Abstract

Current international waste policy promotes the reduction and re-use of waste materials, and in some cases, specifically calls for the use of recycled materials in pavements. Consequently, there is a need to understand the performance of recycled materials in airport pavements, as well as the overall sustainability benefit. This paper reviews several recycled materials and their applications to asphalt concrete, cement concrete, and bound and unbound granular materials in the context of airport pavements. Additionally, it reviews sustainability quantification methods, as well as implementation challenges for using recycled materials in airport pavements. For comparing pavements with and without recycled materials, a triple bottom line approach is appropriate. The triple bottom line approach should use life cycle cost assessment and life cycle assessment for the financial and environmental impacts, respectively, as best-practice, with frameworks and guidelines already established. For social impacts, it is recommended to quantify the reduction in virgin material use which relates to intergenerational equity by ensuring access to materials by future generations. Because there are still implementation challenges for the airport pavement industry, principles are developed that aim to promote uptake of recycled materials. These principles include sorting and processing, minimising haulage distances, and ensuring performance of pavement layers through performance testing and performance-related specifications.

1. Introduction

Aircraft movement areas at airports are constructed of either flexible or rigid pavement. Although the fundamental design, construction and maintenance of airport pavements is similar in nature to roads, the design traffic of aircraft presents increased performance requirements [1]. This is because aircraft are heavier, have higher tyre pressures, are more susceptible to undulations in pavement surface, and can suffer catastrophic damage to fragile aircraft engines by loose stones [2]. This results in a slower uptake of new technologies, such as the incorporation of recycled materials. However, there is significant momentum across multiple governments to reduce and re-use waste for the purposes of environmental sustainability [3,4,5], with examples of policy specifically calling out the use of recycled materials in pavements [5]. Consequently, there is a need to understand the performance of recycled materials in airport pavements, as well as the overall sustainability benefit.

Recycled materials that have been used in pavements include waste plastics, recycled crushed glass, industrial slag, coal combustion products, crumbed rubber, recycled asphalt pavement, and recycled concrete aggregate [6,7,8]. Although some categories of recycled materials have been used in airport pavements for over 50 years [7], not all recycled materials will perform in every application. Additionally, the optimum recycled material content should be confirmed via laboratory performance testing, and validated via field investigation and full-scale tests where possible [9]. Furthermore, the performance of recycled materials in airport pavements should be as good, or better, than virgin materials to ensure suitability for aircraft traffic and to ensure comparable durability.

Implementation of recycled materials into airport pavements requires an objective sustainability quantification method to accurately detail the benefits. Sustainability measurements typically use the triple bottom line (TBL), which includes quantification of financial, environmental, and social impacts [10]. For financial quantification, life cycle cost assessment (LCCA) is preferred to ensure the whole-of-life-costs are accounted for [11]. For environmental quantification, contemporary practice is to assess environmental impacts using a life cycle assessment (LCA), which estimates energy inputs and greenhouse gas (GHG) emissions from material extraction through to end-of-life [12]. Currently, there is no common system to quantitively assess the social benefits of recycled materials in pavements [10].

Although there can be significant benefits in using recycled materials in pavements [6], there are still implementation challenges and barriers that can negatively affect their use [13]. This is especially the case for the airport pavement industry, which is generally risk-averse [14], due to the high consequence if pavements that service aircraft fail. Consequently, this review explores the opportunities, challenges, risks, and principles associated with the use of recycled materials in airport pavements. It also outlines strategies to assist in the future assessment and implementation of recycled materials in airport pavement construction for more sustainable airport pavements.

2. Background

2.1. Airport Pavements

As stated above, airport pavements are similar to road and other pavements, and are usually either rigid or flexible in nature. The main differences between airport and road pavements are the greater thickness required for the heavy aircraft wheel loads and the highly specified material quality, especially for the surface, due to the high consequences of loose aggregate that can cause catastrophic aircraft damage.

Flexible airport pavements are constructed primarily of a bituminous surface layer, over a granular or bound base course, over a granular sub-base course over the natural, improved, or imported subgrade [2,15]. The bituminous surface layer is usually a high performing asphalt mixture, with dense graded asphalt and stone mastic asphalt mixtures preferred [16]. However, for regional airports in countries such as Australia, the bituminous surface layer can be an airport-quality sprayed seal [17] or made of other thin bituminous materials [18].

Rigid airport pavements are typically comprised of an unreinforced 40 mm (maximum aggregate size) Portland cement concrete base, over a granular or bound sub-base, constructed on a natural, improved, or imported subgrade [2]. The pavement is divided into square or almost-square slabs ranging from 4 m to 8 m in length, to account for paver width and contraction joints [19]. Due to the ability of concrete to better accommodate slow moving or stationary aircraft, and its resistance to fuel and other hydrocarbons, when compared to asphalt mixtures, rigid pavements are generally constructed in areas such as aprons and runway thresholds [20]. However, in the United States, the Middle East, and part of Europe, runways constructed of rigid pavement are not uncommon.

Because airport pavements contain asphalt concrete, cement concrete, and bound and unbound granular material layers, there are several opportunities to incorporate recycled materials into airport pavements. However, the performance of the pavement layer containing recycled materials should be as good or better than layers using virgin materials to ensure suitability for the high demand of aircraft traffic and to ensure material and pavement durability is not compromised.

2.2. Waste Policy

The origins of waste management policy were focused on the prevention of negative impacts on human health, before expanding to include immediate impacts on the environment over the 20th century [21]. Effective policies to achieve these aims have been mostly implemented across developed countries and to various degrees of success in developing countries [22]. Since the establishment of waste policies, the continued and sustained growth in the production of waste has required a reassessment of the traditional approaches to waste management, including the collection and isolation from interactions with humans and the environment [21]. Modern waste management policies increasingly emphasise both the reduction of waste generation and the recovery and re-use of resources contained within waste streams, as essential to managing present and future volumes of waste effectively [23,24].

Various strategies have been employed internationally to increase the amount of resource recovery from waste. In 2008, the European Waste Framework Directive established 2025 targets for the 55% re-use and recycling of municipal waste with varying targets for specific packaging materials, such as 75% for paper and cardboard, 70% for glass, 50% for aluminium, 50% for plastic, and 25% for wood [3]. Similarly, the United States has a National Recycling Goal of 50% of all waste by 2030 while in Australia the 2019 National Waste Policy Action Plan has the ambitious target to recover 80% of all waste by 2030 [4,5]. Despite the adoption of clearly defined targets for the recovery of resources in waste in these regions, progress has been limited and further action is required if targets are to be achieved [3,25,26]. Economic instruments such as the extension of waste producer responsibilities alongside the establishment and support of end-markets for products generated from waste streams are identified as potential means to increase resource recovery from waste streams [26,27].

The pavement industry has acknowledged the challenge of resource recovery with several industry bodies developing policies to re-use waste materials in pavement construction in order to reduce GHG emissions. For example, in the United States, the asphalt pavement production industry has set a goal of achieving net zero GHG emissions associated with the production of asphalt [28], and the American Concrete Pavement Association aims for net zero GHG emissions by 2050 [29]. Because the Australian 2019 National Waste Policy Action Plan specifically called out recycling waste materials in road pavements [5], the Australian flexible Pavement Association (AfPA) has developed frameworks that incorporate circular economy concepts and embedded sustainability metrics into procurement, to achieve the Waste Policy Action Plan goals [30]. Although there is a mature market for select recycled materials in road pavements, there are still significant challenges for their implementation, including incorporation of recycled materials into pavement specifications, educating practitioners on the benefits of recycled products, and confirming the long-term benefit of recycled products [13,31]. The challenges towards sustainable practice are more pronounced for the airport pavement industry due to the tighter construction tolerances and more demanding requirements of aircraft traffic [2].

2.3. Sustainability in Airport Pavements

Sustainability is defined as ‘meeting needs of the present without compromising the ability of future generations to meet their own needs’ [32]. Sustainability typically encompasses three discrete components—environmental, social, and financial—collectively referred as the TBL [10]. For infrastructure to be sustainable, it should be designed, constructed, and operated to optimise environmental, social, and financial outcomes for the long term.

Environmental sustainability is the ability to maintain an ecological balance and conserve natural resources for future generations. In the context of pavements, environmental sustainability focuses on reducing energy consumption and GHG emissions from production, construction, use, and end-of-life stages of a pavement lifecycle [33]. Social sustainability components for road pavements focus on safety, smoothness of ride, aesthetics, and operating costs [10]. However, for airport pavements, a number of these components are tightly controlled by the regulatory standards necessary for safe aircraft operations [34,35]. Consequently, social costs are difficult to quantify. Financial components focus on construction, maintenance, and rehabilitation costs [36], and have historically been the dominant decision factor for pavement works [10]. But with the focus towards sustainability; environmental and social aspects should now also be considered as part of pavement works [37].

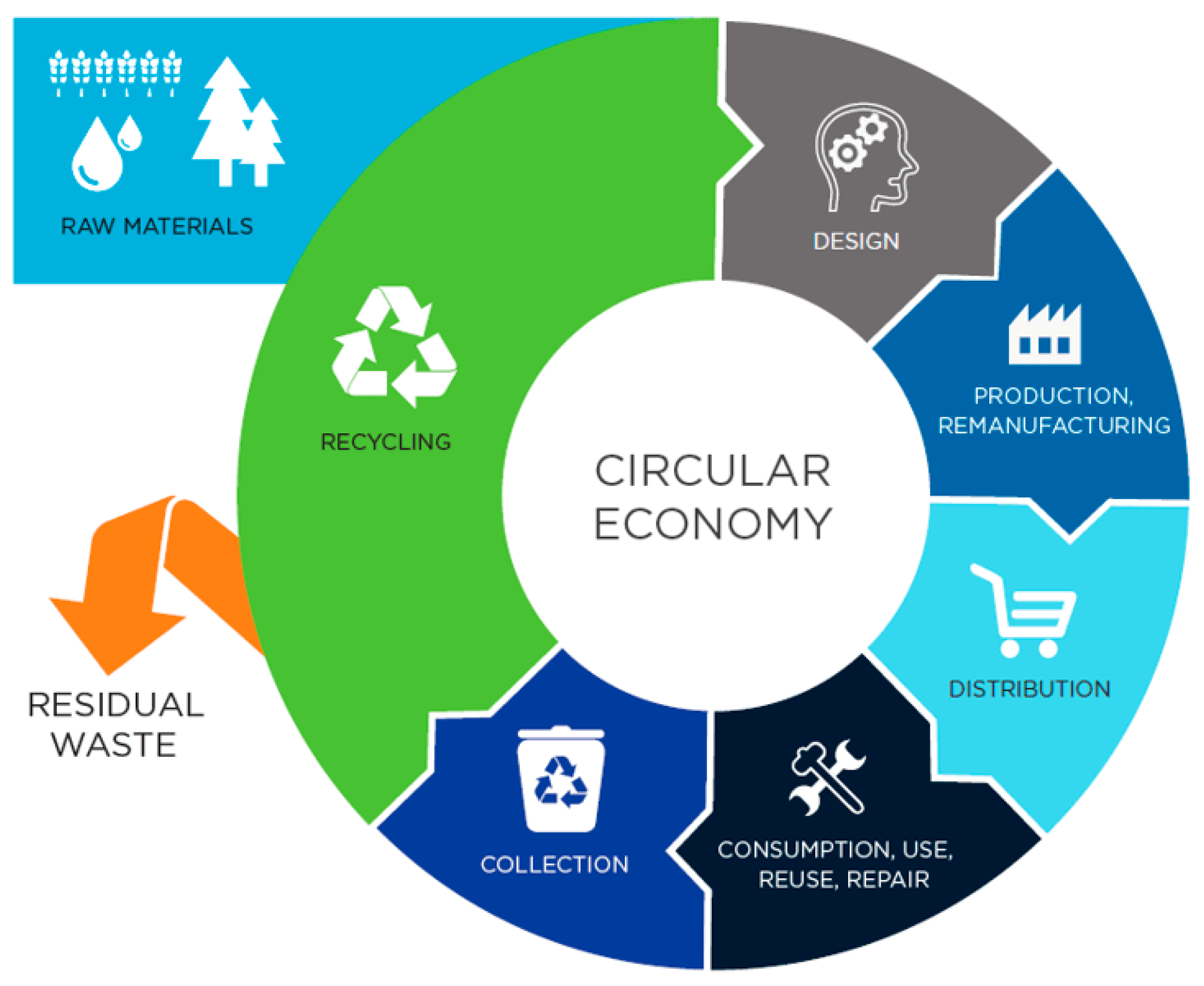

To include sustainability in pavement design, a global trend in recent years is the adoption of circular economy principles as shown in Figure 1 [7]. Different to traditional linear economy principles, which is generally summarised as take–make–dispose [38], circular economy principles focus on re-use, repair, remanufacturing, and recycling [39]. For pavements, a circular economy approach effectively allows the use of recycled materials in value-added applications [7], thereby reducing GHG emissions in new material production, reducing waste to landfill, and reducing the reliance on virgin material sources. However, important to re-using recycled materials in pavements is understanding their performance, limitations, and appropriate applications, which is discussed below.

Figure 1.

Circular economy concept [5].

3. Recycled Materials and Their Applications

As stated above, there are many materials that can be potentially recycled into flexible and rigid airport pavements. The most commonly known materials include waste plastic, crushed glass, industrial slag, coal combustion by-products, crumbed tyre rubber, recycled asphalt, and recycled crushed concrete [31]. Each has different potential applications, different benefits and risks, and is at a different stage of technology maturity, as summarised below.

3.1. Waste Plastics

Waste plastics are polymeric materials derived as waste from commercial and industrial uses [40]. Two of the main sources of waste plastic are plastic drink bottles, made from polyethylene terephthalate (PET), and single-use plastic bags, made from high density polyethylene (HDPE) [41]. However, there are several more polymers found in waste plastic, including low density polyethylene, polyvinyl polypropylene, and polyamide [40]. Waste plastics can be divided into two categories: thermoset and thermoplastic [7]. Thermoset polymers undergo a chemical change when heated and cannot be reformed or remelted, and consequently are very difficult to recycle, whereas thermoplastic polymers can be easily modified through reheating, making them suitable for recycling [42]. Because there is significant variability in plastic types, sorting and processing is generally required before incorporating into pavement structures. The cost of sorting and processing plastics is often high compared to the saving associated with the reduction of new material consumption. Consequently, it is important that the waste materials either provide reduced cost, or improved performance, compared to otherwise similar new material use [43].

The most suitable use for waste plastic in pavements is as bitumen modifier or extender [40]. This is because virgin polymers are already used in bitumen technology to improve the performance of asphalt mixtures or sprayed seal surfacings [7]. This is especially the case for surfaces that are subject to higher stresses, such as airport pavements [16]. Consequently, the waste plastic can be used as a value adding material. White [43] demonstrated that a waste plastic-modified binder can perform similarly to common Australian elastomeric and plastomeric polymer-modified binders. However, the waste plastic in that study used a proprietary method of blending, sorting, and processing. Simply adding waste plastic without engineering design may not guarantee suitable performance outcomes. For example, adding shredded bottles (PET) or plastic bags (HDPE) will not improve binder performance since the melting point of both of those polymers are above that of a typical binder, meaning that the plastics will stay in their hardened state [41]. When engineered and introduced into binder properly, waste plastic can improve the crack resistance and deformation resistance of asphalt mixtures [8].

Waste plastics have also been tested in concrete for road pavement construction, with varying results. Although some studies have shown a slight increase in flexural strength when using up to 20% waste plastic by aggregate fraction [44], the general trend is that with increased plastic content, the flexural strength will decrease [44,45,46]. One study showed that for every 2% increase in PET as coarse aggregate, the flexural strength decreased by 10% to 20% [45]. The decrease in flexural strength was due to the weak bond between plastic aggregates and cement paste, caused by the impermeability of the plastic particles [47]. Waste plastics have also been found to reduce the elastic modulus of concrete mixtures, due to the lower elastic modulus of the plastic particles, compared to mineral aggregates [44,48]. Because flexural strength and elastic modulus are a key design input and design assumption, respectively, in airport pavement thickness determination methods [49], any reduction in these values will likely increase the required thickness, and therefore increase the environmental and financial demand of the pavement. Consequently, waste plastics are not expected to be feasible in concrete airport pavements at this current time.

Other uses for waste plastic in pavements are in geosynthetics such as geotextiles and geogrids [40]. Geotextiles are generally used to separate clay subgrades from sub-base layers to prevent migration of fines into the imported pavement materials, whereas geogrids are plastic meshes with high tensile strength that can delay the propagation of cracks through a new asphaltic layer [50]. Proprietary products already exist for recycled plastic geosynthetics, with mechanical properties verified in the laboratory to meet the relevant specifications for the virgin version of the products they replace [7].

3.2. Recycled Crushed Glass

Recycled crushed glass (RCG) is a product of manufacturing and consumer-mixed glass waste [51], with the majority of RCG being sourced from beverage bottles [52]. Because of the residual sugars and paper debris within the RCG [53], controlled crushing, processing, and cleaning must be performed prior to use in pavements [54], which can be very energy intensive [55]. RCG is typically used in pavements as a partial sand replacement for granular base and sub-base materials, asphalt mixtures, and concrete mixtures [56].

The most frequent use for RCG is as a fine material replacement for unbound granular road applications [7]. Currently, Australian road specifications allow up to 20% of RCG fines in sub-base layers [57], and 10% in base layers [58]. Although the performance between unbound layers containing RCG and those with only virgin materials has shown to be similar in laboratory and field testing [53,59], the difference in allowable percentage reflects the risk appetite of the road authority, with lower pavement layers that are subjected to less stress allowing for higher contents of recycled materials. Because unbound layers in airport pavements are similar to that of roads [2], the use of RCG in airport unbound layers is highly conceivable.

When RCG is used in asphalt mixtures, the optimum bitumen content decreases, due to the bitumen not being absorbed at the same level as natural aggregates [60]. This results in less interlock between aggregate particles, reducing the load-bearing capacity of the asphalt mixture [8]. One study determined that deformation resistance of asphalt mixtures decreases as RCG content increases. In contrast, another study showed that up to 15% of RCG has little effect on performance of the mixture [60]. There have also been studies that found glass particles reduce skid resistance and increase tyre wear. However, this can generally be mitigated through limiting particle sizes to less than 5 mm [7]. These differences in performance highlight that RCG can be suitable for asphalt mixtures, but should be subject to routine and other appropriate performance testing, especially if used for airports. In fact, RCG is already allowed in heavy duty asphalt mixtures by some road authorities, albeit at a reduced mass of total mixture [61]. Furthermore, RCG has been successfully used on an aircraft parking apron at Queenstown international airport in New Zealand. For that project, 50,000 m2 of parking apron was resurfaced with an airport polymer-modified asphalt mixture which used 1.5 million bottles to include 235 tons of beer bottle sand [62], in the fine aggregate portion of the mixture. It is clear that using RCG can reduce waste going to landfill; however, research by Tushar et al. [55] demonstrated that RCG only reduces emissions by 0.4% in an asphalt mixture, due to the small fine aggregate component and energy intensive operation for RCG sorting and cleaning. Consequently, in some situations, the use of RCG may not provide a worthwhile sustainability benefit. Similarly, a cases study on 5% to 10% crushed glass (by mass of the combined aggregate) did not adversely impact asphalt mixture performance for local road surfacing, but provided negligible financial and environmental benefit, because the costs were only marginally lower than the cost of the natural sand it replaced [63].

Research has been conducted to determine if RCG can be used as a coarse and fine aggregate substitute in concrete mixtures [8], as well as a cement substitution [52]. Batayneh et al. [64] demonstrated that the substitution of up to 20% fine aggregate had no significant effect on the flexural strength of a concrete mixture. However, other research showed that RCG as a percentage of fine aggregate reduced flexural strength, due to a decrease in bond strength between the cement paste and RCG as a result of a relatively high smoothness of the RCG particles [65]. The use of RCG as a coarse aggregate generally decreases the mechanical performance of a concrete mixture, once again due to the weak bond caused by the glass smoothness [52], indicating unsuitability for airport pavements. As a cement replacement, previous research has determined that up to 20% cement content can be replaced with RCG without hindering mechanical properties, if milled into a fine powder, due to the pozzolanic properties of the ground RCG [52,66]. However, a risk with the use of RCG in concrete pavements is the threat of alkali–silica reaction, due to the increased silica content [64]. Good mixture design can reduce the risk [52], as well as using non-reactive RCG particles [67]. In fact, the use of RCG in cement will likely create the most sustainable outcome for al RCG applications, since cement production accounts for approximately 62% of emissions in concrete pavement [55]. As an example, and as demonstrated by Tushar et al. [55], due to the high environmental cost of cement production, including up to 20% RCG as fine aggregate may reduce the reliance on virgin materials, but the overall carbon emissions saving was only 0.5%.

3.3. Industrial Slag

Industrial slag is a by-product of the iron- and steel-making processes, and has proven an acceptable alternative to the natural aggregate resource over a wide range of applications [7]. There are three main types of industrial slag used in pavements: Blast Furnace Slag (BFS), Basic Oxygen Steel Slag (BOSS), and Electric Arc Furnace Slag (EAFS) [68]. BFS is created from iron manufacturing, and depending on the cooling procedure and further processing, can be granulated to create granulated BFS (GBFS), or granulated and ground to create ground granulated BFS (GGBFS) [68]. BOSS and EAFS are both types of steel furnace slags (SFS), which are produced from steel manufacturing processes [69].

When produced, BFS and GBFS both have high percentages of fractured faces, making them suitable for pavement layers that require good mechanical interlock [68]. Consequently, some airport specifications allow for the use of these materials in unbound and bound sub-layers [70]. GBFS specifically, has similar appearance to a river sand with a lower density, typically 60% to 70% of the density of natural sand [71]. Although suitable for sub-layers for pavements, it is unsuitable as a drainage layer, due to pozzolanic properties [7].

GGBFS is a white powder consisting of calcium oxide, silica, and alumina, and like GBFS offers pozzolanic properties [72]. Because of these properties, it is typically used as a Portland cement replacement, and can replace up to 60% cement content without hindering concrete performance [73]. When used, GGBFS has been found to enhance the workability of concrete mixtures, reduce the heat of hydration and improve the development of long-term compressive strength [74]. GGBFS can also be used as an asphalt filler, with mixtures containing GGBFS resulting in a decrease in rutting potential and an increase in stiffness [8]. Because of the increased stiffness, asphalt mixtures containing GGBFS may be susceptible to early ageing; however, this can be mitigated with good mixture design [8].

SFS has been used as an aggregate replacement in sprayed sealing and asphalt mixture applications for road pavements [7]. Compared to natural aggregates, SFS aggregates have better abrasion resistance, higher crushing strength, and increased density, making them suitable for use in heavily trafficked pavement areas [75]. Performance tests on asphalt mixtures containing SFS aggregates have found reduced rutting potential when tested with a wheel tracking device and increased fatigue resistance, for both dense graded and stone mastic asphalt mixtures [76]. Furthermore, due to their affinity for bitumen, SFS aggregates have been found to reduce stripping potential [75]. Because the addition of lime is necessary in the production of molten steel [77], SFS aggregates will have a proportion of calcium and magnesium oxides that can cause detrimental volumetric expansion when hydrated [76]. The volumetric expansion can range up to 20%; however, in countries like Australia that use low free lime contents in steel-making processes, expansion values are only up to 2% [75]. Regardless, prior to using SFS aggregates in pavements, conditioning through stockpiling and wetting over a period of months is recommended to screen for this prior to use [75,76]. SFS is currently not permitted in airport concrete pavement specifications [70], likely due to the volumetric expansion potential when in the concrete mixture [78], which can cause concrete failures. However, some SFS aggregates have been found to achieve performance requirements for airport asphalt mixtures [79], making them a suitable natural aggregate replacement for this application.

3.4. Coal Combustion Products

Coal combustion products (CCPs) are materials produced from coal fired power stations in energy production and are generally classified as fly ash, being the finer material produced, or furnace bottom ash (FBA), being the larger particles collected from the bottom of a furnace [7]. Fly ash has been used in pavements since the early 1950s, and has application in all pavement layers [80], whereas FBA is generally used as a fine or coarse aggregate replacement for virgin mineral aggregates. However, there are limited technical specifications that allow the use of FBA in pavements, and even then, it is for the lower risk sub-base layers [81]. This is likely due to its reduced abrasion resistance and high porosity compared to mineral aggregate [81], making it more suited for drainage applications [7].

Fly ash can be used as a chemical stabilisation product for expansive clays and has been shown to improve the unconfined compressive strength, bearing capacity, and resilient modulus of soft soils due to the pozzolanic properties [82]. It is also used in sub-base and base layers as a stabilising agent, typically as a part of triple blend cementitious binders, usually comprised of 30% hydrated lime, 40% Portland cement or GGBFS, and 30% fly ash for cement-stabilised layers [83], and as a secondary binder in foamed bitumen stabilised layers [84]. For asphalt mixtures, fly ash can be used as a mineral filler, and is already an established material in some airport asphalt specifications [85]. For concrete pavements, fly ash is incorporated as a cement substitution, typically at 25% of the total cementitious content [2]. Because fly ash particles are spherical in shape, they increase the workability of concrete when compared to an ordinary Portland cement. Furthermore, fly ash reduces water demand, reduces the risk of shrinkage cracking during curing, and increases the ultimate strength of the concrete mixture [80].

Portland cement production produces large amounts of carbon dioxide (CO2) compared to other pavement materials, and accounts for 5% to 8% of global anthropogenic CO2 emissions every year [86]. Consequently, when substituting cement with recycled products, large environmental and financial gains can be realised. This is especially the case with geopolymer cement, which is produced by treating aluminosilicate minerals, such as fly ash and industrial slag, with alkali solutions [87]. The application of geopolymer cement has been proven for airport pavements, with Wellcamp Airport located in Queensland, Australia, constructing rigid airport pavements entirely of a geopolymer concrete. The flexural strength and workability met all the requirements of a standard airport concrete mixture [88]. The geopolymer cement used for that project incorporated fly ash, industrial slag, and proprietary chemical activators that resulted in a 90% reduction of CO2 emissions, compared to an ordinary Portland cement [89]. Because geopolymer cements are a new technology and available blends are largely proprietary, there has been difficulty in gaining initial acceptance due to specifications that reference ordinary Portland cement or standard fly ash blended cement as the only allowable binder types [90]. Consequently, specifications will need to be updated, and should focus more on performance outputs, rather than prescriptive material requirements to enable use of these and other recycled materials.

3.5. Crumbed Rubber

Crumbed rubber (CR) is recycled rubber produced from end-of-life truck and car tyres [91] that is processed into small particles up to 2 mm in size [92]. The main use of CR is as a bituminous modifier for asphalt mixtures and sprayed seals, where the technology has been well-established since the 1960s [93]. It is estimated that every year 1 billion vehicle tyres reach their end of service life, with over 50% being discarded without appropriate treatments [94]. Not only does the use of a CR modifier in pavements reduce this number, it also enhances asphalt mixture properties, such as fatigue resistance, durability, rutting resistance and resilient modulus [94,95]. To achieve these enhanced mechanical properties, typically CR content is 20% to 30% by mass of the bituminous binder [96].

There are three technologies used for CR modification of binders, namely field wet blending, terminal wet terminal blending, and dry blending [92]. Wet blending involves fine CR being introduced into base bitumen prior to asphalt mixture production, and dry blending is where CR is added directly to the asphalt production plant with the aggregate [96]. The difference between wet terminal blending and wet field blending is the digestion time during which the CR dissolves into the bituminous phase, with terminal blending associated with longer blending times. Dry blending is simpler to implement and less energy intensive; however, when the bitumen is added, the rubber only partially dissolves, resulting in a poorly controlled partial binder blend that does not achieve the full benefits of CR modification [97]. Wet blending leads to a more homogenous and higher performing mixture, but can result in increased asphalt production costs in the range of 10% to 30%, when compared to conventional bitumen, due to viscosity of the bitumen and its effect on asphalt plant efficiency and the required production temperature [98]. This premium is expected to be much lower when compared to airport asphalt mixtures, because airport mixtures typically require polymer-modified bitumen [16], which has different rheological properties to conventional bitumen and behave similarly to CR-modified binders. Riekstins et al. [98] also demonstrated that the energy required to produce a CR mixture is higher than that for a conventional bitumen mixture, but this can be offset if the asphalt layer lasts two to three years longer in the field than conventional bitumen. These findings highlight the importance of assessing a recycled material using a whole-of-life analysis, instead of an upfront financial and environmental cost. Some materials may have higher initial cost, but if they perform better and last longer than conventional pavement materials, the financial and environmental benefit may be significant.

Attempts have been made to incorporate CR and other end-of-life tyre products into concrete pavements. Soeimani et al. [99] introduced CR and larger particle shredded rubber into concrete pavements at 5% and 20%, by volume of the sand and coarse aggregate fractions, respectively. Their research found that the tensile strength of the concrete mixture was reduced by approximately 22% when using the rubber materials. This reduction in tensile strength is significant, because rigid pavement thickness design is most sensitive to concrete flexural strength [100], implying that any reduction in environmental cost by using rubber in concrete may be outweighed by the increased concrete pavement thickness. This highlights that when using recycled products, there may be an overall reduced sustainability benefit if the material does not perform as good or better than the material without the recycled product incorporated.

3.6. Recycled Asphalt Pavement

Recycled asphalt pavement (RAP) is reclaimed asphalt from an older pavement surface and has been shown to provide a significant environmental and financial benefit, with low performance risk compared to other recycled materials [101]. That is because RAP is essentially a one-for-one replacement for fresh binder and virgin aggregate in the asphalt mixture [7], reducing the environmental and financial costs required for raw material extraction and processing, and avoiding the aged asphalt pavement going to landfill. RAP can be in either asphaltic layers, as an almost one-for-one replacement of binder and aggregate, or in unbound layers, as a substitute for virgin aggregate; however, due to it being a premium recycled material, asphaltic layers are preferred [7].

Several authorities have used RAP in airport pavements for over 20 years [102], and the use of RAP is well-established for road authorities [7]. However, a number of airports have resisted or restricted the use of RAP for pavement surfacing due to perceived performance risk [103]. This is because the percentage of RAP within a mixture can alter the performance properties. RAP content below 15% has been shown to have no significant effect on asphalt mixture performance, but for mixtures with RAP percentages above 20%, the performance could be dependent on the quality of the RAP material [104]. Previous laboratory studies that assessed airport asphalt mixtures found negligible difference in performance between mixtures with a RAP content of 20% compared to a non-RAP mixture [102]. With higher RAP percentages (>20%), the aged binder can create an excessively stiff mixture susceptible to cracking, but this can be mitigated with the use of bitumen rejuvenators that soften the RAP binder [105].

When considering RAP for airport surfacing, White and Jamshidi [103] described three different types: low-risk, medium-risk, and high-risk RAP. Low-risk RAP is drawn from the temporary ramps that are produced between paving shifts that occur at night. These ramps are required to tie the new pavement into the existing pavement to allow for aircraft operations during the day when paving is not occurring. Because the material is of the same mixture design and uses the same raw materials, the performance risk is low. However, because it is sourced from the temporary ramps constructed during construction, low-risk RAP is generally only available at a rate of approximately 5% of the total asphalt mixture volume. Medium-risk RAP is sourced from the millings of the older surface prior to overlay. Although they are not of the same mixture design as the fresh asphalt course, it is likely to be made of a similar premium airport asphalt mixture that has consistent grading and volumetrics. Medium-risk RAP is generally available at approximately 10% of the total asphalt mixture volume during resurfacing works, but it not available during new construction. High-risk RAP is drawn from stockpiles off site, from millings sourced from paving projects that may or may not be from an airport surface. Due to the increased variability in the material, there is an increased performance risk. However, the performance risk can be mitigated with crushing, screening, and effective stockpile management [104]. In fact, suitable management can mean that RAP is no more variable than new quarried crushed rock sources [106]. This emphasizes the importance of sorting and processing recycled materials prior to using them in airport pavements, as well as project and mixture specific mixture design.

3.7. Recycled Concrete Aggregate

Recycled concrete aggregate (RCA) are products that primarily derive from the demolition of buildings and old concrete pavements, and are typically used in bound and unbound sub-base and base layers as an aggregate replacement, and as select fill and drainage layers [7]. Because RCA is often contaminated by timber, steel, and plastics, the materials are crushed and screened before being incorporated into pavement infrastructure [107]. The source of the RCA can have an effect on the durability of the material, with one study determining that RCA sourced from vertical structures has higher durability and strength than RCA sourced from horizontal structures, mainly due to the increased presence of foreign objects in the latter [108], once again emphasizing the importance of crushing, screening, and sorting recycled materials prior to pavement construction.

RCA is generally composed of 60% to 75% aggregates (coarse and fine) and 25% to 35% adhered mortar, and because of the mortar content, RCA is typically less dense than virgin aggregates [109]. The excess mortar can also promote increased abrasion loss compared to natural aggregates [110], which can cause durability issues for unbound base and sub-base layers. However, when premium RCA is used that has appropriate material quality control, the abrasion resistance characteristics can be better or similar than for virgin aggregates [111], resulting in RCA base and sub-base layers performing as good as or superior to virgin aggregate layers [7]. Road authorities have had detailed specifications for RCA in base and sub-base layers for over a decade [112], and the material has been used as bound and unbound layers in airport pavements as early as the 1960s [113].

RCA has also been used in surface layers, with Changi International airport incorporating 20% RCA (by mass of coarse aggregate) for a concrete surface parking area [114]. For that project, stringent quality controls were adapted to minimise the risk of shrinkage cracks, which can be higher due to the increased water absorption capacity of RCA. This is caused by the presence of the more porous residual mortar, and can be mitigated by pre-wetting the RCA [109]. Furthermore, RCA in concrete mixtures can reduce the strength of the concrete if the content is above 50% by mass of coarse aggregate [109]; consequently, the material may be able to reduce the reliance on virgin aggregate for concrete pavements, but not replace them completely.

For asphalt concrete pavements, mixtures with RCA have been found to exhibit variable performance and high stripping potential, due to the porous residual mortar [109,110]. Precoating the RCA with bitumen emulsion results in similar performance characteristics to conventional asphalt mixtures [110]; however, the increased bitumen content has been demonstrated to outweigh any environmental or economic benefits of using the RCA for asphalt mixtures up to 55% by mass of coarse aggregate [115]. This highlights the importance of considering a pavement material as a whole, because the benefits of using one recycled material may require other changes that increase the overall environmental and financial costs, failing the goal of a sustainable pavement practice.

4. Measuring Sustainability

Implementation of recycled materials into airport pavements requires an objective sustainability quantification method to accurately detail the benefit. Sustainability measurements typically use the TBL concept, which includes quantification of financial, environmental, and social factors [10]. The use of LCCA for financial assessment is favoured to account for whole-of-life costs [36], rather than just the production and construction impacts. However, as explained below, where the life expectancy and maintenance requirements are identical, the post-construction impacts are also identical, so the analysis can be limited to the production and construction phase. The use of LCA for environmental assessment impacts has become more prevalent for pavements in recent years [116]. Currently, there is no common system to quantitively assess the social benefits of recycled materials in pavements [10]. Considerations for applying a TBL assessment to recycled materials in airport pavements are discussed below.

4.1. Financial Quantification

LCCA is an analysis technique that builds on well-founded economic analysis principles to evaluate the overall long-term economic efficiency between competing alternative investment options [117]. Consequently, it is an appropriate tool for assessing different recycled materials in pavements. Furthermore, LCCA guidelines are already built into road and airport pavement procurement and design policy [15,118]. LCCA considers not only upfront costs, but also costs throughout the lifetime of the pavement [36], which is important because some pavement materials with a higher upfront cost can perform better and will therefore provide longer term savings. For example, stone mastic asphalt can have larger upfront costs than dense graded asphalt, but because of its longer performance period [119], annualised cost savings can be in the order of AUD 200,000 per year, for a typical runway overlay [120].

LCCA requires defined values for upfront costs, a discount rate applied to all future costs, maintenance, and rehabilitation costs, an analysis period, terminal costs, and in some cases, a sensitivity analysis. The discount rate reduces the future costs to present dollars to enable the calculation of net present value (NPV) or equivalent annual cost (EUAC), which is the final output of an LCCA [36]. When discount rates are increased, previous research demonstrated that NPV or EUAC will decrease due to all maintenance costs decreasing [11]. Typical discount rates for analysis are between 3% and 7%, dependent on state and government policy [36,121], and should approximate the return expected if future costs are invested until they are required. When assessing a pavement with recycled material against one with virgin materials, the discount rate should have no effect on the LCCA comparative output for maintenance costs, if the performance, expected life, and, therefore, maintenance are reasonably expected to be the same.

The analysis period for LCCA is recommended to capture at least one major rehabilitation of each of the alternate products [36], with US road authorities recommending an analysis period of 35 years for both rigid and flexible pavement [118]. However, flexible and rigid airport pavements have different service lives, with flexible pavements generally requiring resurfacing once every 12–20 years, and rigid pavements requiring reconstruction once every 40–60 years [2,11,120]. Consequently, if analysing recycled materials in a flexible pavement, the analysis period should be greater than 20 years, and if assessing for rigid pavements, the analysis period should be greater than 60 years.

When data is used to support an LCCA, there may be uncertainty in assigning financial values to inputs and the resulting outputs [118]. Either a deterministic approach, which uses a single value for each cost input, or a probabilistic approach, which allows data to be spread across a set of values, can be used to perform an LCCA [36]. The later approach accounts for uncertainty, by considering low, medium, and high likelihoods of costs, as well as a representative distribution function. Previous researchers have used probabilistic approaches to perform LCCA on pavements, usually through a Monte Carlo simulation [122,123,124]. The benefit of probabilistic approaches compared to deterministic approaches is that it provides a range of outputs that can assist a decision maker in determining the appropriate pavement material based on their risk appetite. For example, Babashamsi et al. [125] demonstrated that delaying maintenance works by one year on an airport pavement increased the LCCA by 16% using deterministic methods, but when performing a sensitivity analysis through probabilistic methods, the increase could be as high as 50%. However, Monte Carlo simulations rely on historical data, and sufficient databases for cost analysis and probability distribution evaluation [36,122]. Consequently, to account for the uncertainty in recycled material cost in airport pavements, probabilistic methods should be used, and cost databases developed to refine cost probability distributions.

A final LCCA consideration for airport pavements with recycled materials is the terminal value of the remaining pavement. The terminal value can be either a salvage value, which quantifies the net value of recycling materials at the end of pavement life, or be a ‘remaining service life’ value, which quantifies the residual value of the pavements service life that extends beyond the analysis period [118]. For recycled materials that are sourced from existing pavements, such as RAP or RCA, the terminal cost should account for these materials, as they provide project savings if used in future pavement applications [36], which aligns with circular economy principles. Additionally, material cost savings of using recycled materials in pavements is significant, with one report demonstrating that savings can range from 2% to 83%, with RAP providing the greatest benefit [6]. In practice, quantifying the cost saving that should be assigned to RAP from a removed surface, when it is incorporated into a new surface at some unknown time in the future, is challenging. Consequently, it is common to assume that RAP removal, transportation, and storage is cost neutral, and that RAP is then cost-free when re-used in the future.

4.2. Environmental Quantification

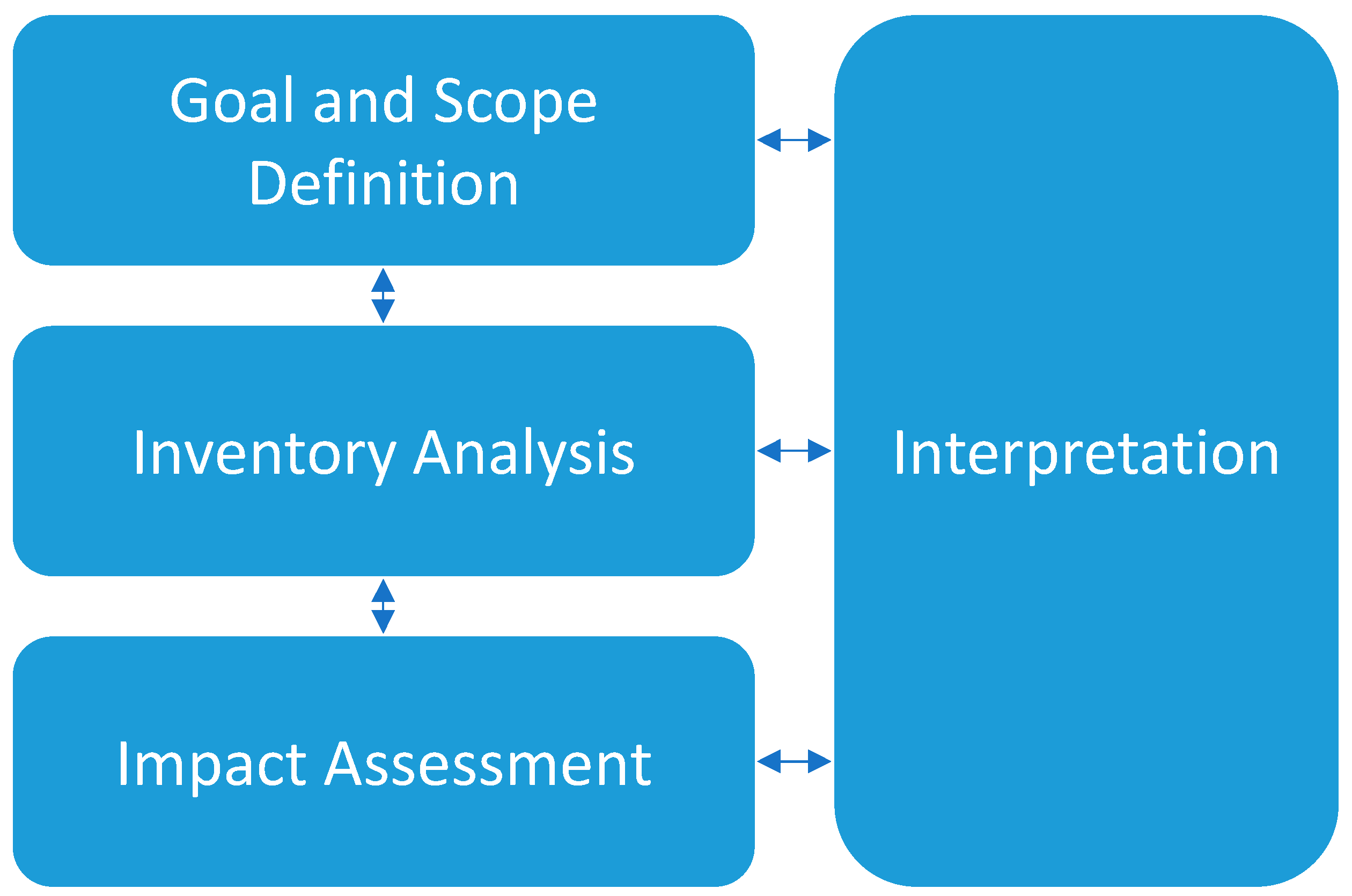

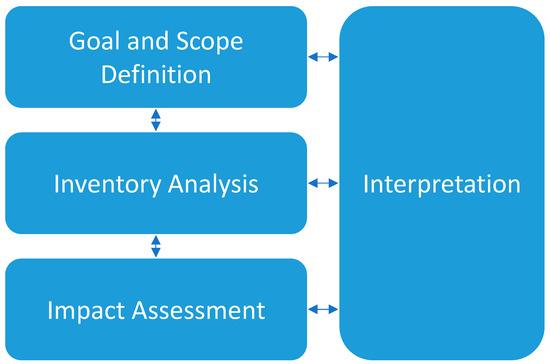

Contemporary methods for quantifying environmental sustainability benefits for both road and airport pavements is the application of an LCA [12,126]. LCA is a systematic process that assesses environmental impacts for the entire life cycle of a product, from raw material extraction to material production and manufacturing, use, and end-of-life treatment [127]. It is effectively the same as LCCA, but with the financial costs replaced by environmental cost rates. However, future environmental costs should not be reduced by a discount rate, because deferred environmental cost cannot be invested and the returns allocated to the future environmental impact. When conducting an LCA, there are four stages, as show in Figure 2.

Figure 2.

LCA process.

The goal and scope definition stage defines the aim of the LCA. For using recycled materials in pavements, the goal would generally be a comparison of pavement layers made with recycled materials against those made using virgin materials, both of which perform the same, also known as a comparative LCA study [12]. An important part of defining the goal and scope definition is establishing the system boundaries [127]. To ensure system boundaries in an LCA only account for processes specifically required for a waste material processing and incorporation into the new pavement material, most researchers provide a ‘cut-off’ allocation that disregards the original product generation [101,128]. For example, waste plastics that are destined for landfill would have a cut-off at the point prior to the cleaning, sorting, and processing, ensuring that the original production of the plastic is not included.

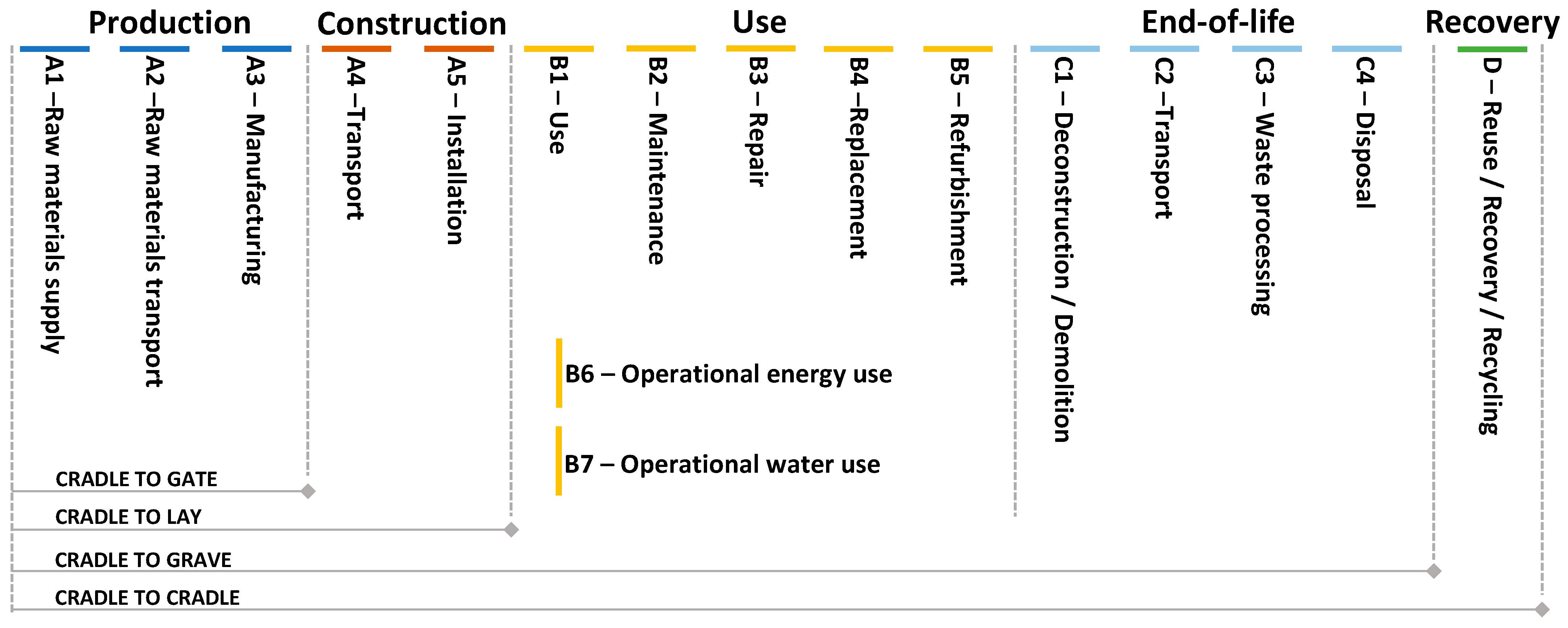

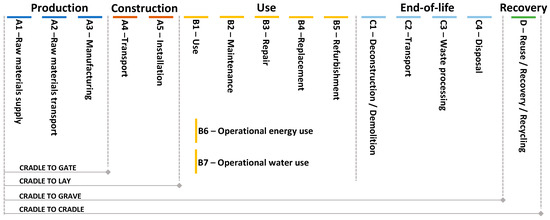

The scope will also define what parts of the life cycle are to be investigated. As defined in the European Standard EN 15804, the product life cycle is divided into five stages: production, construction, use, end-of-life, and recovery [129]. Each of these stages have discrete modules, as shown in Figure 3.

Figure 3.

Life cycle modules for LCA.

An LCA that only includes production is called a cradle-to-gate assessment. In contrast, a cradle-to-lay assessment includes the production and construction stages, and a cradle-to-grave assessment includes the end-of-life processes. A cradle-to-cradle assessments follows circular economy principles and encourages the use of pavement materials for a new system application. When assessing recycled products in pavements, current research favours cradle-to-gate assessments, with one review paper demonstrating that 44% of recent LCA studies stopped at cradle-to-gate analysis, whilst only 7% included the use phase [128]. This is due to the production of binders (bitumen and cement) and mixture production being the greatest contributors to environmental cost [55,130,131], justifying the focus on production-only assessments.

Furthermore, when performance of alternate materials are assumed to be the same, researchers have also assumed that maintenance and repair requirements are equal, negating the need for an assessment of the use phase [132,133], which is entirely appropriate for comparative studies performed on the basis of no expected difference in performance or durability. However, being confident that the inclusion of recycled materials into pavement materials will not adversely affect the durability and life expectancy of the new material is a significant challenge.

Also, when assessing materials that are stored large distances from the paving site, undertaking a cradle-to-lay assessment is more appropriate, because previous studies have demonstrated that increased haulage distances can substantially increase environmental cost [134], and in some cases, the emissions caused from transport outweigh the environmental benefits of using the recycled material [132,133]. Consequently, when maximising the environmental benefits of recycled materials for airport pavement applications, using products obtained from site or close to site is preferred, particularly in large and sparsely populated countries, such as Australia.

The second stage of an LCA is the inventory analysis, whereby energy inputs and outputs are quantified for each element of the system [127]. For example, asphalt production would include the energy inputs for A1—raw material supply (aggregate, bitumen and filler), A2—raw material transport (transport from quarry to asphalt plant), and A3—manufacturing (asphalt mixture production) [135]. Each constituent material has a defined LCA inventory. For example, the production of aggregate would include A1—raw material supply (explosives for rock extraction), A2—raw material transport (transport from extraction to screening site), and A3—manufacturing (crushing, cleaning and screening) [135]. To provide a standardised basis for determining environmental impact, Environmental Product Declarations (EPD) are becoming common in many locations [136], including independent verification and certification to an international standard [129,137].

In addition to EPDs, LCA calculators have been developed specifically for pavement works, such as the Canadian Athena Pavement LCA [138], the Australian AfPA LCA calculator for asphalt [139], and the US LCA Pave Tool [140]. These tools are largely Microsoft Excel-based or can be replicated in Microsoft Excel. LCA calculators allow for the determination of environmental impacts over the defined system boundary. However, to ensure suitable accuracy, inputs must be well defined, and generalisations should be avoided for project specific applications. This is because local data sources for life cycle inventory can differ from typical default international values [130]. That is, regardless of how sophisticated the tool appears, without accurate environmental cost rates, the output can have limited value. For example, generalising the impacts for coarse aggregate production will not account for the differences in extraction techniques, washing and screening processes, or power supply at different quarries. This is significant since existing EPDs within the same country demonstrate the environmental impact of coarse aggregate production can differ by over 100%, depending on the quarry procedures [135]. When assessing recycled materials using LCA calculators, it is appropriate to have a cut-off for A1—raw material supply due to the material being re-used for a pavement application. However, A2 and A3 modules should be included, because environmental costs due to the requirement for cleaning and sorting select recycled materials can be significant [55,60], as well as transportation requirements if the material is located a large distance from site [133,141].

The third stage of the LCA is the impact analysis whereby the total contributions of the environmental impacts are calculated for the life cycle stages assessed [12]. A key part of the impact analysis is selecting the impact categories that satisfy the LCA’s definition and scope [127]. Impact categories include total global warming potential (GWP-t), acidification potential, water consumption, freshwater ecotoxicity potential, and ozone depletion potential [128]. Of these categories, GWP-t is the most commonly reported [128] and has been established as the key sustainability metric for LCA [130]. GWP-t is a measure of all atmospheric emissions that contribute to global warming represented as equivalent kilograms of CO2 produced per tonne [142], and includes global warming potential via fossil fuels, biogenic carbon, land use, and land-use change [130]. To ensure consistency in the environmental assessment of recycled products in airport pavements, it is recommended that GWP-t remains the primary metric.

The final stage of the LCA is the interpretation stage, whereby results from the impact analysis are presented against each LCA module to determine the environmental impacts throughout the life of the pavement [128], and which life cycle stage has the largest impact [12]. For recycled materials in airport pavements, this stage will inform the decision point of whether to use a recycled material or not. Generally included in the interpretation stage is a sensitivity analysis of LCA inputs [127], which is commonly achieved through methods such as Monte Carlo simulation [128]. This is especially important for benchmark studies, which use industry averages instead of project specific data [12], and will therefore have more inherent uncertainty. For example, when determining the environmental cost probability for an airport RAP mixture, Jamieson and White [133] determined an approximate 50% difference in lowest to highest cost using a 90% confidence interval, based on industry average GWP-t values.

4.3. Social Quantification

The social impact of many road pavement construction works includes the safety and comfort of passengers, damage to vehicles, smoothness of ride, vehicle operation costs, and aesthetics [10]. For airport pavements, these components are tightly controlled by regulatory safety policy [34,35]; consequently, social comparison between different pavement types is difficult to quantify. For example, deciding on a pavement surfacing that reduces noise, such as open graded friction course [143], will have a social benefit for a suburban road. However, for airports, any noise reduction of tyres on pavement will be massively over-shadowed by the sound of jet engines. Furthermore, an aircraft typically taxis for a few minutes and takes off in less than one minute, but might spend 15 h in the air. Consequently, most of the usage-related impact occurs in the air rather than on the ground, meaning the contribution of the pavement to aircraft use social impacts is minimal. The difficulty relating to the quantification is also apparent in constituent materials of pavement layers, such as recycled materials, because currently, there is no common system to quantitatively assess the social benefits of recycled materials in pavements [10].

Qualitatively, there are social benefits to using recycled materials in pavements, such as improving welfare through job creation, reducing the use of natural resources, reducing material going to landfill, improving community satisfaction and civic pride, and improving public health through reduction of GHG emissions [13]. Of these benefits, the reduction of natural resources and quantity of material to landfill is easy to quantify, and as such has been used as a social benefit indicator for previous airport pavement research [144]. Although this is also related to environmental benefits, the preservation of natural resources improves intergenerational equity by ensuring future generations have the same access to materials as today [13], and is therefore a social impact. Consequently, when quantifying social cost for using recycled materials in airport pavements, it is recommended to determine the amount of virgin materials required, and the quantity of waste sent from site to landfill for a specific project.

Airport pavement projects are generally significant in size, and typically result in operational constraints that can range from continuous closures to single- or multi-day closures to time-limited works [2]. Because airports serve communities in facilitating tourism, business travel, and emergency response [145], extended closures due to pavement works can cause a social disbenefit. For example, a runway asphalt overlay project, which is typically required every 12 to 20 years and performed during night shifts [2], may reduce the available runway length for night operations. This will result in a weight limitation on aircraft to satisfy minimum field lengths, and therefore a reduced payload [146] which can mean limitations on passengers or supplies to local communities. Therefore, increasing the period between required maintenance works will minimise the social disbenefit. Consequently, when using recycled materials in airport pavements, it is recommended that the performance of the pavement layer should be as good or better than a pavement using virgin materials, to ensure the period between maintenance works is equal or increased.

5. Implementation Challenges

Although there can be significant benefits in using recycled materials in pavements [6], and these benefits can be quantified using a TBL approach, there are still implementation challenges and barriers that can negatively affect the use of recycled materials [13]. This is especially the case for airport pavements, which generally require higher performing materials due to the design of aircraft traffic and the low tolerance for failure. These challenges and potential mitigation measures are discussed below.

5.1. Risk-Averse Nature of the Airport Industry

Compared to road traffic, aircraft are heavier, have higher tyre pressures, are more susceptible to undulations in pavement surface, and can suffer catastrophic damage to fragile aircraft engines if loose stones are ingested [2]. Airports are also intolerant of unplanned closures because of the significant impact they have on airport operations. This in turn leads to higher performance expectations for pavement structures and surfaces, compared to roads and other pavements. Consequently, compared to road construction and maintenance, aircraft pavement works carry a larger risk profile. This is especially the case for airports that have a single runway, which results in no operational contingency should the runway be unexpectedly closed. Because of this, the airport industry is generally risk-averse, which has resulted in new solutions and innovative technologies being resisted [14].

To increase the likelihood of uptake of recycled materials in pavements, all pavement layers should be performance tested prior to laying to confirm they can sustain aircraft traffic. This can be achieved through a performance-related specification, which is discussed below. Another way to improve uptake of recycled materials in pavements is to initially construct these layers deep in the pavement, where stresses caused by aircraft tyres are less severe [147], or away from critical movement areas like the runway centreline. For example, aggregate layers with large volumes of RCG could be used as a sub-base layer, with a virgin aggregate layer used as the base layer. Additionally, because runway and taxiway shoulders are rarely trafficked by aircraft and require significantly less structural capacity [15], they have reduced risk if performing marginally. Consequently, shoulders are a good option for testing new technologies with relatively low risk. The same is true for taxiways and aprons, especially at airports that have multiple movement areas that can be used for contingency.

5.2. Long-Term Durability

The durability of a pavement material reflects the period that the material will maintain its integrity within the service environment [148]. For asphalt pavements, long-term durability distress will typically appear as ravelling, caused by age-related bituminous-mastic erosion [149]. For concrete pavements, durability distress can be in the form of sulphate attack, freeze–thaw damage, or alkali–aggregate reactivity [148]. Currently, there is no robust laboratory method for directly assessing concrete and asphalt surface durability [148,149]. Rather, tests are conducted on pavement constituent materials to indicate durability characteristics [148,150]. Recycled materials will have different durability characteristics to virgin aggregates, posing a challenge for implementation in airport pavements. However, because durability is largely a cause of environmental conditions, and not related to aircraft loads [151], review of the durability of road pavements with recycled materials can inform the long-term durability of airport pavements.

5.3. Procurement Guidelines

Legislative and regulatory frameworks can either stimulate or hinder sustainability initiatives and the transition to circular economy principles [152]. Consequently, countries like Australia have established government level procurement guides to enhance the use of recycled materials in new products [153]. However, there are still gaps in current procurement policies that must be addressed to optimise the application of these materials in pavements [13]. For example, the Australian Government Sustainable Procurement Guide recommends setting mandatory, minimum, or desirable requirements for the use of recycled materials [153]. However, only two Australian state road authorities have explicit guidance around establishing these minimum requirements, whereas the remainder only present recycled material utilisation as a desirable procurement outcome [31]. Having airport owners set minimum recycled material limits will increase the uptake of recycled materials, because if not explicitly stipulated, sustainability efforts can be seen as going beyond project requirements, or as a ‘donation’, and not necessarily meeting the minimum project requirements [154]. However, there are still challenges with introducing recycled materials into project requirements, because the liability for airport pavement design and specification generally sits with design consultants [2], who gain little benefit from delivering more sustainable infrastructure to the airport owner. Nonetheless, businesses that address sustainability tend to be more successful and more profitable [154], and several recycled materials can perform as good, or better, than virgin materials, with a fraction of the economic and environmental cost [6]. Consequently, updating procurement policies to incentivise recycled materials in airport pavements will improve uptake. Additionally, increased awareness and education of the benefits of recycled materials is required [31].

5.4. Standards and Specifications

Standards are documents that set out specifications, procedures and guidelines that aim to ensure products, service and systems are safe, consistent, and reliable [155]. In the context of airport pavements, standards are required to ensure airport owners receive consistent and reliable design, and that technology remains current [156]. Traditionally, airport pavements have been specified using a prescriptive or recipe-based approach [157], whereby constituent material properties are specified prescriptively [1]. Prescriptive specifications limit the use of recycled or alternate materials in pavements, due to their differences in intrinsic properties when compared to virgin materials. More appropriate for including recycled materials into pavements are performance-related specifications. These specifications focus on performance outcomes, and will generally include laboratory performance testing at the mixture design stage, to determine whether the physical characteristics indicative of good performance are met [150]. Currently, there is a lack of standards that allow for recycled materials in pavements, and for those that do, there are inconsistencies and limits on their applications through the remaining prescriptive requirements [13]. For airport pavements specifically, there are international standards that allow for recycled materials that have proven historical performance, such as fly ash and GGBS [70,158]. However, recycled materials with limited performance history are either relegated to non-wearing course layers, or to low-risk pavements such as shoulders [159]. Consequently, to increase the use of recycled materials in airport pavements, further standards should be developed and these standards should be performance-related. To enable this, government bodies, standards authorities, and key industry bodies should collaborate in modifying or creating the new standards, which can be used as a tool to drive demand for recycled materials, by building confidence in their performance [13].

6. Principles

After reviewing the existing waste policy, recycled material pavement application, sustainability quantification methods, and implementation challenges, the following principles have been developed to aid in the use of recycled materials in airport pavements. The principles focus on assessment techniques and considerations for implementation, rather than recommending specific solutions.

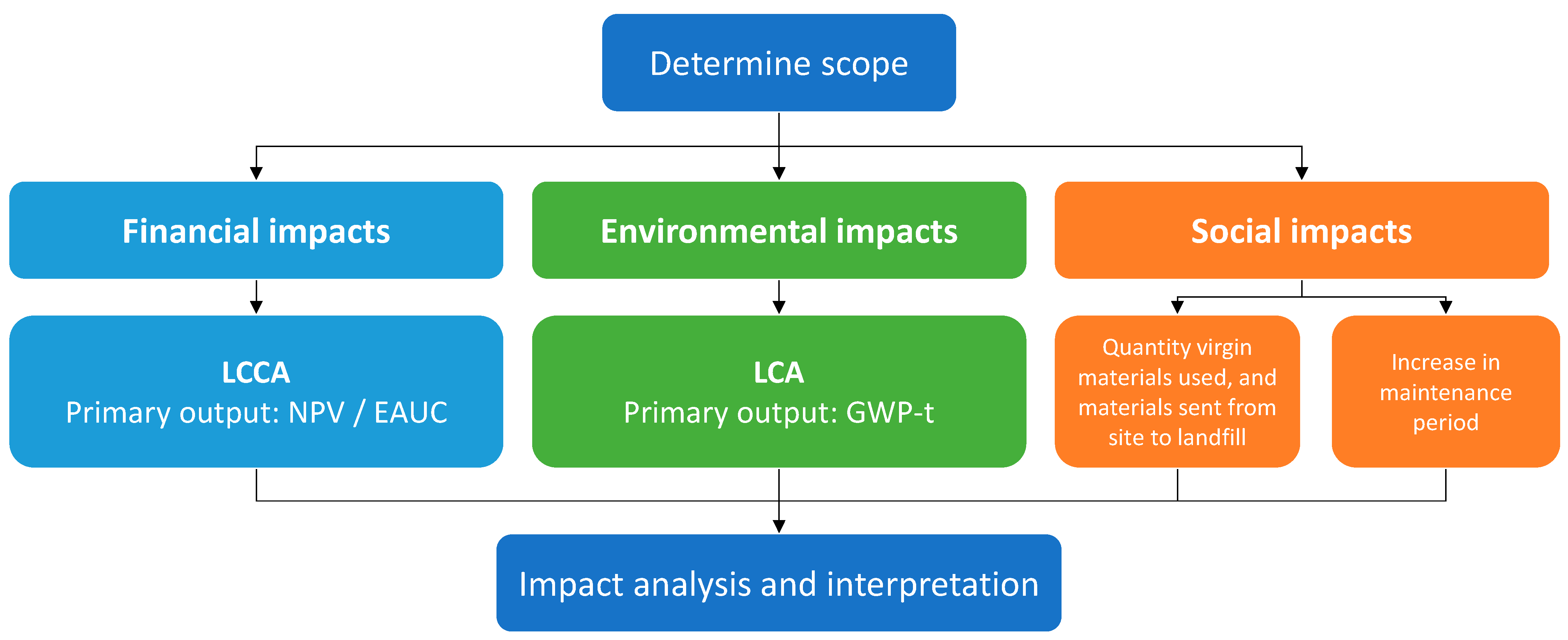

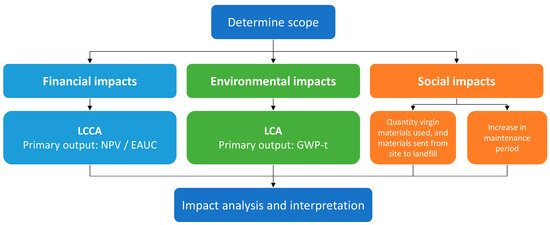

6.1. Triple Bottom Line Assessment

As shown in Figure 4, to assess the suitability of recycled materials in airport pavements, the most appropriate method is through a TBL assessment. The first part of the assessment would be determining the scope, which involves defining what recycled material is being assessed and comparing it against conventional pavement materials.

Figure 4.

TBL approach for assessing recycled materials in airport pavements.

For financial analysis, the established method is an LCCA that accounts for whole-of-life-costs. Specific to recycled materials in airport pavements is that the analysis period should be at least 20 years if assessing asphalt concrete materials, and at least 60 years if assessing concrete mixtures and pavements. However, for comparison of materials that are reasonably expected to have similar performance, maintenance requirements, and serviceable life, the analysis can be simplified by focusing on the production and construction phases. Furthermore, when assessing recycled materials that come from pavements, such as RAP and RCA, these materials should be assigned a salvage value at the end of the analysis period, as they can be used for further pavement applications.

For environmental analysis, an LCA is most appropriate and has already been established as the primary environmental assessment tool for several road and airport authorities [12,126]. To ensure consistency in reporting, the primary output metric is GWP-t, and the system bounds should ensure a fair comparison of competing materials [130]. For example, if assessing competing materials that are negligible distance from the work site, and have the same performance and maintenance requirements, a cradle-to-gate assessment is appropriate. However, if one material is situated a considerable distance further than the other, transport impacts should be accounted for, which would result in a cradle-to-lay assessment. Furthermore, the system bounds should apply a cut-off value to recycled materials prior to their incorporation into pavement construction.

For social impact analysis, determining the amount of virgin material consumed and material sent from site to landfill will quantify intergenerational equity via the access to materials of future generations. Furthermore, determining the change in maintenance period will assess the social benefit or disbenefit to airport users during times of work. It is recommended that any use of recycled materials does not reduce maintenance periods, by performing as good or better than conventional materials, therefore minimising social disbenefits.

The final step in the TBL assessment is an impact analysis and interpretation of the economic, environmental, and social impacts. In this stage, the decision maker will determine if the use of the recycled material provides worthwhile benefit. When using industry averages, or undertaking benchmark studies, it is recommended that a sensitivity analysis such as a Monte Carlo simulation is performed to account for the inherent uncertainty.

6.2. Sorting and Processing

Prior to use in airport pavement applications, recycled materials require sorting and processing to ensure consistency; with different materials requiring different treatments. For example, RCG processing includes cleaning due to the residual sugars [53], waste plastic processing includes sorting to ensure inappropriate polymers are not included [41], and RCA requires screening to remove contaminants from demolition operations [107]. Because sorting and processing can be energy intensive and costly [55,60], their financial and environmental impact should be included in the TBL assessment. Furthermore, efforts to optimise equipment and procedures for sorting and processing should be performed to minimise the energy burden. All pavement layers are engineered materials, and simply adding recycled materials without appropriate processing can result in poor performing pavements.

6.3. Source Location

When using recycled materials in airport pavements, maximising the use of on-site materials, or materials close to site, should be a priority. This is because environmental and financial costs can be reduced by limiting haulage distances for materials, with multiple case studies demonstrating significant savings when maximising on site materials such as RAP and RCA [134,144]. In fact, some studies have demonstrated that large haulage distances can completely negate the environmental benefit associated with the use of recycled materials [133,141].

6.4. Performance Testing

For all recycled materials reviewed above, there is strong evidence that they can perform as good, or better than virgin materials, if used in the right application and to the right content. However, simply adding recycled materials without proper mixture design may result in poor performance. Consequently, any mixture that includes recycled materials should be performance tested to confirm it meets the requirements of the pavement layer it is used in. For example, concrete surfaces would be required to meet the minimum flexural strengths stipulated in design and construction [160,161]; asphalt surfaces would be required to meet requirements for deformation resistance, fatigue resistance, surface texture, skid resistance, and durability [16]; and granular layers would be required to meet requirements for soaked strength and proving [162] as well as the confirmed repeated load modulus [163].

To ensure performance testing is undertaken, when considering recycled materials in airport pavements, performance-related specifications should be used, which focus on performance outcomes instead of prescriptive requirements [13]. Performance-related specifications should confirm through laboratory testing that the conglomerate mixture either meets or exceeds the requirements of a mixture with virgin materials only. For physical requirements that are difficult to test, such as age-related durability, experience from roads should inform the application to airport pavements, since durability is largely an environment-related issue, and not load related [151]. However, in the future, an objective test for age-related ravelling resistance of asphalt mixtures is required to better understand the long-term effect of recycled materials on asphalt surface life [164].

7. Summary and Conclusions

International waste policy is promoting the reduction and re-use of waste materials, and in some cases, specifically calling for the use of recycled materials in pavements. Consequently, there is a need to understand the performance of recycled materials in airport pavements, as well as the overall sustainability benefit. This paper reviewed several recycled materials and their applications to asphaltic, concrete, and bound and unbound pavement layers in the context of airport pavements. Additionally, it reviewed sustainability quantification methods, as well as implementation challenges for using recycled materials in airport pavements. Finally, principles were developed for the assessment and implementation of recycled materials.

For comparing pavements with and without recycled materials, a TBL assessment that uses LCCA and LCA for financial and environmental impacts, respectively, is best-practice, with frameworks and guidelines already established for airport pavements. In lieu of a defined system for social impact quantification, it is recommended to determine the virgin material use, as well as the quantity of material destined for landfill, which relates to intergenerational equity by ensuring access to materials by future generations. Additionally, it is recommended that pavement layers with recycled materials perform as good or better than conventional materials to ensure maintenance requirements are not increased, which would result in a social disbenefit during construction and significant maintenance works.

Principles for recycled material implementation focused on sorting and processing, source location, and performance testing. Sorting and processing are required to ensure consistency in materials, and the environmental and financial costs should be included in sustainability assessments. This is because sorting and processing can carry a significant energy burden for some recycled materials. The source location should be as close to site as possible to minimise haulage costs, which in some cases can provide an overall environmental disbenefit. Specifically for performance testing, it is recommended that performance-related specifications be developed in collaboration with industry bodies to facilitate the uptake of recycled materials, as well as a test method for long-term durability.

Author Contributions

Conceptualization, G.W.; investigation, S.J.; writing—original draft preparation, S.J. and L.V.; writing—review and editing, G.W. and L.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Smart Pavements Australia Research Collaboration (SPARC) Hub.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data generated.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Jamieson, S.; White, G. Developing a Performance-Based Specification for Stone Mastic Apshalt as an Ungrooved Runway Surface. In Proceedings of the International Airfield and Highway Pavements Conference 2019, Chicago, IL, USA, 21–24 July 2019. [Google Scholar]

- Australian Airports Association. Airport Practice Note 12—Airfield Pavement Essentials; Australian Airports Association: Canberra, Australia, 2017. [Google Scholar]

- European Commission. Identifying Member States at Risk of Not Meeting the 2025 Preparing for Re-Use and Recycling Target for Municipal Waste, the 2025 Recycling Target for Packaging Waste and the 2035 Municipal Waste Landfilling Reduction Target; European Commision: Brussels, Belgium, 2023.

- Environmental Protection Agency. The New National Recycling Goal; US Environmental Protection Agency: Washington, DC, USA, 2020.

- Australian Government. National Waste Policy Action Plan; Australian Government: Canberra, Australia, 2019.

- Australian Road Research Board. Best Practice Expert Advice on the Use of Recycled Materials in Road and Rail Infrastructure: Part B Sustainability Impacts Report; Australian Road Research Board: Melbourne, Australia, 2022. [Google Scholar]

- Austroads. AGPT04E-22—Guide to Pavement Technology Part 4E: Recylced Materials; Austroads: Sydney, Australia, 2022. [Google Scholar]

- Jamshidi, A.; White, G. Evaluation of Performance and Challenges of Use of Waste Materials in Pavement Construction: A Critical review. Appl. Sci. 2020, 10, 226. [Google Scholar] [CrossRef]

- Jamshidi, A.; White, G. Use of recycled materials in pavement construction for environmental sustainability. In Proceedings of the Eighteenth Annual International Conference on Pavement Engineering, Asphalt Technology and Infrastructure, Liverpool, UK, 27–28 February 2019. [Google Scholar]

- Van Dam, T.J.; Harvey, J.T.; Muench, S.T.; Smith, K.D.; Snyder, M.B.; Al-Qadi, I.L.; Ozer, H.; Meijef, J.; Ram, P.V.; Reosler, J.R.; et al. FHWA-HIF-15-002 Towards Sustainable Pavement Systems: A Reference Document; Federal Highway Administration: Washington, DC, USA, 2015.

- White, G.; Kitchen, R. Parametric comparison of the whole of life cycle cost of rigid and flexible aircraft pavements. In Proceedings of the 18th Annual International Conference on Pavement Engineering, Asphalt Technology and Infrastructure, Liverpool, UK, 27–28 February 2019. [Google Scholar]

- Butt, A.A.; Harvey, J.T.; Reger, D.; Ostovar, M.; Bejarano, M. DOT/FAA/TC-19/2 Life-Cycle Assessment of Airfield Pavements and Other Airside Features: Framework, Guidelines, and Case Studies; Federal Aviation Administration: Washington, DC, USA, 2019.