupted. | 0.709 | |||

| SCRE-4: We can easily adjust to a disturbance in the supply chain. | 0.778 | |||

| SCRE-5: We can adjust to the changes that an interruption in the supply chain brings about | 0.765 | |||

| Supply Chain Robustness (SCRO) | 0.810 | 0.857 | 0.547 | |

| SCRO-1: Our supply chain can continue to function effectively and sustain, even in the face of internal or external interruptions. | 0.731 | |||

| SCRO-2: Our supply chain able to lessen or prevent risk occurrence by foreseeing and getting ready for them. | 0.740 | |||

| SCRO-3: Our supply chain able to absorbed a sizable portion of the negative effects of recurring risks. | 0.718 | |||

| SCRO-4: our supply chain gives us enough time to figure out a reasonable response when changes occur. | 0.720 | |||

| SCRO-5: Our supply chain has enough time to consider the optimal course of effective reactions. | 0.787 | |||

| Supply Chain Complexity (SCC) | 0.921 | 0.928 | 0.616 | |

| SCC-1: We have several buyers for every product. | 0.722 | |||

| SCC-2: For every material or part, we have several suppliers. | 0.735 | |||

| SCC-3: Our suppliers are spread throughout a variety of geographic areas. | 0.695 | |||

| SCC-4: Our company/plant serves a numerous client. | 0.720 | |||

| SCC-5: We have several production and logistical facilities spread across various locations. | 0.801 | |||

| SCC-6: In this supply chain, we can rely on suppliers to deliver goods on-time. | 0.888 | |||

| SCC-7: In order to avoid inventory and stockouts, our company works to reduce supplier lead times. | 0.863 | |||

| SCC-8: We frequently experience variation in our products demand. | 0.821 | |||

| SCC-9: Our customers want different products with numerous characteristics. | 0.793 | |||

| Sustainable Environmental Performance (SEP) | 0.892 | 0.904 | 0.651 | |

| SEP-1: Our company have substantially reduced energy consumption in production processes. | 0.837 | |||

| SEP-2: Our company have reduced noxious chemicals into the air and water substantially | 0.910 | |||

| SEP-3: Our company have substantially improved recycle of waste. | 0.832 | |||

| SEP-4: The use of sustainable fuels and renewable energy has increased in our company. | 0.735 | |||

| SEP-5: Our company do business with green suppliers and customers. | 0.707 | |||

| SEP-6: Our company has improved its environmental status and decreased the number of environmental accidents. | 0.804 |

| DTs | SCC | SCRE | SCRO | SEP | |

|---|---|---|---|---|---|

| DT-1 | 0.824 | 0.547 | 0.469 | 0.572 | 0.595 |

| DT-2 | 0.822 | 0.462 | 0.403 | 0.507 | 0.581 |

| DT-3 | 0.859 | 0.593 | 0.593 | 0.562 | 0.549 |

| DT-4 | 0.849 | 0.533 | 0.509 | 0.475 | 0.575 |

| DT-5 | 0.738 | 0.516 | 0.462 | 0.586 | 0.561 |

| SCC-1 | 0.387 | 0.722 | 0.462 | 0.385 | 0.534 |

| SCC-2 | 0.489 | 0.735 | 0.499 | 0.526 | 0.547 |

| SCC-3 | 0.458 | 0.695 | 0.457 | 0.386 | 0.591 |

| SCC-4 | 0.492 | 0.720 | 0.536 | 0.497 | 0.555 |

| SCC-5 | 0.596 | 0.801 | 0.608 | 0.535 | 0.601 |

| SCC-6 | 0.613 | 0.888 | 0.573 | 0.585 | 0.528 |

| SCC-7 | 0.600 | 0.863 | 0.541 | 0.528 | 0.533 |

| SCC-8 | 0.533 | 0.821 | 0.526 | 0.488 | 0.548 |

| SCC-9 | 0.556 | 0.793 | 0.585 | 0.518 | 0.608 |

| SCRE-1 | 0.266 | 0.320 | 0.717 | 0.543 | 0.314 |

| SCRE-2 | 0.378 | 0.363 | 0.726 | 0.592 | 0.432 |

| SCRE-3 | 0.357 | 0.321 | 0.709 | 0.561 | 0.375 |

| SCRE-4 | 0.516 | 0.515 | 0.778 | 0.543 | 0.546 |

| SCRE-5 | 0.563 | 0.536 | 0.765 | 0.576 | 0.583 |

| SCRO-1 | 0.269 | 0.384 | 0.558 | 0.731 | 0.319 |

| SCRO-2 | 0.299 | 0.401 | 0.584 | 0.740 | 0.351 |

| SCRO-3 | 0.365 | 0.342 | 0.566 | 0.718 | 0.374 |

| SCRO-4 | 0.532 | 0.404 | 0.459 | 0.720 | 0.493 |

| SCRO-5 | 0.521 | 0.563 | 0.520 | 0.787 | 0.548 |

| SEP-1 | 0.562 | 0.530 | 0.453 | 0.526 | 0.837 |

| SEP-2 | 0.581 | 0.554 | 0.580 | 0.524 | 0.910 |

| SEP-3 | 0.539 | 0.563 | 0.571 | 0.523 | 0.832 |

| SEP-4 | 0.549 | 0.577 | 0.468 | 0.522 | 0.735 |

| SEP-5 | 0.530 | 0.527 | 0.526 | 0.473 | 0.707 |

| SEP-6 | 0.600 | 0.606 | 0.518 | 0.521 | 0.804 |

| Fornell–Larcker | HTMT | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| DTs | SCC | SCRE | SCRO | SEP | DTs | SCC | SCRE | SCRO | SEP | |

| 1. DTs | 0.827 | |||||||||

| 2. SCC | 0.675 | 0.785 | 0.742 | |||||||

| 3. SCRE | 0.600 | 0.734 | 0.815 | 0.649 | 0.748 | |||||

| 4. SCRO | 0.659 | 0.635 | 0.740 | 0.749 | 0.688 | 0.669 | 0.848 | |||

| 5. SEP | 0.807 | 0.770 | 0.642 | 0.682 | 0.825 | 0.820 | 0.862 | 0.703 | 0.711 | |

| Hypotheses | Beta (β) | T-Statistics | Results | |

|---|---|---|---|---|

| Direct effects | ||||

| H-1 | DTs -> SCRE | 0.210 *** | 3.842 | Accepted |

| H-2 | DTs -> SCRO | 0.461 *** | 5.733 | Accepted |

| H-3 | DTs -> SEP | 0.653 *** | 13.750 | Accepted |

| H-6 | SCRE -> SEP | 0.136 * | 2.380 | Accepted |

| H-7 | SCRO -> SEP | 0.141 * | 2.077 | Accepted |

| Moderating effects | ||||

| H-4 | DTs × SCC -> SCRE | 0.075 * | 2.187 | Accepted |

| H-5 | DTs × SCC -> SCRO | 0.148 *** | 3.758 | Accepted |

| Mediating effects (partial mediation) | ||||

| H-8 | DTs -> SCRE -> SEP | 0.029 * | 2.094 | Accepted |

| H-9 | DTs -> SCRO -> SEP | 0.065 * | 2.146 | Accepted |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Metwally, A.B.M.; Ali, H.A.A.; Aly, S.A.S.; Ali, M.A.S. The Interplay between Digital Technologies, Supply Chain Resilience, Robustness and Sustainable Environmental Performance: Does Supply Chain Complexity Matter? Sustainability 2024, 16, 6175. https://doi.org/10.3390/su16146175

Metwally ABM, Ali HAA, Aly SAS, Ali MAS. The Interplay between Digital Technologies, Supply Chain Resilience, Robustness and Sustainable Environmental Performance: Does Supply Chain Complexity Matter? Sustainability. 2024; 16(14):6175. https://doi.org/10.3390/su16146175

Chicago/Turabian StyleMetwally, Abdelmoneim Bahyeldin Mohamed, Hesham Ali Ahmed Ali, Saleh Aly Saleh Aly, and Mohamed Ali Shabeeb Ali. 2024. "The Interplay between Digital Technologies, Supply Chain Resilience, Robustness and Sustainable Environmental Performance: Does Supply Chain Complexity Matter?" Sustainability 16, no. 14: 6175. https://doi.org/10.3390/su16146175