A Sustainable Production Planning Scheme for New Energy Vehicles in China

Abstract

1. Introduction

2. Literature Review

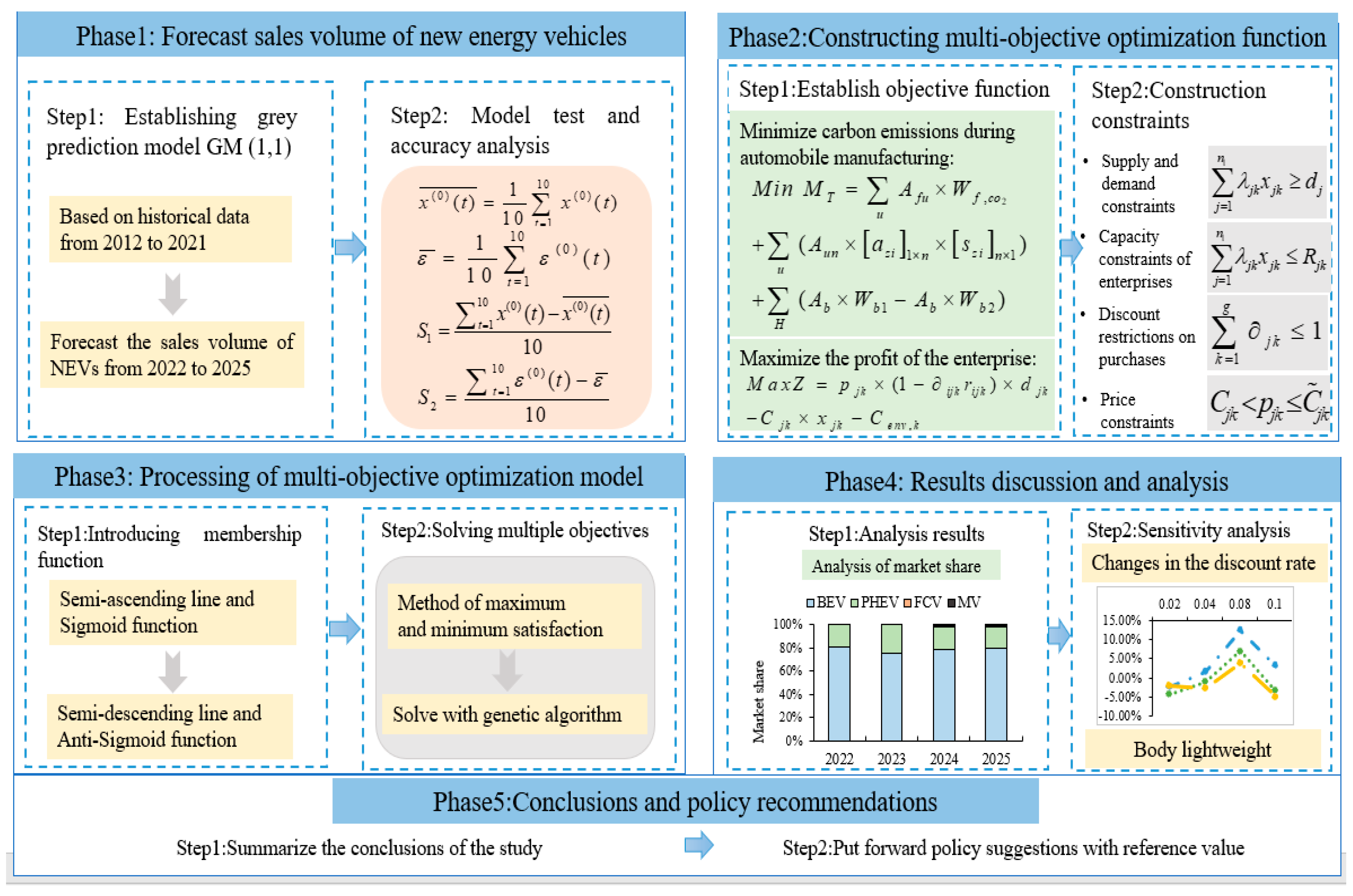

3. Methodology

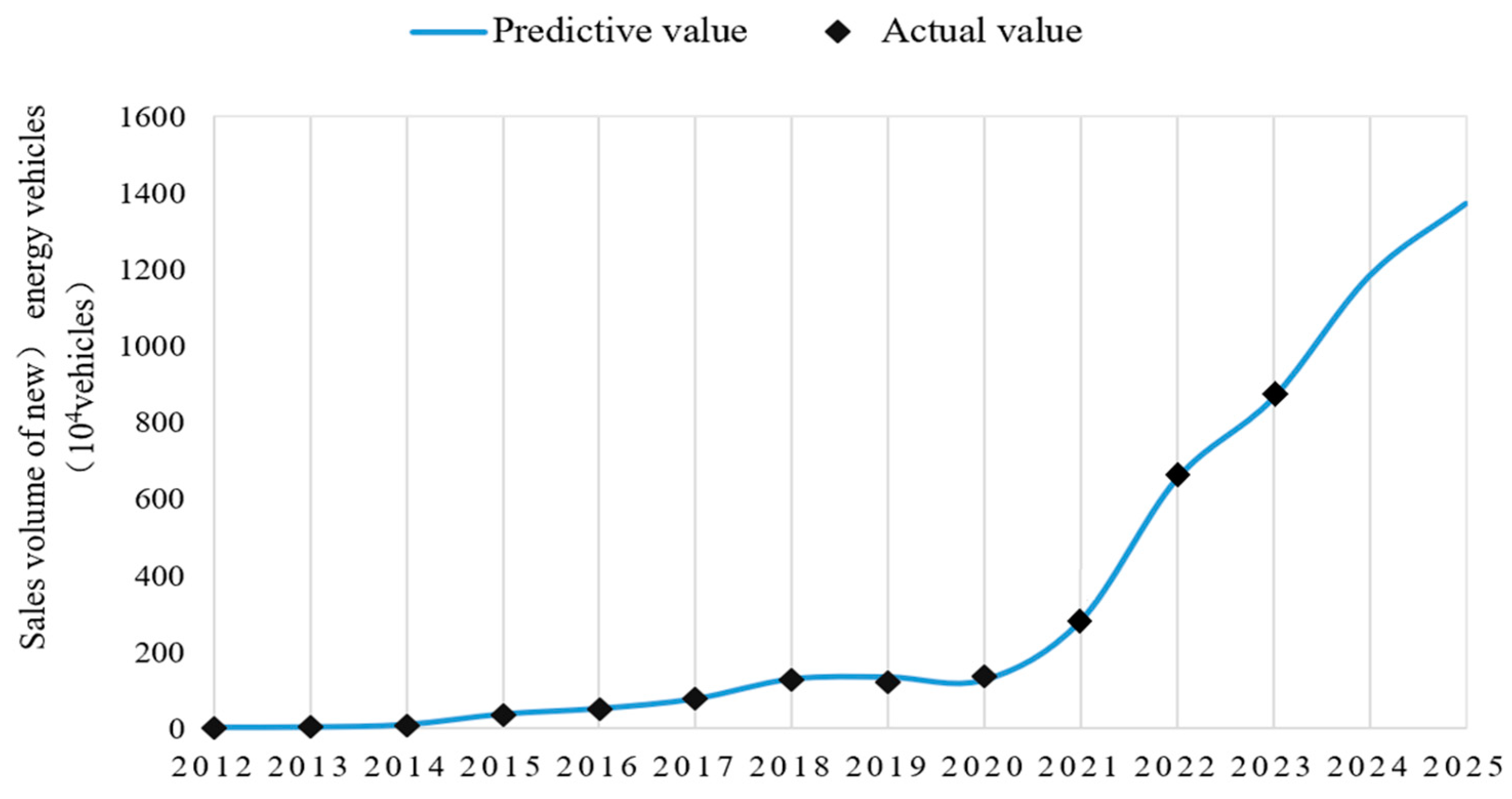

3.1. Grey Prediction Model GM (1,1)

3.1.1. Model Establishment

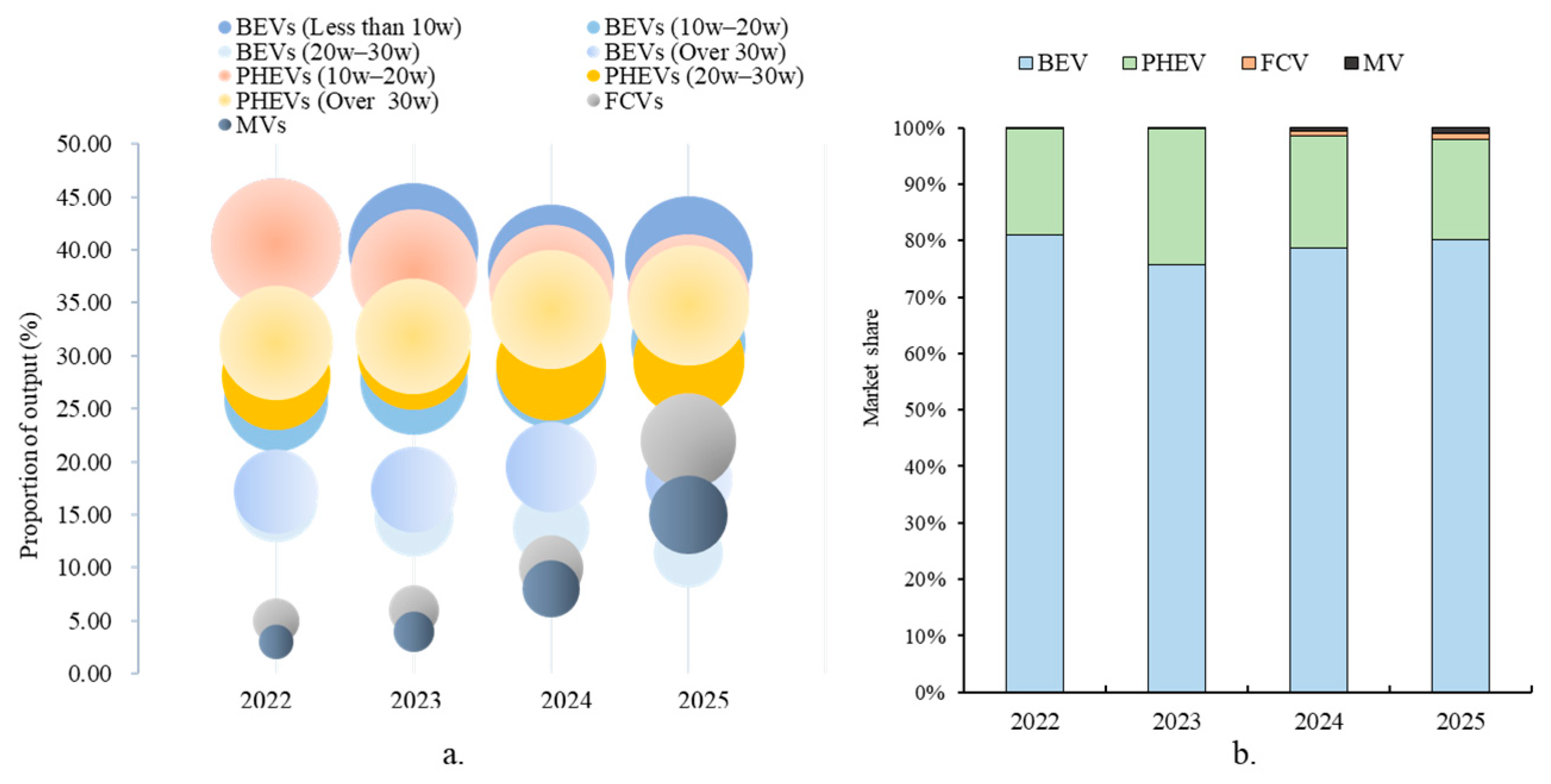

3.1.2. Analysis of Original Data and Prediction Results

3.2. Objective Function

3.2.1. Minimize Carbon Emissions

- (1)

- Vehicle raw material acquisition stage

- (2)

- Manufacturing and assembly stage

- (3)

- Scrap recovery stage

3.2.2. Maximize Profits

3.3. Constraints

- (1)

- Supply and demand constraints. The number of cars manufactured by enterprises should meet the market demand as much as possible. Therefore, the supply and demand constraints are as follows:

- (2)

- Capacity constraints of automobile enterprises. The maximum production capacity that vehicle enterprise k can provide is , the number of cars manufactured by any enterprise should not exceed its maximum production capacity, namely:

- (3)

- Discount restrictions on car purchases. Different automobile enterprises develop different discount strategies for customers when purchasing different models,

- (4)

- Price constraints. The upper limit of the sales price of automobiles is set as , is the cost of automobile manufacturing, and is the elasticity coefficient of the price [69].

4. Multi-Objective Optimization Model

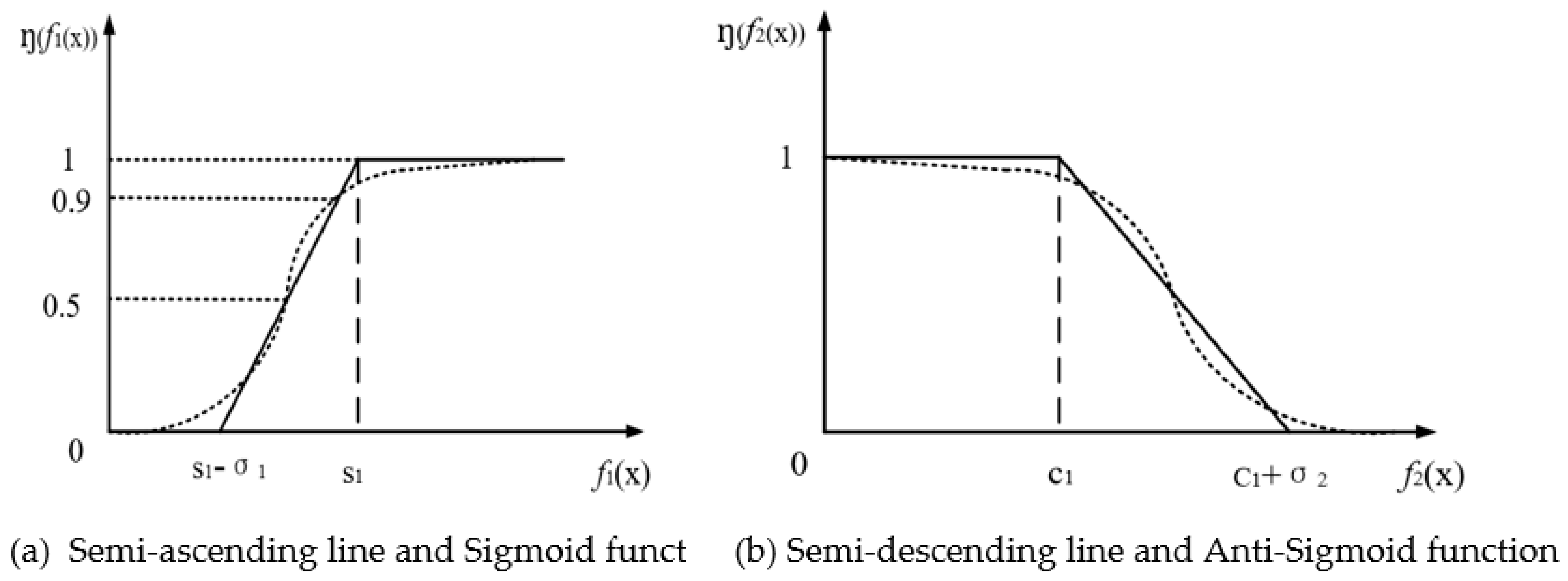

4.1. Membership Transformation of the Objective Function

4.2. Application of Sigmoid and Anti-Sigmoid Functions

4.3. Method of Maximum and Minimum Satisfaction

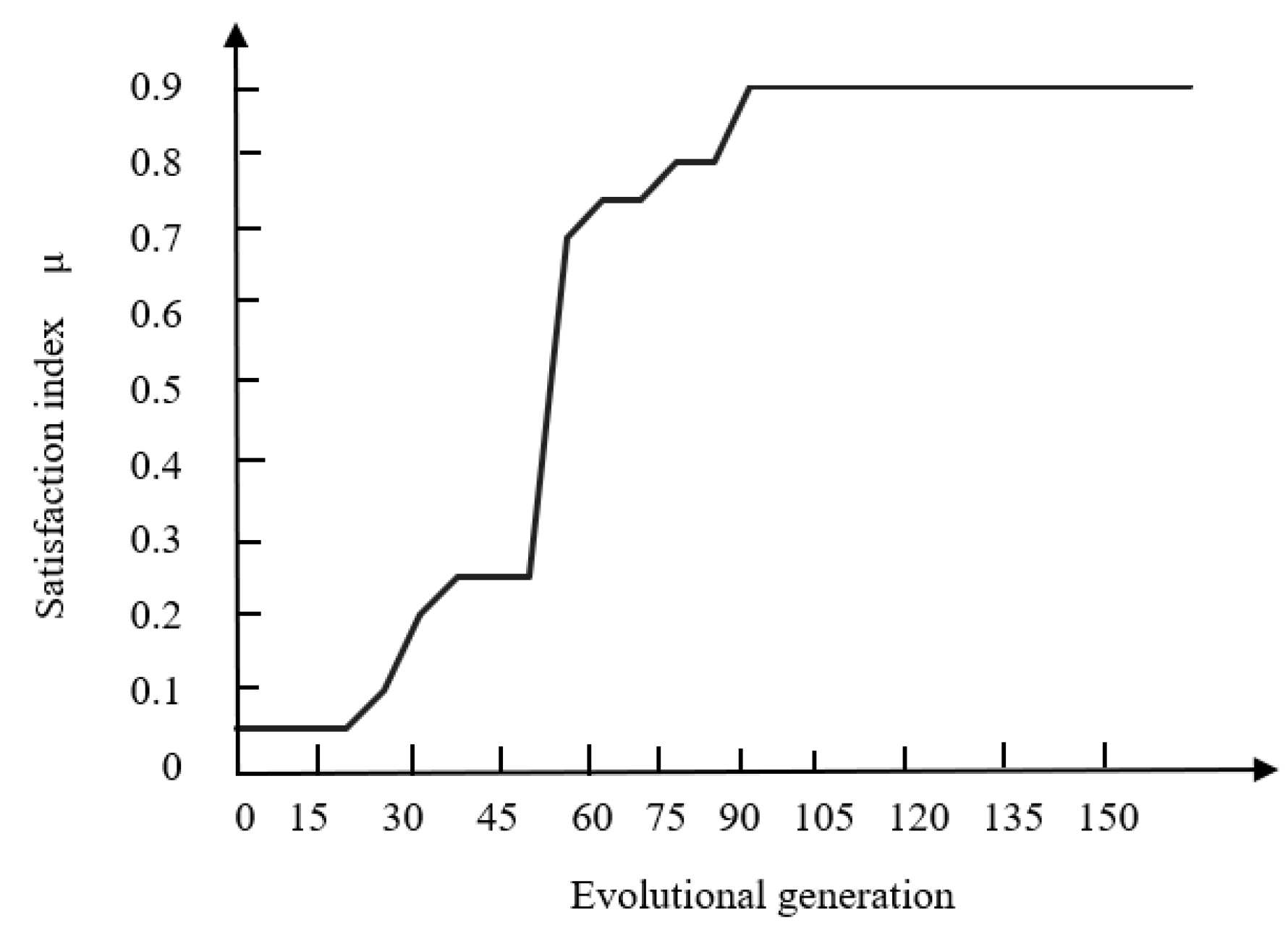

4.4. Genetic Algorithm Solution

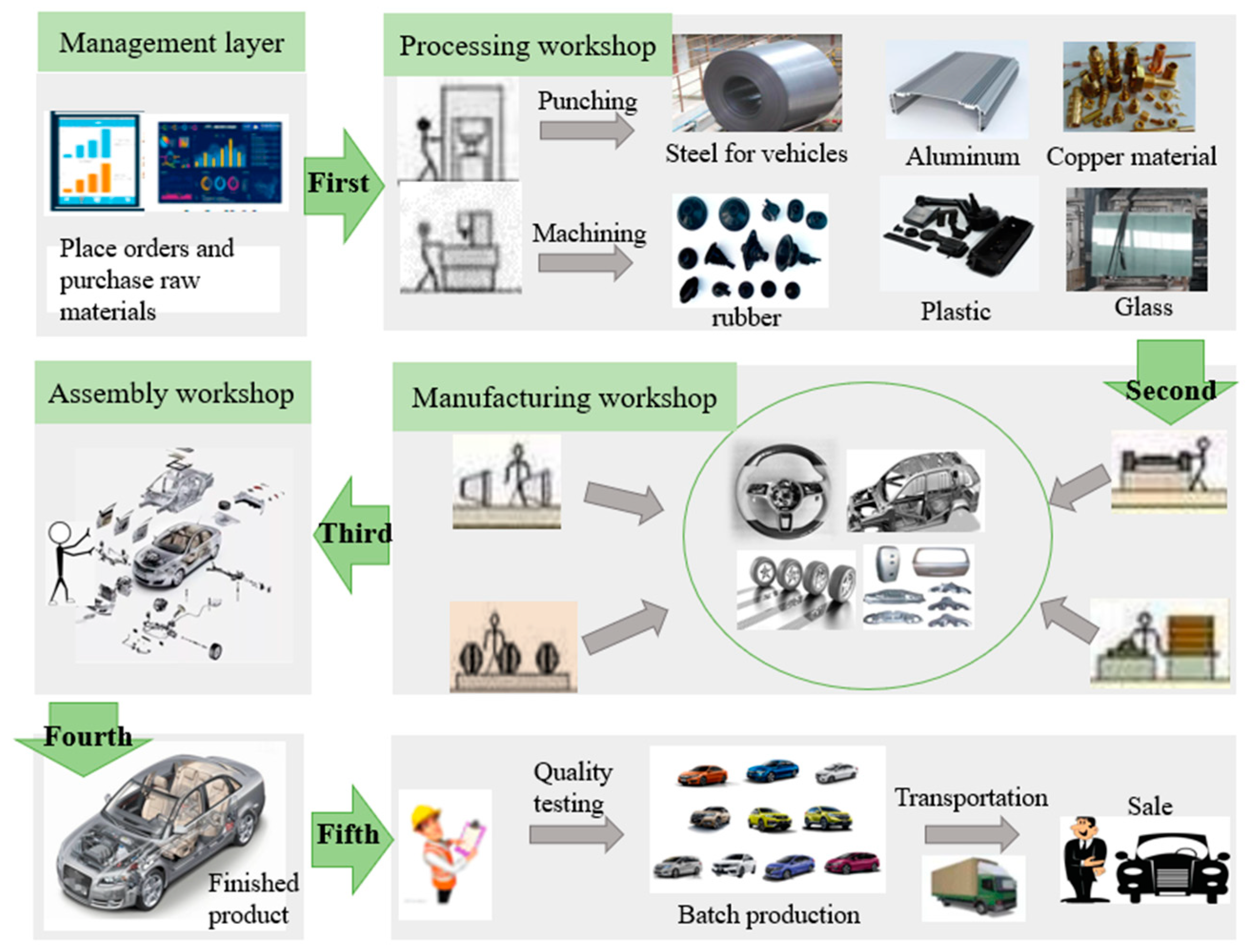

5. Scenario Design and Case Analysis

5.1. Information About Case

5.2. Analysis of the Results of the Case

5.3. Sensitivity Analysis

- (1)

- Changes in the discount rate

- (2)

- Body lightweight

6. Conclusions and Policy Implications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

Appendix A

Appendix A.1. The Steps of Grey Model GM (1,1) Are as Follows

- (1)

- Accumulate the original data to obtain a new data sequence:where each data of represents the accumulation of the previous data. Therefore,

- (2)

- The first order linear differential equation of is established based on year t:

- (3)

- Generate B and constant vector Y by averaging the accumulated data, that is:

- (4)

- Solving grey parameter by the least square method

- (5)

- Substitute the grey parameter into (1.4) and solve.

- (6)

- Discrete the function expressions and , and make a difference between them to restore the original sequence of . The approximate data sequence is as follows:

Appendix A.2. Model Inspection and Precision Analysis

- (1)

- Calculate the residual and relative error between and ,

- (2)

- Calculate the mean and variance S1 of the original data

- (3)

- Calculate the average value of and the variance S2 of the residual.

- (4)

- Calculate variance ratio C

References

- Li, C.; Negnevitsky, M.; Wang, X.; Yue, W.L.; Zou, X. Multi-criteria analysis of policies for implementing clean energy vehicles in China. Energy Policy 2019, 129, 826–840. [Google Scholar] [CrossRef]

- Li, P.; Xia, X.; Guo, J. A review of the life cycle carbon footprint of electric vehicle batteries. Sep. Purif. Technol. 2022, 296, 121389. [Google Scholar] [CrossRef]

- Liang, L.; Mei, Q.; Li, C. Does “Dual Credit Policy” Really Matter in Corporate Competitiveness? Sustainability 2024, 16, 6991. [Google Scholar] [CrossRef]

- Robles, J.O.; Azzaro-Pantel, C.; Garcia, G.M.; Lasserre, A.A. Social cost-benefit assessment as a post-optimal analysis for hydrogen supply chain design and deployment: Application to Occitania (France). Sustain. Prod. Consum. 2020, 24, 105–120. [Google Scholar] [CrossRef]

- Irfan, M.; Hao, Y.; Ikram, M.; Wu, H.; Akram, R.; Rauf, A. Assessment of the public acceptance and utilization of renewable energy in Pakistan. Sustain. Prod. Consum. 2021, 27, 312–324. [Google Scholar] [CrossRef]

- Li, C.; Negnevitsky, M.; Wang, X.; Wang, H.; Hu, Y. Evaluating Consumer Acceptance of the Commercial Fleet of Methanol Vehicles in China. Front. Energy Res. 2021, 9, 792982. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Reliable, Affordable Access to All Fuels and Energy Sources. 2024. Available online: https://www.iea.org/topics/energy-security (accessed on 1 September 2024).

- Jia, T.; Li, C.; Wang, H.; Hu, Y.-J.; Wang, S.; Xu, G.; Hoang, A.T. Subsidy policy or dual-credit policy? Evolutionary game analysis of green methanol vehicles promotion. Energy 2024, 293, 130763. [Google Scholar] [CrossRef]

- Chen, Q.; Li, C. The Green Paradox in NEV Manufacturing: Regulatory Impacts on Innovation from a Stakeholder Perspective. Energies 2024, 17, 3508. [Google Scholar] [CrossRef]

- Yang, Y.; Li, Q.; Li, C.; Qin, Q. User Requirements Analysis of New Energy Vehicles Based on Improved Kano Model. Energy 2024, 309, 133134. [Google Scholar] [CrossRef]

- Li, C.; Jia, T.; Wang, H.; Wang, X.; Negnevitsky, M.; Hu, Y.-J.; Zhao, G.; Wang, L. Assessing the prospect of deploying green methanol vehicles in China from energy, environmental and economic perspectives. Energy 2023, 263, 125967. [Google Scholar] [CrossRef]

- Li, S.; Wang, D.; Wang, S.; Zhou, C. Structure–connection–performance integration lightweight optimisation design of multimaterial automotive body skeleton. Struct. Multidiscip. Optim. 2023, 66, 198. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, Q.; Liu, J.; Hao, Y.; Tang, Y.; Li, Y. The impacts of critical metal shortage on China’s electric vehicle industry development and countermeasure policies. Energy 2022, 248, 123646. [Google Scholar] [CrossRef]

- Ma, S.-C.; Xu, J.-H.; Fan, Y. Characteristics and key trends of global electric vehicle technology development: A multi-method patent analysis. J. Clean. Prod. 2022, 338, 130502. [Google Scholar] [CrossRef]

- Aguilar, P.; Groß, B. Battery electric vehicles and fuel cell electric vehicles, an analysis of alternative powertrains as a mean to decarbonise the transport sector. Sustain. Energy Technol. Assess. 2022, 53, 102624. [Google Scholar] [CrossRef]

- Li, C.; Hao, Q.; Wang, H.; Hu, Y.-J.; Xu, G.; Qin, Q.; Wang, X.; Negnevitsky, M. Assessing green methanol vehicles’ deployment with life cycle assessment-system dynamics model. Appl. Energy 2024, 363, 123055. [Google Scholar] [CrossRef]

- Ren, J.; Toniolo, S. Life cycle sustainability decision-support framework for ranking of hydrogen production pathways under uncertainties: An interval multi-criteria decision making approach. J. Clean. Prod. 2018, 175, 222–236. [Google Scholar] [CrossRef]

- Hu, Y.-J.; Yang, L.; Cui, H.; Wang, H.; Li, C. Developing a balanced strategy: A multi-objective model for emissions reduction and development of civil aviation in China. Energy 2024, 307, 132597. [Google Scholar] [CrossRef]

- Chen, Z.; Shen, Q.; Sun, N.; Wei, W. Life cycle assessment of typical methanol production routes: The environmental impacts analysis and power optimization. J. Clean. Prod. 2019, 220, 408–416. [Google Scholar] [CrossRef]

- García, I.; Miguel, L.J. Is the electric vehicle an attractive option for customers? Energies 2012, 5, 71–91. [Google Scholar] [CrossRef]

- Perčić, M.; Vladimir, N.; Fan, A. Techno-economic assessment of alternative marine fuels for inland shipping in Croatia. Renew. Sustain. Energy Rev. 2021, 148, 111363. [Google Scholar] [CrossRef]

- Oliveira, G.D.; Dias, L.C. Influence of Demographics on Consumer Preferences for Alternative Fuel Vehicles: A Review of Choice Modelling Studies and a Study in Portugal. Energies 2019, 12, 318. [Google Scholar] [CrossRef]

- Wang, S.; Li, C.; Hu, Y.-J.; Wang, H.; Xu, G.; Zhao, G.; Wang, S. Assessing the prospect of bio-methanol fuel in China from a life cycle perspective. Fuel 2024, 358, 130255. [Google Scholar] [CrossRef]

- Sun, X.; Li, Z.; Wang, X.; Li, C. Technology Development of Electric Vehicles: A Review. Energies 2019, 13, 90. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, C.; Wang, Y. A fuzzy multi-objective optimization-based evaluation model of wind power accommodation capability. Power Syst. Technol. 2015, 39, 426–431. [Google Scholar] [CrossRef]

- Yao, C. Lightweight automotive design technology and material application analysis. In Proceedings of the 2019 4th International Conference on Mechanical, Control and Computer Engineering (ICMCCE 2019), Hohhot, China, 24–26 October 2019; pp. 514–519. [Google Scholar] [CrossRef]

- Burd, J.T.J.; Moore, E.A.; Ezzat, H.; Kirchain, R.; Roth, R. Improvements in electric vehicle battery technology influence vehicle lightweighting and material substitution decisions. Appl. Energy 2021, 283, 116269. [Google Scholar] [CrossRef]

- Gao, Y.; Zou, X.; Chen, R.; Ma, Y.; Li, C.; Zhang, Y. Freight Mode Coordination in China: From the Perspective of Regional Differences. Sustainability 2020, 12, 2996. [Google Scholar] [CrossRef]

- Duan, L.; Xiao, N.C.; Hu, Z.; Li, G.; Cheng, A. An efficient lightweight design strategy for body-in-white based on implicit parameterization technique. Struct. Multidiscip. Optim. 2017, 55, 1927–1943. [Google Scholar] [CrossRef]

- Attir, A.; Naït-Abdesselam, F.; Faraoun, K.M. Lightweight anonymous and mutual authentication scheme for wireless body area networks. Comput. Netw. 2023, 224, 109625. [Google Scholar] [CrossRef]

- Li, C.; Jia, T.; Wang, S.; Wang, X.; Negnevitsky, M.; Wang, H.; Hu, Y.; Xu, W.; Zhou, N.; Zhao, G. Methanol Vehicles in China: A Review from a Policy Perspective. Sustainability 2023, 15, 9201. [Google Scholar] [CrossRef]

- Anyasodor, G.; Koroschetz, C. Industrial based volume manufacturing of lightweight aluminium alloy panel components with high-strength and complex-shape for car body and chassis structures. J. Phys. Conf. Ser. 2017, 896, 012093. [Google Scholar] [CrossRef]

- Tisza, M.; Lukács, Z. High strength aluminum alloys in car manufacturing. In International Deep Drawing Research Group 37th Annual Conference, 37th Annual Conference of the International-Deep-Drawing-Research-Group (IDDRG)—Forming of High Performance Sheet Materials and Components; Worswick, M., Butcher, C., Bardelcik, A., Eds.; IOP Publishing: Bristol, UK, 2018. [Google Scholar] [CrossRef]

- Yang, L.; Yu, B.; Yang, B.; Chen, H.; Malima, G.; Wei, Y.-M. Life cycle environmental assessment of electric and internal combustion engine vehicles in China. J. Clean. Prod. 2021, 285, 124899. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M.; Li, C. An up-to-date review on the design improvement and optimization of the liquid-cooling battery thermal management system for electric vehicles. Appl. Therm. Eng. 2023, 219, 119626. [Google Scholar] [CrossRef]

- Zhang, L.; Qin, Q. China’s new energy vehicle policies: Evolution, comparison and recommendation. Transp. Res. Part A Policy Pract. 2018, 110, 57–72. [Google Scholar] [CrossRef]

- Zheng, W.; Li, Y.; Zhang, M.; Shao, Z.; Wang, X. Reliability evaluation and analysis for NEV charging station considering the impact of charging experience. Int. J. Hydrogen Energy 2022, 47, 3980–3993. [Google Scholar] [CrossRef]

- Lan, H.; Hao, D.; Hao, W.; He, Y. Development and comparison of the test methods proposed in the Chinese test specifications for fuel cell electric vehicles. Energy Rep. 2022, 8, 565–579. [Google Scholar] [CrossRef]

- Ullah, K.; Hamid, S.; Mirza, F.M.; Shakoor, U. Prioritizing the gaseous alternatives for the road transport sector of Pakistan: A multi criteria decision making analysis. Energy 2018, 165, 1072–1084. [Google Scholar] [CrossRef]

- Xue, F.; Huang, Q.; He, C.; Pathak, B. Using an Entropy-GRA, TOPSIS, and PCA Method to Evaluate the Competitiveness of AFVs—The China Case. Promet-Zagreb 2020, 32, 655–666. [Google Scholar] [CrossRef]

- Li, C.; Negnevitsky, M.; Wang, X. Prospective assessment of methanol vehicles in China using FANP-SWOT analysis. Transp. Policy 2020, 96, 60–75. [Google Scholar] [CrossRef]

- Sehatpour, M.-H.; Kazemi, A.; Sehatpour, H.-E. Evaluation of alternative fuels for light-duty vehicles in Iran using a multi-criteria approach. Renew. Sustain. Energy Rev. 2017, 72, 295–310. [Google Scholar] [CrossRef]

- Ma, Y.; Shi, T.; Zhang, W.; Hao, Y.; Huang, J.; Lin, Y. Comprehensive policy evaluation of NEV development in China, Japan, the United States, and Germany based on the AHP-EW model. J. Clean. Prod. 2019, 214, 389–402. [Google Scholar] [CrossRef]

- Ren, J.; Ren, X.; Shen, W.; Man, Y.; Lin, R.; Liu, Y.; He, C.; Manzardo, A.; Toniolo, S.; Dong, L. Industrial system prioritization using the sustainability-interval-index conceptual framework with life-cycle considerations. AIChE J. 2020, 66, e16961. [Google Scholar] [CrossRef]

- Zhili, D.; Boqiang, L.; Chunxu, G. Development path of electric vehicles in China under environmental and energy security constraints. Resour. Conserv. Recycl. 2019, 143, 17–26. [Google Scholar] [CrossRef]

- Dai, Z.; Zhang, B. Electric vehicles as a sustainable energy Technology: Observations from travel survey data and evaluation of adoption with Machine learning method. Sustain. Energy Technol. Assess. 2023, 57, 103267. [Google Scholar] [CrossRef]

- Wei, H.; Fan, L.; Ai, Q.; Zhao, W.; Huang, T.; Zhang, Y. Optimal energy allocation strategy for electric vehicles based on the real-time model predictive control technology. Sustain. Energy Technol. Assess. 2022, 50, 101797. [Google Scholar] [CrossRef]

- Dai, B.; Wang, H.; Li, B.; Li, C.; Tan, Z. Capacity model and optimal scheduling strategy of multi-microgrid based on shared energy storage. Energy 2024, 306, 132472. [Google Scholar] [CrossRef]

- Lonan, E.S.; Ardi, R. Electric Vehicle Diffusion in the Indonesian Automobile Market: A System Dynamics Modelling. In Proceedings of the 2020 IEEE International Conference on Industrial Engineering and Engineering Management (IEEE IEEM), Singapore, 14–17 December 2020; pp. 43–47. [Google Scholar]

- Jiao, Y.; Yu, L.; Wang, J.; Wu, D.; Tang, Y. Diffusion of new energy vehicles under incentive policies of China: Moderating role of market characteristic. J. Clean. Prod. 2022, 353, 131660. [Google Scholar] [CrossRef]

- Li, X.; Xiao, X.; Guo, H. A novel grey Bass extended model considering price factors for the demand forecasting of European new energy vehicles. Neural Comput. Appl. 2022, 34, 11521–11537. [Google Scholar] [CrossRef]

- Xian, Y.; Xia, M.; Su, S.; Guo, M.; Chen, F. Research on the Market Diffusion of Fuel Cell Vehicles in China Based on the Generalized Bass Model. IEEE Trans. Ind. Appl. 2022, 58, 2950–2960. [Google Scholar] [CrossRef]

- Kumar, R.R.; Guha, P.; Chakraborty, A. Comparative assessment and selection of electric vehicle diffusion models: A global outlook. Energy 2022, 238, 121932. [Google Scholar] [CrossRef]

- He, L.-Y.; Pei, L.-L.; Yang, Y.-H. An optimised grey buffer operator for forecasting the production and sales of new energy vehicles in China. Sci. Total. Environ. 2020, 704, 135321. [Google Scholar] [CrossRef] [PubMed]

- Celli, G.; Pilo, F.; Monni, G.; Soma, G.G. Optimal Multi-Objective Allocation of Fast Charging Stations. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018; pp. 1–6. [Google Scholar]

- Lou, J.; Qiu, Z.; Yu, J.; Guo, C. Urban charging station location model based on multi-objective programming. J. Phys. Conf. Ser. 2018, 1053, 012028. [Google Scholar] [CrossRef]

- Battapothula, G.; Yammani, C.; Maheswarapu, S. Multi-Objective Optimal Scheduling of Electric Vehicle batteries in Battery Swapping Station. In Proceedings of the 2019 IEEE PES Innovative Smart Grid Technologies Europe (ISGT-Europe), Bucharest, Romania, 29 September–2 October 2019; pp. 1–5. [Google Scholar]

- Han, T.; Yan, Y.; Safar, B. Optimal integration of CCHP with electric Vehicle parking lots in energy hub. Sustain. Energy Technol. Assess. 2023, 58, 103324. [Google Scholar] [CrossRef]

- Swief, R.A.; El-Amary, N.H.; Kamh, M.Z. Optimal Energy Management Integrating Plug in Hybrid Vehicle Under Load and Renewable Uncertainties. IEEE Access 2020, 8, 176895–176904. [Google Scholar] [CrossRef]

- Hong, T.; Cao, J.; Zhao, W.; Lu, M. Electric Vehicle Charging Scheduling Algorithm Based on Online Multi-objective Optimization. In Proceedings of the 17th IEEE International Wireless Communications and Mobile Computing Conference (IEEE IWCMC), Harbin, China, 28 June–2 July 2021; pp. 1141–1146. [Google Scholar] [CrossRef]

- Kong, W.; Cai, T.; Fan, Y.; Jiang, F.; Wan, S. Multi-objective Optimal Charging Scheduling Strategy for Electric Vehicles Considering Traffic Flow, Power Grid, and Charging Stations. In International Conference On Intelligent Traffic Systems And Smart City (ITSSC 2021); Tan, G., Cen, F., Eds.; SPIE: Bellingham, WA, USA, 2022. [Google Scholar] [CrossRef]

- Sehatpour, M.-H.; Kazemi, A. Sustainable fuel portfolio optimization: Integrated fuzzy multi-objective programming and multicriteria decision making. J. Clean. Prod. 2018, 176, 304–319. [Google Scholar] [CrossRef]

- Zhou, X.; Qin, D.; Yao, M.; Xie, Z. Representation, generation, and optimization methodology of hybrid electric vehicle powertrain architectures. J. Clean. Prod. 2020, 256, 120711. [Google Scholar] [CrossRef]

- Yumiki, S.; Susuki, Y.; Oshikubo, Y.; Ota, Y.; Masegi, R.; Kawashima, A.; Ishigame, A.; Inagaki, S.; Suzuki, T. Autonomous vehicle-to-grid design for provision of frequency control ancillary service and distribution voltage regulation. Sustain. Energy Grids Netw. 2022, 30, 100664. [Google Scholar] [CrossRef]

- Eckert, J.J.; Barbosa, T.P.; Silva, F.L.; Roso, V.R.; Silva, L.C.; da Silva, L.A.R. Optimum fuzzy logic controller applied to a hybrid hydraulic vehicle to minimize fuel consumption and emissions. Expert Syst. Appl. 2022, 207, 117903. [Google Scholar] [CrossRef]

- Wang, X.; Sun, P.; Zuo, W.; Bai, J. Multi-objective optimization of automobile body frame considering weight, rigidity, and frequency for conceptual design. Adv. Mech. Eng. 2022, 14, 16878132221078495. [Google Scholar] [CrossRef]

- Yan, X. Energy demand and greenhouse gas emissions during the production of a passenger car in China. Energy Convers. Manag. 2009, 50, 2964–2966. [Google Scholar] [CrossRef]

- Qin, Q.; He, H.; Li, L.; He, L.-Y. A Novel Decomposition-Ensemble Based Carbon Price Forecasting Model Integrated with Local Polynomial Prediction. Comput. Econ. 2020, 55, 1249–1273. [Google Scholar] [CrossRef]

- Zhao, J.-H.; Zeng, D.-L.; Che, L.-P.; Zhou, T.-W.; Hu, J.-Y. Research on the profit change of new energy vehicle closed-loop supply chain members based on government subsidies. Environ. Technol. Innov. 2020, 19, 100937. [Google Scholar] [CrossRef]

- Guo, X. Multi-objective task scheduling optimization in cloud computing based on fuzzy self-defense algorithm. Alex. Eng. J. 2021, 60, 5603–5609. [Google Scholar] [CrossRef]

- Yin, L.; Sun, Z. Multi-layer distributed multi-objective consensus algorithm for multi-objective economic dispatch of large-scale multi-area interconnected power systems. Appl. Energy 2021, 300, 117391. [Google Scholar] [CrossRef]

- Mahajan, S.; Gupta, S.K. On fully intuitionistic fuzzy multiobjective transportation problems using different membership functions. Ann. Oper. Res. 2021, 296, 211–241. [Google Scholar] [CrossRef]

- Shojaeefard, M.H.; Mollajafari, M.; Pishe, N.E.; Mousavi, S.M. Plug-in fuel cell vehicle performance and battery sizing optimization based on reduced fuel cell energy consumption and waste heat. Sustain. Energy Technol. Assess. 2023, 56, 103099. [Google Scholar] [CrossRef]

- Medynskaya, M.K. Fuzzy set theory. The concept of fuzzy sets. In Proceedings of the 2015 XVIII International Conference on Soft Computing and Measurements (SCM), St. Petersburg, Russia, 19–21 May 2015; pp. 30–31. [Google Scholar]

- Mustapha, H.; Buhari, M.; Ahmad, A.S. An Improved Genetic Algorithm based Power System Stabilizer for power system stabilization. In Proceedings of the 2019 IEEE Africon, Accra, Ghana, 25–27 September 2019; pp. 1–5. [Google Scholar]

- Wang, Z.; Jia, Y.; Cai, C.; Chen, Y.; Li, N.; Yang, M.; Li, Q. Study on the Optimal Configuration of a Wind-Solar-Battery-Fuel Cell System Based on a Regional Power Supply. IEEE Access 2021, 9, 47056–47068. [Google Scholar] [CrossRef]

- Harighi, T.; Padmanaban, S.; Bayindir, R.; Hossain, E.; Holm-Nielsen, J.B. Electric Vehicle Charge Stations Location Analysis and Determination—Ankara (Turkey) Case Study. Energies 2019, 12, 3472. [Google Scholar] [CrossRef]

- Zheng, Y.; Xie, S.; Hu, Z.; Wang, J.; Kong, S. The optimal configuration planning of energy hubs in urban integrated energy system using a two-layered optimization method. Int. J. Electr. Power Energy Syst. 2020, 123, 106257. [Google Scholar] [CrossRef]

- Federation, A.E. Transformation and Challenges of the Automotive Industry in 2022, Prediction of the Time Point of Carbon Peak in the Automotive Industry, Emission Reduction Efforts and Realization Paths. 2022. Available online: https://www.vzkoo.com/read/20220825842b4500607976e0be38becf.html (accessed on 5 September 2022).

- Center, C.A.T.R. Research Report on China’s Low Carbon Automobile Action Plan. 2021. Available online: https://baijiahao.baidu.com/s?id=1705395243056129836&wfr=spider&for=pc (accessed on 5 September 2022).

- Federation, A.G.A.A. Transformation and Challenges: How Zero Emission Vehicle Transformation Can Help China Reach the Peak of Carbon and Reduce Carbon Emissions in the Automotive Industry. 2022. Available online: http://www.tanpaifang.com/tanguwen/2022/0119/81909.html (accessed on 5 September 2023).

- Center, C.A.T.R. Research Report on China’s Automobile Low Carbon Action Plan. 2022. Available online: https://www.cdmfund.org/31352.html (accessed on 5 September 2023).

- Shi, Y.; Wang, H.; Li, C.; Negnevitsky, M.; Wang, X. Stochastic optimization of system configurations and operation of hybrid cascade hydro-wind-photovoltaic with battery for uncertain medium- and long-term load growth. Appl. Energy 2024, 364, 123127. [Google Scholar] [CrossRef]

- Commission, G.D.A.R. Action Plan for Accelerating the Construction of Fuel Cell Vehicle Demonstration City Clusters in Guangdong Province (2022–2025). 2022. Available online: http://drc.gd.gov.cn/gkmlpt/content/3/3993/post_3993253.html#877 (accessed on 6 May 2023).

- Commission, G.D.A.R. The Latest Policy of Methanol Vehicles: Guizhou Province Issued the Support Policy for the Promotion and Application of Methanol Vehicles. 2022. Available online: http://www.nyjinghong.com.cn/page-22-243.html (accessed on 5 September 2023).

- Ministry Of Finance, M.O.I.A. Notice on the Financial Subsidy Policy for the Promotion and Application of New Energy Vehicles in 2022. 2021. Available online: http://jjs.mof.gov.cn/zhengcefagui/202112/t20211231_3780322.htm (accessed on 5 September 2023).

- Tanç, B.; Arat, H.T.; Conker, Ç.; Baltacioğlu, E.; Aydin, K. Energy distribution analyses of an additional traction battery on hydrogen fuel cell hybrid electric vehicle. Int. J. Hydrogen Energy 2019, 45, 26344–26356. [Google Scholar] [CrossRef]

| Indices | Description | Variables Related to Carbon Emissions | |

|---|---|---|---|

| j | Vehicle type, j ∈ {1,2, …, n1} | u | The items of parts and components |

| k | Auto companies, k ∈ {1,2, …, g} | The quality of the i raw material of vehicle j | |

| Variables related to enterprise profits | αnn | The processing utilization rate of the n material | |

| xjk | The number of vehicles of type j produced by enterprise k | The conversion rate of the preparation process of the i material | |

| Rmax | Maximum carbon emissions of NEVs at the peak of carbon (annual/100 million tons) | The quantity of raw material f required for part u | |

| Pjk | The price of vehicle of type j sold by enterprise k | The CO2 emission of the f unit mass raw material during acquisition | |

| Cjk | The cost of a vehicle of type j sold by enterprise k | Matrix of the mass of the n part required by component u | |

| Discount rate provided by enterprise k for consumer i who j-type vehicles(0 < < 1) | The CO2 emission of the n part during the manufacturing | ||

| rijk | If rijk = 1, enterprise k offers discounts; if rijk = 0, enterprise k does not offer discounts | Quality of vehicle materials consumed in the manufacturing process of parts processing | |

| λjk | If λjk = 1, enterprise k produces vehicles of type j; If λjk = 0, enterprise k does not produce vehicles of type j | The quality of the i component of the vehicle | |

| dj | The demand for vehicles of type j | The CO2 emission intensity of the i component in the manufacturing process | |

| The environmental pollution expenditure of enterprise k | H | Recovered parts and components | |

| The penalty price of CO2 (kg/yuan) | Ab | The matrix of materials in the scrap recycling process | |

| The CO2 emissions of vehicles in the manufacturing stage (kg) | Wb1 | The matrix of CO2 emissions per unit mass of recovered materials | |

| q* | Price elasticity coefficient | Wb2 | The matrix of CO2 emission reduction per unit mass |

| Name of Material | The Emission Factor of CO2 (kg·t−1) | Name of Material | The Emission Factor of CO2 (kg·t−1) |

|---|---|---|---|

| Steel | 8.2 | copper | 18.382 |

| Cast iron | 0.942 | Glass | 1.471 |

| Wrought aluminum | 19.436 | rubber | 2.908 |

| Cast aluminum | 20.588 | plastic | 2.427 |

| Related Parameters | Numerical Value |

|---|---|

| Vehicle mileage in one year (km) | 15,000.00 |

| Carbon emissions of NEVs in vehicle cycle (100 million tons/year) | 0.165 |

| The penalty price for CO2 emission (tons/yuan) | 50.00 |

| The rate of discount on sales (%) | 88.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, L.; Yang, F.; Yang, Y.; Chen, C.; Ha, W. A Sustainable Production Planning Scheme for New Energy Vehicles in China. Sustainability 2024, 16, 8543. https://doi.org/10.3390/su16198543

Xiao L, Yang F, Yang Y, Chen C, Ha W. A Sustainable Production Planning Scheme for New Energy Vehicles in China. Sustainability. 2024; 16(19):8543. https://doi.org/10.3390/su16198543

Chicago/Turabian StyleXiao, Lu, Feiyue Yang, Yong Yang, Che Chen, and Wuer Ha. 2024. "A Sustainable Production Planning Scheme for New Energy Vehicles in China" Sustainability 16, no. 19: 8543. https://doi.org/10.3390/su16198543

APA StyleXiao, L., Yang, F., Yang, Y., Chen, C., & Ha, W. (2024). A Sustainable Production Planning Scheme for New Energy Vehicles in China. Sustainability, 16(19), 8543. https://doi.org/10.3390/su16198543