Coupled Analysis of Risk Factor for Tailing Pond Dam Failure Accident Based on N–K Model and SNA

Abstract

1. Introduction

2. Materials and Methods

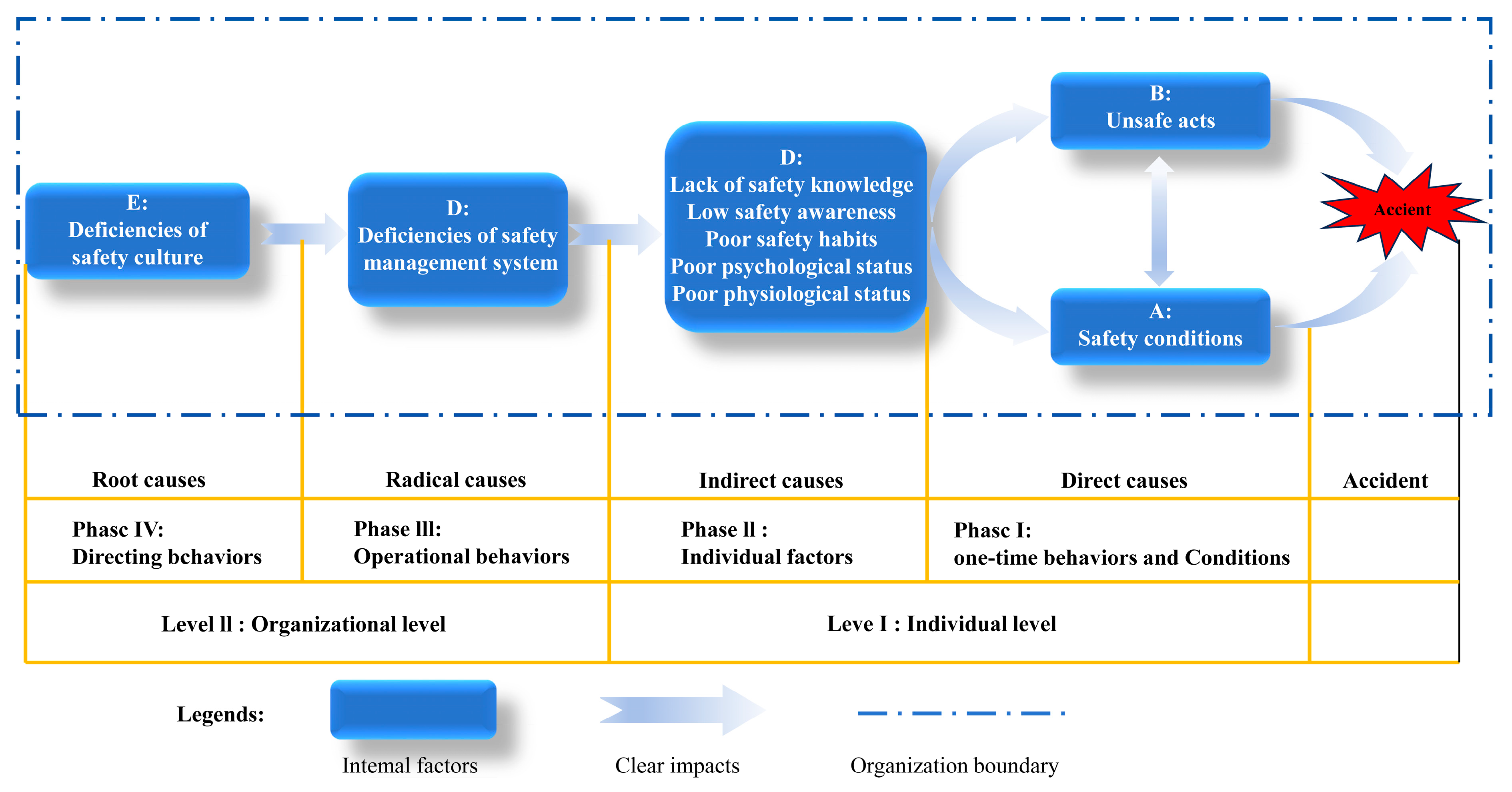

2.1. Analysis of the Risk Coupling Mechanism of a Tailing Pond Dam Failure Accident

2.1.1. Analysis of the Risk Factors for a Tailing Pond Failure Accident

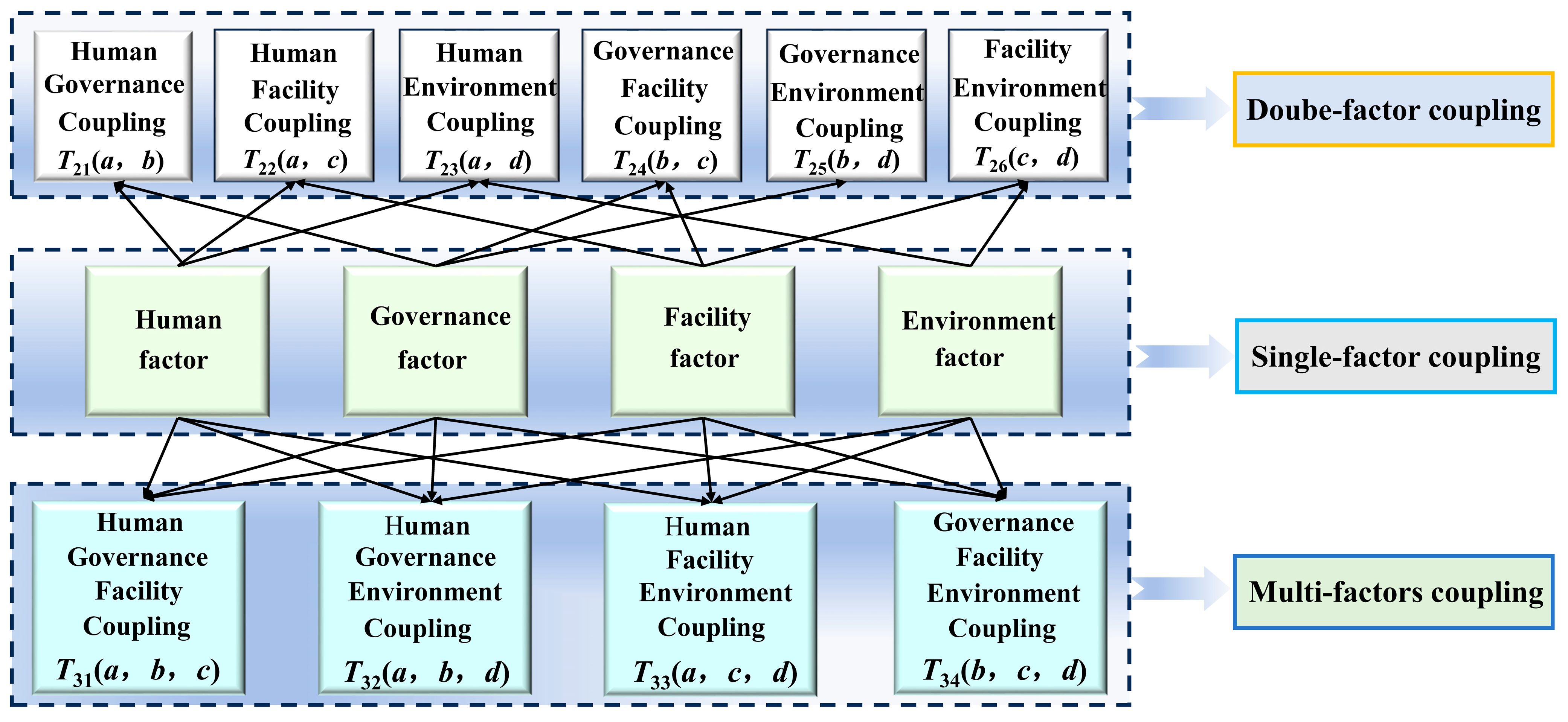

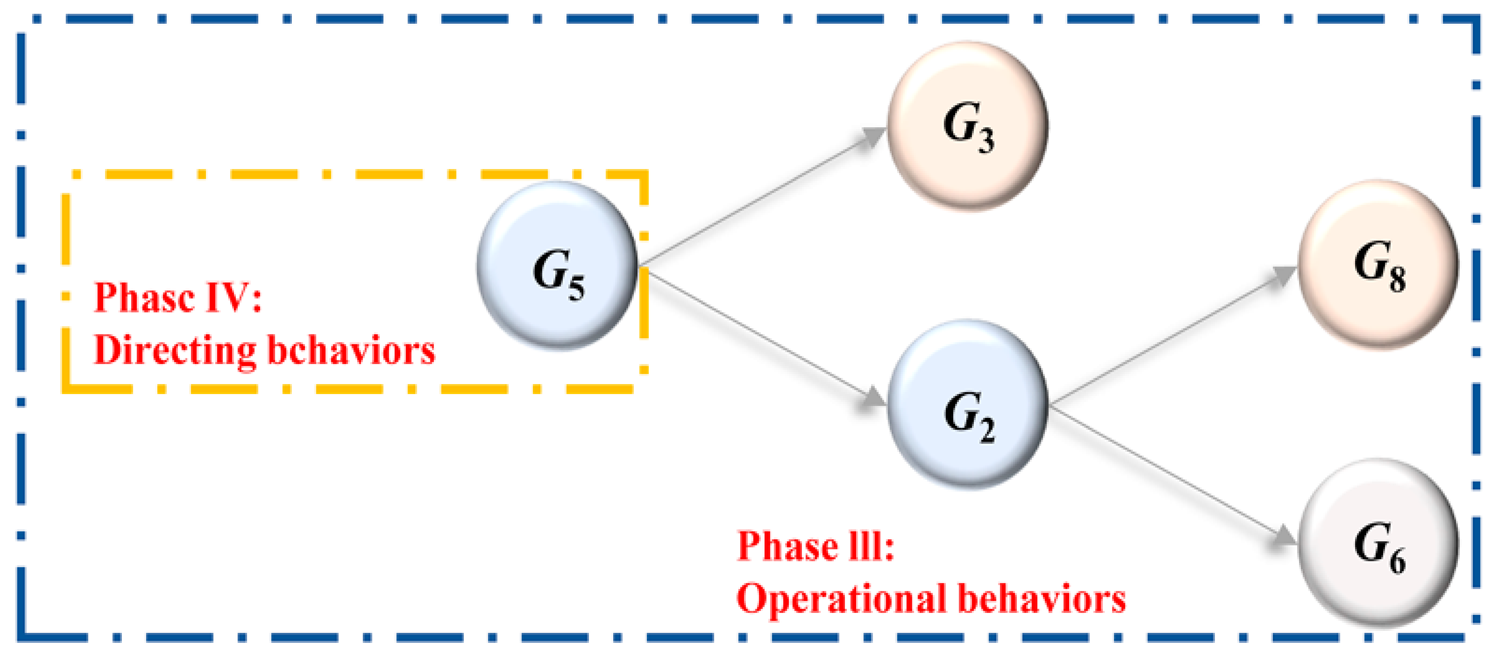

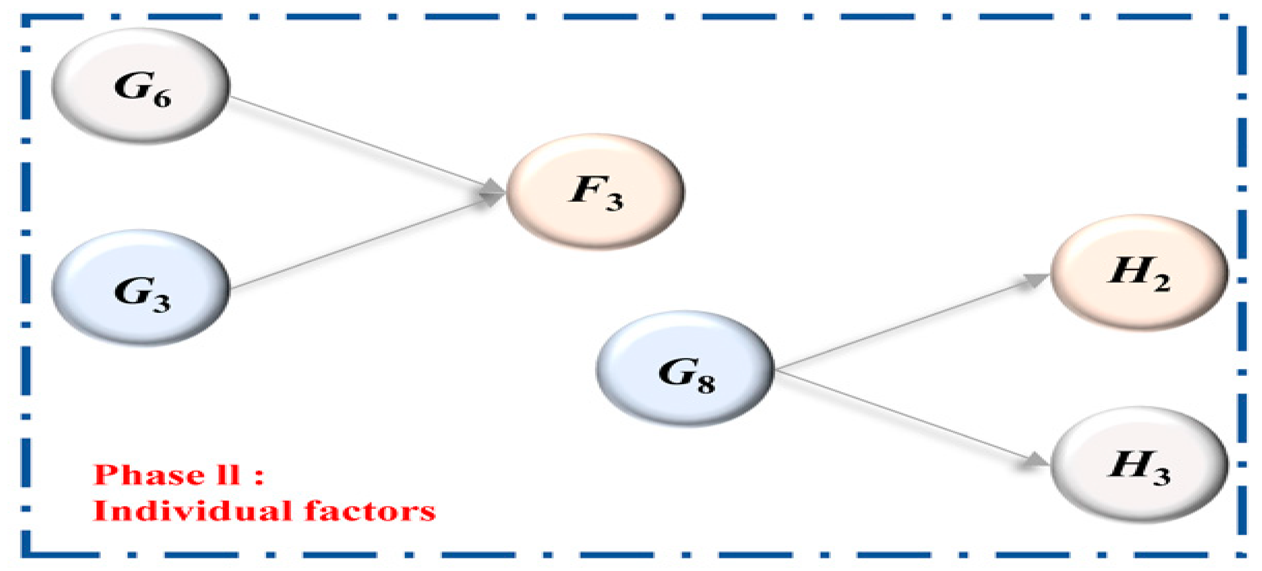

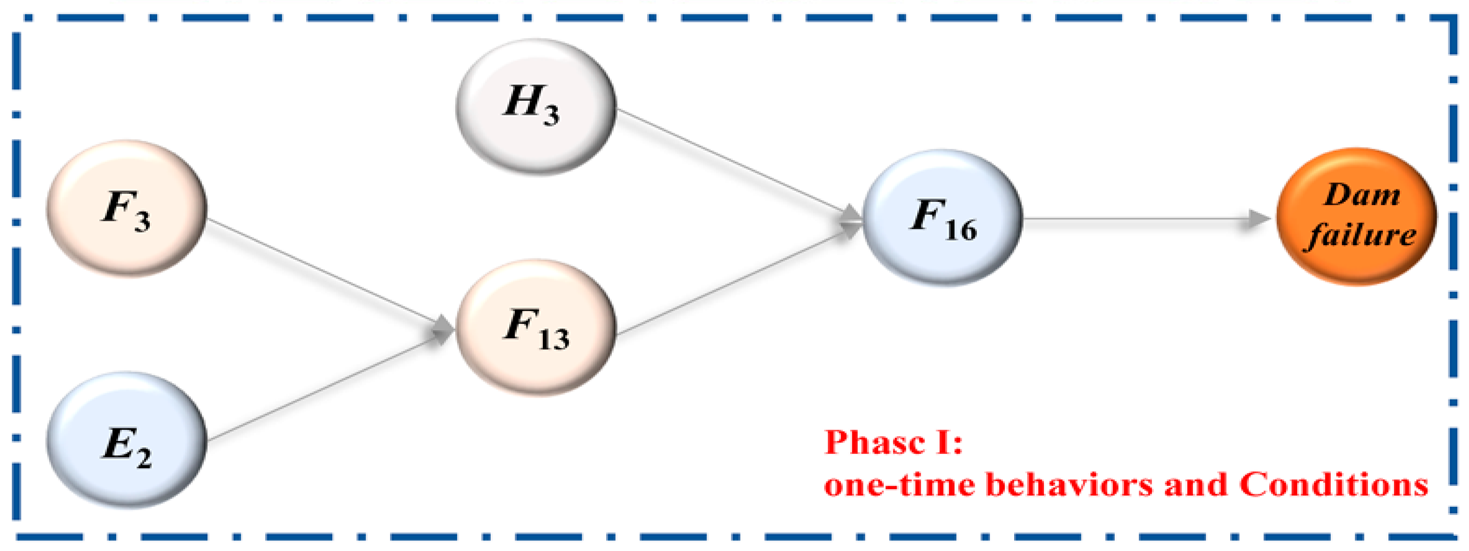

2.1.2. Coupling Mechanism of the Risk Factor for a Tailing Pond Dam Failure Accident

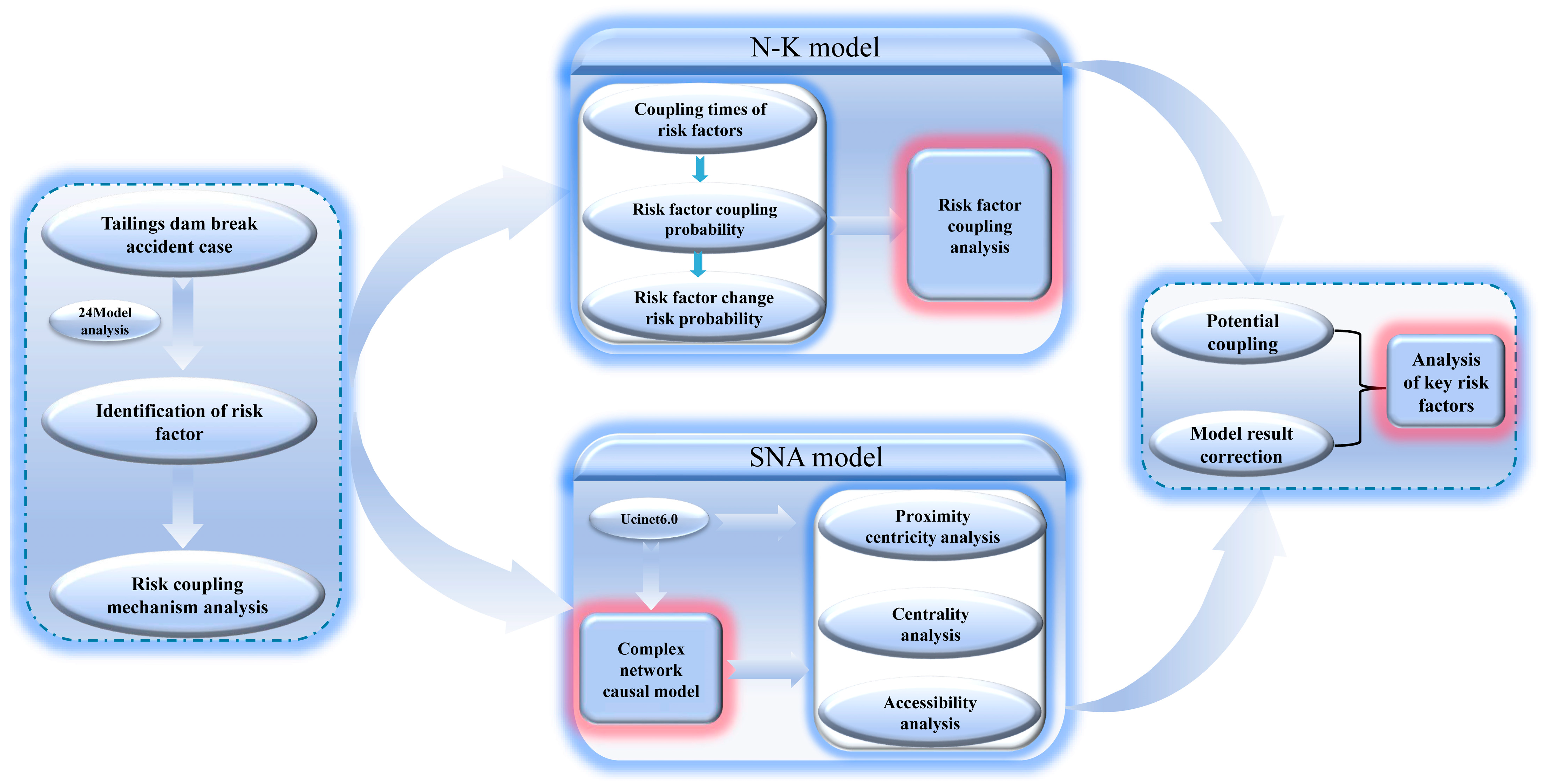

2.2. Construction of a Coupled Model of Tailing Pond Dam Failure Accident Risk Based on the N–K Model and SNA

2.2.1. N–K Risk Coupling Model Construction

2.2.2. SNA Model Construction

2.2.3. SNA/N–K Model Method Construction

3. Results

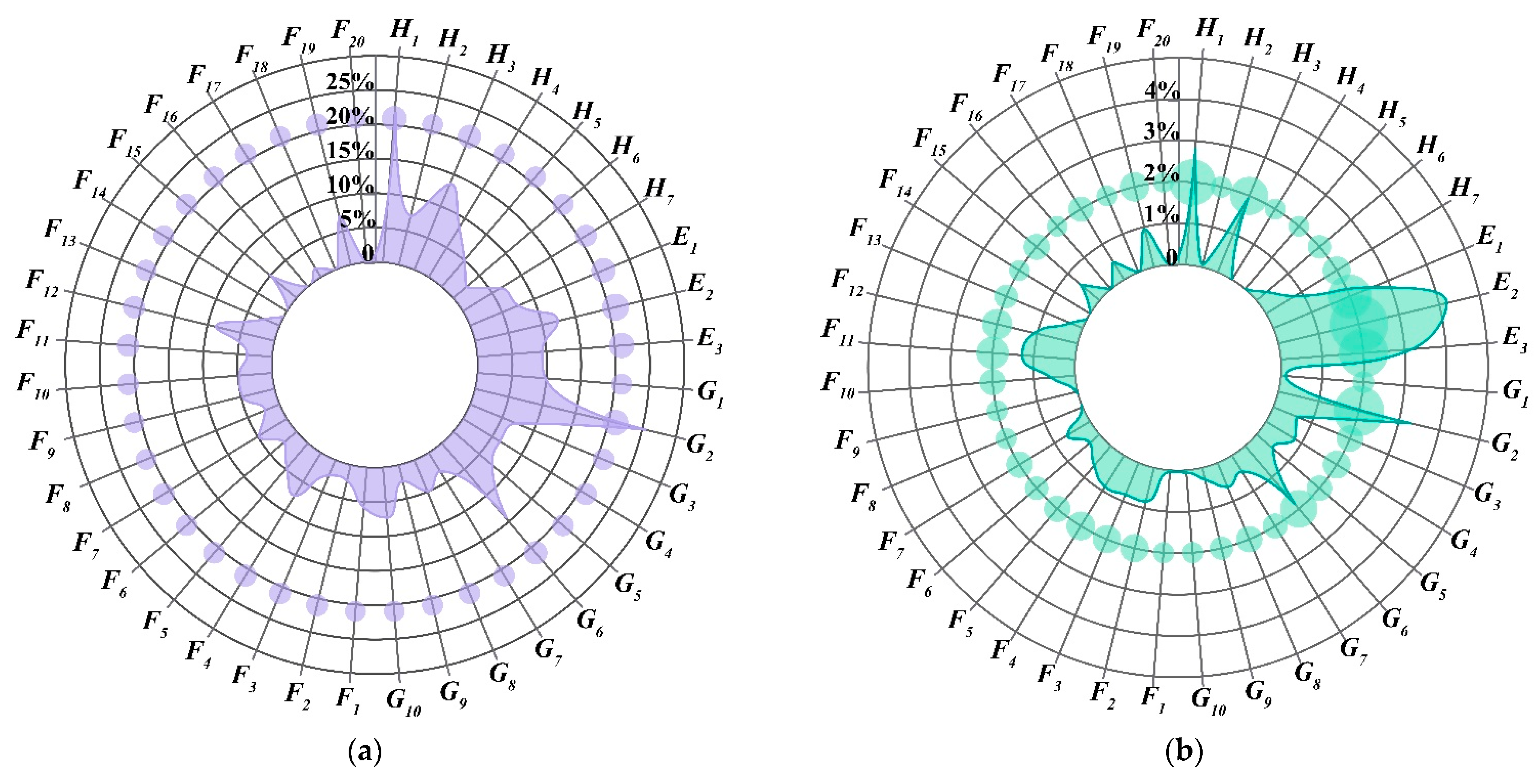

3.1. Analysis of the Results of the N–K Model Calculation

- The more the risk coupling factors, the greater the risk coupling value T. The H–G–F–E four risk coupling value is the largest (0.3421), significantly higher than the risk coupling value of the overall safety accident of the construction project (0.2582) [42]. It can be seen that the association between factors in the system network of tailings impoundment dam failure accidents is much closer. This shows that the factors in the system network of tailings pond dam failure accidents are more closely related, and the management of tailings ponds should make great efforts to avoid the occurrence of the multi-risk factor coupling state.

- In the three-factor risk coupling, the H–G–F factor coupling value is significantly higher than the other factor coupling forms, indicating that the occurrence of tailings pond dam failure accidents is more closely related to the subsystems composed of H–G–F and less related to the facility factors.

- In the two-factor risk coupling, the G–E coupling risk value is the largest, and from the point of view of practical management, the emergence of unfavorable environmental factors may lead to both the failure of management decisions and the amplification of shortcomings in daily management, which in turn exacerbates the occurrence of accidents. Therefore, for the safety risk management of tailings ponds, when unfavorable environmental factors appear, it is necessary to take corresponding preventive measures to control the coupling between G–E factors.

3.2. Analysis of the SNA Model Calculation Results

3.2.1. Risk Factor Centrality Analysis

3.2.2. Risk Factor Accessibility Analysis

4. Analysis and Discussion of the Model Result Correction

5. Conclusions and Future Research

- The results derived from the N–K model indicate that mitigating the coupling of multiple risk factors is a viable strategy for reducing the risk of tailing pond dam failures. Additionally, findings from the SNA reveal that flood discharge facility damage, inadequate safety supervision, inadequate receipt and inspection, insufficient flood capacity, and irregular operation exhibit high betweenness centrality within the risk network. Addressing these risk factors can effectively disrupt the connectivity of the risk network, thereby preventing the emergence of systemic risks.

- In the modified analysis results of the N–K/SNA model, inadequate safety supervision, heavy rainfall, weak safety awareness, inadequate receipt and inspection, and irregular operation are identified as the key risk factors for tailings dam failure. From a systematic risk coupling perspective, environmental factors exhibit a significant ability to induce multi-factor risk coupling and numerous uncertainties. Therefore, specific management of environmental risk factors is essential, alongside enhanced safety training for employees, improved facility reliability, and strengthened safety supervision to mitigate potential risks and achieve proactive risk management.

- This study employs the N–K/SNA model to explore the coupling mechanisms of multiple risk factors and identify key risk factors in tailings dam failure accidents, providing a novel approach to investigating the multi-factor coupling mechanism. However, certain limitations exist. We propose integrating advanced optimization algorithms into the current research framework to address deficiencies in resource optimization and decision support. Additionally, the causes of tailings dam failures are inherently complex, involving a vast array of risk points and factors. Yet, due to the limitations of available accident data, considering only 40 risk factors is insufficient. Furthermore, the analysis lacks an assessment of the influence of surrounding environmental factors, necessitating further research for improvement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| No. | Time of Accident | Name of Tailing Dam | Cause of the Accident |

|---|---|---|---|

| 1 | August 1960 | Himeishan Tailings Dam | E2, G4, F17, F12, F20 |

| 2 | July 1962 | Yinshan Lead-Zinc Mine Tailing Dam | E2, F17, F12, F20, H1, G10, F6 |

| 3 | September 1962 | Huogudu Tailing Storage Facility | F1, F4, F14, G4, H1, G5 |

| 4 | March 1965 | EI Cobre Tailing Dam | E1 |

| 5 | March 1980 | Hebei Baimiaozi Tailing Dam | H1, G4 |

| 6 | October 1980 | Phelps Dodge Company Tailing Dam | E3, G7, F14 |

| 7 | July 1985 | Italy Preal Mineraia | F3, F7, F15 |

| 8 | August 1985 | Hunan Niujiaoqang Tailing Storage Facility | E2, F2, F20, F12, H2, G2, G6 |

| 9 | April 1986 | Huangmeishan tailing dam | H1, G2, G6, F7, F15, F14 |

| 10 | April 1988 | Lixigou tailing dam | H1, G1, F17, F15 |

| 11 | June 1993 | Panglao Iron Ore Mine Tailing Dam | H3 |

| 12 | July 1994 | Longjiao Mountain tailing dam | E2, H5, F20, F16, F15 |

| 13 | August 1995 | Cambior Inc Tailing Dam, Guyana | G5, H3, F16 |

| 14 | January 2000 | Romania Aurul S A tailing dam | E2, F2, F20 |

| 15 | September 2000 | Tailing dam at Polliton, Sweden | F17, H3, F13, F15 |

| 16 | October 2000 | Hongtu beneficiation plant tailing dam | G2, G6, G3, F10, F16, H3, G5 |

| 17 | June 2001 | Donggan Tailing Dam in Huanjiang County | E2, F10, F17, F12, F20 |

| 18 | July 2001 | Tailing dam at Dechang titanium mine site | E3, F8, F16 |

| 19 | July 2003 | Ying Beneficiation Plant Tailing Dam | E2, F2, F12, F20 |

| 20 | October 2003 | Cia Minera Cerro Negro | G2, G6, F4, F15 |

| 21 | July 2004 | Xingyuan Lead-Zinc Mining Company Tailing Dam | E1, E2, F18 |

| 22 | November 2004 | Teccominco tailing dams | E3 |

| 23 | December 2004 | Nandan Baojin Tailing Dam | H2, F3, E2, F20, F13, F15 |

| 24 | March 2005 | Niutoushan Copper Mine Tailing Dam | H5, F14 |

| 25 | May 2005 | Luchuan Kangwu Concentrator Tailing Dam | G10, H6 |

| 26 | May 2005 | Lonestar Mining Company Tailing Dam | E2, F20, F12 |

| 27 | November 2005 | Linfen Phoenix South Tailings Dam | G2, G3 |

| 28 | April 2006 | Zhen’an Gold Tailings Dam | G2, G3, G8, H7, F1, G4, F16 |

| 29 | April 2006 | Miaolinggou Iron Ore Mine Tailing Dam | E2, H6, F17, F12, F20 |

| 30 | July 2006 | Hanzhong Gold Mine Tailing Dam | E2, H5, F17, F13, F15 |

| 31 | July 2006 | Dadi Mining Company Tailing Dam | H4, G7 |

| 32 | August 2006 | Silverstone Concentrator Tailing Dam | E2, G7, H1 |

| 33 | December 2006 | Zijin Mining Shuiyindong Gold Mine Tailing Dam | G5, H3, G7, H2 |

| 34 | May 2007 | Shanxi Baoshan Mining Company Tailing Dam | H1, G1, F17, E2, F13, F19, F15, F16, G2, G6 |

| 35 | June 2007 | Luojiadun Gold Mine Tailing Dam | E2, H5 |

| 36 | November 2007 | Dingyang Mining Tailing Dam | H1, G8, H7, H3, F4, F14, G2, G6 |

| 37 | March 2008 | Sangxin Mining Company Tailing Dam | E3, G1, F17 |

| 38 | April 2008 | Hengyuan Mining Company Tailing Dam | H1, G3, F6, F17, F15 |

| 39 | April 2008 | Huao Tailing Dam | H3, G1 |

| 40 | April 2008 | Laibin Power Plant Tailing Dam | F9, F19, F13, F15, F14 |

| 41 | April 2008 | Maguan Zinc-Lead Tailing Dam | E2, G6 |

| 42 | May 2008 | Yanmen Sulfide Iron Ore Tailing Dam | G5, G10, F6, F17, F15 |

| 43 | May 2008 | Mudeng Refuge Tailing Dam in Jiegu | H1, G7, H3, F17, G8, H7 |

| 44 | June 2008 | Shantou Lianhuashan Tailing Dam | G2, G3, H3, F4, F15, F19 |

| 45 | July 2008 | Wulong Gold Mining Company Tailing Dam | H1, G10, F7, F17, F15, F14 |

| 46 | July 2008 | Shuiheng Tailing Dam | E3, F14, G2, G3, G8, G6, H7, F6, F17, F15, H1, G1 |

| 47 | September 2008 | Xiangfen Xinta Mining Company Tailing Depot | H3, G2, G3, G8, H2, F3, F16, F13, E2, G6 |

| 48 | October 2008 | Anhui Changshan Tailing Dam | G1, F17, F15 |

| 49 | May 2009 | Yunnan Luquan Tailing Dam | G2, H4, G3, F4, F16 |

| 50 | July 2009 | Donghang Tailing Dam of Ninglong Company | E2, G7 |

| 51 | July 2009 | Cave Tin Mine Tailing Dam | H3, F9, F19, F15 |

| 52 | August 2009 | Russian Karamken goldmine | G5, H36 |

| 53 | August 2009 | Hanin Huanglong Gold Mine Tailing Dam | H2, F8, F16 |

| 54 | February 2010 | Shanxi Wenxi Tailing Dam | H1, G3, F17 |

| 55 | June 2010 | Unidad Minera Caudalosa Chica | G2, G6, F5, F16 |

| 56 | July 2010 | Yinyu Minerals Company Tailing Dam | E2, E3 |

| 57 | October 2010 | MAL Magyar Aluminium | H1, G10, F7, F17 |

| 58 | October 2010 | Longtang Titanium Mine Tailing Dam | G5, H3 |

| 59 | March 2011 | Li Feng Mining Limited Tailing Dam | H1, G7, G1, F17, F15, G2, G3 |

| 60 | December 2011 | Xinfengyuan Mining Company Tailing Dam | G5, H3, F6, F17, F15 |

| 61 | December 2011 | Liujiagou tailing dam | H1, G10, F6, F17, F13, F15, G2, G6 |

| 62 | December 2012 | Former Gullbrige mine | H2, F1, G10, F20, F16, G2, G6 |

| 63 | December 2012 | Lengkengchong tailing dam | G5, H3 |

| 64 | April 2014 | Dajinzhuang Mining Tailing Dam | H1, G1, F9, F19, F13, F15 |

| 65 | August 2014 | Canadian Mt Polleytailing dam | F1, E3, F14 |

| 66 | November 2015 | Samarco Tailing Dam | E3, G7, F17, F15, H1 |

| 67 | March 2017 | Tailing Depot of Daye Nonferrous Metals Co. | E3, F14, H4, F4, F13, F9, G1, H1, G2, G6 |

| 68 | September 2017 | Liberia Gold Mine Tailing Dam | H6, F17, F15 |

| 69 | March 2018 | Cadia Tailing Dam, Australia | G10, G7, F20, H1 |

| 70 | January 2019 | Brazilian Brumadinho dam | H7, F3, F17, F15 |

| 71 | March 2020 | Yichun Luming Mining Company Tailing Depot | H1, G8, H7, H3, F6, F17, F15, F16, G2, G6 |

| 72 | April 2020 | Dam Creek Iron Ore Mine Tailing Dam | E2, F17, F12, F20 |

| 73 | January 2021 | Yichuan Mining Company Tailing Dam | H3, F16 |

| 74 | March 2022 | Doyle Aluminum Company Limited Tailing Dam | H1, G7, G1, G2, G3 |

Appendix B

| H1 | H2 | H3 | H4 | H5 | H6 | H7 | E1 | E2 | E3 | G1 | G2 | G3 | G4 | G5 | G6 | G7 | G8 | G9 | G10 | F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | F10 | F11 | F12 | F13 | F14 | F15 | F16 | F17 | F18 | F19 | F20 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 7 | 4 | 1 | 1 | 0 | 0 | 3 | 2 | 0 | 4 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| H2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 2 | 3 | 0 | 1 | 2 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| H3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 2 | 0 | 3 | 4 | 0 | 1 | 0 |

| H4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| H5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 2 | 0 | 0 | 0 |

| H6 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3 | 0 | 0 | 0 |

| H7 | 0 | 0 | 3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| E1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 2 | 0 |

| E2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 7 |

| E3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3 | 2 | 1 | 0 | 0 | 0 | 0 |

| G1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 4 | 0 | 0 | 0 |

| G2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 7 | 0 | 0 | 12 | 0 | 2 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| G3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| G4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 |

| G5 | 1 | 0 | 7 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 |

| G6 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| G7 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 2 | 0 | 0 | 0 |

| G8 | 0 | 1 | 0 | 0 | 0 | 0 | 6 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| G9 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| G10 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| F1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 2 | 0 | 0 | 0 | 0 |

| F2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 0 |

| F5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 2 | 0 | 0 | 0 | 0 |

| F6 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 8 | 0 | 0 | 0 |

| F7 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 5 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 |

| F8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F9 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 3 | 0 |

| F10 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 2 | 0 | 0 | 0 |

| F11 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 5 | 0 | 0 | 0 | 0 | 0 |

| F12 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 8 |

| F13 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 7 | 0 | 0 | 0 | 0 | 0 |

| F14 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 6 | 0 | 3 | 0 | 0 | 0 | 0 |

| F16 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F17 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 5 | 3 | 0 | 7 | 0 | 0 | 0 | 1 | 0 |

| F18 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F19 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 2 | 0 | 2 | 0 | 0 | 0 | 0 | 0 |

| F20 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

References

- Wu, M.; Ye, Y.; Hu, N.; Wang, Q.; Tan, W. Scientometric analysis on the review research evolution of tailings dam failure disasters. Environ. Sci. Pollut. Res. 2023, 30, 13945–13959. [Google Scholar] [CrossRef]

- Ribas, J.R.; Pérez-Díaz, J.I. A multicriteria fuzzy approximate reasoning approach for risk assessment of dam safety. Environ. Earth Sci. 2019, 78, 514. [Google Scholar] [CrossRef]

- Wang, S.; Yong, S.; Wanyin, W. Comprehensive Safety Evaluation of Tailings Reservoir Based on Fuzzy Multivariate Contact Model. Gold Sci. Technol. 2019, 27, 903–911. [Google Scholar]

- Wang, X.H.; Gu, X.W.; Xu, X.C.; Wang, Q. Risk evaluation of break-dam in mine tailings pond based on GA-AHP and cloud-matter element model. J. Northeast. Univ. (Nat. Sci.) 2017, 38, 1464. [Google Scholar]

- Dai, X.; Wu, X.; Hong, Y.; Xie, J.; Lin, D.; Chen, Y.; Liu, Y. Safety and stability evaluation of the uranium tailings impoundment dam: Based on the improved AHP-cloud model. J. Radiat. Res. Appl. Sci. 2022, 15, 21–31. [Google Scholar] [CrossRef]

- Li, Z.; Wang, T.; Ge, W.; Wei, D.; Li, H. Risk analysis of earth-rock dam breach based on dynamic Bayesian network. Water 2019, 11, 2305. [Google Scholar] [CrossRef]

- Chen, H.; Ye, Y.C.; Wang, Q.H.; Luo, B.Y.; Liu, R.; Wang, X.H. Tailings pond dam break risk classification study based on both ISM and factor frequency method. China Saf. Sci. J. 2018, 28, 150. [Google Scholar]

- Zhang, L.; Huang, Y.; Wu, X.; Skibniewski, M.J. Risk-based estimate for operational safety in complex projects under uncertainty. Appl. Soft Comput. 2018, 54, 108–120. [Google Scholar] [CrossRef]

- Xu, Z.K.; Liu, X.; Wei, B.W.; Zhang, L.; Wen, Y.B. Tailings dam risk fuzzy evaluation model based on the cloud model. Transf. Water Sci. Technol. 2016, 14, 122127. [Google Scholar]

- Frigerio Porta, G.; Bebbington, M.; Xiao, X.; Jones, G. Bayesian lifetime analysis for landslide dams. Landslides 2010, 17, 1835–1848. [Google Scholar] [CrossRef]

- Wang, W.; Wang, Y.; Wang, G.; Li, M.; Jia, L. Identification of the critical accident causative factors in the urban rail transit system by complex network theory. Phys. A Stat. Mech. Its Appl. 2023, 610, 128404. [Google Scholar] [CrossRef]

- Deng, J.; Liu, S.; Shu, Y.; Hu, Y.; Xie, C.; Zeng, X. Risk evolution and prevention and control strategies of maritime accidents in China’s coastal areas based on complex network models. Ocean Coast. Manag. 2023, 237, 106527. [Google Scholar] [CrossRef]

- Wang, Y.; Zhai, H.; Cao, X.; Geng, X. Cause Analysis and Accident Classification of Road Traffic Accidents Based on Complex Networks. Appl. Sci. 2023, 13, 12963. [Google Scholar] [CrossRef]

- Yang, J.F.; Wang, P.C.; Liu, X.Y.; Bian, M.C.; Chen, L.C.; Lv, S.Y.; Dou, Z. Analysis on causes of chemical industry accident from 2015 to 2020 in Chinese mainland: A complex network theory approach. J. Loss Prev. Process Ind. 2023, 83, 105061. [Google Scholar] [CrossRef]

- Miao, D.; Wang, W.; Liu, L.; Yao, K.; Sui, X. Coal mine roof accident causation modeling and system reliability research based on directed weighted network. Process Saf. Environ. Prot. 2024, 183, 653–664. [Google Scholar] [CrossRef]

- Qin, X.; Li, Z.X.; Zhao, Y.Q. A complex network model for analyzing risks and major hazards of tailing impoundments. Chinese.] Sys. Eng.-Theory Pract. 2017, 37, 1648–1653. [Google Scholar]

- Zhen, Z.; Wu, X.; Ma, B.; Zhao, H.; Zhang, Y. Propagation network of tailings dam failure risk and the identification of key hazards. Sci. Rep. 2022, 12, 5580. [Google Scholar] [CrossRef]

- Dai, J.Y.; Wang, W.W.; Huang, X.Q.G. Safety assessment of tailings reservoirdam break based on network cloud model. J. Saf. Environ. 2022, 22, 1–7. [Google Scholar]

- Hao, T.T.; Zheng, X.; Wang, H.; Xu, K.; Yu, Y. Development of a method for weight determination of disaster-causing factors and quantitative risk assessment for tailings dams based on causal coupling relationships. Stoch. Environ. Res. Risk Assess. 2023, 37, 749–775. [Google Scholar] [CrossRef]

- Liu, J.; Wan, L.; Wang, W.; Yang, G.; Ma, Q.; Zhou, H.; Lu, F. Integrated fuzzy DEMATEL-ISM-NK for metro operation safety risk factor analysis and multi-factor risk coupling study. Sustainability 2023, 15, 5898. [Google Scholar] [CrossRef]

- Xiong, M.; Wang, H.; Che, C.; Sun, M. Application of text mining and coupling theory to depth cognition of aviation safety risk. Reliab. Eng. Syst. Saf. 2024, 245, 110032. [Google Scholar] [CrossRef]

- Xiang, P.; Yang, Y.; Yan, K.; Jin, L. Identification of Key Safety Risk Factors and Coupling Paths in Mega Construction Projects. J. Manag. Eng. 2024, 40, 04024023. [Google Scholar] [CrossRef]

- Ding, J.; Han, X.; Ni, L. Research on multi factor coupling accident triggering mechanism and accident risk control of gas pipeline leakage. Emerg. Manag. Sci. Technol. 2024, 4, e009. [Google Scholar] [CrossRef]

- Shao, Z.G.; Zhang, J.X.; Wang, W. Coupling analysis of new energy vehicle combustion-explosion risk factors based on N–K model and SNA. J. Saf. Environ. 2023, 23, 363–371. [Google Scholar]

- Mendes, R.G.; do Valle Junior, R.F.; de Melo, M.M.A.P.; de Morais Fernandes, G.H.; Fernandes, L.F.S.; Pissarra, T.C.T.; Pacheco, F.A.L. Scenarios of environmental deterioration in the Paraopeba River, in the three years after the breach of B1 tailings dam in Brumadinho (Minas Gerais, Brazil). Sci. Total Environ. 2023, 891, 164426. [Google Scholar] [CrossRef]

- Lin, S.Q.; Wang, G.J.; Liu, W.L.; Zhao, B.; Shen, Y.M.; Wang, M.L.; Li, X.S. Regional distribution and causes of global mine tailings dam failures. Metals 2022, 12, 905. [Google Scholar] [CrossRef]

- Darbra, R.M.; Palacios, A.; Casal, J. Domino effect in chemical accidents: Main features and accident sequences. J. Hazard. Mater. 2010, 183, 565–573. [Google Scholar] [CrossRef]

- Suryoputro, M.R.; Sari, A.D.; Kurnia, R.D. Preliminary study for modeling train accident in Indonesia using Swiss Cheese Model. Procedia Manuf. 2015, 3, 3100–3106. [Google Scholar] [CrossRef][Green Version]

- Lower, M.; Magott, J.; Skorupski, J. A system-theoretic accident model and process with human factors analysis and classification system taxonomy. Saf. Sci. 2018, 110, 393–410. [Google Scholar] [CrossRef]

- Li, J.; Qin, Y.; Wang, Z.; Xin, Y. How to analyse the injury based on 24Model: A case study of coal mine gas explosion injury. Inj. Prev. 2021, 27, 542–553. [Google Scholar] [CrossRef]

- GB 39496-2020; Safety Regulation for Tailings Pond. Standardization Administration of China: Beijing, China, 2020.

- Zhang, W.; Zhang, Y. Research on coupling mechanism of intelligent ship navigation risk factors based on NK model. J. Mar. Sci. Technol. 2023, 28, 195–207. [Google Scholar] [CrossRef]

- Wu, B.J.; Jin, L.H.; Zheng, X.Z.; Chen, S. Coupling analysis of crane accident risks based on Bayesian network and the NK model. Sci. Rep. 2024, 14, 1133. [Google Scholar]

- Guo, J.; Luo, C.; Ma, K. Risk coupling analysis of road transportation accidents of hazardous materials in complicated maritime environment. Reliab. Eng. Syst. Saf. 2023, 229, 108891. [Google Scholar] [CrossRef]

- Zaefarian, G.; Misra, S.; Koval, M.; Iurkov, V. Social network analysis in marketing: A step-by-step guide for researchers. Ind. Mark. Manag. 2022, 107, A11–A24. [Google Scholar] [CrossRef]

- Shi, J.; Liu, Z.; Feng, Y.; Wang, X.; Zhu, H.; Yang, Z.; Wang, H. Evolutionary model and risk analysis of ship collision accidents based on complex networks and DEMATEL. Ocean Eng. 2024, 305, 117965. [Google Scholar] [CrossRef]

- Klockner, K.; Toft, Y. Railway accidents and incidents: Complex socio-technical system accident modelling comes of age. Saf. Sci. 2018, 110, 59–66. [Google Scholar] [CrossRef]

- Es’haghi, M.; Nikravesh, A.; Allah-Bakshi, H.; Yarahmadi, H.; Poursheikhali, E. Identifying the indicators influencing zero accident vision through social network analysis: Case study in a mine. Int. J. Min. Miner. Eng. 2022, 13, 185–204. [Google Scholar]

- Feng, J.R.; Zhao, M.; Yu, G.; Zhang, J.; Lu, S. Dynamic risk analysis of accidents chain and system protection strategy based on complex network and node structure importance. Reliab. Eng. Syst. Saf. 2023, 238, 109413. [Google Scholar] [CrossRef]

- Wang, N.; Yin, J.; Khan, R.U. Risk Coupling Assessment of Vehicle Scheduling for Shipyard in a Complicated Road Environment. J. Mar. Sci. Eng. 2024, 12, 685. [Google Scholar] [CrossRef]

- Wang, F.; Ding, L.; Love, P.E.; Edwards, D.J. Modeling tunnel construction risk dynamics: Addressing the production versus protection problem. Saf. Sci. 2016, 87, 101–115. [Google Scholar] [CrossRef]

- Yan, X.L.; Hu, X.J.; Wang, Y.Z. Coupling mechanism of safety risk in construction projects and the countermeasures: From the perspective of construction workers. Saf. Environ. Eng. 2016, 23, 106–113. [Google Scholar]

| Cause of the Accident | Accident Causation Chain |

|---|---|

| In 2008, a dam failure accident occurred at the 980 Gully tailings pond of Xinta Company in Shanxi Province. According to the accident investigation report, the cause of the accident was inadequate supervision by local government departments at all levels and the unlawful construction of the tailings pond by Xinta, coupled with its extended illegal operations and disorganized safety management, which resulted in the steepening of the tailings accumulation dam slope. Concurrently, the use of inadequately designed seepage discharge facilities within the reservoir resulted in localized infiltration damage to the dam, leading to sliding and subsequent dam failure. |  |

| |

|

| First-Level Risk Factors | No. | Secondary Risk Factors |

|---|---|---|

| H: Human | H1 | Weak safety awareness |

| H2 | Lack of professional skills | |

| H3 | Irregular operation | |

| H4 | Violate command | |

| H5 | Misoperation | |

| H6 | Maloperation | |

| H7 | Lack of qualification | |

| E: Environment | E1 | Earthquake |

| E2 | Heavy rainfall | |

| E3 | Unfavorable geology | |

| G: Governance | G1 | Poor rectification of hidden dangers |

| G2 | Inadequate safety supervision | |

| G3 | Illegal construction production | |

| G4 | Poor emergency response | |

| G5 | Insufficient safety training | |

| G6 | Inadequate receipt and inspection | |

| G7 | Insufficient safety precautions | |

| G8 | Insufficient qualification technical review | |

| G9 | Insufficient safety investment | |

| G10 | Failure to construct as designed | |

| F: Facilities | F1 | Improper dam design |

| F2 | Inadequate flood control design | |

| F3 | Inadequate design of exfiltration | |

| F4 | Improper treatment of dam foundation | |

| F5 | Improper dam construction | |

| F6 | Improper flood discharge construction | |

| F7 | Dam liquefaction | |

| F8 | Failure of monitoring facilities | |

| F9 | Improper water level control | |

| F10 | Improper facilities materials | |

| F11 | Drainage facilities failure | |

| F12 | Insufficient flood capacity | |

| F13 | High infiltration line | |

| F14 | Dam structure damage | |

| F15 | Dam infiltration pipe surge | |

| F16 | Dam sliding | |

| F17 | Flood discharge facility damage | |

| F18 | Improper drainage construction | |

| F19 | Insufficient length of dry beach | |

| F20 | Flood overtopping |

| Risk Factor | Potential Coupling | Risk Factor r | Potential Coupling | Risk Factor | Potential Coupling |

|---|---|---|---|---|---|

| H1 | H–G–F | G5 | H–G | F9 | E–F |

| H2 | H–F | G6 | H–G–F | F10 | E–G–F |

| H3 | H–G–F | G7 | H–E–G | F11 | H–E–G–F |

| H4 | H–F | G8 | H–G–F | F12 | E–G–F |

| H5 | H–F | G9 | E–G–F | F13 | E–G–F |

| H6 | H–G–F | G10 | H–G–F | F14 | H–G–F |

| H7 | H–G–F | F1 | G–F | F15 | E–G–F |

| E1 | H–E–G–F | F2 | H–E–G–F | F16 | E–F |

| E2 | H–E–G–F | F3 | H–E–G–F | F17 | H–E–G–F |

| E3 | H–E–G–F | F4 | E–G–F | F18 | E–F |

| G1 | H–F | F5 | H–G–F | F19 | H–G–F |

| G2 | H–G–F | F6 | H–G–F | F20 | F |

| G3 | H–G–F | F7 | H–G–F | / | / |

| G4 | E–G–F | F8 | G–F | / | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, L.; Chen, D.; Li, S.; Wang, G.; Li, Y.; Li, B.; Chen, M. Coupled Analysis of Risk Factor for Tailing Pond Dam Failure Accident Based on N–K Model and SNA. Sustainability 2024, 16, 8686. https://doi.org/10.3390/su16198686

Yuan L, Chen D, Li S, Wang G, Li Y, Li B, Chen M. Coupled Analysis of Risk Factor for Tailing Pond Dam Failure Accident Based on N–K Model and SNA. Sustainability. 2024; 16(19):8686. https://doi.org/10.3390/su16198686

Chicago/Turabian StyleYuan, Liwei, Di Chen, Sumin Li, Guolong Wang, Yanlin Li, Bin Li, and Minghui Chen. 2024. "Coupled Analysis of Risk Factor for Tailing Pond Dam Failure Accident Based on N–K Model and SNA" Sustainability 16, no. 19: 8686. https://doi.org/10.3390/su16198686

APA StyleYuan, L., Chen, D., Li, S., Wang, G., Li, Y., Li, B., & Chen, M. (2024). Coupled Analysis of Risk Factor for Tailing Pond Dam Failure Accident Based on N–K Model and SNA. Sustainability, 16(19), 8686. https://doi.org/10.3390/su16198686