Bridging Housing and Climate Needs: Bamboo Construction in the Philippines

Abstract

1. Introduction

1.1. Bamboo in Construction

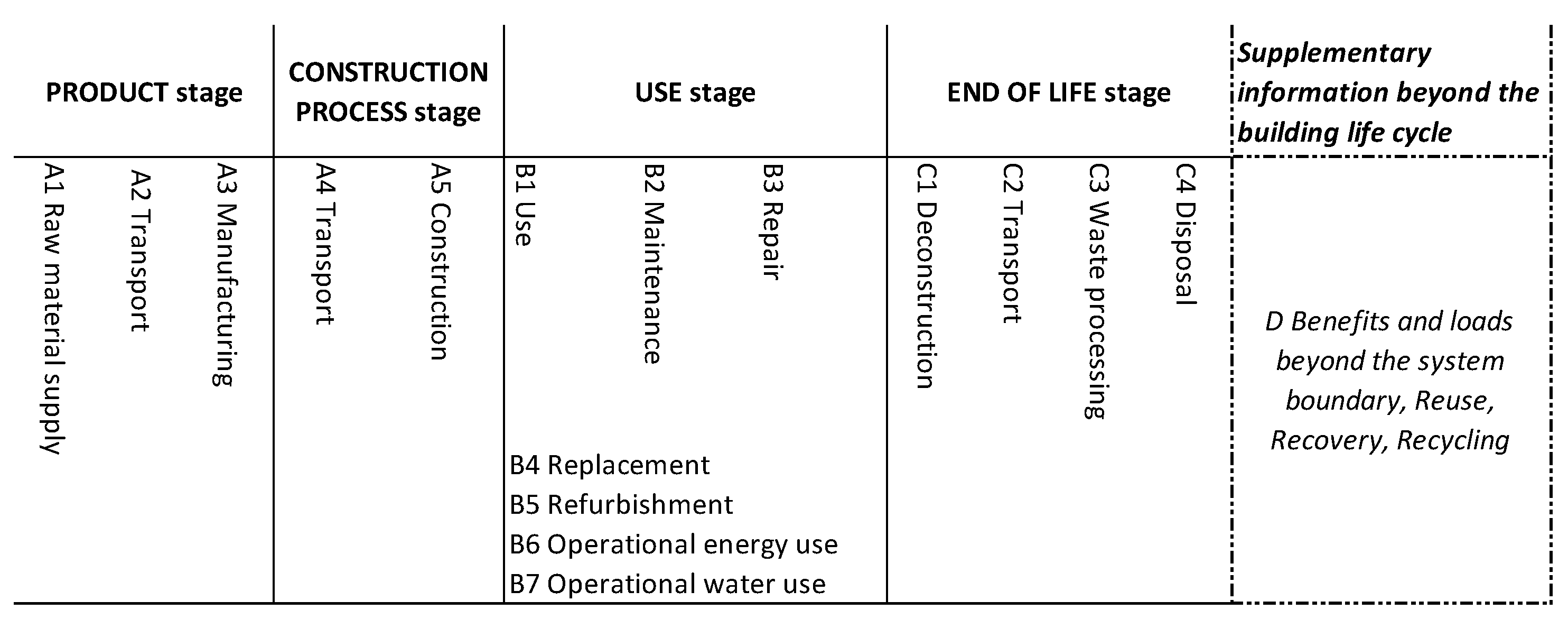

1.2. Life Cycle Assessment (LCA)

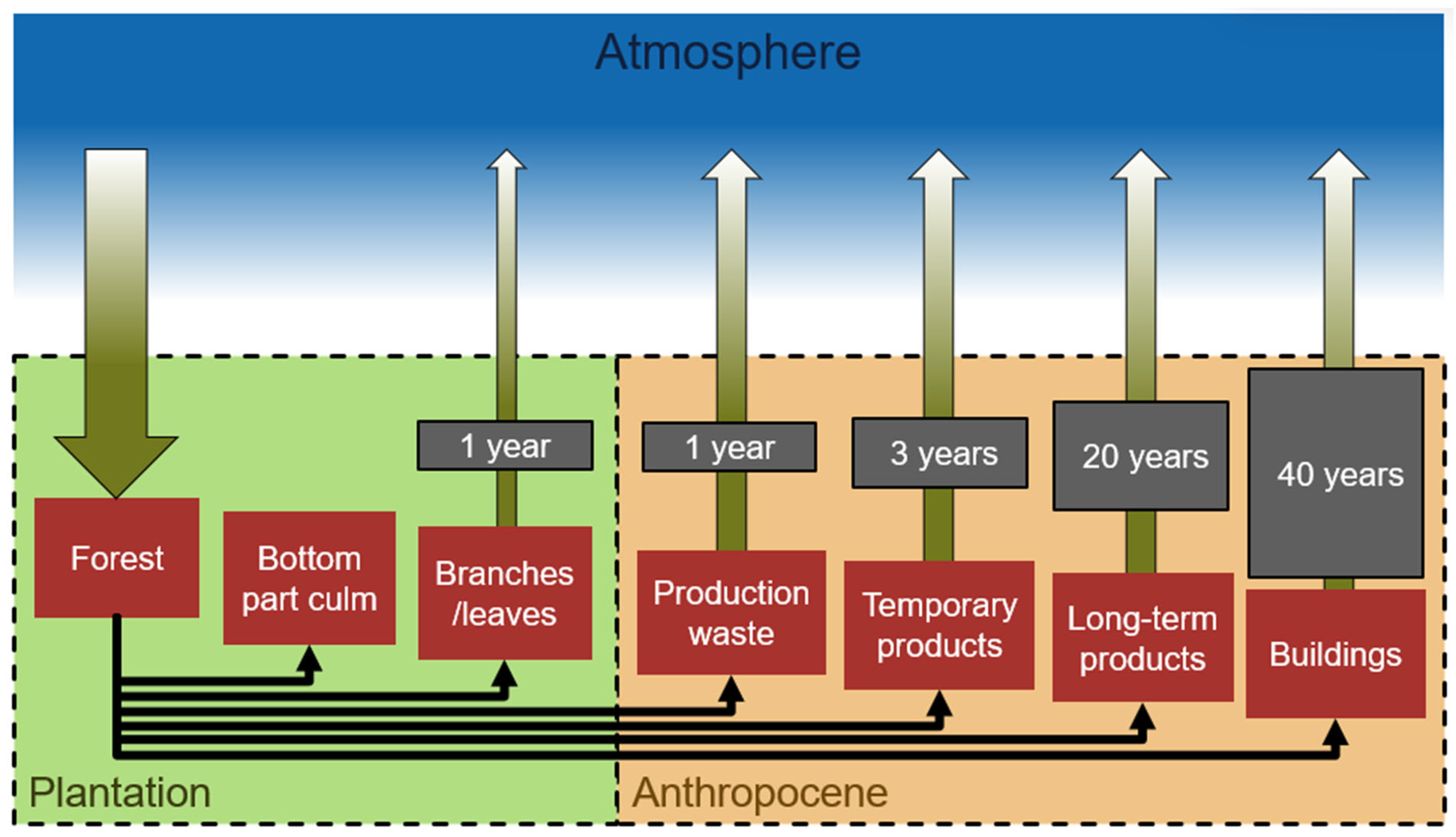

1.3. LCA and Bamboo

1.4. Methodologies for Carbon Storage Quantification

1.5. Carbon Storage and Bamboo

1.6. Economic Assessments and Bamboo

2. Materials and Methods

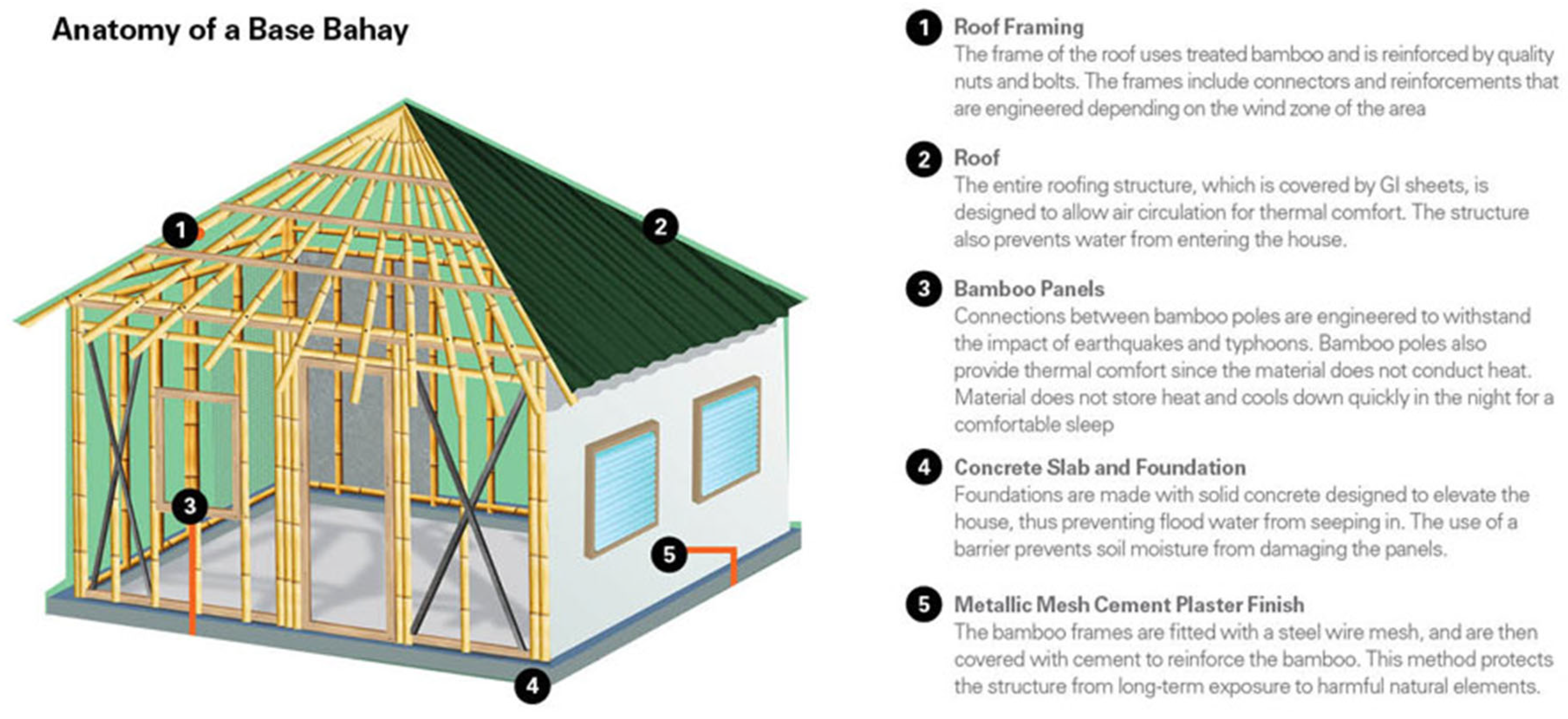

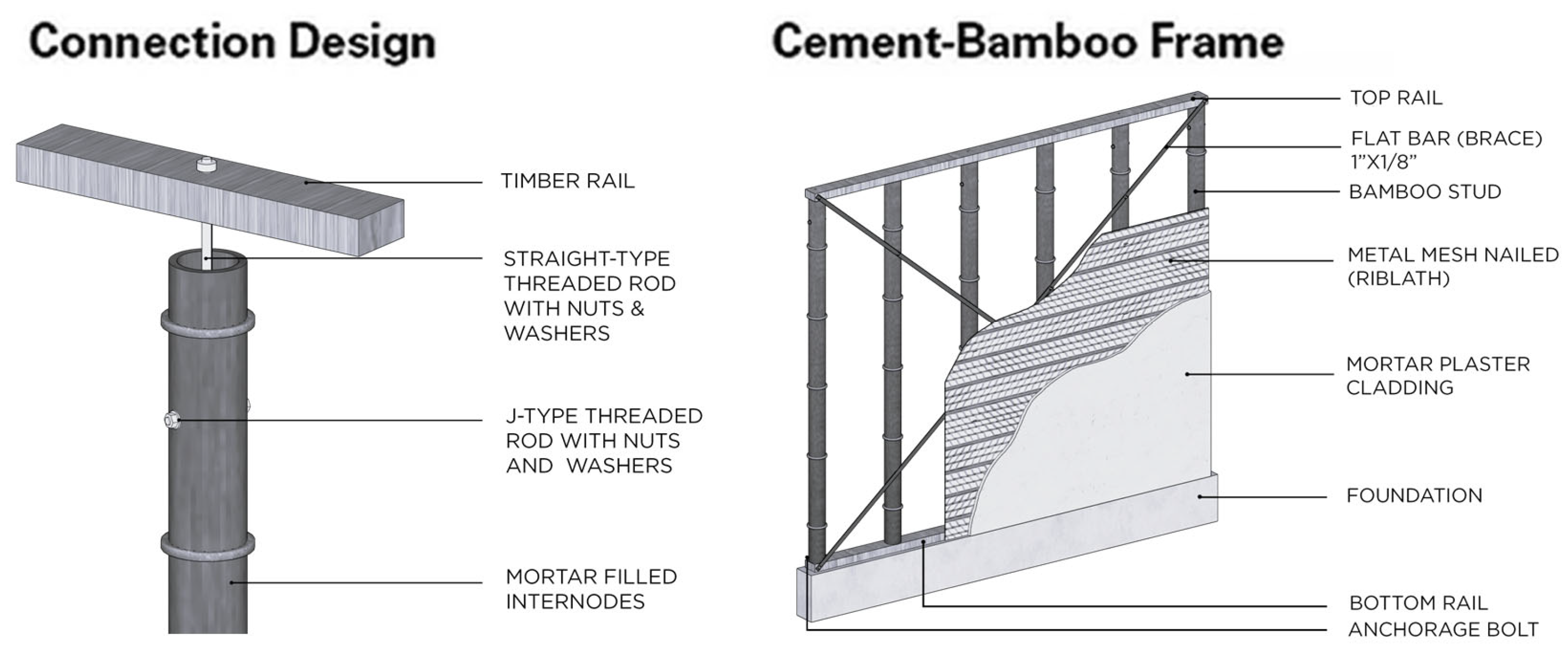

2.1. Case Study—The Philppines

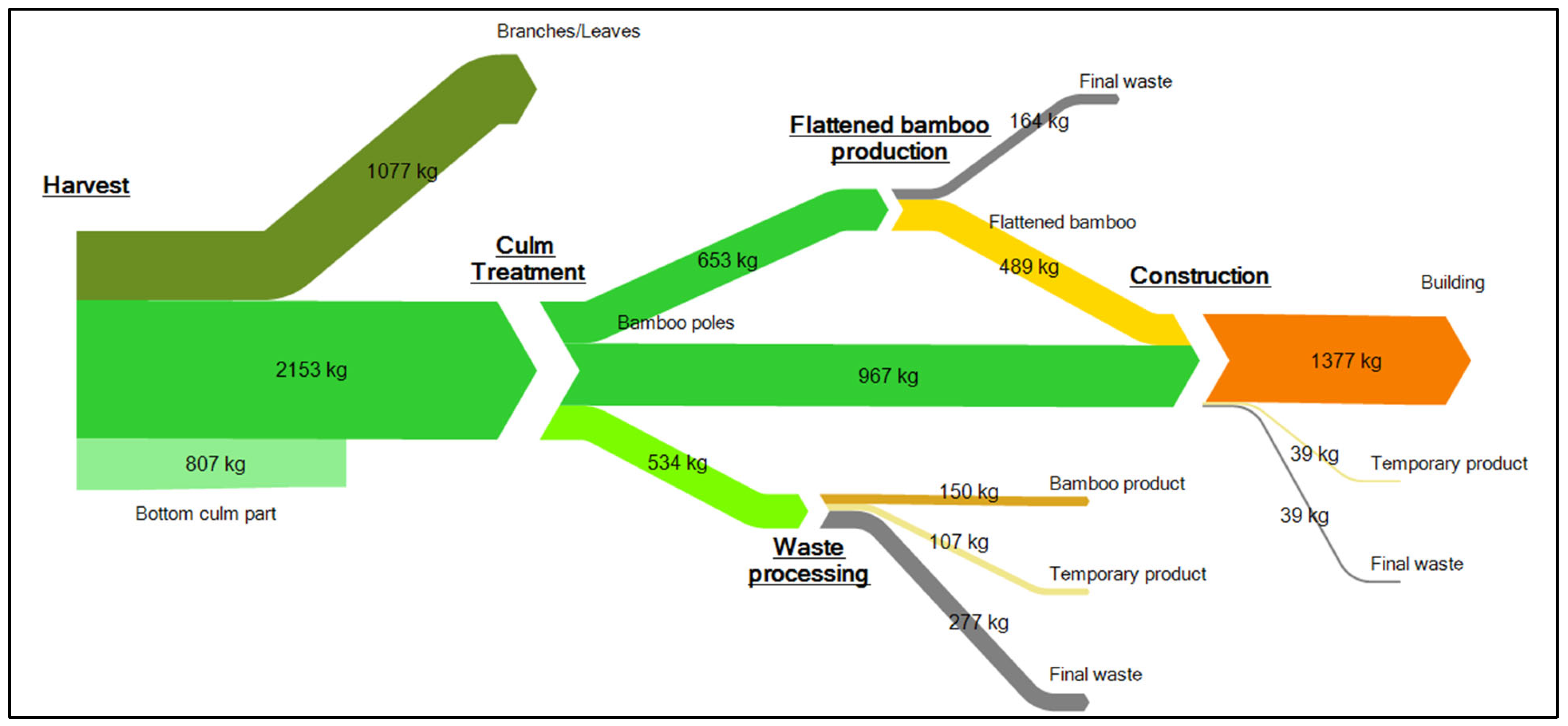

2.2. Mass Flow Model

2.3. Bill of Materials

2.4. Dynamic Mass Flow Model

2.5. Land-Use Calculation

2.6. LCA of Bamboo-Based Housing Units

2.6.1. Production of Bamboo (A1–A4)

- -

- Removing the entry for fertilizers, as none are used in the relevant bamboo forests;

- -

- Deleting the entry for technical wood drying, as such poles are sun-dried;

- -

- Indicating the lack of an electricity requirement for trimming, as this process is manually performed with a knife;

- -

- Removing the need for an air compressor to pump boric acid into the pole, as the poles are instead fully submerged;

- -

- Setting the waste residues to zero, as they are calculated separately;

- -

- Making additional general adjustments in the material flows, such as correcting underestimated amounts of waste in the production of bamboo poles (Villanueva et al., 2022 [39]).

2.6.2. End-of-Life (C)

2.7. Dynamic Life Cycle Assessment (DLCA)

2.8. Economic Model

3. Results

3.1. Material Flows

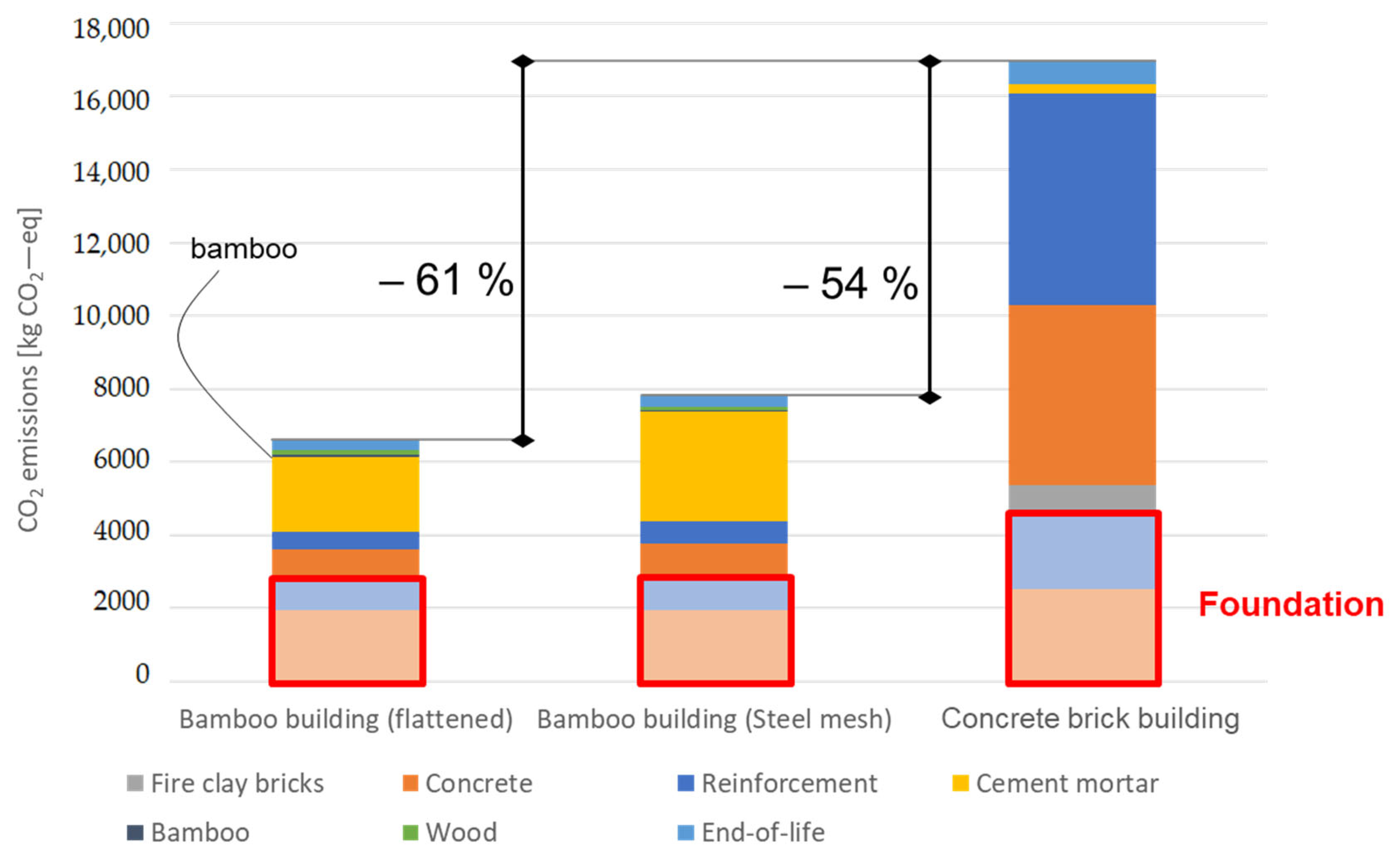

3.2. Classic LCA

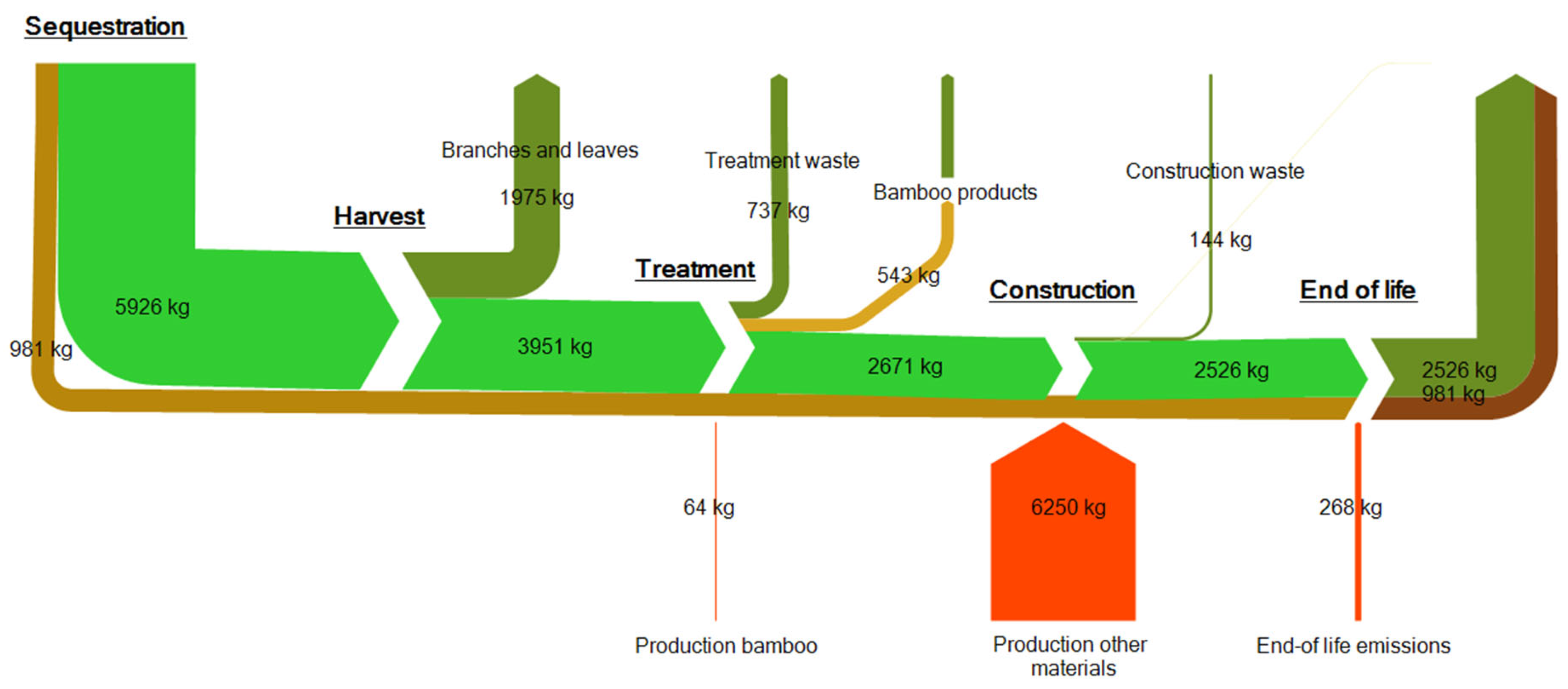

3.3. CO2 Flow Model

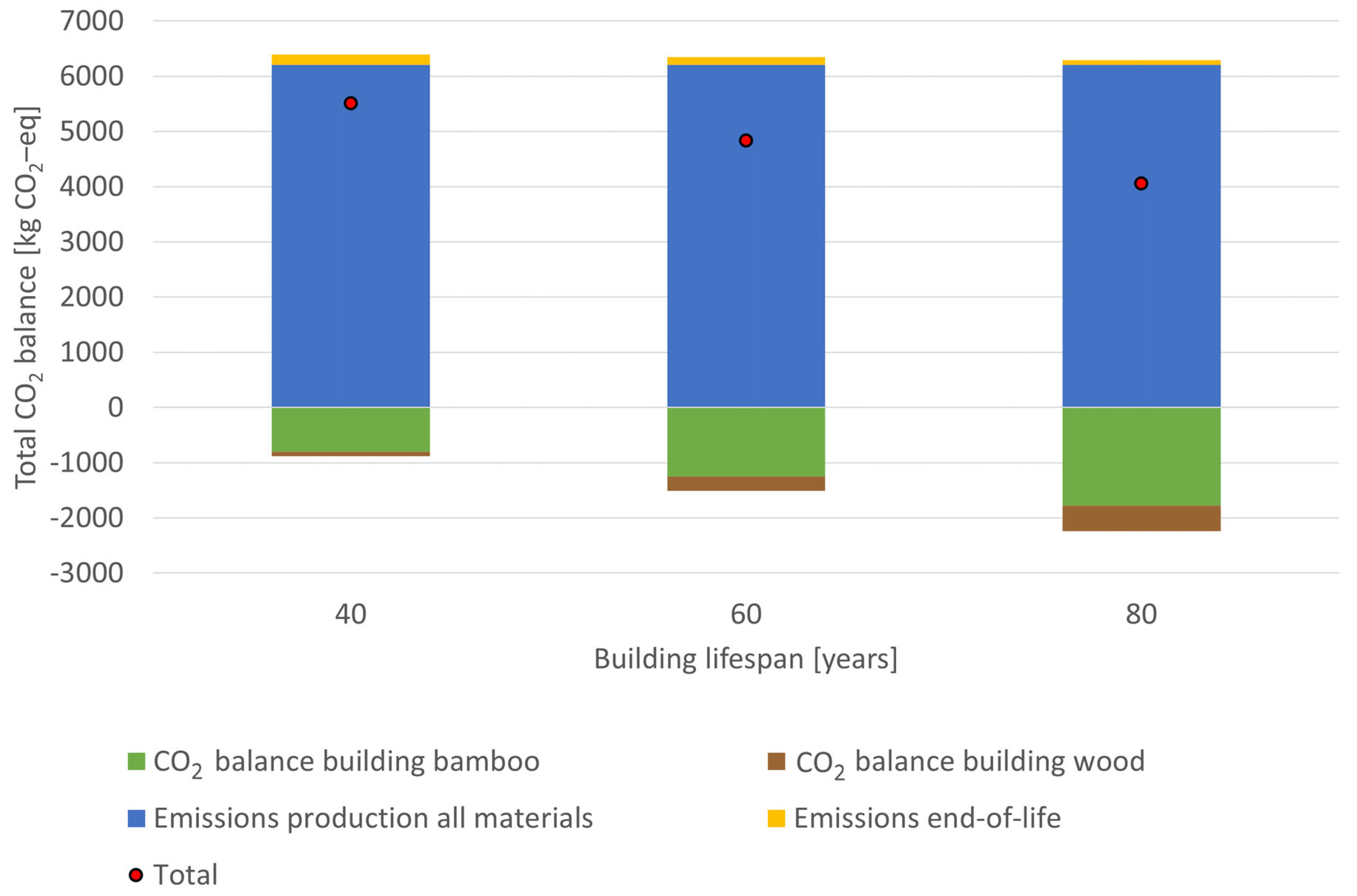

3.4. Dynamic LCA Results

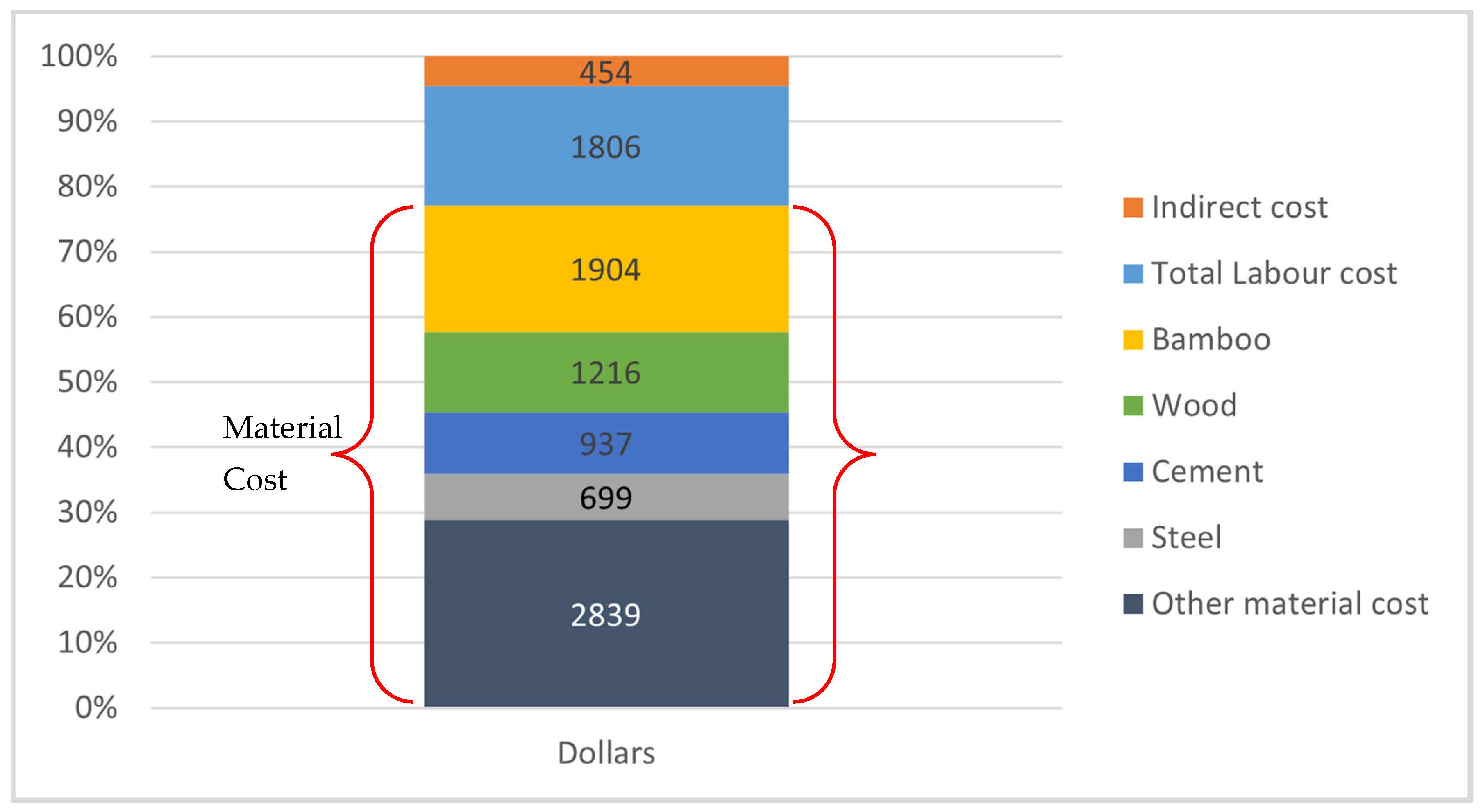

3.5. Economic Assessment

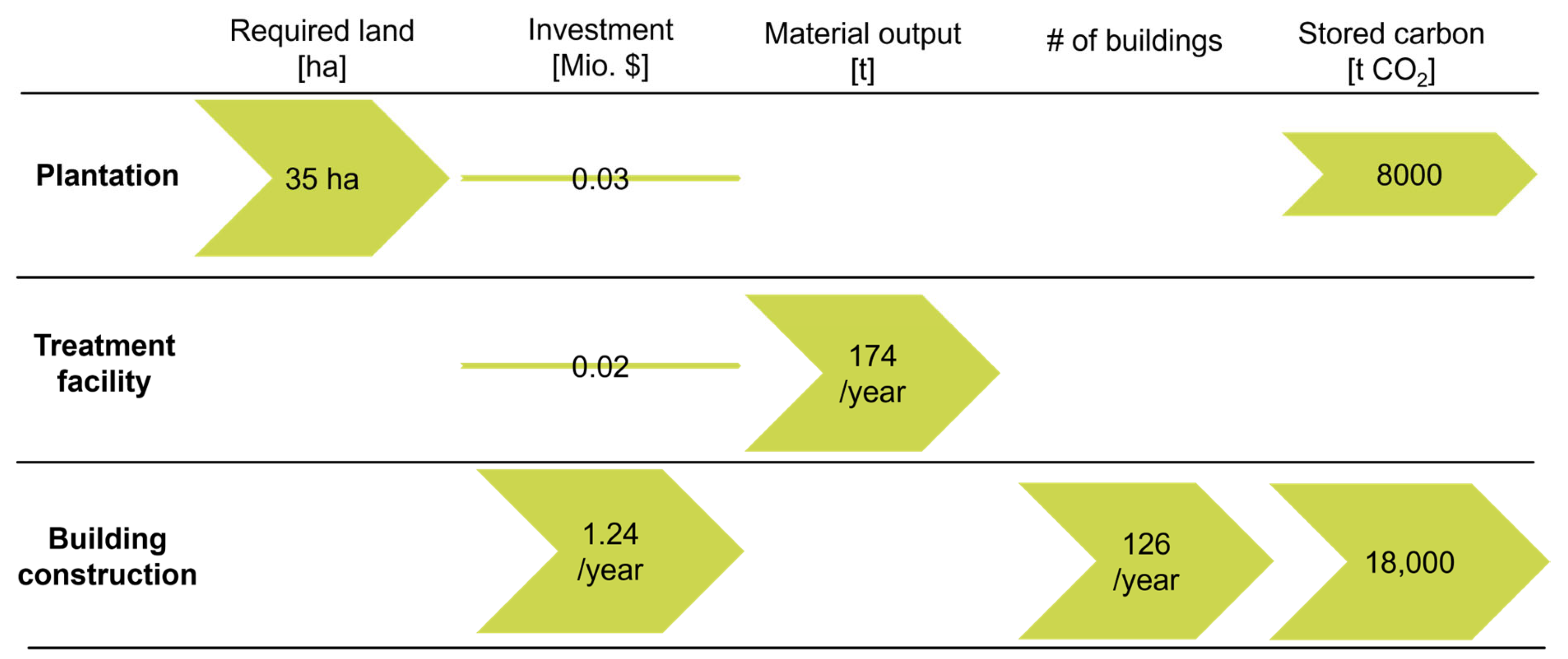

3.6. Investment and Outputs

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Asian Development Bank. Poverty Data: Philippines. Available online: https://www.adb.org/countries/philippines/poverty (accessed on 30 June 2022).

- Chandran, R. Manila’s Homeless Set to Move Into More Empty Homes If Official Handover Delayed. Available online: https://www.reuters.com/article/us-philippines-landrights-lawmaking/manilas-homeless-set-to-move-into-more-empty-homes-if-official-handover-delayed-idUSKBN1H41L7 (accessed on 30 June 2022).

- Hilti Foundation. A Bamboo Construction Eco-System for Social Housing in Negros Occidental, Philippines. Available online: https://www.hiltifoundation.org/projects/sustainable-social-housing-in-the-philippines (accessed on 30 June 2022).

- Win, T.L. We Can’t Tackle the Climate Change Crisis without Changing Construction. Here’s Why. Available online: https://www.weforum.org/agenda/2021/01/planet-warming-emissions-buildings-construction-climate-goals-risk/ (accessed on 30 June 2022).

- ClimateWatch. Philippines. Available online: https://www.climatewatchdata.org/countries/PHL?end_year=2019&start_year=1990 (accessed on 30 June 2022).

- Zea Escamilla, E.; Archilla, H.; Nuramo, D.A.; Trujillo, D. Bamboo: An Engineered Alternative for Buildings in the Global South. In Bioclimatic Architecture in Warm Climates; Springer: Berlin/Heidelberg, Germany, 2019; pp. 397–414. [Google Scholar]

- Goh, Y.; Soon Poh, Y.; Tong, T. Bamboo: The Emerging Renewable Material for Sustainable Construction. Encycl. Renew. Sustain.Mater. 2020, 2, 365–376. [Google Scholar] [CrossRef]

- Kaminski, S.; Lawrence, A.; Trujillo, D. Structural use of bamboo. Part 1: Introduction to bamboo. Struct. Eng. 2016, 94, 40–43. [Google Scholar]

- Dalbiso, A.D.; Nuramo, D. Ethiopian vernacular bamboo architecture and its potentials for adaptation in modern urban housing: A case study. In Modern Engineered Bamboo Structures; CRC Press: Boca Raton, FL, USA, 2019; pp. 91–98. [Google Scholar]

- Kawayan Collective; (Philippines, Dauin). Personal communication, 2022.

- Kaminski, S.; Lawrence, A.; Trujillo, D.; King, C. Structural use of bamboo—Part 2: Durability and preservation. Struct. Eng. J. Inst. Struct. Eng. 2016, 94, 38–43. [Google Scholar]

- Kaminski, S.; Lopez, L.F.; Trujillo, D.; Zea Escamilla, E. Composite Bamboo Shear Walls—A Shear Wall System For Affordable and Sustainable Housing in Tropical Developing Countries. In Proceedings of the Earthquake Engineering and Dynamics for a Sustainable Future, Cambridge, UK, 14–15 September 2023. [Google Scholar]

- BASE Bahay. The Rejoice Children’s Village. Available online: http://www.base-builds.com/project/nasugbu-batangas/ (accessed on 15 June 2022).

- ISO 22156:2021; Bamboo Structures—Bamboo Culms—Structural Design. ISO: Geneva, Switzerland, 2021.

- Yulo, A. Bamboo for Social Housing? Base Bahay Shows Us How It Can Be Done. Available online: https://bluprint.onemega.com/base-bahay-bamboo-social-housing/ (accessed on 30 June 2022).

- Baumann, H.; Tillman, A.-M.; Tillman, A.-M. The Hitch Hiker’s Guide to LCA: An Orientation in Life Cycle Assessment Methodology and Application, 1:9. ed.; Studentlitteratur: Lund, Sweden, 2004; 543p. [Google Scholar] [CrossRef]

- EN 15978:2011; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. CEN: Oak Brook, IL, USA, 2011.

- Toniolo, S.; Tosato, R.C.; Gambaro, F.; Ren, J. Life cycle thinking tools: Life cycle assessment, life cycle costing and social life cycle assessment. In Life Cycle Sustainability Assessment for Decision-Making; Elsevier: Amsterdam, The Netherlands, 2020; pp. 39–56. [Google Scholar]

- Escamilla, E.Z.; Habert, G. Environmental Impacts of Bamboo-based Construction Materials Representing Global Production Diversity. J. Clean. Prod. 2014, 69, 117–127. [Google Scholar] [CrossRef]

- Eleftheriou, E.; Lopez Muñoz, L.F.; Habert, G.; Zea Escamilla, E. Parametric Approach to Simplified Life Cycle Assessment of Social Housing Projects. Sustainability 2022, 14, 7409. [Google Scholar] [CrossRef]

- Devi, A.S.; Singh, K.S. Carbon storage and sequestration potential in aboveground biomass of bamboos in North East India. Sci. Rep. 2021, 11, 837. [Google Scholar] [CrossRef] [PubMed]

- Hoxha, E.; Passer, A.; Saade, M.R.M.; Trigaux, D.; Shuttleworth, A.; Pittau, F.; Allacker, K.; Habert, G. Biogenic carbon in buildings: A critical overview of LCA methods. Build. Cities 2020, 1, 404–524. [Google Scholar] [CrossRef]

- Levasseur, A.; Lesage, P.; Margni, M.; Deschênes, L.; Samson, R.J. Considering time in LCA: Dynamic LCA and its application to global warming impact assessments. Environ. Sci. Technol. 2010, 44, 3169–3174. [Google Scholar] [CrossRef]

- Levasseur, A.; Lesage, P.; Margni, M.; Samson, R. Biogenic carbon and temporary storage addressed with dynamic life cycle assessment. J. Ind. Ecol. 2013, 17, 117–128. [Google Scholar] [CrossRef]

- Pittau, F.; Habert, G. Methodology for Biogenic Carbon Accounting and Carbonation in LCA of Buildings and Construction Products; ETH Zurich, Institute of Construction & Infrastructure Management: Zürich, Switzerland, 2021. [Google Scholar]

- Cherubini, F.; Stromman, A.H.; Hertwich, E. Effects of boreal forest management practices on the climate impact of CO2 emissions from bioenergy. Ecol. Model. 2011, 223, 59–66. [Google Scholar] [CrossRef]

- Guest, G.; Cherubini, F.; Strømman, A.H. Global warming potential of carbon dioxide emissions from biomass stored in the anthroposphere and used for bioenergy at end of life. J. Ind. Ecol. 2013, 17, 20–30. [Google Scholar] [CrossRef]

- Vogtländer, J.G.; van der Velden, N.M.; van der Lugt, P. Carbon sequestration in LCA, a proposal for a new approach based on the global carbon cycle; cases on wood and on bamboo. Int. J. Life Cycle Assess. 2014, 19, 13–23. [Google Scholar] [CrossRef]

- Kuittinen, M.; Zernicke, C.; Slabik, S.; Hafner, A. How can carbon be stored in the built environment? A review of potential options. Archit. Sci. Rev. 2021, 66, 91–107. [Google Scholar] [CrossRef]

- Xu, X.X.; Xu, P.Y.; Zhu, J.J.; Li, H.T.; Xiong, Z.H. Bamboo construction materials: Carbon storage and potential to reduce associated CO2 emissions. Sci. Total. Environ. 2022, 814, 152697. [Google Scholar] [CrossRef] [PubMed]

- Gu, L.; Zhou, Y.; Mei, T.-T.; Zhou, G.; Xu, L. Carbon Footprint Analysis of Bamboo Scrimber Flooring—Implications for Carbon Sequestration of Bamboo Forests and Its Products. Forests 2019, 10, 51. [Google Scholar] [CrossRef]

- Lugt, P.; Vogtlander, J. The Environmental Impact of Industrial Bamboo Products—Life-Cycle Assessment and Carbon Sequestration; International Network for Bamboo and Rattan (INBAR): Beijing, China, 2015. [CrossRef]

- Phuong, V.; Viet, N. Life Cycle Assessment for Key Bamboo Products in Viet Nam. INBAR Work. Pap. 2020. [Google Scholar]

- Mestre, A.; Vogtlander, J. Eco-efficient value creation of cork products: An LCA-based method for design intervention. J. Clean. Prod. 2013, 57, 101–114. [Google Scholar] [CrossRef]

- Zuraida, S.; Larasati, D. The assessment of marginal prevention costs on bamboo preservation method. Procedia Environ. Sci. 2015, 28, 789–798. [Google Scholar] [CrossRef]

- Ecoinvent Association. Ecoinvent Version 3.8 (2021) Database. Available online: https://v38.ecoquery.ecoinvent.org (accessed on 30 June 2022).

- Krausmann, F. Material flow accounting. In Elgar Encyclopedia of Ecological Economics; Edward Elgar Publishing: Cheltenham, UK, 2023; pp. 357–362. [Google Scholar]

- Heeren, N. Dynamic Material Flow Analysis. Prospect. Environ. Assess. Lect. 2021. [Google Scholar]

- Villanueva, R.; Lopez, L.F.; Trujillo, D.; Tanilou, M.; Absin, C.; Tubog, K.; Tubat, O.K. Adoption of grading practices according to ISO 16624:2018 for Bambusa blumeana in the Philippines: A case study. In Proceedings of the 18th International Conference on Non-conventional Materials and Technologies (NOCIMAT 2022), Online, 7–23 June 2022. [Google Scholar]

- Riaño, N.; Londoño, X.; López, Y.; Gómez, J.H. Plant growth and biomass distribution on Guadua angustifolia Kunth in relation to ageing in the Valle del Cauca—Colombia. J. Am. Bamboo Soc. 2002, 16, 43–51. [Google Scholar]

- BASE Bahay; (Philippines, Manila). Personal communication, 2022.

- Deka, H.K.; Mishra, R.R. Decomposition of Bamboo (Dendrocalamus hamiltonii Nees.) Leaf-Litter in Relation to Age of Jhum Fallows in Northeast India. Plant Soil 1982, 68, 151–159. [Google Scholar] [CrossRef]

- EN 16449:2014; Wood and Wood-Based Products—Calculation of the Biogenic Carbon Content of Wood and Conversion to Carbon Dioxide. CEN: Oak Brook, IL, USA, 2014.

- Sohel, M.S.I.; Alamgir, M.; Akhter, S.; Rahman, M. Carbon storage in a bamboo (Bambusa vulgaris) plantation in the degraded tropical forests: Implications for policy development. Land Use Policy 2015, 49, 142–151. [Google Scholar] [CrossRef]

- Lamlom, S.H.; Savidge, R.A. A reassessment of carbon content in wood: Variation within and between 41 North American species. Biomass Bioenergy 2003, 25, 381–388. [Google Scholar] [CrossRef]

- Edenhofer, O.; Pichs-Madruga, R.; Sokona, Y.; Farahani, E.; Kadner, S.; Seyboth, K. IPCC, 2014: Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

- Ioannidou, D.; Zerbi, S.; García de Soto, B.; Habert, G. Where does the money go? Economic flow analysis of construction projects. Build. Res. Inf. 2018, 46, 348–366. [Google Scholar] [CrossRef]

- Cancio Diaz, Y.; Archila, H.; Celentano, G.; Habert, G.; Zea Escamilla, E. Low investment costs as key driver for upscaling alternative construction technologies. In Proceedings of the Low/No Cost Housing Conference, Zurich, Switzerland, 30 June–1 July 2016. [Google Scholar]

- Carbon Credits. Live Carbon Prices Today. Available online: https://carboncredits.com/carbon-prices-today/ (accessed on 30 June 2022).

| Variant | Bamboo Poles | Flattened Bamboo | Wood | Concrete | Reinforcement | Cement Mortar | Fired Clay Bricks |

|---|---|---|---|---|---|---|---|

| Flattened bamboo | 967 | 489 | 535 | 28,375 | 609 | 8074 | 0 |

| Steel mesh | 967 | 0 | 535 | 28,375 | 746 | 11,784 | 0 |

| Concrete + CHB building | 0 | 0 | 0 | 82,703 | 4169 | 1009 | 2402 |

| Total | Main Contributors | ||||

|---|---|---|---|---|---|

| Product | Production emissions [kg CO2-eq] | Transportation to construction site | Transportation to treatment facility | Power sawing | Other |

| Bamboo pole | 0.041 | 71% | 17% | 11% | 1% |

| Flattened bamboo | 0.050 | 65% | 20% | 14% | 1% |

| Process | Input | Output | Transfer Coefficient |

|---|---|---|---|

| Harvest | Harvested culms | Bottom part | |

| Branches/leaves | |||

| Rejects | |||

| Cut culms | |||

| Treatment | Cut culms | Water | |

| Bamboo waste | |||

| Poles | |||

| Flattened bamboo production | Poles | Bamboo waste | |

| Flattened bamboo | |||

| Waste processing | Waste from treatment | Final waste | |

| Temporary products | |||

| Long-term products | |||

| Construction | Bamboo poles Flattened bamboo | Final waste | |

| Temporary products | |||

| Bamboo in building |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bundi, T.; Lopez, L.F.; Habert, G.; Zea Escamilla, E. Bridging Housing and Climate Needs: Bamboo Construction in the Philippines. Sustainability 2024, 16, 498. https://doi.org/10.3390/su16020498

Bundi T, Lopez LF, Habert G, Zea Escamilla E. Bridging Housing and Climate Needs: Bamboo Construction in the Philippines. Sustainability. 2024; 16(2):498. https://doi.org/10.3390/su16020498

Chicago/Turabian StyleBundi, Timo, Luis Felipe Lopez, Guillaume Habert, and Edwin Zea Escamilla. 2024. "Bridging Housing and Climate Needs: Bamboo Construction in the Philippines" Sustainability 16, no. 2: 498. https://doi.org/10.3390/su16020498

APA StyleBundi, T., Lopez, L. F., Habert, G., & Zea Escamilla, E. (2024). Bridging Housing and Climate Needs: Bamboo Construction in the Philippines. Sustainability, 16(2), 498. https://doi.org/10.3390/su16020498