Comparative Analysis of Cement Production Methods Using a Life Cycle Assessment and a Multicriteria Decision-Making Approach

Abstract

:1. Introduction

2. Literature Review

3. Methodology

3.1. Integrating MCDM into LCA for Cement Production Assessment

3.2. LCA Assessment

3.3. Goal and Scope Definition

3.4. Life Cycle Inventory Analysis

3.5. Life Cycle Impact Assessment

3.6. Interpretation

3.7. Multi-Criteria Decision-Making Approach

3.8. Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) Method

- Normalization of Decision Matrix: A decision matrix is created by transforming the initial decision matrix into a normalized version. All the matrix’s elements are divided in this process by the square root of the sum of the squares of the relevant column.

- Weighted Normalized Decision Matrix: By multiplying the normalized decision matrix R by the weight vector , the weighted normalized decision matrix is generated.

- Determine the Positive-Ideal and Negative-Ideal Solutions: For each criterion, identify the maximum and minimum values across all alternatives.

- Distance Calculation: Calculate the Euclidean distance from each alternative to the ideal positive solution and to the negative ideal solution.

- Calculate the Relative Closeness to the Ideal Solution: Determine the relative closeness of each alternative to the ideal solution.

- Ranking: The options should be ranked according to their respective similarity scores. The alternative that achieves the highest similarity score is assigned the highest rank, signifying its status as the most favored answer.

3.9. Evaluation Based on Distance from Average Solution (EDAS)

4. Results and Discussion

4.1. Results

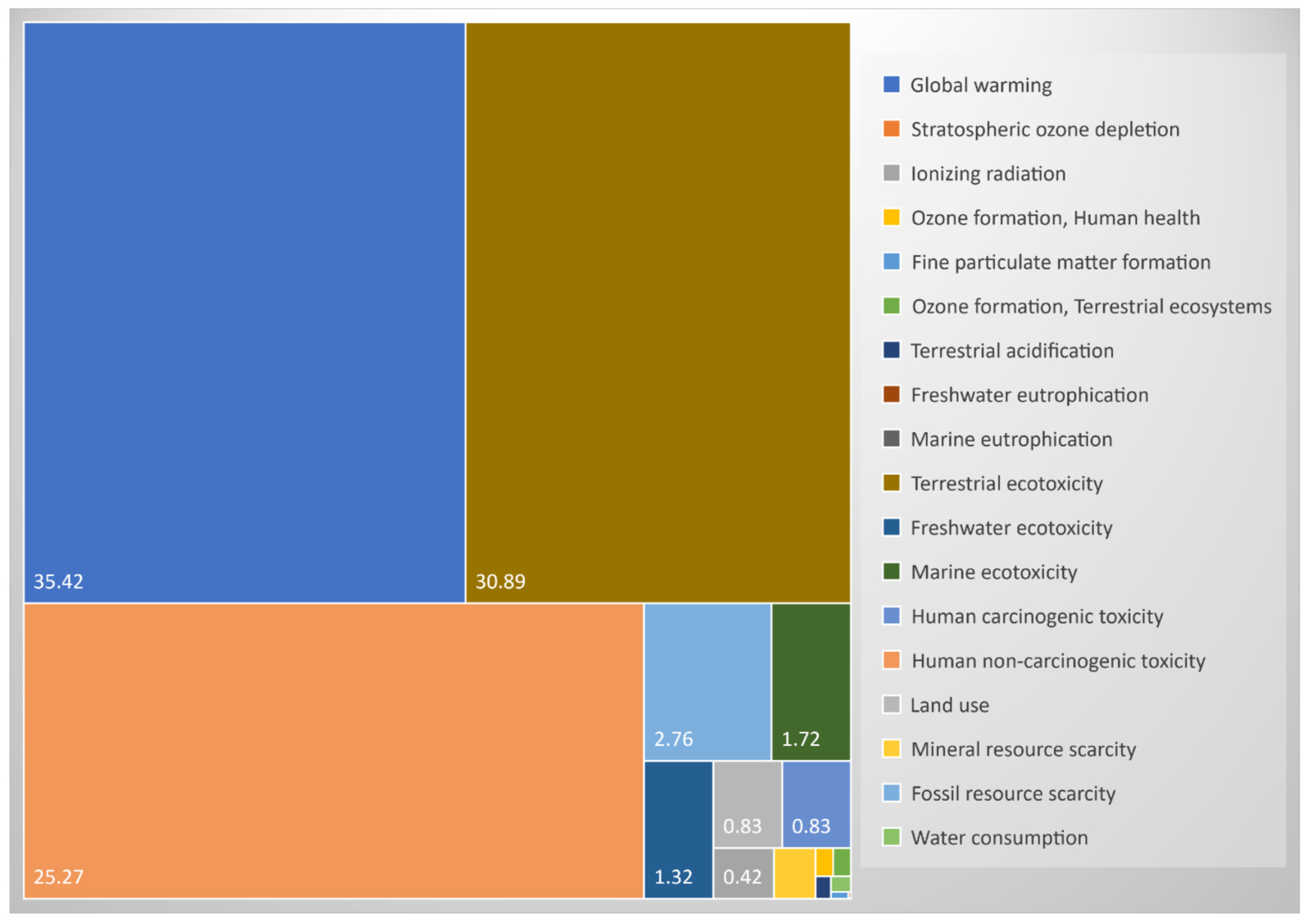

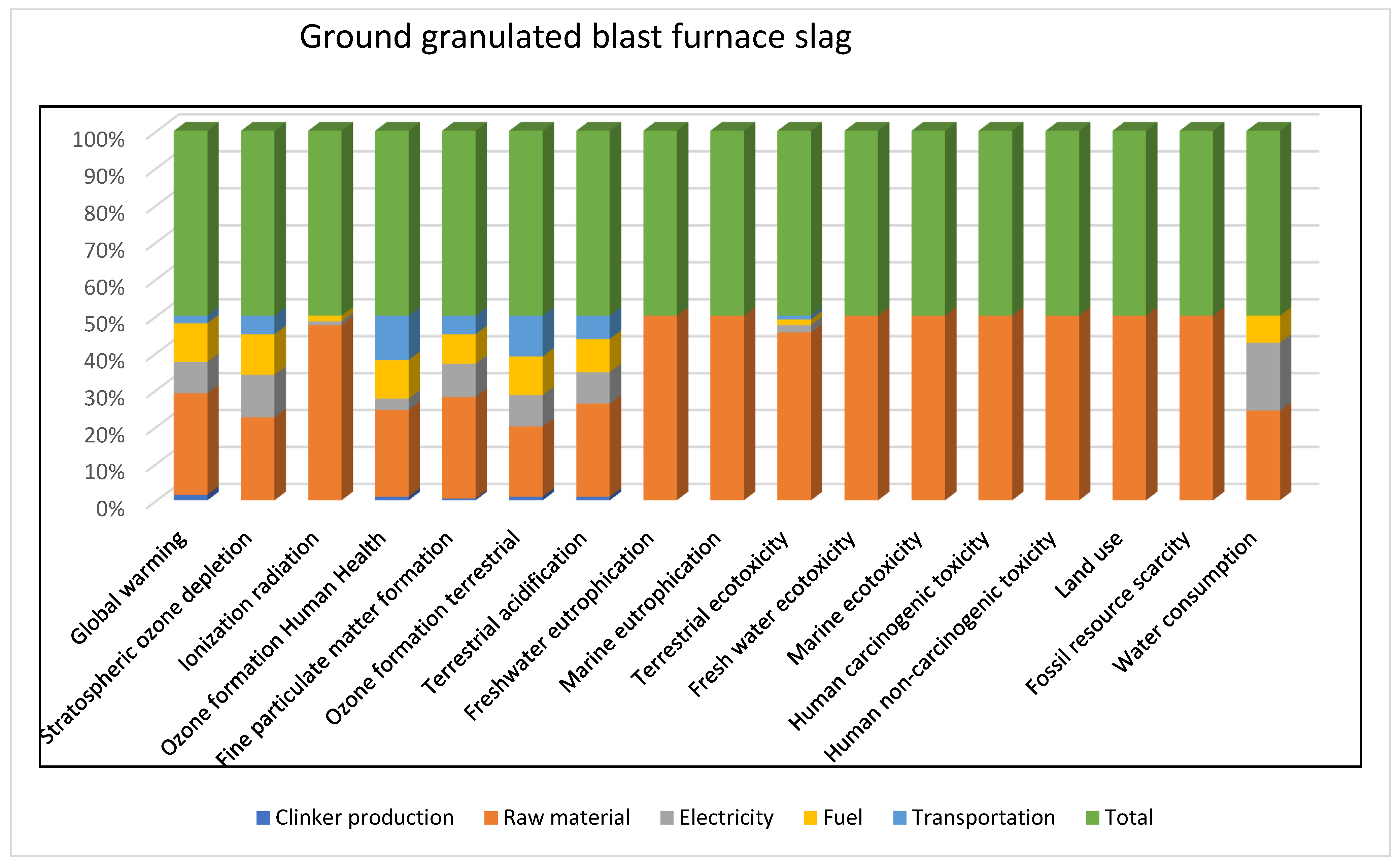

4.1.1. LCA Results

4.1.2. Weight of Criteria

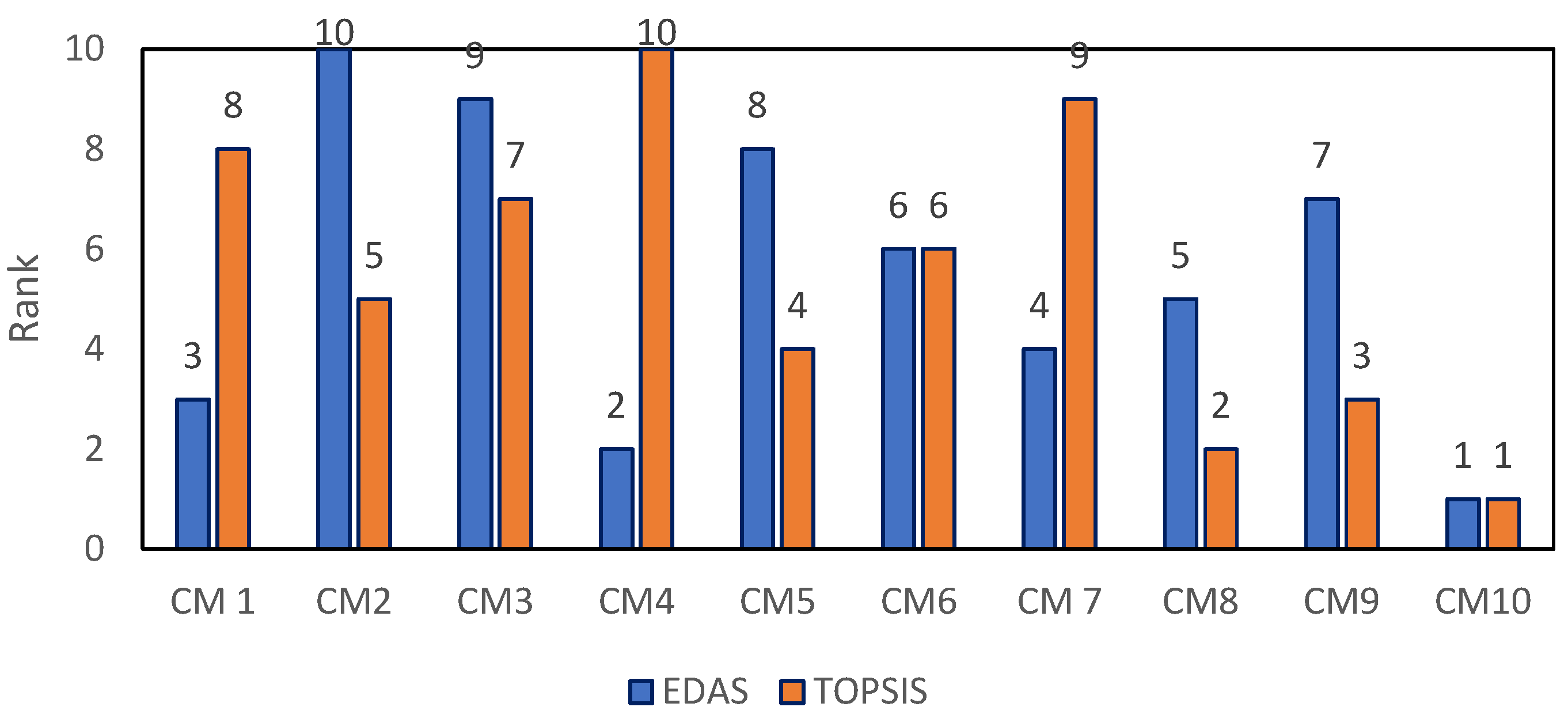

4.1.3. MCDM Results

4.1.4. Midpoint Characterization Results

4.2. Discussion

Interconnection with Sustainable Development Goals

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sev, A. How can the construction industry contribute to sustainable development? A conceptual framework. Sustain. Dev. 2009, 17, 161–173. [Google Scholar] [CrossRef]

- Ayodele, A.; Ayoninuoluwa, O.; Binuyo, B.; Olanrewaju, G.O.R. Impact of globalisation on the industrial growth in Nigeria (1981–2014): Implication to psychologist and economist. Eur. J. Bus. Econ. Account. 2017, 5, 52–60. [Google Scholar]

- Shahidehpour, M.; Li, Z.; Ganji, M. Smart cities for a sustainable urbanization: Illuminating the need for establishing smart urban infrastructures. IEEE Electrif. Mag. 2018, 6, 16–33. [Google Scholar] [CrossRef]

- Bribián, I.Z.; Capilla, A.V.; Usón, A.A. Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Build. Environ. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Bodo, T.; Gimah, B.G.; Seomoni, K.J. Deforestation and habitat loss: Human causes, consequences and possible solutions. J. Geogr. Res. 2021, 4, 22–30. [Google Scholar] [CrossRef]

- Vezzoli, C.; Manzini, E. Design for Environmental Sustainability; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Yildirim, A.E.; Yildirim, M.O. Revisiting the determinants of carbon emissions for Turkey: The role of construction sector. Environ. Sci. Pollut. Res. 2021, 28, 42325–42338. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L.; Lin, E. Emerging energy-efficiency and CO2 emission-reduction technologies for cement and concrete production: A technical review. Renew. Sustain. Energy Rev. 2012, 16, 6220–6238. [Google Scholar] [CrossRef]

- Sanal, I. Significance of concrete production in terms of carbondioxide emissions: Social and environmental impacts. Politek. Derg. 2018, 21, 369–378. [Google Scholar]

- Tetteh, E.K.; Amankwa, M.O.; Yeboah, C. Emerging carbon abatement technologies to mitigate energy-carbon footprint-a review. Clean. Mater. 2021, 2, 100020. [Google Scholar] [CrossRef]

- Akadiri, P.O.; Chinyio, E.A.; Olomolaiye, P.O. Design of a sustainable building: A conceptual framework for implementing sustainability in the building sector. Buildings 2012, 2, 126–152. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J.; Hu, F.; Wang, Y. Comparison of evaluation standards for green building in China, Britain, United States. Renew. Sustain. Energy Rev. 2017, 68, 262–271. [Google Scholar] [CrossRef]

- Omer, A.M. Energy, environment and sustainable development. Renew. Sustain. Energy Rev. 2008, 12, 2265–2300. [Google Scholar] [CrossRef]

- Bungau, C.C.; Bungau, T.; Prada, I.F.; Prada, M.F. Green Buildings as a Necessity for Sustainable Environment Development: Dilemmas and Challenges. Sustainability 2022, 14, 13121. [Google Scholar] [CrossRef]

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Bosoaga, A.; Masek, O.; Oakey, J.E. CO2 capture technologies for cement industry. Energy Procedia 2009, 1, 133–140. [Google Scholar] [CrossRef]

- Kajaste, R.; Hurme, M. Cement industry greenhouse gas emissions–management options and abatement cost. J. Clean. Prod. 2016, 112, 4041–4052. [Google Scholar] [CrossRef]

- Mohamad, N.; Muthusamy, K.; Embong, R.; Kusbiantoro, A.; Hashim, M.H. Environmental impact of cement production and Solutions: A review. Mater. Today Proc. 2022, 48, 741–746. [Google Scholar] [CrossRef]

- Nassani, A.A.; Aldakhil, A.M.; Zaman, K. Ecological footprints jeopardy for mineral resource extraction: Efficient use of energy, financial development and insurance services to conserve natural resources. Resour. Policy 2021, 74, 102271. [Google Scholar] [CrossRef]

- Madlool, N.A.; Saidur, R.; Hossain, M.S.; Rahim, N.A. A critical review on energy use and savings in the cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2042–2060. [Google Scholar] [CrossRef]

- Panesar, D.K.; Zhang, R. Performance comparison of cement replacing materials in concrete: Limestone fillers and supplementary cementing materials—A review. Constr. Build. Mater. 2020, 251, 118866. [Google Scholar] [CrossRef]

- da Cruz, T.T.; Balestieri, J.A.P.; de Toledo Silva, J.M.; Vilanova, M.R.N.; Oliveira, O.J.; Ávila, I. Life cycle assessment of carbon capture and storage/utilization: From current state to future research directions and opportunities. Int. J. Greenh. Gas Control 2021, 108, 103309. [Google Scholar] [CrossRef]

- Tun, T.Z.; Bonnet, S.; Gheewala, S.H. Life cycle assessment of Portland cement production in Myanmar. Int. J. Life Cycle Assess. 2020, 25, 2106–2121. [Google Scholar] [CrossRef]

- Vizcaino-Andrés, L.M.; Sánchez-Berriel, S.; Damas-Carrera, S.; Pérez-Hernández, A.; Scrivener, K.L.; Martirena-Hernández, J.F. Industrial trial to produce a low clinker, low carbon cement. Mater. Constr. 2015, 65, e045. [Google Scholar]

- Cao, Z.; Myers, R.J.; Lupton, R.C.; Duan, H.; Sacchi, R.; Zhou, N.; Miller, T.R.; Cullen, J.M.; Ge, Q. The sponge effect and carbon emission mitigation potentials of the global cement cycle. Nat. Commun. 2020, 11, 3777. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.-N.; Liu, X.-Y.; Hu, Z.; Zhang, R.; Lu, X.-Y. Improving the sustainability of cement clinker calcination process by assessing the heat loss through kiln shell and its influencing factors: A case study in China. J. Clean. Prod. 2019, 224, 132–141. [Google Scholar] [CrossRef]

- Biernacki, J.J.; Bullard, J.W.; Sant, G.; Banthia, N.; Brown, K.; Glasser, F.P.; Jones, S.; Ley, T.; Livingston, R.; Nicoleau, L.; et al. Cements in the 21st century: Challenges, perspectives, and opportunities. J. Am. Ceram. Soc. 2017, 100, 2746–2773. [Google Scholar] [CrossRef] [PubMed]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Krishnan, S.; Emmanuel, A.; Shah, V.; Parashar, A. Industrial production of limestone calcined clay cement: Experience and insights. Green Mater. 2018, 7, 15–27. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production, 1928–2018. Earth Syst. Sci. Data 2019, 11, 1675–1710. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterization, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Amran, M.; Makul, N.; Fediuk, R.; Lee, Y.H.; Vatin, N.I.; Lee, Y.Y.; Mohammed, K. Global carbon recoverability experiences from the cement industry. Case Stud. Constr. Mater. 2022, 17, e01439. [Google Scholar] [CrossRef]

- Walling, S.A.; Provis, J.L. Magnesia-based cements: A journey of 150 years, and cements for the future? Chem. Rev. 2016, 116, 4170–4204. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.; Su, R.K.L. A review on durability of foam concrete. Buildings 2023, 13, 1880. [Google Scholar] [CrossRef]

- Sereewatthanawut, I.; Prasittisopin, L. Effects of accelerating and retarding agents on nucleation and crystal growth of calcium aluminate cement. Open Ceram. 2022, 11, 100290. [Google Scholar] [CrossRef]

- Environment, U.N.; Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar]

- Diaz-Loya, I.; Juenger, M.; Seraj, S.; Minkara, R. Extending supplementary cementitious material resources: Reclaimed and remediated fly ash and natural pozzolans. Cem. Concr. Compos. 2019, 101, 44–51. [Google Scholar] [CrossRef]

- Radwan, M.K.H.; Onn, C.C.; Mo, K.H.; Yap, S.P.; Chin, R.J.; Lai, S.H. Sustainable ternary cement blends with high-volume ground granulated blast furnace slag—Fly ash. Environ. Dev. Sustain. 2021, 24, 4751–4785. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Siddique, R. Recent advances in understanding the role of supplementary cementitious materials in concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Vijayan, D.S.; Devarajan, P.; Sivasuriyan, A. A review on eminent application and performance of nano based silica and silica fume in the cement concrete. Sustain. Energy Technol. Assess. 2023, 56, 103105. [Google Scholar] [CrossRef]

- Dixon, N.; Fowmes, G.; Frost, M. Global challenges, geosynthetic solutions and counting carbon. Geosynth. Int. 2017, 24, 451–464. [Google Scholar] [CrossRef]

- Bayraktar, O.Y. The possibility of fly ash and blast furnace slag disposal by using these environmental wastes as substitutes in portland cement. Environ. Monit. Assess. 2019, 191, 560. [Google Scholar] [CrossRef] [PubMed]

- Gholampour, A.; Ozbakkaloglu, T. Performance of sustainable concretes containing very high volume Class-F fly ash and ground granulated blast furnace slag. J. Clean. Prod. 2017, 162, 1407–1417. [Google Scholar] [CrossRef]

- Olagunju, B.D.; Olanrewaju, O.A. Comparative Analysis of Different Fly Ash Percentage of Pozzolanic Cement. In Proceedings of the 5th NA International Conference on Industrial Engineering and Operations Management, Detroit, MI, USA, 10–14 August 2020. [Google Scholar]

- Gartner, E.; Sui, T. Alternative cement clinkers. Cem. Concr. Res. 2018, 114, 27–39. [Google Scholar] [CrossRef]

- Yoris-Nobile, A.I.; Slebi-Acevedo, C.J.; Lizasoain-Arteaga, E.; Indacoechea-Vega, I.; Blanco-Fernandez, E.; Castro-Fresno, D.; Alonso-Estebanez, A.; Alonso-Cañon, S.; Real-Gutierrez, C.; Boukhelf, F.; et al. Artificial reefs built by 3D printing: Systematisation in the design, material selection and fabrication. Constr. Build. Mater. 2023, 362, 129766. [Google Scholar] [CrossRef]

- Ige, O.E.; Olanrewaju, O.A.; Duffy, K.J.; Obiora, C. A review of the effectiveness of Life Cycle Assessment for gauging environmental impacts from cement production. J. Clean. Prod. 2021, 324, 129213. [Google Scholar] [CrossRef]

- AUTODESK. Energy Settings|Revit Products 2020|Autodesk Knowledge Network. Energy Settings; AUTODESK: San Francisco, CA, USA, 2020. [Google Scholar]

- Bonissone, P.P.; Subbu, R.; Lizzi, J. Multicriteria decision making (MCDM): A framework for research and applications. IEEE Comput. Intell. Mag. 2009, 4, 48–61. [Google Scholar] [CrossRef]

- Castro-Nuño, M.; Arévalo-Quijada, M.T. Assessing urban road safety through multidimensional indexes: Application of multicriteria decision making analysis to rank the Spanish provinces. Transp. Policy 2018, 68, 118–129. [Google Scholar] [CrossRef]

- Yang, J.; Ogunkah, I.C.B. A multi-criteria decision support system for the selection of low-cost green building materials and components. J. Build. Constr. Plan. Res. 2013, 1, 89. [Google Scholar] [CrossRef]

- Ahmed, M.; Mallick, J.; AlQadhi, S.; Kahla, N.B. Development of concrete mixture design process using MCDM approach for sustainable concrete quality management. Sustainability 2020, 12, 8110. [Google Scholar] [CrossRef]

- Gökcekucs, H.; Ghaboun, N.; Ozsahin, D.U.; Uzun, B. Evaluation of Cement Manufacturing Methods Using Multi Criteria Decision Analysis (MCDA). In Proceedings of the 2021 14th International Conference on Developments in eSystems Engineering (DeSE), Sharjah, United Arab Emirates, 7–10 December 2021; pp. 39–43. [Google Scholar]

- Marinelli, M.; Janardhanan, M. Green cement production in India: Prioritization and alleviation of barriers using the best—worst method. Environ. Sci. Pollut. Res. 2022, 29, 63988–64003. [Google Scholar] [CrossRef]

- Bathrinath, S.; Nagesh, S.M.; Dinesh, V.; Ganesh, M.S.R.; Koppiahraj, K.; Bhalaji, R.K.A. Analysing the Primary Influential Factors in Cement Manufacturing Industry Using DEMATEL Methodology. In Materials, Design and Manufacturing for Sustainable Environment: Select Proceedings of ICMDMSE 2022; Springer: Berlin/Heidelberg, Germany, 2022; pp. 489–498. [Google Scholar]

- Akintayo, B.D.; Ige, O.E.; Babatunde, O.M.; Olanrewaju, O.A. Evaluation and Prioritization of Power-Generating Systems Using a Life Cycle Assessment and a Multicriteria Decision-Making Approach. Energies 2023, 16, 6722. [Google Scholar] [CrossRef]

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S.I. Life Cycle Assessment; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Babatunde, S.; Ighravwe, D. A fuzzy multi-criteria approach for hosting-right selection: A case study of sport event. Int. J. Data Netw. Sci. 2019, 3, 1–12. [Google Scholar] [CrossRef]

- Jacquemin, L.; Pontalier, P.-Y.; Sablayrolles, C. Life cycle assessment (LCA) applied to the process industry: A review. Int. J. Life Cycle Assess. 2012, 17, 1028–1041. [Google Scholar] [CrossRef]

- Moretti, C.; Hamelin, L.; Jakobsen, L.G.; Junginger, M.H.; Steingrimsdottir, M.M.; Høibye, L.; Shen, L. Cradle-to-grave life cycle assessment of single-use cups made from PLA, PP and PET. Resour. Conserv. Recycl. 2021, 169, 105508. [Google Scholar] [CrossRef]

- Olagunju, B.D.; Olanrewaju, O.A.; Irusta-Mata, R. A Comparative Life Cycle Assessment Study of Conventional and Best Available Techniques Incorporated Cement Production Processes using midpoint approach. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Monterrey, Mexico, 3–5 November 2021. [Google Scholar]

- Singh, A.; Malik, S.K. Major MCDM Techniques and their application—A Review. IOSR J. Eng. 2014, 4, 15–25. [Google Scholar] [CrossRef]

- Chakraborty, S.; Chatterjee, P.; Das, P.P. Evaluation Based on Distance from Average Solution (Edas) Method. In Multi-Criteria Decision-Making Methods in Manufacturing Environments; Apple Academic Press: Palm Bay, FL, USA, 2024; pp. 183–189. [Google Scholar]

| Impact Category | Unit | CM 1 | CM2 | CM3 | CM4 | CM5 | CM6 | CM 7 | CM8 | CM9 | CM10 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Fine particulate matter formation | kg PM2.5 eq | 0.00054 | 0.00042 | 0.00043 | 0.00045 | 0.00039 | 0.00048 | 0.00059 | 0.00044 | 0.00045 | 0.00019 |

| Fossil resource scarcity | kg oil eq | 0.07881 | 0.06017 | 0.05802 | 0.06266 | 0.05145 | 0.06767 | 0.08488 | 0.06196 | 0.06247 | 0.02076 |

| Freshwater ecotoxicity | kg 1,4-DCB | 0.00893 | 0.00946 | 0.01165 | 0.01627 | 0.01232 | 0.00697 | 0.00742 | 0.00662 | 0.00711 | 0.02148 |

| Freshwater eutrophication | kg P eq | 0.00009 | 0.00007 | 0.00007 | 0.00008 | 0.00007 | 0.00008 | 0.0001 | 0.00008 | 0.00007 | 0.00005 |

| Global warming | kg CO2 eq | 0.8516 | 0.55978 | 0.53205 | 0.55376 | 0.43525 | 0.67726 | 0.83768 | 0.60719 | 0.58763 | 0.10087 |

| Human carcinogenic toxicity | kg 1,4-DCB | 0.01437 | 0.01509 | 0.01567 | 0.02112 | 0.01583 | 0.01249 | 0.01486 | 0.01123 | 0.01391 | 0.02213 |

| Human non-carcinogenic toxicity | kg 1,4-DCB | 0.25982 | 0.24304 | 0.29774 | 0.39562 | 0.30486 | 0.19769 | 0.23665 | 0.18481 | 0.19629 | 0.48882 |

| Ionizing radiation | kBq Co-60 eq | 0.00721 | 0.00843 | 0.00616 | 0.01154 | 0.00577 | 0.00905 | 0.01179 | 0.00941 | 0.00555 | 0.00298 |

| Land use | m2a crop eq | 0.01592 | 0.02228 | 0.01634 | 0.02025 | 0.01617 | 0.02183 | 0.02425 | 0.01603 | 0.01748 | 0.00665 |

| Marine ecotoxicity | kg 1,4-DCB | 0.01205 | 0.01267 | 0.01558 | 0.02175 | 0.01644 | 0.00941 | 0.01016 | 0.00889 | 0.00955 | 0.02837 |

| Marine eutrophication | kg N eq | 0.00001 | 0.00001 | 0.00001 | 0.00001 | 0.00001 | 0.00001 | 0.00001 | 0.00001 | 0.00001 | 0.00001 |

| Mineral resource scarcity | kg Cu eq | 0.00339 | 0.00415 | 0.00307 | 0.00431 | 0.00295 | 0.00252 | 0.00304 | 0.00224 | 0.00586 | 0.00466 |

| Ozone formation, Human health | kg NOx eq | 0.00165 | 0.00118 | 0.00111 | 0.00114 | 0.00094 | 0.0014 | 0.00169 | 0.00124 | 0.00128 | 0.00025 |

| Ozone formation, Terrestrial ecosystems | kg NOx eq | 0.00166 | 0.00119 | 0.00112 | 0.00116 | 0.00095 | 0.00141 | 0.0017 | 0.00125 | 0.00129 | 0.00026 |

| Stratospheric ozone depletion | kg CFC11 eq | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Terrestrial acidification | kg SO2 eq | 0.00139 | 0.00103 | 0.00102 | 0.0011 | 0.00089 | 0.00119 | 0.00145 | 0.00107 | 0.00108 | 0.00036 |

| Terrestrial ecotoxicity | kg 1,4-DCB | 0.41804 | 0.55775 | 0.58726 | 0.88496 | 0.6294 | 0.45152 | 0.52567 | 0.37455 | 0.41454 | 0.61552 |

| Water consumption | m3 | 0.00151 | 0.00127 | 0.00128 | 0.00193 | 0.00123 | 0.00123 | 0.00168 | 0.00119 | 0.00096 | 0.00148 |

| Cement Production Alternative | EDAS | TOPSIS | ||

|---|---|---|---|---|

| Appraisal Score (Asi) | Rank | Relative Closeness (Ci) | Rank | |

| CM1 | 0.4362 | 3 | 0.8314 | 8 |

| CM2 | 0.0891 | 10 | 1.2235 | 5 |

| CM3 | 0.1108 | 9 | 1.1064 | 7 |

| CM4 | 0.5199 | 2 | 0.5103 | 10 |

| CM5 | 0.2605 | 8 | 1.3342 | 4 |

| CM6 | 0.3304 | 6 | 1.1756 | 6 |

| CM7 | 0.3775 | 4 | 0.7595 | 9 |

| CM8 | 0.3460 | 5 | 1.5131 | 2 |

| CM9 | 0.2722 | 7 | 1.4988 | 3 |

| CM10 | 0.9094 | 1 | 1.7228 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akintayo, B.D.; Babatunde, O.M.; Olanrewaju, O.A. Comparative Analysis of Cement Production Methods Using a Life Cycle Assessment and a Multicriteria Decision-Making Approach. Sustainability 2024, 16, 484. https://doi.org/10.3390/su16020484

Akintayo BD, Babatunde OM, Olanrewaju OA. Comparative Analysis of Cement Production Methods Using a Life Cycle Assessment and a Multicriteria Decision-Making Approach. Sustainability. 2024; 16(2):484. https://doi.org/10.3390/su16020484

Chicago/Turabian StyleAkintayo, Busola Dorcas, Olubayo Moses Babatunde, and Oludolapo Akanni Olanrewaju. 2024. "Comparative Analysis of Cement Production Methods Using a Life Cycle Assessment and a Multicriteria Decision-Making Approach" Sustainability 16, no. 2: 484. https://doi.org/10.3390/su16020484

APA StyleAkintayo, B. D., Babatunde, O. M., & Olanrewaju, O. A. (2024). Comparative Analysis of Cement Production Methods Using a Life Cycle Assessment and a Multicriteria Decision-Making Approach. Sustainability, 16(2), 484. https://doi.org/10.3390/su16020484