Analysis of Industrial Water Use Efficiency Based on SFA–Tobit Panel Model in China

Abstract

:1. Introduction

2. Method and Data

2.1. The Stochastic Frontier Analysis Model

lnYit = β0 + βslnSit + βllnLit + βwlnWit + βtstlnSit + βtltlnLit + βtwtlnWit +

βsllnSitlnLit + βswlnSitlnWit + βlwlnLitlnWit + ½βsslnSitlnSit + ½βwwln

WitlnWit + ½βlllnLitlnLit + ½βttT2 + Vit − Uit

2.2. Tobit Regression Model

yi* = yi if yi*>0

yi* = 0 if yi*≤0

2.3. Data Resource

3. Result and Discussion

3.1. The SFA Model Validation

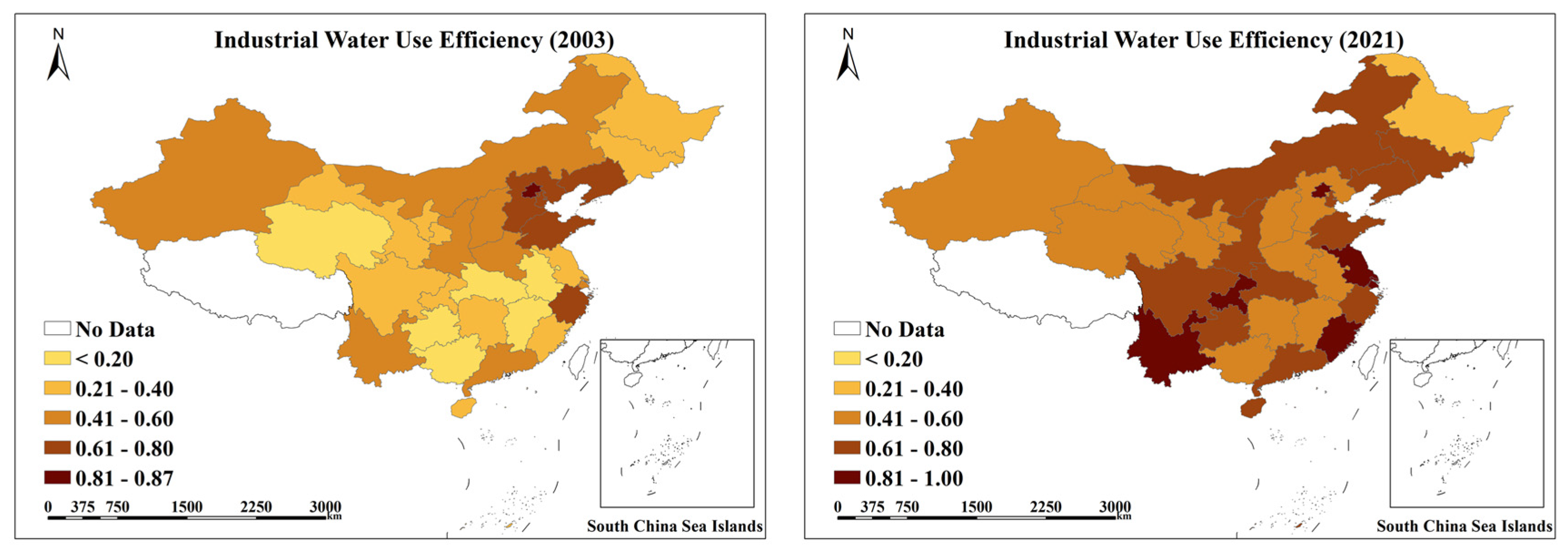

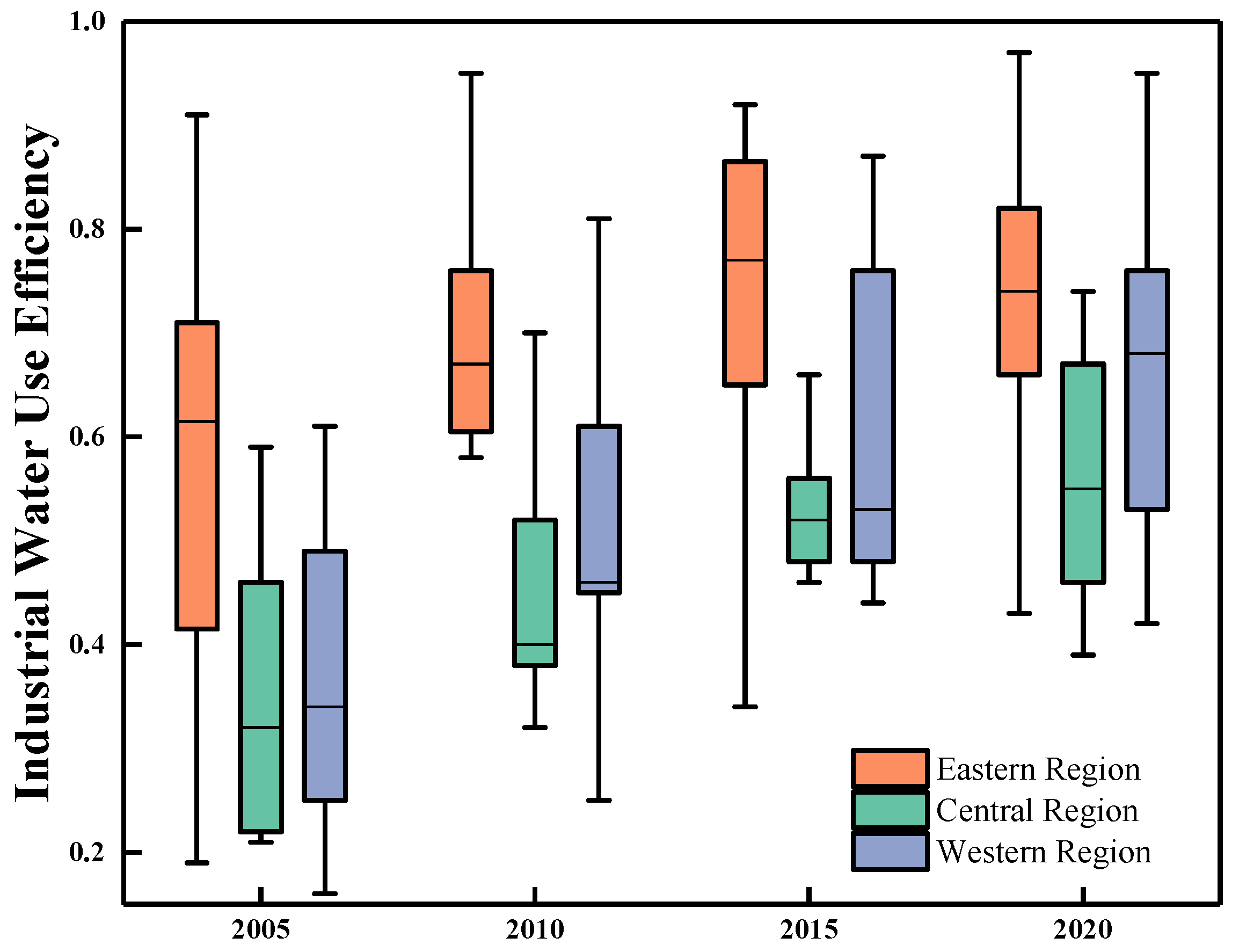

3.2. Industrial Water Use Efficiency Distribution

3.3. Water-Saving Potential and Tobit Regression

4. Conclusions and Policy Implication

4.1. Conclusions

4.2. Political Implications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, W.; Ren, L.; Deng, C.; Wang, Q.; Yu, J. The water-saving management contract in China: Current status, existing problems, and countermeasure suggestions. Water 2022, 14, 3116. [Google Scholar] [CrossRef]

- Xu, R.; Wu, Y.; Wang, G.; Zhang, X.; Wu, W.; Xu, Z. Evaluation of industrial water use efficiency considering pollutant discharge in China. PLoS ONE 2019, 14, 0221363. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Du, X.; Huang, A.; Yin, H. Analysis and comprehensive evaluation of water use efficiency in China. Water 2019, 11, 2620. [Google Scholar] [CrossRef]

- Yang, G.; Yang, D. Industrial water-use efficiency in China: Regional heterogeneity and incentives identification. J. Clean. Prod. 2020, 258, 120828. [Google Scholar] [CrossRef]

- Song, M.; Wang, R.; Zeng, X. Water resources utilization efficiency and influence factors under environmental restrictions. J. Clean. Prod. 2018, 184, 611–621. [Google Scholar] [CrossRef]

- Wu, W.; Zhu, F.; Zeng, W.; Wang, M.; Yang, D.; Chen, W. Green efficiency of water resources in Northwest China: Spatial-temporal heterogeneity and convergence trends. J. Clean. Prod. 2021, 320, 128651. [Google Scholar] [CrossRef]

- Deng, M. “Three Water Lines” strategy: Its spatial patterns and effects on water resources allocation in northwest China. Acta Geogr. Sin. 2018, 73, 1189–1203. [Google Scholar] [CrossRef]

- Zeng, H.; Zhang, T.; Zhou, Z.; Zhao, Y.; Chen, X. Water disclosure and firm risk: Empirical evidence from highly water-sensitive industries in China. Bus. Strategy Environ. 2020, 29, 17–38. [Google Scholar] [CrossRef]

- Chen, Y.; Yin, G.; Liu, K. Regional differences in the industrial water use efficiency of China: The spatial spillover effect and relevant factors. Resour. Conserv. Recycl. 2021, 167, 105239. [Google Scholar] [CrossRef]

- Sun, B.; Yang, X.; Zhang, Y.; Chen, X. Evaluation of Water Use Efficiency of 31 Provinces and Municipalities in China Using Multi-Level Entropy Weight Method Synthesized Indexes and Data Envelopment Analysis. Sustainability 2019, 11, 4556. [Google Scholar] [CrossRef]

- Cheng, L.; Song, S.; Xie, Y. Evaluation of water resources utilization efficiency in Guangdong Province based on the DEA–Malmquist model. Front. Environ. Sci. 2022, 10, 819693. [Google Scholar] [CrossRef]

- Li, N.; Wei, Y.; Wang, L.; Zeng, C.; Ma, X.; Wu, H. Impact of industrialization on water protection in the Huai River Basin within Shandong Province, China. Nat. Hazards 2016, 81, 1193–1207. [Google Scholar] [CrossRef]

- Zhang, R.; Lu, C.; Lee, J.; Feng, Y.; Chiu, Y. Dynamic Environmental Efficiency Assessment of Industrial Water Pollution. Sustainability 2019, 11, 3053. [Google Scholar] [CrossRef]

- Wang, Q.; Yang, Z. Industrial water pollution, water environment treatment, and health risks in China. Environ. Pollut. 2016, 218, 358–365. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.; Yang, D. Investigating industrial water-use efficiency in mainland China: An improved SBM-DEA model. J. Environ. Manag. 2020, 270, 110859. [Google Scholar] [CrossRef]

- Ali, H.; Guellil, M.; Mokhtari, F.; Tsabet, A. The effect of subsidies on technical efficiency of Algerian agricultural sector: Using stochastic frontier model (SFA). Discov. Sustain. 2024, 5, 98. [Google Scholar] [CrossRef]

- Shi, C.; Miao, X.; Zhang, L.; Chiu, Y.; Zeng, Q.; Zhang, C. Spatial patterns of industrial water efficiency and influencing factors—Based on dynamic two-stage DDF recycling model and geographically weighted regression model. J. Clean. Prod. 2022, 374, 134028. [Google Scholar] [CrossRef]

- Dan, S. Theories and Practices of China’s Industrial Green Development: Policy Options for Deepening the Green Development. Contemp. Financ. Econ. 2018, 01, 183. [Google Scholar]

- Cai, Z.; Li, H. Spatio-Temporal Differences in Relative Efficiency of Water Resource Utilization in Liaoning Province. Resour. Sci. 2008, 30, 1442–1448. [Google Scholar]

- Liu, X.; Peng, D. Green efficiency of industrial water resourece in China and its influencing factors: Empirical evidence from China’s 30 provinces. Appl. Ecol. Environ. Res. 2020, 18, 3057–3072. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, N.; Shang, J.; Zhang, J. Sustainable utilization of water resources in China: A system dynamics model. J. Clean. Prod. 2016, 142, 613–625. [Google Scholar] [CrossRef]

- Daraio, C.; Léopold, S. Advanced Robust and Nonparametric Methods in Efficiency Analysis; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Geng, Q.; Ren, Q.; Nolan, R.; Wu, P.; Yu, Q. Assessing China’s agricultural water use efficiency in a green-blue water perspective: A study based on data envelopment analysis. Ecol. Indic. 2019, 96, 329–335. [Google Scholar] [CrossRef]

- Hjalmarsson, L.; Kumbhakar, S.; Heshmati, A. DEA, DFA and SFA: A comparison. J. Product. Anal. 1996, 7, 303–327. [Google Scholar] [CrossRef]

- Lampe, H.; Hilgers, D. Trajectories of efficiency measurement: A bibliometric analysis of DEA and SFA. Eur. J. Oper. Res. 2015, 240, 1–21. [Google Scholar] [CrossRef]

- Moutinho, V.; Madaleno, M.; Macedo, P.; Robaina, M.; Marques, C. Efficiency in the European agricultural sector: Environment and resources. Environ. Sci. Pollut. Res. 2018, 25, 17927–17941. [Google Scholar] [CrossRef]

- Xu, R.; Cai, Y.; Wang, X.; Li, C.; Liu, Q.; Yang, Z. Agricultural nitrogen flow in a reservoir watershed and its implications for water pollution mitigation. J. Clean. Prod. 2020, 267, 9–10. [Google Scholar] [CrossRef]

- Yu, S.; Lu, H. An integrated model of water resources optimization allocation based on projection pursuit model—Grey Wolf Optimization method in a transboundary river basin. J. Hydrol. 2018, 559, 156–165. [Google Scholar] [CrossRef]

- Liang, X.; Zhou, Z. Technical efficiency measurement of urban industrial water: A case study of cities in China. Manag. Environ. Qual. 2022, 33, 1046–1060. [Google Scholar] [CrossRef]

- Suarez-Fernandez, S.; Quiroga-Garcia, R.; Manzano-Perez, I. A Comparison of DEA and SFA Approaches: Application to the US Non-Life Insurance Market. Appl. Econ. J. 2021, 28, 107–127. [Google Scholar] [CrossRef]

- Battese, G.; Coelli, T. Frontier production functions, technical efficiency and panel data: With application to paddy farmers in India. J. Product. Anal. 1992, 3, 153–169. [Google Scholar] [CrossRef]

- Xiong, L.; Wang, F.; Cheng, B.; Wu, C. Identifying factors influencing the forestry production efficiency in Northwest China. Resour. Conserv. Recycl. 2018, 130, 12–19. [Google Scholar] [CrossRef]

- Battese, G.; Coelli, T. A model for technical inefficiency effects in a stochastic frontier production function for panel data. Empir. Econ. 1995, 20, 325–332. [Google Scholar] [CrossRef]

- Battese, G.; Corra, G. Estimation of a production frontier model: With application to the pastoral zone of eastern Australia. Aust. J. Agric. Econ. 2012, 21, 169–179. [Google Scholar] [CrossRef]

- Krljan, T.; Grbi, A.; Hess, S.; Grubisic, N. The Stochastic Frontier Model for Technical Efficiency Estimation of Interconnected Container Terminals. J. Mar. Sci. Eng. 2021, 9, 515. [Google Scholar] [CrossRef]

- Craven, B.; Islam, S. Ordinary least-squares regression. In The SAGE Dictionary of Quantitative Management Research, 1st ed.; Sage Publications: New York, NY, USA, 2011; pp. 224–228. [Google Scholar]

- Dempster, A.; Schatzoff, M.; Wermuth, N. A simulation study of alternatives to ordinary least squares. J. Am. Stat. Assoc. 1977, 72, 77–91. [Google Scholar] [CrossRef]

- Vinod, H. A survey of ridge regression and related techniques for improvements over ordinary least squares. Rev. Econ. Stat. 1978, 60, 121–131. [Google Scholar] [CrossRef]

- Chib, S. Bayes inference in the Tobit censored regression model. J. Econom. 1992, 51, 79–99. [Google Scholar] [CrossRef]

- Kirjavainen, T.; Loikkanent, H. Efficiency Differences of Finnish Senior Secondary Schools: An Application of DEA and Tobit Analysis. Econ. Educ. Rev. 1996, 17, 377–394. [Google Scholar] [CrossRef]

- Masuda, K. Trade Policy and the Marshall–Lerner Condition: Application of the Tobit Model. SocArXiv 2021. [Google Scholar] [CrossRef]

- Yue, Y. Bayesian Tobit quantile regression model for medical expenditure panel survey data. Stat. Model. Appl. Contemp. Issues 2012, 12, 323–346. [Google Scholar] [CrossRef]

- Cheng, Z.; He, J.; Liu, Y.; Zhang, Q.; Deng, Y. Exploring the spatial structure and impact factors of water use efficiency in China. Environ. Impact Assess. Rev. 2023, 103, 107258. [Google Scholar] [CrossRef]

| Variable | Coefficient | Std Err | Variable | Coefficient | Std Err |

|---|---|---|---|---|---|

| β0 | 13.1 *** | 1.004 | βsl | −0.540 *** | 0.063 |

| βs | −11.430 *** | 0.638 | βsw | 0.152 *** | 0.038 |

| βl | 13.849 *** | 0.880 | βtw | −0.550 *** | 0.052 |

| βw | −5.898 *** | 0.778 | βss | 0.609 *** | 0.067 |

| βt | 0.974 *** | 0.132 | βww | 0.483 *** | 0.039 |

| βts | −0.035 *** | 0.008 | βll | 0.871 *** | 0.088 |

| βtl | 0.054 *** | 0.007 | βtt | 0.004 *** | 0.001 |

| βtw | −0.037 *** | 0.003 | γ | 0.997 *** | 0.005 |

| δ2 | 0.0194 | 0.0018 | LR−test | 620.32 | |

| Log-likelihood | 352.17 |

| Province | Mean | 2003 | 2021 | Change | Province | Mean | 2003 | 2021 | Change |

|---|---|---|---|---|---|---|---|---|---|

| Beijing/BJ | 0.919 | 0.870 | 0.999 | 0.129 | Henan/HA | 0.594 | 0.526 | 0.487 | −0.039 |

| Tianjin/TJ | 0.812 | 0.727 | 0.775 | 0.048 | Hubei/HB | 0.494 | 0.193 | 0.698 | 0.505 |

| Hebei/HB | 0.705 | 0.626 | 0.587 | −0.039 | Hunan/HN | 0.413 | 0.208 | 0.528 | 0.320 |

| Shanxi/SX | 0.514 | 0.457 | 0.441 | −0.016 | Guangdong/GD | 0.772 | 0.523 | 0.742 | 0.218 |

| Inner Mongolia IM/NM | 0.583 | 0.487 | 0.727 | 0.240 | Guangxi/GX | 0.306 | 0.196 | 0.446 | 0.250 |

| Liaoning/LN | 0.666 | 0.752 | 0.611 | −0.141 | Hainan/HI | 0.609 | 0.263 | 0.668 | 0.405 |

| Jilin/JL | 0.477 | 0.269 | 0.710 | 0.441 | Chongqing/CQ | 0.591 | 0.337 | 0.825 | 0.488 |

| Heilongjiang/HL | 0.378 | 0.324 | 0.387 | 0.063 | Sichuan/SC | 0.626 | 0.288 | 0.730 | 0.442 |

| Shanghai/SH | 0.725 | 0.404 | 0.940 | 0.536 | Guizhou/GZ | 0.387 | 0.163 | 0.657 | 0.495 |

| Jiangsu/JS | 0.611 | 0.385 | 0.852 | 0.466 | Yunnan/YN | 0.682 | 0.485 | 0.967 | 0.482 |

| Zhejiang/ZJ | 0.751 | 0.646 | 0.623 | −0.023 | Shaanxi/SX | 0.769 | 0.513 | 0.704 | 0.191 |

| Anhui/AH | 0.393 | 0.181 | 0.553 | 0.372 | Gansu/GS | 0.442 | 0.229 | 0.522 | 0.294 |

| Fujian/FJ | 0.663 | 0.346 | 0.841 | 0.495 | Qinghai/QH | 0.371 | 0.176 | 0.512 | 0.335 |

| Jiangxi/JX | 0.374 | 0.173 | 0.486 | 0.313 | Ningxia/NX | 0.426 | 0.269 | 0.434 | 0.165 |

| Shangdong/SD | 0.706 | 0.724 | 0.724 | 0.000 | Xinjiang/XJ | 0.503 | 0.535 | 0.444 | −0.092 |

| Variable | Coefficient | Std Err | T Value | p Value |

|---|---|---|---|---|

| Constant | 0.629 *** | 0.0700 | 9.03 | 0.000 |

| Economic Development Level | 0.000 *** | 0.0000 | 5.01 | 0.000 |

| Water Resource Endowment | 0.000 | 0.0000 | −1.15 | 0.250 |

| Industrialization Level | 0.077 | 0.0920 | 0.84 | 0.399 |

| Technology Progress Level | 2.934 *** | 1.0736 | 2.77 | 0.006 |

| Water Use Intensity | −0.001 *** | 0.0001 | −16.13 | 0.000 |

| Openness Level | −0.084 *** | 0.0284 | −2.94 | 0.003 |

| Environmental Regulation | −1.377 | 1.1888 | −1.16 | 0.247 |

| Urbanization Level | −0.203 ** | 0.0971 | −2.09 | 0.036 |

| Log-likelihood | 629.978 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Liu, H.; Geng, L. Analysis of Industrial Water Use Efficiency Based on SFA–Tobit Panel Model in China. Sustainability 2024, 16, 8708. https://doi.org/10.3390/su16198708

Liu H, Liu H, Geng L. Analysis of Industrial Water Use Efficiency Based on SFA–Tobit Panel Model in China. Sustainability. 2024; 16(19):8708. https://doi.org/10.3390/su16198708

Chicago/Turabian StyleLiu, Han, Heng Liu, and Leihua Geng. 2024. "Analysis of Industrial Water Use Efficiency Based on SFA–Tobit Panel Model in China" Sustainability 16, no. 19: 8708. https://doi.org/10.3390/su16198708