Sustainability, Resiliency, and Artificial Intelligence in Supplier Selection: A Triple-Themed Review

Abstract

:1. Introduction

2. Research Methodology

- How to formulate the supplier selection problem in the sustainability and resiliency framework?

- What are the best practices for ensuring resilience in supplier selection to mitigate disruption effects?

- Which issues constitute avenues for future research for sustainable resilience supplier selection regarding the gaps and strengths found in the literature of supplier selection?

- What methodologies are best for solving supplier selection problems?

3. Descriptive Analysis

3.1. Distribution of Papers Based on Publication Year Journal

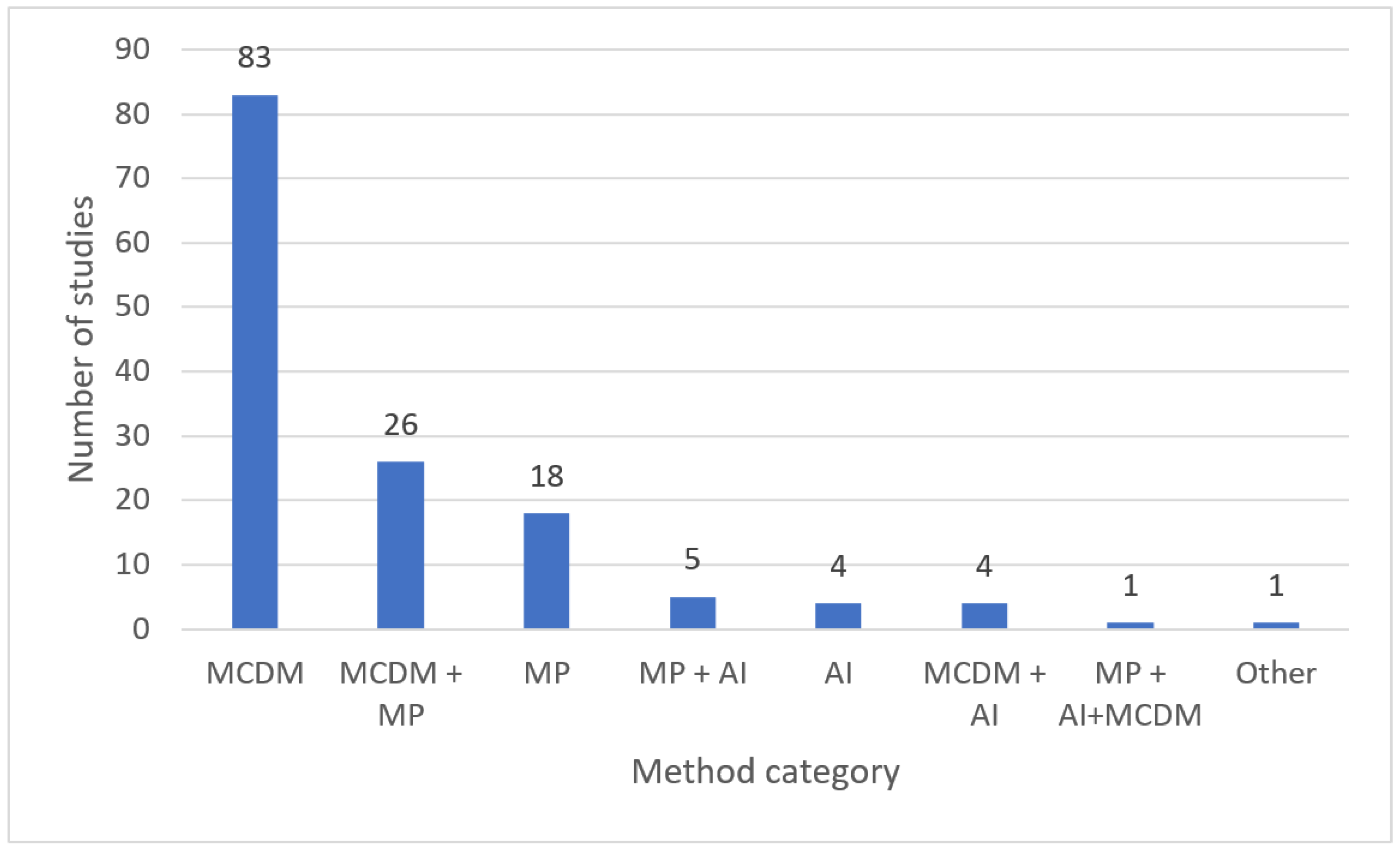

3.2. Applied Methods to Model and Solve the Supplier Selection Problem

3.3. Sustainability Criteria

4. Discussion

4.1. Gaps and Findings

- Developing comprehensive frameworks that integrate economic, environmental, social, and resilience criteria in supplier selection while expanding on the social criteria to include Diversity, Equity, and Inclusion (DEI).

- Creating practical tools and models that incorporate AI and machine learning to handle the complexities of modern supply chains.

- Exploring best practices for operationalizing social and resilience criteria in the supplier evaluation process.

- Investigating the role of supplier diversity and flexibility in enhancing supply chain resilience.

- Examining the long-term impacts of sustainable and resilient supplier selection on business performance and competitiveness.

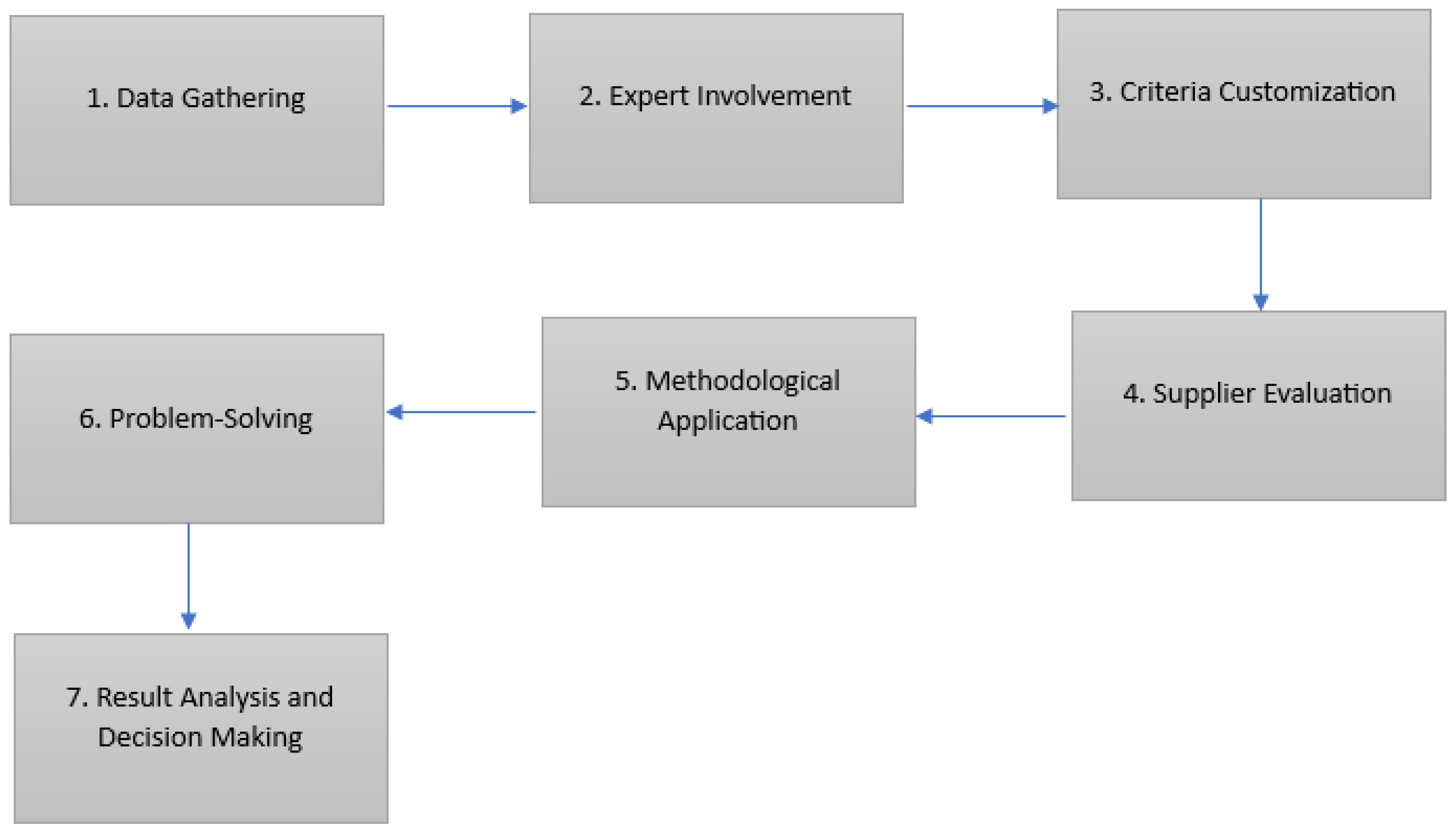

4.2. A Decision-Making Framework for Supplier Selection

4.3. Avenues for Future Research

4.3.1. Developing a Weighting System for Supplier Evaluation Criteria Using Machine Learning

4.3.2. Combination of Multi-Objective Mathematical Modeling and Machine Learning in Developing a Sustainable Supplier Selection Framework

4.3.3. Fortifying Supply Chains: Strategic Supplier Selection for Enhanced Resilience

4.3.4. Strategic Maneuvers in Supply Chain: A Game Theory Approach to Buyer Competition in Constrained Supplier Markets

4.3.5. The Green Link: Deciphering the Dynamics of Sustainability in Supplier Selection and Consumer Demand

4.3.6. Application of Exact Algorithms in Obtaining Robust Solutions for Large-Scale Supplier Evaluation Models: Benders Decomposition Algorithm

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Reference | Methodology | Technique Used | Sustainability and Resiliency Aspects | Uncertainty |

|---|---|---|---|---|

| [25] | MCDM + AI | VC-DRSA, CRITIC, and CTOPSIS | Economic, environmental, and social | Machine Learning |

| [14] | MCDM + Mathematical programming | Stochastic Fuzzy Best–Worst Method (SFBWM), SARIMA | Environmental and social | Fuzzy set theory, Stochastic optimization, Robust optimization |

| [26] | AI | Artificial Neural Network (ANN) | Resilience | Fuzzy DEA |

| [27] | MCDM | DAHP-DEMATEL hybrid method | Economic, environmental, and resilience | The D number method |

| [15] | Mathematical programming | Multi-objective robust optimization model | Environmental and economic | Robust optimization |

| [16] | Mathematical programming | Robust fuzzy multi-objective goal programming | Economic, environmental, and social | Robust optimization, Fuzzy set theory |

| [28] | MCDM + Mathematical programming | Augmented epsilon-constrained, AHP | Economic, environmental, and social | |

| [17] | AI | Random forest method | Economic, environment, and social | |

| [29] | MCDM + AI | Integration of Best–Worst Method (BWM) and gradient boosting machine learning | Resilience | — |

| [30] | Mathematical programming + MCDM | MILP, fuzzy DEMATEL, TOPSIS, and AHP | Economic, environmental, and resilience | Fuzzy triangular numbers |

| [31] | MCDM | BWM | Economic, environmental, and social | — |

| [32] | Mathematical programming + AI | MILP + Distributed Artificial Intelligence as part of the MAS. AI = MAS (multi-agent system) | Economic, environmental, and social | Managed through MAS for real-time data processing |

| [33] | MCDM | q-rung orthopair fuzzy hypersoft (q-ROFH) | Environmental | Fuzzy logic |

| [34] | MCDM | AHP–R method | Resilience | — |

| [35] | MCDM | AHP and TOPSIS | Economic, social, environmental | — |

| [36] | MCDM | DEMATEL-based ANP (DANP), VIKOR | Economic, environmental, social | — |

| [3] | Mathematical programming | DEA | Environmental | — |

| [37] | MCDM | D numbers-based fuzzy Ordinal Priority Approach (OPA) and Combinative Distance-based Assessment (CODAS) | Economic, environmental, and resilience | Fuzzy |

| [38] | MCDM | TOPSIS | Economic, social, and resilience | Trapezoidal intuitionistic fuzzy |

| [39] | MCDM | EDAS (Evaluation Based on Distance from Average Solution) | Economic, social, environmental, and resilience | Fuzzy logic |

| [40] | MCDM | Fuzzy BWM | Economic, social, environmental, and resilience | Fuzzy |

| [41] | MCDM | fuzzy SECA (Simultaneous Evaluation of Criteria and Alternatives) | Economic, social, environmental, and resilience | Fuzzy logic |

| [42] | MCDM + Mathematical programming | BWM, WASPAS, Type-2 Neutrosophic Fuzzy Numbers, and Robust multi-objective optimization model | Resilience | — |

| [43] | MCDM | VIKOR | Economic, snvironmental, and social | Single-Valued Neutrosophic Sets (SVNS) |

| [44] | Mathematical programming | Genetic algorithm | Economic, environmental, social | — |

| [45] | MCDM | Delphi, AHP, and EDAS | Economic, environmental, social | q-rung orthopair fuzzy sets |

| [46] | MCDM | BWM and TRUST | Environmental and resilience | Fuzzy sets |

| [47] | MCDM | MACBETH and CODAS | Economic, environmental, social, and resilience | Fuzzy rough numbers |

| [48] | MCDM | Rough BWM and Interval Rough MABAC | Economic, environmental, social | Rough numbers |

| [49] | MCDM + Mathematical programming | BWM, MARCOS, Epsilon constraint method and min-max fuzzy approach | Economic, environmental, social | Fuzzy |

| [50] | MCDM | AHP, Fuzzy TOPSIS, and SECA | Economic, environmental, social | Fuzzy logic |

| [51] | MCDM + Mathematical programming | AHP, Fuzzy TOPSIS, and Fuzzy MINLP | Economic, environmental, social and resilience | Fuzzy set theory |

| [52] | MCDM | BWM, TOPSIS | Environmental | — |

| [53] | MCDM | Delphi Method and BWM | Economic, environmental, social, and resilience | Neutrosophic sets and fuzzy set theory |

| [54] | MCDM | COPRAS (Complex Proportional Assessment) | Economic, environmental, social | Fuzzy sets |

| [55] | Mathematical programming | Novel Grey Stratified Decision-Making | Social | Grey numbers |

| [23] | MCDM + Mathematical modeling | Fuzzy-Delphi method, FBWM, GC-TOPSIS, Multi-objective planning model | Environmental and resilience | Fuzzy set theory |

| [1] | MCDM | Fuzzy TOPSIS | Economic, environmental, and social | Fuzzy numbers |

| [56] | Mathematical programming + AI | mixed-integer optimal control model + dynamic Bayesian network | Resilience | — |

| [57] | MCDM | DEMATEL | Economic, social, and environmental | Pythagorean fuzzy sets |

| [18] | AI + Mathematical programming | LSTM networks, MLP, Multi-objective programming model | Environmental | Trapezoidal fuzzy numbers |

| [58] | MCDM | BWM, SEM, DMM, Fuzzy MULTIMOORA method | Economic, environmental, and social | Fuzzy set theory |

| [59] | MCDM | AHP, TOPSIS | Economic and environmental | |

| [60] | MCDM +AI | PROMETHEE, ANP, and K-means cluster analysis | Economic, environmental, and social | — |

| [61] | MCDM | AHP, TOPSIS | Economic, environmental, and social | Fuzzy logic |

| [62] | MCDM | ARAS, BWM | Economic, environmental, social, and resilience | Fuzzy |

| [63] | MCDM | DEMATEL, ANP | Environmantal, social | — |

| [64] | MCDM | Weighted Sum-Product, BWM | Economic, environmental, and social | Grey theory |

| [65] | MCDM | Spherical Fuzzy AHP, CoCoSo | Economic, environmental, and social | Spherical fuzzy sets |

| [66] | MCDM | BWM, TOPSIS | Economic, environmental, social, and resilience | Fuzzy + grey relational analysis |

| [67] | MCDM | normalized Euclidean distance + Taguchi loss function | Economic, environmental, and social | Fuzzy sets |

| [68] | AI + Mathematical programming | Pythagorean Fuzzy Entropy SWARA-COPRAS method | Economic, environmental, and social | Pythagorean fuzzy sets |

| [69] | MCDM | COPRAS + ANP | Economic, environmental, and social | Spherical fuzzy sets + Grey numbers |

| [70] | MCDM | DEA, AHP, WASPAS | Economic, environmental, and social | Spherical fuzzy sets |

| [71] | MCDM + Mathematical programming | MILP + ANP + TOPSIS | Economic, environmental, and social | Fuzzy set theory |

| [72] | MCDM + Mathematical programming | VIKOR + MARCOS | Economic, environmental, and social | Interval-Valued Intuitionistic Fuzzy Sets |

| [73] | MCDM | COPRAS + AHP | Economic, environmental, and social | Interval-Valued Intuitionistic Fuzzy Sets |

| [74] | MCDM | TODIM | Economic, environmental, and social | Fuzzy logic + probabilistic linguistic term sets |

| [75] | AI + Mathematical programming | Relational regression chain (RRC), ARIMA, Stochastic MILP | Environmental | Stochastic optimization |

| [76] | Mathmatical programming | MIP | Resilience | Fuzzy set theory |

| [77] | AI + MCDM | Machine learning, BWM | Economic, environmental, and social | Fuzzy Inference System |

| [78] | MCDM | ITARA + PROMETHEE | Economic, environmental, and social | — |

| [79] | MCDM | Failure Mode and Effects Analysis, entropy weight method, and DEMATEL. | Economic, environmental, and social | Fuzzy sets and entropy methods |

| [80] | Mathematical programming + MCDM | ITARA, multi-objective linear programming | Economic, environmental, and social | Fuzzy logic |

| [81] | MCDM | BWM, TOMID | Economic, environmental, and social | — |

| [82] | MCDM | FBWM, Two-stage Fuzzy inference system (FIS) | Economic, environmental, and social | Fuzzy set theory |

| [83] | Mathematical programming | Multi-objective MIP | Economic, environmental, social, and resilience | — |

| [84] | MCDM + Mathematical programming | Choquet integral-based geometric Bonferroni mean and Bonferroni mean operators, DEMATEL, MABAC, Multi-objective optimization model | Economic, environmental, social, and resilience | Interval type-2 Pythagorean fuzzy set + Grey relational analysis |

| [85] | Mathematical programming + MCDM | Multi-objective MINLP, fuzzy MCDM | Economic, environmental, and social | Fuzzy sets |

| [86] | MCDM | Interpretive Structural Modeling (ISM), VIKOR | Economic, environmental, and social | Fuzzy logic |

| [87] | MCDM | PIPRECIA + MABAC | Economic, environmental, and social | Interval fuzzy logic |

| [88] | MCDM | AHP, TOPSIS | Social | — |

| [89] | MCDM | BWM, WASPAS, TOPSIS | Economic, environmental, and social | Grey theory |

| [90] | MCDM | TOPSIS | Environmental | Q-ROF |

| [91] | MCDM | AHP, DEMATEL, TOPSIS | Economic, environmental, and social | Fuzzy logic |

| [92] | Mathematical programming + MCDM | AHP + MULTIMOORA | Economic, environmental, social, and resilience | Fuzzy logic |

| [93] | Mathematical programming | multi-objective MINLP | Economic, environmental, and social | Fuzzy logic |

| [94] | MCDM | SWARA, WASPAS | Economic, environmental, and social | — |

| [95] | Mathematical programming | Multi-objective Genetic Algorithm, Multi-objective Particle Swarm Optimization | Economic, environmental, and social | — |

| [96] | AI + MCDM | AHP, TOPSIS, ELECTRE + Artificial Neural Networks | Environmental | Fuzzy logic |

| [97] | MCDM | Fuzzy BWM, Interval VIKOR method | Social and environmental | Fuzzy set theory |

| [98] | MCDM | Analytic network Process (ANP) | Environmental, social, economic | — |

| [99] | MCDM | Fuzzy AHP, TOPSIS-Grey | Environmental | Fuzzy set theory, Grey theory |

| [19] | Mathematical programming | Interpretive structural modeling (ISM) | Economic, environmental, and social | — |

| [100] | MCDM | DEMATEL, VIKOR | Economic, environmental, and resilience | — |

| [101] | MCDM | Interval Type-2 Fuzzy Sets in MCDM | Economic, environmental, and social | Interval type-2 trapezoidal fuzzy sets |

| [102] | MCDM | MARCOS | Economic, environmental, and social | — |

| [103] | Mathematical programming + MCDM | multi-objective optimization + AHP | Economic, environmental, and social | Fuzzy sets |

| [104] | MCDM | SWARA, DNMA | Economic and environmental | Hesitant fuzzy linguistic term sets |

| [105] | MCDM | AHP, TOPSIS | Economic, environmental, and social | Fuzzy logic |

| [106] | MCDM | AHP, TOPSIS, VIKOR, MULTIMOORA | Economic, environmental, and social | Fuzzy logic |

| [107] | MCDM | TOPSIS | Environmental | Fuzzy set theory |

| [108] | Mathematical programming | MINLP | Economic and resiliency | — |

| [109] | MCDM | Copeland method, AHP, ELECTRE-TR | Economic, environmental, and social | — |

| [110] | Mathematical programming | Stochastic bi-objective MIP | Resiliency | Stochatic optimization |

| [111] | Mathematical programming | DEA | Environmental | Sensitivity analysis |

| [21] | MCDM | Fuzzy AHP | Economic, environmental, social | Fuzzy set theory |

| [112] | AI | Supervised Machine Learning | Resilience | Data analytics |

| [113] | MCDM | BWM and TOPMID | Economic, environmental, and social | Grey numbers |

| [114] | MCDM | Voting AHP + game-theoretic approaches | Economic, environmental, and social | — |

| [115] | Mathematical programming | MILP | Economic, environmental, and social | — |

| [116] | MCDM + Mathematical programming | Multi-objective optimization, Markowitz portfolio theory, ANP | Economic, environmental, and social | — |

| [117] | MCDM | AHP | Economic, environmental, and social | — |

| [118] | MCDM + Mathematical programming | TOPSIS + Fuzzy Goal Programming | Environmental | Fuzzy logic |

| [119] | MCDM | FUCOM, rough Dombi aggregator, and rough COPRAS method | Economic, environmental, and social | Rough set theory |

| [120] | MCDM + Mathematical programming | AHP, TOPSIS + Multi-Objective Optimization | Economic, environmental, and social | Fuzzy logic |

| [121] | Mathematical programming | Epsolin-constraint | Environmental | — |

| [122] | MCDM | DEMATEL, ANP, and modified VIKOR | Economic, environmental, and social | Intuitionistic fuzzy set theory |

| [123] | MCDM | FUCOM, the SAW | Economic, environmental, and social | Interval rough numbers |

| [22] | MCDM | TOPSIS | Economic, environmental, and social | Grey Theory |

| [124] | MCDM | Shannon Entropy | Economic, environmental, and social | Fuzzy logic |

| [125] | MCDM | ANP | Resiliency | Fuzzy logic |

| [126] | Mathematical programming | MAX-MIN method | Economic, environmental, and social | Fuzzy logic |

| [127] | MCDM | TOMID | Economic, environmental, and social | Rough set theory |

| [128] | MCDM | AHP, VIKOR | Economic, environmental, and social | Fuzzy set theory |

| [129] | MCDM + Mathematical programming | AHP, TOPSIS, E-constraint method, LP-metrics method | Economic, environmental, and social | Fuzzy logic |

| [130] | MCDM | AHP, TOPSIS | Economic and environmental | — |

| [131] | MCDM + Mathematical programming | Fuzzy possibilistic statistical approach + VIKOR and MULTIMOORA methods. | Economic, environmental, and social | Interval-valued fuzzy sets and asymmetric uncertainty information |

| [132] | MCDM | ANP, DEMATEL, FPP, TOPSIS | Economic, environmental, and social | Fuzzy set theory |

| [133] | MCDM | Delphi, ISM, ANP, and COPRAS-G | Economic and social | Fuzzy set theory |

| [134] | MCDM | portfolio approach | Economic, environmental, social, and resiliency | — |

| [135] | MCDM | ELECTRE | Economic, environmental, and social | Rough set theory |

| [136] | MCDM | AHP, VIKOR | Economic, environmental, social | — |

| [137] | MCDM | Analytic Network Process (ANP) | Environmental, social, and economic | Sensitivity analysis |

| [138] | MCDM + Mathematical programming | Integrated ANP-QFD, AHP, WASPAS, MOORA, Multi-objective optimization model | Economic, environmental, social | — |

| [139] | MCDM + Mathematical programming | AHP, Improved grey relational Analysis (IGRA), Mathematical modeling | Environmental, social, and economic | Grey theory |

| [140] | AI + Mathematical programming | Least Squares–Support Vector Machine (LS-SVM), Cuckoo Optimization Algorithm (COA) | Economic, environmental, social | — |

| [141] | MCDM | TODIM, PROMETHEE | Environmental | Fuzzy set theory |

| [142] | Mathematical programming | DEA | Economic, environmental, and social | Type-2 fuzzy sets |

| [143] | Mathematical programming | Multidimensional decision-making framework | Economic, environmental, and social | Stochastic optimization |

| [144] | MCDM | TOPSIS | Resiliency | Fuzzy set theory |

| [145] | MCDM | BWM | Environmental | — |

| [20] | Mathematical programming | Mixed-integer linear programming | Economic, environmental, and social | — |

| [146] | MCDM | ISM, ANP, ELECTRE II, VIKOR | Economic, environmental, and social | Fuzzy logic |

| [147] | MCDM | DEMATEL | Economic, environmental, social | Grey theory |

| [148] | MCDM + Mathematical programming | ILP + AHP, TOPSIS, IRP | Economic, environmental, and social | — |

| [149] | Mathematical programming | Monte Carlo Markov Chain | Economic, environmental, and social | Bayesian framework |

| [150] | MCDM + Simulation | System dynamic simulation | Economic, environmental | Fuzzy logic |

| [151] | MCDM | AHP | Environmental | — |

| [152] | MCDM | TOPSIS | Economic, environmental, and social | Fuzzy logic |

| [153] | Mathematical programming + MCDM | LP + AHP | Environmental | — |

| [24] | MCDM | Fuzzy TOPSIS | Economic, environmental, and social | Fuzzy set theory |

References

- Hou, Y.; Khokhar, M.; Zia, S.; Sharma, A. Assessing the best supplier selection criteria in supply chain management during the COVID-19 pandemic. Front. Psychol. 2022, 12, 804954. [Google Scholar] [CrossRef] [PubMed]

- Tundys, B.; Wiśniewski, T. Triple bottom line aspects and sustainable supply chain resilience: A structural equation modelling approach. Front. Environ. Sci. 2023, 11, 1161437. [Google Scholar]

- Chen, Y.; Chung, W. Sustainable supplier selection with multidimensional overlapping criteria under carbon neutrality. Ind. Manag. Data Syst. 2023, 123, 2607–2630. [Google Scholar] [CrossRef]

- Skipworth, H.; Godsell, J.; Wong, C.Y.; Saghiri, S.; Julien, D. Supply chain alignment for improved business performance: An empirical study. Supply Chain Manag. Int. J. 2015, 20, 511–533. [Google Scholar] [CrossRef]

- Meena, P.L.; Katiyar, R.; Kumar, G. Supplier performance and selection from sustainable supply chain performance perspective. Int. J. Product. Perform. Manag. 2023, 72, 2420–2445. [Google Scholar] [CrossRef]

- Taghavi, S.M.; Ghezavati, V.; Mohammadi Bidhandi, H.; Mirzapour Al-e Hashem, S.M.J. Sustainable and resilient supplier selection, order allocation, and production scheduling problem under disruption utilizing conditional value at risk. J. Model. Manag. 2023, 19, 658–692. [Google Scholar] [CrossRef]

- Govindan, K.; Rajendran, S.; Sarkis, J.; Murugesan, P. Multi criteria decision making approaches for green supplier evaluation and selection: A literature review. J. Clean. Prod. 2015, 98, 66–83. [Google Scholar] [CrossRef]

- Deng, X.; Hu, Y.; Deng, Y.; Mahadevan, S. Supplier selection using AHP methodology extended by D numbers. Expert Syst. Appl. 2014, 41, 156–167. [Google Scholar] [CrossRef]

- Schramm, V.B.; Cabral, L.P.B.; Schramm, F. Approaches for supporting sustainable supplier selection—A literature review. J. Clean. Prod. 2020, 273, 123089. [Google Scholar] [CrossRef]

- Igarashi, M.; de Boer, L.; Fet, A.M. What is required for greener supplier selection? A literature review and conceptual model development. J. Purch. Supply Manag. 2013, 19, 247–263. [Google Scholar] [CrossRef]

- Vörösmarty, G.; Dobos, I. A literature review of sustainable supplier evaluation with Data Envelopment Analysis. J. Clean. Prod. 2020, 264, 121672. [Google Scholar] [CrossRef]

- Spina, G.; Caniato, F.; Luzzini, D.; Ronchi, S. Assessing the use of external grand theories in purchasing and supply management research. J. Purch. Supply Manag. 2016, 22, 18–30. [Google Scholar] [CrossRef]

- Bakkalbasi, N.; Bauer, K.; Glover, J.; Wang, L. Three options for citation tracking: Google Scholar, Scopus and Web of Science. Biomed. Digit. Libr. 2006, 3, 7. [Google Scholar] [CrossRef] [PubMed]

- Nayeri, S.; Khoei, M.A.; Rouhani-Tazangi, M.R.; GhanavatiNejad, M.; Rahmani, M.; Tirkolaee, E.B. A data-driven model for sustainable and resilient supplier selection and order allocation problem in a responsive supply chain: A case study of healthcare system. Eng. Appl. Artif. Intell. 2023, 124, 106511. [Google Scholar] [CrossRef]

- Mirzaee, H.; Samarghandi, H.; Willoughby, K. A robust optimization model for green supplier selection and order allocation in a closed-loop supply chain considering cap-and-trade mechanism. Expert Syst. Appl. 2023, 228, 120423. [Google Scholar] [CrossRef]

- Nazari-Shirkouhi, S.; Jalalat, S.M.; Sangari, M.S.; Sepehri, A.; Vandchali, H.R. A robust-fuzzy multi-objective optimization approach for a supplier selection and order allocation problem: Improving sustainability under uncertainty. Comput. Ind. Eng. 2023, 186, 109757. [Google Scholar] [CrossRef]

- Wu, C.; Jia, Y.; Barnes, D. Criteria system construction for sustainable supplier selection: A product-category-oriented intelligent model. Appl. Soft Comput. 2023, 145, 110586. [Google Scholar] [CrossRef]

- Islam, S.; Amin, S.H.; Wardley, L.J. Supplier selection and order allocation planning using predictive analytics and multi-objective programming. Comput. Ind. Eng. 2022, 174, 108825. [Google Scholar] [CrossRef]

- Chauhan, A.S.; Badhotiya, G.K.; Soni, G.; Kumari, P. Investigating interdependencies of sustainable supplier selection criteria: An appraisal using ISM. J. Glob. Oper. Strateg. Sourc. 2020, 13, 195–210. [Google Scholar] [CrossRef]

- Aktin, T.; Gergin, Z. Mathematical modelling of sustainable procurement strategies: Three case studies. J. Clean. Prod. 2016, 113, 767–780. [Google Scholar] [CrossRef]

- Kumar, D. Buyer-supplier relationship selection for A sustainable supply chain: A case of the Indian automobile industry. Int. J. Anal. Hierarchy Process 2019, 11, 215–227. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J. Integrating sustainability into supplier selection: A grey-based TOPSIS analysis. Technol. Econ. Dev. Econ. 2018, 24, 2202–2224. [Google Scholar] [CrossRef]

- Goodarzi, F.; Abdollahzadeh, V.; Zeinalnezhad, M. An integrated multi-criteria decision-making and multi-objective optimization framework for green supplier evaluation and optimal order allocation under uncertainty. Decis. Anal. J. 2022, 4, 100087. [Google Scholar] [CrossRef]

- Govindan, K.; Khodaverdi, R.; Jafarian, A. A fuzzy multi criteria approach for measuring sustainability performance of a supplier based on triple bottom line approach. J. Clean. Prod. 2013, 47, 345–354. [Google Scholar] [CrossRef]

- Lo, H.W. A data-driven decision support system for sustainable supplier evaluation in the Industry 5.0 era: A case study for medical equipment manufacturing. Adv. Eng. Inform. 2023, 56, 101998. [Google Scholar] [CrossRef]

- Nazari-Shirkouhi, S.; Tavakoli, M.; Govindan, K.; Mousakhani, S. A hybrid approach using Z-number DEA model and Artificial Neural Network for Resilient supplier Selection. Expert Syst. Appl. 2023, 222, 119746. [Google Scholar] [CrossRef]

- Gökler, S.H.; Boran, S. A novel resilient and sustainable supplier selection model based on D-AHP and DEMATEL methods. J. Eng. Res. 2023. [Google Scholar] [CrossRef]

- Suryadi, A.; Rau, H. Considering region risks and mitigation strategies in the supplier selection process for improving supply chain resilience. Comput. Ind. Eng. 2023, 181, 109288. [Google Scholar] [CrossRef]

- Khan, M.M.; Bashar, I.; Minhaj, G.M.; Wasi, A.I.; Hossain, N.U.I. Resilient and sustainable supplier selection: An integration of SCOR 4.0 and machine learning approach. Sustain. Resilient Infrastruct. 2023, 8, 453–469. [Google Scholar] [CrossRef]

- Mohammadnazari, Z.; Alipour-Vaezi, M.; Hassannayebi, E. Green inventory management in a multi-product, multi-vendor post-disaster construction supply chain. Environ. Dev. Sustain. 2023, 1–36. [Google Scholar] [CrossRef]

- Chang, J.P.; Chen, Z.S.; Wang, X.J.; Martínez, L.; Pedrycz, W.; Skibniewski, M.J. Requirement-driven sustainable supplier selection: Creating an integrated perspective with stakeholders’ interests and the wisdom of expert crowds. Comput. Ind. Eng. 2023, 175, 108903. [Google Scholar] [CrossRef]

- Zekhnini, K.; Chaouni Benabdellah, A.; Cherrafi, A. A multi-agent based big data analytics system for viable supplier selection. J. Intell. Manuf. 2023, 1–21. [Google Scholar] [CrossRef]

- Khan, S.; Gulistan, M.; Kausar, N.; Pamucar, D.; Ozbilge, E.; El-Kanj, N. q-Rung orthopair fuzzy hypersoft ordered aggregation operators and their application towards green supplier. Front. Environ. Sci. 2023, 10, 1048019. [Google Scholar] [CrossRef]

- Jessin, T.A.; Rajeev, A.; Rajesh, R. Supplier selection framework to evade pseudo-resilience and to achieve sustainability in supply chains. Int. J. Emerg. Mark. 2023, 18, 1425–1452. [Google Scholar] [CrossRef]

- Koc, K.; Ekmekcioğlu, Ö.; Işık, Z. Developing a probabilistic decision-making model for reinforced sustainable supplier selection. Int. J. Prod. Econ. 2023, 259, 108820. [Google Scholar] [CrossRef]

- Rahardjo, B.; Wang, F.K.; Lo, S.C.; Chou, J.H. A hybrid multi-criteria decision-making model combining DANP with VIKOR for sustainable supplier selection in electronics industry. Sustainability 2023, 15, 4588. [Google Scholar] [CrossRef]

- Yazdani, M.; Pamucar, D.; Erdmann, A.; Toro-Dupouy, L. Resilient sustainable investment in digital education technology: A stakeholder-centric decision support model under uncertainty. Technol. Forecast. Soc. Chang. 2023, 188, 122282. [Google Scholar] [CrossRef]

- Majumdar, A.; Kaliyan, M.; Agrawal, R. Selection of resilient suppliers in manufacturing industries post-COVID-19: Implications for economic and social sustainability in emerging economies. Int. J. Emerg. Mark. 2023, 18, 3657–3675. [Google Scholar] [CrossRef]

- Agarwal, R.; Nishad, A.K. A Fuzzy Mathematical Modeling for Evaluation and Selection of a Best Sustainable and Resilient Supplier by Using EDAS Technique. Process Integr. Optim. Sustain. 2024, 8, 71–80. [Google Scholar] [CrossRef]

- Hailiang, Z.; Khokhar, M.; Islam, T.; Sharma, A. A model for green-resilient supplier selection: Fuzzy best–worst multi-criteria decision-making method and its applications. Environ. Sci. Pollut. Res. 2023, 30, 54035–54058. [Google Scholar] [CrossRef]

- Eghbali-Zarch, M.; Zabihi, S.Z.; Masoud, S. A novel fuzzy SECA model based on fuzzy standard deviation and correlation coefficients for resilient-sustainable supplier selection. Expert Syst. Appl. 2023, 231, 120653. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Torkayesh, A.E.; Tavana, M.; Goli, A.; Simic, V.; Ding, W. An integrated decision support framework for resilient vaccine supply chain network design. Eng. Appl. Artif. Intell. 2023, 126, 106945. [Google Scholar] [CrossRef]

- Luo, X.; Wang, Z.; Yang, L.; Lu, L.; Hu, S. Sustainable supplier selection based on VIKOR with single-valued neutrosophic sets. PLoS ONE 2023, 18, e0290093. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.J.; Chen, Z.S.; Su, Q.; Chin, K.S.; Pedrycz, W.; Skibniewski, M.J. Enhancing the sustainability and robustness of critical material supply in electrical vehicle market: An AI-powered supplier selection approach. Ann. Oper. Res. 2023, 1–38. [Google Scholar] [CrossRef]

- Güneri, B.; Deveci, M. Evaluation of supplier selection in the defense industry using q-rung orthopair fuzzy set based EDAS approach. Expert Syst. Appl. 2023, 222, 119846. [Google Scholar] [CrossRef]

- Bonab, S.R.; Haseli, G.; Rajabzadeh, H.; Ghoushchi, S.J.; Hajiaghaei-Keshteli, M.; Tomaskova, H. Sustainable resilient supplier selection for IoT implementation based on the integrated BWM and TRUST under spherical fuzzy sets. Decis. Mak. Appl. Manag. Eng. 2023, 6, 153–185. [Google Scholar] [CrossRef]

- Pamucar, D.; Torkayesh, A.E.; Biswas, S. Supplier selection in healthcare supply chain management during the COVID-19 pandemic: A novel fuzzy rough decision-making approach. Ann. Oper. Res. 2023, 328, 977–1019. [Google Scholar] [CrossRef]

- ForouzeshNejad, A.A. Leagile and sustainable supplier selection problem in the Industry 4.0 era: A case study of the medical devices using hybrid multi-criteria decision making tool. Environ. Sci. Pollut. Res. 2023, 30, 13418–13437. [Google Scholar] [CrossRef]

- Aditi.; Kannan, D.; Darbari, J.D.; Jha, P. Sustainable supplier selection model with a trade-off between supplier development and supplier switching. Ann. Oper. Res. 2023, 331, 351–392. [Google Scholar] [CrossRef]

- Rasmussen, A.; Sabic, H.; Saha, S.; Nielsen, I.E. Supplier selection for aerospace & defense industry through MCDM methods. Clean. Eng. Technol. 2023, 12, 100590. [Google Scholar]

- Kayani, S.A.; Warsi, S.S.; Liaqait, R.A. A smart decision support framework for sustainable and resilient supplier selection and order allocation in the pharmaceutical industry. Sustainability 2023, 15, 5962. [Google Scholar] [CrossRef]

- Asadabadi, M.R.; Ahmadi, H.B.; Gupta, H.; Liou, J.J. Supplier selection to support environmental sustainability: The stratified BWM TOPSIS method. Ann. Oper. Res. 2023, 322, 321–344. [Google Scholar] [CrossRef] [PubMed]

- Ambilkar, P.; Verma, P.; Das, D. Sustailient supplier selection using neutrosophic best–worst approach: A case study of additively manufactured trinkets. Benchmarking Int. J. 2024, 31, 1515–1547. [Google Scholar] [CrossRef]

- Nafteh, M.; Shahrokhi, M. Improving the COPRAS Multicriteria Group Decision-Making Method for Selecting a Sustainable Supplier Using Intuitionistic and Fuzzy Type 2 Sets. Jordan J. Mech. Ind. Eng. 2023, 17. [Google Scholar]

- Rajesh, R.; Aljabhan, B. A novel grey stratified decision-making (GSDM) model for social sustainability-based supplier selection. IEEE Trans. Comput. Soc. Syst. 2022, 11, 531–545. [Google Scholar] [CrossRef]

- Liu, M.; Liu, Z.; Chu, F.; Zheng, F.; Chu, C. Integrated inventory management, supplier selection, disruption risk assessment problem under ripple effect. IFAC-PapersOnLine 2022, 55, 3094–3099. [Google Scholar] [CrossRef]

- Giri, B.C.; Molla, M.U.; Biswas, P. Pythagorean fuzzy DEMATEL method for supplier selection in sustainable supply chain management. Expert Syst. Appl. 2022, 193, 116396. [Google Scholar] [CrossRef]

- Shang, Z.; Yang, X.; Barnes, D.; Wu, C. Supplier selection in sustainable supply chains: Using the integrated BWM, fuzzy Shannon entropy, and fuzzy MULTIMOORA methods. Expert Syst. Appl. 2022, 195, 116567. [Google Scholar] [CrossRef]

- Cinnirella, V.; Carpitella, S.; Coco, A.; Frangiamore, D.D.M.; de Geronimo, R.P. Sustainable suppliers evaluation in the waste management sector: The case of a leading Sicilian enterprise. IFAC-PapersOnLine 2022, 55, 66–71. [Google Scholar] [CrossRef]

- Coşkun, S.S.; Kumru, M.; Kan, N.M. An integrated framework for sustainable supplier development through supplier evaluation based on sustainability indicators. J. Clean. Prod. 2022, 335, 130287. [Google Scholar] [CrossRef]

- Rahman, M.M.; Bari, A.M.; Ali, S.M.; Taghipour, A. Sustainable supplier selection in the textile dyeing industry: An integrated multi-criteria decision analytics approach. Resour. Conserv. Recycl. Adv. 2022, 15, 200117. [Google Scholar] [CrossRef]

- Boz, E.; Çizmecioğlu, S.; Çalık, A. A novel MDCM approach for sustainable supplier selection in healthcare system in the era of logistics 4.0. Sustainability 2022, 14, 13839. [Google Scholar] [CrossRef]

- Göncü, K.K.; Çetin, O. A decision model for supplier selection criteria in healthcare enterprises with dematel ANP method. Sustainability 2022, 14, 13912. [Google Scholar] [CrossRef]

- Ulutaş, A.; Topal, A.; Pamučar, D.; Stević, Ž.; Karabašević, D.; Popović, G. A new integrated multi-criteria decision-making model for sustainable supplier selection based on a novel grey WISP and grey BWM methods. Sustainability 2022, 14, 16921. [Google Scholar] [CrossRef]

- Wang, C.N.; Chou, C.C.; Dang, T.T.; Nguyen, H.P.; Nguyen, N.A.T. Integrating triple bottom line in sustainable chemical supplier selection: A compromise decision-making-based spherical fuzzy approach. Processes 2022, 10, 889. [Google Scholar] [CrossRef]

- Afrasiabi, A.; Tavana, M.; Di Caprio, D. An extended hybrid fuzzy multi-criteria decision model for sustainable and resilient supplier selection. Environ. Sci. Pollut. Res. 2022, 29, 37291–37314. [Google Scholar] [CrossRef]

- Turk, S. Taguchi loss function in intuitionistic fuzzy sets along with personal perceptions for the sustainable supplier selection problem. Sustainability 2022, 14, 6178. [Google Scholar] [CrossRef]

- Xie, Z.; Tian, G.; Tao, Y. A multi-criteria decision-making framework for sustainable supplier selection in the circular economy and Industry 4.0 era. Sustainability 2022, 14, 16809. [Google Scholar] [CrossRef]

- Dang, T.T.; Nguyen, N.A.T.; Nguyen, V.T.T.; Dang, L.T.H. A two-stage multi-criteria supplier selection model for sustainable automotive supply chain under uncertainty. Axioms 2022, 11, 228. [Google Scholar] [CrossRef]

- Nguyen, T.L.; Nguyen, P.H.; Pham, H.A.; Nguyen, T.G.; Nguyen, D.T.; Tran, T.H.; Le, H.C.; Phung, H.T. A novel integrating data envelopment analysis and spherical fuzzy MCDM approach for sustainable supplier selection in steel industry. Mathematics 2022, 10, 1897. [Google Scholar] [CrossRef]

- Kumar, D.; Soni, G.; Joshi, R.; Jain, V.; Sohal, A. Modelling supply chain viability during COVID-19 disruption: A case of an Indian automobile manufacturing supply chain. Oper. Manag. Res. 2022, 15, 1224–1240. [Google Scholar] [CrossRef]

- Salimian, S.; Mousavi, S.M.; Antucheviciene, J. An interval-valued intuitionistic fuzzy model based on extended VIKOR and MARCOS for sustainable supplier selection in organ transplantation networks for healthcare devices. Sustainability 2022, 14, 3795. [Google Scholar] [CrossRef]

- Perçin, S. Circular supplier selection using interval-valued intuitionistic fuzzy sets. Environ. Dev. Sustain. 2022, 24, 5551–5581. [Google Scholar] [CrossRef]

- Zhong, S.; Zhang, J.; He, X.; Liu, S. Sustainable supply chain partner selection and order allocation: A hybrid fuzzy PL-TODIM based MCGDM approach. PLoS ONE 2022, 17, e0271194. [Google Scholar] [CrossRef]

- Islam, S.; Amin, S.H.; Wardley, L.J. Machine learning and optimization models for supplier selection and order allocation planning. Int. J. Prod. Econ. 2021, 242, 108315. [Google Scholar] [CrossRef]

- Kaur, H.; Singh, S.P. Multi-stage hybrid model for supplier selection and order allocation considering disruption risks and disruptive technologies. Int. J. Prod. Econ. 2021, 231, 107830. [Google Scholar] [CrossRef]

- Alavi, B.; Tavana, M.; Mina, H. A dynamic decision support system for sustainable supplier selection in circular economy. Sustain. Prod. Consum. 2021, 27, 905–920. [Google Scholar] [CrossRef]

- Chang, T.W.; Pai, C.J.; Lo, H.W.; Hu, S.K. A hybrid decision-making model for sustainable supplier evaluation in electronics manufacturing. Comput. Ind. Eng. 2021, 156, 107283. [Google Scholar] [CrossRef]

- Wu, C.; Lin, Y.; Barnes, D. An integrated decision-making approach for sustainable supplier selection in the chemical industry. Expert Syst. Appl. 2021, 184, 115553. [Google Scholar] [CrossRef]

- Lo, H.W.; Liaw, C.F.; Gul, M.; Lin, K.Y. Sustainable supplier evaluation and transportation planning in multi-level supply chain networks using multi-attribute-and multi-objective decision making. Comput. Ind. Eng. 2021, 162, 107756. [Google Scholar] [CrossRef]

- Baki, R. An integrated, multi-criteria approach based on environmental, economic, social, and competency criteria for supplier selection. RAIRO-Oper. Res. 2021, 55, 1487–1500. [Google Scholar] [CrossRef]

- Fallahpour, A.; Wong, K.Y.; Rajoo, S.; Fathollahi-Fard, A.M.; Antucheviciene, J.; Nayeri, S. An integrated approach for a sustainable supplier selection based on Industry 4.0 concept. Environ. Sci. Pollut. Res. 2021, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Shafiee, M.; Zare Mehrjerdi, Y.; Keshavarz, M. Integrating lean, resilient, and sustainable practices in supply chain network: Mathematical modelling and the AUGMECON2 approach. Int. J. Syst. Sci. Oper. Logist. 2022, 9, 451–471. [Google Scholar] [CrossRef]

- Mondal, A.; Roy, S.K. Application of Choquet integral in interval type-2 Pythagorean fuzzy sustainable supply chain management under risk. Int. J. Intell. Syst. 2022, 37, 217–263. [Google Scholar] [CrossRef]

- Liaqait, R.A.; Warsi, S.S.; Agha, M.H.; Zahid, T.; Becker, T. A multi-criteria decision framework for sustainable supplier selection and order allocation using multi-objective optimization and fuzzy approach. Eng. Optim. 2022, 54, 928–948. [Google Scholar] [CrossRef]

- Khan, A.U.; Ali, Y. Sustainable supplier selection for the cold supply chain (CSC) in the context of a developing country. Environ. Dev. Sustain. 2021, 23, 13135–13164. [Google Scholar] [CrossRef]

- Puška, A.; Nedeljković, M.; Hashemkhani Zolfani, S.; Pamučar, D. Application of interval fuzzy logic in selecting a sustainable supplier on the example of agricultural production. Symmetry 2021, 13, 774. [Google Scholar] [CrossRef]

- Marzouk, M.; Sabbah, M. AHP-TOPSIS social sustainability approach for selecting supplier in construction supply chain. Clean. Environ. Syst. 2021, 2, 100034. [Google Scholar] [CrossRef]

- Aslani, B.; Rabiee, M.; Tavana, M. An integrated information fusion and grey multi-criteria decision-making framework for sustainable supplier selection. Int. J. Syst. Sci. Oper. Logist. 2021, 8, 348–370. [Google Scholar] [CrossRef]

- Pınar, A.; Babak Daneshvar, R.; Özdemir, Y.S. q-Rung orthopair fuzzy TOPSIS method for green supplier selection problem. Sustainability 2021, 13, 985. [Google Scholar] [CrossRef]

- Ortiz-Barrios, M.; Cabarcas-Reyes, J.; Ishizaka, A.; Barbati, M.; Jaramillo-Rueda, N.; de Jesús Carrascal-Zambrano, G. A hybrid fuzzy multi-criteria decision making model for selecting a sustainable supplier of forklift filters: A case study from the mining industry. Ann. Oper. Res. 2021, 307, 443–481. [Google Scholar] [CrossRef]

- Orji, I.J.; Ojadi, F. Investigating the COVID-19 pandemic’s impact on sustainable supplier selection in the Nigerian manufacturing sector. Comput. Ind. Eng. 2021, 160, 107588. [Google Scholar] [CrossRef] [PubMed]

- Liaqait, R.A.; Warsi, S.S.; Zahid, T.; Ghafoor, U.; Ahmad, M.S.; Selvaraj, J. A decision framework for solar PV panels supply chain in context of sustainable supplier selection and order allocation. Sustainability 2021, 13, 13216. [Google Scholar] [CrossRef]

- Erdogan, H.; Tosun, N. Evaluation of sustainable supplier problem: A hybrid decision making model based on SWARA-WASPAS. LogForum 2021, 17, 465–476. [Google Scholar]

- Ehtesham Rasi, R.; Sohanian, M. A multi-objective optimization model for sustainable supply chain network with using genetic algorithm. J. Model. Manag. 2021, 16, 714–727. [Google Scholar] [CrossRef]

- Gegovska, T.; Koker, R.; Cakar, T. Green Supplier Selection Using Fuzzy Multiple-Criteria Decision-Making Methods and Artificial Neural Networks. Comput. Intell. Neurosci. 2020, 2020, 8811834. [Google Scholar] [CrossRef]

- Kannan, D.; Mina, H.; Nosrati-Abarghooee, S.; Khosrojerdi, G. Sustainable circular supplier selection: A novel hybrid approach. Sci. Total Environ. 2020, 722, 137936. [Google Scholar] [CrossRef]

- Giannakis, M.; Dubey, R.; Vlachos, I.; Ju, Y. Supplier sustainability performance evaluation using the analytic network process. J. Clean. Prod. 2020, 247, 119439. [Google Scholar] [CrossRef]

- Musaad O, A.S.; Zhuo, Z.; Siyal, Z.A.; Shaikh, G.M.; Shah, S.A.A.; Solangi, Y.A.; Musaad O, A.O. An integrated multi-criteria decision support framework for the selection of suppliers in small and medium enterprises based on green innovation ability. Processes 2020, 8, 418. [Google Scholar] [CrossRef]

- Mohammed, A. Towards ‘gresilient’supply chain management: A quantitative study. Resour. Conserv. Recycl. 2020, 155, 104641. [Google Scholar] [CrossRef]

- Hendiani, S.; Liao, H.; Ren, R.; Lev, B. A likelihood-based multi-criteria sustainable supplier selection approach with complex preference information. Inf. Sci. 2020, 536, 135–155. [Google Scholar] [CrossRef]

- Stević, Ž.; Pamučar, D.; Puška, A.; Chatterjee, P. Sustainable supplier selection in healthcare industries using a new MCDM method: Measurement of alternatives and ranking according to COmpromise solution (MARCOS). Comput. Ind. Eng. 2020, 140, 106231. [Google Scholar] [CrossRef]

- Khoshfetrat, S.; Rahiminezhad Galankashi, M.; Almasi, M. Sustainable supplier selection and order allocation: A fuzzy approach. Eng. Optim. 2020, 52, 1494–1507. [Google Scholar] [CrossRef]

- Liao, H.; Ren, R.; Antucheviciene, J.; Šaparauskas, J.; Al-Barakati, A. Sustainable Construction Supplier Selection by a Multiple Criteria Decision-Making Method with Hesitant Linguistic Information; Technická Univerzita v Liberci: Liberec, Czech Republic, 2020. [Google Scholar]

- Jain, N.; Singh, A.; Upadhyay, R. Sustainable supplier selection under attractive criteria through FIS and integrated fuzzy MCDM techniques. Int. J. Sustain. Eng. 2020, 13, 441–462. [Google Scholar] [CrossRef]

- Çalık, A. A comparative perspective in sustainable supplier selection by integrated mcdm techniques. Sigma J. Eng. Nat. Sci. 2020, 38, 835–852. [Google Scholar]

- Rouyendegh, B.D.; Yildizbasi, A.; Üstünyer, P. Intuitionistic fuzzy TOPSIS method for green supplier selection problem. Soft Comput. 2020, 24, 2215–2228. [Google Scholar] [CrossRef]

- Esmaeili-Najafabadi, E.; Nezhad, M.S.F.; Pourmohammadi, H.; Honarvar, M.; Vahdatzad, M.A. A joint supplier selection and order allocation model with disruption risks in centralized supply chain. Comput. Ind. Eng. 2019, 127, 734–748. [Google Scholar] [CrossRef]

- Guarnieri, P.; Trojan, F. Decision making on supplier selection based on social, ethical, and environmental criteria: A study in the textile industry. Resour. Conserv. Recycl. 2019, 141, 347–361. [Google Scholar] [CrossRef]

- Hosseini, S.; Morshedlou, N.; Ivanov, D.; Sarder, M.; Barker, K.; Al Khaled, A. Resilient supplier selection and optimal order allocation under disruption risks. Int. J. Prod. Econ. 2019, 213, 124–137. [Google Scholar] [CrossRef]

- Krmac, E.; Djordjević, B. A new DEA model for evaluation of supply chains: A case of selection and evaluation of environmental efficiency of suppliers. Symmetry 2019, 11, 565. [Google Scholar] [CrossRef]

- Cavalcante, I.M.; Frazzon, E.M.; Forcellini, F.A.; Ivanov, D. A supervised machine learning approach to data-driven simulation of resilient supplier selection in digital manufacturing. Int. J. Inf. Manag. 2019, 49, 86–97. [Google Scholar] [CrossRef]

- Bai, C.; Kusi-Sarpong, S.; Badri Ahmadi, H.; Sarkis, J. Social sustainable supplier evaluation and selection: A group decision-support approach. Int. J. Prod. Res. 2019, 57, 7046–7067. [Google Scholar] [CrossRef]

- Pishchulov, G.; Trautrims, A.; Chesney, T.; Gold, S.; Schwab, L. The Voting Analytic Hierarchy Process revisited: A revised method with application to sustainable supplier selection. Int. J. Prod. Econ. 2019, 211, 166–179. [Google Scholar] [CrossRef]

- Mujkić, Z.; Qorri, A.; Kraslawski, A.; Gashi, S. Supplier selection and optimization of supply chains. Int. J. Manag. Sustain. 2019, 8, 98–110. [Google Scholar] [CrossRef]

- Kellner, F.; Lienland, B.; Utz, S. An a posteriori decision support methodology for solving the multi-criteria supplier selection problem. Eur. J. Oper. Res. 2019, 272, 505–522. [Google Scholar] [CrossRef]

- Suraraksa, J.; Shin, K.S. Comparative analysis of factors for supplier selection and monitoring: The case of the automotive industry in Thailand. Sustainability 2019, 11, 981. [Google Scholar] [CrossRef]

- Bhayana, N.; Gandhi, K.; Bajpai, A.; Jha, P. An integrated supplier selection approach in supply chain system under fuzzy environment. Yugosl. J. Oper. Res. 2019, 29, 483–505. [Google Scholar] [CrossRef]

- Matić, B.; Jovanović, S.; Das, D.K.; Zavadskas, E.K.; Stević, Ž.; Sremac, S.; Marinković, M. A new hybrid MCDM model: Sustainable supplier selection in a construction company. Symmetry 2019, 11, 353. [Google Scholar] [CrossRef]

- Mohammed, A.; Harris, I.; Govindan, K. A hybrid MCDM-FMOO approach for sustainable supplier selection and order allocation. Int. J. Prod. Econ. 2019, 217, 171–184. [Google Scholar] [CrossRef]

- Kellner, F.; Utz, S. Sustainability in supplier selection and order allocation: Combining integer variables with Markowitz portfolio theory. J. Clean. Prod. 2019, 214, 462–474. [Google Scholar] [CrossRef]

- Phochanikorn, P.; Tan, C. A new extension to a multi-criteria decision-making model for sustainable supplier selection under an intuitionistic fuzzy environment. Sustainability 2019, 11, 5413. [Google Scholar] [CrossRef]

- Stević, Ž.; Durmić, E.; Gajić, M.; Pamučar, D.; Puška, A. A novel multi-criteria decision-making model: Interval rough SAW method for sustainable supplier selection. Information 2019, 10, 292. [Google Scholar] [CrossRef]

- Khan, S.A.; Kusi-Sarpong, S.; Arhin, F.K.; Kusi-Sarpong, H. Supplier sustainability performance evaluation and selection: A framework and methodology. J. Clean. Prod. 2018, 205, 964–979. [Google Scholar] [CrossRef]

- Zhou, K.; Xun, H. Intelligent decision method for supplier selection. J. Eng. 2018, 2018, 1682–1687. [Google Scholar] [CrossRef]

- Moradi, M.; Jolai, F. Purchasing Planning and Order Allocation in the Pharmaceutical Sustainable Supply Chain with Using Theoretical-Graph (GT-MP-DM)(Case Study: Supplying the clotting factor for patients with hemophilia). Int. J. Supply Oper. Manag. 2018, 5, 361–378. [Google Scholar]

- Li, J.; Fang, H.; Song, W. Sustainability evaluation via variable precision rough set approach: A photovoltaic module supplier case study. J. Clean. Prod. 2018, 192, 751–765. [Google Scholar] [CrossRef]

- Awasthi, A.; Govindan, K.; Gold, S. Multi-tier sustainable global supplier selection using a fuzzy AHP-VIKOR based approach. Int. J. Prod. Econ. 2018, 195, 106–117. [Google Scholar] [CrossRef]

- Mohammed, A.; Setchi, R.; Filip, M.; Harris, I.; Li, X. An integrated methodology for a sustainable two-stage supplier selection and order allocation problem. J. Clean. Prod. 2018, 192, 99–114. [Google Scholar] [CrossRef]

- Azimifard, A.; Moosavirad, S.H.; Ariafar, S. Selecting sustainable supplier countries for Iran’s steel industry at three levels by using AHP and TOPSIS methods. Resour. Policy 2018, 57, 30–44. [Google Scholar] [CrossRef]

- Foroozesh, N.; Tavakkoli-Moghaddam, R.; Meysam Mousavi, S. Sustainable-supplier selection for manufacturing services: A failure mode and effects analysis model based on interval-valued fuzzy group decision-making. Int. J. Adv. Manuf. Technol. 2018, 95, 3609–3629. [Google Scholar] [CrossRef]

- Petrudi, S.; Abdi, M.; Goh, M. An integrated approach to evaluate suppliers in a sustainable supply chain. Uncertain Supply Chain Manag. 2018, 6, 423–444. [Google Scholar] [CrossRef]

- Kannan, D. Role of multiple stakeholders and the critical success factor theory for the sustainable supplier selection process. Int. J. Prod. Econ. 2018, 195, 391–418. [Google Scholar] [CrossRef]

- Torres-Ruiz, A.; Ravindran, A.R. Multiple criteria framework for the sustainability risk assessment of a supplier portfolio. J. Clean. Prod. 2018, 172, 4478–4493. [Google Scholar] [CrossRef]

- Lu, H.; Jiang, S.; Song, W.; Ming, X. A rough multi-criteria decision-making approach for sustainable supplier selection under vague environment. Sustainability 2018, 10, 2622. [Google Scholar] [CrossRef]

- Luthra, S.; Govindan, K.; Kannan, D.; Mangla, S.K.; Garg, C.P. An integrated framework for sustainable supplier selection and evaluation in supply chains. J. Clean. Prod. 2017, 140, 1686–1698. [Google Scholar] [CrossRef]

- Faisal, M.N.; Al-Esmael, B.; Sharif, K.J. Supplier selection for a sustainable supply chain: Triple bottom line (3BL) and analytic network process approach. Benchmarking Int. J. 2017, 24, 1956–1976. [Google Scholar] [CrossRef]

- Tavana, M.; Yazdani, M.; Di Caprio, D. An application of an integrated ANP–QFD framework for sustainable supplier selection. Int. J. Logist. Res. Appl. 2017, 20, 254–275. [Google Scholar] [CrossRef]

- Badri Ahmadi, H.; Hashemi Petrudi, S.H.; Wang, X. Integrating sustainability into supplier selection with analytical hierarchy process and improved grey relational analysis: A case of telecom industry. Int. J. Adv. Manuf. Technol. 2017, 90, 2413–2427. [Google Scholar] [CrossRef]

- Foroozesh, N.; Tavakkoli-Moghaddam, R. Sustainable supplier selection by a new Hybrid support vector-model based on the Cuckoo optimization algorithm. Int. J. Eng. 2017, 30, 867–875. [Google Scholar]

- Sen, D.K.; Datta, S.; Mahapatra, S.S. Dominance based fuzzy decision support framework for g-resilient (ecosilient) supplier selection: An empirical modelling. Int. J. Sustain. Eng. 2017, 10, 338–357. [Google Scholar] [CrossRef]

- Zhou, X.; Pedrycz, W.; Kuang, Y.; Zhang, Z. Type-2 fuzzy multi-objective DEA model: An application to sustainable supplier evaluation. Appl. Soft Comput. 2016, 46, 424–440. [Google Scholar] [CrossRef]

- Ahi, P.; Jaber, M.Y.; Searcy, C. A comprehensive multidimensional framework for assessing the performance of sustainable supply chains. Appl. Math. Model. 2016, 40, 10153–10166. [Google Scholar] [CrossRef]

- Mavi, R.K.; Goh, M.; Mavi, N.K. Supplier selection with Shannon entropy and fuzzy TOPSIS in the context of supply chain risk management. Procedia-Soc. Behav. Sci. 2016, 235, 216–225. [Google Scholar] [CrossRef]

- Rezaei, J.; Nispeling, T.; Sarkis, J.; Tavasszy, L. A supplier selection life cycle approach integrating traditional and environmental criteria using the best worst method. J. Clean. Prod. 2016, 135, 577–588. [Google Scholar] [CrossRef]

- Girubha, J.; Vinodh, S.; Kek, V. Application of interpretative structural modelling integrated multi criteria decision making methods for sustainable supplier selection. J. Model. Manag. 2016, 11, 358–388. [Google Scholar] [CrossRef]

- Su, C.M.; Horng, D.J.; Tseng, M.L.; Chiu, A.S.; Wu, K.J.; Chen, H.P. Improving sustainable supply chain management using a novel hierarchical grey-DEMATEL approach. J. Clean. Prod. 2016, 134, 469–481. [Google Scholar] [CrossRef]

- Kaur, H.; Singh, S.P.; Glardon, R. An integer linear program for integrated supplier selection: A sustainable flexible framework. Glob. J. Flex. Syst. Manag. 2016, 17, 113–134. [Google Scholar] [CrossRef]

- Sarkis, J.; Dhavale, D.G. Supplier selection for sustainable operations: A triple-bottom-line approach using a Bayesian framework. Int. J. Prod. Econ. 2015, 166, 177–191. [Google Scholar] [CrossRef]

- Orji, I.J.; Wei, S. Dynamic modeling of sustainable operation in green manufacturing environment. J. Manuf. Technol. Manag. 2015, 26, 1201–1217. [Google Scholar] [CrossRef]

- Sivaprakasam, R.; Selladurai, V.; Sasikumar, P. Integrating environmental factors in the suppliers assessment using analytic hierarchy process as a decision making tool. J. Mater. Environ. Sci. 2015, 6, 2097–2104. [Google Scholar]

- Jia, P.; Govindan, K.; Choi, T.M.; Rajendran, S. Supplier selection problems in fashion business operations with sustainability considerations. Sustainability 2015, 7, 1603–1619. [Google Scholar] [CrossRef]

- Tektas, A.; Aytekin, A. Supplier selection in the international environment: A comparative case of a Turkish and an Australian company. IBIMA Bus. Rev. 2011, 2011, 598845. [Google Scholar] [CrossRef]

| Journal | Number of Publications |

|---|---|

| Sustainability | 14 |

| Journal of Cleaner Production | 12 |

| Computers & Industrial Engineering | 10 |

| International Journal of Production Economics | 9 |

| Expert Systems with Applications | 7 |

| Annals of Operations Research | 5 |

| Environmental Science and Pollution Research | 4 |

| Processes | 3 |

| Symmetry | 3 |

| Applied Soft Computing | 3 |

| Others | 73 |

| Criteria | Subcriteria | Repeat |

|---|---|---|

| Economic | Cost | 101 |

| Quality | 95 | |

| Delivery Performance | 72 | |

| Flexibility | 35 | |

| Financial Capability/Stability | 33 | |

| Technology Capability | 31 | |

| Service Efficiency | 21 | |

| Production Facilities and Capacity | 18 | |

| Reputation | 16 | |

| Innovation | 15 | |

| R&D | 14 | |

| After Sales Service | 13 | |

| Relationship/Partnership | 13 | |

| Supplier’s Past Performance | 12 | |

| Geographical Location | 10 | |

| Logistics Performance/Cost | 10 | |

| Continuous Improvement | 8 | |

| Management Capacity and Organization | 8 | |

| Product Reliability | 7 | |

| Technical Capability | 7 | |

| Payment Terms | 6 | |

| Predetermined Order Quantity | 4 | |

| Productivity | 4 | |

| Foundation of Industry 4.0 | 4 | |

| Attitude | 4 | |

| Efficient Production Methods | 4 | |

| Process Capability | 3 | |

| Quantity Discount | 3 | |

| Enterprise Size | 3 | |

| E-commerce Capability | 3 | |

| Information Sharing | 2 | |

| Political Situation | 2 | |

| Organization Commitment | 2 | |

| Product Durability | 2 | |

| Others | 148 | |

| Environmental | GHG Emissions (Air Pollution Control) | 48 |

| Environmental Management Systems | 41 | |

| Waste Management | 33 | |

| Green Design (Eco-design) | 32 | |

| Energy (Resource) Consumption | 30 | |

| Product Recyclability | 24 | |

| Environmental Competencies | 16 | |

| Green Image | 15 | |

| Use of Environmentally Friendly Material/Green Products | 12 | |

| Green Technology | 9 | |

| Green R&D/Innovation | 8 | |

| GHG Legislation | 7 | |

| Green Packing and Labeling | 3 | |

| Reverse Logistics | 5 | |

| Use of Clean Energy | 3 | |

| Environmental Training of Staff | 3 | |

| End-of-Pipe Pollution Control | 2 | |

| Management Commitment | 2 | |

| Green Warehousing | 2 | |

| Others | 66 | |

| Social | Work Safety and Labor Health | 53 |

| Worker Education and Training | 28 | |

| Information Disclosure (Sharing) | 26 | |

| Human Rights (Rights of Employees) | 24 | |

| Stakeholders’ Rights Protection | 20 | |

| Social Commitment (Responsibility) | 17 | |

| Local Communities Influence | 14 | |

| Respect for Policy | 11 | |

| Job Safety (Employee Unemployment) | 6 | |

| Attention to the Child and Forced-Labor Problem | 6 | |

| Reputation | 4 | |

| Ethical Issues and Legal Complaints | 3 | |

| Job Creation | 3 | |

| Employee Welfare and Protection | 3 | |

| Employment Compensation (Contracts) | 3 | |

| Philanthropy and Ethics | 3 | |

| No Discrimination (Gender, Salary) | 3 | |

| Mutual Trust | 3 | |

| Social Management | 2 | |

| Legal Requirements | 2 | |

| Others | 62 | |

| Resilience | Risk Management (Awareness) | 15 |

| Responsiveness | 12 | |

| Flexibility | 12 | |

| Surplus Inventory | 6 | |

| Agility | 6 | |

| Robustness | 5 | |

| Backup Supplier | 3 | |

| Adaptability | 2 | |

| Vulnerability | 2 | |

| Reliability | 2 | |

| Others | 28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mirzaee, H.; Ashtab, S. Sustainability, Resiliency, and Artificial Intelligence in Supplier Selection: A Triple-Themed Review. Sustainability 2024, 16, 8325. https://doi.org/10.3390/su16198325

Mirzaee H, Ashtab S. Sustainability, Resiliency, and Artificial Intelligence in Supplier Selection: A Triple-Themed Review. Sustainability. 2024; 16(19):8325. https://doi.org/10.3390/su16198325

Chicago/Turabian StyleMirzaee, Hossein, and Sahand Ashtab. 2024. "Sustainability, Resiliency, and Artificial Intelligence in Supplier Selection: A Triple-Themed Review" Sustainability 16, no. 19: 8325. https://doi.org/10.3390/su16198325