Sustainable Modernization of Wastewater Treatment Plants

Abstract

:1. Introduction

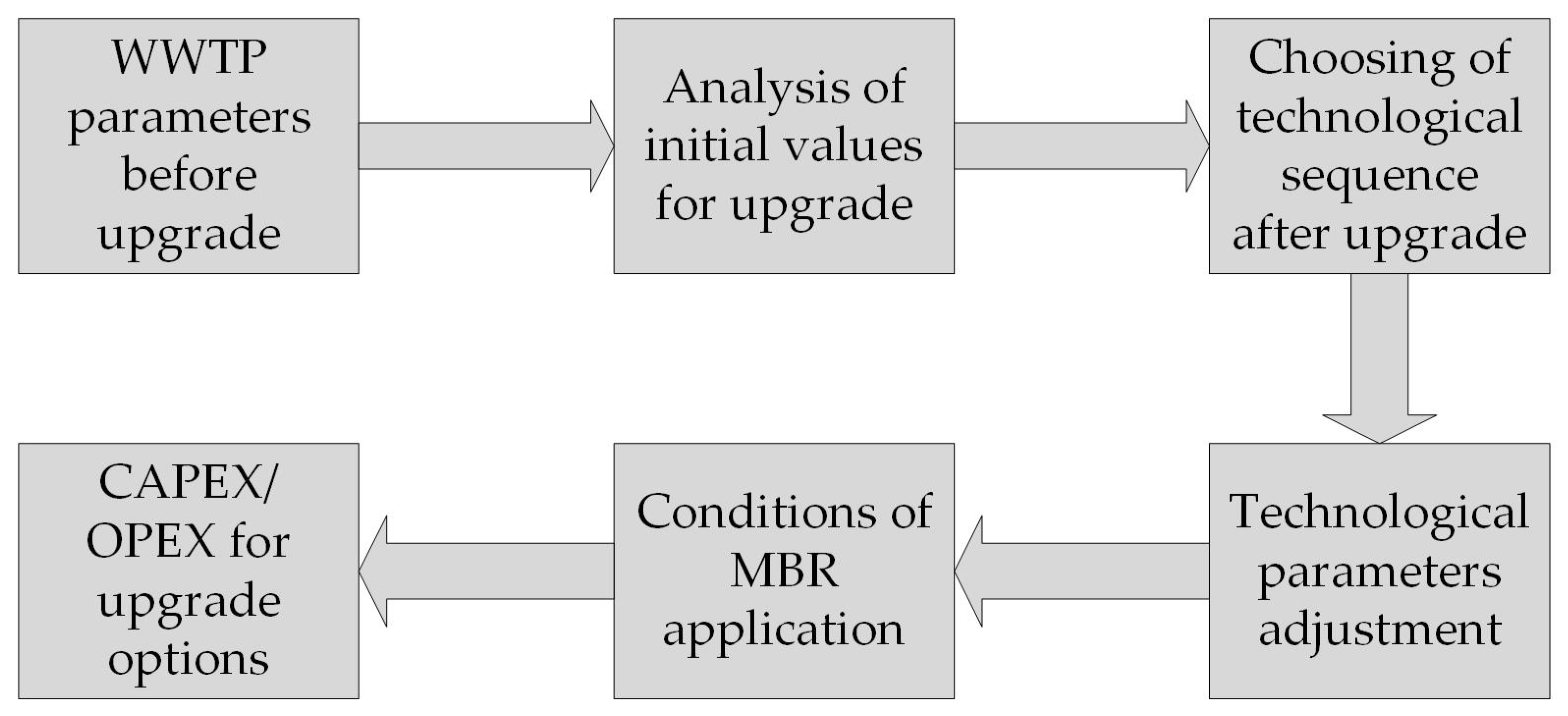

2. Materials and Methods

3. Results

3.1. Treatment Efficiency

- Inspection of structures with determination of their condition and degree of wear;

- Determination of the technological efficiency of existing facilities (verification calculation);

- Development of the modernization project;

- Construction and installation works;

- Launch of the upgraded WWTP into service.

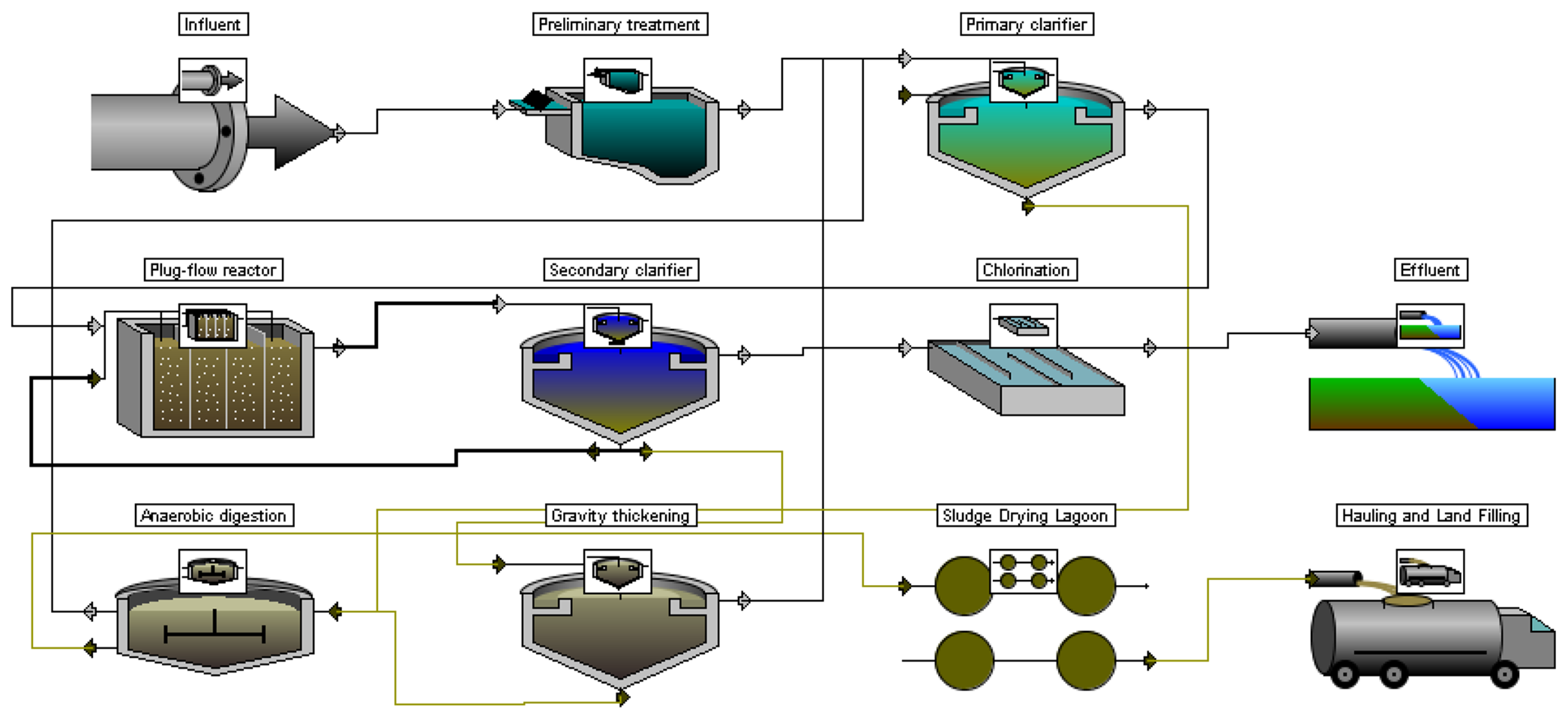

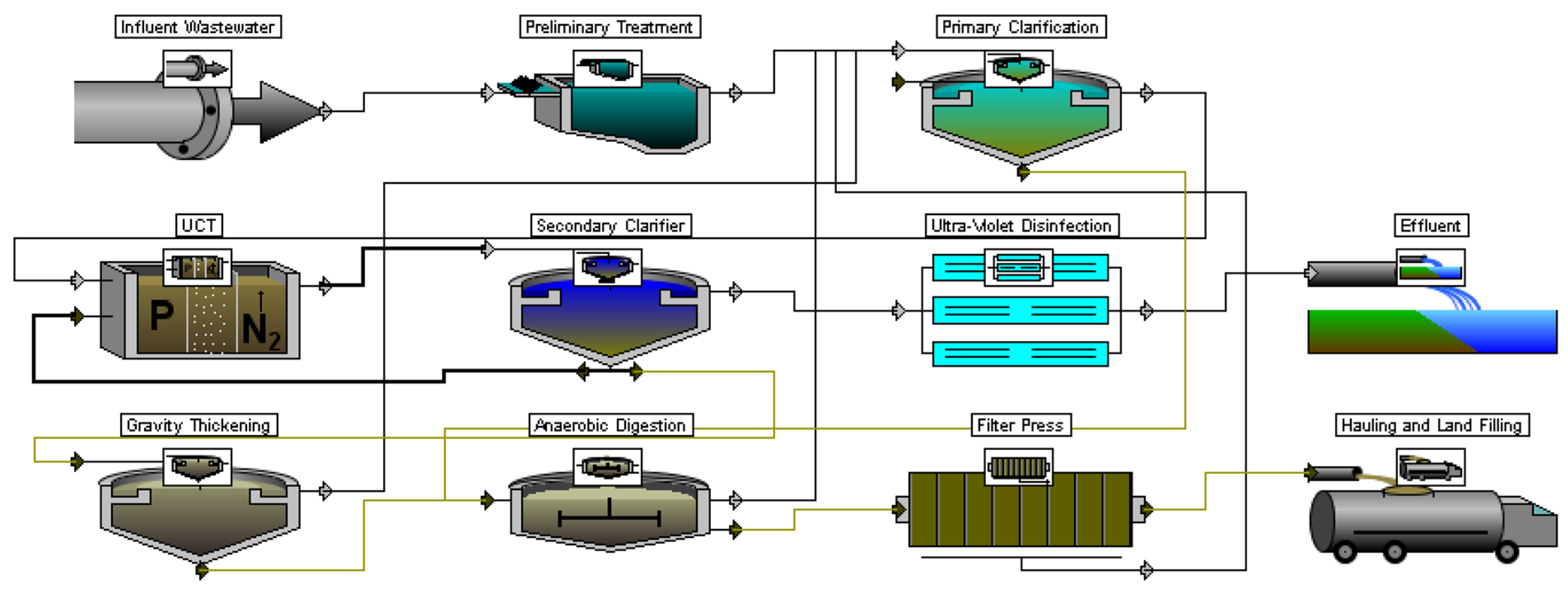

- Preliminary treatment: removal of solid impurities (screens and sand traps);

- Primary treatment: removal of suspended solids (primary settling tanks);

- Secondary treatment: removal of dissolved pollutants (in 95 cases out of 100, treatment goes into activated sludge reactors (ASRs), which are accompanied by the facilities for separation of sludge and treated wastewater);

- Tertiary treatment: additional removal of pollutants (optional stage, usually filters);

- Disinfection: removal of pathogenic microorganisms (chlorination, UV radiation);

- Sludge treatment.

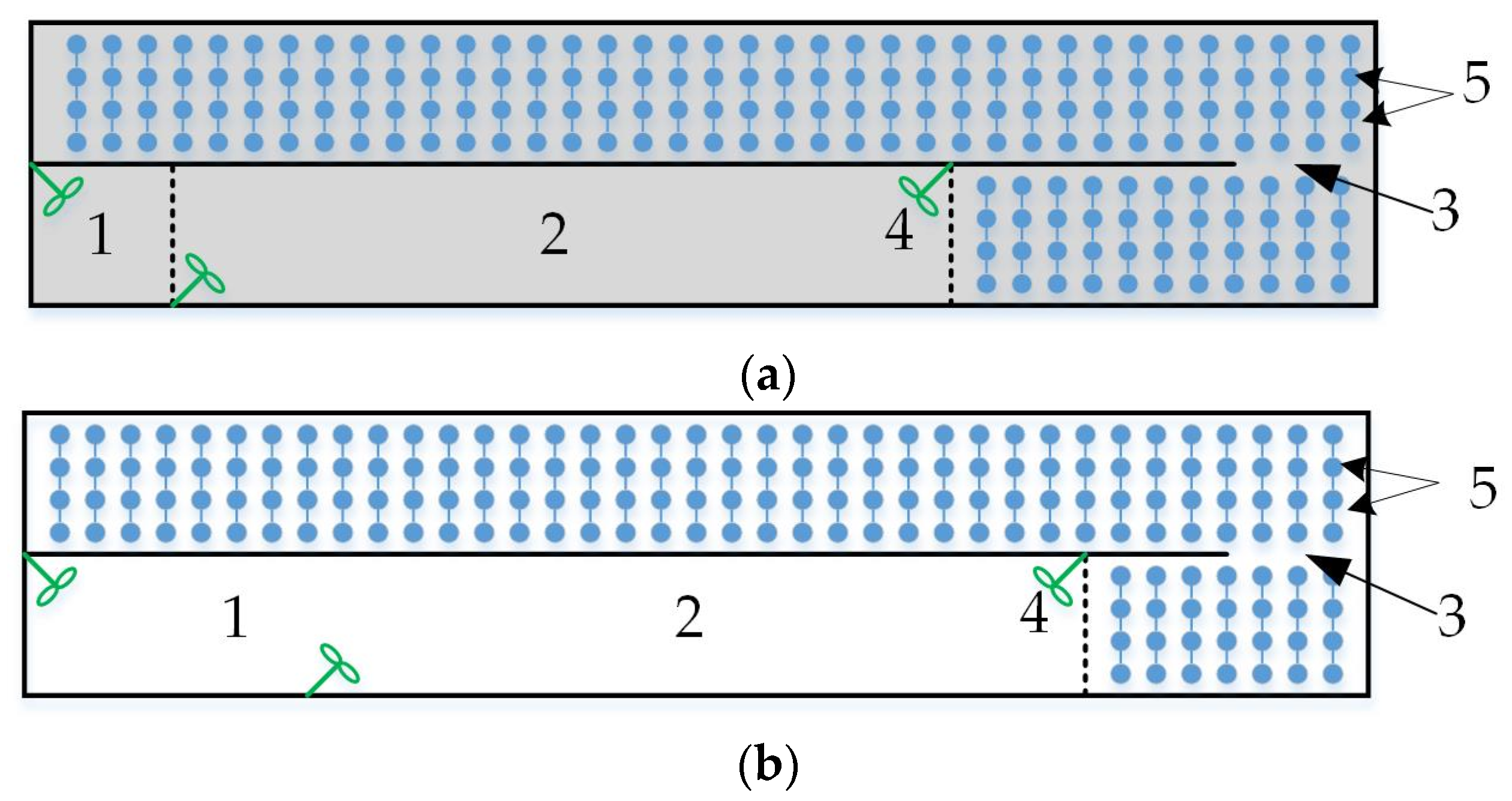

3.2. Application of Membrane Treatment

- Despite the overall reduction in the cost of membranes, the installation of membranes still requires high capital costs;

- An increased MLSS value in MBR leads to physical and chemical fouling of membranes, which complicates and increases the cost of operation due to regular washing and cleaning as well as constant aeration of membrane modules;

- The service life of the membranes is limited to 7–10 years, so during operation of the WWTP, the membranes can be completely renewed several times.

- The concentration of pollutants in the influent wastewater;

- Treatment quality requirements (concentrations of pollutants in discharged wastewater);

- Availability of free space within the WWTP area to locate additional tanks;

- Cost comparison of the various technological solutions.

3.3. Cost Analysis

- (1)

- Maintenance chemical cleaning (NaClO);

- (2)

- Recovery chemical cleaning (NaClO and citric acid).

4. Conclusions

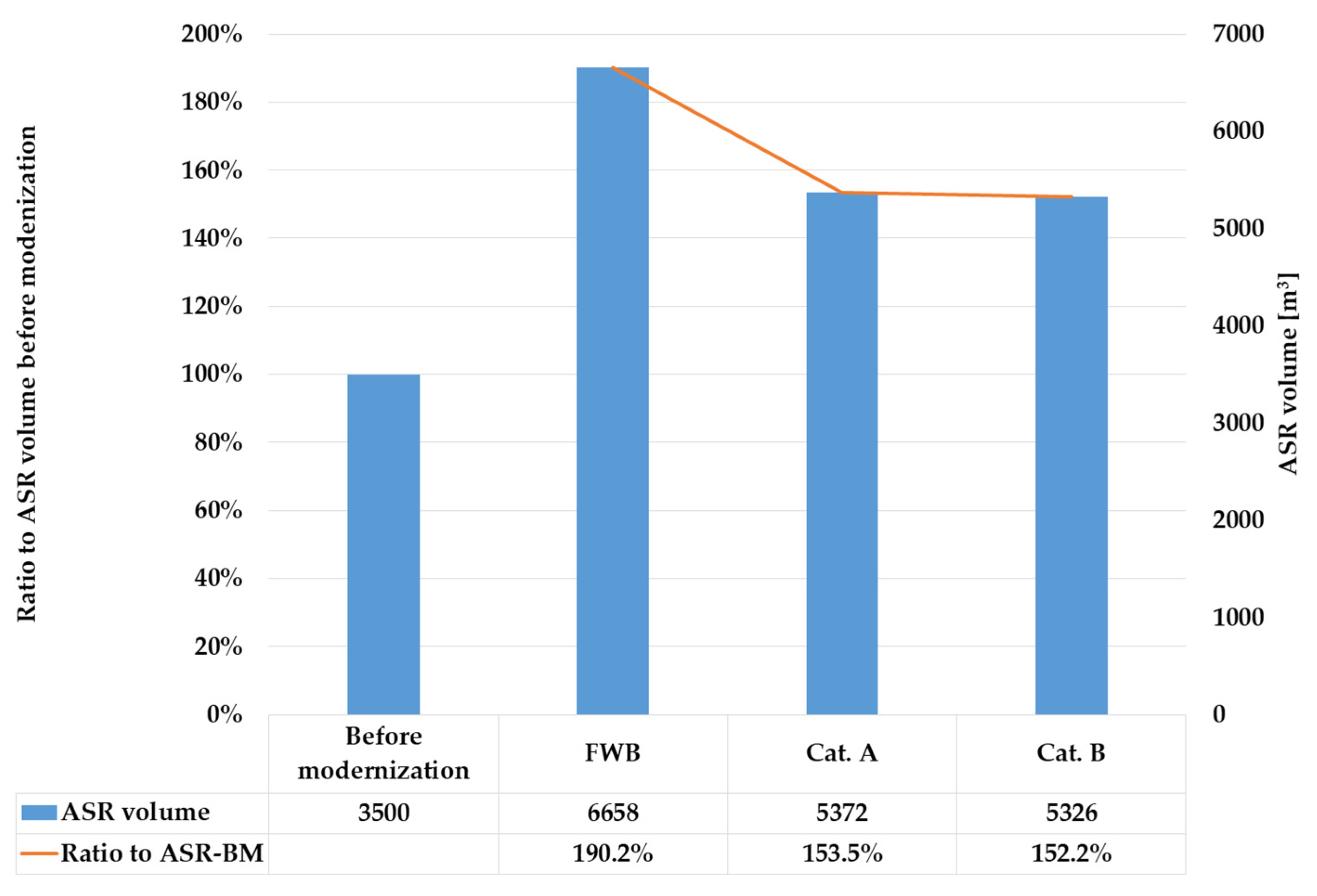

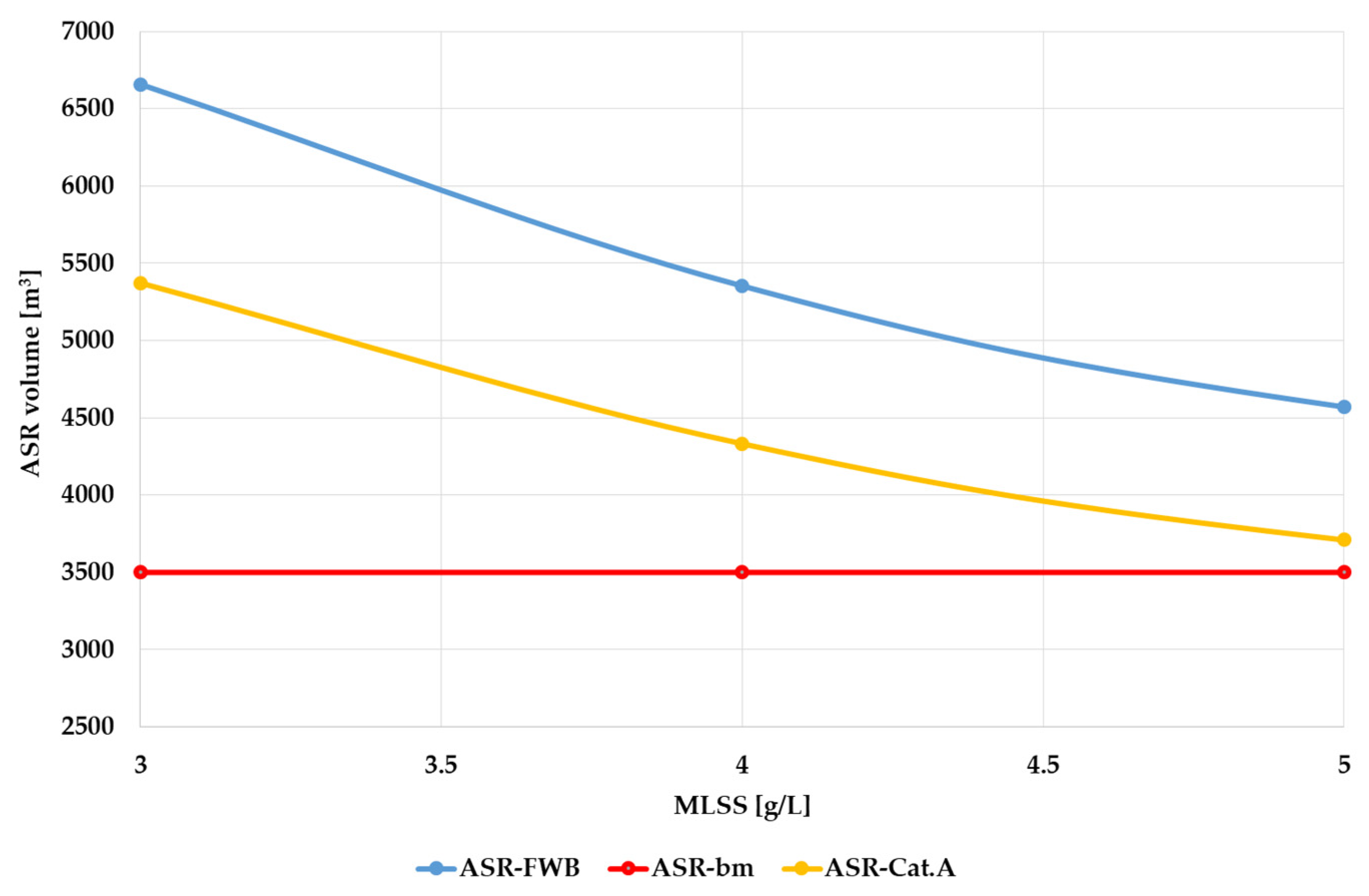

- The research presented the technical evaluation and cost analysis of WWTP modernization of a typical settlement in the Russian Federation. If the treatment efficiency for the needs of fishery water bodies is considered, the volume of an activated sludge reactor can be reduced twice due to the application of membrane sludge separation in comparison to conventional gravity sludge separation.

- As long as the extra volume of the tank is not required, the capital costs for equipment (mixers, aeration units) are also reduced proportionally.

- Within the case study, the cost for additional construction was comparable to the cost of membrane purchase, which gave an overall cost parity for the two estimated cases.

- Despite a double reduction in air supply for ASR aeration (1800 m3/h vs. 3800 m3/h), when a membrane is applied, a significant air demand is required for membrane aeration to mitigate fouling. The overall OPEX in cases of membrane application grew by 60% (EUR 0.127/(m3/d) vs. EUR 0.078/(m3/d)).

- If membrane application is considered as an operation cost (due to their relatively short lifetime), an extra 33% is added to the overall OPEX value up to EUR 0.17/(m3/d).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Poupyrev, E.I. Solution of problems of energy efficient water treatment facilities design. Constr. Reconstr. 2015, 4, 173–182. [Google Scholar]

- Ghimire, U.; Sarpong, G.; Gude, V.G. Transitioning Wastewater Treatment Plants toward Circular Economy and Energy Sustainability. ACS Omega 2021, 6, 11794–11803. [Google Scholar] [CrossRef]

- Meng, X.; Huang, Z.; Ge, G. Upgrade and reconstruction of biological processes in municipal wastewater treatment plants. Desalination Water Treat. 2024, 317, 100299. [Google Scholar] [CrossRef]

- Gogina, E.; Gulshin, I. Characteristics of low-oxygen oxidation ditch with improved nitrogen removal. Water 2021, 13, 3603. [Google Scholar] [CrossRef]

- Wang, Y.; Yuan, Y.; Xue, H.; Yu, Y.; Shi, Y.; Wen, H.; Xu, M. Analysis on Operation and Water Quality Characteristics of Centralized Wastewater Treatment Plants of Industrial Parks in Yellow River Basin, China. Water 2024, 16, 806. [Google Scholar] [CrossRef]

- Guryeva, A.A. Wastewater treatment plants and requirements for their safety. Bull. State Expert. 2022, 3, 56–61. [Google Scholar]

- Ponomarenko, A.M.; Vlasov, D.Y.; Belov, N.A.; Ganin, A.V.; Zinchenko, A.V. Innovative directions of development of lyu-bertsy wastewater treatment plants. Water Supply Sanit. Tech. 2021, 1, 36–48. [Google Scholar] [CrossRef]

- Phillips, H.M.; Sahlstedt, K.E.; Frank, K.; Bratby, J.; Brennan, W.; Rogowski, S.; Pier, D.; Anderson, W.; Mulas, M.; Copp, J.B.; et al. Wastewater treatment modelling in practice: A collaborative discussion of the state of the art. Water Sci. Technol. 2009, 59, 695–704. [Google Scholar] [CrossRef]

- Ezzahraoui, F.-Z.; Hamza, R. Optimized process intensification through dynamic performance simulation and evaluation of treatment alternatives for a wastewater treatment plant in Toronto. Results Eng. 2024, 22, 102047. [Google Scholar] [CrossRef]

- Pires, A.; Morato, J.; Peixoto, H.; Botero, V.; Zuluaga, L.; Figueroa, A. Sustainability Assessment of Indicators for Integrated Water Resources Management. Sci. Total Environ. 2017, 578, 139–147. [Google Scholar] [CrossRef]

- Chonova, T.; Keck, F.; Labanowski, J.; Montuelle, B.; Rimet, F.; Bouchez, A. Separate Treatment of Hospital and Urban Wastewaters: A Real Scale Comparison of Effluents and Their Effect on Microbial Communities. Sci. Total Environ. 2016, 542, 965–975. [Google Scholar] [CrossRef]

- Kharkina, O.V. The main technological errors in the reconstruction of treatment facilities. Ecol. Ind. 2023, 7, 96–105. [Google Scholar] [CrossRef]

- Egorova, Y.A.; Levin, D.I.; Lyushina, L.F.; Petropavlovskiy, S.A.; Bazhenov, V.I.; Danilovich, D.A.; Noskova, I.A. Complex reconstruction of urban sewage treatment facilities in Samara. Water Supply Sanit. Tech. 2016, 8, 80–88. [Google Scholar]

- Rai, H.S. Wastewater treatment optimization—Culling the devil in the details. Lect. Notes Civ. Eng. 2019, 21, 22–34. [Google Scholar] [CrossRef]

- Gikas, P. Towards Energy Positive Wastewater Treatment Plants. J. Environ. Manag. 2017, 203, 621–629. [Google Scholar] [CrossRef]

- Bolorinos, J.; Mauter, M.S.; Rajagopal, R. Integrated Energy Flexibility Management at Wastewater Treatment Facilities. Environ. Sci. Technol. 2023, 57, 18362–18371. [Google Scholar] [CrossRef]

- Yu, Y.; Zou, Z.; Wang, S. Statistical Regression Modeling for Energy Consumption in Wastewater Treatment. J. Environ. Sci. 2019, 75, 201–208. [Google Scholar] [CrossRef]

- Li, X.; Bao, D.; Zhang, Y.; Xu, W.; Zhang, C.; Yang, H.; Ru, Q.; Wang, Y.-F.; Ma, H.; Zhu, E.; et al. Development and Application of Membrane Aerated Biofilm Reactor (MABR)—A Review. Water 2023, 15, 436. [Google Scholar] [CrossRef]

- Atkinson, S. ZeeLung technology shows its ability to quickly, easily and cost-effectively upgrade existing WWTPs. Membr. Tech. 2020, 11, 5. [Google Scholar] [CrossRef]

- Kevbrina, M.V.; Gavrilin, A.M.; Pronin, A.A. Introduction of Modern Technologies in the Construction and Reconstruction of Treatment Facilities of Mosvodokanal JSC. Water Supply Sanit. Tech. 2021, 6, 36–45. [Google Scholar] [CrossRef]

- Bunse, P.; Orschler, L.; Agrawal, S.; Lackner, S. Membrane aerated biofilm reactors for mainstream partial nitritation/anammox: Experiences using real municipal wastewater. Water Res. X 2020, 9, 100066. [Google Scholar] [CrossRef]

- Makisha, N. Advanced Research on Polymer Floating Carrier Application in Activated Sludge Reactors. Polymers 2022, 14, 2604. [Google Scholar] [CrossRef] [PubMed]

- Siriweera, W.B.S.; Lee, Y.-J.; Masumi, K.; Visvanathan, C. Organic matter and total nitrogen removal from wastewater using a pilot-scale membrane-aerated biofilm reactor. Bioresour. Technol. Rep. 2021, 15, 100817. [Google Scholar] [CrossRef]

- Kuzmin, V.A.; Lominoga, O.A.; Koloskova, E.G. Introduction of membrane technologies at the WWTP of the village Molodezhnoe. Water Supply Sanit. Tech. 2021, 3, 26–32. [Google Scholar] [CrossRef]

- Federal State Statistics Service. Availability of Wastewater Treatment Plants and Installed Production Capacity of Wastewater Treatment Plants for 2021. Available online: https://rosstat.gov.ru/storage/mediabank/Kom_knlz_21.xls (accessed on 30 July 2024).

- Streltsov, S.A.; Belov, N.A.; Zaborovsky, S.V.; Kazakova, E.A. Reconstruction of Small Treatment Facilities of Tinao with the Use of Modern Technologies. Water Supply Sanit. Tech. 2021, 6, 43–48. [Google Scholar]

- Yang, J.; Chen, B. Energy efficiency evaluation of wastewater treatment plants (WWTPs) based on data envelopment analysis. Appl. Energ. 2021, 289, 116680. [Google Scholar] [CrossRef]

- Makisha, N. Assessment of Wastewater Treatment Plant Upgrading with MBR Implementation. Membranes 2023, 13, 746. [Google Scholar] [CrossRef]

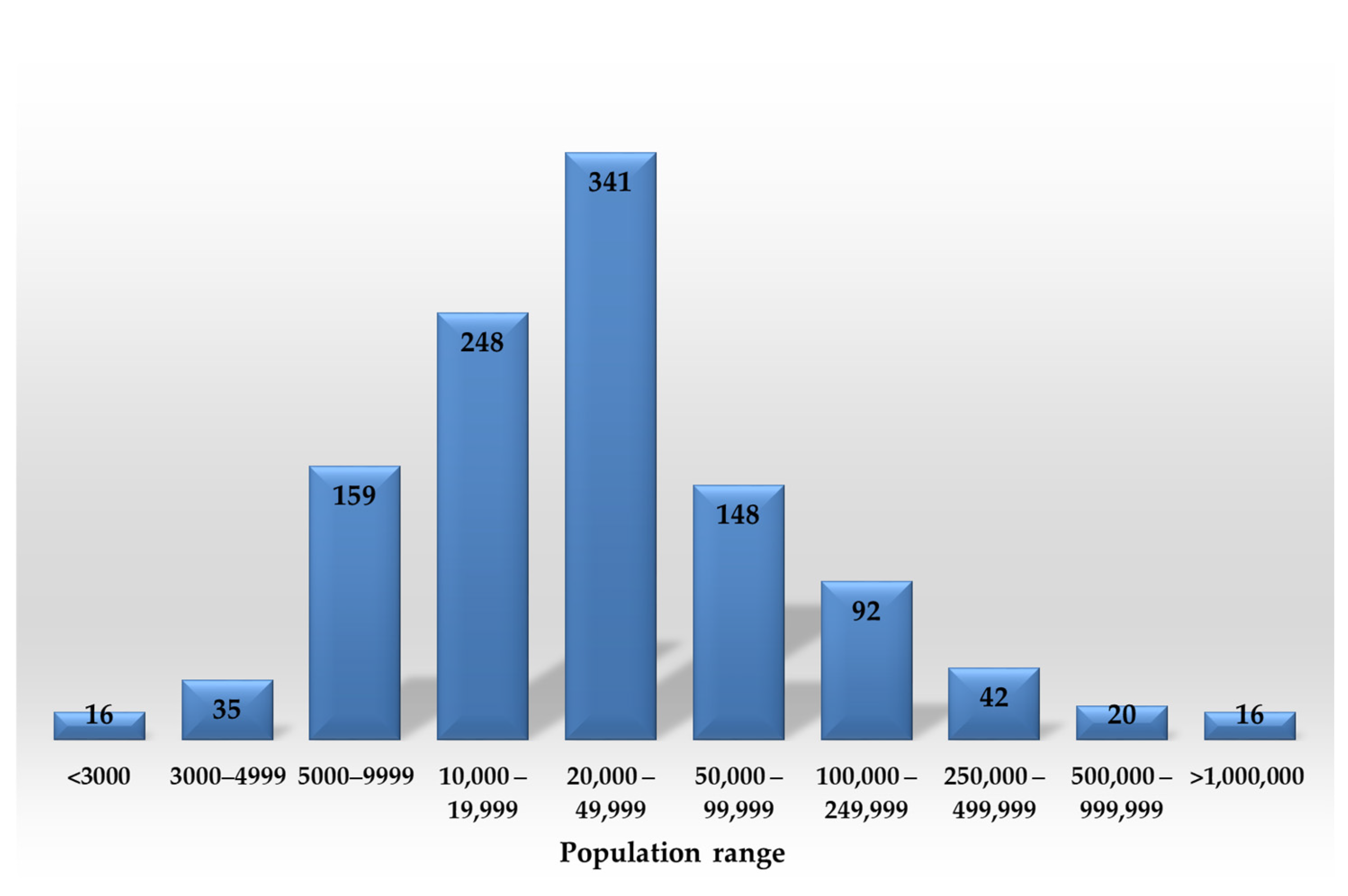

- Federal State Statistics Service. The Population of the Russian Federation as of January 1, 2020. Grouping the Number of Cities by the Number of People Living in Them as of January 1, 2020. Available online: https://rosstat.gov.ru/storage/mediabank/CcG8qBhP/mun_obr2020.rar (accessed on 30 July 2024).

- Construction Norms and Rules “SNiP 2.04.03-85 Sewerage. Pipelines and Wastewater Treatment Plants”. Available online: https://docs.cntd.ru/document/5200017?marker=7D20K3 (accessed on 25 July 2024).

- Construction Code of Russian Federation “SP 30.13330.2020. Internal Water Supply and Sewerage of Buildings”. Available online: https://docs.cntd.ru/document/573741260 (accessed on 25 July 2024).

- Danilovich, D.A. State standard GOST 70953-2023 on basic technical solutions—A new tool for improving the quality of projects of wastewater treatment plants. Water Supply Sanit. Tech. 2023, 12, 4. [Google Scholar] [CrossRef]

- Construction Code of Russian Federation “SP 32.13330.2018. Sewerage. Pipelines and Wastewater Treatment Plants”. Available online: https://docs.cntd.ru/document/554820821 (accessed on 25 July 2024).

- Makisha, N.A. Simulation of reconstruction of sewage treatment plants using membrane bioreactors. Ecol. Urban Terr. 2020, 2, 88–93. [Google Scholar] [CrossRef]

- Makisha, N. Preliminary Design Analysis of Membrane Bioreactors Application in Treatment Sequences for Modernization of Wastewater Treatment Plants. Membranes 2022, 12, 819. [Google Scholar] [CrossRef]

- Khan, M.T.; Ahmad, R.; Liu, G.; Zhang, L.; Santagata, R.; Lega, M.; Casazza, M. Potential Environmental Impacts of a Hospital Wastewater Treatment Plant in a Developing Country. Sustainability 2024, 16, 2233. [Google Scholar] [CrossRef]

- Order of the Ministry of Agriculture of Russian Federation No. 552 Dated December 13, 2016 “On Approval of Water Quality Standards for Water Bodies for Fishery, Including Standards for Maximum Permissible Concentrations of Harmful Substances in the Waters of Water Bodies for Fishery”. Available online: https://docs.cntd.ru/document/420389120 (accessed on 25 July 2024).

- Decree of the Government of the Russian Federation No. 1430 Dated September 15, 2020 “On Approval of Technological Indicators of the Best Available Technologies in the Field of Wastewater Treatment Using Centralized Wastewater Disposal Systems of Settlements or Urban Districts”. Available online: https://docs.cntd.ru/document/565798086 (accessed on 25 July 2024).

- Stepanov, S.V. Technological Calculation of Activated Sludge Reactors and Membrane Bioreactors; ASV Publishing House: Moscow, Russia, 2020; 224p. [Google Scholar]

- Werkneh, A. Application of membrane-aerated biofilm reactor in removing water and wastewater pollutants: Current advances, knowledge gaps and research needs—A review. Environ. Chall. 2022, 8, 100529. [Google Scholar] [CrossRef]

- Wang, S.; Zou, L.; Li, H.; Zheng, K.; Wang, Y.; Zheng, G.; Li, J. Full-scale membrane bioreactor process WWTPs in East Taihu basin: Wastewater characteristics, energy consumption and sustainability. Sci. Tot. Environ. 2020, 723, 137983. [Google Scholar] [CrossRef] [PubMed]

- Sabia, G.; Petta, L.; Avolio, F.; Caporossi, E. Energy saving in wastewater treatment plants: A methodology based on common key performance indicators for the evaluation of plant energy performance, classification and benchmarking. Energy Convers. Manag. 2020, 220, 113067. [Google Scholar] [CrossRef]

- Gil, J.A.; Túa, L.; Rueda, A.; Montaño, B.; Rodríguez, M.; Prats, D. Monitoring and analysis of the energy cost of an MBR. Desalination 2010, 250, 997–1001. [Google Scholar] [CrossRef]

- Echevarría, C.; Valderrama, C.; Cortina, J.L.; Martín, I.; Arnaldos, M.; Bernat, X.; De la Cal, A.; Boleda, M.R.; Vega, A.; Teuler, A.; et al. Techno-economic evaluation and comparison of PAC-MBR and ozonation-UV revamping for organic micro-pollutants removal from urban reclaimed wastewater. Sci. Total Environ. 2019, 671, 288–298. [Google Scholar] [CrossRef]

| Pollutant | MPC [g/d] [30] | CXX.bm [mg/L] | Effluent Limits [mg/L] * |

|---|---|---|---|

| TSS | 65 | 186 | 10–15 |

| BODFULL | 75 | 214 | 10–15 |

| COD | n/d | n/d | N/A |

| N-NH4 | 8 | 23 | N/A |

| P-РО4 | 3.3 | 9.4 | N/A |

| Pollutant | MPC.rev [g/d] [33] | CXX.am [mg/L] |

|---|---|---|

| TSS | 67 | 285 |

| BODFULL | 72 | 306 |

| COD | 120 | 510 |

| N-NH4 | 8.8 | 37.4 |

| P-РО4 | 1.0 | 4.3 |

| Facility | Parameter | Value |

|---|---|---|

| Primary clarifier | Shape | Rectangular |

| Amount | 2 | |

| Volume [m3] | 500 | |

| Depth [m] | 3.1 | |

| Train area [m2] | 19 × 4.5 | |

| TSS removal efficiency | 50% | |

| BOD removal efficiency | 20% | |

| ASR | Type | Plug-flow reactor |

| Volume [m3] | 3456 | |

| Length [m] | 48 | |

| Width of train [m] | 4.5 | |

| Depth [m] | 4.0 | |

| Number of trains | 2 | |

| Number of batteries | 2 | |

| Air consumption [m3/h] | 3300 | |

| DO [mg/L] | 2.0 | |

| MLSS [g/L] | 3.0 | |

| HRT [h] | 5.26 | |

| Secondary clarifier | Shape | Rectangular |

| Number of trains | 4 | |

| Volume [m3] | 1116 | |

| Depth [m] | 3.1 | |

| Train area [m2] | 19 × 4.5 |

| Pollutant | Limits for Pollutant Concentrations [mg/L] | ||

|---|---|---|---|

| FWB [37] | Cat. A [38] | Cat. B [38] | |

| TSS | +0.25 mg/L to TSS value in water body | 5.0 | 10 |

| BODFULL | 3 | 3.6 | 9.6 |

| COD | N/A | 40 | 80 |

| N-NH4 | 0.4 | 1.0 | 1.0 |

| N-NO2 | 0.02 | 0.1 | 0.1 |

| N-NO3 | 9.0 | 9.0 | 9.0 |

| P-РО4 | 0.2 | 0.5 | 0.7 |

| Cost Type | Case 1 | Case 2 | |

|---|---|---|---|

| CAPEX [EUR] | Tank repair | 280,000 | 280,000 |

| Tank construction | 1,074,500 | 0 | |

| Compressor units | 41,400 | 64,200 | |

| Aerator units | 51,612 | 23,903 | |

| Mixers | 154,800 | 77,400 | |

| Membranes | 0 | 1,152,000 | |

| Overall | 1,602,312 | 1,597,503 | |

| OPEX [EUR/year] | Energy for ASR aeration | 152,425 | 119,400 |

| Energy for MBR aeration | 0 | 188,000 | |

| Energy for mixers | 60,970 | 30,485 | |

| Chemicals | 0 | 7521 | |

| Overall | 213,394 | 345,406 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Makisha, N.; Gulshin, I. Sustainable Modernization of Wastewater Treatment Plants. Sustainability 2024, 16, 8757. https://doi.org/10.3390/su16208757

Makisha N, Gulshin I. Sustainable Modernization of Wastewater Treatment Plants. Sustainability. 2024; 16(20):8757. https://doi.org/10.3390/su16208757

Chicago/Turabian StyleMakisha, Nikolay, and Igor Gulshin. 2024. "Sustainable Modernization of Wastewater Treatment Plants" Sustainability 16, no. 20: 8757. https://doi.org/10.3390/su16208757