Assessing the Carbon Footprint of Viticultural Production in Central European Conditions

Abstract

1. Introduction

2. Materials and Methods

2.1. The Viticultural Area

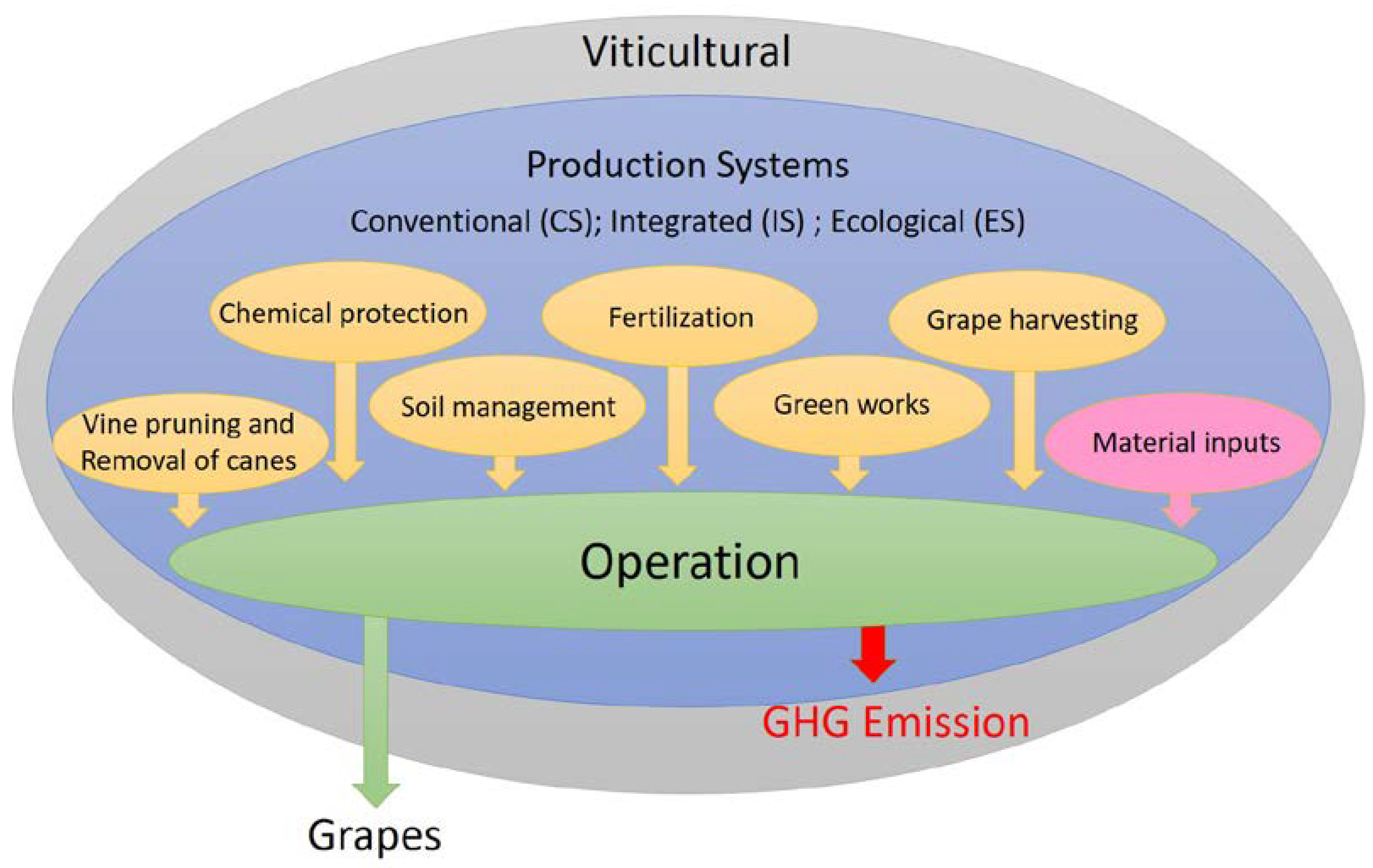

2.2. Data Acquisition and System Boundaries

2.3. Life Cycle Inventory (LCI)

2.4. The Software Used and Determination of the Carbon Footprint (CO2eq)

- Greenhouse gas emissions from fertilizer production and transport (kg CO2eq·ha−1·year−1), these calculations include emissions due to the neutralization of acidification caused by fertilizer. The calculation used here accounts for CO2 emissions from the neutralization of nitrogen fertilizer acidity;

- Greenhouse gas emissions from the pesticides used (kg CO2eq·ha−1·year−1);

- Greenhouse gas emissions from the fuel used for the operation of machinery means (kg CO2eq∙ha−1·year−1) [41].

- mhni je is the amount of the i-th fertilizer (expressed in pure nutrients) that is used on one hectare of land per year;

- efhni is the emission factor from the production and transport of i-th fertilizer (kg CO2eq·kg nutrient−1) [41].

- 4.5719 kg CO2eq·kg nutrient−1 applied for nitrogen fertilizers;

- 0.5417 kg CO2eq·kg nutrient−1 applied for phosphate fertilizer (P2O5);

- 0.4167 kg CO2eq·kg nutrient−1 applied for potassium fertilizer application in the form of K2O.

- mpei is the amount of the i-th pesticide used per one hectare of land per year;

- efpei is the emission factor from the production of the i-th pesticide (kg CO2eq·kg nutrients−1) [41].

- 11.552 kg CO2eq·kg active substance−1 for glyphosate;

- 10.970 kg CO2eq·kg active substance−1 for other plant protection products (ISCC System GmbH, Koeln, Germany, 2021).

- Spali is the total annual amount of the i-th fuel (in this case diesel) used per hectare of land per year (l·ha−1·year−1);

- efpali is the emission factor from the consumption of the i-th fuel (kg CO2eq·l−1).

2.5. Statistical Evaluation Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Raihan, A.; Begum, R.; Nizam, M. A meta-analysis of the economic value of forest carbon stock. Malays. J. Soc. Space 2021, 17, 321–338. [Google Scholar] [CrossRef]

- Metz, B.; Davidson, O.R.; Bosch, P.R.; Dave, R.; Meyer, L.A. (Eds.) Climate Change 2007 Mitigation of Climate Change; Cambridge University Press: New York, NY, USA, 2007; p. 851. [Google Scholar]

- Rinaldi, S.; Bonamente, E.; Scrucca, F.; Merico, M.C.; Asdrubali, F.; Cotana, F. Water and Carbon Footprint of Wine: Methodology Review and Application to a Case Study. Sustainability 2016, 8, 621. [Google Scholar] [CrossRef]

- Report: International Organization of Vine and Wine, OIV State of the World Vine and Wine Sector in 2023, Dijon, France. 2024, p. 21. Available online: https://www.oiv.int/sites/default/files/2024-04/OIV_STATE_OF_THE_WORLD_VINE_AND_WINE_SECTOR_IN_2023.pdf (accessed on 14 June 2024).

- FAOSTAT. Food and Agriculture Organization of the United Nations (FAO). Statistics. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 7 July 2024).

- European Commission. Commission Implementing Regulation (EU) 2020/2087 of 14 December 2020, Concerning the Non-Renewal of the Approval of the Active Substance Mancozeb. Off. J. Eur. Union 2020, L 423, 50–52.

- Roy, P.; Nei, D.; Orikasa, T.; Xu, Q.; Okadome, H.; Nakamura, N.; Shiina, T. A review of life cycle assessment (LCA) on some food products. J. Food Eng. 2009, 90, 1–10. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Villanueva-Rey, P.; Iribarren, D.; Teresa Moreira, M.; Feijoo, G. Joint life cycle assessment and data envelopment analysis of grape production for vinification in the Rías Baixas appellation (NW Spain). J. Clean. Prod. 2012, 27, 92–102. [Google Scholar] [CrossRef]

- Neto, B.; Dias, A.C.; Machado, M. Life cycle assessment of the supply chain of a Portuguese wine: From viticulture to distribution. Int. J. Life Cycle Assess. 2013, 18, 590–602. [Google Scholar] [CrossRef]

- Rugani, B.; Vázquez-Rowe, I.; Benedetto, G.; Benetto, E. A comprehensive review of carbon footprint analysis as an extended environmental indicator in the wine sector. J. Clean. Prod. 2013, 54, 61–77. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Čuček, L.; Klemeš, J.J.; Kravanja, Z. A Review of Footprint analysis tools for monitoring impacts on sustainability. J. Clean. Prod. 2012, 34, 9–20. [Google Scholar] [CrossRef]

- Laurent, A.; Olsen, S.; Hauschild, M. Limitations of Carbon Footprint as Indicator of Environmental Sustainability. Environ. Sci. Technol. 2012, 46, 4100–4108. [Google Scholar] [CrossRef] [PubMed]

- Scipioni, A.; Mazzi, A.; Manzardo, A.; Mastrobuono, M. Monitoring the carbon footprint of products: A methodological proposal. J. Clean. Prod. 2012, 36, 94–101. [Google Scholar] [CrossRef]

- Wiedmann, T.; Minx, J. A Definition of Carbon Footprint. CC Pertsova Ecol. Econ. Res. Trends 2008, 2, 55–65. [Google Scholar]

- Bosco, S.; Di Bene, C.; Galli, M.; Remorini, D.; Massai, R.; Bonari, E. Greenhouse gas emissions in the agricultural phase of wine production in the Maremma rural district in Tuscany, Italy. Ital. J. Agron. 2011, 6, e15. [Google Scholar] [CrossRef]

- Hammerschlag, R.; Barbour, W. Life-Cycle Assessment and Indirect Emission Reductions: Issues Associated with Ownership and Trading; Institute for Lifecycle Environmental Assessment: Seattle, WA, USA, 2003; p. 15. [Google Scholar]

- Gao, T.; Liu, Q.; Wang, J. A comparative study of carbon footprint and assessment standards. Int. J. Low-Carbon Technol. 2014, 9, 237–243. [Google Scholar] [CrossRef]

- Galli, A.; Kitzes, J.; Pulselli, R.; Borsa, S.; Marchettini, N. Ecological Footprint Analysis Applied to the Production of Two Italian Wines. Agric. Ecosyst. Environ. 2008, 128, 162–166. [Google Scholar] [CrossRef]

- Pizzigallo, A.C.I.; Granai, C.; Borsa, S. The joint use of LCA and emergy evaluation for the analysis of two Italian wine farms. J. Environ. Manag. 2008, 86, 396–406. [Google Scholar] [CrossRef]

- Benedetto, G. The environmental impact of a Sardinian wine by partial Life Cycle Assessment. Wine Econ. Policy 2013, 2, 33–41. [Google Scholar] [CrossRef]

- Fusi, A.; Guidetti, R.; Benedetto, G. Delving into the environmental aspect of a Sardinian white wine: From partial to total life cycle assessment. Sci. Total Environ. 2014, 472, 989–1000. [Google Scholar] [CrossRef]

- Ghiglieno, I.; Simonetto, A.; Facciano, L.; Tonni, M.; Donna, P.; Valenti, L.; Gilioli, G. Comparing the Carbon Footprint of Conventional and Organic Vineyards in Northern Italy. Sustainability 2023, 15, 5252. [Google Scholar] [CrossRef]

- Rouault, A.; Beauchet, S.; Renaud-Gentie, C.; Jourjon, F. Life Cycle Assessment of Viticultural Technical Management Routes (TMRs): Comparison Between an Organic and an Integrated Management Route. OENO One 2016, 50, 77–89. [Google Scholar] [CrossRef]

- Navarro, A.; Puig, R.; Kılıç, E.; Penavayre, S.; Fullana-i-Palmer, P. Eco-innovation and benchmarking of carbon footprint data for vineyards and wineries in Spain and France. J. Clean. Prod. 2017, 142, 1661–1671. [Google Scholar] [CrossRef]

- Valenti, L.; Ghiglieno, I.; Sambo, F.; Pitacco, A.; Tezza, L.; Vendrame, N.; Virgili, G.; Minardi, I.; Giovenali, E.; LoBello, J. LIFE15 ENV/IT/000392—LIFE VITISOM Project, viticulture innovation technology and GHG emission monitoring. BIO Web Conf. 2019, 13, 02008. [Google Scholar] [CrossRef]

- Schneider, N.; Islam, M.; Wehrle, R.; Pätzold, S.; Brüggemann, N.; Töpfer, R.; Herzog, K. Deep incorporation of organic amendments into soils of a ‘Calardis Musqué’ vineyard: Effects on greenhouse gas emissions, vine vigor, and grape quality. Front. Plant Sci. 2023, 14, 1253458. [Google Scholar] [CrossRef]

- Lazcano, C.; Gonzalez-Maldonado, N.; Yao, E.H.; Wong, C.T.F.; Falcone, M.; Dodson Peterson, J.; Casassa, L.F.; Malama, B.; Decock, C. Assessing the Short-Term Effects of No-Till on Crop Yield, Greenhouse Gas Emissions, and Soil C and N Pools in a Cover-Cropped, Biodynamic Mediterranean Vineyard. Aust. J. Grape Wine Res. 2022, 2022, 8100818. [Google Scholar] [CrossRef]

- Zhang, J.; Ji, Y.; Guo, Y.; Yin, X.; Li, Y.; Han, J.; Liu, Y.; Wang, C.; Wang, W.; Liu, Y.; et al. Responses of soil respiration and microbial community structure to fertilizer and irrigation regimes over 2 years in temperate vineyards in North China. Sci. Total Environ. 2022, 840, 156469. [Google Scholar] [CrossRef]

- Rose, D.C.; Sutherland, W.J.; Parker, C.; Lobley, M.; Winter, M.; Morris, C.; Twining, S.; Ffoulkes, C.; Amano, T.; Dicks, L.V. Decision support tools for agriculture: Towards effective design and delivery. Agric. Syst. 2016, 149, 165–174. [Google Scholar] [CrossRef]

- Agency, E.E. EMEP/EEA Air Pollutant Emission Inventory Guidebook 2023. Available online: https://www.eea.europa.eu/publications/emep-eea-guidebook-2023/part-b-sectoral-guidance-chapters/1-energy/1-a-combustion/1-a-4-non-road/at_download/file (accessed on 28 July 2024).

- Dvořáková, I.; Filipenská, M.; Kassymova, A.; Machálek, P.; Saarikivi, R.J.; Vodičková, B.; Dědina, M.; Dufek, J.; Geiplová, H.; Kačmárová, Z.; et al. Informative Inventory Report Czechia 2023. Emission Inventories from the Base Year of the Protocols to the Year 2021. Available online: https://cdr.eionet.europa.eu/cz/un/clrtap/iir/envy90dea/CZ_IIR_2023.pdf (accessed on 20 July 2024).

- Rich, V. Soviet fertilizers: Going it alone. Nature 1980, 288, 314. [Google Scholar] [CrossRef]

- Boller, E.F.; Avilla, J.; Joerg, E.; Malavolta, C.; Wijnands, F.G.; Esbjerg, P. Integrated Production Principles and Technical Guidelines; International Organization for Biological and Integrated Control of Noxious Animals and Plants: Zurich, Switzerland, 2004; Volume 27. [Google Scholar]

- Wijnands, F.; Malavolta, C.; Alaphilippe, A.; Gerowitt, B.; Baur, R. IOBC-WPRS IP Objectives and Principles. Available online: https://iobc-wprs.org/wp-content/uploads/2022/06/IOBC-WPRS_IP_objectives_and_principles_4th_edition_2018_EN.pdf (accessed on 28 July 2024).

- Malavolta, C.; Duso, C. Grapes (for Wine and Table Grapes). Available online: https://iobc-wprs.org/ip-tools/general-and-crop-specific-ip-guidelines/grapes/ (accessed on 10 July 2024).

- Basler, P. Integrierte Produktion im Weinbau. Die Grüne 1990, 39, 9–15. [Google Scholar]

- Murisier, F.; Ryser, J.P.; Schwarz, J.J.; Hugon, F. Domaines à techniques intégrées (DTI) en viticulture: Bilan nutritionnel et viticole—Techniques of integrated production in viticulture: Nutritive and viticultural evaluation. Rev. Suisse De Vitic. Arboric. Hortic. 1992, 24, 373–379. [Google Scholar]

- EUR-Lex. Commission Implementing Regulation (EU) 2022/996 of 14 June 2022 on Rules to Verify Sustainability and Greenhouse Gas Emissions Saving Criteria and Low Indirect Land-Use Change-Risk Criteria. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32022R0996 (accessed on 14 June 2024).

- Dědina, M.; Jevič, P.; Abrham, Z.; Čermák, P.; Klír, J.; Wollnerová, J.; Beranová, J. Výpočet Typických Měrných Emisí Skleníkových Plynů z Pěstovaní a Zpracování Zemědělských Surovin pro Stanovení Hodnoty Jejich Emisních Faktorů: Certifikovaná Metodika. [Calculation of Typical Specific Emissions of Greenhouse Gases from the Cultivation and Processing of Agricultural Raw Materials to Determine the Value of Their Emission Factors: A Certified Methodology.]; Výzkumný Ústav Zemědělské Techniky: Praha, Czech Republic, 2023; p. 64. (In Czech) [Google Scholar]

- Edwards, R.; Padella, M.; Giuntoli, J.; Koeble, R.; O’ Connell, A.; Bulgheroni, C.; Marelli, L. Definition of Input Data to Assess GHG Default Emissions from Biofuels in EU Legislation; Publications Office of the European Union: Luxembourg, 2017. [Google Scholar]

- ISCC. ISCC EU 205 Greenhouse Gas Emissions; ISCC System GmbH: Köln, Germany, 2021; 61p, Available online: https://www.iscc-system.org/wp-content/uploads/2024/01/ISCC_EU_205_Greenhouse-Gas-Emissions_v4.1_January2024.pdf (accessed on 14 June 2024).

- Walg, O. Taschenbuch der Weinbautechnik, 2nd ed.; Fachverlag Dr. Fraund GmbH: Mainz, Germany, 2007. [Google Scholar]

- Villanueva-Rey, P.; Vázquez-Rowe, I.; Moreira, M.T.; Feijoo, G. Comparative life cycle assessment in the wine sector: Biodynamic vs. conventional viticulture activities in NW Spain. J. Clean. Prod. 2014, 65, 330–341. [Google Scholar] [CrossRef]

- Ponstein, H.J.; Meyer-Aurich, A.; Prochnow, A. Greenhouse gas emissions and mitigation options for German wine production. J. Clean. Prod. 2019, 212, 800–809. [Google Scholar] [CrossRef]

- Marras, S.; Masia, S.; Duce, P.; Spano, D.; Sirca, C. Carbon footprint assessment on a mature vineyard. Agric. For. Meteorol. 2015, 214, 350–356. [Google Scholar] [CrossRef]

- Pinto da Silva, L.; Esteves da Silva, J.C.G. Evaluation of the carbon footprint of the life cycle of wine production: A review. Clean. Circ. Bioecon. 2022, 2, 100021. [Google Scholar] [CrossRef]

- Tsalidis, G.A.; Kryona, Z.-P.; Tsirliganis, N. Selecting south European wine based on carbon footprint. Resour. Environ. Sustain. 2022, 9, 100066. [Google Scholar] [CrossRef]

- Tuomisto, H.L.; Hodge, I.D.; Riordan, P.; Macdonald, D.W. Does organic farming reduce environmental impacts?—A meta-analysis of European research. J. Environ. Manag. 2012, 112, 309–320. [Google Scholar] [CrossRef]

- Gierling, F.; Blanke, M. Carbon reduction strategies for regionally produced and consumed wine: From farm to fork. J. Environ. Manag. 2021, 278, 111453. [Google Scholar] [CrossRef]

- Steenwerth, K.L.; Strong, E.B.; Greenhut, R.F.; Williams, L.; Kendall, A. Life cycle greenhouse gas, energy, and water assessment of wine grape production in California. Int. J. Life Cycle Assess. 2015, 20, 1243–1253. [Google Scholar] [CrossRef]

- Bartocci, P.; Fantozzi, P.; Fantozzi, F. Environmental impact of Sagrantino and Grechetto grapes cultivation for wine and vinegar production in central Italy. J. Clean. Prod. 2017, 140, 569–580. [Google Scholar] [CrossRef]

- Litskas, V.D.; Irakleous, T.; Tzortzakis, N.; Stavrinides, M.C. Determining the carbon footprint of indigenous and introduced grape varieties through Life Cycle Assessment using the island of Cyprus as a case study. J. Clean. Prod. 2017, 156, 418–425. [Google Scholar] [CrossRef]

- Hefler, Y.T.; Kissinger, M. Grape Wine Cultivation Carbon Footprint: Embracing a Life Cycle Approach across Climatic Zones. Agriculture 2023, 13, 303. [Google Scholar] [CrossRef]

- Venkat, K. Comparison of Twelve Organic and Conventional Farming Systems: A Life Cycle Greenhouse Gas Emissions Perspective. J. Sustain. Agric. 2012, 36, 620–649. [Google Scholar] [CrossRef]

- Korsaeth, A. Relations between nitrogen leaching and food productivity in organic and conventional cropping systems in a long-term field study. Agric. Ecosyst. Environ. 2008, 127, 177–188. [Google Scholar] [CrossRef]

| Agricultural Practices | Production System | ||||||

|---|---|---|---|---|---|---|---|

| Conventional | Integrated | Ecological | |||||

| Frequency per Year | Hectare Rate | Frequency per Year | Hectare Rate | Frequency per Year | Hectare Rate | ||

| Active ingredients of fungicides and insecticides | Sulfur | 1× | 12 kg·ha−1 | 1× | 12 kg·ha−1 | 1× | 12 kg·ha−1 |

| Sulfur | – | – | – | – | 4–8× | 4 kg·ha−1 | |

| Iprovalicarb | 1× | 0.9 L·ha−1 | 1× | 0.9 L·ha−1 | – | – | |

| Metrafenone | 1–2× | 0.16 L·ha−1 | 1–2× | 0.16 L·ha−1 | – | – | |

| Cyprodinil, Fludioxonyl | 3–5× | 0.5 kg·ha−1 | 3–5× | 0.5 kg·ha−1 | – | – | |

| Fluopyram, Tebuconazole | 1–2× | 0.4 L·ha−1 | 1–2× | 0.4 L·ha−1 | – | – | |

| Valifenalate | 1–2× | 2 kg·ha−1 | 1× | 2 kg·ha−1 | – | – | |

| Difenoconazole, Cyflufenamid | 1–2× | 0.65 L·ha−1 | 1–2× | 0.65 L·ha−1 | – | – | |

| Fosetyl-Al | 1× | 3 kg·ha−1 | 1× | 3 kg·ha−1 | – | – | |

| Boscalid, Kresoxim-Methyl | 1× | 0.6 L·ha−1 | 1× | 0.6 L·ha−1 | – | – | |

| Bacillus amyloliquefaciens Folpet | 1–2× | 2 kg·ha−1 | 1–2× | 2 kg·ha−1 | – | – | |

| Cymoxanil | 1–2× | 0.25 kg·ha−1 | 1× | 0.25 kg·ha−1 | – | – | |

| Tetraconazole | 1–2× | 2 kg·ha−1 | 1× | 2 kg·ha−1 | – | – | |

| Cyazofamid | – | – | 1× | 2 L·ha−1 | – | – | |

| Lambda-Cyhalothrin | – | – | 1× | 0.15 L·ha−1 | – | – | |

| Mefentrifluconazol | – | – | 1–2× | 1 L·ha−1 | – | – | |

| Copper hydroxide | – | – | – | – | 2–4× | 2 kg·ha−1 | |

| Copper oxychloride | – | – | – | – | 3–5× | 1 L·ha−1 | |

| Magnesium sulfate—Bitter salt | – | – | – | – | 1× | 7 kg·ha−1 | |

| extract from fermentation of Lactobacillus sp., Yucca extract | – | – | – | – | 2–4× | 1 L·ha−1 | |

| Potassium hydrogen carbonate | – | – | – | – | 2–4× | 10 kg·ha−1 | |

| Sulfuric acid clay with yeast and plant extracts | – | – | – | – | 1x | 4 kg·ha−1 | |

| Active components of herbicides | Glyphosate | 1–4× | 5 L·ha−1 | 1–2× | 5 L·ha−1 | – | – |

| Fertilizer | Fertilizer PK 22 × 9 | 1× | 300 kg·ha−1 | 1× | 300 kg·ha−1 | – | – |

| Humic acids made from activated Leonardite | – | – | – | – | 1× | 200 kg·ha−1 | |

| Seeds | Standard | – | – | – | – | 1× | 30 kg·ha−1 |

| Operation | System Management (Frequency per Year; Labor Intensity; Average Diesel Consumption on One Operation) | Production System | ||

|---|---|---|---|---|

| Conventional | Integrated | Ecological | ||

| Vine pruning and related work operations (cane tying, repairing the trellis) | Mechanical winter pruning (1×; 2.5 h·ha−1; 11.5 ± 1.32 L·ha−1) with manual cutting (1×; 50 h·ha−1) | YES | YES | YES |

| Manual cane tying (1×; 25 h·ha−1) | YES | YES | YES | |

| Repair of trellis (1×; 4 h·ha−1; 6.00 ± 0.88 L·ha−1) | YES | YES | YES | |

| Removal of grape canes | Shredding of grape canes in the inter-row (1×; 1.7 h·ha−1; 8.5 ± 1.45 L·ha−1) | YES | YES | YES |

| Maintenance of the strips between two rows and in the weed free strips under the trellis | Inter-row mulching (2–4×; 1.2 h·ha−1; 8.1 ± 0.79 L·ha−1) | YES | YES | YES |

| Inter-row cultivation (3–5×; 1.0 h·ha−1; 6.9 ± 2.19 L·ha−1) | YES | YES | YES | |

| Intra-row cultivation (under the trellis) (2–4×; 2.5 h·ha−1; 13.1 ± 1.48 L·ha−1) | YES | YES | YES | |

| Chemical treatment of the strips (intra-row) (1–4×; 1.5 h·ha−1; 8.20 ± 0.32 L·ha−1) | YES | NO | NO | |

| Cover crops sowing (1×; 2.0 h·ha−1; 10.9 ± 0.55 L·ha−1) | NO | NO | YES | |

| Green works (canopy management) | Manual shoot thinning (suckering) (1×; 40 h·ha−1) | YES | YES | YES |

| Manual shoot positioning (2–3×; 50 h·ha−1) | YES | YES | YES | |

| Shoot topping (2–3×; 1.7 h·ha−1; 9.5 ± 0.15 L·ha−1) | YES | YES | YES | |

| Defoliation (1–2×; 2.5 h·ha−1; 9.0 ± 1.12 L·ha−1) | YES | YES | YES | |

| Chemical protection | Mistblowing (4–8×; 1.2 h·ha−1; 5.8 ± 1.29 L·ha−1) | YES | YES | YES |

| Fertilization | Deep root fertilization (1×; 2.6 h·ha−1; 16.5 ± 3.21 L·ha−1) | YES | YES | NO |

| Spreading organic fertilizer (1×; 1.2 h·ha−1; 7.1 ± 1.44 L·ha−1) | NO | NO | YES | |

| Grape harvesting | Fully mechanized harvesting (1×; 3.0 h·ha−1; 23.1 ± 2.45 L·ha−1) | YES | YES | YES |

| Grape removal (distance 5 km) (1×; 0.2 h·ha−1; 1.5 ± 0.10 L·ha−1) | YES | YES | YES | |

| Sum of labor intensity (h·ha−1) | 278 | 360 | 371 | |

| Sum of diesel consumption (L·ha−1) | 185 | 198 | 210 | |

| Vineyard Inputs (kg CO2eq·ha−1·Year−1) | Production System | ||

|---|---|---|---|

| Conventional | Integrated | Ecological | |

| Mean ± SD | Mean ± SD | Mean ± SD | |

| min; max | min; max | min; max | |

| Fuels for field work | 673.93 ± 62.01a | 671.86 ± 58.54a | 716.14 ± 35.27a |

| 585.24; 736.15 | 595.80; 748.10 | 640.25; 745.95 | |

| Synthetic fertilizers | 47.00 ± 16.55a | 46.83 ± 0.50a | – |

| 15.60; 62.70 | 45.40; 58.54 | – | |

| Manufacture and use of seeds | – | – | 9.49 ± 1.98a |

| – | – | 7.80; 12.40 | |

| Fungicides and insecticides | 190.68 ± 7.92b | 190.65 ± 9.22b | 753.52 ± 17.76a |

| 180.90; 210.15 | 180.00; 210.15 | 723.00; 770.1 | |

| Herbicides | 60.13 ± 18.14a | 20.74 ± 19.55b | – |

| 7.92; 82.96 | 0.00; 41.48 | – | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bača, P.; Mašán, V.; Vanýsek, P.; Burg, P.; Binar, T.; Burgová, J.; Abrham, Z. Assessing the Carbon Footprint of Viticultural Production in Central European Conditions. Sustainability 2024, 16, 6561. https://doi.org/10.3390/su16156561

Bača P, Mašán V, Vanýsek P, Burg P, Binar T, Burgová J, Abrham Z. Assessing the Carbon Footprint of Viticultural Production in Central European Conditions. Sustainability. 2024; 16(15):6561. https://doi.org/10.3390/su16156561

Chicago/Turabian StyleBača, Petr, Vladimír Mašán, Petr Vanýsek, Patrik Burg, Tomáš Binar, Jana Burgová, and Zdeněk Abrham. 2024. "Assessing the Carbon Footprint of Viticultural Production in Central European Conditions" Sustainability 16, no. 15: 6561. https://doi.org/10.3390/su16156561

APA StyleBača, P., Mašán, V., Vanýsek, P., Burg, P., Binar, T., Burgová, J., & Abrham, Z. (2024). Assessing the Carbon Footprint of Viticultural Production in Central European Conditions. Sustainability, 16(15), 6561. https://doi.org/10.3390/su16156561