Optimisation of the Circular Economy Based on the Resource Circulation Equation

Abstract

:1. Introduction

- (1)

- Developing an evaluation method that can synthesise economic benefits, environmental benefits, and social benefits to evaluate the effect of enterprise circular economy and make up for the shortcomings of the existing indicators such as incomplete evaluation and strong subjectivity.

- (2)

- Proposing a comprehensive and effective optimisation method of CE, which can analyse the defects existing in the implementation of CE by enterprises from the internal mechanism of circular economy

- (3)

- Predicting the environmental and economic benefits generated from implementing the CE optimisation method.

2. Literature Review

3. Research Methods

3.1. The Definition of Resource Circulation Efficiency

3.2. The Factorisation of the Resource Circulation Efficiency

3.3. Optimising CE Efficiency Based on the Resource Circulation Efficiency Index

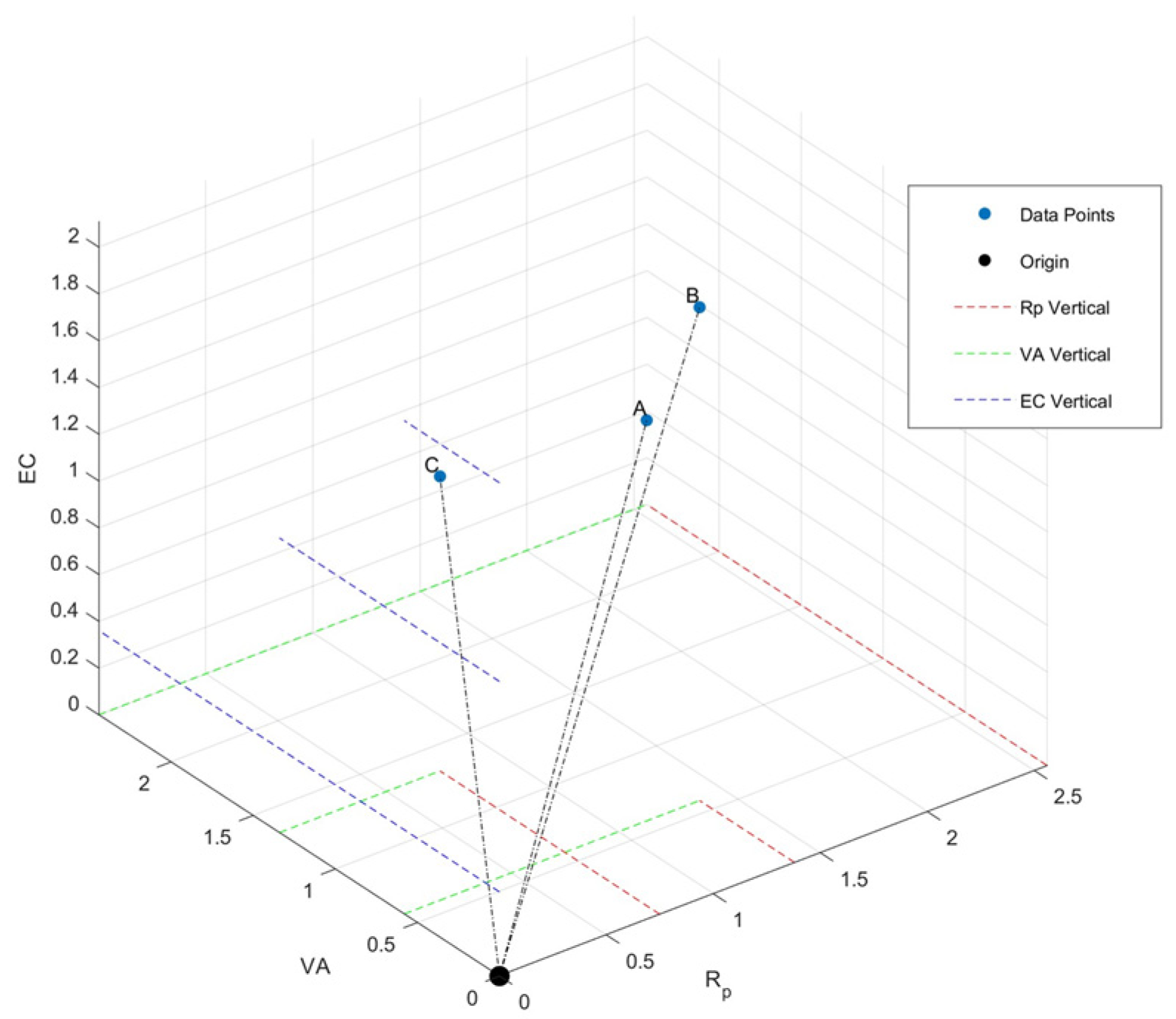

3.3.1. Three-Dimensional Diagnosis and Analysis of Circular Economy Efficiency

3.3.2. Factor Decomposition Analysis of Resource Circulation Efficiency

- (1)

- Decomposition of resource productivity indicators at the input end

- (2)

- Decomposition of end value-added output rate at circulation end

- (3)

- Decomposition of environmental efficiency index at output end

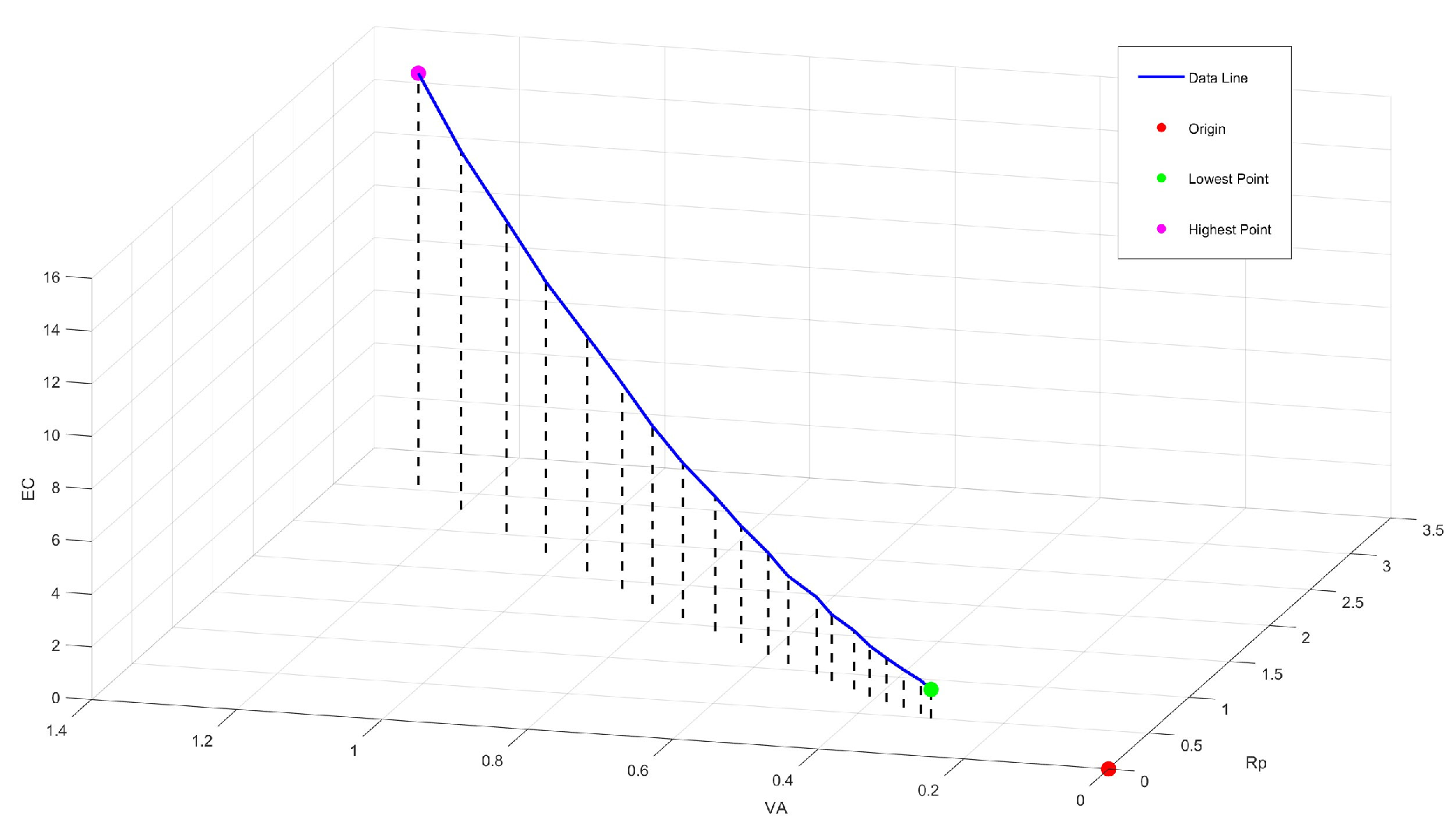

3.3.3. Optimisation Planning Analysis

- (1)

- Single-factor change analysis. Under the condition that other factors remain unchanged, the influence of changing a single factor on the resource circulation efficiency () is analysed. If the resource productivity () is increased, the resource circulation efficiency ( will increase at the same time, while other factors remain unchanged. Or, even if the environmental efficiency ( is reduced if the output rate of added value ( increases year-on-year, it will not affect the overall efficiency of resource circulation ( and will not lead to a decline in the CE’s overall efficiency. Assuming that the effective utilisation value of resources in an enterprise remains unchanged and the resource recycling rate increases, the input value of new resources will decrease while the transfer value will increase, which will eventually enhance the value-added output rate (. Meanwhile, an increase in the resource recycling rate will drive down resource abandonment loss and improve environmental efficiency (.

- (2)

- Multi-factor structure linkage analysis. In the practice of CE, the efficiency of resource circulation is usually not attributed to a change in a single factor but to multiple factors. Due to the interdependencies among factors, a change in one factor causes changes in other factors. When enterprises implement CE policies, they can make use of this rule to make optimal plans. For example, in the production process, recycling resources will reduce the amount of waste discharged to the environment, reduce the waste discharge per unit resource, and improve the environmental efficiency (. On the other hand, it will increase the utilisation of resources and increase the output rate of added value (. Combined with the multiplier effect of time and process, the effect of CE optimisation will be more promising. The resource circulation efficiency of the base period is marked as , and it is assumed that the average speed of environmental efficiency improvement caused by the increase in resource recovery ( is . After stages of m processes, the environmental efficiency ( should change from the original to ; The corresponding rate that affects the value-added output rate is After n stages of m processes, the value-added output rate should change from to . The resource circulation efficiency at that time becomes:

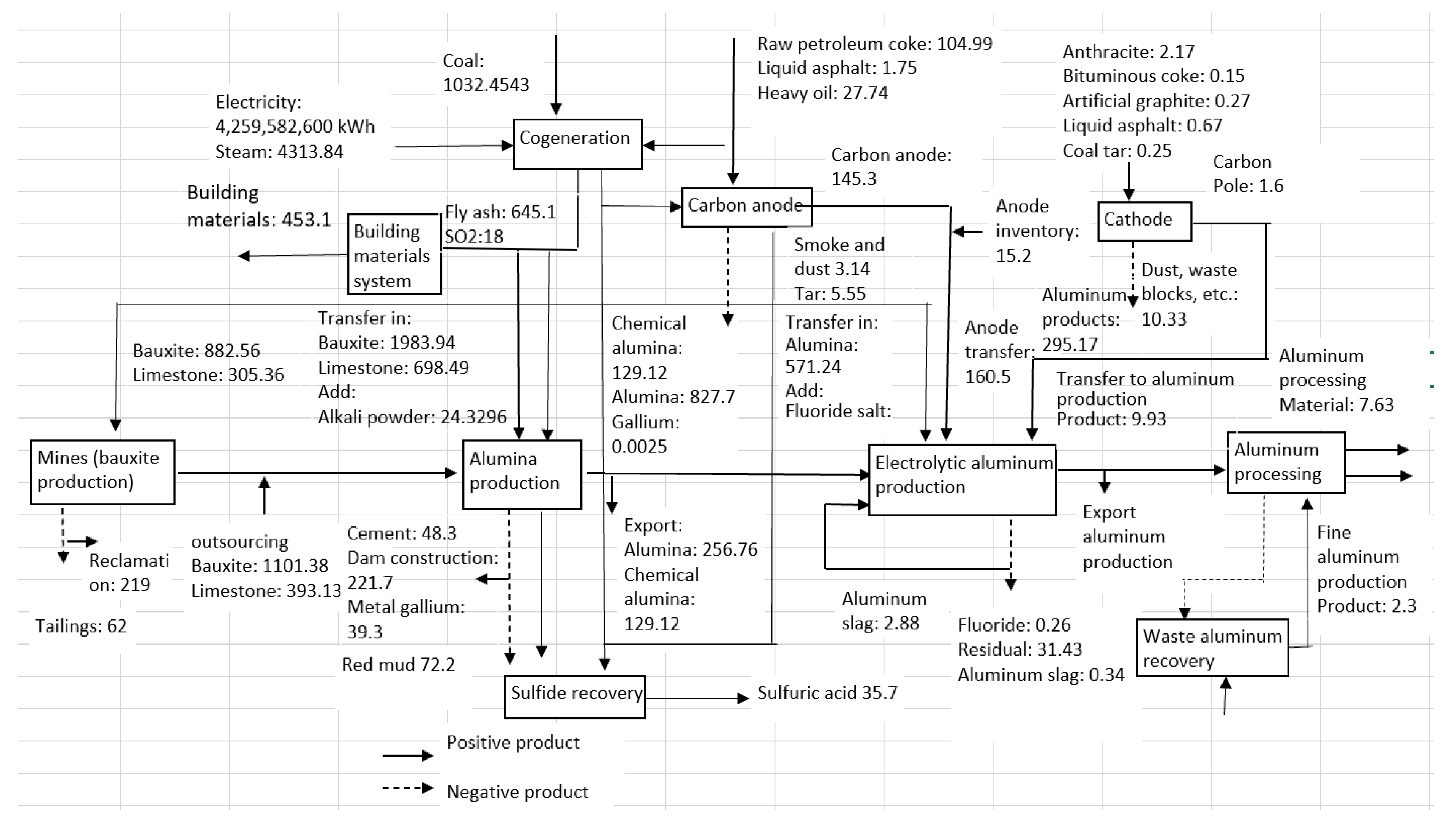

4. Case Study

4.1. Case Enterprise Resource Circulation Efficiency Status

4.2. Selection of Optimisation Measures

- (1)

- Measures to improve resource productivity at the input end

- (2)

- Improving the value-added efficiency of the circulation end.

- (3)

- Measures to improve environment efficiency at the output end

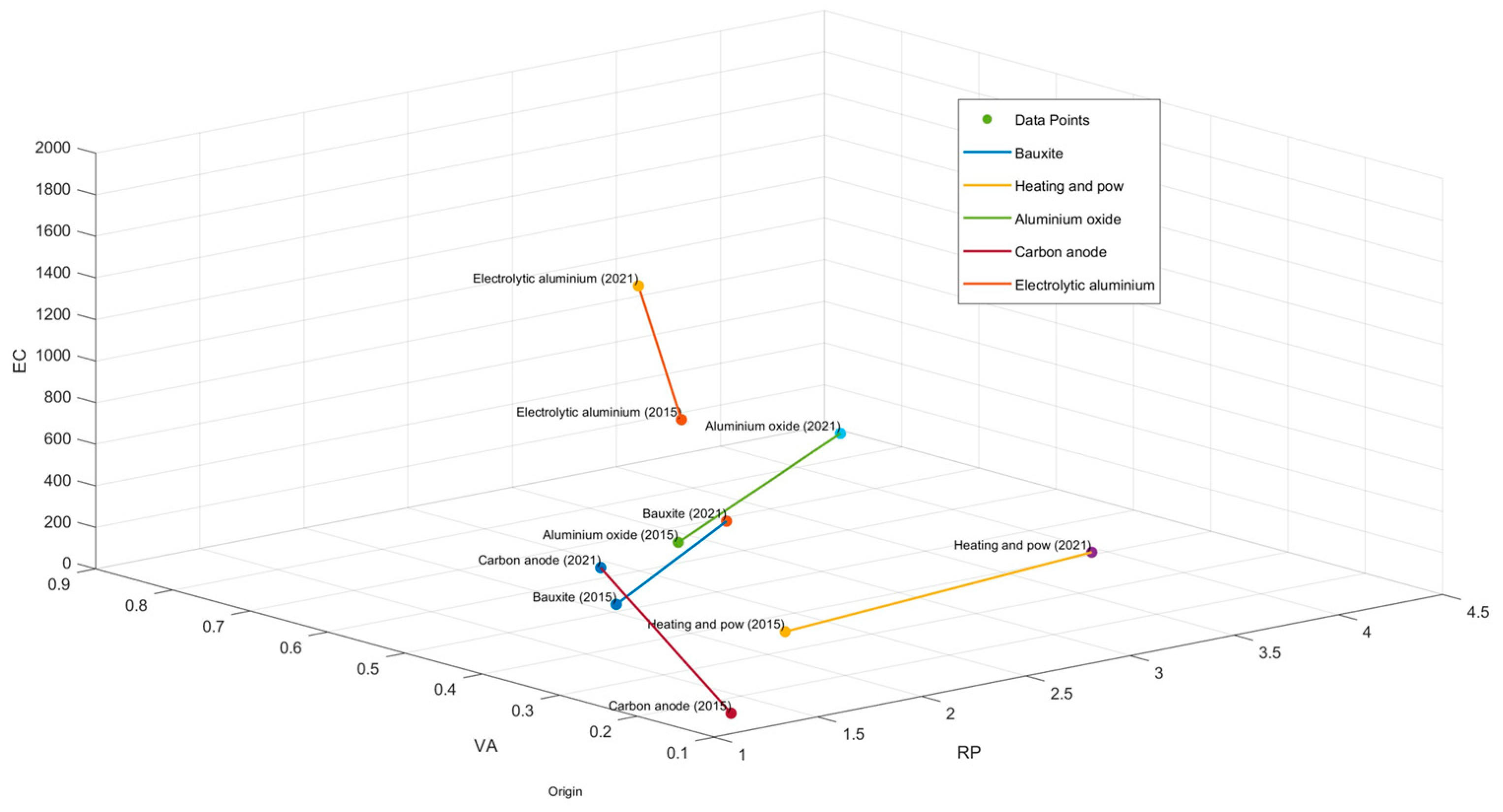

4.3. Optimisation Results and Comparison

5. Discussions of Findings

- (1)

- The resource circulation efficiency equation and associated evaluation methods could measure both environmental and economic benefits. They effectively assess circular economy implementation efficiency by decomposing the indicators according to the resource flow path. This approach not only aligns with the “3R” principle of the circular economy but also identifies optimisation pathways, offering clear guidance for enterprises to implement the circular economy.

- (2)

- However, the evaluation method system presented in this paper has limitations. It relies heavily on acquiring data related to physical quantities, costs, environmental factors, and technologies; these data were sourced from various literature, production site specifications, financial records, and environmental management reports. The broad range of data sources and the complexity of accounting processes somewhat compromise result accuracy. The cost-benefit analyses in the case studies are partly theoretical, requiring further validation to ascertain the actual economic and environmental benefits during implementation.

- (3)

- When the resource cycle efficiency equation optimises a circular economy, it may also produce results that do not meet our expectations. One possible reason is the cost-benefit comparison of optimisation measures; another is the lack of motivation for enterprises to improve; they may be more inclined to improve economic benefits rather than environmental benefits, or to improve economic benefits while ignoring environmental benefits, which will eventually lead to the decline of resource recycling efficiency, especially in some areas with poor environmental protection concepts. This requires that, in addition to economic power, there also needs to be other external power to promote the improvement of circular economy efficiency.

- (4)

- To improve accuracy and applicability, enterprises should consider establishing relevant databases for information collection when implementing the resource recycling efficiency equation for circular economy optimisation. A comprehensive database not only provides more reliable data sources but also facilitates long-term data comparison across different periods, enabling more effective cost-benefit analyses of optimisation measures.

6. Conclusions

- (1)

- The resource circulation efficiency equation draws inspiration from the resource value distribution theory within the value flow analysis. It posits that waste’s value encompasses both the loss of resources and potential environmental harm. This method’s formulated resource circulation efficiency equation encompasses not only economic gains (resource recycling value) but also addresses environmental benefits (external environmental damage value) and social advantages (economic added value). By quantifying these three dimensions, the resulting assessment and analysis system becomes more comprehensive and succinct.

- (2)

- The resource circulation efficiency equation is dissected into three components: input, circulation, and output—aligned with the CE’s “3R” principle. Here, the resource input’s productivity corresponds to CE’s “reduction” principle, while the output’s value-added rate relates to the “recycling” concept. Furthermore, environmental efficiency aligns with the CE’s “reuse” objective. These segments form a visual decision-making tool, aiding enterprises in making optimal CE choices.

- (3)

- Employing the resource circulation efficiency equation as a foundation, the use of a three-dimensional diagram, factorisation, and optimisation planning analysis empowers enterprises to streamline CE practices. By applying this methodology, the case study company enhances resource circulation efficiency, demonstrating the practical effectiveness of this approach.

- (4)

- The case study used in this paper is limited to an aluminium company located in the western province of China and does not represent other industries or regions. Theoretically, the evaluation model is suitable for most process-oriented production enterprises, but due to many limitations, it has not been applied at a larger level. Therefore, the universality of this model still has some defects and needs more case verification. In addition, the resource circulation efficiency equation and its optimisation model are based on the value stream analysis of the circular economy, and the data comes from the value stream analysis. Therefore, the proposed index system is more applicable to enterprises that actually apply value stream analysis.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mahroof, K.; Omar, A.; Rana, N.P.; Sivarajah, U.; Weerakkody, V. Drone as a Service (DaaS) in promoting cleaner agricultural production and Circular Economy for ethical Sustainable Supply Chain development. J. Clean. Prod. 2020, 287, 125522. [Google Scholar] [CrossRef]

- Garza-Reyes, J.A.; Kumar, V.; Batista, L.; Cherrafi, A.; Rocha-Lona, L. From linear to circular manufacturing business models. J. Manuf. Technol. Manag. 2019, 30, 554–560. [Google Scholar] [CrossRef]

- Garcia-Bernabeu, A.; Hilario-Caballero, A.; Pla-Santamaria, D.; Salas-Molina, F. A Process Oriented MCDM Approach to Construct a Circular Economy Composite Index. Sustainability 2020, 12, 618. [Google Scholar] [CrossRef]

- Agrawal, R.; Wankhede, V.A.; Kumar, A.; Luthra, S.; Huisingh, D. Progress and trends in integrating Industry 4.0 within Circular Economy: A comprehensive literature review and future research propositions. Bus. Strat. Environ. 2021, 31, 559–579. [Google Scholar] [CrossRef]

- Morais, J.; Corder, G.; Golev, A.; Lawson, L.; Ali, S. Global review of human waste-picking and its contribution to poverty alleviation and a circular economy. Environ. Res. Lett. 2022, 17, 063002. [Google Scholar] [CrossRef]

- Bassi, F.; Guidolin, M. Resource Efficiency and Circular Economy in European SMEs: Investigating the Role of Green Jobs and Skills. Sustainability 2021, 13, 12136. [Google Scholar] [CrossRef]

- Ludlow, J.; Jalil-Vega, F.; Rivera, X.S.; Garrido, R.A.; Hawkes, A.; Staffell, I.; Balcombe, P. Organic waste to energy: Resource potential and barriers to uptake in Chile. Sustain. Prod. Consum. 2021, 28, 1522–1537. [Google Scholar] [CrossRef]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The circular economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Schaltegger, S.; Synnestvedtb, T. The link between ‘green’ and economic success: Environmental management as the crucial trigger between environmental and economic performance. J. Environ. Manag. 2002, 65, 339–346. [Google Scholar] [CrossRef]

- Brunner, P.H.; Rechberger, H. Practical Handbook of Material Flow Analysis. Int. J. Life Cycle Assess. 2004, 9, 337–338. [Google Scholar] [CrossRef]

- Boulding, K. The economics of the coming spaceship earth. In Environmental Quality in a Growing Economy; Jarrett, H., Ed.; Resources for the Future/Johns Hopkins University Press: London, UK, 1966; pp. 3–14. [Google Scholar]

- Rizos, V.; Behrens, A.; Van der Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Flamos, A.; Rinaldi, R.; Papadelis, S.; Hirschnitz-Garbers, M.; et al. Implementation of Circular Economy Business Models by Small and Medium-Sized Enterprises (SMEs): Barriers and Enablers. Sustainability 2016, 8, 1212. [Google Scholar] [CrossRef]

- Škrinjarić, T. Dynamic portfolio optimization based on grey relational analysis approach. Expert Syst. Appl. 2020, 147, 113207. [Google Scholar] [CrossRef]

- Huyen, D.T.T.; Tram, L.T.B.; Truong, H.N.; Van Thanh, T. Application of fuzzy analytic hierarchy process and linear goal programing for selection of best available techniques of the cold rolled coil manufacturing processes: A case study in Binh Duong, Vietnam. Environ. Qual. Manag. 2021, 31, 325–346. [Google Scholar] [CrossRef]

- Govindan, K.; Nasr, A.K.; Karimi, F.; Mina, H. Circular economy adoption barriers: An extended fuzzy best–worst method using fuzzy DEMATEL and Supermatrix structure. Bus. Strat. Environ. 2022, 31, 1566–1586. [Google Scholar] [CrossRef]

- Tian, X.; Xie, J.; Xu, M.; Wang, Y.; Liu, Y. An infinite life cycle assessment model to re-evaluate resource efficiency and environmental impacts of circular economy systems. Waste Manag. 2022, 145, 72–82. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, X.; Wu, X.; Lu, C.-C. The environmental health and energy efficiency in China: A network slacks-based measure. Energy Environ. 2021, 33, 170–188. [Google Scholar] [CrossRef]

- Ding, L.-L.; Lei, L.; Wang, L.; Zhang, L.-F. Assessing industrial circular economy performance and its dynamic evolution: An extended Malmquist index based on cooperative game network DEA. Sci. Total. Environ. 2020, 731, 139001. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, Y.; Tian, S.; Yuan, X.; Ma, Q.; Liu, M.; Li, Y.; Liu, J. Evaluation and optimization of a circular economy model integrating planting and breeding based on the coupling of emergy analysis and life cycle assessment. Environ. Sci. Pollut. Res. 2021, 28, 62407–62420. [Google Scholar] [CrossRef]

- Gervasio, H. The role of resource efficiency towards circular economy. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012057. [Google Scholar] [CrossRef]

- Strothman, P.; Sonnemann, G. Circular economy, resource efficiency, life cycle innovation: Same objectives, same impacts? Int. J. Life Cycle Assess. 2017, 22, 1327–1328. [Google Scholar] [CrossRef]

- Tashkeel, R.; Rajarathnam, G.P.; Wan, W.; Soltani, B.; Abbas, A. Cost-Normalized Circular Economy Indicator and Its Application to Post-Consumer Plastic Packaging Waste. Polymers 2021, 13, 3456. [Google Scholar] [CrossRef] [PubMed]

- Rem, M.P.C. A Robust Indicator for Promoting Circular Economy through Recycling. J. Environ. Prot. 2015, 6, 1095–1104. [Google Scholar]

- Maldonado-Romo, J.; Aldape-Pérez, M. Sustainable Circular Micro Index for Evaluating Virtual Substitution Using Machine Learning with the Path Planning Problem as a Case Study. Sustainability 2021, 13, 13436. [Google Scholar] [CrossRef]

- Vardopoulos, I.; Konstantopoulos, I.; Zorpas, A.A.; Limousy, L.; Bennici, S.; Inglezakis, V.J.; Voukkali, I. Sustainable metropolitan areas perspectives through assessment of the existing waste management strategies. Environ. Sci. Pollut. Res. 2020, 28, 24305–24320. [Google Scholar] [CrossRef] [PubMed]

- Nowakowski, P.; Król, A. The influence of preliminary processing of end-of-life tires on transportation cost and vehicle exhausts emissions. Environ. Sci. Pollut. Res. 2020, 28, 24256–24269. [Google Scholar] [CrossRef] [PubMed]

- Gu, F.; Hall, P.; Miles, N.J. Performance evaluation for composites based on recycled polypropylene using principal component analysis and cluster analysis. J. Clean. Prod. 2016, 115, 343–353. [Google Scholar] [CrossRef]

- Aloini, D.; Dulmin, R.; Mininno, V.; Stefanini, A.; Zerbino, P. Driving the Transition to a Circular Economic Model: A Systematic Review on Drivers and Critical Success Factors in Circular Economy. Sustainability 2020, 12, 10672. [Google Scholar] [CrossRef]

- Antonopoulos, I.; Faraca, G.; Tonini, D. Recycling of post-consumer plastic packaging waste in the EU: Recovery rates, material flows, and barriers. Waste Manag. 2021, 126, 694–705. [Google Scholar] [CrossRef] [PubMed]

- Puntillo, P.; Gulluscio, C.; Huisingh, D.; Veltri, S. Reevaluating waste as a resource under a circular economy approach from a system perspective: Findings from a case study. Bus. Strat. Environ. 2020, 30, 968–984. [Google Scholar] [CrossRef]

- Meglin, R.; Kytzia, S.; Habert, G. Regional circular economy of building materials: Environmental and economic assessment combining Material Flow Analysis, Input-Output Analyses, and Life Cycle Assessment. J. Ind. Ecol. 2021, 26, 562–576. [Google Scholar] [CrossRef]

- Iacovidou, E.; Hahladakis, J.N.; Purnell, P. A systems thinking approach to understanding the challenges of achieving the circular economy. Environ. Sci. Pollut. Res. 2020, 28, 24785–24806. [Google Scholar] [CrossRef] [PubMed]

- Higashida, A. Supply chain MFCA implementation: Emphasizing evidence on coordination. Sustain. Account. Manag. Policy J. 2020, 12, 695–718. [Google Scholar] [CrossRef]

- Xiao, X.; Zhen, J.; Zeng, H. Research on MFCA-Based Priority Ranking Method for Waste Recycling and Its Application. Sci. Technol. Prog. Policy. 2017. Available online: http://en.cnki.com.cn/Article_en/CJFDTotal-KJJB201709009.htm (accessed on 2 July 2024).

- Fakoya, M.B.; Imuezerua, E.O. Identifying ‘True’ Water Loss Information through the MFCA Model for Improved Cost-Saving Decisions in a Water Utility: A Case Study of the Doorndraai Water Treatment Scheme in South Africa. Sustainability 2020, 12, 7824. [Google Scholar] [CrossRef]

- Nakajima, M.; Kimura, A.; Wagner, B. Introduction of material flow cost accounting (MFCA) to the supply chain: A questionnaire study on the challenges of constructing a low-carbon supply chain to promote resource efficiency. J. Clean. Prod. 2015, 108, 1302–1309. [Google Scholar] [CrossRef]

- Prox, M. Material Flow Cost Accounting Extended to the Supply Chain—Challenges, Benefits and Links to Life Cycle Engineering. Procedia CIRP 2015, 29, 486–491. [Google Scholar] [CrossRef]

- Wan, Y.K.; Ng, R.T.; Ng, D.K.; Tan, R.R. Material flow cost accounting (MFCA)–based approach for prioritisation of waste recovery. J. Clean. Prod. 2015, 107, 602–614. [Google Scholar] [CrossRef]

- Tran, T.T.; Herzig, C. Material Flow Cost Accounting in Developing Countries: A Systematic Review. Sustainability 2020, 12, 5413. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhao, W.; Chen, X.; Zeng, H. MFCA extension from a circular economy perspective: Model modifications and case study. J. Clean. Prod. 2017, 149, 110–125. [Google Scholar] [CrossRef]

- Hyršlová, J.; Vágner, M.; Palásek, J. Material Flow Cost Accounting (Mfca)—Tool for the Optimization of Corporate Production Processes. Bus. Manag. Educ. 2011, 9, 5–18. [Google Scholar] [CrossRef]

- Ho, J.Y.; Ng, D.K.; Wan, Y.K.; Andiappan, V. Synthesis of wastewater treatment plant based on minimal waste generation cost: A material flow cost accounting (MFCA) approach. Process. Saf. Environ. Prot. 2020, 148, 559–578. [Google Scholar] [CrossRef]

- Jin, Y. Study on the Expansion of Resource Value Flow Accounting in the Eco-Industrial Park:From the Perspective of Waste Recovery. Accounting Research. 2018. Available online: http://en.cnki.com.cn/Article_en/CJFDTotal-KJYJ201809003.htm (accessed on 2 July 2024).

- Sinha, E. Circular economy—A way forward to Sustainable Development: Identifying Conceptual Overlaps and Contingency Factors at the Microlevel. Sustain. Dev. 2021, 30, 771–783. [Google Scholar] [CrossRef]

- Zou, T.; Zeng, H.; Zhou, Z.; Xiao, X. A three-dimensional model featuring material flow, value flow and organization for environmental management accounting. J. Clean. Prod. 2019, 228, 619–633. [Google Scholar] [CrossRef]

- Arieftiara, D.; Theresa, R.M.; Sari, R. Sustainability in Health Service Industry: The Implementation of Material Flow Cost Accounting (MFCA) as an Eco-Efficient Analysis. J. Southeast Asian Res. 2021, 2021, 747009. [Google Scholar] [CrossRef]

- Ehrlich, P.; Holdren, J. Impact of Population Growth in Population, Esources and the Environment; US Government Printing Office: Washington, DC, USA, 1972.

- Ma, S.; Hu, S.; Chen, D.; Zhu, B. A case study of a phosphorus chemical firm’s application of resource efficiency and eco-efficiency in industrial metabolism under circular economy. J. Clean. Prod. 2015, 87, 839–849. [Google Scholar] [CrossRef]

- Kaya, Y. Impact of Carbon Dioxide Emission Control on GNP Growth: Interpretation of Proposed Scenarios IPCC Energy and Industry Subgroup, Response Strategies Working Group. 1990. Available online: http://www.researchgate.net/publication/312468754_Impact_of_carbon_dioxide_emission_control_on_GNP_growth_interpretation_of_proposed_scenarios_IPCC_energy_and_industry_subgroup_response_strategies_working_group (accessed on 2 July 2024).

- BS EN ISO 14051:2011; Environmental Management. Material Flow Cost Accounting. General Framework. 2011. Available online: https://bsol.bsigroup.com/Bibliographic/BibliographicInfoData/000000000030252700 (accessed on 2 July 2024).

- Wagiman, A.; Mustapa, M.S.; Lajis, M.A.; Shamsudin, S.; Masirin, M.I.M.; Rady, M.H. Direct Recycling of Aluminium Chips into Composite Reinforced with In Situ Alumina Enrichment. Mater. Sci. Forum 2020, 975, 165–170. [Google Scholar] [CrossRef]

- McGee, C.F.; Storey, S.; Clipson, N.; Doyle, E. Soil microbial community responses to contamination with silver, aluminium oxide and silicon dioxide nanoparticles. Ecotoxicology 2017, 26, 449–458. [Google Scholar] [CrossRef] [PubMed]

- Soo, V.K.; Peeters, J.R.; Compston, P.; Doolan, M.; Duflou, J.R. Economic and Environmental Evaluation of Aluminium Recycling based on a Belgian Case Study. Procedia Manuf. 2019, 33, 639–646. [Google Scholar] [CrossRef]

- Wang, L.; Hu, G.; Lyu, F.; Yue, T.; Tang, H.; Han, H.; Yang, Y.; Liu, R.; Sun, W. Application of Red Mud in Wastewater Treatment. Minerals 2019, 9, 281. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X. Current Situations of Tailings Utilization and Sustainable Development of Mines. Mineral Engineering Research. 2018. Available online: http://en.cnki.com.cn/Article_en/CJFDTOTAL-KTGC201801007.htm(accessed on 2 July 2024).

| Index | Notation | Formula | Component in Input-Output Transformation Map |

|---|---|---|---|

| Resource Circulation Efficiency | Whole system | ||

| Factors | Notations | Formula | Component in Input-Output Transformation Map |

| Resource Productivity | Input | ||

| Value-added output rate | Resource circulation | ||

| Environmental efficiency | Waste discharge |

| Factor | Notation | Formula |

|---|---|---|

| energy productivity | ||

| r aw material productivity | ||

| productivity of other resources | ||

| new resource input rate | ||

| secondary energy input rate | ||

| effective utilisation rate of resource cost | ||

| waste cost loss rate of the i process | ||

| internal recycling rate | ||

| pollution damage value per unit added value | ||

| recovery rate of the added value |

| Factors/Efficiency | Bauxite Mining | Heating and Power Plant | Aluminium Oxide | Carbon Anode | Electrolytic Aluminium | Aluminium Processing |

|---|---|---|---|---|---|---|

| Resource productivity () | 2.08648 | 2.273544 | 2.870313 | 1.119183 | 1.28989 | 1.280985 |

| Output rate of added value ( | 0.520724 | 0.347748 | 0.651605 | 0.106486 | 0.22474 | 0.219351 |

| Environmental efficiency ( | 0.276087 | 5.27919 | 13.89719 | 82.2098 | 1349.528 | 20,533.88 |

| Resource circulation efficiency ( | 0.299964 | 4.173832 | 25.99225 | 9.797294 | 391.2363 | 5767.013 |

| Index/Factor | Bauxite | Heating and Power Plant | Aluminium Oxide | Carbon | Electrolytic Aluminium | Aluminium Processing | Recycled Aluminium |

|---|---|---|---|---|---|---|---|

| Resource productivity ( | 3.247565 | 3.894779 | 4.390702 | 1.572901 | 1.381099 | 1.534799 | 1.649101 |

| Output rate of added value ( | 0.685251 | 0.389494 | 0.8466 | 0.3993 | 0.3025 | 0.382 | 0.4315 |

| Environmental efficiency ( | 0.483355 | 28.96032 | 36.90037 | 400 | 1893.939 | 76,923.08 | / |

| Resource circulation efficiency ( | 1.075656 | 43.93287 | 137.1742 | 251.1932 | 791.1392 | 45,454.55 | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Xie, Y.; Liang, W. Optimisation of the Circular Economy Based on the Resource Circulation Equation. Sustainability 2024, 16, 6514. https://doi.org/10.3390/su16156514

Liu S, Xie Y, Liang W. Optimisation of the Circular Economy Based on the Resource Circulation Equation. Sustainability. 2024; 16(15):6514. https://doi.org/10.3390/su16156514

Chicago/Turabian StyleLiu, Sanhong, Ying Xie, and Wen Liang. 2024. "Optimisation of the Circular Economy Based on the Resource Circulation Equation" Sustainability 16, no. 15: 6514. https://doi.org/10.3390/su16156514

APA StyleLiu, S., Xie, Y., & Liang, W. (2024). Optimisation of the Circular Economy Based on the Resource Circulation Equation. Sustainability, 16(15), 6514. https://doi.org/10.3390/su16156514