Abstract

The sustainable utilization of biomass, particularly troublesome waste biomass, has become one of the pathways to meet the urgent demand for providing energy safety and environmental protection. The variety of biomass hinders the design of energy devices and systems, which must be highly efficient and reliable. Along with the technological developments in this field, broad works have been carried out on the mathematical modeling of the processes to support design and optimization for decreasing the environmental impact of energy systems. This paper aims to provide an extensive review of the various approaches proposed in the field of the mathematical modeling of the thermochemical conversion of biomass. The general focus is on pyrolysis and gasification, which are considered among the most beneficial methods for waste biomass utilization. The thermal and flow issues accompanying fuel conversion, with the basic governing equations and closing relationships, are presented with regard to the micro- (single particle) and macro-scale (multi-particle) problems, including different approaches (Eulerian, Lagrangian, and mixed). The data-driven techniques utilizing artificial neural networks and machine learning, gaining increasing interest as complementary to the traditional models, are also presented. The impact of the complexity of the physicochemical processes and the upscaling problem on the variations in the modeling approaches are discussed. The advantages and limitations of the proposed models are indicated. Potential options for further development in this area are outlined. The study shows that efforts towards obtaining reliable predictions of process characteristics while preserving reasonable computational efficiency result in a variety of modeling methods. These contribute to advancing environmentally conscious energy solutions in line with the global sustainability goals.

1. Introduction

Over the past two decades, a strong emphasis on implementing sustainable energy development based on distributed generation has emerged worldwide. Biomass, as a valuable net zero carbon alternative to fossil fuels, besides other renewable forms of energy, is perceived as a crucial part of the bioenergy sector contributing to reducing energy dependency and offering socio-economic and environmental benefits [1]. Furthermore, through the use of the available local resources, in particular woody and waste biomass of various origins, especially in combined heat and power (CHP) systems [2,3], it contributes to implementing the waste-to-energy concept underlying the circular economy strategies. Along with this, there has naturally been a dynamic development of research, both experimental and theoretical, related to the thermochemical processing of biomass. What lies behind the viable, reliable, and environmentally sound technological solutions is their flexibility to the energy needs, type of biomass feedstock available, and implementation in integrated systems under possible energy mix scenarios [4,5].

The processes accompanying the thermochemical conversion of the solid fuels are a set of coupled thermal and flow phenomena. Understanding their nature is the key to the proper and efficient design of equipment such as pyrolysis reactors, gasifiers, or combustion chambers. The complex structure of the fuel particle bed and the complexity of the processes, as well as limitations of a technical nature, make a detailed experimental analysis of each phenomenon individually impossible, even on a laboratory scale; therefore, mathematical modeling is an essential step in supporting the development of modern and reliable energy conversion technologies.

The heat and mass transfer phenomena occurring in a reactive bed are in general three-dimensional. However, due to their complexity, among the works devoted to the mathematical modeling of solid fuel thermal conversion processes, analyses based on a one-dimensional description of the issues dominate. Such an approach significantly reduces computation time. The key to a proper mathematical description of the physicochemical transitions and thermal–fluid phenomena in a reactive bed is the analysis of the processes on a micro-scale. Hence, the majority of the papers available in the literature focus on the thermal decomposition of single biomass particles. Among them, a significant aspect concerns calculations based on one-dimensional (1D) models in the context of the combustion process of fuel particles on a grate or in a solid bed. These models take into account moisture evaporation, decomposition, and particle–gas reactions [6] and, in addition, the change in particle volume during the process [7,8]. Examples include the mathematical description of the pyrolysis process for a radiatively heated wood particle, taking into account the change in particle size due to decomposition [9] and in the diameter range from a few micrometers to a few dozen millimeters [10]. An experimentally verified three-dimensional (3D) model of the pyrolysis and gasification of a large wood particle using Computational Fluid Dynamics (CFDs) has been presented in [11]. On the other hand, the authors of [12] applied modular computational schemes in the in-house code based on a 1D model to simulate the thermal conversion of a wood particle. The authors postulated that the developed model can be successfully implemented into the description for a packed bed.

The closest representation to the reality of the physicochemical processes in a bed of solid fuel particles that may account for its complex structure and the particle–particle and particle–fluid interactions is offered by discrete models. These include the DPM (Discrete Particle Method)-based approach, which has been applied, for instance, in 1D simulations of laboratory-scale processes: drying and pyrolysis [13] and combustion [14], as well as in 2D simulations of combustion [15]. The application of this method to model the bed conversion process is based on a combination of several computational tools: (i) CFDs to describe thermal–fluid phenomena, (ii) the Discrete Element Method (DEM) to describe bed motion, and (iii) object-oriented programming to simulate the bed as a set of particles [16]. It is worth noting, however, that the DPM method requires the particle size and position to be determined at each time step, and the balance equations for each particle are solved in coupling with the balance equations for the fluid filling the interparticle spaces throughout a given volume. This entails enormous and costly computational power. Therefore, although it offers good agreement with the experimental data, it is rather useless for modeling and verifying the operation of technical-scale reactors where the number of particles reaches millions. An alternative approach to reduce the computation time is the so-called RPM (Representative Particle Model), which has been applied to the 1D modeling of solid bed pyrolysis [17] and biomass bed combustion on a moving grate [18]. It involves solving balance equations for fuel particles representative of each control volume, with the gas phase filling the spaces between the particles treated as homogeneous within the control volume.

The high computational cost of the numerical modeling of the transport processes in reactive packed beds based on discrete methods, despite their established reliability, is a significant obstacle to their widespread use in the design and optimization of real-scale thermochemical solid fuel conversion systems. Competing in this case are models considering the bed as a multiphase continuous medium in which the solid and fluid (gas and liquid) phases coexist. Such a simplification of the description necessitates the use of additional empirical correlations [14,17]. Nevertheless, homogeneous models have been successfully used to simulate the heat and mass transfer in solid fuel bed conversion processes. These include, among others, the transient 1D model for pyrolysis of segregated waste [19] and woody biomass [20], biomass gasification in downdraft reactors [21,22] and updraft ones [23,24,25], as well as a 2D description of the wood pyrolysis process [26].

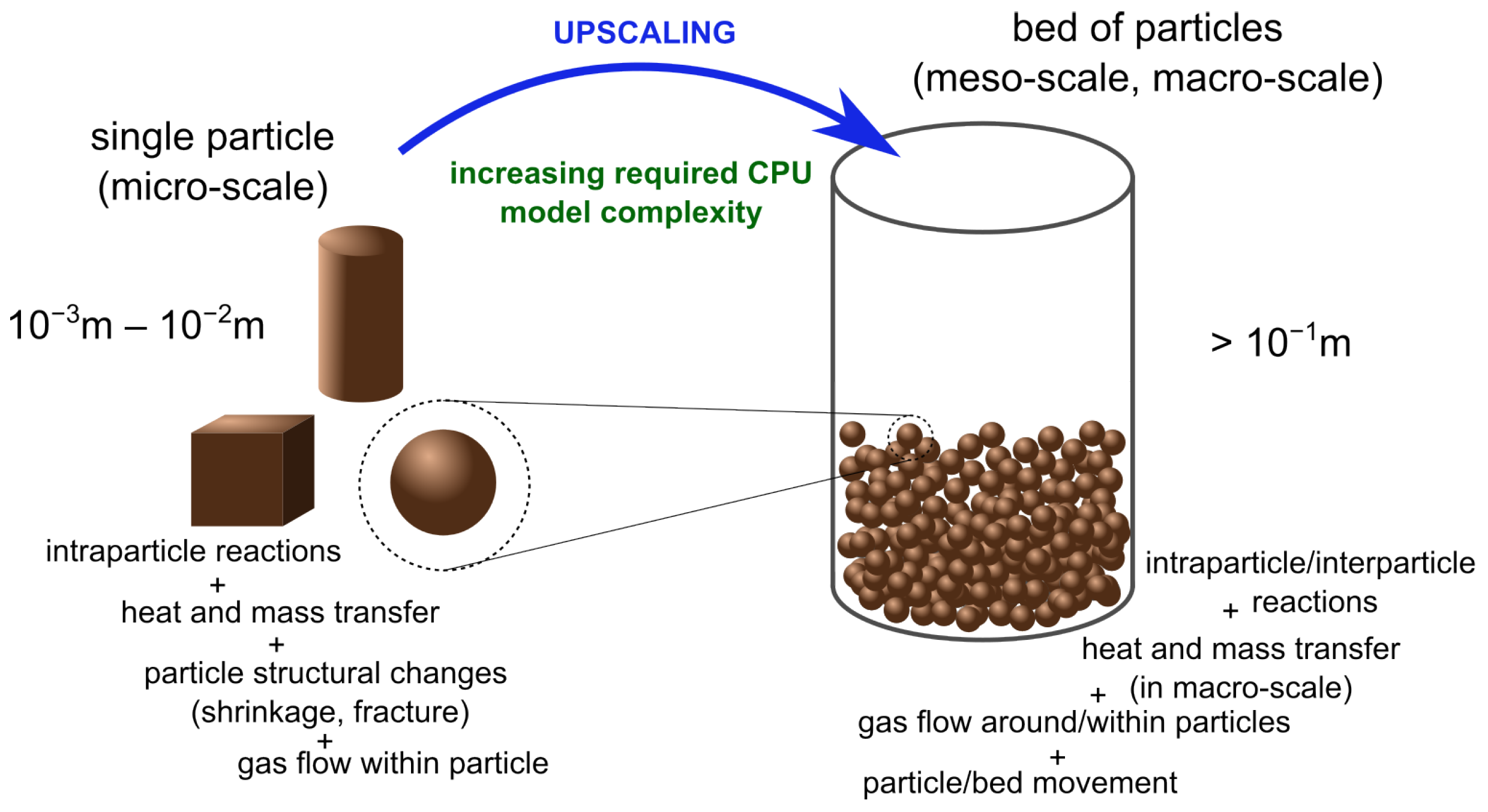

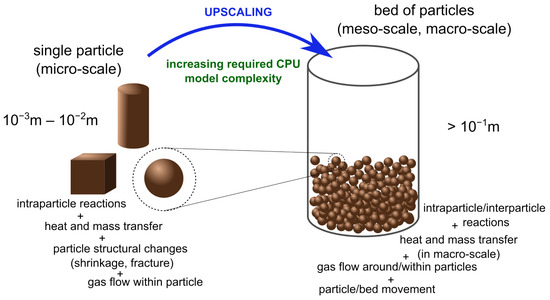

Given the biodiversity of the available raw materials, including plant and animal waste biomass, representing the potential for use to meet energy needs, methods and tools are being sought for analyzing the thermal conversion processes to support the intensified development of modern CHP technologies. The issue to be faced is to find a trade-off between the complexity of the mathematical model and the computational cost and accuracy of the predicted process parameters. This is, naturally, a matter of the simplifications used in the model. The present work therefore aims to demonstrate various approaches to modeling the thermal conversion of solid fuels in more detail. The essence behind the overview carried out and discussed in the paper is, in the first place, to distinguish the modeling issues into micro-scale (the level of a single particle) and meso-(macro-)scale (involving packed beds) cases, as shown in Figure 1. In both cases, the basic heat and mass transfer phenomena are essentially the same and governed by the same conservation equations. At the macro-scale level, additional phenomena to consider are the particles’ movement and interparticle interactions. Regardless of the scale, simple and more advanced models are available, but the model sophistication is to a large extent a question of its dimensionality, implemented reaction kinetics, and the definitions of the source terms.

Figure 1.

Logical structure of the analysis.

It is widely accepted that fuel composition strongly affects its behavior during thermal treatment and, consequently, the conversion characteristics of a material. This is particularly exhibited in the case of biomass, which differs significantly depending on its type and origin. Thus, predicting the effect of the material’s composition on its performance during the process is a question of defining and implementing its physicochemical properties.

The current trends, promoting sustainable management and the use of all the available resources while being as climate-neutral as possible, favor highly efficient technologies dedicated to the conversion of low-value biogenic fuels and preserving low emissions. Consequently, more important than combustion itself are the methods of conversion to liquid or gaseous products that can be further used as fuels or for the production of synthetic materials. Therefore, the focus here is on the modeling of the pyrolysis and gasification processes. Particular attention is paid to the recent advances in the field, including machine learning methods that enable predicting the system behavior under different operational conditions and fuel types, thus offering a more adaptable approach to modeling dynamic and complex systems like waste-to-energy plants or biomass gasifiers.

2. Granular Reactive Beds—From Micro- to Macro-Scale

A bed of solid fuel particles is a non-homogeneous medium of an irregular structure–a collection of particles of different shapes, sizes and random spatial arrangements. Such complex geometry makes a mathematical description difficult. Detailed information on the spatial structure of the packed bed can be provided by experimental analyses using, for example, methods of computed tomography and image analysis [27]. However, given the uniqueness of the structure of fuel particle beds, the usefulness of measurements in this respect is limited. Here, the aforementioned DEM approach fully based on the Lagrange description [16,28] could be helpful, enabling simulations of random arrangements of single grains. Although it offers the possibility of generating particles of other shapes than spherical, the additional assumption of non-sphericity of the grains and varying size entails an extension of the computation time, making this tool less attractive in terms of effective designing and optimizing of real-scale technical solutions. A commonly used approach assumes spherical particle structures of uniform size, arranged in a cubic, tetrahedral, or hexagonal arrangement [29], enabling geometrical relationships to be determined for a representative elementary cell. This serves to determine the substitute (effective) thermophysical properties of the packed bed, which are the basis of the alternative averaged approach commonly used due to its significantly lower computational cost.

The basic phenomena involved in the thermal processing of solid fuels are (i) heat transfer in a packed bed as a primary factor initiating further process stages, including (ii) phase transitions of moisture and tars, (iii) thermal decomposition of fuel particles (pyrolysis), (iv) homo- and heterogeneous reactions, and (v) gas flow through the bed. Each of these phenomena as separate issues present challenges for mathematical modeling, especially in the area of transient processes. Obviously, the dynamics of fuel conversion in the bed is determined by the nature of the physicochemical processes at the micro-scale, i.e., at the particle level. Here, of importance are the rates of intraparticle heat transfer, moisture release, and particle devolatilization. The complexity of the description of transport processes in a reactive bed is thus mainly due to the difference in the spatial and timescales of the individual phenomena. The smallest scale of the process is the size of the pores in the particles, which is of the order of micrometers. On the other hand, the analysis of the phenomena concerns devices with dimensions of the order of meters. When it comes to the speed of phenomena, the issue covers heat front propagating with a velocity of the order of , gas flow of the order of , and combustion reactions with the reaction front velocities of the order of [30,31].

2.1. Basic Governing Equations

A complete description of the processes involved in the conversion of fuel particles in a packed bed comprises time- and space-dependent conservation equations, including mass, momentum, and energy for gases, liquids, and solids. During conversion, the solid phase (s) undergoes physical and chemical processes, transforming into gaseous, liquid, and solid residues (char). Gaseous phase (g) is a mixture of gas compounds, such as , , , , lighter hydrocarbons, and the heavier ones (tars (t)). The latter as the condensing compounds contribute to the liquid phase, along with the moisture (w). Assuming that phase transitions of moisture and tars occur at the particle surface, the system of mass conservation equations for the solid–fluid system in the averaged-type Eulerian approach include the following [32]:

- mass balance for solid and liquid phases

- mass balance for gas phase

- mass balance for species in gas phase

In the above, i stands for the phase (s, w, and t), and represent the volume fraction and density of a component (phase), respectively, the mass fraction of j-th gas compound, the velocity vector, and is the volumetric mass source. The quantity denotes the diffusive mass flux of j-th compound.

Further, assuming low gas flow velocity (Re < 10) owing to dense particle packing, the momentum conservation for gas flow takes the form [29,32]

where denotes pressure and is gas dynamic viscosity. The second term on the right-hand side of the equation represents the Darcy flow of viscous fluid in micro-scale (through pores), wherein is the matrix permeability.

The formulation of the packed bed energy balance is dictated by the nature of the process and, more specifically, by the local temperature differences between the solid and gas phases. In the case of processes that are characterized by fast flows and/or large bed particles, as well as in the case of slow-moving processes but where the solid and liquid phases move countercurrently, these differences can be significant. The description of heat transport then requires a two-fluid approach, i.e., involving separate energy balance equations for the solid and gas phases, provided as follows [32]:

where represents temperature and stands for enthalpy. Parameter denotes specific heat of i-th phase, and is the heat flux in the i-th phase. The last terms on the right-hand side of both equations represent the convective heat transfer between phases at an interfacial boundary of area with an intensity determined by the heat transfer coefficient . Subscript k in terms representing thermal effects in Equation (5) refers to chemical reactions in the solid phase (including decomposition and heterogeneous (gas–solid) reactions due to oxidation and reduction). Similarly, subscript l in terms of representing thermal effects in Equation (6) stands for the homogeneous reactions (in gaseous phase) between the combustible gas components (e.g., , , and ).

For slow flows through reactive granular beds with relatively small particle sizes on the order of millimeters, either stationary or moving cocurrently with respect to the gas movement, local temperature differences can be assumed to be negligible, . The energy balance for the bed can then be reduced to the following general equation [32]:

where the properties of the bed (, c) are the volume-averaged values.

2.2. Phase Transitions

Modeling the moisture evaporation and condensation in porous media is numerically challenging, mainly because these processes are very intense. Their characteristic times are much shorter than those in devolatilization process, yielding mass fluxes on the order of , an order larger than the mass fluxes during pyrolysis. This requires the use of numerical schemes that ensure the stability of the calculations while keeping computational costs low. Furthermore, the phase transition in a porous packed bed is a heterogeneous process, so the volumetric mass flux of the media due to transition is also a function of the interfacial area. For moisture evaporation, it may thus be written as [33]

where represents the unit rate of moisture mass flow. The interfacial area is a parameter strongly dependent on the material structure of the particles, their fineness, and the structure of the bed itself and is, therefore, a case-specific quantity difficult to generalize to a wider range of cases. Various approaches to the description of evaporation and condensation in a reactive packed bed have been proposed to determine the unit rate or, directly, the mass flux . These can be categorized into three groups:

- based on mass and energy balance equations at the surface representing phase change [16,34,35,36];

- described by the process kinetics in analogy to chemical reaction kinetics [26,37];

- based on the kinetic theory of gases [38].

The first two model types involve temperature as the only parameter. Unlike the third category of models that account for both temperature and pressure, their applicability is limited to cases with relatively low pressure variations.

The first group of approaches generally refer to one-dimensional problems with the propagating fronts of evaporation () and condensation (), whose locations are determined by, respectively [34]:

where “+” sign represents the region at the saturation temperature in the case of propagating evaporation front, whereas, in the case of condensation front, it refers to the region at the temperature below saturation. For the evaporation front, the “−” sign denotes the high-temperature region (dried material), and for the condensation front it corresponds to the zone of saturation temperature. Surface mass fluxes for the respective fronts are then expressed by [34]

In the above, index 0 refers to the initial values. More simplified model of moisture evaporation, considered by Osinski et al. [35] and Peters [16], is based on the local energy balance for the evaporation front, which essentially involves determining the volumetric mass rate of water vapor in the following form:

where represents the enthalpy available for evaporation.

A similar simplified approach was proposed by Polesek-Karczewska and Kardaś [39] to describe moisture evaporation in one-dimensional model of wood biomass pyrolysis in laboratory scale reactor while taking into account the interphase surface. Assuming that the heat flux (q) transferred through the surface area (a) of the evaporation front , i.e., from the dry to the wet region of a packed bed, is intended for phase transition, and considering Equation (8), the authors arrived at

The models of the second group, i.e., based on the process kinetics, were considered with respect to wood pyrolysis by, for instance, Krieger-Brockett and Glaister [37], Bryden et al. [10], and Lamarche et al. [26]. This concept involves the formulation of the volumetric mass flux as

where is a reaction rate constant defined by Arrhenius equation:

In the above, and represent the pre-exponential factor and activation energy, respectively. Such an approach is said to be advantageous in terms of numerical stability and accounting for the process variability with temperature and varying water binding forces. The disadvantage of the approach is, however, the dependency of the experimentally derived kinetic data on the process conditions, which significantly limits its applicability [16].

A more detailed description of water–vapor phase transitions is provided by the third group of models that are based on the kinetic theory of gases [33]. This approach utilizes the definition of the net mass flux, expressed in the simplified form proposed by Hertz–Knudsen–Schrage:

where stands for the molar mass of water, is the vapor pressure above the interphase surface, and is the water saturation pressure. Parameter is the factor that takes values in the range between near-zero to 1. Such problem formulation does not require determining the separate fronts of evaporation and condensation, and the type of transition is clearly defined through the sign of the flux, i.e.:

This approach to water phase transition modeling was successfully applied in the mathematical description of coal carbonization by Polesek-Karczewska et al. [33,40], enabling reproducing the measurement data. It has also been implemented by Wardach-Święcicka and Kardaś [41] to model a single-particle thermal decomposition in a hot gas flow. A similar model to the same issue, based on the modified Hertz–Knudsen equation, was proposed by Słupik et al. [38].

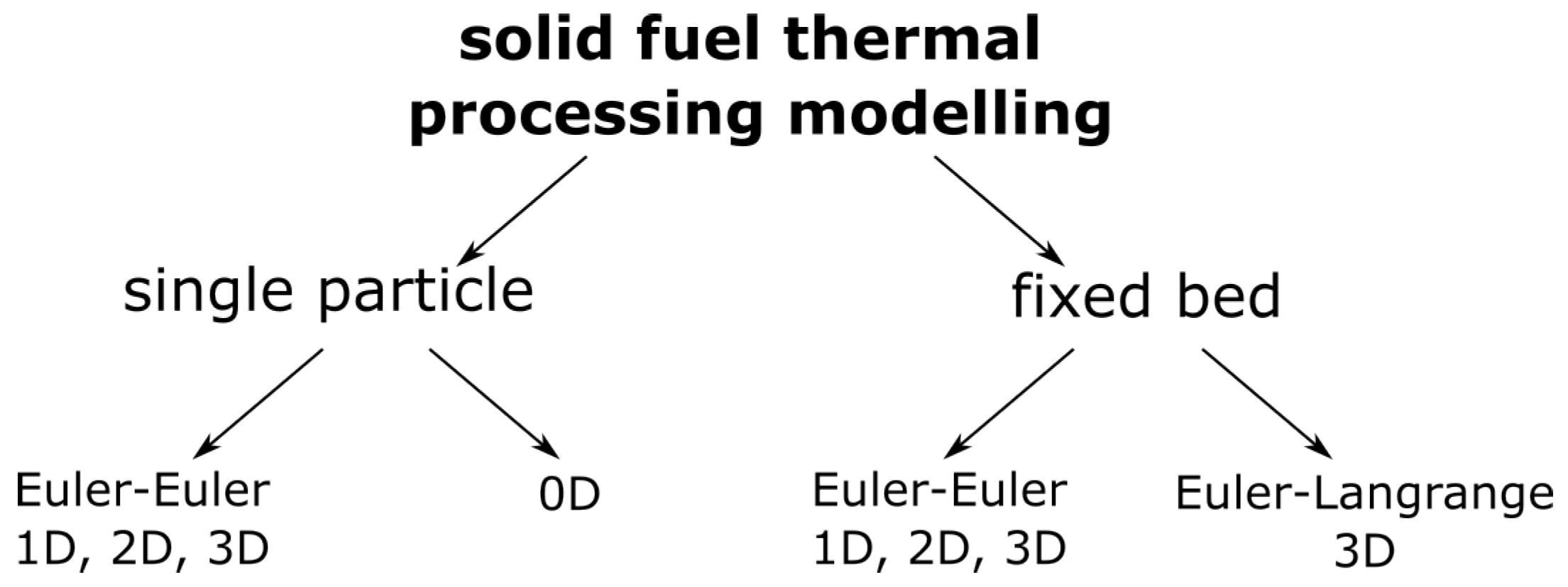

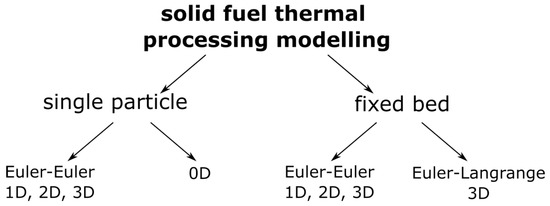

From the above, it is clear that mathematical modeling of thermal conversion of biogenic fuels is a very complex problem to solve. To properly describe the reality, the multiphase, multicomponent, and multiscale issues have to be taken into account. Combining all phenomena is challenging and requires complex numerical schemes that demand increased computing power. Many researchers have decided to undertake different types of simplifications to obtain solutions faster. The variety of available models provide a wide range of possibilities to predict the behavior of solid fuels during heating, although the answers depend on the questions. Following the considered distinction between single- and multi-particle models, in the following sections of the paper, an overview of different approaches used in both model types are discussed, as depicted in Figure 2.

Figure 2.

Logical structure of the analyzed models.

3. Single-Particle Models

A very important role in modeling the thermal decomposition of solid fuel is to know and understand the intricate chemical and physical mechanisms occurring during this process, in particular at the micro-scale (single-particle) level.

It is accepted that the course of pyrolysis is controlled and initiated by heat transfer [42]. In other words, the rate and behavior of the material during pyrolysis depend on temperature distribution and heat transfer. Intraparticle gradients play a significant role, particularly in the context of larger particle sizes and higher ambient temperatures, when the thermal decomposition is primarily influenced by transport processes rather than chemical kinetics [43,44]. This issue is therefore of consideration in macro- and large-scale processes, in which thermal and flow phenomena have a more prominent impact. Consequently, many research studies focus on examining how heating rate and particle size affect the heat and mass transfer during thermal decomposition processes [45,46,47]. These studies highlight the unpredictability of a pyrolysis course due to temperature variations within the particle and emphasize that assuming a uniform temperature throughout the particle can lead to inaccurate predictions and significant result discrepancies.

Previous studies [42,48] have demonstrated that one of the effective methods for estimating the progress of thermochemical conversion is to analyze the process taking into account the characteristic process timescales. The proposed timescales include mass and energy transport effects, as well as chemical kinetics. By examining the ratios of the values represented in the timescales, it becomes possible to predict the optimal duration of the conversion process. Furthermore, if thermal effects are involved in the analysis, it is crucial to accurately evaluate the physical properties of the sample in order to simulate the process effectively. Of primary importance are the specific heat capacity and thermal conductivity of the material as they significantly influence heat transfer and the resulting temperature profile. Assuming these properties remain constant throughout the entire pyrolysis process simplifies the analysis considerably but may be insufficient for accurately reproducing the behavior of particles in real-scale thermochemical conversion, which involves larger particles (up to a few centimeters in size) and varying heating rates.

Heating a solid fuel particle in an inert atmosphere leads to the evaporation of moisture and the thermal decomposition of volatile parts. The chemical transformations taking place during this process can be divided into two groups. The first one regards the reactions leading to the decomposition of the solid part, while the second one involves the reactions occurring between the products released. The first stage of pyrolysis leads to the release of gases and the production of tars and char. The tars, along with the char, may undergo further transformations, resulting in the formation of the so-called secondary gases and secondary char. The rates of these transformations strongly depend on heat transfer and mass flow. The complexity of the phenomenon, therefore, leads to the need for many assumptions and simplifications while developing a mathematical model reflecting the actual processes.

The mathematical modeling of the processes occurring during the heating of a single solid fuel grain can be generally, due to the size of the phenomenon, separated into two groups, which include micro- and macro-particle approaches. Micro-type modeling considers predicting physical processes in which the diffusion effect can be ignored due to its small characteristic size. Pyrolysis, the heating stage in the absence of oxygen, is then controlled by the kinetics of the process. The critical size of fuel particles, which defines the division between these approaches, ranges from 0.1 to 1 mm [49]. In larger particles, diffusion plays a significant role [42,50].

3.1. Micro-Particle Approach

In modeling kinetically controlled processes, the following aspects should be taken into account:

- time phenomena—knowledge of these is essential when modeling the chemical reaction dynamics, the duration of which differs in a wide range: from days in the case of charcoal production to milliseconds for so-called flash pyrolysis. Both processes are characterized by different values of high heating rates [51,52,53];

- quantity and quality of the pyrolysis products, which are usually solid clumped substance (carbon-rich char), tars (condensed vapors with high molar mass), and different content gas mixtures (characterized by low molar mass) [51,52,53,54];

- variations in the yields of products depending on the process operating conditions, e.g., temperatures or heating rates [51,52,55].

In micro-particle types of models, schemes are sought that prevent complex analyses of surface reactions, particularly when one does not have information about the permeability value of a material, i.e., no knowledge about the size and distribution of pores. These, in the case of thermal treatment, are generally time-dependent values. Furthermore, the variability of the products’ yields dependent on the process operating conditions (pressure, heating times, and temperature) must be taken into consideration.

The approaches developed in the field of solid fuels involve simplified and more complex mechanisms of decomposition. The simplified ones account for the formation of an intermediate state of the raw material. An example of this is the model proposed by Krevelen [56] with regard to coal pyrolysis, wherein an unstable post-initial stage form called metaplastic was considered to break down in the second phase into semi-coke and primary volatile products (gases and tar). The mechanism also assumed the formation of secondary gases and coke from the semi-coke. In turn, Ścia̧żko [57] considered a two-stage approach, assuming secondary reactions between the products. The model (0-dimensional (0D), stationary), based only on the temperature-varying parameters, involves the primary reactions (stage I) leading to gaseous product formation, followed by secondary reactions between the products (stage II) with further increase in process temperature resulting in gas and tar formation. The residue of the process is char-carbonate-enriched, relative to the original substance, which no longer undergoes further decomposition reactions.

In the literature, numerous similar models are devoted to biomass.

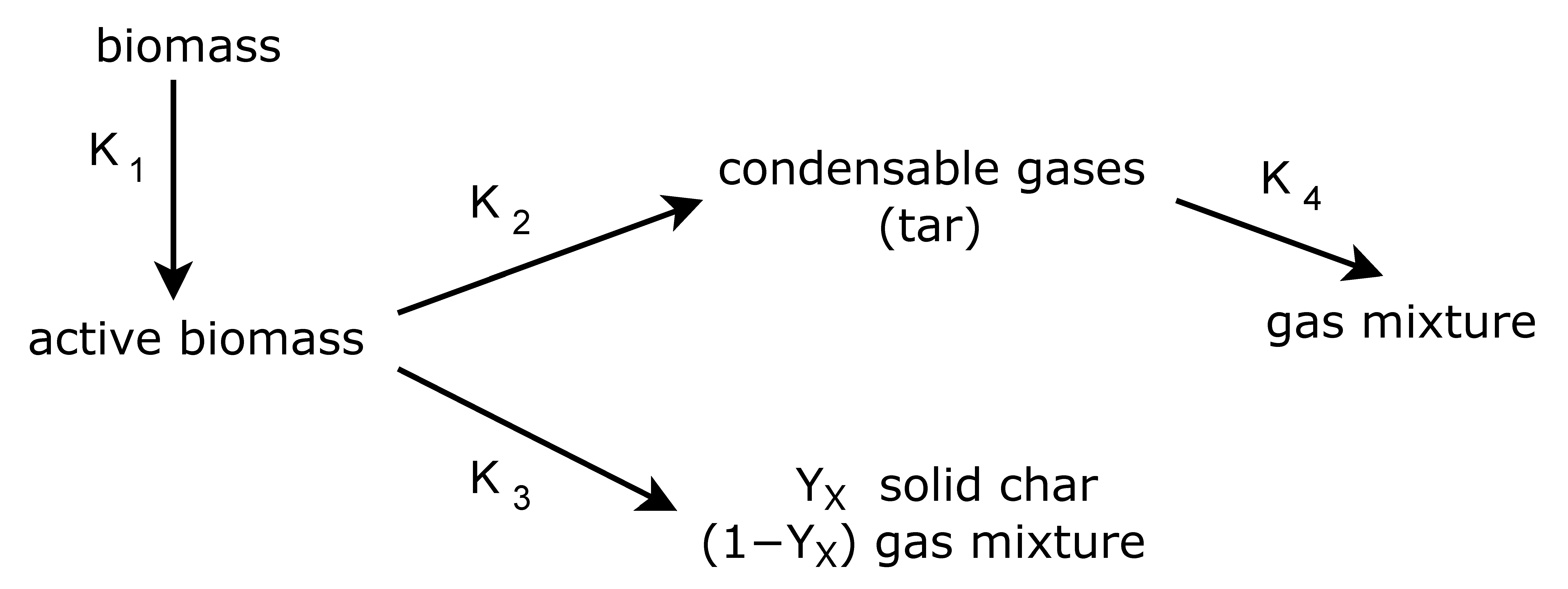

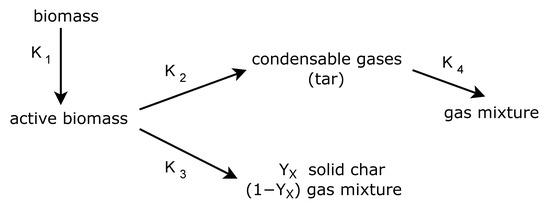

A simplified model of the wood pyrolysis process was proposed by Koufopanos et al. [58] and further developed by Miller and Bellan [49], which is schematically shown in Figure 3. It assumes that the first stage of the process (for T < 473 K) occurs with a reaction rate constant and no apparent mass loss. This is said to be associated with depolymerization of long hydrocarbon chains that, although the percentage change in mass is negligible, leads to a change in composition and, consequently, to a change in physical properties such as porosity. Only reactions with constant rates and lead to the formation of tars and char, respectively, and are mainly associated with pyrolysis. Gases are formed only from the decomposition of tars (). For simplicity, the reaction rate is limited to the value derived from the Arrhenius equation for first-order irreversible reactions (Equation (16)).

Figure 3.

The multistage mechanism model of biomass pyrolysis.

It is worth noting that the parameters describing gas production in the fourth stage of the pyrolysis (marked with ) are independent of the initial composition. The model requires only determining the pre-exponential constants (A), energies of activation (), and the mass fractions of char () in the product for chemical reactions with hemicellulose, cellulose, and lignin. Example parameters are provided in the papers [49,58,59].

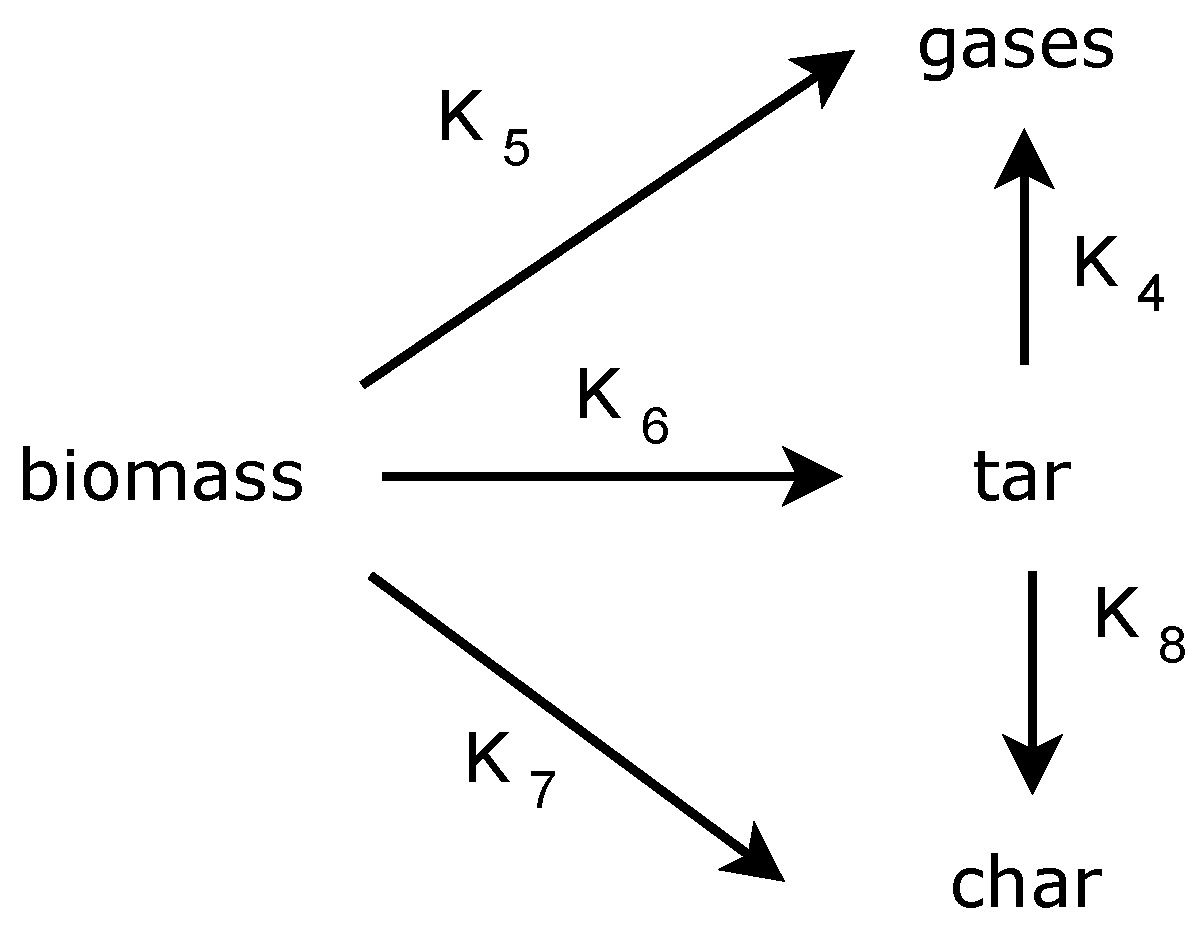

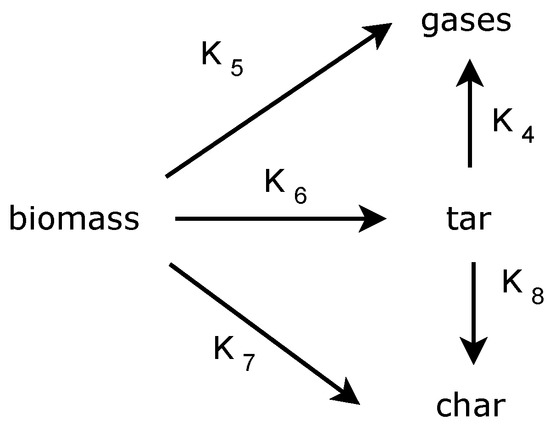

As regards more elaborate models, the most common ones consider biomass to be converted directly to gases, tars, and char and account for the reactions between the products of pyrolysis [9,60], as schematically shown in Figure 4. In the first stage, wood (a homogeneous material) undergoes thermal degradation, including initial chemical reactions (, , and ) to products [9]. In addition, tars can undergo further reactions ( and ), the rates of which depend on the heat and mass flow in the reacting medium. This type of chemical transformation can be associated either with intermolecular long-chain hydrocarbon bonds breaking, yielding light hydrocarbons, or with re-polymerization, yielding char. The reactions arising in the first stage are first-order reactions represented by Arrhenius’ law (Equation (16)). In the second one, only the gas–vapor phase changes inside the pores of a solid take place, and their rate depends on the concentration of tar vapors, among other factors.

Figure 4.

Global one-stage mechanism model of wood pyrolysis involving reactions between pyrolysis products.

3.2. Macro-Particle Approach

Modeling the decomposition of single fuel particles (coal, biomass, and waste) is a difficult task due to the complexity of the issue (the multiphase and multicomponent structures of the substances and products). In the macro-particle approach, a single grain is assumed as a porous zone where two- or even three-phase phenomena take place. The difficulty in determining the proper mathematical model also lies in the definition of boundary conditions while considering the heterogeneous reactions between the produced char and the gaseous components occupying the free space around it. In the thermal conversion of solid fuels, the following basic physical phenomena processes take place [9,49,56,61]:

- chemical reactions occurring both on the surface and inside the fuel grain;

- solid–fluid-type reactions on the particle’s surface and in a particle’s interior;

- homogeneous (volumetric gas–gas-type reactions) on the particle’s surface and in a particle’s neighborhood;

- diffusion of gas and liquid molecules, including diffusion in pores, as well as convection in a grain;

- mass and heat transfer between the particle and its vicinity.

Macro-type modeling is a very difficult and complicated issue as it requires not only knowledge of the kinetic phenomena taking place but also knowledge of the physical and chemical properties of substances and the ability to correctly relate them to the physical model. The main goal of the mathematical modeling of such a complicated task should be focused on an integrated solution based on balance equations and closure equations. The simplest methods take into account static and constant-shape particles, while more complicated ones assume their movement and deformability.

Biomass, like coal, is a porous material. Pore network structure in particles can be identified by their volume, surface area, as well as their distribution. But, the determination of the dependence of grain reactivity on its internal surface is very challenging due to the so-called molecular sieve effect [56]. This stems from the fact that some parts of pores may not be available for reactants due to insufficient dimensions of interpore connections. In general, porosity is defined as the ratio of the pores’ volume accessible to the fluid that can fill those pores to the total considered volume. Thus, for example, as regards the pore network structure of coal, three groups can be distinguished: so-called micropores of size <2 nm, mesopores of size in the range of 2–50 nm, and macropores of size >50 nm. At that, more than 90% of the inner surface is formed by micro- and mesopores, which are reported to account for only 20% to 70% of the total porosity of a grain.

The description of a single particle decomposition depends on the chemical reactions taking place. The ratio of the chemical reaction time to the diffusion time is generally too small for the kinetic models described earlier to be sufficient in this case. The mass diffusion within pores can control the reaction rate by limiting the inflow of ambient gases to the particle’s interior, or by cooling released volatiles flowing out of the grain. The reactions between gases in the vicinity of the particle have an impact on mass and heat transfer. As a rule, the first stage of pyrolysis is endothermic; this involves the decomposition of a solid fuel into tars and gases due to an increase in the internal energy of the whole particle related to its heating. The formation of the carbon-enriched char and the tar secondary reactions involve exothermic reactions [9]. In addition, the grain density may change due to swelling or shrinking [56], and indirectly formed solid or liquid components may further cause a temporary shrinkage of the pores. Moreover, the presence of formed gases within the particles’ pores causes large gradients in the concentration of the components. In view of this, assuming a kinetic mechanism to be the only one controlling the entire process is in this case not justified. Numerous macro-type particle approaches adopt a linear dependence of product properties on the composition of raw material and assume that the gas velocity inside the particle satisfies Darcy’s law [9,61,62,63,64]. The boundary conditions are then determined by diffusion of mass and radiation heat transfer.

In general, during single-particle (biomass/coal) pyrolysis, heating causes a rapid local increase in the temperature of the grain in the direction from the outer surface to the core, initiating the thermal decomposition reactions. As the temperature front moves, a porous carbon-enriched material (char) is formed. The formed gases and tars diffuse through the pores in the opposite direction, i.e., to the outer surface of a particle and its surroundings. Other phenomena accompanying the process include secondary reactions of products flowing through the charcoal, or an increase in pressure inside the grain due to the formation of gases. The overpressure must be high enough to overcome the gas flow resistance associated with the porosity of the heated substance. The volatiles, portions of a solid fuel, are released in the form of a gas mixture of low molar mass when the particle is heated in the absence of oxygen. Heating results in an increase in internal energy and leads to changes in the structure of the base material. The bonds of long hydrocarbon chains are then broken and released as a mixture of lighter ones (methane , hydrogen , carbon dioxide , carbon monoxide , and water vapor ) and slightly heavier gases (phenol , acetic acid , and benzene ).

In [41], the authors showed that not only do the physical parameters of the fuel affect the evaporation, the heating, and the devolatilization times but the convection of the gases inside the particle also plays an important role in each process stage. Considering a simple 1D spherical model accounting for mass, momentum, and energy balance equations for gas, solid, and liquid phases, it was shown that, in the first stage of the particle heating, the released gases are transported toward the core of the particle and only subsequently are evacuated outside. This phenomenon and the fact that gas outflow is opposite to the heat transfer direction extends the whole fuel conversion time.

An additional complex issue is connected to the prediction of a pyrolysis gas composition. Conventional numerical and mathematical methods used to calculate the composition of a gas mixture are based on the kinetics of the chemical reactions. The mechanism of those reactions is usually unknown, which makes the computations more difficult. Solving a nonlinear set of equations that describes complex chemical reactions’ kinetics requires a time-demanding CPU process. An alternative approach is to predict the gas mixture composition in an equilibrium state. The most common method uses the Gibbs free energy minimization procedure. It requires only the material’s initial composition and the process operation parameters as the input data. This simple mathematical approach can be used for determining the pyrolysis gas composition from biogenic fuels depending on the process temperature and pressure [65].

3.3. Kinetics of Decomposition

In the study of pyrolysis kinetics, TGA (themogravimetric analysis) method stands as one of the most prevalent and effective approaches. By subjecting a sample to controlled heating in an inert atmosphere while measuring its weight loss over time, thermogravimetric analysis offers crucial insights into the decomposition behavior of materials. The reaction rate of pyrolysis has been the subject of numerous research studies. Significant number of experiments have been conducted using various thermogravimetric analyzers to determine the kinetic constants for biomass pyrolysis reactions. Based on the results, the two kinetic constants are estimated to describe the function of the reaction rate according to the Arrhenius equation (Equation (16)). Another advantage of the TGA method is that, based on the obtained solid mass loss data, the total gas yield can be obtained [65] without the need for in-depth knowledge of the reaction mechanism.

The resulting curves depicting mass change as a function of temperature are highly dependent on the heating rate and the specific method employed during the process [66,67]. Li et al. [68] suggest that the traditional TGA method cannot replicate the conditions of fast pyrolysis. Even when examining pure wood compounds such as cellulose, it remains challenging to obtain a definitive answer regarding the rate of the pyrolysis reaction [69,70,71]. To draw attention to the differences in magnitude between the values of kinetic constants obtained for biomass, a few experimentally derived values for biomass samples are presented in Table 1.

Table 1.

Kinetic data for reaction of the pyrolysis of biomass.

These values apply to the simplest approach assuming the whole pyrolysis process is a single-step reaction and using only one reaction rate equation with one set of kinetic constants (activation energy and pre-exponential factor A). Such a concept was used by Di Blasi and Branca [74], Van de Velden et al. [76], Wagenaar et al. [75], and Anca-Couce et al. [77], who presented their experimental results based on TGA for variety of biomass types.

More advanced mathematical models consider multiple (usually 2 or 3) first-order reactions of biomass decomposing into tar, char, and gases with individual kinetic constants for each reaction. This method was adopted in numerous research papers [78,79]. For instance, Ratte at al. [80], simulated a low-temperature pyrolysis of 1 cm spherical wooden particle using two first-order reactions of wood decomposing into char and volatiles. The two first-order reaction approach was also successfully used by Thi et al. [81] (wood to char and wood to gas) in their model of wet wood pyrolysis in order to achieve more realistic simulation for wood subjected to fire.

More complex methods for pyrolysis kinetics description are based on the assumption that the process is a two-stage reaction. In other words, after the first-stage reaction, the products decompose into secondary pyrolysis products in the next stage. These methods were used in numerous works [82,83,84,85]. One of them was the work of Zeng et al. [86], who used a two-stage kinetics model considering primary and secondary tar as well as intermediate solid and char for modeling of wooden pellet pyrolysis in concentrated solar radiation. Lanzetta et al. [87] proposed a two-stage reaction with initial, intermediate, and final products, wherein the initial one (raw biomass) decomposed in the first stage into volatiles and intermediate solid product decomposed later into volatiles and final char.

Müller-Hagedorn et al. [88] and Liu et al. [45] used an approach based on the evaluation of kinetic parameters for individual components of wood. A very similar method was used by Yuen et al. [89] for simulations on the pyrolysis of plywood and particle board. Also, Anca-Couce et al. [77] proposed a model of the pyrolysis process using a three-pseudo-component model in which the wood was composed of cellulose, hemicellulose, and lignin. Each of the components had individual kinetics constants set. The authors obtained better fitting results of experimental data when using their three-component approach rather than in the case of a single-component model. Similarly, Koufopanos et al. [58] presented a model based on the chemical composition of biomass, i.e., on its contents of cellulose, hemicellulose, and lignin. Moreover, in this case, the model included two-stage reactions with intermediate and final products, combining the mentioned constituents of wood. Its advantage is that it provides an opportunity to study the behavior of different materials depending on the process conditions.

Another interesting approach was presented by Tinney [90]. The author presented the analysis of thermal decomposition process of wooden dowels. The approach proposed two first-order reactions and assumed that the change in the reaction kinetics is dependent on the degree of decomposition. Comparing the numerical results with experimental data, the author achieved the best agreement between the data for a breakpoint set between and ( and are the bulk densities at time t and , respectively).

There are even more complex models of pyrolysis kinetics, e.g., the one proposed by Richter and Guillermo [91], successfully applied in their latter work [92] on modeling wood pyrolysis during fire. The mentioned approach proposes a combination of 8 reactions in three stages including components like cellulose, lignin, and hemicellulose, as well as char, ash, and volatiles.

It is also possible to take into account the reactions between the various products of pyrolysis [9,60], leading directly to the production of gases, tars, and char. In the first stage, wood (a homogeneous material) undergoes thermal degradation, during which initial chemical reactions occur and gas, tar, and char are produced (one reaction for one product). In addition, tars can undergo two further reactions, producing secondary tar and gas. The rates of this reaction depend on the heat and mass flow in the reacting medium. This type of chemical transformation can be associated either with intermolecular hydrocarbon long-chain bond breaking, yielding light hydrocarbons, or with re-polymerization, yielding char. The reactions arising in the first stage are first-order reactions represented by Arrhenius’ law. The second, on the other hand, occurs only in the gas–vapor phase inside the pores of the solid, and their rate depends on the concentration of tar vapors, among other factors.

3.4. Thermal Effect

The heat of reaction of the decomposition process is a challenging parameter. The measurement of this quantity is technically troublesome due to a combination of endothermic reactions and secondary exothermic reactions occurring between char and released gaseous components. The determination of the thermal effect of the process is significantly uncertain due to the complex structure of the biomass materials and the phase transitions of moisture and tars accompanying the chemical reactions. As a result, there are substantial discrepancies in the literature regarding the values of the heat of pyrolysis [32,93]. According to Kardaś et al. [52], these values range from (indicating an exothermic process) to 750 kJ/kg (indicating an endothermic process). Gomez et al. [94] performed series of experiments on different biomass samples and obtained values ranging from to 222.2 kJ/kg. Other works suggest even higher positive values, up to 2000 kJ/kg [95,96]. Kardaś et al. [52], based on their performed measurements on pine wood sample with heating rate of 20 K/min, obtained a value of 1473 kJ/kg. Values of heat of reaction of wood pyrolysis found in various literature sources are presented in Table 2.

Table 2.

Reported values of heat of wood pyrolysis.

So far, it is known that the process of pyrolysis is endothermic at the beginning of the process. Then, the value of the endotherm is increasing slowly, which is correlated with simply increasing the temperature of the sample, and then peaks at approximately 100–150 °C due to moisture evaporation, which is a highly endothermal process. In some cases, depending on the conditions and state of decomposition, after reaching a certain temperature, exothermic processes might begin to prevail. Reaching the end of pyrolysis, the net energetic effect is again endothermic [100].

The intensity and influence of the mentioned exothermic processes are key reasons for the inconsistencies in the reported values of heat of wood pyrolysis. Roberts [100] analyzed the pyrolysis of wood by studying thermal decomposition of its components: cellulose and lignin. Based on the obtained results, he suggests that the exothermic effects are mostly the result of lignin decomposition. The author states that pyrolysis can be an endothermic process under some specific conditions, such as reduced pressure, which results in easy and fast volatile gas discharge; hence, no secondary reactions occur. In atmospheric pressure conditions, however, primary pyrolysis is exothermic. He observed that, for temperatures over 320 °C, the heat of reaction of primary pyrolysis of wood amounts from to . However, if the temperature does not exceed 320 °C, the heat of reaction will be significantly influenced by the highly exothermic secondary reactions occurring between the volatile gas and primary char. This is because maintaining lower temperature slows down the degradation of wood. The produced volatile gas is trapped inside the wooden structure. The author estimates that the presence of secondary reactions might contribute to additional to the net value of heat of reaction. Considering the order of magnitude of the endothermic values reported in the literature (Table 2), it can be concluded that these highly exothermic secondary reactions can easily shift the energetic effect of the pyrolysis process.

3.5. Complex Thermal and Flow Models

More sophisticated models analyzing the pyrolysis process in two or three dimensions usually include, except for chemical phenomena, the physical processes, such as mass and energy transfer. Despite being more advanced, some of the works address the decomposition process within a single particle, going deeper into the micro-scale phenomena.

A cylindrical sample of sizes from 1 mm to 10 mm was simulated by Kardaś et al. [48]. The calculations were performed using cylindrical coordinates system, one-dimensional, along the radius. Additionally, experimental validation occurred with the use of TGA method based on the results for 5 mm sample. A thorough analysis was conducted on the numerous kinetic constant values reported by other works, and, based on the research, two sets of kinetic constants were chosen and adapted into the simulation, correlated with the function of stage of decomposition.

Two-dimensional (2D) transient model of pyrolysis process of cellulose particles of size above 5 mm was presented by Di Blasi [103]. The author considered heat, mass, and momentum conservation equations for porous media and a multistep (2 steps and 3 reactions) approach for thermal decomposition. The model included conductive, convective, and radiative heat transfer in the particle described as a porous medium with distinct physical properties along and across the grain. The study involved the temperature distribution, gas overpressure distribution, reaction rate contours, and a thorough analysis of heat fluxes within the investigated volume of the particle. Another two-dimensional model of biomass (wooden) particle pyrolysis including moisture content, gaseous phase flow through a porous material, and shrinkage of the solid domain was reported by Hagge [104]. To simulate the volume change in the particle, the author used the unstructured grid development technique. The model includes mass, momentum, and energy conservation equations. Blondeau and Jeanmart [105] developed a 2D model to simulate thermal decomposition of a wooden particle, including shrinking effects and porosity. The authors proposed a multicomponent kinetic approach in order to simulate the pyrolysis process. They combined and slightly modified several kinetic approaches proposed by other research groups in order to obtain the best fitting results, especially in terms of the product yield with various process conditions applied. As a result, their model enables accurate predictions of the gas and tar generation during wood pyrolysis.

A three-dimensional (3D) model of a single wooden particle pyrolysis using CFD modeling in OpenFoam was presented by Wickramaarachchi and Narayana [106]. The two samples were of cylindrical shape, both 9.5 mm in diameter. The small particle was 9.5 mm long, and the large particle was 38 mm. The model included drying process, mass transfer of the gas, and solid phase, and heat transfer with a radiation mechanism incorporated. The kinetic model included three components of wood: cellulose, lignin, and hemicellulose.

A 3D model of a fuel particle in a fluidized bed reactor including the particle shrinkage was proposed by Papadikis et al. [107]. The commercial software was used (Fluent) with incorporated user-defined functions prepared by the authors. Two 0.5 mm particles were injected into the fluidized bed reactor, partially filled with sand. The main focus of the authors was to compare two different shrinking effects. One particle was decreasing its volume proportionally with the devolatilization process, and the second particle had shrinkage parameters equal to approximately half the particle volume (linear volume decrease based on the final yield). The authors concluded that, for such small particles in a fluidized bed reactor, there is no significant difference between the two shrinkage approaches.

Further details regarding the aforementioned models applied for simulating the single-particle thermal decomposition of biomass are provided in Table 3.

Table 3.

Developed complex numerical models of single-particle biomass decomposition.

Pyrolysis is the initial step of the gasification process. Thus, devolatilization followed by oxidation of the pyrolysis products and reduction (solid–gas) reactions are usually involved in the gasification modeling as the particular processes representing its stages. Yadav et al. [108] performed a simulation of steam gasification of a single char particle. The aim of their work was to calculate the production of synthesis gas. Effects of various parameters such as temperature, particle size, and pressure were investigated. Calculations were performed in MATLAB 2010 software, and the Finite Volume Method was adapted. Using the mole balance equations, the authors calculated the concentrations of various species—gasifying agent and product gas. Similar work was presented by Guizani et al. [109], who performed a simulation of the gasification process of a single biomass char particle. They modeled a process conducted in the atmospheres of and and their mixtures. Their model, validated with the use of their own experimental work, included equations describing char’s apparent reactivity towards the gas, and conversion level expressed with the mass of the sample and the ash. Kinetics were expressed with a standard Arrhenius-type reaction. In order to estimate the gas concentration inside the particle, they decided to introduce the Thielle effectiveness factor. The model allowed the authors to analyze the influence of the particle size and the composition of the gasifying agent on the process course process. Dasappa et al. [110] presented an experimental and numerical work on both a wooden single particle and a bed of particles gasification process. The single-particle one-dimensional model consisted of conservation equations for species and energy. Another model that included the energy conservation equation was presented by Fan et al. [111]. Their work focused strongly on the heat transfer within the particle and between the particle and the surrounding gas, as well as the gas flow field around the particle. Ion et al. [112] decided to use commercial CFD software (ANSYS Fluent) to model biomass combustion. Their goal was to present a solution for simulating biomass decomposition for any particle size and shape in either neutral or oxidizing conditions. The simulation procedure can be split into two stages. In the first stage, static modeling was conducted in order to provide the macro functions for a CFD model. There, specific input data were calculated, such as the source terms and local material properties. In the second dynamic modeling stage, the CFD model was connected with the external biomass decomposition model with the use of user-defined functions. The RANS model was used for flow modeling. For turbulence, the STT k- model was used. Chemical reactions were simulated with the EDC model. Furthermore, gasification as one of the processes occurring during combustion often appears as a modeling step in simulations of biomass particle combustion [113].

4. Multi-Particle Modeling

The yield and quality of gas generated through the thermochemical conversion of biogenic fuels depend not only on the type of raw material and oxidizer but also on a number of other parameters, such as the particle size, fuel residence time in a reactor, and heating rate. The process of gasification itself includes three stages: (i) pyrolysis, which covers the moisture and volatiles release; (ii) oxidation of the process products; and (iii) surface reactions between char and the pyrolysis products and/or gasifying agent. The models of pyrolysis in packed beds, incorporating thermal and flow phenomena, therefore become crucial in the context of predicting the performance of gasifiers.

A 1D model for biomass pyrolysis in a fixed-bed reactor was developed by Polesek-Karczewska and Kardaś [39]. The proposed approach includes complex physical and chemical phenomena, such as heat, momentum and mass transfer, moisture evaporation, and convection of pyrolysis gases. The moisture evaporation simulation included the specific structure and the specific surface area of biomass particles. The results of numerical simulations were validated by data obtained from experimental work. Ghabi et al. [114] proposed a 2D model for the simulation of wooden particles’ pyrolysis in a fixed-bed reactor. The authors used mass and energy conservation equations and the momentum equation in the gas phase. Kinetics of pyrolysis were described with two parallel reactions, one for wood and one for primary tar. The model was validated with the use of experimental data first for a single wooden particle and then adapted for the simulation of the whole bed of particles. The paper provides a simulated temperature field of the bed inside the reactor in two dimensions (radial and axial) for different times of reaction. Similar distributions of char mass were presented. The authors prepared an in-depth investigation on the reactive zone (pyrolysis front) and its widening with the time of reaction. Another work using commercial software (also Fluent) for modeling pyrolysis is the research of Xue et al. [115]. The authors simulated a fixed-bed reactor and pyrolysis of two materials: pure cellulose and oak wood. The model included multiphase interactions between the pyrolysed particles and released gasses. Both two- and three-dimensional simulations were conducted, showing no significant differences in the results. The simulations and experimental validations were performed with respect to the product yields—solid (char), liquid (bio-oil), and gaseous products, and showed better agreement in the case of cellulose than in the case of oak wood.

More details on the referenced models used to simulate thermal decomposition of biomass in fixed bed are summarized in Table 4.

Table 4.

Developed complex numerical models of multi-particle biomass thermal treatment.

It appears that obtaining a univariate mathematical model is challenging. There are an extensive variety of gasifiers that can be utilized for biomass gasification that have some contrast in operating condition and design [116]. Fixed bed, fluidized bed, plasma gasification, rotary kiln, and entrained flow bed are the five most typical types of gasifiers. The most basic gasifier technology used by a slow-moving system is a fixed-bed gasifier. It uses oxidizing chemicals and maintains a high pressure for a residence time duration of 900–1800 s [117]. Updraft and downdraft reactors are two types of fixed-bed gasifiers that differ in their reactor configuration. In both types, the biomass feeding location is at the top and ash is discharged at the bottom. Synthesis gas is distributed at the lower level of the fuel bed in downdraft gasifiers, while in updraft gasifiers it flows upwards from the reactor and is distributed at the upper level of the bed. When employed with various waste types, fixed-bed reactors have a high conversion rate and negligible ash production. However, they require a certain kind of feedstock with a low moisture content, which is a problem for most feedstocks [118,119]. In fluidized bed procedures, feedstocks are delivered into the reactor, and then air and more sand are injected to initiate the reaction at an operating temperature of roughly 800–900 °C. In order to decompose different types of biomass quickly and maintain a constant temperature inside the reactor, fluidized bed reactors are used in biomass gasification. They can also be upgraded to become large-scale power plants [120].

A new technology called plasma gasification converts municipal solid waste (MSW) into synthesis gas and slag by heating electrically ionized gas to temperatures of up to 10,000 °C in plasma torches with pressures ranging from 1 to 30 bar [121]. In particular, for waste incineration, rotary kiln reactors are frequently utilized in industry [122]. Commercially, integrated gasification cycle (IGCC) plants and the chemical industry use entrained flow bed gasifiers [123].

Among all the gasifiers, fixed-bed biomass gasifier is the most preferred configuration for modest to medium amounts of heat and power production [124]. Especially, research and development are quite interested in downdraft gasifiers because they are easy to assemble and operate. In fact, downdraft gasifiers accounted for 75% of the gasifiers produced in Europe [125]. Moreover, the syngas produced in the downdraft gasifier has a low tar content, so it is suitable for use in gas turbines and engines with less effort in gas purification as compared to updraft gasification. Nevertheless, it usually requires drying of the feed and is not appropriate for biomass with high moisture content; in addition, channelling and blocking of the grate are other disadvantages [126].

Both experimental and computer simulation data are used in the construction of gasifiers. Key operating variables that significantly affect the gasification process are the flow rate of the feedstock and gasifying agent, the equivalence ratio, the process pressure, and temperature. The performance of the gasifier and the gas composition are significantly impacted by any alteration to any of the parameters. Different feedstocks have a range of compositions and thermochemical properties. The ideal conditions for a particular reactor type with a particular feedstock must therefore be determined through time- and money-consuming experimentation. In these conditions, computer analysis has shown to be an effective tool for understanding the behavior of gasifiers and optimizing their design and operation without the need for actual trials [127,128]. Many researchers have examined the detailed computer modeling of the gasification process within fixed-bed gasifiers [129].

The following categories can be used to organize gasifier simulation models [51]:

- Thermodynamic equilibrium;

- Kinetics of the processes;

- CFDs and coupled models;

- Machine learning methods.

4.1. Thermodynamic Equilibrium

The greatest yield of a desired product from a reacting system that can be achieved is predicted by the thermodynamic equilibrium model. In other words, the reactants will approach equilibrium yield if they are allowed to react indefinitely. The equilibrium model, which only considers the reaction and ignores the gasifier’s shape, provides the yield and composition of the product under these conditions [130]. The gas composition that emerges from the equilibrium calculations frequently does not match the actual chemical composition at the gasifier’s exit [130,131].

Numerous researchers have discovered a strong correlation between modeling and theoretical predictions based on equilibrium modeling. For instance, Pradhan et al. [132] used varied equilibrium reaction rates to test five different biomass gasification models. When compared to other models, they discovered that the model that incorporated basic methanation and the water–gas shift reaction produced syngas with the best composition. Melgar et al. [133] presented a numerical method to calculate gasification in a downdraft biomass gasifier. This model was easy to use and predicted the effects of the air/fuel ratios and moisture levels on the composition of production gases. However, the model overestimated the amount of generated, as well as the heating value of the and outputs. Tavares et al. [134] performed a sensitivity analysis of downdraft gasification of forest debris using the Aspen Plus process simulation. The effects of key variables, such as the steam-to-biomass ratio and gasification process temperature, on the composition of the produced gas were investigated. The simulation results demonstrate that utilizing steam as a gasifying agent enhances the amount of and thereby the calorific value of the gas produced when compared to using air as a gasifier agent. The stoichiometric equilibrium model created by Aydin et al. [135] accounts for equivalence ratios as well as the pitch and char yields produced by downdraft gasifiers for various types of timber biofuels. For correcting the equilibrium constants of methanation and the water–gas shift reaction, they developed two correction factors. Gambarotta et al. [136] created another non-stoichiometric equilibrium strategy that included unreacted carbon. In this model, equilibrium is created by minimizing Gibbs free energy, which ignores the formation of tar.

4.2. Process Kinetics

Kinetic models are more precise and representative of the actual events since they are based on the chemical kinetics of the heterogeneous char–gas reactions. They enable more accurate simulation of the conversion by describing the thermochemical processes using experimentally discovered kinetic rate correlations. However, as char gasification is a process governed by both chemical reactions and internal and external mass and heat transfer processes, kinetic models must include thorough transport phenomena. In fact, the connection between the transport and chemical pathways during gasification is crucial for understanding the process [129].

Equilibrium models cannot examine a variety of aspects, whereas kinetic models can. Different operational factors (density, feedstock flow rate, particle size, temperature, pressure, and gasifier height) and reaction kinetics comprise the framework for establishing a kinetic model. An approach developed by Wang and Kinoshita [137] considered elements like retention period, reaction temperature, pressure, moisture content, char particle size, and equivalence ratio. In order to predict results that were in line with experimental data, Babu and Sheth [138] further modified these reaction rates using a variable char reactivity factor. The downdraft gasifier model, developed by Gao and Li [139], combined the pyrolysis and reduction region to predict the temperature and producer gas concentration field patterns over time and space. There are two techniques to change the temperature of the pyrolysis zone: one uses a constant temperature of 1400 K to heat the pyrolysis zone, and the other uses a gas heating rate of 25 K/min. The simulation results for temperature and gaseous species concentrations are fairly close to the published experimental data. Sharma [140] suggested a kinetic model with unique submodels for each location. However, the thermochemical conversion of biomass into combustible materials would increase with further improvement in the reaction temperature for such a range of flow rates, increasing the gasifier’s energy efficiency and power production.

4.3. Advanced CFD-Assisted Models

4.3.1. Computational Fluid Dynamics

A set of simultaneous equations for the conservation of mass, momentum, energy, and species over a discrete region of the gasifier are solved by CFD models (Euler type). They provide distributions of temperature, concentration, and other characteristics as a result. A CFD model can estimate temperature and gas yield in the reactor with a high degree of accuracy if the reactor’s hydrodynamics are well understood [51].

CFD models were used in several studies to forecast gasifier behavior. Typically, a CFD code for gasification includes a collection of submodels for the series of processes, such as the vaporization of a biomass particle, its pyrolysis (devolatilization), the secondary reaction in pyrolysis, and char oxidation [141]. Additionally, more complex features, including a subroutine for feedstock fragmentation throughout gasification and combustion, are added [142]. Turbulent mixing can be modeled using a variety of equations, including Direct Numerical Simulation (DNS), Large-eddy Simulation (LES), and Reynolds-averaged Navier–Stokes (RANS) [143]. Two-fluid or discrete particle models are used to simulate the phase flow to predict the flow characteristics of the gas and solid phases in the bed and freeboard, which are difficult to quantify experimentally [144]. Comprehensive CFD simulations for biomass gasification are rare due to a lack of powerful computational resources and the anisotropic structure of biomass [124]. However, other researchers have created a number of more straightforward CFD models to replicate gasification behavior [145,146].

Jahromi et al. [147] utilized a novel Euler–Euler multiphase approach, integrating exchange terms for mass, momentum, energy, and species to distinguish the gas (primary flow) and solid (secondary flow) phases within a downdraft fixed-bed gasifier. Salem et al. [148] presented a pioneering study investigating tar species (benzene, naphthalene, toluene, and phenol) evolution in a downdraft biomass gasifier via a 20-reaction model incorporating residence time. In a different research effort, the discrete phase model (DPM) employing the Euler–Lagrangian approach and species transport was employed in the context of a downdraft gasifier. The utilization of DPM results in an improved representation of gasification phenomena by enhancing particle-continuous phase interactions [149]. Another study highlights the significance of multistage model advancements in accounting for distinct chemical processes in consecutive pyrolysis and partial oxidation units [150]. This research contributes to the field by creating and evaluating a three-stage biomass gasifier model. This model integrates separate submodels for the drying and pyrolysis stages, as well as for partial oxidation and char reduction.

A detailed overview in Table 5 can be consulted to obtain insight into different types of gasifiers, software used, feedstock, processes taken into consideration, kinetic modeling methodologies, and publishing years (2022–2024) in order to investigate recent developments in gasification CFD modeling.

Table 5.

Recent advances in gasification CFD modeling: a comprehensive overview.

Following the discussion of the CFD modeling in various software platforms, Table 6 presents an in-depth examination of recent advancements in mathematical models for gasification and combustion in packed beds, focusing on in-house models. These models encompass various processes, such as drying, pyrolysis, gasification, reduction, and oxidation, along with their governing equations, targets, and considerations.

Table 6.

Overview of gasification/combustion mathematical models in packed beds—in-house models.

4.3.2. Coupled Computations

The methods based on coupled CFD–DEM computations enable predicting the particles’ motion in the fluid. The most common commercial code, Ansys Fluent, provides two types of Eulerian–Lagrangian approaches. One is the DPM (Discrete Particle Method) [166] based on a hard-sphere assumption where only the binary collisions with no particle overlap are considered. Such simplification is valid in dilute systems of particles. The second one is DEM, which includes the so-called soft-particle type of modeling where multiple collisions and particle overlapping may occur [167]. Such situations take place in dense granular media. The prediction of the particle position in the fluid flow can be managed by the ROCKY [168] module, which is provided by ANSYS. It solves the particle motion equation using the DEM method. The CFD solver (Fluent) and DEM module are running on two separate nodes. After the CFD and DEM are initialized, the CFD solver transfers physical fluid properties data to the DEM, which tracks the positions of the particles based on the flow parameters. Next, from DEM, the position data and particle–fluid interaction forces are sent to the CFD solver, and the solid-phase information is updated. Coupling CFD with DEM by the ROCKY module does not use heat transfer between the phases, so only the cold flow can be analyzed.

Different shapes of particles were considered during the simulation of movement by Ma et al. [169]. The authors studied the distribution of real-shape particles in a blast furnace. They used the in-house code with the DEM approach for different particle-shape models: multi-sphere, polyhedral, and super-ellipsoid. The numerical computations compared with the experiments with non-spherical quartz sand particles in a lab-scale blast furnace were performed. Authors showed that using advanced-shape models provides reasonable accuracy and efficiency but necessitates higher computational power costs.

Coupled cold CFD–DEM simulations can be a good tool for designing and optimizing geometry in order to improve the thermal efficiency of devices, as demonstrated by Li et al. [170]. Similar study was performed by Gao et al. [171], who focused on the size characteristics and mechanical properties of the industrial-scale blast furnace raceway. The mentioned authors considered the spherical particles (in diameter of from 10 to 150 mm) without thermal conditions.

Spherical particles undergoing chemical reactions were considered by Wang et al. [172]. The authors used CFD–DEM modeling for the prediction of the pyrolysis process of different types of dry solid fuels in a fixed-bed reactor. For this purpose, the open source code called MFix [173] was adopted. The particles with initial average diameters of 10 mm lose mass during heating (the final diameter even decreases twice depending on the type of material), but, in this computation, the radiative heat transfer was not considered.

Rosser et al. [174] used STAR-CCM+ software for CFD–DEM to study the impact of ore pellet moisture, heating, and ice formation between pellets on the jamming event in a hopper above the furnace. This work is not connected to the combustion processes, but the authors were using an additional energy equation for the solid particle to calculate the particle temperature changes due to external conditions.

The method coupling CFDs with DEM in a two-way approach called XDEM (eXtended Discrete Element Method) was developed by Peters et al. [175]. This is an in-house code for predicting the behavior of solid fuel particles during thermal treatment. This software is based on the mixed Lagrangian–Eulerian approach to predict the movement of granular materials in an external fluid field. CFDs, in the frame of OpenFOAM source [176], combined with DEM enables predicting the positions of moving solid fuel particles in the flow field, and the module of extended classic DEM (XDEM) additionally enables obtaining information about their thermal conversion with the change in structure that occurs. The main assumption made in this approach is that each particle, due to the heat transfer from the hot surrounding gas, undergoes various thermodynamic transformations. These are described by a set of transient 1D balance equations for mass, momentum, and energy, which are solved in the XDEM module [177,178]. Each particle can consist of liquid, solid, and gas phases. Additionally, a multicomponent gas mixture can be transported by diffusion and convection inside the particle through the gas-occupied pore network. To simplify the model and reduce the required computation time, all gaseous species are treated as ideal gases. Moreover, the particles are assumed to be an isotropic material, in which the properties may change only along the radial direction. At the same time, assuming local thermal equilibrium between phases inside the particle is an additional simplification of the model. In such a multi-grain system, heat transfer may occur between neighboring particles by conduction and radiation. Heat and mass exchange between fluid and particles are computed through boundary conditions at the particle–fluid interphase. Chemical reactions are modeled as equilibrium reactions for the available species; thereby, a gas mixture composition inside the particle can also be obtained.

The prediction of fluid flow is analyzed based on the Eulerian approach, which treats fluid as a continuum phase. The computational domain filled with particles is considered a porous media with the fluid flowing through. The motion of fluid inside the free space is described by 3D Navier–Stokes and energy equations for incompressible flow. Additionally, the Brinkmann or Forchheimer relations are used to determine the pressure drop in a porous medium. Heat and mass flow between particle and fluid is numerically realized through the source terms that combine the DEM with the CFD modules.

XDEM module can predict both the dynamics and the thermodynamic parameters of each particle in the discrete element system. Motion parameters such as position, velocity, and acceleration are calculated via the dynamics module of the XDEM, while other thermochemical ones like particle composition, temperature, mass, and volume are calculated using its conversion module [179].

4.3.3. Basic Equations in the Dynamic Module of XDEM

The dynamics module uses classical DEM and is based on the soft sphere model. In that kind of approach, it is assumed that particles are deformable and can overlap each other. The overlap is computed by determining the contact force using the force–displacement law. Particle hardness is expressed via Young’s modulus for a variety of materials. The translational and rotational movements of individual particles are predicted based on the classical mechanics equations. For the transitional motion of a particle, the following equation is used: