The Influence of Structural Parameters on the Ultimate Strength Capacity of a Designed Vertical Axis Turbine Blade for Ocean Current Power Generators

Abstract

:1. Introduction

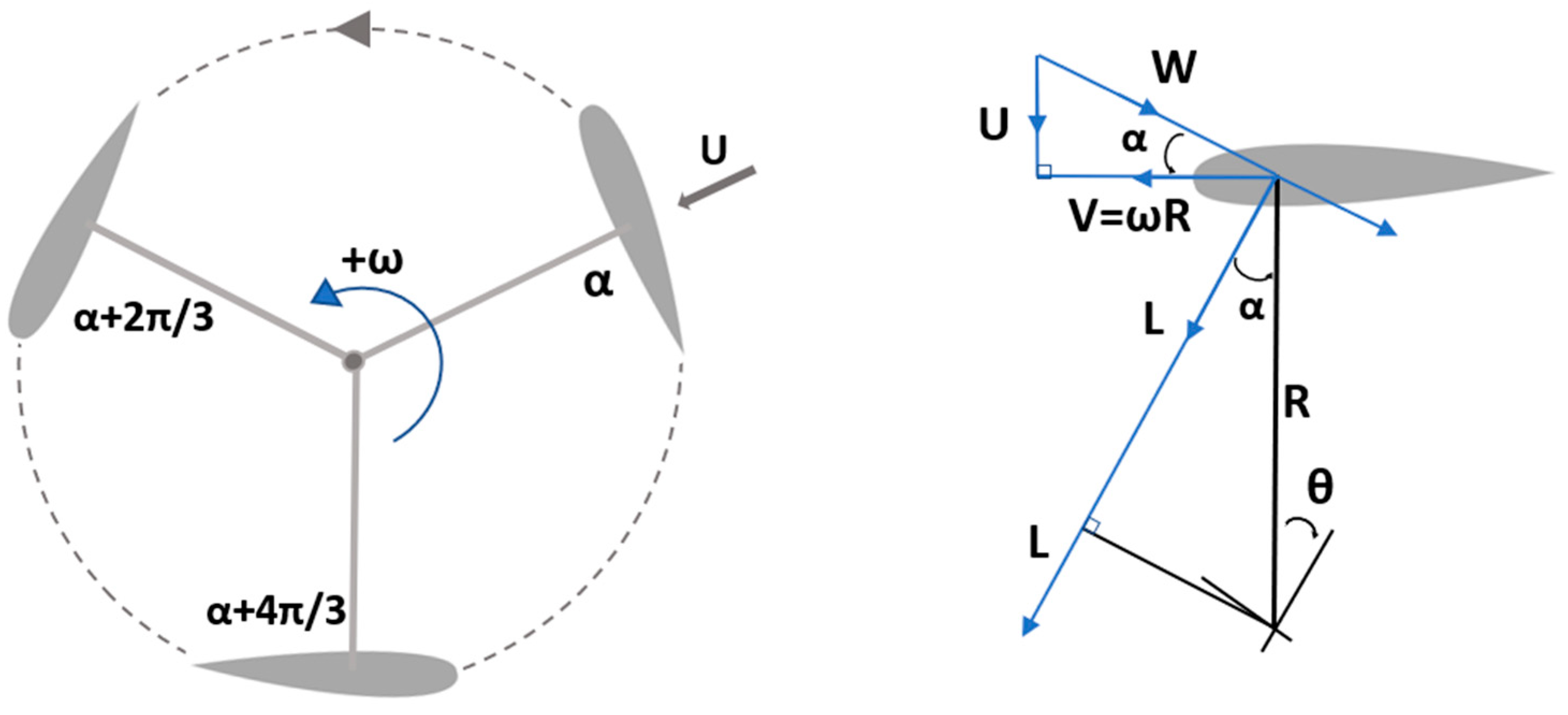

2. Turbine Configuration

3. Finite Element Method

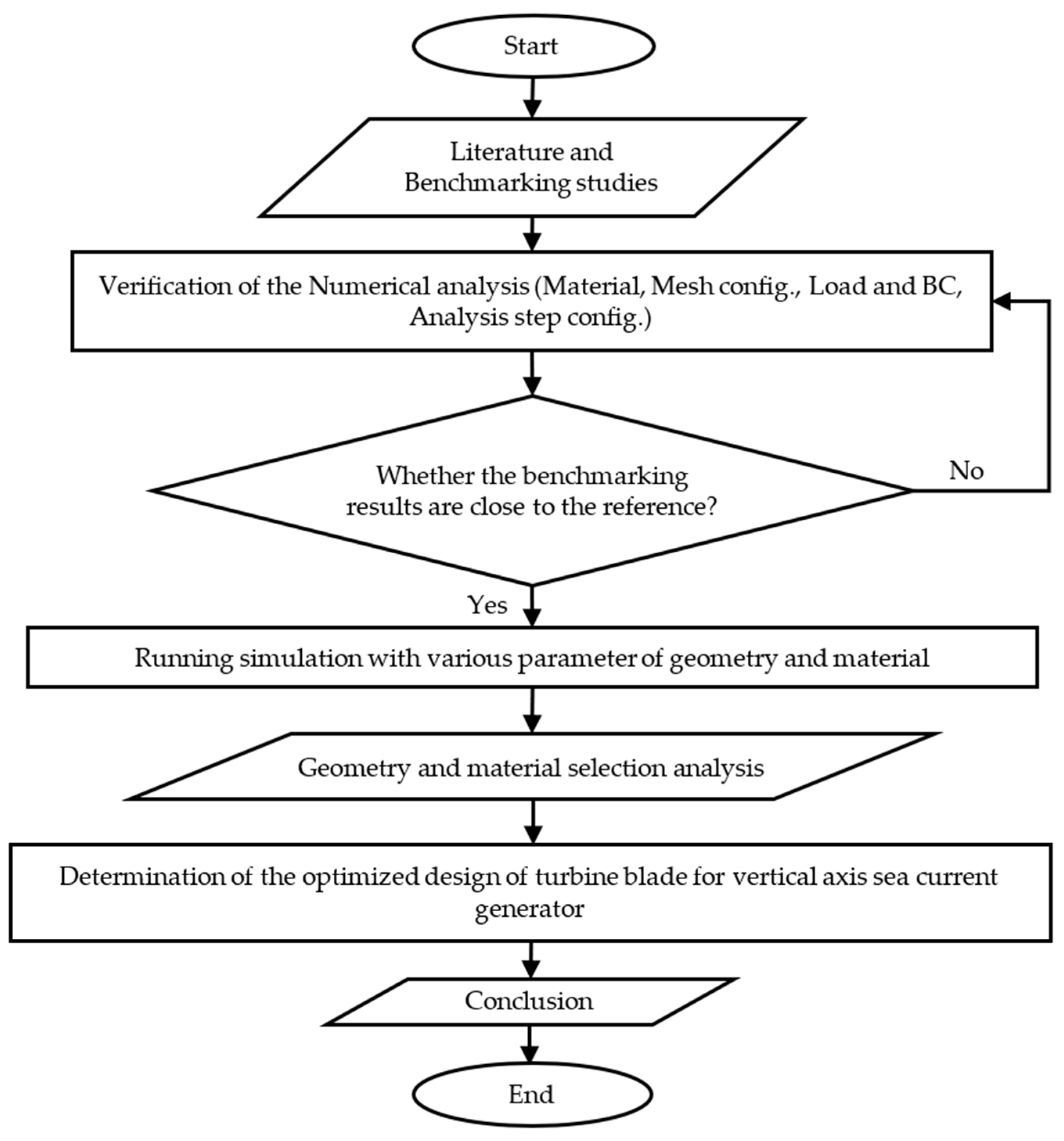

4. Methodology

4.1. Flowchart

4.2. Numerical Validation

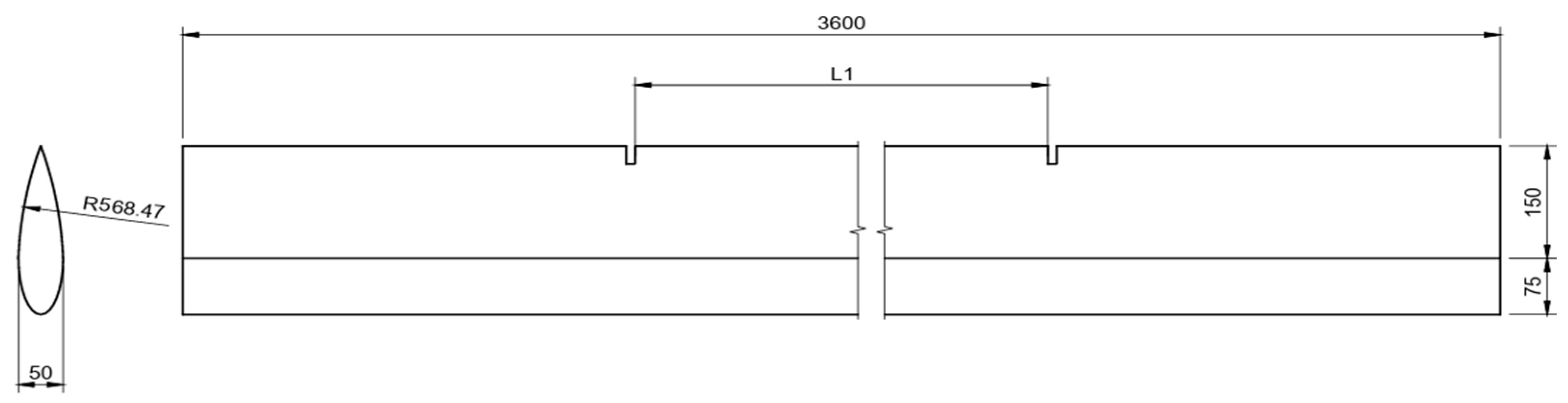

4.3. Numerical Modeling

4.4. Mesh Convergence Study

4.5. Space between Support Variation

4.6. Pitch Angle Variation

4.7. Frame Variation

4.8. Materials Variation

5. Result and Discussion

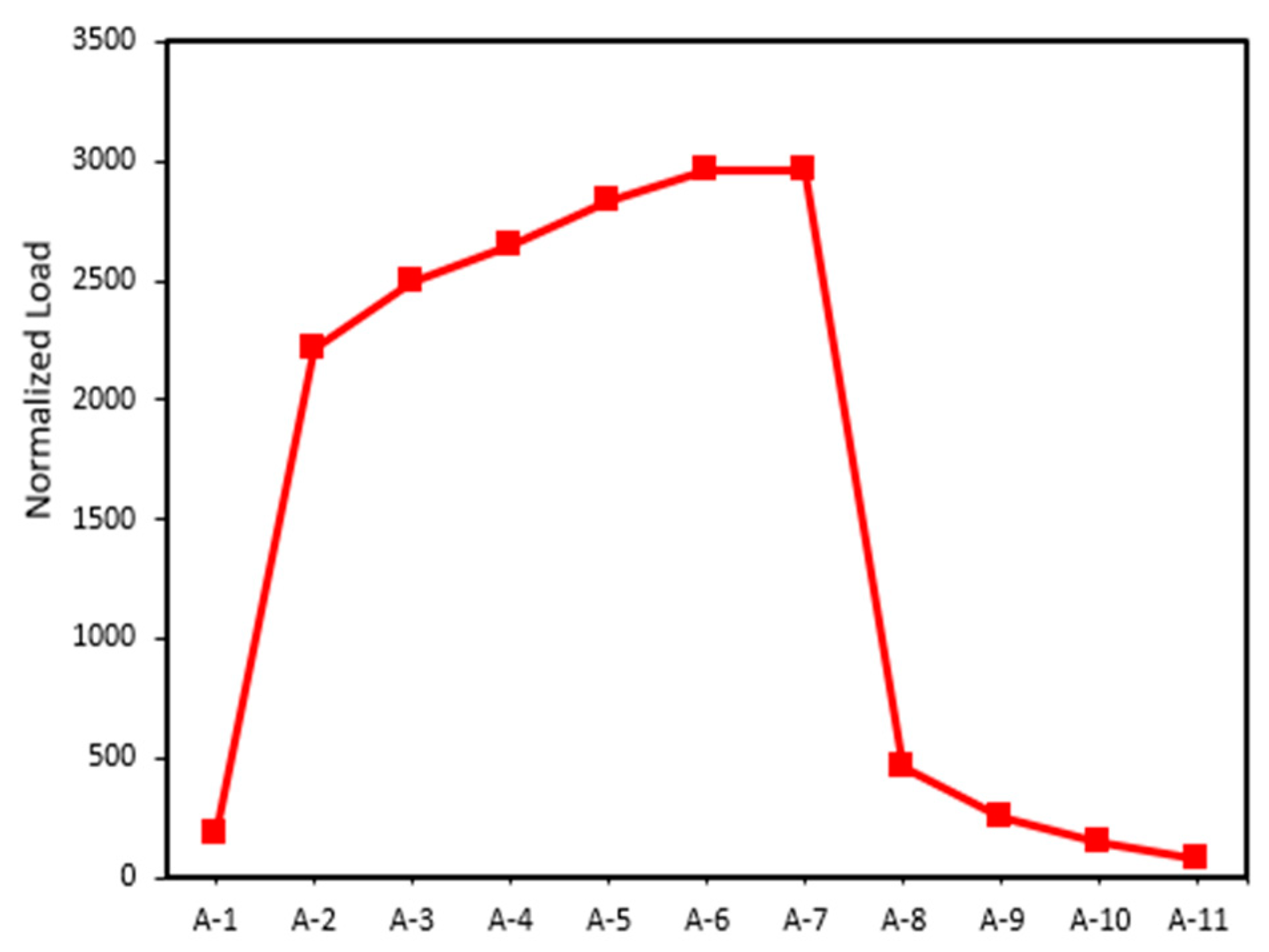

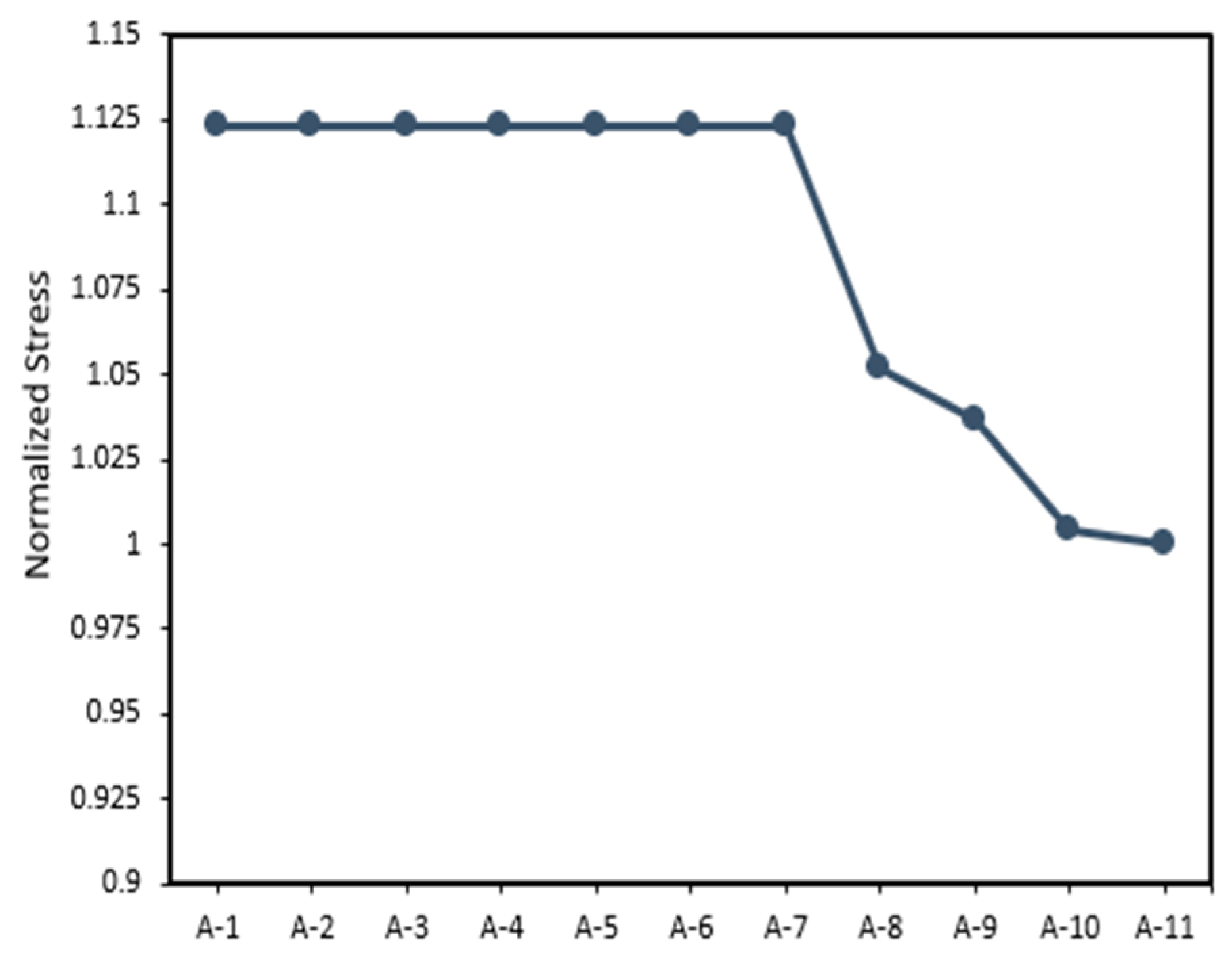

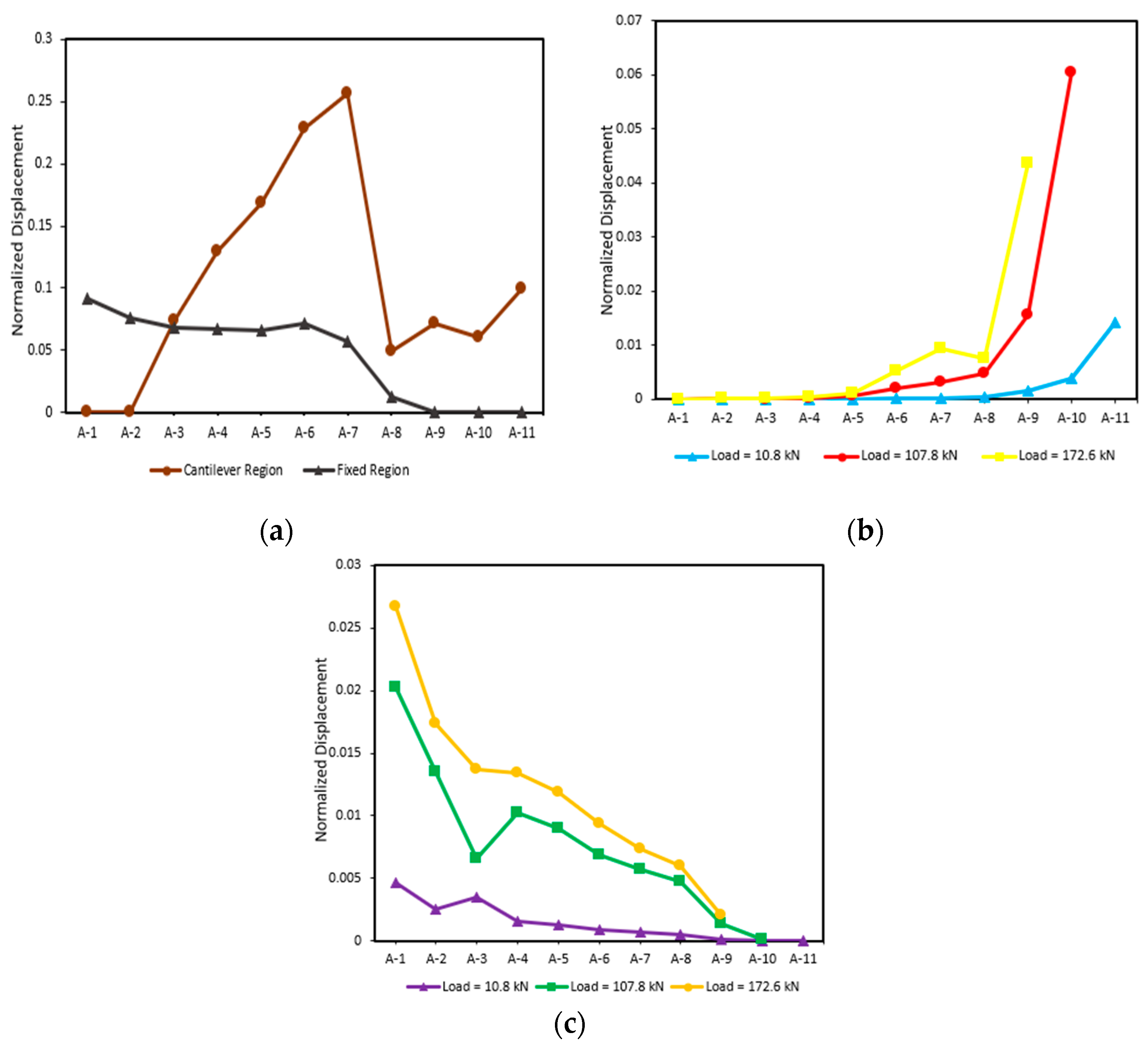

5.1. Space between Support

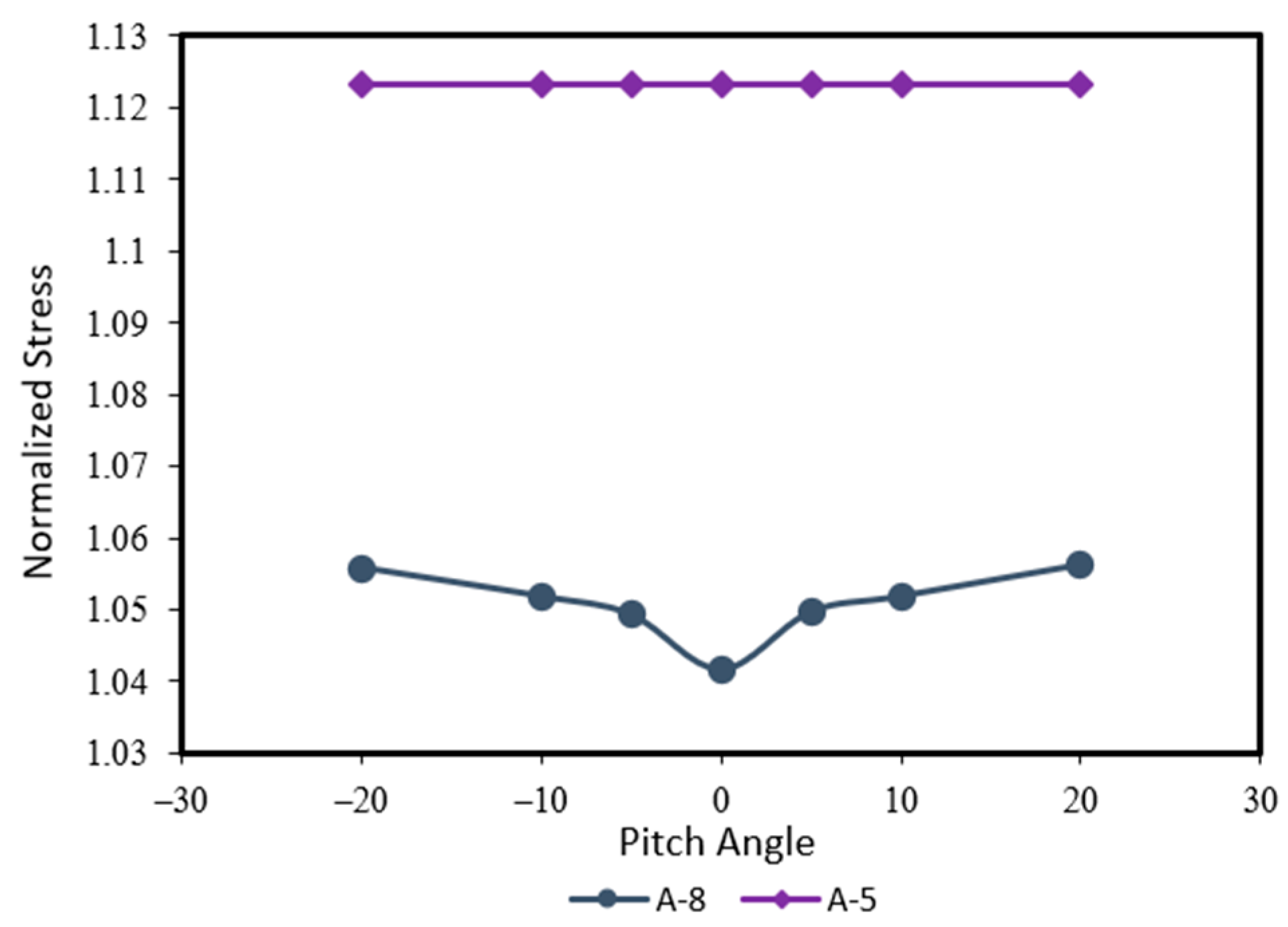

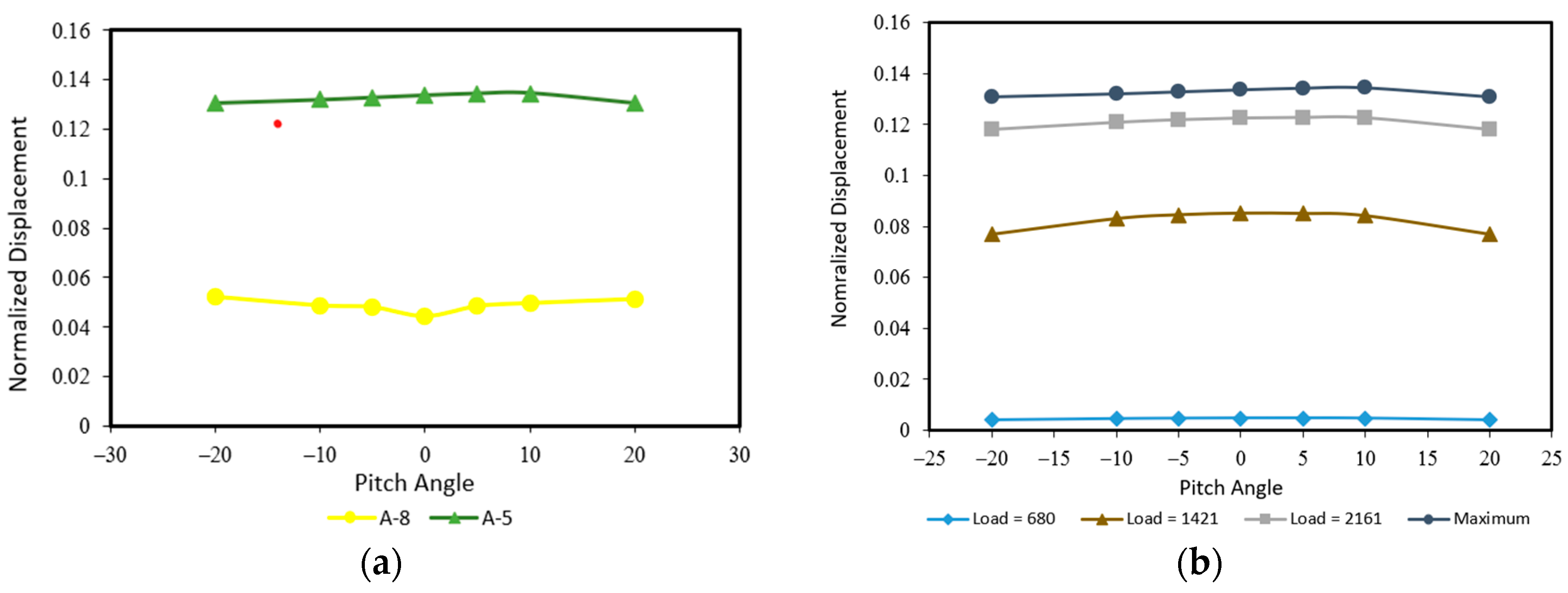

5.2. Pitch Angle

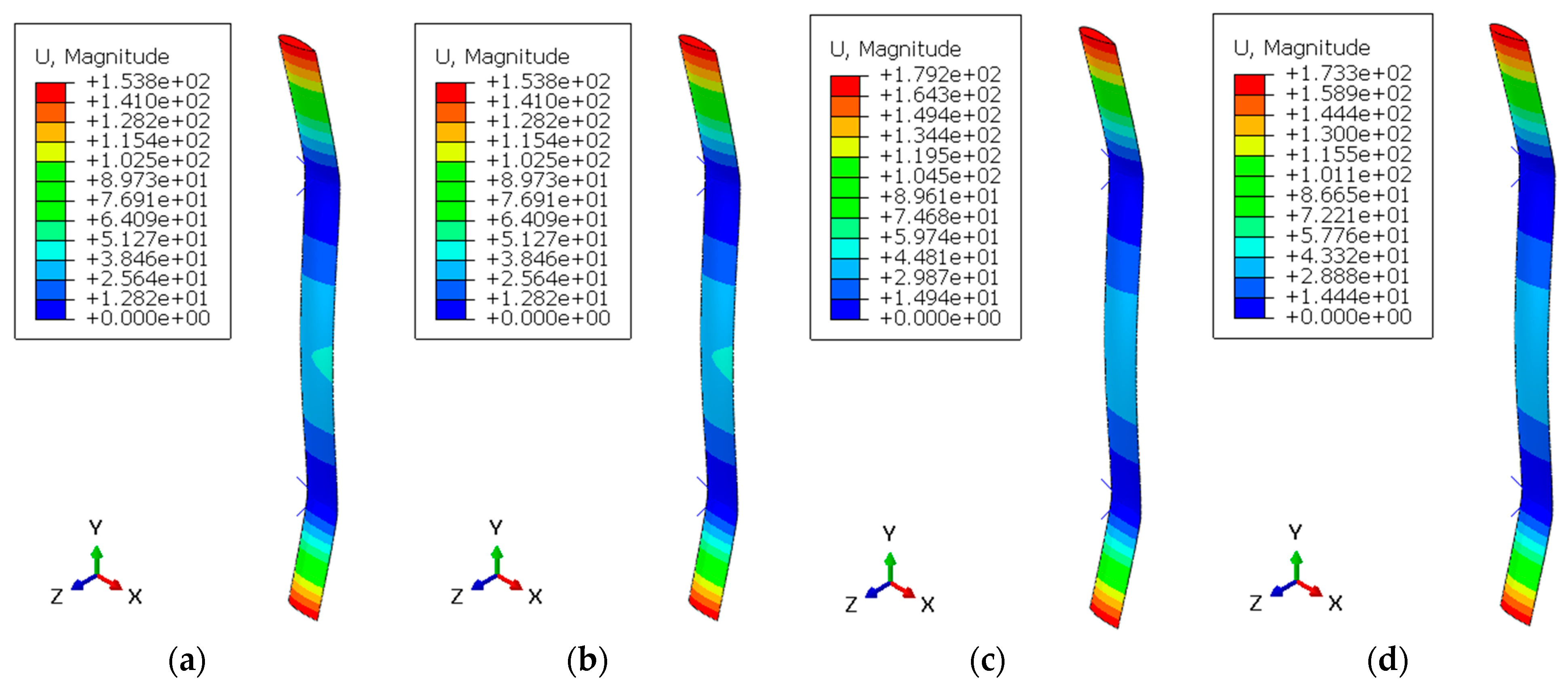

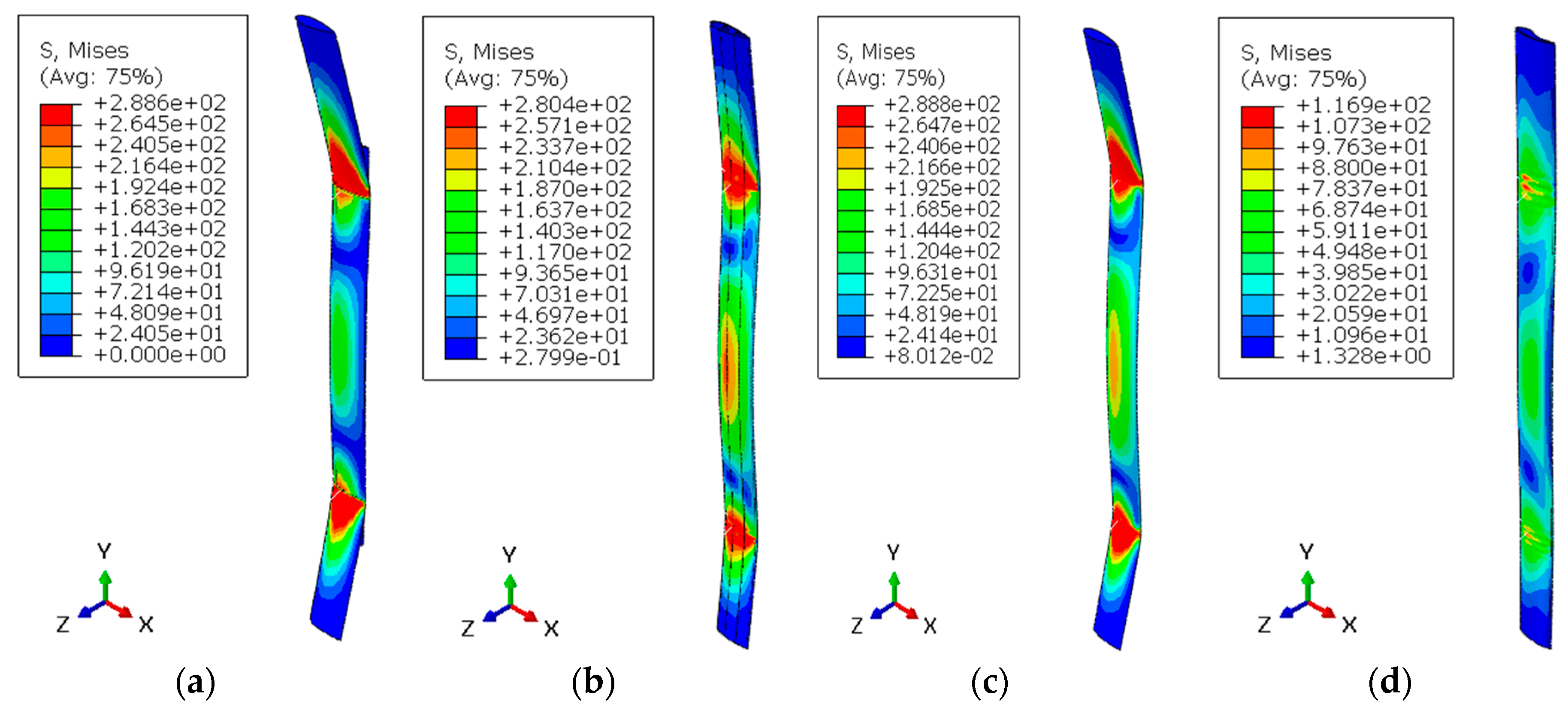

5.3. Frame Geometry

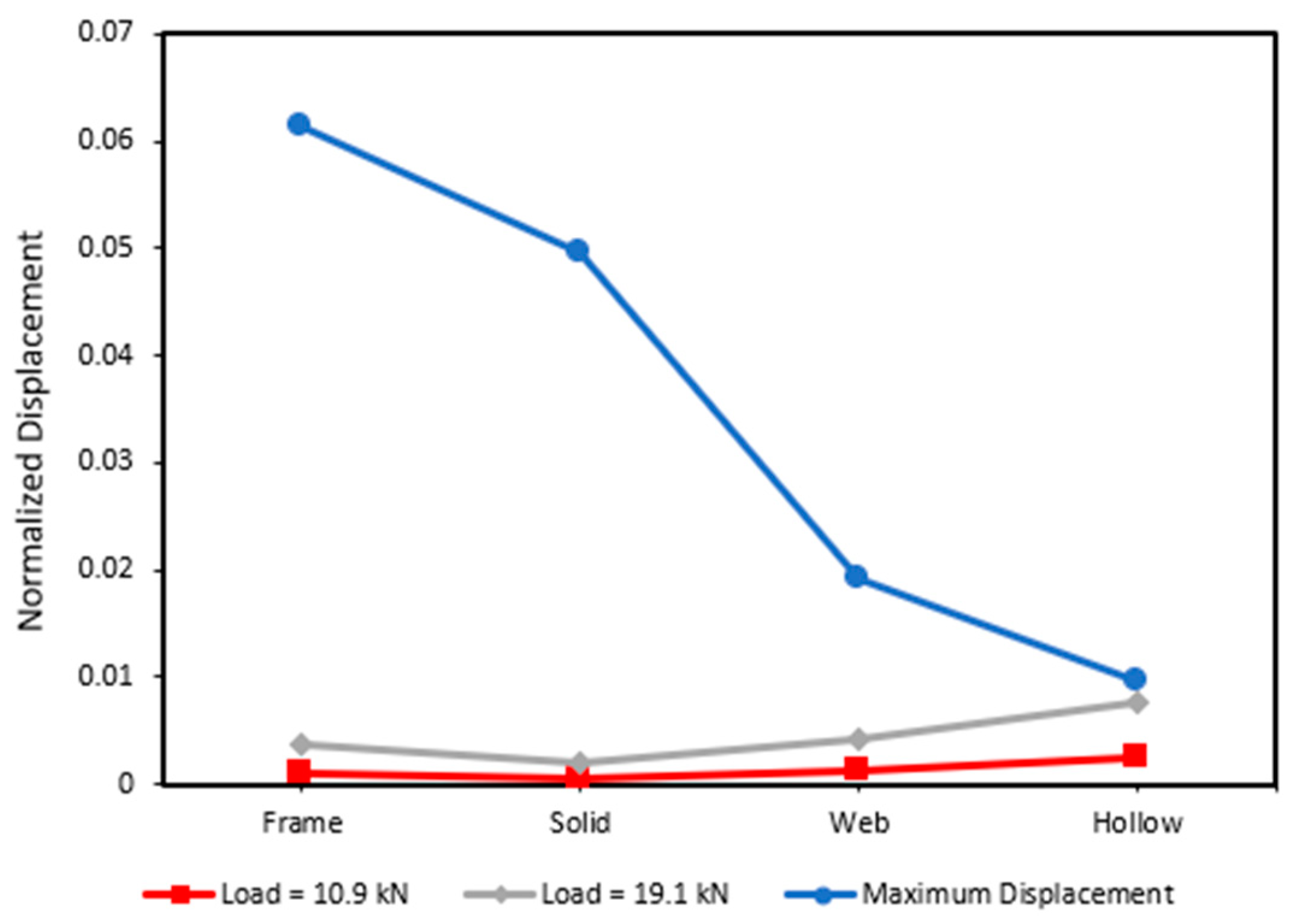

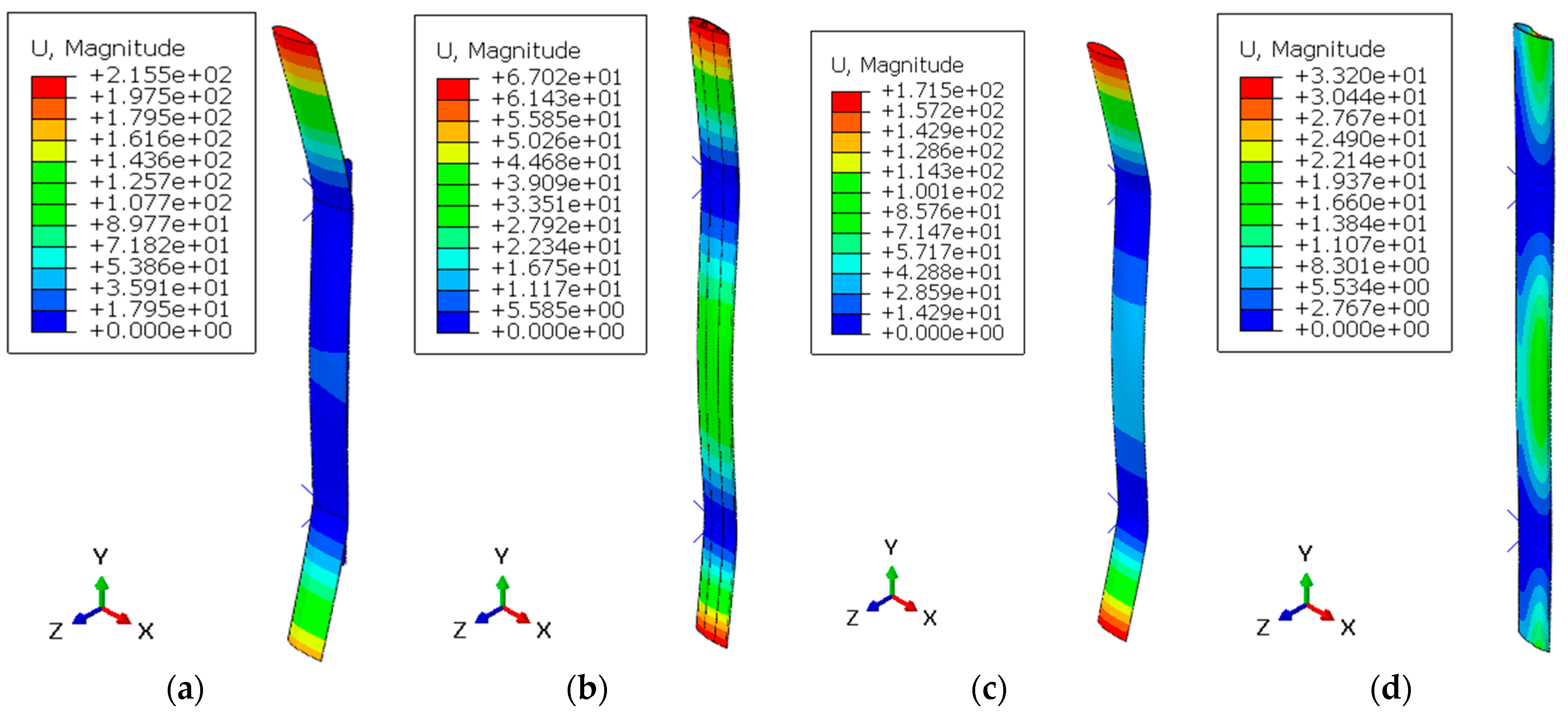

5.4. Material

6. Conclusions

- The optimal distance between supports for the turbine blade in an ocean current power generator is 2200 mm. This distance provides the most optimal load distribution, resulting in an even distribution of stress. The even stress distribution allows this support distance to achieve a high maximum load and, consequently, a high maximum displacement.

- A pitch angle between −20° and 20° does not significantly affect the structural strength of a turbine blade. This is because the load on the axial component of the blade is much smaller than the load on the normal component. Therefore, as long as the aerodynamics of the blade are not considered, the pitch angle can be freely adjusted within this range.

- The frame geometry used in turbine blades affects rigidity, weight, and blade surface area. This variation causes the maximum load, stress, displacement, and maximum load-to-weight ratio to differ for each geometry. The more solid a blade frame is, the higher the maximum load, stress, and displacement due to better stress distribution. However, a more solid frame results in a smaller maximum load-to-weight ratio. Therefore, a blade-shaped frame is chosen because it offers the best maximum load-to-weight ratio among the various frame shapes.

- Each material has different mechanical properties. The higher ultimate strength of a material increases the maximum stress it can withstand. A higher Young’s Modulus increases the blade stiffness, thereby reducing the displacement. However, a higher material density increases the blade weight, reducing the maximum load-to-weight ratio. Therefore, CFRP material is selected because it offers a high maximum load-to-weight ratio and can withstand high maximum stress.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Farmer, G.T.; Cook, J. The World Ocean BT—Climate Change Science: A Modern Synthesis: Volume 1—The Physical Climate; Farmer, G.T., Cook, J., Eds.; Springer: Dordrecht, The Netherlands, 2013; pp. 247–259. [Google Scholar] [CrossRef]

- Adie, P.W.; Adiputra, R.; Prabowo, A.R.; Erwandi, E.; Muttaqie, T.; Muhayat, N.; Huda, N. Assessment of the OTEC cold water pipe design under bending loading: A benchmarking and parametric study using finite element approach. J. Mech. Behav. Mater. 2023, 32, 20220298. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, X.; Xu, Y. Modeling, simulation, and experiment of switched reluctance ocean current generator system. Adv. Mech. Eng. 2013, 2013, 5. [Google Scholar] [CrossRef]

- Madi, M.; Mukhtasor; Rahmawati, S.; Satrio, D.; Tuswan, T.; Ismail, A. Experimental Study on the Effect of Single Flow Disturber on the Performance of the Straight-Bladed Hydrokinetic Turbine at Low Current Speed. Pomorstvo 2024, 38, 43–54. [Google Scholar] [CrossRef]

- Madi, M.; Mukhtasor, M.; Satrio, D.; Tuswan, T.; Ismail, A.; Rafi, R.; Yunesti, P.; Buana, S.W.; Jarwinda, J. Experimental Study on the Effect of Foil Guide Vane on the Performance of a Straight-Blade Vertical Axis Ocean Current Turbine. Nase More 2024, 71, 1–11. [Google Scholar] [CrossRef]

- Chiang, H.W.D.; Lin, C.Y.; Hsu, C.N. Design and performance study of an ocean current turbine generator. Int. J. Turbo Jet Engines 2013, 30, 293–302. [Google Scholar] [CrossRef]

- Fizari, A.J.; Wijaya, F.D.; Cahyadi, A.I.; Adiyasa, I.W. Design and Simulation Permanent Magnet Synchronous Generator 1.5 kW for Ocean Current Turbine. In Proceedings of the CENCON 2019—2019 IEEE Conference on Energy Conversion (CENCON), Yogyakarta, Indonesia, 16–17 October 2019. [Google Scholar] [CrossRef]

- Tian, W.; Ni, X.; Mao, Z.; Zhang, T. Influence of surface waves on the hydrodynamic performance of a horizontal axis ocean current turbine. Renew. Energy 2020, 158, 37–48. [Google Scholar] [CrossRef]

- Mubarok, M.A.; Arini, N.R.; Satrio, D. Optimization of Horizontal Axis Tidal Turbines Farming Configuration Using Particle Swarm Optimization (PSO) Algorithm. In Proceedings of the 2023 International Electronics Symposium (IES), Denpasar, Indonesia, 8–10 August 2023. [Google Scholar] [CrossRef]

- Ng, K.W.; Lam, W.H.; Ng, K.C. 2002–2012: 10 Years of Research Progress in Horizontal-Axis Marine Current Turbines. Energies 2013, 6, 1497–1526. [Google Scholar] [CrossRef]

- Sasmita, A.F.; Arini, N.R.; Satrio, D. Numerical Analysis of Vertical Axis Tidal Turbine: A Comparison of Darrieus and Gorlov Type. In Proceedings of the 2023 International Electronics Symposium (IES), Denpasar, Indonesia, 8–10 August 2023. [Google Scholar] [CrossRef]

- Akimoto, H.; Tanaka, K.; Uzawa, K. A conceptual study of floating axis water current turbine for low-cost energy capturing from river, tide and ocean currents. Renew. Energy 2013, 57, 283–288. [Google Scholar] [CrossRef]

- Erwandi, E.; Kasharjanto, A.; Satrio, D.; Rahuna, D.; Suyanto, E.M.; Mintarso, C.S.J.; Irawanto, Z.; Ramadhani, M.A. Numerical Analysis of Resistance and Motions on Trimaran Floating Platform for Tidal Current Power Plant. Int. Rev. Model. Simul. 2024, 17, 6–16. [Google Scholar] [CrossRef]

- Zhou, Z.; Benbouzid, M.; Charpentier, J.F.; Scuiller, F.; Tang, T. Developments in large marine current turbine technologies—A review. Renew. Sustain. Energy Rev. 2017, 71, 852–858. [Google Scholar] [CrossRef]

- Xie, J.; Chen, J. Vertical-axis ocean current turbine design research based on separate design concept. Ocean Eng. 2019, 188, 106258. [Google Scholar] [CrossRef]

- Zeiner-Gundersen, D.H. A novel flexible foil vertical axis turbine for river, ocean, and tidal applications. Appl. Energy 2015, 151, 60–66. [Google Scholar] [CrossRef]

- Nguyen, M.T.; Balduzzi, F.; Goude, A. Effect of pitch angle on power and hydrodynamics of a vertical axis turbine. Ocean Eng. 2021, 238, 109335. [Google Scholar] [CrossRef]

- Hasankhani, A.; VanZwieten, J.; Tang, Y.; Dunlap, B.; De Luera, A.; Sultan, C.; Xiros, N. Modeling and numerical simulation of a buoyancy controlled ocean current turbine. Int. Mar. Energy J. 2021, 4, 47–58. [Google Scholar] [CrossRef]

- Chen, J.H.; Wang, X.C.; Li, H.; Jiang, C.H.; Bao, L.J. Design of the blade under low flow velocity for horizontal axis tidal current turbine. J. Mar. Sci. Eng. 2020, 8, 989. [Google Scholar] [CrossRef]

- Wang, H.-M.; Qu, X.-K.; Chen, L.; Tu, L.-Q.; Wu, Q.-R. Numerical study on energy-converging efficiency of the ducts of vertical axis tidal current turbine in restricted water. Ocean Eng. 2020, 210, 107320. [Google Scholar] [CrossRef]

- Satrio, D.; Suntoyo; Widyawan, H.B.; Ramadhani, M.A.; Muharja, M. Effects of the distance ratio of circular flow disturbance on vertical-axis turbine performance: An experimental and numerical study. Sustain. Energy Technol. Assess. 2024, 63, 103635. [Google Scholar] [CrossRef]

- Rahuna, D.; Erwandi; Satrio, D.; Utama, I.K.A.P. Opportunities for Utilizing Vortex Generators on Vertical Axis Ocean Current Turbines: A Review. BIO Web Conf. 2024, 89, 10003. [Google Scholar] [CrossRef]

- Hatoro, R.; Utama, I.K.A.P.; Erwandi, E.; Sulistyono, A. An Experimental Investigation of passive Variable-pitch Vertical Axis Ocean Current Turbine. J. Eng. Technol. Sci. 2011, 43, 27–40. [Google Scholar] [CrossRef]

- Liu, T. Evolutionary understanding of airfoil lift. Adv. Aerodyn. 2021, 3, 37. [Google Scholar] [CrossRef]

- Bora, M.; Sharma, A.V.; Kumari, P.; Sahoo, N. Investigation of bamboo-based vertical axis wind turbine blade under static loading. Ocean. Eng. 2023, 285, 115317. [Google Scholar] [CrossRef]

- Patel, V.; Rathod, V.; Patel, C. Optimal utilization of hydrokinetic energy resources through performance improvement of the darrieus turbine using concave and flat blocking plates. Ocean Eng. 2023, 283, 115099. [Google Scholar] [CrossRef]

- Asadbeigi, M.; Ghafoorian, F.; Mehrpooya, M.; Chegini, S.; Jarrahian, A. A 3D Study of the Darrieus Wind Turbine with Auxiliary Blades and Economic Analysis Based on an Optimal Design from a Parametric Investigation. Sustainability 2023, 15, 4684. [Google Scholar] [CrossRef]

- Patel, V.; Eldho, T.I.; Prabhu, S.V. Performance enhancement of a Darrieus hydrokinetic turbine with the blocking of a specific flow region for optimum use of hydropower. Renew. Energy 2019, 135, 1144–1156. [Google Scholar] [CrossRef]

- Li, Z.; Xu, H.; Feng, J.; Chen, H.; Kan, K.; Li, T.; Shen, L. Fluctuation characteristics induced by energetic coherent structures in air-core vortex: The most complex vortex in the tidal power station intake system. Energy 2024, 288, 129778. [Google Scholar] [CrossRef]

- Ainsworth, M.; Parker, C. Unlocking the secrets of locking: Finite element analysis in planar linear elasticity. Comput. Methods Appl. Mech. Eng. 2022, 395, 115034. [Google Scholar] [CrossRef]

- Cascio, I.; Milazzo, M.L.; Benedetti, A. Virtual element method for computational homogenization of composite and heterogeneous materials. Compos. Struct. 2020, 232, 111523. [Google Scholar] [CrossRef]

- Anderson, R.; Andrej, J.; Barker, A.; Bramwell, J.; Camier, J.-S.; Cerveny, J.; Dobrev, V.; Dudouit, Y.; Fisher, A.; Kolev, T.; et al. MFEM: A modular finite element methods library. Comput. Math. Appl. 2021, 81, 42–74. [Google Scholar] [CrossRef]

- Genao, F.Y.; Kim, J.; Żur, K.K. Nonlinear finite element analysis of temperature-dependent functionally graded porous micro-plates under thermal and mechanical loads. Compos. Struct. 2021, 256, 112931. [Google Scholar] [CrossRef]

- Hartmann, S. A remark on the application of the Newton-Raphson method in non-linear finite element analysis. Comput. Mech. 2005, 36, 100–116. [Google Scholar] [CrossRef]

- Pho, K.H. Improvements of the Newton–Raphson method. J. Comput. Appl. Math. 2022, 408, 114106. [Google Scholar] [CrossRef]

- Zhang, A.; Mohr, D. Using neural networks to represent von Mises plasticity with isotropic hardening. Int. J. Plast. 2020, 132, 102732. [Google Scholar] [CrossRef]

- Hameed, M.S.; Afaq, S.K. Design and analysis of a straight bladed vertical axis wind turbine blade using analytical and numerical techniques. Ocean Eng. 2013, 57, 248–255. [Google Scholar] [CrossRef]

- Ponnusamy, P.; Rashid, R.A.R.; Masood, S.H.; Ruan, D.; Palanisamy, S. Mechanical properties of slm-printed aluminium alloys: A review. Materials 2020, 13, 4301. [Google Scholar] [CrossRef]

- Holst, D.; Church, B.; Wegner, F.; Pechlivanoglou, G.; Nayeri, C.N.; Paschereit, C.O. Experimental Analysis of a NACA 0021 Airfoil under Dynamic Angle of Attack Variation and Low Reynolds Numbers. J. Eng. Gas Turbine Power 2019, 141, 031020. [Google Scholar] [CrossRef]

- Adie, P.W.; Prabowo, A.R.; Muttaqie, T.; Adiputra, R.; Muhayat, N.; Carvalho, H.; Huda, N. Non-linear assessment of cold water pipe (CWP) on the ocean thermal energy conversion (OTEC) installation under bending load. Procedia Struct. Integr. 2023, 47, 142–149. [Google Scholar] [CrossRef]

- Ardaneh, F.; Abdolahifar, A.; Karimian, S.M.H. Numerical analysis of the pitch angle effect on the performance improvement and flow characteristics of the 3-PB Darrieus vertical axis wind turbine. Energy 2022, 239, 122339. [Google Scholar] [CrossRef]

- Wang, L.; Kolios, A.; Nishino, T.; Delafin, P.L.; Bird, T. Structural optimisation of vertical-axis wind turbine composite blades based on finite element analysis and genetic algorithm. Compos. Struct. 2016, 153, 123–138. [Google Scholar] [CrossRef]

- Satrio, D.; Musabikha, S.; Junianto, S.; Prifiharni, S.; Kusumastuti, R.; Nikitasari, A.; Priyotomo, G. The Advantages and Challenges of Carbon Fiber Reinforced Polymers for Tidal Current Turbine Systems—An Overview. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Surabaya, Indonesia, 2024; p. 1298. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, R.; Kumar, S.; Verma, P. A review on machining performance of AISI 304 steel. Mater. Today Proc. 2022, 56, 2945–2951. [Google Scholar] [CrossRef]

- Muttaqie, T.; Park, S.H.; Sohn, J.M.; Cho, S.-R.; Nho, I.S.; Han, S.; Lee, P.-S.; Cho, Y.S. Experimental investigations on the implosion characteristics of thin cylindrical aluminium-alloy tubes. Int. J. Solids Struct. 2020, 200–201, 64–82. [Google Scholar] [CrossRef]

- Abbood, I.S.; Odaa, S.A.; Hasan, K.F.; Jasim, M.A. Properties evaluation of fiber reinforced polymers and their constituent materials used in structures—A review. Mater. Today Proc. 2021, 43, 1003–1008. [Google Scholar] [CrossRef]

- Zhou, B.; Zhang, M.; Wang, L.; Ma, G. Experimental study on mechanical property and microstructure of cement mortar reinforced with elaborately recycled GFRP fiber. Cem. Concr. Compos. 2021, 117, 103908. [Google Scholar] [CrossRef]

| Wall Thickness (mm) | Total Force (kN) |

|---|---|

| Solid | 26.02 |

| 5 | 11.83 |

| 4 | 9.76 |

| 3 | 7.59 |

| Wall Thickness (mm) | Deformation (mm) | Difference (%) | |

|---|---|---|---|

| Hameed and Afaq [37] | Current Study | ||

| Solid | 7.39 | 7.90 | 6.9 |

| 5 | 4.51 | 4.76 | 5.5 |

| 4 | 4.27 | 3.99 | 6.5 |

| 3 | 4.07 | 3.93 | 3.4 |

| Code | L1 (mm) | Distance from End (mm) |

|---|---|---|

| A-1 | 3600 | 0 |

| A-2 | 3000 | 300 |

| A-3 | 2800 | 400 |

| A-4 | 2700 | 450 |

| A-5 | 2500 | 550 |

| A-6 | 2300 | 650 |

| A-7 | 2200 | 700 |

| A-8 | 2000 | 800 |

| A-9 | 1600 | 1000 |

| A-10 | 1000 | 1300 |

| A-11 | 0 | 1800 |

| Code | Pitch Angle |

|---|---|

| B-1 | −20° |

| B-2 | −10° |

| B-3 | −5° |

| B-4 | 0° |

| B-5 | +5° |

| B-6 | +10° |

| B-7 | +20° |

| Code | Frame Shape |

|---|---|

| C-1 | Frame |

| C-2 | Web |

| C-3 | Solid Blade |

| C-4 | Hollow Blade |

| Code | Material | Density (kg/m3) | Young’s Modulus (GPa) | Yield Strength (MPa) | Ultimate Strength (MPa) |

|---|---|---|---|---|---|

| D-1 | Stainless Steel [44] | 8000 | 193 | 539 | 766 |

| D-2 | Al 6061 [45] | 2700 | 68.9 | 276 | 310 |

| D-3 | CFRP [46] | 1800 | 130 | 1756 | - |

| D-4 | GFRP [47] | 2500 | 45.6 | 1280 | - |

| Code | Normalized by (N) |

|---|---|

| C-1 (frame) | 237.6 |

| C-2 (web) | 150.2 |

| C-3 (solid) | 129.6 |

| C-4 (hollow) | 729.0 |

| Code | Normalized by (N) | |

|---|---|---|

| Hollow Blade | Solid Blade | |

| D-1 (Stainless Steel) | 384.0 | 2160 |

| D-2 (Aluminum) | 129.6 | 729 |

| D-3 (CFRP) | 86.4 | 486 |

| D-4 (GFRP) | 120.0 | 675 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rasgianti; Mukhtasor; Satrio, D. The Influence of Structural Parameters on the Ultimate Strength Capacity of a Designed Vertical Axis Turbine Blade for Ocean Current Power Generators. Sustainability 2024, 16, 7655. https://doi.org/10.3390/su16177655

Rasgianti, Mukhtasor, Satrio D. The Influence of Structural Parameters on the Ultimate Strength Capacity of a Designed Vertical Axis Turbine Blade for Ocean Current Power Generators. Sustainability. 2024; 16(17):7655. https://doi.org/10.3390/su16177655

Chicago/Turabian StyleRasgianti, Mukhtasor, and Dendy Satrio. 2024. "The Influence of Structural Parameters on the Ultimate Strength Capacity of a Designed Vertical Axis Turbine Blade for Ocean Current Power Generators" Sustainability 16, no. 17: 7655. https://doi.org/10.3390/su16177655

APA StyleRasgianti, Mukhtasor, & Satrio, D. (2024). The Influence of Structural Parameters on the Ultimate Strength Capacity of a Designed Vertical Axis Turbine Blade for Ocean Current Power Generators. Sustainability, 16(17), 7655. https://doi.org/10.3390/su16177655