Abstract

This research work focuses on the recycling of gypsum, a key component of drywall panels commonly used in construction. It proposes this practice as a technically and economically viable strategy that also aligns with the circular economy model. In this context, waste loses its status as refuse and is transformed back into raw material. A technical feasibility analysis was conducted based on a sample extracted from a specific project, which was subjected to characterization tests and mechanical behavior assessments in both laboratory and real construction conditions. Additionally, an economic feasibility analysis was performed by comparing the budgets of the same project in two scenarios: the traditional plastering process and the use of recycled gypsum. This analysis highlighted the fiscal and legal benefits that adopting the circular model could offer to stakeholders in the construction industry. This study began with a market analysis to determine the availability of recyclable material and to assess the multiple benefits that its reuse can provide. Based on the characterization of the material obtained from the construction site and the mechanical tests conducted, the economic advantages were evaluated for contractors as well as for the potential establishment of companies focused on gypsum recycling. All of this analysis was framed within the context of sustainability, emphasizing the positive environmental impacts of this practice, as well as the development of a strategy that serves as a valuable proposal for the construction sector. This work concludes that recycling gypsum in construction projects represents a technically, environmentally, and economically sustainable alternative that can positively transform the industry.

1. Introduction

In recent decades, the concept of a circular economy has gained prominence as a promising approach to promoting sustainability and the efficient use of resources, challenging the traditional linear model of “extract, produce, dispose” [1]. Construction, being one of the sectors with the highest consumption of raw materials and generation of waste, represents a key area for implementing circular economy practices [2]. The extensive use of gypsum boards (also known as drywall) in partition systems, flooring, ceilings, and wall coverings has raised growing concerns about the volumes of waste generated. This waste, resulting from cutting, damage during handling and dismantling, is often discarded as common debris, wasting its potential to be recycled and reintegrated into production cycles. Numerous studies have explored the recycling of gypsum boards, primarily focusing on the recovery of gypsum through wet separation processes, calcination, and thermal treatments. Although these methods have demonstrated the viability of high-quality recycled gypsum, they involve additional costs, complexity, and, in some cases, environmental impacts associated with energy consumption and emissions [3]. Recognizing these limitations, this paper proposes an alternative strategy for the direct recycling of gypsum board waste at construction sites, assessing its technical and economic feasibility as a substitute for conventional gypsum used in the manufacture of stucco and finishes. This approach avoids complex and costly treatments, facilitating the on-site reuse of generated waste and aligning with the principles of a circular economy and sustainable construction. In addition to the potential environmental and economic benefits, the recycling of gypsum boards helps address the challenges associated with their final disposal, as this waste can generate pollution problems if not managed properly. In this context, various international initiatives and regulations have promoted responsible management and recycling of these construction wastes [4]. This study contributes to this trend by providing a practical and cost-effective solution for utilizing gypsum board waste, fostering the transition toward a more circular and sustainable construction industry [5].

2. Materials and Methods

The main objective of the implemented methodological strategy was to transform gypsum board waste, through mechanical grinding and filtering processes, into recycled gypsum that met the minimum characteristics required to be used as a substitute for conventional commercial gypsum in plastering and finishing applications in construction projects. Once a suitable recycled material was obtained, its properties were thoroughly studied and its potential for application as finishing plaster was evaluated through a series of standardized technical tests, comparing it with a reference sample of standard commercial gypsum widely used in Colombian construction projects for plastering and finishing processes.

To ensure the representativeness and practical relevance of the study, samples of gypsum board waste were selected from an ongoing commercial project in the city of Bogotá, Colombia, where this type of material was being intensively used. In the first stage, these samples were homogenized through a grinding and filtering process (Figure 1). The waste material underwent a total of 4 cycles of grinding and sieving in order to achieve an acceptable degree of fineness, meeting the requirement established by the Colombian standard [6], which defines a maximum particle size of 600 μm, equivalent to the mesh opening of the No. 30 sieve in the standard series.

Figure 1.

Detail of waste uniformization and homogenization.

This initial preparation of the samples was crucial to ensure that the obtained recycled material met the necessary fineness standards for its use in finishing processes, laying the groundwork for its subsequent characterization and performance evaluation.

Once a suitable recycled material was obtained, with particles smaller than the size required for use as stucco plaster, a thorough characterization process was carried out to evaluate its physical and mechanical properties. This stage was crucial in determining the technical feasibility of using recycled gypsum as a substitute for conventional gypsum.

To carry out this characterization, a battery of standardized tests widely recognized in the construction industry were applied. Table 1 presents a detailed list of the test methods used, which are based on current international and Colombian technical standards.

Table 1.

List of applied characterization tests.

These tests, conducted strictly following the protocols established in the mentioned standards, allowed for precise and reliable characterization of key aspects of the recycled material’s behavior, such as its workability, mechanical strength, setting times, and fundamental physical properties. The results obtained were compared with those of a reference sample of standard commercial gypsum, widely used in Colombian construction projects, in order to evaluate the technical feasibility of recycled gypsum as an effective substitute.

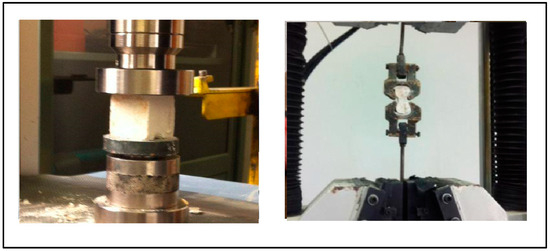

In the first characterization stage, the index properties of both recycled and reference gypsums were established. Subsequently, the fresh state properties of pastes made with both materials were determined (Figure 2 and Figure 3). These tests allowed for the evaluation of crucial aspects such as initial and final setting times, as well as consistency and workability indicators—such as the optimal water/gypsum ratio for mixing—through the determination of paste fluidity. Additionally, a series of mechanical tests were performed on the mixtures in the hardened state to characterize fundamental properties such as compressive and tensile strength (Figure 4). These mechanical tests were complemented by detailed observations made using scanning electron microscopy (SEM), which allowed for an in-depth analysis of the morphology and microstructure of the materials, providing valuable information on the interaction between the components of recycled gypsum. Finally, as a key stage of the methodology, performance tests were carried out in which both recycled and reference gypsums were applied under real-use conditions (Figure 5). These tests aimed to evaluate the behavior and durability of the materials when used for plastering and finishing surfaces, simulating the conditions they would be exposed to in a construction project. This comprehensive methodology, which combines standardized characterization tests with performance tests under real conditions and microstructural analysis, allowed for a deep and reliable understanding of the behavior of recycled gypsum, laying the foundation for evaluating its technical viability as a substitute for conventional gypsum in finishing applications in the construction industry.

Figure 2.

Details of the consistency test.

Figure 3.

Details of the flow test.

Figure 4.

Details of the mechanical test.

Figure 5.

Details of performance tests of gypsum plasters.

3. Results, Discussion, and Analysis

3.1. Testing Phyisical and Mechanical Properties

Table 2 presents a comparative summary of the main parameters resulting from the characterization process carried out for recycled gypsum and conventional reference gypsum. One of the fundamental aspects that influenced the behavior of recycled gypsum was the presence of remaining cardboard particles in the mixture, which could not be completely removed during the sieving process. This presence of organic matter was clearly evidenced in the results of the chemical analysis, which reported values close to 4% for recycled gypsum. While this percentage is well below the 7% that corresponds to the typical cardboard content in a standard gypsum board [15], it is significant and reflects that the material used in this study, being homogenized only through grinding and screening processes, retained an appreciable fraction of cardboard particles smaller than the meshes used.

Table 2.

Summary of characterization results for reference and recycled gypsum.

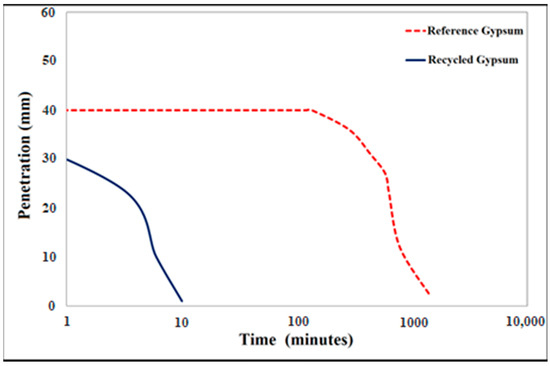

It is worth noting that this minimal processing approach, avoiding wet separation methods or thermal treatments commonly applied in recycling plants [16,17], was implemented with the aim of simulating the processing that could be performed on waste directly at the construction site, facilitating its on-site reuse. The remaining cardboard particles, composed mainly of cellulose fibers, had a significant impact on the hydration kinetics of recycled gypsum. This retarding effect of cellulose on gypsum hydration has been widely documented in previous studies [18,19,20] and was reflected in the setting times obtained. While the conventional reference gypsum set in normal times, recycled gypsum experienced a substantial delay in its initial and final setting times, as observed in the evolution of the setting process presented in (Figure 6). This phenomenon can be explained according to the setting stages described [21], where the presence of cellulose fibers delays the transition between the fluid phase and the moldable phase in which the paste acquires a plastic consistency. Although these prolonged setting times exceed the limits established in some regulations [22], recent research has shown that gypsum mixtures with delayed hydration kinetics can be used in applications requiring greater workability and extended use times, avoiding the use of retarding additives [23].

Figure 6.

Analysis of setting evolution.

The setting of recycled gypsum with cardboard particles experienced a significant delay, requiring almost a full day to complete its setting. This behavior is explained by the retarding effect caused by cellulose from the cardboard, as has been reported in numerous studies where cellulose pulp has been incorporated to generate composite materials with gypsum [18,19,20]. Although these prolonged setting times exceed the maximums allowed by the current Colombian Technical Standard [6], which establishes a limit of 50 min, it is important to note that the final state of the stucco with cardboard particles after completing its setting was acceptable and did not present significant surface effects. This finding suggests that the recycled material could be used in complex work areas that require longer utilization times compared to conventional stuccos, providing greater workability without the need to incorporate additional retarding additives. Regarding mechanical properties, the test results revealed that the presence of cardboard particles generated a 31.5% reduction in compressive strength and a 70% reduction in tensile strength, compared to the standard sample of conventional gypsum. These values, although lower than those of the reference sample, are in line with those reported in previous studies that have evaluated the effect of incorporating natural fibers into gypsum mixtures.

For example, Refs. [24,25] have documented similar reductions in compressive strength when incorporating different types of natural fibers into gypsum, attributing this behavior to the lack of adequate integration between the fibers and the gypsum matrix, as evidenced in the scanning electron microscopy observations carried out in the present study. However, it is important to highlight that, despite these decreases in mechanical properties, the compressive strength values obtained for recycled gypsum (5.2 MPa) meet the minimum requirements established by the European standard EN 13279-1 [26] (2 MPa) for construction gypsums. This result supports the technical feasibility of using recycled material in plastering and finishing applications, coinciding with the findings of other studies that have evaluated mixtures of recycled and conventional gypsums.

For example, compressive strength values between 6 and 7 MPa have been reported for mixtures of conventional and recycled gypsums (70/30 ratio) that were subjected to thermal processes between 100 and 140 °C to remove cardboard. In comparison, the variation with respect to the recycled gypsum in the present study would be only 13–25%, which is considered favorable given that the recycled material was only subjected to grinding processes, without additional thermal treatments. It is important to note that, as in the study by [27], the reference sample of conventional gypsum used in this work did not meet the compressive strength requirement established by the Colombian standard (12.4 MPa), adopted from ASTM standards. This fact suggests that national standards might be excessively strict compared to international requirements, such as those of European regulations.

3.2. Performance Test

In order to comprehensively and objectively evaluate the performance of recycled gypsum under real-use conditions, extensive application and on-site tests were carried out. These tests were conducted in both indoor and outdoor environments (Figure 7), preparing the mixtures with the optimal dosage previously determined in the characterization tests.

Figure 7.

Detail of stucco application during indoor and outdoor performance tests.

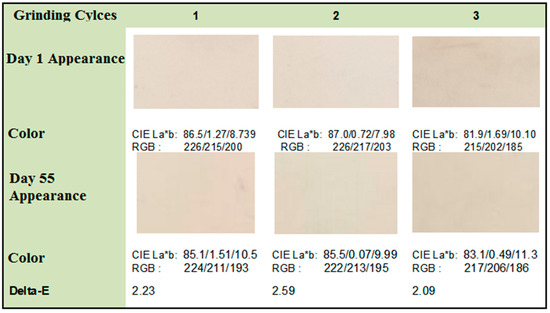

The main purpose of these tests was to evaluate the final appearance of the stucco made with recycled gypsum and to monitor any changes in appearance that might occur when varying the grinding process and, consequently the fineness of the material. Additionally, the aim was to analyze possible changes in the properties of the stucco over time and its response to wetting and drying processes. To this end, stucco samples were prepared using recycled gypsum subjected to 1, 2, and 3 grinding cycles and were exposed to the outdoor environment for an extended period of 55 days. During this time, periodic and detailed monitoring was carried out, evaluated through visual inspection of any changes in surface texture or alterations in the color of the stucco.

These observations were complemented with an objective analysis of colorimetric variations using advanced digital image analysis techniques. Following the methodology defined by [28], Def-Lab-Geo-Imagen software GEO5 2022 [29] was applied to compare the average colors of the samples in different color spaces (CIELa*b and RGB) before and after the exposure period. Additionally, Euclidean distances between initial and final chromatic values were calculated, using a threshold of 2 units established by [30] as an indication that two materials or bodies present the same color.

The results obtained, both from visual evaluations and image analysis, led to the conclusion that the stucco made with recycled gypsum exhibited excellent stability and durability over time (Figure 8). No significant changes were observed in surface appearance, texture, or color, regardless of the degree of grinding of the recycled material used. Even after prolonged exposure to the elements, the stucco did not show any detachment, alterations, or loss of consistency.

Figure 8.

Evolution of color changes in stucco through image analysis.

Additionally, to evaluate the material’s resistance to extreme conditions, two stucco samples were subjected to multiple wetting and drying cycles. These tests simulated exposure to sudden changes in humidity, such as those that could occur in real construction conditions due to environmental factors or cleaning processes. Again, the recycled gypsum demonstrated optimal behavior, without presenting significant changes in its appearance or surface properties.

These results support the practical viability of using recycled gypsum in plastering and finishing applications, demonstrating its ability to maintain its integrity and appearance even under adverse conditions. The stability and durability exhibited by the recycled material are consistent with the findings reported by [31] in their technical feasibility analysis of gypsum board recycling, reinforcing the promising potential of this circular economy-based strategy in the construction industry.

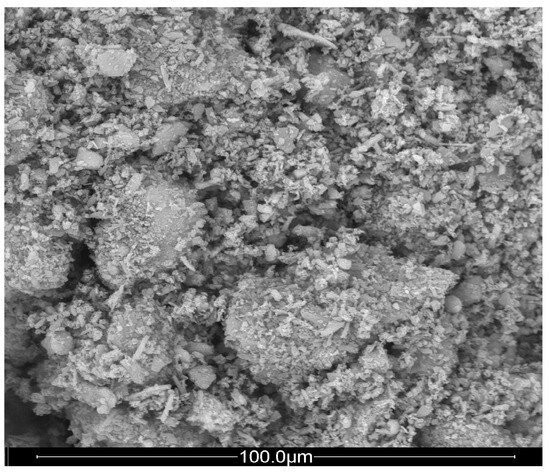

3.3. Observation of Morphology and Microstructure

In order to gain a deep understanding of the microstructure and organization of recycled gypsum, as well as the distribution and interaction of remaining cardboard fibers with the present gypsum crystals and their agglomeration levels, detailed observations were carried out using scanning electron microscopy (SEM). These observations were conducted at the facilities of the Geosciences Laboratories at the National University of Colombia. Figure 9 shows a representative micrograph of a recycled gypsum sample obtained through SEM. In it, agglomerated particles with different crystalline morphologies can be observed. Needle-like or prismatic shapes predominate and are characteristic of dehydrated gypsum crystals (CaSO4·2H2O), the main mineralogical component of gypsum. Additionally, crystals with a spherical morphology can be distinguished in smaller proportions, which could indicate the presence of other mineralogical phases or compounds formed during the gypsum hydration process. These observations align with the results reported by other researchers who have studied the microstructure of recycled gypsum mixtures [16,32]. A key aspect evident in the micrographs is the presence of fibers dispersed among the crystalline agglomerations. These fibers correspond to cardboard particles that could not be completely removed during the screening process and were incorporated into the recycled gypsum matrix. Although these cellulose fibers are heterogeneously distributed in the microstructure, no significant integration or embedding of gypsum crystals into them is observed. This phenomenon could explain, at least in part, the observed decrease in the mechanical properties of recycled gypsum compared to conventional gypsum, as discussed earlier.

Figure 9.

Detail of recycled gypsum morphology microstructure.

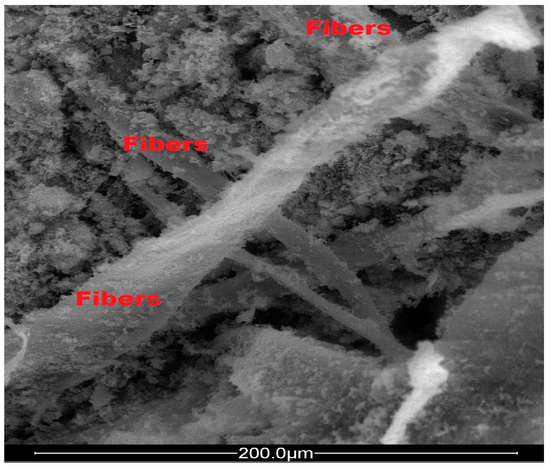

On the other hand, the lack of adequate adhesion and interaction between the cardboard fibers and the gypsum matrix could be due to the hydrophilic nature of cellulose, which hinders the formation of strong bonds with gypsum crystals during the hydration process. This behavior has been previously documented in studies that have analyzed the incorporation of natural fibers into gypsum matrices [24,25]. These microstructural observations provide valuable information about the mechanisms underlying the observed macroscopic behavior in recycled gypsum and will serve as a basis for future research aimed at optimizing the integration of cardboard fibers into the gypsum matrix, in order to improve mechanical properties without compromising workability and setting times. Figure 10 shows a detail of the gypsum crystal agglomerations around the cellulose fibers from the cardboard present in the recycled gypsum board waste. It can be observed that there is no appreciable embedding of gypsum crystals into the cellulose fibers.

Figure 10.

Detail of cardboard fiber presence.

4. Discussion on Circular Economy

In addition to the above, the life cycle analysis of gypsum board supports the technical feasibility of its direct recycling in construction projects, while highlighting the inherent advantages of the circular economy. By avoiding complex and costly treatments for gypsum recovery, this approach significantly reduces the environmental impacts associated with raw material extraction and the production of new materials. Furthermore, by reincorporating gypsum board waste into productive cycles, waste generation is minimized and a more efficient use of resources is promoted, contributing to sustainability throughout the entire value chain of this construction material.

The life cycle analysis of gypsum board, or drywall, spans from raw material extraction to the recycling of waste generated on-site. The production of virgin gypsum, the main component of these boards, leads to high CO2 emissions due to the use of fossil fuels. However, recycling allows for a 49.8% reduction in greenhouse gas emissions compared to production from primary sources, as well as decreasing energy consumption and depletion of natural resources.

In the same context, among the environmental benefits of recycling gypsum board, a reduction of up to 50% in electricity consumption stands out, as more is used for the production of the original material. Additionally, it promotes the development of ecological awareness, encouraging responsible environmental behaviors from construction companies and contractors. Furthermore, from a slightly broader perspective, using recycled material generates Certified Emission Reductions (CERs), which are units of reduction in greenhouse gas (GHG) emissions resulting from Clean Development Mechanism (CDM) projects. These reductions are expressed in metric tons of carbon dioxide equivalent (tCO2e), and in the case study featured in this research, we found a reduction of 7.2525277 × 10−5 tCO2 eq/t (CERs) in the global warming category and 0.001372033271 tCO2 eq/t (CERs) in the non-renewable energy category. The characterization results were obtained using SimaPro 8.3.0 software [33]. See Table 3.

Table 3.

Characterization results for natural gypsum.

Now, from an economic standpoint, and considering that this factor is of great importance for builders when making decisions, recycling gypsum board becomes a viable and sustainable alternative to its final disposal in landfills or dumps, while avoiding costly disposal fees. Additionally, there is potential to generate new income by commercializing recovered materials to produce new construction products.

In the same vein, and seeking to incentivize Colombian contracting companies in this activity, in the business context, the adoption of recycling practices not only boosts corporate image by reflecting a commitment to sustainability but also positively influences the loyalty and satisfaction of consumers aware of these causes.

On the other hand, regarding material consumption, it is estimated that approximately 100 million tons of construction materials are used nationally. Of this amount, about 91.5 million tons (equivalent to 91%) are used in the construction of buildings, housing, and civil works in the country. The remaining 2% is destined for export as construction products, while the remaining 7%, equivalent to 7.4 million tons, is considered debris resulting from construction works (Government of the Republic of Colombia, 2019) [34]. Moreover, specific regulations promote the recycling of materials, and complying with these regulations is not only an environmental responsibility but also a smart strategy to avoid fines and penalties, ultimately having a direct and positive effect on the finances of companies in the sector.

In this context, the proposal to recycle gypsum board in the construction industry strategically aligns with the principles of the circular economy promoted by the Colombian government through various initiatives such as the National Circular Economy Strategy 2018–2022, which sought continuous resource valorization, closing material cycles, and above all, the adoption of new, more efficient and sustainable business models; Resolution 1407 of 2018, which sought to regulate environmental waste management, assigning responsibilities to producers; or CONPES 3874 of 2016 [35], which established the National Policy for Integrated Solid Waste Management 2016–2030.

The construction project that served as a case study for this research is located in the city of Bogotá, Colombia. To document the economic benefit, the official budget of the contractor in charge of the activity was worked on, and only the items representing the use of both gypsum board and stucco were impacted, showing that the savings make up only 1% of the total direct cost value of the project when implementing the recycling strategy. However, this work was carried out experimentally without contemplating truly efficient logistics. Furthermore, there are not many studies that focus on the empirical analysis of this type of strategy, and therefore, there was no frame of reference or comparison. Nevertheless, it was also evident that the behavior of several companies in obtaining a typology of implementation of these practices is a gradual process that begins with the implementation of recycling and material reuse measures to continue with minimizing energy consumption and redesigning products (in this case, substituting stucco for gypsum). Only after this process will it be possible to analyze the economic benefits in their full dimension.

5. Conclusions

The on-site application tests conducted over nearly two months with stucco made from recycled gypsum containing around 4% cardboard particles demonstrated that this material is stable over time and does not easily deteriorate. There were no changes in its surface finish, with no detachment or alterations, maintaining its consistency even when exposed to the elements.

The setting of recycled gypsum with cardboard particles is much slower than conventional gypsum, taking almost a full day to complete setting. This is due to the retarding effect caused by the cellulose present in the cardboard. Although the setting times exceed the maximum allowed by Colombian regulations, the final state of the cardboard-containing stucco after setting is acceptable. This slower setting could allow the use of recycled gypsum in work areas that require longer usage times than conventional stuccos, providing greater workability and avoiding the use of retarding additives.

Microstructure observations suggest that the hydrophilic nature of cellulose fibers may affect the adhesion between the fibers and the matrix composed of dehydrated gypsum crystals (gypsita), resulting in poor phase integration. This could explain the reduction in the mechanical properties of recycled gypsum compared to mixtures made with conventional gypsum without cellulose fibers.

Author Contributions

Conceptualization, S.U. and J.D.P.; methodology, S.U.; validation, L.A., A.R. and A.P.; formal analysis, S.U.; investigation, J.D.P.; writing—original draft preparation, L.A.; writing—review and editing, A.R.; visualization, A.P.; supervision, J.D.P. All authors have read and agreed to the published version of the manuscript.

Funding

This Research received no external funding.

Institutional Review Board Statement

The study did not require ethical approval.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data that supporting the findings of this research are available from the corresponding author upon reasonable request. However, due to ethical considerations and privacy concerns, these data cannot be made publicly available. Restrictions apply to the availability of these data, which were used under license for the current study, and so are not publicly accessible. Researchers interested in accessing the data should contact the corresponding author, who will consider requests on a case-by-case basis, subject to obtaining appropriate ethical approvals and data sharing agreements.

Acknowledgments

Engineer Cristian Camilo Flores Suesca.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Hossain, M.U.; Ng, S.T.; Antwi-Afari, P.; Amor, B. Circular economy and the construction industry: Existing trends, challenges and prospective framework for sustainable construction. Renew. Sust. Energ. Rev. 2020, 130, 109948. [Google Scholar] [CrossRef]

- Purnell, P.; Renzetti, A. Challenges and opportunities for recycling gypsum waste in construction: A comprehensive review. J. Clean. Prod. 2021, 300. [Google Scholar]

- Koçan, S.; Gómez-Camacho, C.E.; Martínez-Rocamora, A. An international review of waste management and recycling strategies in the construction industry. Waste Manag. Res. 2021, 39, 1012–1028. [Google Scholar]

- Yuan, H.; Huang, Z.; Xu, P. A framework for eco-efficiency of construction and demolition waste management. Waste Manag. 2022, 138, 153–163. [Google Scholar]

- NTC_4914; Norma Técnica Colombiana NTC 4914: Cementos. Especificaciones para el uso de yeso de estucado para fundido y para modelado. INCONTEC: Bogotá, Colombia, 2001.

- ASTM C230; Standard Specification for Flow Table for Use in Tests of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2023.

- NTC 111; Norma Técnica Colombiana NTC 111: Método para determinar la fluidez de morteros de cemento hidráulico. ICONTEC: Bogotá, Colombia, 2024.

- ASTM C471M; Standard Test Methods for Chemical Analysis of Gypsum and Gypsum Products (Metric). ASTM International: West Conshohocken, PA, USA, 2024.

- NTC 5227; Norma Técnica Colombiana NTC 5227: Yeso y productos de yeso. Métodos de ensayo químicos. ICONTEC: Bogotá, Colombia, 2021.

- ASTM C472; Standard Test Methods for Physical Testing of Gypsum, Gypsum Plasters and Gypsum Concrete. ASTM International: West Conshohocken, PA, USA, 2014.

- NTC 490; Norma Técnica Colombiana NTC 490: Yesos para construcción. Especificaciones físicas y mecánicas. ICONTEC: Bogotá, Colombia, 1971.

- ASTM C188-17; Standard Test Method for Density of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2023.

- NTC 221; Norma Técnica Colombiana NTC 221: Método de ensayo para determinar la densidad del cemento hidráulico. ICONTEC: Bogotá, Colombia, 2019.

- Kara, S. Gypsum board waste management in construction: A review. Waste Manag. 2022, 138, 210–224. [Google Scholar]

- Arroyo, R.; Horta, R.; Álvarez, G.; Pérez, N.; Aguilera, E. Reciclaje de residuos de placas de yeso laminado: Análisis de métodos y propuesta de proceso optimizado. Rev. Constr. 2019, 18, 107–122. [Google Scholar]

- López, M.; García, A.; Sánchez, J.; Martínez, P. Comparative study of wet and thermal recycling methods for gypsum board waste. J. Clean. Prod. 2021.

- Carvalho, M.A.; Calil Junior, C.; Savastano Junior, H.; Tubino, R.; Carvalho, M.T. Microstructure and mechanical properties of gypsum composites reinforced with recycled cellulose pulp. Mater. Res. 2008, 11, 391–397. [Google Scholar] [CrossRef]

- Cárdenas, H.E.; Arteaga, J.C.; Fernández-Gómez, J.A.; Solarte, N. Efecto de fibras de celulosa en las propiedades físicas y mecánicas de compuestos de yeso. Rev. Ing. Constr. 2015, 30, 284–294. [Google Scholar]

- Muniz-Villarreal, M.S.; Manzano-Ramírez, A.; Sampieri-Bulbarela, S.; Gasca-Tirado, J.R.; Reyes-Araiza, J.L. Influence of cellulose fibers on the hydration kinetics and mechanical properties of gypsum composites. Constr. Build. Mater. 2022, 315, 125710. [Google Scholar]

- Lewry, A.J.; Williamson, J. The setting of gypsum plaster. J. Mater. Sci. 1994, 29, 6085–6090. [Google Scholar] [CrossRef]

- Karni, J. Gypsum in construction: Origin and properties. Mater. Struct. 1995, 28, 92–100. [Google Scholar] [CrossRef]

- Pavlidou, E.; Economidou, A.; Papageorgiou, D.; Efthimiadou, E.; Bakolas, A. Modified gypsum-based plasters with enhanced workability: Effect of organic additives on hydration kinetics and mechanical properties. Constr. Build. Mater. 2016, 121, 530–539. [Google Scholar]

- Ashrapov, A.K.; Abdullaev, I.A.; Abdullaev, A.M.; Umarov, K.S. Effect of natural fibers on mechanical properties of gypsum composites. Constr. Build. Mater. 2020, 252, 119088. [Google Scholar]

- Stães, J.; Van Der Bergh, J.M.; Ascione, E.; Segers, S.; Vandewalle, L.; Van Balen, K. Influence of natural fibers on the mechanical properties of gypsum-based composites: A comprehensive review. Compos. Part B Eng. 2021, 215, 108790. [Google Scholar]

- EN 13279-1 (2008); Gypsum Binders and Gypsum Plasters—Part 1: Definitions and Requirements. European Committee for Standardization (CEN): Brussels, Belgium, 2008.

- Begliardo, H.F.; Sánchez, M.A.; Panigatti, M.C.; Garrappa, S.E. Recuperación de yeso a partir de placas de yeso laminado de desecho. Inf. Tecnol. 2013, 24, 53–62. [Google Scholar]

- Rincón, J.M.; Ocampo, M.A. Análisis colorimétrico de materiales de construcción mediante técnicas de imagen digital: Metodología y aplicaciones. Rev. Constr. 2017, 16, 104–114. [Google Scholar]

- Def-Lab-Geo-Imagen. Software de Análisis Digital de Imágenes para Geomateriales; Universidad Complutense de Madrid: Madrid, Spain, 2022. [Google Scholar]

- Rincón, J.M. Evaluación objetiva del color en materiales de construcción: Propuesta de un nuevo método basado en distancias euclidianas. Mater. Constr. 2016, 66, 30–89. [Google Scholar]

- Gómez, A.M.; Arciniegas, C.S. Gestión de residuos de placas de yeso laminado en la construcción: Oportunidades de reciclaje y reincorporación. Rev. Ing. Construcción 2017, 32, 105–120. [Google Scholar]

- López, M.; García, A.; Sánchez, J.; Martínez, P. Estudio comparativo de los métodos de reciclado húmedo y térmico de residuos de placas de yeso laminado. J. Clean. Prod. 2021, 278, 123948. [Google Scholar]

- SimaPro 8.3.0, Software de Análisis de Ciclo de Vida; PRé Sustainability: Amersfoort, The Netherlands, 2017.

- Government of the Republic of Colombia. Report on Construction Material Consumption and Waste in Colombia; Ministry of Environment and Sustainable Development: Bogotá, Colombia, 2019.

- Consejo Nacional de Política Económica y Social (CONPES). CONPES 3874: Política Nacional para la Gestión Integral de Residuos Sólidos; Departamento Nacional de Planeación, República de Colombia: Bogotá, Colombia, 2016. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).