Abstract

In light of mounting environmental concerns surrounding the overuse and accumulation of plastic waste, the United Nations (UN) has turned its attention towards sustainable materials and the Circular Economy (CE). Polymer recycling technologies have the potential to reduce the environmental impact and carbon footprint of plastic waste production, thereby contributing to the achievement of several Sustainable Development Goals (SDGs). In response to this challenge, students enrolled in the fourth year of secondary education, specializing in technology, during the 2021–2022 academic year, developed an open-source prototype that automatically transforms polyethylene terephthalate (PET) bottles into recycled rPET filament for 3D printing using an automated pultrusion model. In this working group, one of the students identified as gifted developed the pultrusion prototype using challenge-based learning and the project method (PM), which is now known as project-based learning. The resulting prototype has the capacity to transform PET bottles into rPET filament with mechanical properties comparable to those of commercial filaments, thereby enabling the manufacture of a wide range of products through 3D printing. It is not the intention of this work to create a commercial product. Rather, it is designed to promote social and sustainable entrepreneurship, CE, and the values of Education for Sustainable Development (ESD) through the recycling of polymers by means of 3D printing production. In addition, it seeks to develop the key competences for sustainability described in the methodological framework established by UNESCO in 2017.

1. Introduction

The global demand for plastic materials has increased exponentially in various industrial sectors, creating significant challenges in waste management [1]. Plastic materials represent a significant global environmental concern due to their inherent toxicity [2], which has a direct impact on the environment, human health, and marine life. As indicated by data from researchers [3], it is estimated that an excess of 30,000 tons of plastic waste is deposited into the Mediterranean Sea on an annual basis. The decomposition of plastics can take up to 400 years, and their presence in the form of microparticles in water can integrate into the food chain, thereby posing a significant risk to human health [4].

As reported by Plastics Europe [5], in 2021, 90.2% of global plastics production was derived from fossil sources, while post-consumer recycled plastics and bio-based plastics accounted for 8.3% and 1.5% of global plastics production, respectively. The catastrophic consequences of plastic production have underscored the necessity for the development of novel methodologies and technologies to enhance current practices and advance a sustainable world. The concept of the circular economy (CE) proposes an alternative approach to reducing the use of natural resources and the emission of pollutants [6].

The recycling of polymers is of paramount importance in the context of waste management, given the exponential growth in population and consumption of a plethora of plastic materials [7]. It is estimated that by 2050, the quantity of plastic waste generated will reach approximately 25 billion tons [8]. The only viable solution for recycling is the implementation of economically sustainable methods that maximize the value chain of products [9,10].

The field of technology education has undergone a notable shift towards a more hands-on, project-based approach to learning. This shift has been driven by the need to provide students with a comprehensive understanding of the subject matter, as evidenced by the findings of numerous studies [11,12,13,14,15,16]. This has facilitated the development of active learning maker spaces, which provide students with the opportunity to undertake design and construction projects. In these spaces, plastics assume a pivotal role, particularly in the utilization of 3D printers to fabricate three-dimensional components.

These projects frequently utilize virgin plastic filament, the use of which in 3D printers is increasing at a rate of 25% per year [17]. This trend is in line with estimates of the global plastic waste crisis, whereby global virgin plastic production is projected to triple by 2050 [18] and annual plastic consumption in Europe is expected to increase by over 150% from 2020 to 2050 [19].

In light of the Sustainable Development Goals (SDGs) for 2030, which call for significant increases in the use of circular and sustainable alternatives, it is essential to address the low utilization of recycled materials, despite local demand. This is hindered by the low cost of virgin materials. This emphasizes the necessity of making recycling processes economically viable through a closed-loop approach within the local infrastructure. It is imperative that students are equipped with the knowledge and skills to specify and utilize recycled materials, with a particular focus on plastics [20,21]. However, it has been observed that a significant proportion of educational programs currently lack training in sustainable development [22,23]. A lack of exposure to the properties of recycled plastics hinders students’ ability to utilize these materials in their future professional roles.

Such questions as the following arise: What are the comparative performance characteristics of recycled plastic and commercial-grade plastic? It would be beneficial to ascertain whether printer settings require adjustment when utilizing recycled plastic. The objective is to enhance awareness of the actuality versus the preconceived notions regarding the quality issues associated with recycled plastic, as well as the methods to address them.

In this context, a group of students in the fourth year of secondary education, studying technology during the 2021–2022 academic year, developed an open-source prototype that automatically transforms polyethylene terephthalate (PET) bottles into recycled rPET filament for 3D printing by means of an automated pultrusion model. The project, which was conducted through project-based learning, included a student identified as gifted, who contributed innovative ideas to the development process.

The prototype is capable of transforming PET bottles into rPET filament with mechanical properties comparable to those of commercial filaments, thereby enabling the manufacture of a multitude of new products. It is not the intention of this work to create a commercial product; rather, it is designed to promote social and sustainable entrepreneurship, the principles of the CE, and the values of education for sustainable development (ESD).

2. Theoretical Framework

2.1. The Utilization of Recycled Plastics in 3D Printing

In recent years, three-dimensional printing technology has transformed the process of rapid and efficient prototyping and manufacturing. This additive manufacturing technology creates three-dimensional objects by successively depositing layers of material, typically plastic [24,25]. This method enables the rapid production of three-dimensional objects on relatively small-scale machines, and its use has become pervasive in a diverse range of settings, including specialized companies, training centers and homes. In secondary schools, 3D printing is becoming increasingly prevalent in projects associated with Science, Technology, Engineering, and Mathematics (STEM) subjects, where the manufactured parts are required to be durable and withstand mechanical stresses, such as structures, mechanisms, and gears. The potential of 3D printing technology is currently unparalleled, with the capacity to rapidly transform 3D models generated through Computer-Aided Design (CAD) into tangible entities. Furthermore, it enables the fabrication of bespoke components that would be challenging to procure through alternative means.

However, one of the primary disadvantages of 3D printing is the cost of the filament, which is also known as thermoplastic or consumable. As the cost of 3D printers continues to decline, the price of filament has been observed to increase in response to rising demand. Consequently, the industry is engaged in research and development activities aimed at the production of filament at a lower cost and on a larger scale [26].

The incorporation of CE into the fabric of everyday life is a crucial undertaking. The definitions of CE proposed by various authors are, despite their differences, essentially similar. The objective of this concept is to disrupt the established linear production and consumption model, which involves the extraction, production, utilization and ultimate disposal of materials. This process has been identified as a key contributor to unsustainable economic, social, and environmental outcomes [27]. The objective of CE is to replace the traditional system with a regenerative and cyclical one [28]. In their 2014 study [6], Wu and colleagues define CE as a production system that minimizes the use of natural resources and the emission of pollutants while also reducing the amount of waste through recycling and reuse. Singh and Ordóñez [29] define it in economic terms as a strategy that transforms the linear system of production and consumption into a circular one, thereby achieving sustainability with energy and material savings.

In order to reincorporate plastic waste into the consumption chain, several researchers have focused their studies on the development of plastic waste shredding and extrusion machines [30,31,32]. While these machines are effective for recycling a range of plastic materials, they do present certain drawbacks. These include high cost, high power consumption, large size, and weight, which collectively make them inaccessible to the majority of 3D printing users. Nevertheless, there is a clear opportunity for student workspaces to utilize recycled plastic materials, such as recycled filament. In a study conducted by Peeters et al. [33], teachers were surveyed to ascertain their interest in utilizing recycled filament. The findings indicated that there was considerable enthusiasm for the use of recycled filament, provided that it was readily available and exhibited comparable characteristics to commercial filament. This included the ability to prevent blockages in the printing apparatus and to produce prints of a satisfactory quality.

Recent research has demonstrated that conventional plastic waste can be recycled and employed as 3D printing filament, although challenges remain in terms of dimensional control and the potential degradation of material properties. Sanchez et al. [34] observed a significant deterioration in the mechanical properties of polylactic acid (PLA) following five iterations of mechanical recycling. Guo et al. [35] successfully converted post-consumer waste polyethylene into printing filament but encountered difficulties in maintaining dimensional control. Additionally, other studies have demonstrated the efficacy of additives and composites in the production of superior filament [36].

The contemporary era is characterized by consumerism, which has resulted in the generation of considerable quantities of waste, particularly in the form of plastic materials such as PET bottles. The objective of our research is to design and fabricate a prototype for the conversion of PET bottles into a new raw material, namely filament for 3D printing. As other researchers have done [37,38], our aim is to reduce the environmental impact and identify ways of reusing materials for 3D printing by reintroducing discarded PET plastic bottles back into the production and consumption chain.

2.2. Challenge-Based Learning and Education for Sustainable Development

In response to the changes that society and the economy are undergoing, and with it, the challenges that learners will have to face in the 21st century, as well as the commitment to the SDGs, the Council of the European Union on 22 May 2018, the Council amended its 2006 Recommendation [39] by adopting a new recommendation on key competences for lifelong learning [40]. It is thus recommended that the new curricula for pre-primary, primary, and secondary education in the Member States endorse this recommendation by incorporating the aforementioned European reference framework of key competences for lifelong learning.

In accordance with the proposal of SDG 4, the Council’s initial recommendation is designed to ensure the right to inclusive and quality education, training, and lifelong learning. It is thus incumbent upon member states to provide support and reinforcement for the development of key competences in education from an early age and throughout life, including for those who are disadvantaged or have special needs, so that they may realize their full potential. In this sense, in alignment with SDG target 4.7, the ESD approach contributes to the advancement of quality education and the achievement of the other SDG targets. ESD is a pivotal instrument for this, as evidenced by the findings of Lozano et al. [41], who assert that ESD achieves its purpose by transforming society in a manner that integrates specific learning content addressing pivotal sustainability concerns. This is in line with the key competences for sustainability established by UNESCO [42].

It is evident that the optimal method for ensuring that students are equipped to confront the various challenges that life may present them with throughout their lives is through the cultivation of resilience through the navigation of challenges or tasks. Challenge-based learning is an active learning methodology that acknowledges students as the primary agents of their own learning. Based on real-world experience, participants are tasked with solving a problem in their environment, designing a product, developing a social campaign, or other similar activities, culminating in the formulation of a proposed solution.

The objective of this paper is not to distinguish between the Project Method (PM), in which the development of a project culminates in the creation of a tangible final product, and project-based learning, whose final product or result can be either tangible or non-tangible, which aims to provide a solution to a problem or answer a research question after solving a series of steps or challenges. It is evident that these active methodologies can be situated within the challenge-based learning framework, as they provide students with opportunities to engage with projects, challenges, and problems, which in turn facilitate the application of diverse strategies and skills for analyzing and understanding phenomena, situations, and events that are pertinent to their lived experiences. The essential element of integrating challenges into student learning is that they necessitate students to engage in actions that align with the competency focus of the curriculum. The objective is not only to acquire content but also to learn to utilize it to address present needs.

In light of the aforementioned definition, the crux of challenge-based learning and its associated methodologies lies in the simultaneous development of students’ knowledge and skills, commensurate with their educational level or stage. These active methodologies are proposed at the various educational levels in Spain, and, in accordance with the curricula of each level, they are introduced into the classroom through learning situations that facilitate motivation, exploration, practice, and the transfer of learning.

In essence, the discussion revolves around the tenets of instructional learning, wherein the educator assumes the role of an instructor, guide, facilitator, or team leader, while the learners, as previously stated, are the primary actors in their own educational journey. In light of the aforementioned methodologies that favor group work, it is incumbent upon the instructor to design the learning situations in a manner that allows for the integration of all students (gifted students, autism spectrum disorder, etc.) among the various work roles assumed by the students in each group. In this context, Merrill [43] has made a significant contribution to the field of instructional design, with the aim of achieving quality learning outcomes. The researcher posits that there are five fundamental principles underpinning his instructional design theory. These are that learning is: fostered when students are engaged in real-world problem solving; facilitated when existing knowledge is activated as a basis for acquiring new knowledge; enhanced when new knowledge is demonstrated to the student; optimized when the student applies the new knowledge; and consolidated when the new knowledge is integrated into the student’s context. Moreover, Merrill posits that the most efficacious approach in the domain of instructional design is project-based or problem-based learning, as this methodology fosters a more profound and contextualized comprehension of knowledge. Similarly, del Cerro and Morales [44] and del Cerro and Lozano [45] emphasize the pivotal role of student engagement and awareness in the advancement of sustainable development, particularly when students undertake the development of social and sustainable projects within the classroom.

3. Hypotheses and Research Objectives

The objective of this work is to establish a connection between the aforementioned concepts by proposing a viable and sustainable solution. This solution encompasses the design and manufacture of a prototype for the recycling of PET bottles, the recycling process of rPET filament, which is subjected to thermal and mechanical tests, and finally, the printing of a product. The project was undertaken by a group of four students in their fourth year of compulsory secondary education. The group comprised two girls and two boys, one of whom was identified as a gifted student. The students were coordinated and tutored by the technology teacher and supported by the therapeutic pedagogy teacher (TP), who guided them through each stage of the process.

The overarching objective of this research is to design and construct a prototype PET plastic bottle extruder machine, predominantly comprising 3D-printed components and reusing parts from a damaged 3D printer, with the aim of producing recycled filament exhibiting thermal and mechanical properties conducive to 3D printing. In turn, as previously stated, the education for sustainable development target (SDG 4.7) will contribute to the achievement of the remaining SDGs.

The research process is oriented towards a number of specific objectives: (1) the needs analysis of the project and the determination of the functional and technical requirements of the prototype, (2) the design and construction of the prototype mechanisms, ensuring the integration and functionality of the components, (3) the connection of the electrical circuits and control electronics necessary for the operation of the extruder machine, (4) the determination of the optimal printing parameters for the rPET recycled filament. (5) Conducting 3D printing trials utilizing the recycled filament and assessing its performance and quality, (6) undertaking mechanical analysis and testing of the recycled filament to verify its thermal and mechanical properties, (7) contributing to the advancement of CE and the SDGs by reusing discarded PET bottles and promoting sustainable practices in additive manufacturing.

The hypothesis of this research is that the design and construction of a prototype extruder machine using 3D-printed components and reused parts from a broken 3D printer, carried out by a group of students using active methodologies, will not only enable the production of recycled filament with thermal and mechanical properties suitable for 3D printing but will also foster the development of key competences in sustainability and problem solving, in alignment with the SDGs. It is anticipated that this project will meet both technical and environmental objectives while also fostering an active, hands-on learning environment that will enhance critical thinking and computational and problem-solving skills in students. Furthermore, the project seeks to address the educational needs of high-ability students by providing supplementary challenges and advanced learning opportunities. In conclusion, the project aims to cultivate awareness and practice of CE principles and sustainable development, thereby contributing to the achievement of several SDGs and ESD values. In this way, the project aims to provide students with the requisite skills and knowledge to enable them to meet the environmental and technological challenges of the future.

4. Materials and Methods

The first part of this section presents the design and mechanical construction of the prototype, which is largely composed of 3D printed parts. The second part describes the electrical and electronic system responsible for temperature control, filament winding speed regulation, and head cooling and heating. The third part describes the filament creation process and the overall operation of the machine. The final part of the document presents the experimental results, including the comparison of the characteristics and mechanical properties of the rPET filament, such as temperature resistance, tensile tests, and physical structure, with equivalent filaments available on the market.

In addition, the project was disseminated and documented through a dedicated website: https://sites.google.com/view/reciclator3d (accessed on 20 September 2024), a short explanatory video: https://www.youtube.com/watch?v=r1OQgc9lNVY (accessed on 20 September 2024), and various social networks. In addition, a report was produced using a project study tool, covering the project’s needs, approach, benefits, competitors, and hook (NABCH). Photographs of the project’s design, manufacture, and testing process are also included.

The recycled filament was to create products for educational and social purposes, such as the manufacture of low-cost prosthetic hands and arms donated to groups with limited resources, the printing of cases for children’s chemotherapy bags, and the development of educational resources such as engine blocks and two-stroke pistons. This initiative not only demonstrates the technical feasibility of the project but also highlights its positive impact on the community and its contribution to education and sustainability.

4.1. Open-Source Design of the Mechanical Part

The prototype consists mainly of 3D-designed and printed parts. Its design has a modular structure that allows each part of the prototype to be completely redesigned and replaced. Each part is mounted on the machine using screws on two aluminum V-groove profiles. The model was developed using Autodesk’s Fusion 360 (v. 15.3.0.1657) and TinkerCAD (v. 1.4) modelling software. Initially, the parts were made from PLA because of its strength, flexibility and low flammability. However, it is also possible to use rPET filament produced by the prototype itself, which allows for self-replication.

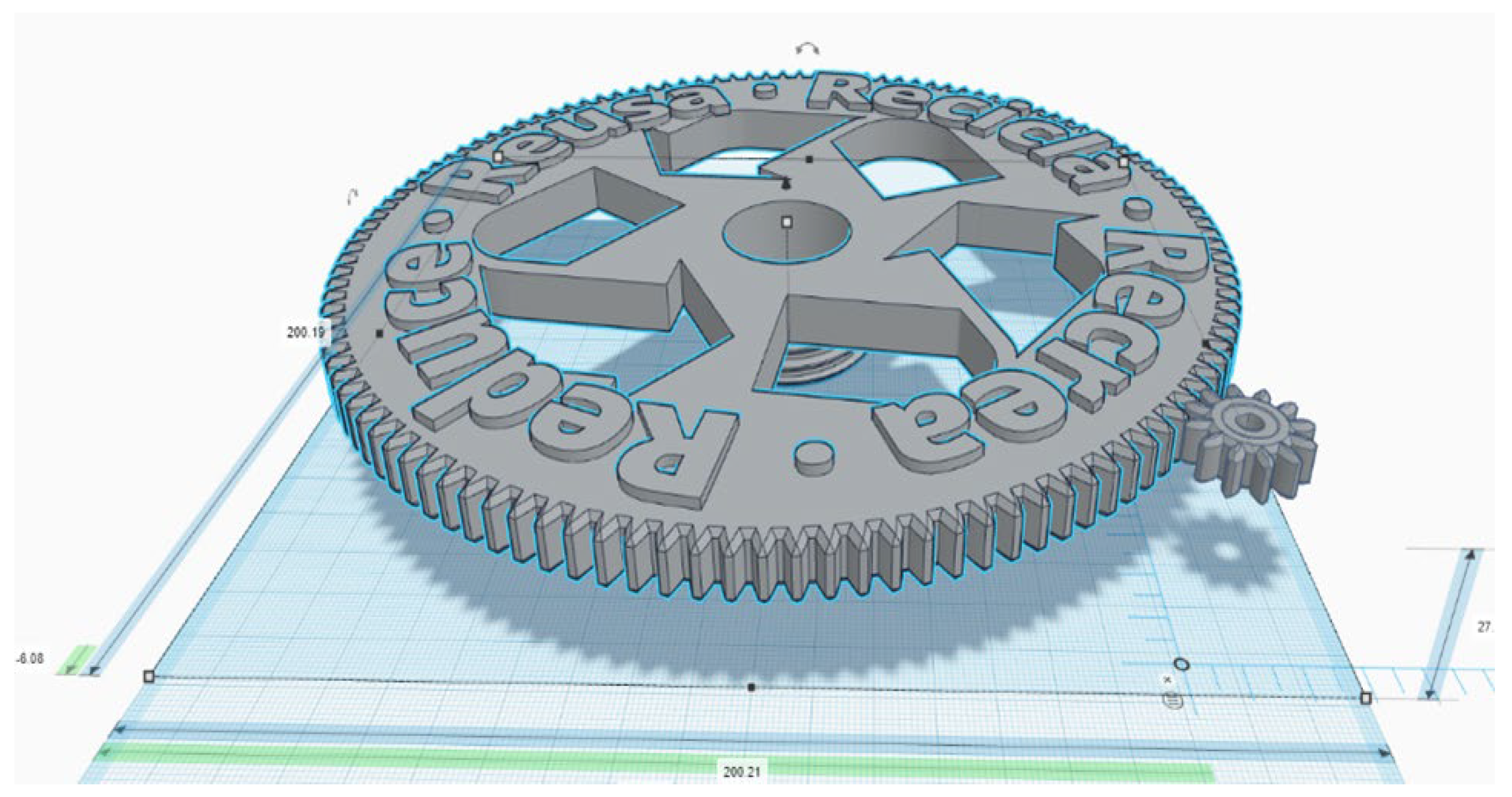

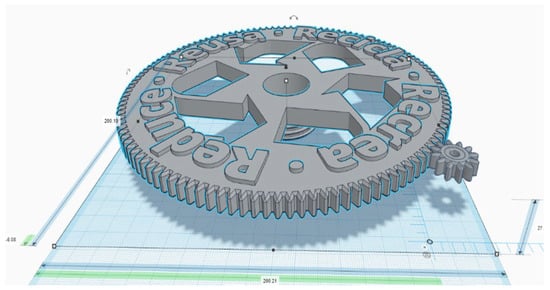

The main gear of the prototype is driven by a two-stage gearbox with a ratio of 1:20, driven by a stepper motor (Figure 1). This stepper motor is powered by 12 V and has a torque of 0.59 2 Nm at a speed of 30 rpm. Taking into account friction and transmission losses, this results in a torque of approximately 6 Nm and a speed of 2.7 rpm at the coil. This amount of torque is essential for the correct operation of the machine, as extruding and pulling the filament requires a considerable amount of force.

Figure 1.

Design of the gear ratio on the 1:20 bobbin.

The educational approach to the design of the mechanical part focuses on providing students with practical and applicable experience in the field of additive manufacturing. By involving the students in the design, modeling, and prototyping process, technical and problem-solving skills are developed, as well as an in-depth understanding of the mechanical principles involved. The modularity of the design not only facilitates adaptive learning, allowing for continuous adjustment and improvement, but also encourages creativity and innovation among students.

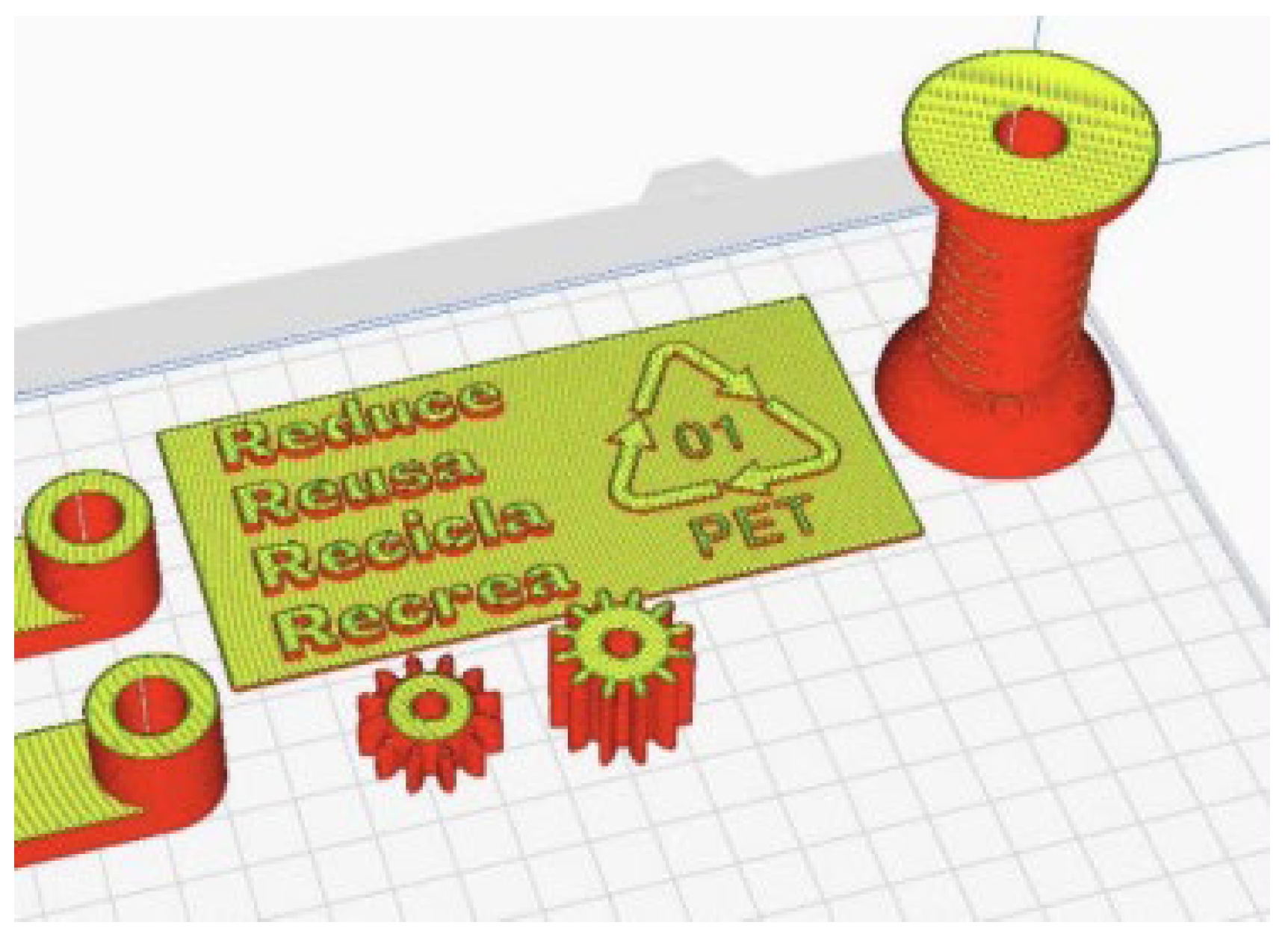

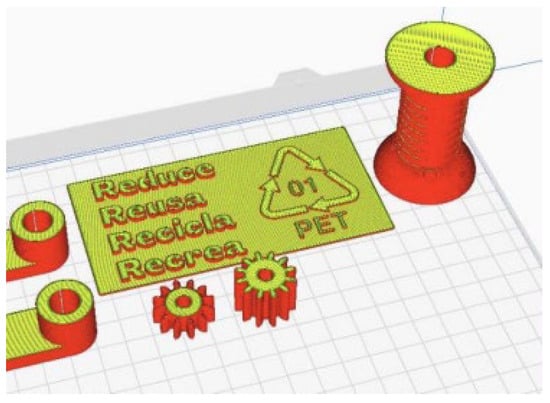

The dimensions, 3D designs, and other documentation required to recreate the prototype are available online at: https://sites.google.com/view/reciclator3d/reciclator-3d/%C3%BAnete (accessed on 20 September 2024) under a completely free, open-source model so that anyone can download the designs and replicate and modify the components (Figure 2). An additional aim of the project is to create a constantly evolving community to support this initiative. It aims to promote actions such as the correct recycling of PET bottles, solidarity through the creation of useful objects or machines, and the exchange of improvements and knowledge between participants. This approach not only facilitates the dissemination of technical knowledge but also promotes educational and community values, integrating technology with social and environmental commitment.

Figure 2.

Open-source design of different mechanical components of the prototype.

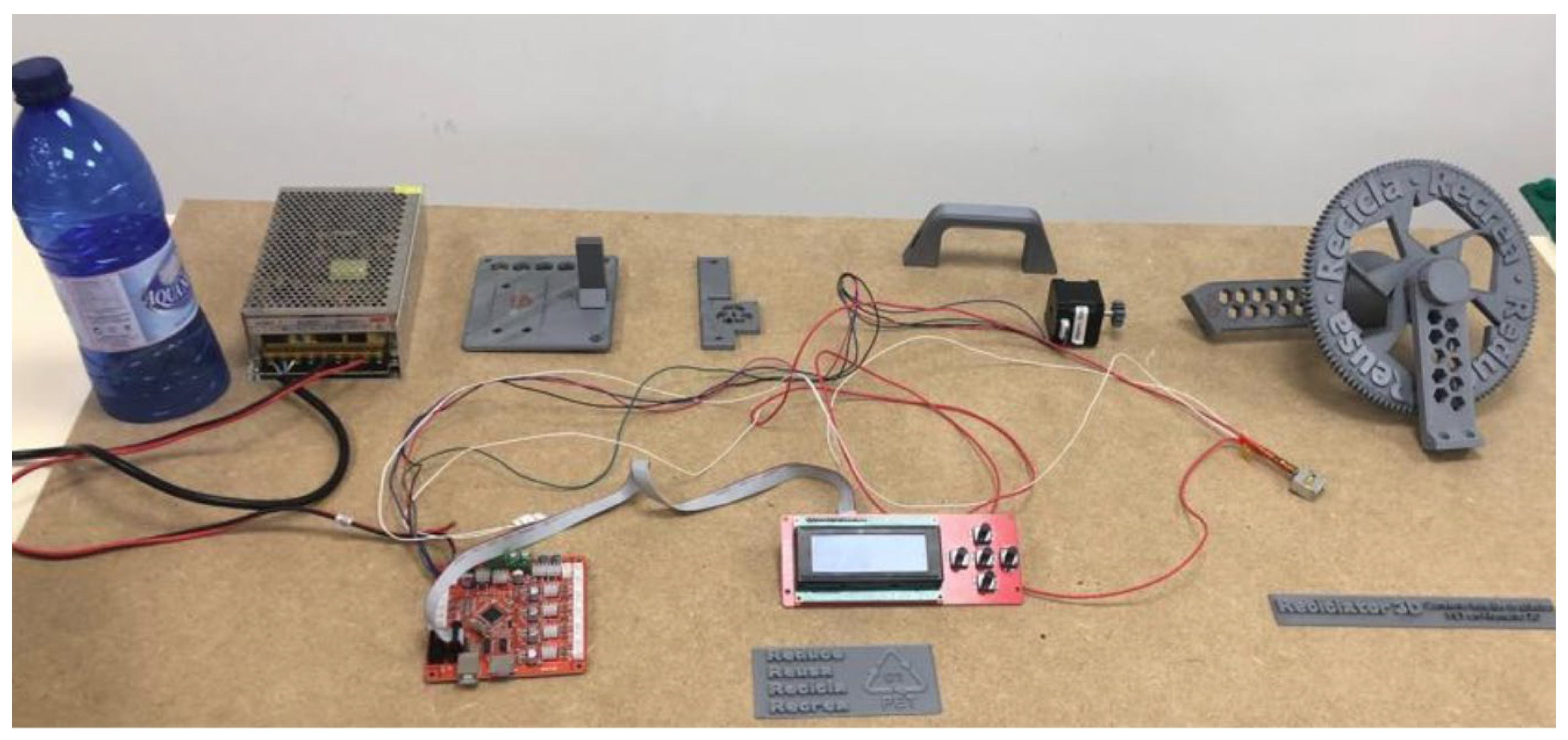

4.2. Open-Source Design of the Mechanical Part

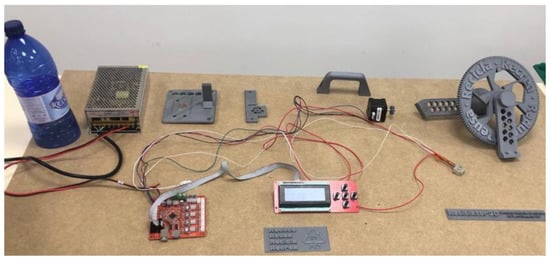

The electrical and electronic components of the prototype (Figure 3) include a 240 W power supply with a voltage output of 12 V and a rated current of 20 A, connected to a motherboard model Anet3d v1.7 or similar. Several key components are connected to this control board: an LCD display with built-in analogue controller model 2004/12864, a 48 mm 1.68 A stepper motor from manufacturer Moons’ Industries located in Shanghai, China and a 12 V–40 W heater block with an operating temperature range of 40~+260 °C, incorporating a temperature sensor and a 1.75 mm diameter hole nozzle for rPET filament output. In addition, a 12 V fan is incorporated at the outlet of the heater block to create an airflow to cool and solidify the rPET filament. All of these electrical and electronic components were salvaged and reused from a 3D printer that was not working at the school. If a 3D printer is not available to obtain the components, they can be purchased at a relatively low cost.

Figure 3.

Distribution of electrical and electronic materials.

The temperature sensor in the heater block, which is connected to the base plate and powered by 12 V, provides temperature data and allows temperatures up to 260 °C to be reached. The lower part of Figure 3 shows the control board, which is responsible for controlling the speed of the large coil using the stepper motor.

The reuse of electrical and electronic components from an inoperative 3D printer not only reduces costs but also introduces students to the principles of sustainability and CE. This hands-on approach allows students to learn about electronics and programming while developing problem-solving and critical thinking skills. By disassembling and reusing components, students gain a deeper understanding of how machines and electronic systems work, enriching their learning experience and preparing them for future technological challenges.

4.3. rPET Production Process

The 3D filament production process starts with PET plastic bottles, which are converted into a new raw material, rPET filament, through an automated pultrusion process. Pultrusion is a highly efficient, continuous manufacturing process in which a material is forced through a heated die to give it a specific shape. The process for producing rPET filament is detailed below (Figure 4):

Figure 4.

rPET filament production process via pultrusion.

- Initial cleaning: First, the empty PET bottle is cleaned of debris using soap and water, taking care to remove dust, labels, and glue.

- Initial cutting: Cut the bottle at the heel end and remove the rest of the bottle.

- Insert into the prototype: Remove the cap and insert the bottle from the base to the mouthpiece through the metal bar incorporated into the prototype.

- Cutting into strips: Using the prototype’s own cutter, a long strip of 10 mm width is cut from the base of the bottle.

- Pultrusion: The cut strip is fed into the extruder at a temperature of 140 °C. This temperature was found to be optimal after experimental tests. The plastic strip must be manually stretched until it can be attached to the coil.

- Automatic winding: The plastic thread comes out of the extruder and is automatically wound onto the spool.

- Production of the filament: Finally, the bottle reaches the ring section, producing approximately 25 g of rPET filament per 1.5 L bottle (Figure 5).

Figure 5. rPET filament produced from 1.5 L PET bottles.

Figure 5. rPET filament produced from 1.5 L PET bottles.

The parameters of the rPET filament extrusion process were optimized with the objective of improving its mechanical properties. The process was conducted at an extrusion temperature of 140 °C, as determined through experimental tests which demonstrated that this was the optimal point for achieving consistent filament quality. The filament was pulled at a controlled speed to ensure a uniform distribution of the material, with a speed of 2.7 rpm on the take-up spool. These conditions were optimized to prevent the formation of air bubbles and to ensure the mechanical strength of the filament.

This process not only teaches students the technical aspects of 3D filament production but also incorporates important lessons about sustainability and recycling. By participating in the PET cleaning, cutting, and pultrusion process, students develop practical skills in handling materials and machinery. In addition, the process encourages a project-based learning approach, where students work on a real-world problem and apply theoretical knowledge in a practical context.

This educational approach provides a holistic learning experience from the collection and preparation of recyclable materials to the final production of a useful product. By integrating sustainability into the curriculum, students are made aware of the importance of recycling and reusing materials, preparing them for future environmental challenges. In addition, the project promotes the development of transversal skills such as collaboration, problem solving, and critical thinking, which are essential in today’s education.

5. Results and Discussion

A number of research studies have been conducted with the objective of examining the mechanical properties of filaments and 3D prints. These studies have employed a set of experiments [46,47,48,49]. We elected to assess the fundamental parameters of filaments and prints utilizing the machinery and tools provided by the research group E0B9-04 Engineering for Sustainability, Didactics of Technologies and VET and Learning Engineering of the University of Murcia.

The students encountered a number of challenges throughout the course of the project. One of the principal challenges was the control of the quality of the recycled filament, given the irregularities in the internal structure of the rPET, which presented difficulties in terms of filament diameter consistency and mechanical integrity. To address this issue, the students conducted a series of extruder flow and temperature control experiments with the objective of identifying the optimal conditions for the minimization of air bubble formation in the filament. Another significant challenge was the reuse of electronic and mechanical components from obsolete 3D printers, necessitating modifications to align with the prototype design. This process not only enhanced their technical abilities but also cultivated resilience in responding to unanticipated circumstances during the construction and evaluation of the system. From an educational standpoint, the challenge-based learning methodology enabled students to apply theoretical knowledge to a tangible practical issue, thereby facilitating a comprehensive comprehension of the recycling process and its ramifications for sustainability.

5.1. Printing Parameters

Firstly, the data for the primary printing parameters of the most commonly utilized filaments in 3D printing, including PLA, acrylonitrile butadiene styrene (ABS), and polyester glycol (PETG), were collated and evaluated in comparison with our rPET filament (Table 1). The following parameters were set indiscriminately for all tests: interlayer height, 0.15mm; filler density, 15%; and printing speed, 35mm/s. As can be observed, the PETG filament exhibits nearly identical printing parameters to those of the rPET filament.

Table 1.

Printing parameters of different filaments.

5.2. Printing Tests with rPET

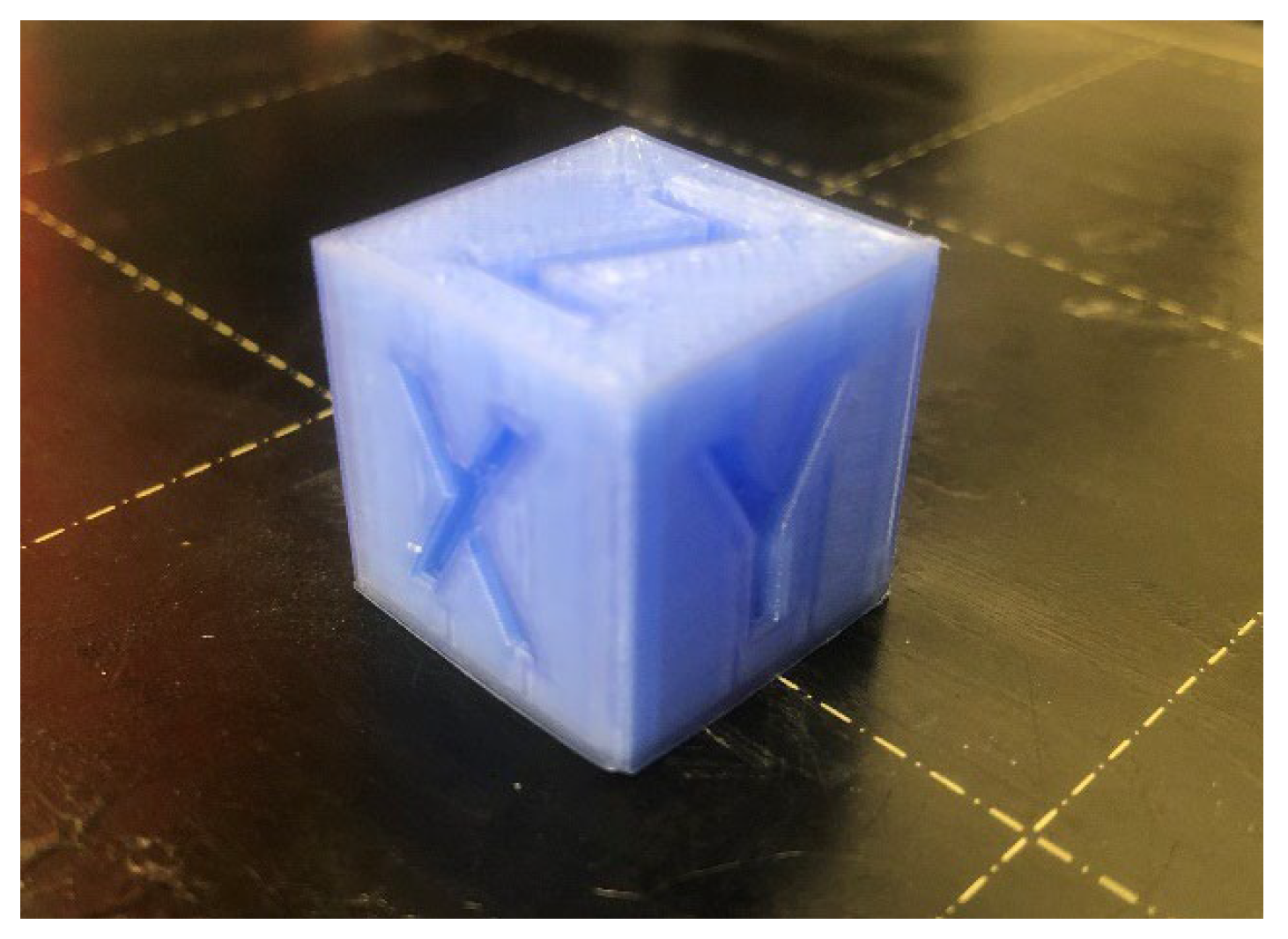

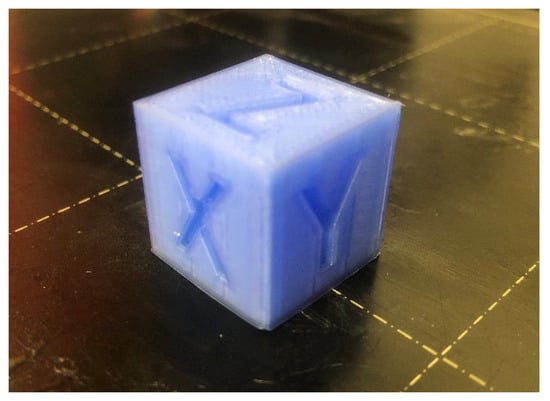

Calibration cubes were produced using rPET filament, with a series of experimental tests conducted to calibrate the temperature and print speed parameters of the designs. The tests yielded satisfactory results at temperatures of up to 230 °C, a hot bed temperature of 80 °C, and a print speed of 35 mm/s. The printing process is illustrated in the accompanying figure (Figure 6). The material exhibits high hardness following the printing process, with a surface finish that is glossy.

Figure 6.

Calibration cube made of rPET.

5.3. Mechanical Properties of rPET

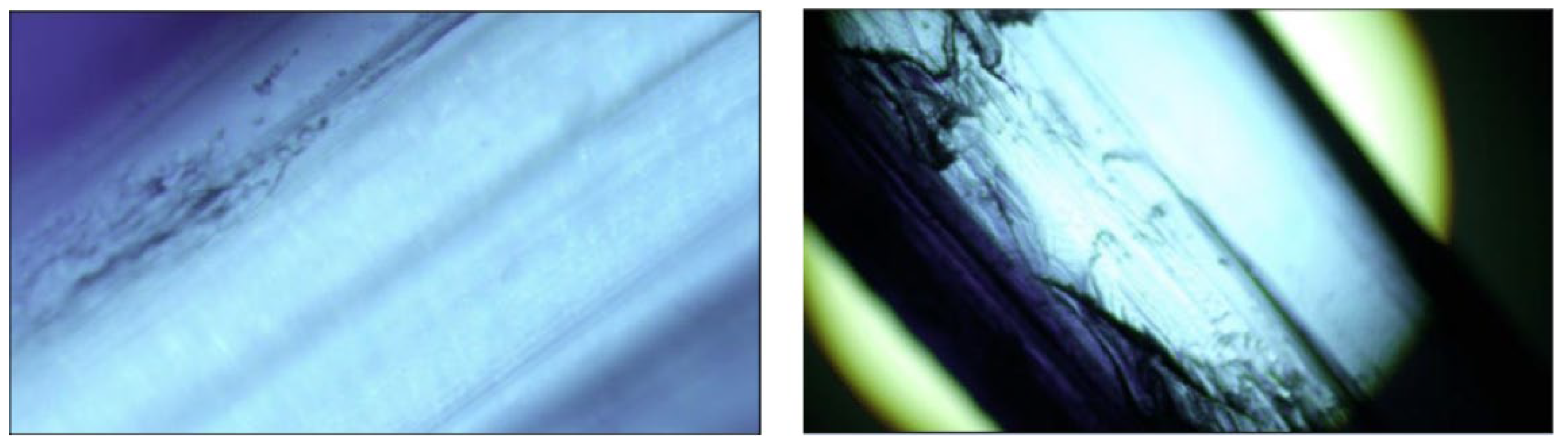

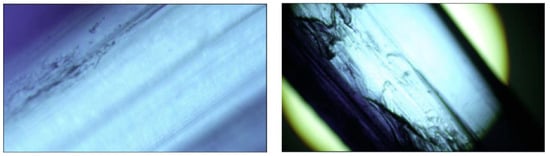

At the structural level, the two types of filaments were examined under a microscope (Figure 7). It was observed that both filaments exhibited transparency. However, there was a significant discrepancy in the internal structure of the PETG filament, which was uniform, in comparison to that of the rPET filament, which was irregular. The aforementioned heterogeneities in the internal structure had a negligible impact on the printing process, as the external structure was smooth and homogeneous, allowing the filament to be extruded in the 3D printer. It seems plausible to suggest that these internal structural irregularities are the result of a void space created during the rPET processing stage. This discrepancy could be rectified by incorporating a filament flow control mechanism into the prototype, thereby achieving enhanced uniformity at the nozzle outlet of the heating block.

Figure 7.

Structure of commercial PETG filament (left) and rPET filament (right).

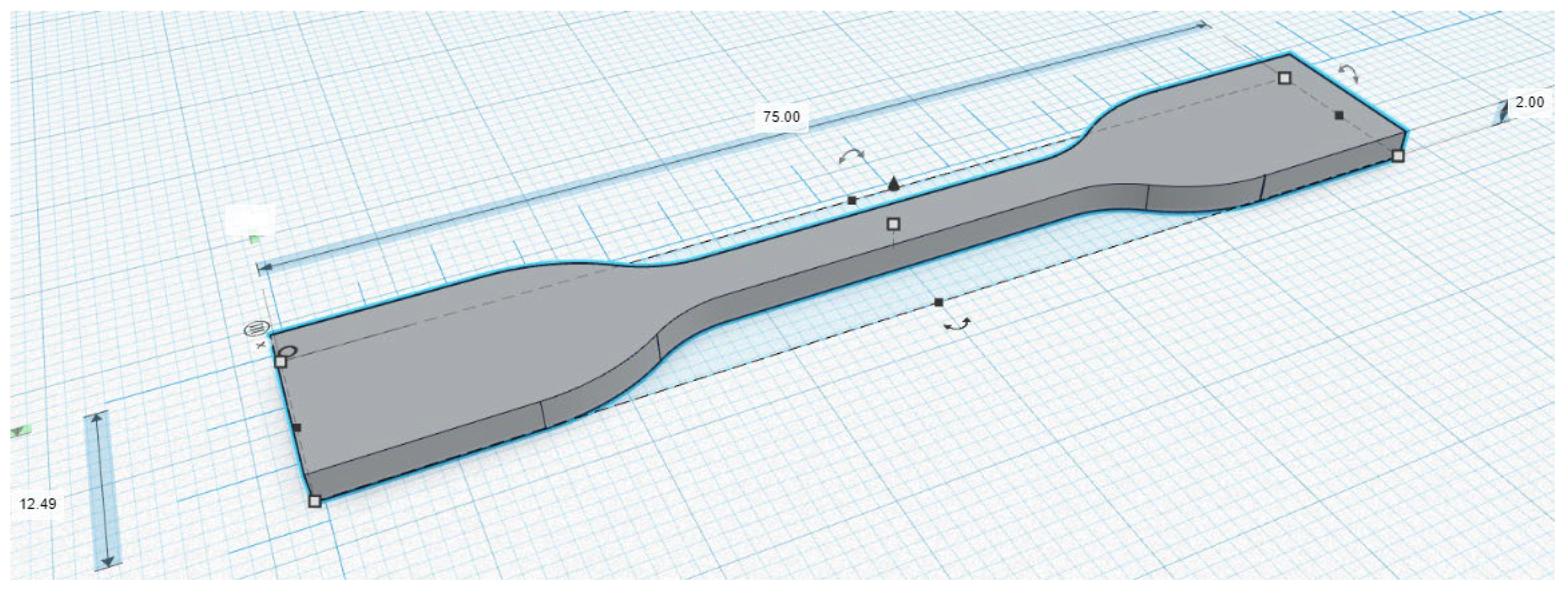

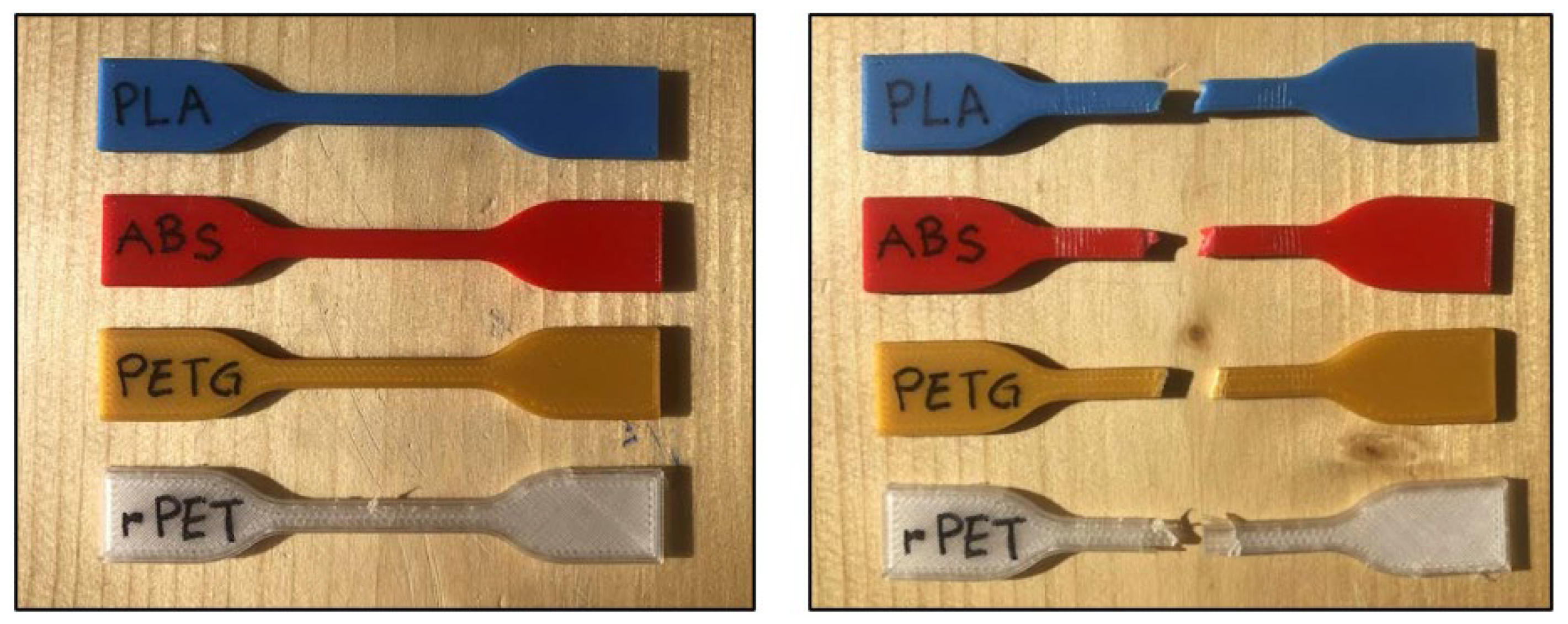

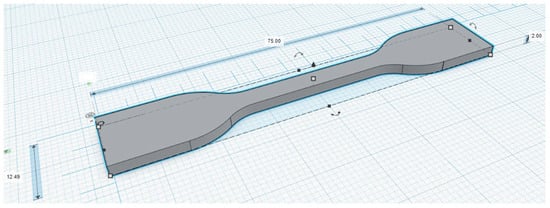

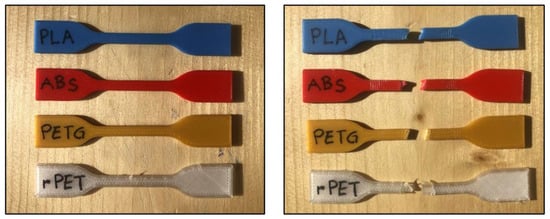

Subsequently, a series of tests were conducted to determine the tensile strength of materials commonly employed in 3D printing, including our rPET filament. The tests were conducted using a high-precision column machine that was specifically designed for the testing of materials with a load of less than 10 kN. A specimen model was designed in accordance with ISO 527-1:2020 [50] (Figure 8) for the purpose of the test. Subsequently, the aforementioned design was employed for the 3D printing of specimens representing each of the filaments under investigation: PLA, ABS, PETG, and rPET (Figure 9). The tensile strength of each specimen was determined through testing using a specialized machine, the results of which are presented in Table 2.

Figure 8.

Test specimen design according to ISO 527-1:2020 [50].

Figure 9.

Specimens of the 3D-printed specimens before (left) and after (right) the tensile test.

Table 2.

Tensile strength test results.

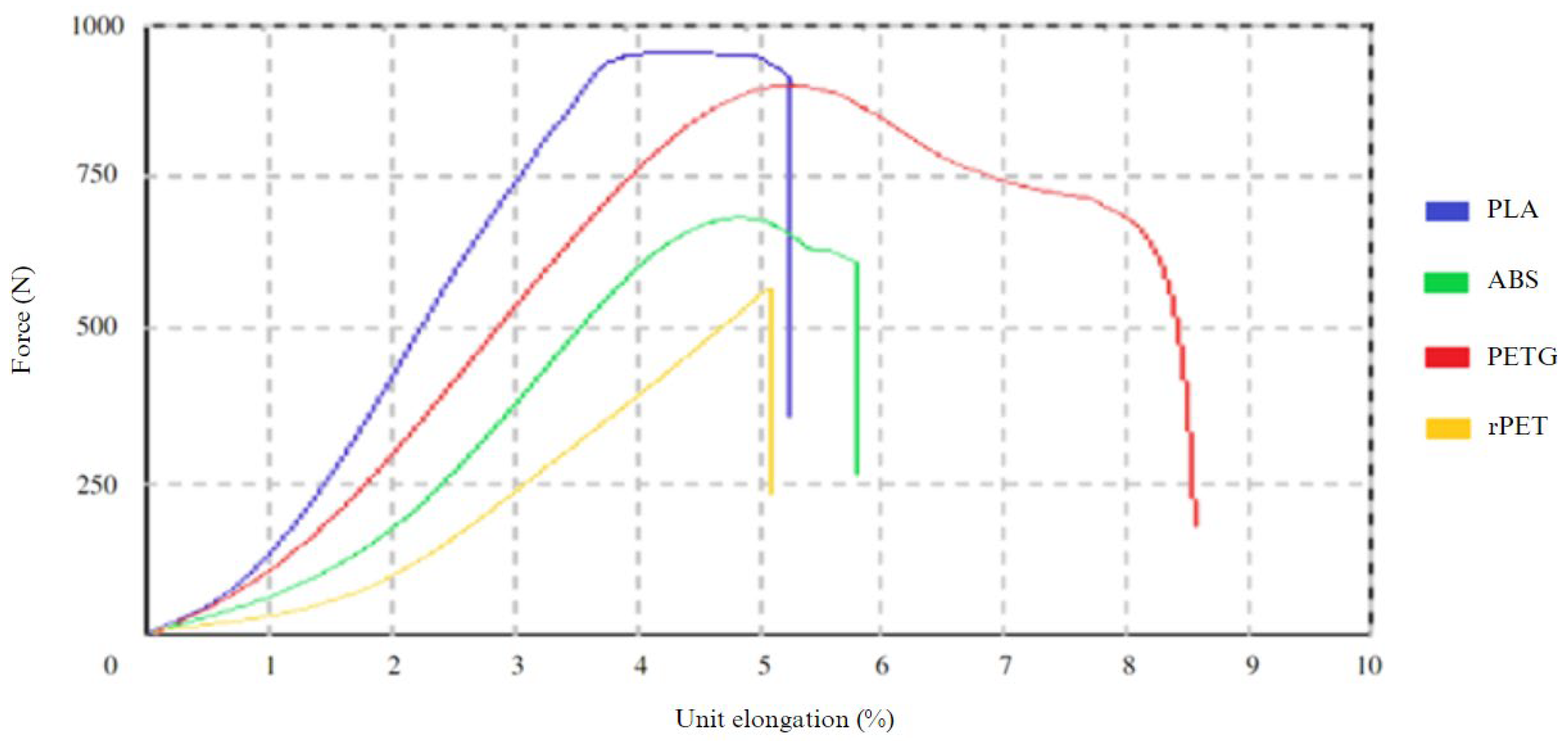

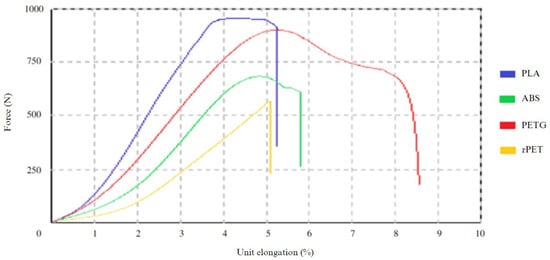

Figure 10 illustrates that the PLA, ABS, PETG, and rPET specimens exhibited brittle failure. The PETG sample demonstrated the highest breaking limit, followed by ABS, PLA, and rPET. These results align with the characteristics of these types of plastics. The observed reduction in the tensile strength of the rPET filament can be attributed to the presence of internal structural failures and the formation of air bubbles during the filament production process, which have a detrimental impact on its structural integrity.

Figure 10.

Unit stress–strain graph of the 3D-printed specimens.

The mechanical properties of the rPET filament were slightly inferior to those of commercial filaments. This may be attributed to the lack of industrial means for its manufacture. Nevertheless, the rPET filament possesses numerous advantages, including:

- From an economic standpoint, the raw material is plastic waste, with the only associated cost being that of the electricity required for its manufacture.

- The rPET filament exhibits resistance to mechanical stress, with mechanical characteristics that are slightly below those of the most commonly used commercial plastic filaments, including Young’s modulus, tensile strength, breaking strength, etc.

- The product is manufactured entirely from recycled PET bottles, thereby ensuring a sustainable production process.

- It is environmentally friendly, in that it facilitates the recycling of plastic waste and contributes to the reduction of carbon emissions.

5.4. Project Contribution to the CE and SDGs

In a socio-economic system based on the linear chain model of production, the deployment of more obsolete and less efficient technologies is prioritized, with minimal consideration for the environmental damage and harm they cause. The 3Rs rule initiative, which refers to the reduction, reuse, and recycling of materials, subsequently saw the addition of a fourth principle, “recover”, within the European Union’s framework for action [51].

Our proposal introduces a new fourth R, “replicate”, which allows for the reuse of plastic waste as a new raw material in the form of recycled rPET filament. This material, used for 3D printing, enables the manufacturing of an infinite number of objects at a low production cost while respecting the principles of the CE. The potential applications of the prototype extend to the manufacturing of spare parts and enhancements to the prototype itself. Furthermore, the self-replicating capabilities of the prototype could be employed to print the majority of the structural and mechanical components, thus facilitating the fabrication of an entirely new machine. Table 3 illustrates the proposed 4R framework, delineating the principles and their respective meanings.

Table 3.

Proposed 4R framework based on our prototype.

As previously stated, the fundamental premise of CE is to achieve greater autonomy from raw materials in the production of goods while simultaneously minimizing the environmental impact of waste. This has led to the evolution of the ‘end-of-life’ concept, which has been superseded by an alternative that strives to foster economic prosperity, environmental quality, and social equity [52].

In comparison to other studies utilizing plastic recycling techniques for 3D printing, this project is distinguished by its educational and accessible approach. While the majority of studies on PET recycling for filament manufacturing concentrate on industrial optimization, this project places emphasis on the creation of an accessible prototype for high school students, thereby fostering innovation from an educational perspective. The students not only replicated industrial processes on a small scale but also developed an automated pultrusion model using limited resources, including reused parts from discarded 3D printers. This makes the project an affordable and straightforward initiative that can be implemented in schools with basic infrastructure. Furthermore, the open-source approach and modular design allow other students and users to reproduce and enhance the prototype, thereby reinforcing the project’s impact in the context of CE.

This novel concept is predicated on the utilization of extracted raw materials in a manner that precludes their disposal in a landfill or the ecosystem, and instead facilitates their conversion into a novel product. This transition has significant potential for both the environment and businesses, as it can lead to increased recycling rates and the reduction of material usage. Furthermore, the framework for action proposed in our research contributes to the achievement of various SDGs. The contribution of the proposed recycling model to some of the SDGs is outlined below:

- SDG 4: Quality education. In addition to facilitating the development of technical and creative abilities among students, our proposal presents an opportunity to educate them in sustainable development, fostering awareness and imparting knowledge about social values, environmental respect, and the significance of recycling and reducing plastic consumption.

- SDG 6: Clean water and sanitation. The use of rPET filament can assist in the reduction of plastic waste, which may subsequently contribute to a reduction in water pollution. It is, however, important to note that this does not guarantee universal access to clean water and sanitation.

- SDG 7: Affordable and clean energy. The recycling of PET bottles serves to mitigate environmental pollution and reduce the carbon footprint. Furthermore, the recycling of plastic into rPET filament necessitates less energy than the production of new plastic, thereby contributing to a reduction in overall energy consumption.

- SDG 8: Decent work and economic growth. The open-source design of the prototype, developed through a collaborative process, and its low manufacturing cost, facilitate sustainable and inclusive economic growth.

- SDG 9: Industry, innovation and infrastructure. The proposal encourages innovation and the development of new recycling technologies and the reuse of materials. It is also important to note that the use of rPET filament can facilitate improvements in the accessibility and sustainability of small-scale production, as it enables the production of user-level products with reduced environmental impacts and at a lower cost.

- SDG 10: Reducing inequalities. The designed recycling prototype is accessible and low-cost, which makes it an effective tool for promoting employment and skills development in low-income areas. By promoting sustainable manufacturing practices, it can contribute to reducing economic and social inequalities.

- SDG 11: Sustainable cities and communities. The project has the potential to reduce the amount of plastic waste, which could in turn lead to a reduction in environmental pollution and an improvement in the quality of life in urban areas. Furthermore, the utilization of rPET filament can facilitate the production of sustainable and cost-effective products and structures for low-income communities, which could contribute to the advancement of inclusive urban environments.

- SDG 12. Responsible consumption and production: This objective is directly attributable to a reduction in the environmental impact of the production of goods, enabling the manufacture of parts and products using fewer materials and energy, improving efficiency in production processes, and reducing costs. Consequently, it facilitates the attainment of objectives associated with CE while also encouraging the utilization of recycled materials, curbing the necessity for natural resource exploitation and advancing a sustainable production and consumption system.

- SDG 13: Climate action. The utilization of rPET filament has the potential to indirectly contribute to a reduction in the quantity of plastic waste, which in turn could lead to a reduction in the carbon footprint associated with the production of plastics. Furthermore, the recycling process utilizes less energy than the production of plastic, which could also result in a reduction of greenhouse gas emissions.

- SDG 14: Conservation of marine life and SDG 15: Conservation of terrestrial ecosystem life. This project has the potential to contribute to the reduction of environmental pollution, the protection of marine and terrestrial ecosystems, and the conservation of biodiversity.

The aforementioned examples illustrate the interconnection between the prototype and the SDGs. Additionally, it is noteworthy to mention the collaboration between SDG17 institutions, as the partnership between secondary schools and universities provides students with an opportunity to engage in innovation and research prior to pursuing university studies.

In the context of the educational project, the implementation of active methodologies, such as challenge-based learning and project-based learning, has been demonstrated to be an effective approach for developing key competencies in students. The application of challenge-based learning enabled students to confront a genuine technical issue pertaining to PET recycling while simultaneously motivating them to devise creative and innovative solutions to achieve the project’s objectives. In contrast, project-based learning enabled the acquisition of technical and practical skills, as the students were actively involved in all stages of the prototype development process, from design to construction and mechanical testing of the recycled filament. This approach enabled the students to apply theoretical concepts to real-world problems, thereby enhancing their comprehension and retention. Furthermore, the project fostered a collaborative environment in which the students worked in teams, thereby facilitating the development of interpersonal and teamwork skills. The impact of these active methodologies is reflected in the students’ ability to integrate knowledge of sustainability, recycling, and technology in a manner that aligns with the SDGs. Furthermore, the project experience enhanced their capacity for problem-solving, critical thinking, and technical skills, thereby equipping them with a more robust foundation for future educational and professional endeavors.

This project was awarded the first prize in the Science, Engineering and Values category at the 23rd edition of “Ciencia en Acción” international competition, which serves to highlight its success in technological innovation, sustainability, and education.

6. Conclusions

The teaching of ESD in the classroom provides students with the opportunity to develop theoretical knowledge and a range of practical skills while engaging with social and sustainable challenges or projects. This approach is fundamental to the promotion of genuine sustainable development, as it encourages the adoption of sustainable lifestyles that are compatible with CE and, through group work, fosters values of inclusion and gender equality. It is also noteworthy to emphasize the attitude, involvement, and awareness of students in relation to sustainable development when they encounter social and sustainable challenges or projects. This not only contributes to the realization of SDG 4 but also to the achievement of other SDGs. It is therefore imperative that a cultural shift occurs within our society, modifying habits towards sustainable lifestyles from an early age (from early childhood education) if we are to meet the SDGs. ESD must therefore be one of the fundamental axes in schools and at all other educational levels.

The project is based on a CE model that promotes eco-design, utilizing plastic waste and retaining it within the consumption cycle. It should be noted that the prototype is not intended for commercial distribution. However, its design allows any user with access to a 3D printer to create their own automated pultrusion system using reused, 3D-printed, accessible, and economical components. This approach will facilitate the global expansion of our modest recycling initiative.

Following the completion of a series of 3D printing and mechanical tests on the rPET filament, alongside the most commonly utilized commercial filaments, it can be concluded that the rPET filament is suitable for use in a 3D printer, exhibiting comparable results to commercial filaments, albeit with slightly inferior mechanical properties. In order to enhance the internal structure of rPET and consequently its mechanical properties, it is our intention to incorporate a filament flow control system in the future. This will serve to prevent the formation of air bubbles that may occur during the recycling process.

In light of the exorbitant cost of commercial filament for 3D printing, its inaccessibility to a significant proportion of the population, and the inability to reuse it in the event of a printing error or failure, the rPET filament represents a sustainable, ecological, accessible, and economical solution. Its overarching objective is to facilitate 3D printing with equal opportunities for all and in a manner that is respectful of the environment.

In conclusion, the utilization of rPET filament in 3D printing has a beneficial impact on the attainment of the SDGs, as it facilitates a reduction in the carbon footprint and plastic waste, encourages CE, stimulates innovation, and enhances accessibility and the sustainability of production. Furthermore, this project was developed in the classroom and supported the challenge posed, with the objects created using the rPET filament destined for the teaching–learning process and the promotion of the social values and inclusion of the students.

Author Contributions

Conceptualization, G.M.M. and A.d.C.P.; methodology, G.M.M., A.d.C.P. and F.d.C.V.; software, G.M.M. and A.d.C.P.; validation, G.M.M., A.d.C.P. and F.d.C.V.; formal analysis, G.M.M., A.d.C.P. and F.d.C.V.; investigation, G.M.M. and A.d.C.P.; resources, G.M.M., A.d.C.P. and F.d.C.V.; data curation, G.M.M., A.d.C.P. and F.d.C.V.; writing—original draft preparation, G.M.M. and A.d.C.P.; writing—review and editing, G.M.M., A.d.C.P. and F.d.C.V.; visualization, G.M.M., A.d.C.P. and F.d.C.V.; supervision, G.M.M. and F.d.C.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Obande, W.; Brádaigh, C.M.Ó.; Ray, D. Continuous fibre-reinforced thermoplastic acrylic-matrix composites prepared by liquid resin infusion—A review. Compos. Part B Eng. 2021, 215, 108771. [Google Scholar] [CrossRef]

- Alabi, O.A.; Ologbonjaye, K.I.; Awosolu, O.; Alalade, O.E. Public and environmental health effects of plastic wastes disposal: A review. J. Toxicol. Risk Assess. 2019, 5, 1–13. [Google Scholar]

- Van Sebille, E.; Wilcox, C.; Lebreton, L.; Maximenko, N.; Hardesty, B.D.; Van Franeker, J.A.; Eriksen, M.; Siegel, D.; Galgani, F.; Law, K.L. A global inventory of small floating plastic debris. Environ. Res. Lett. 2015, 10, 124006. [Google Scholar] [CrossRef]

- Evans, A.E.; Hanjra, M.A.; Jiang, Y.; Qadir, M.; Drechsel, P. Water quality: Assessment of the current situation in Asia. Int. J. Water Resour. Dev. 2012, 28, 195–216. [Google Scholar] [CrossRef]

- PlasticsEurope. Plastics—The Facts 2022. An Analysis of European Latest Plastics Production, Demand and Waste Data. Available online: https://plasticseurope.org/wp-content/uploads/2022/10/PE-PLASTICS-THE-FACTS_V7-Tue_19-10-1.pdf (accessed on 5 August 2024).

- Wu, H.Q.; Shi, Y.; Xia, Q.; Zhu, W.D. Effectiveness of the policy of circular economy in China: A DEA-based analysis for the period of 11th five-year-plan. Resour. Conserv. Recycl. 2014, 83, 163–175. [Google Scholar] [CrossRef]

- Conroy, A.; Halliwell, S.; Reynolds, T. Composite recycling in the construction industry. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1216–1222. [Google Scholar] [CrossRef]

- Saha, A.; Gupt, C.B.; Sekharan, S. Recycling natural fibre to superabsorbent hydrogel composite for conservation of irrigation water in semi-arid regions. Waste Biomass Valorization 2021, 12, 6433–6448. [Google Scholar] [CrossRef]

- Feng, Z.; Adolfsson, K.H.; Xu, Y.; Fang, H.; Hakkarainen, M.; Wu, M. Carbon dot/polymer nanocomposites: From green synthesis to energy, environmental and biomedical applications. Sustain. Mater. Technol. 2021, 29, e00304. [Google Scholar] [CrossRef]

- Despeisse, M.; Baumers, M.; Brown, P.; Charnley, F.; Ford, S.J.; Garmulewicz, A.; Rowley, J. Unlocking value for a circular economy through 3D printing: A research agenda. Technol. Forecast. Soc. Change 2017, 115, 75–84. [Google Scholar] [CrossRef]

- Arts, B.; Buizer, M.; Horlings, L.; Ingram, V.; Van Oosten, C.; Opdam, P. Landscape approaches: A state-of-the-art review. Annu. Rev. Environ. Resour. 2017, 42, 439–463. [Google Scholar] [CrossRef]

- Nurius, P.S.; Coffey, D.S.; Fong, R.; Korr, W.S.; McRoy, R. Preparing professional degree students to tackle grand challenges: A framework for aligning social work curricula. J. Soc. Soc. Work Res. 2017, 8, 99–118. [Google Scholar] [CrossRef]

- Cederberg, L.; Axehill, J.W.; Herzog, E. Experience from a Program for Accelerating the Creation of T-shaped Technical Leaders. INCOSE Int. Symp. 2019, 29, 707–722. [Google Scholar] [CrossRef]

- Kokoc, M.; Ersöz, S. T-Shaped Engineer: Horizontal component comprising of soft skills. Endüstri Mühendisliği 2020, 31, 180–197. [Google Scholar] [CrossRef]

- Pennington, D.; Ebert-Uphoff, I.; Freed, N.; Martin, J.; Pierce, S.A. Bridging sustainability science, earth science, and data science through interdisciplinary education. Sustain. Sci. 2020, 15, 647–661. [Google Scholar] [CrossRef]

- Asfaw, A.; Blais, A.; Brown, K.R.; Candelaria, J.; Cantwell, C.; Carr, L.D.; Combes, J.; Debroy, D.M.; Donohue, J.M.; Economou, S.E.; et al. Building a quantum engineering undergraduate program. IEEE Trans. Educ. 2022, 65, 220–242. [Google Scholar] [CrossRef]

- Petersen, E.E.; Kidd, R.W.; Pearce, J.M. Impact of DIY home manufacturing with 3D printing on the toy and game market. Technologies 2017, 5, 45. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- van Oosterhout, L.; Dijkstra, H.; Borst, D.; Duijndam, S.; Rehdanz, K.; van Beukering, P. Triggering sustainable plastics consumption behavior: Identifying consumer profiles across Europe and designing strategies to engage them. Sustain. Prod. Consum. 2023, 36, 148–160. [Google Scholar] [CrossRef]

- Biancardi, A.; Colasante, A.; D’Adamo, I.; Daraio, C.; Gastaldi, M.; Uricchio, A.F. Strategies for developing sustainable communities in higher education institutions. Sci. Rep. 2023, 13, 20596. [Google Scholar] [CrossRef]

- Beagon, U.; Kövesi, K.; Tabas, B.; Nørgaard, B.; Lehtinen, R.; Bowe, B.; Gillet, C.; Spliid, C.M. Preparing engineering students for the challenges of the SDGs: What competences are required? Eur. J. Eng. Educ. 2023, 48, 1–23. [Google Scholar] [CrossRef]

- Högfeldt, A.K.; Gumaelius, L.; Berglund, P.; Kari, L.; Pears, A.; Kann, V. Leadership, support and organisation for academics’ participation in engineering education change for sustainable development. Eur. J. Eng. Educ. 2023, 48, 240–266. [Google Scholar] [CrossRef]

- Hidayat, R.; Nugroho, I.; Zainuddin, Z.; Ingai, T.A. A systematic review of analytical thinking skills in STEM education settings. Inf. Learn. Sci. 2024, 125, 565–586. [Google Scholar] [CrossRef]

- Turner, B.N.; Strong, R.; Gold, S.A. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp. J. 2014, 20, 192–204. [Google Scholar] [CrossRef]

- Elhajjar, R.; Gill, T. Studies into Additive Manufacturing for In-Space Manufacturing: Student Research Papers; SAE International: Warrendale, PA, USA, 2016; pp. 1–94. [Google Scholar]

- Prusinowski, A.; Kaczyński, R. Simulation of processes occurring in the extrusion head used in additive manufacturing technology. Acta Mech. Autom. 2017, 11, 317–321. [Google Scholar] [CrossRef][Green Version]

- Frosch, R.A.; Gallopoulos, N.E. Strategies for manufacturing. Sci. Am. 1989, 261, 144–153. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Singh, J.; Ordoñez, I. Resource recovery from post-consumer waste: Important lessons for the upcoming circular economy. J. Clean. Prod. 2016, 134, 342–353. [Google Scholar] [CrossRef]

- Ayo, A.W.; Olukunle, O.J.; Adelabu, D.J. Development of a waste plastic shredding machine. Int. J. Waste Resour. 2017, 7, 1–4. [Google Scholar]

- Aryani, N.; Buchori, D.; Setiawan, A.B. Design of a plastic shredder machine. IPTEK J. Proc. Ser. 2019, 3, 35–39. [Google Scholar] [CrossRef]

- Mikula, K.; Skrzypczak, D.; Izydorczyk, G.; Warchoł, J.; Moustakas, K.; Chojnacka, K.; Witek-Krowiak, A. 3D printing filament as a second life of waste plastics—A review. Environ. Sci. Pollut. Res. 2021, 28, 12321–12333. [Google Scholar] [CrossRef]

- Peeters, B.; Kiratli, N.; Semeijn, J. A barrier analysis for distributed recycling of 3D printing waste: Taking the maker movement perspective. J. Clean. Prod. 2019, 241, 118313. [Google Scholar] [CrossRef]

- Sánchez, F.A.C.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer recycling in an open-source additive manufacturing context: Mechanical issues. Addit. Manuf. 2017, 17, 87–105. [Google Scholar]

- Guo, J.; Luo, C.; Wittkowski, C.; Fehr, I.; Chong, Z.; Kitzberger, M.; Alassali, A.; Zhao, X.; Leineweber, R.; Feng, Y.; et al. Screening the impact of surfactants and reaction conditions on the de-inkability of different printing ink systems for plastic packaging. Polymers 2023, 15, 2220. [Google Scholar] [CrossRef]

- Kováčová, M.; Kozakovičová, J.; Procházka, M.; Janigová, I.; Vysopal, M.; Černičková, I.; Krajčovič, J.; Špitalský, Z. Novel hybrid PETG composites for 3D printing. Appl. Sci. 2020, 10, 3062. [Google Scholar] [CrossRef]

- Mosaddek, A.; Kommula, H.K.; Gonzalez, F. Design and testing of a recycled 3D printed and foldable unmanned aerial vehicle for remote sensing. In Proceedings of the 2018 International Conference on Unmanned Aircraft Systems (ICUAS), Dallas, TX, USA, 12–15 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1207–1216. [Google Scholar]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled polypropylene blends as novel 3D printing materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Council Recommendation of 18 December 2006 on Key Competences for Lifelong Learning. Available online: http://data.europa.eu/eli/reco/2006/962/oj (accessed on 5 August 2024).

- Council Recommendation of 22 May 2018 on Key Competences for Lifelong Learning. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018H0604(01) (accessed on 5 August 2024).

- Lozano Rivas, F.; Del Cerro Velázquez, F.; Morales Méndez, G. Key Competences for Sustainability: Technical Project Supported by Ecodesign of Educational Spaces to Achieve SDGs. Sustainability 2023, 15, 3959. [Google Scholar] [CrossRef]

- UNESCO. Education for Sustainable Development Goals: Learning Objectives. Available online: https://unesdoc.unesco.org/ark:/48223/pf0000247444 (accessed on 5 August 2024).

- Merrill, M.D. First principles of instruction. Educ. Technol. Res. Dev. 2002, 50, 43–59. [Google Scholar] [CrossRef]

- del Cerro Velázquez, F.; Morales Méndez, G. Augmented reality and mobile devices: A binominal methodological resource for inclusive education (SDG 4). An example in secondary education. Sustainability 2018, 10, 3446. [Google Scholar]

- del Cerro Velázquez, F.; Lozano Rivas, F. Education for sustainable development in STEM (technical drawing): Learning approach and method for SDG 11 in classrooms. Sustainability 2020, 12, 2706. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Espera, A.H., Jr.; Chen, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Woern, A.L.; Byard, D.J.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Fused particle fabrication 3-D printing: Recycled materials’ optimization and mechanical properties. Materials 2018, 11, 1413. [Google Scholar] [CrossRef] [PubMed]

- Chadha, A.; Haq, M.I.U.; Raina, A.; Singh, R.R.; Penumarti, N.B.; Bishnoi, M.S. Effect of fused deposition modelling process parameters on mechanical properties of 3D printed parts. World J. Eng. 2019, 16, 550–559. [Google Scholar] [CrossRef]

- Suteja, T.J.; Soesanti, A. Mechanical properties of 3D printed Polylactic acid product for various infill design parameters: A review. J. Phys. Conf. Ser. 2020, 1569, 042010. [Google Scholar] [CrossRef]

- ISO 527-1:2020; Plastics—Determination of Tensile Properties—Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2020.

- European Commission. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32008L0098 (accessed on 5 August 2024).

- van Buren, N.; Demmers, M.; Van der Heijden, R.; Witlox, F. Towards a circular economy: The role of Dutch logistics industries and governments. Sustainability 2016, 8, 647. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).