An Innovative Approach to Enhance the Durability and Sustainability of Shoe Insoles

Abstract

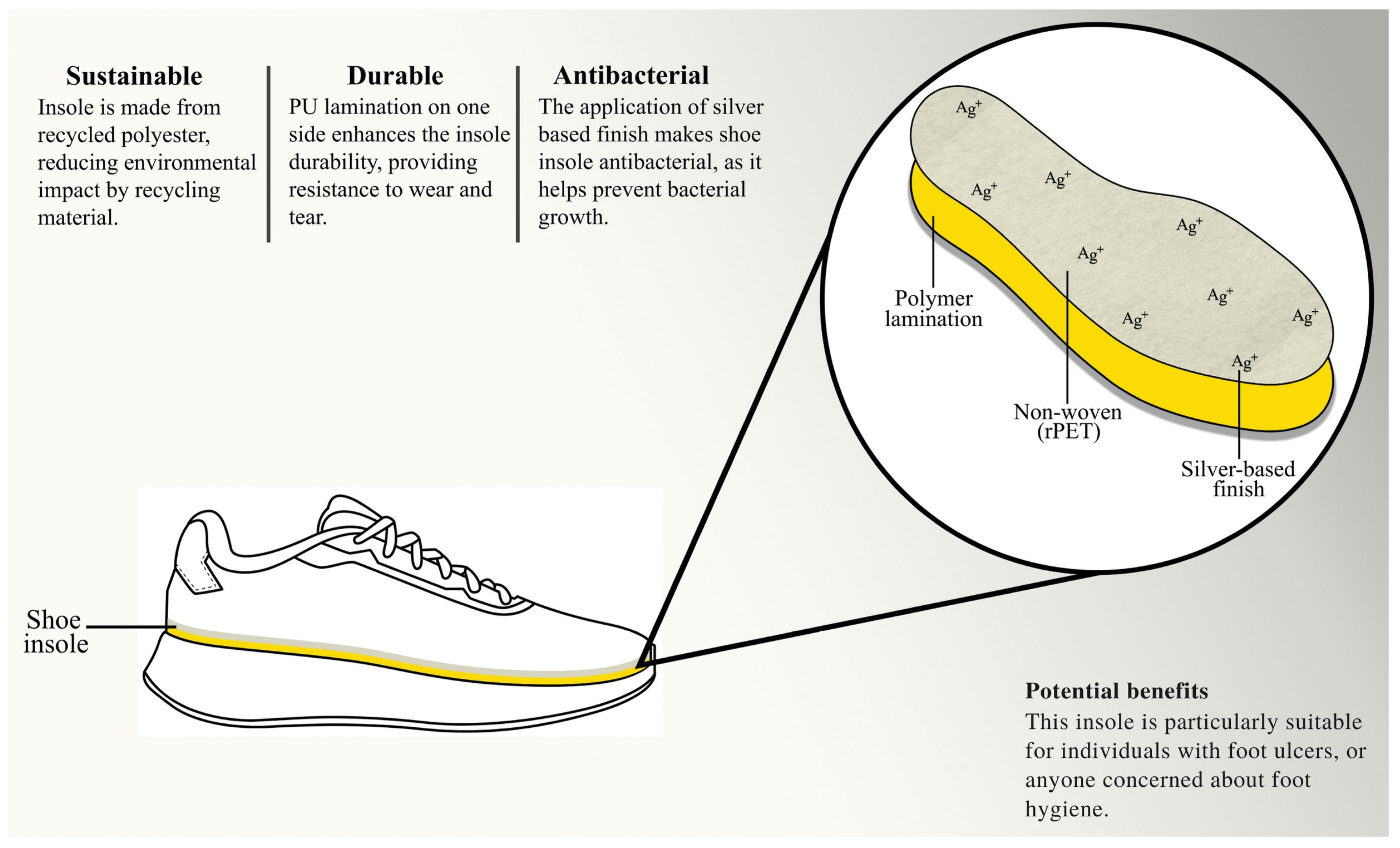

1. Introduction

2. Experimental

2.1. Materials

2.2. Design of Experiment

2.3. Methodology

2.3.1. Development of rPET Non-Woven Fabric

2.3.2. PU Lamination

2.3.3. Silver-Based Finish Application

2.3.4. Washing

2.4. Characterization

2.4.1. Relative Hand Value Test

2.4.2. Moisture Management Test

2.4.3. Antibacterial Test

2.4.4. Tensile Strength

2.4.5. Abrasion

3. Results and Discussion

3.1. Relative Hand Value

3.2. Moisture Management

3.3. Antibacterial Test

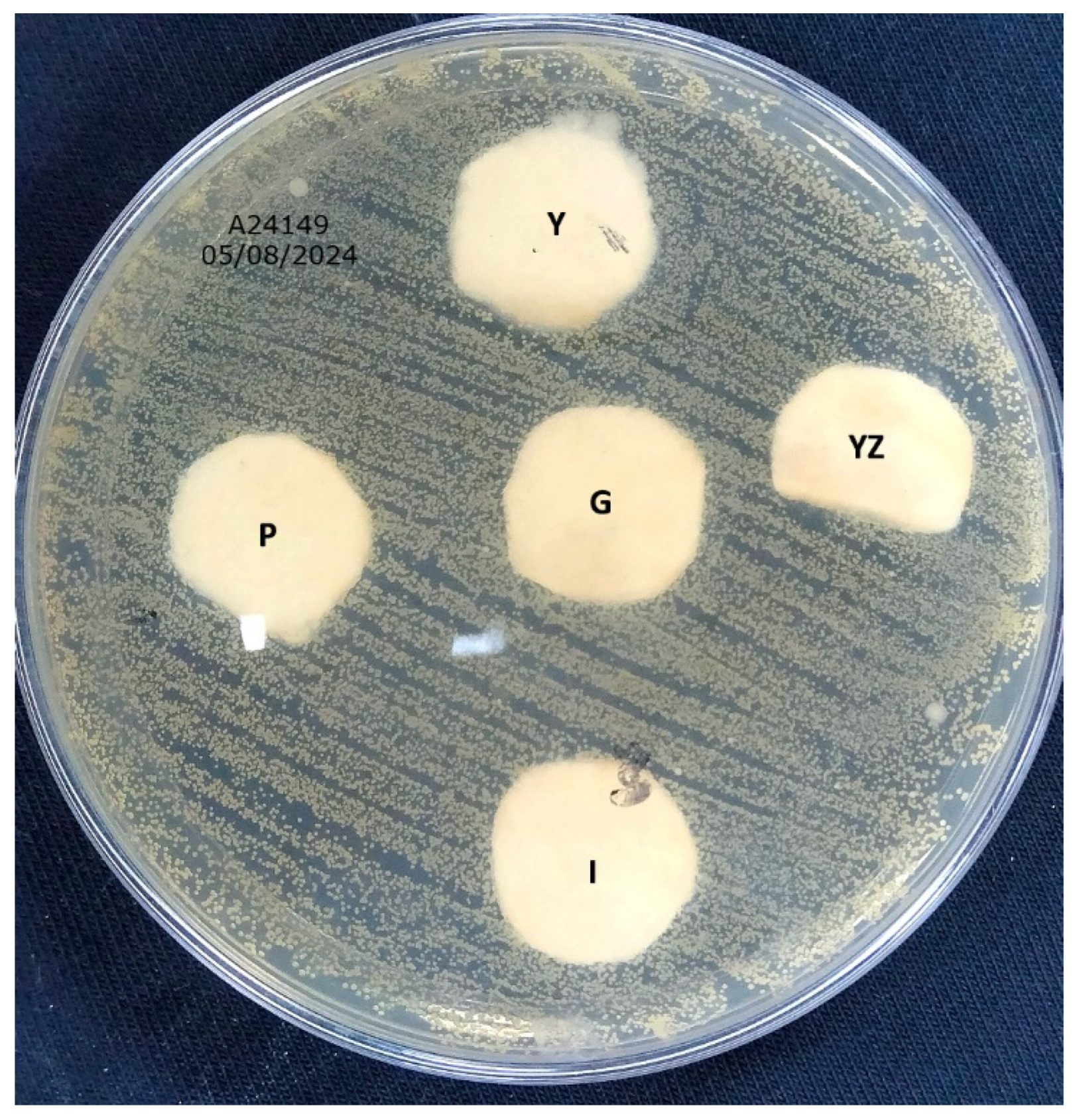

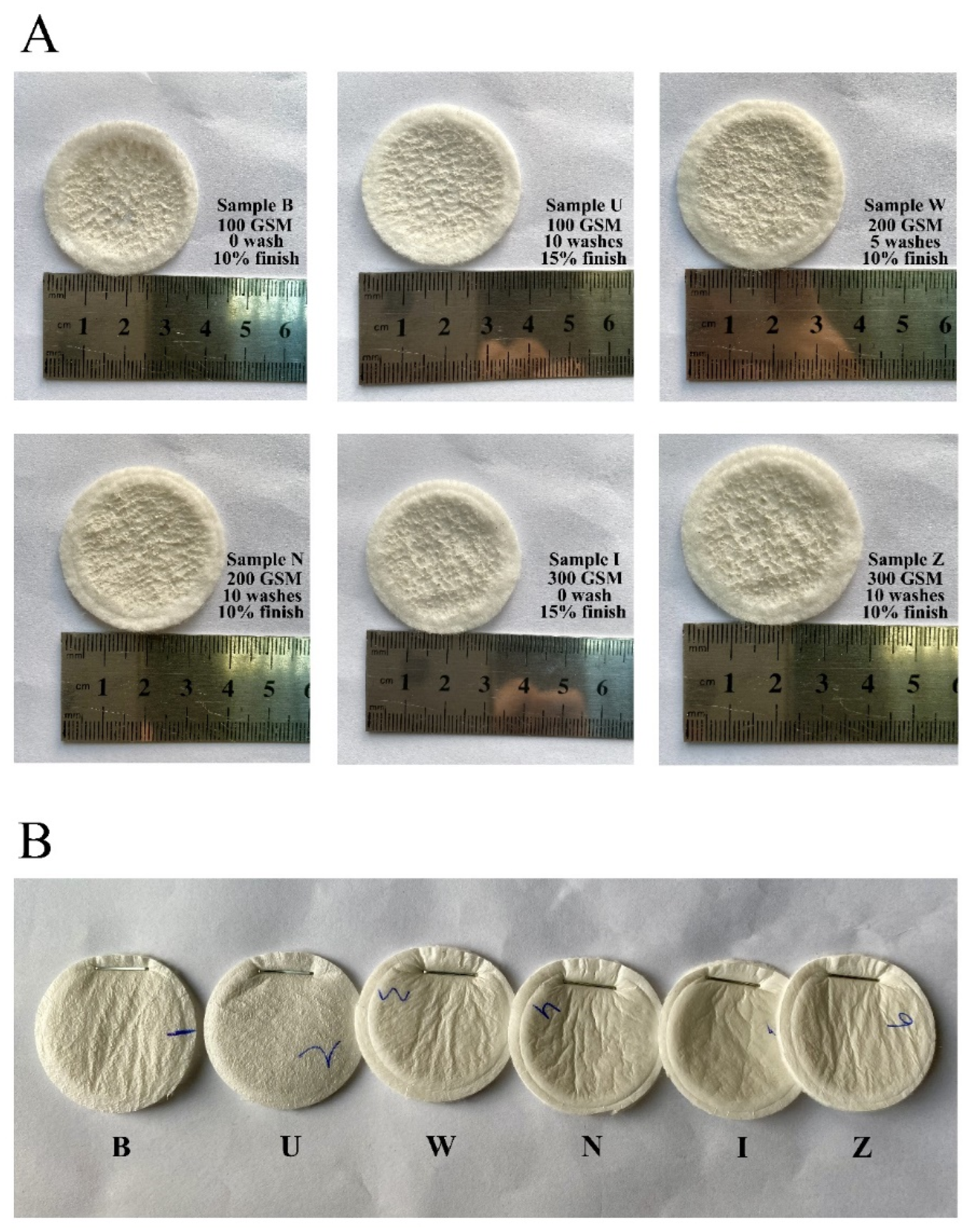

3.3.1. Qualitative Antibacterial Test

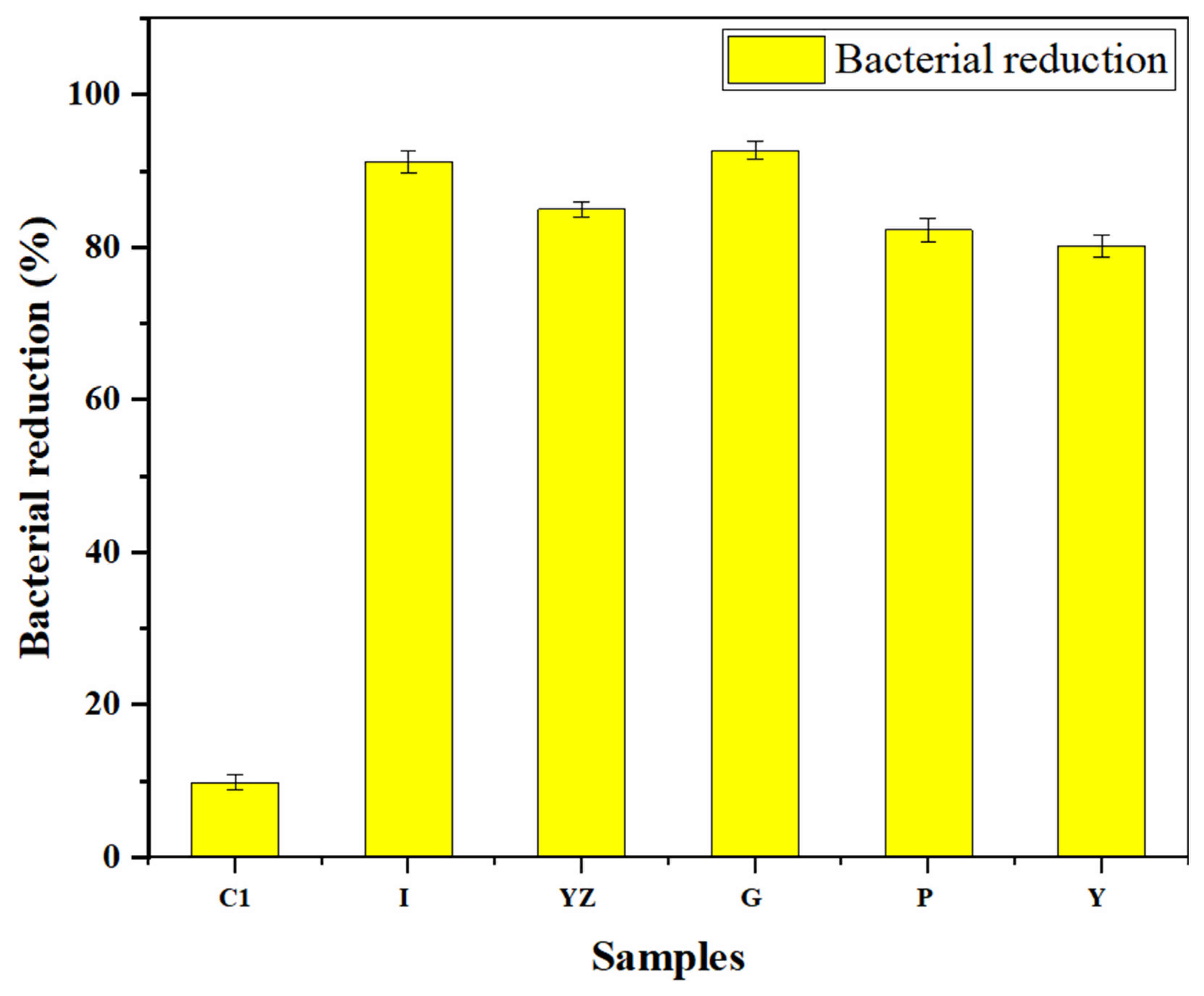

3.3.2. Quantitative Antibacterial Test

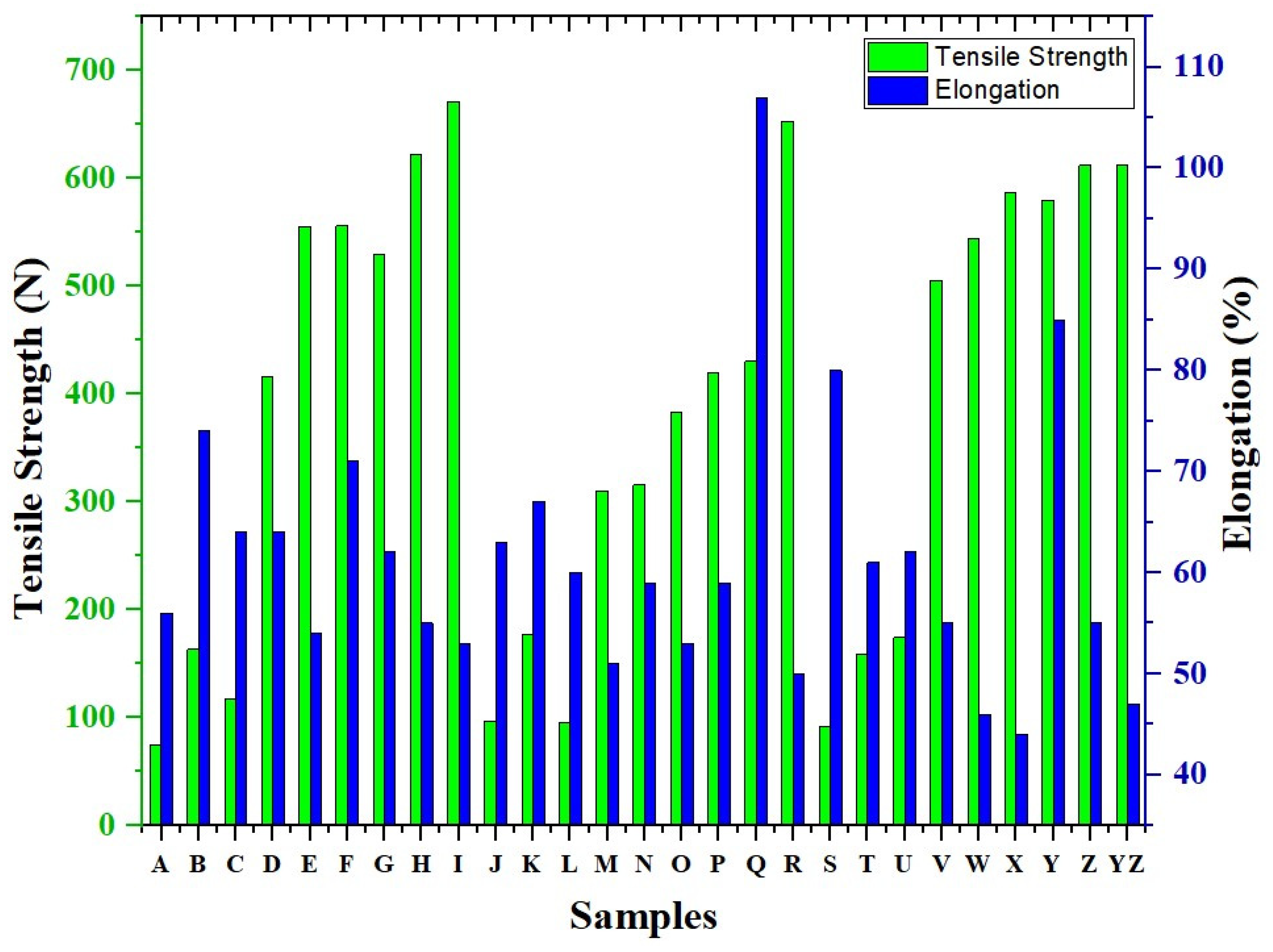

3.4. Tensile Strength Evaluation

3.5. Abrasion Resistance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Morris, H.; Murray, R. Medical textiles. Text. Prog. 2020, 52, 1–127. [Google Scholar] [CrossRef]

- Ulbrecht, J.S.; Cavanagh, P.R.; Caputo, G.M. Foot Problems in Diabetes: An Overview. Clin. Infect. Dis. 2004, 39 (Suppl. S2), S73–S82. [Google Scholar] [CrossRef] [PubMed]

- Yick, K.L.; Tse, C.Y. Textiles and other materials for orthopaedic footwear insoles. In Handbook of Footwear Design and Manufacture; Woodhead Publishing: Sawston, UK, 2013. [Google Scholar] [CrossRef]

- Sun, D.; McCullough, H. An Investigation into the Performance Viability of Recycled Polyester from Recycled Polyethylene Terephthalate (R-PET). J. Text. Sci. Fash. Technol. 2019, 2, 1–8. [Google Scholar] [CrossRef]

- Kumar, P.S.; Suganya, S. Test Methods and Identification of Recycled Polyester. In Recycled Polyester; Springer: Singapore, 2020. [Google Scholar] [CrossRef]

- Hegyi, A.; Vermeșan, H.; Lăzărescu, A.-V.; Petcu, C.; Bulacu, C. Thermal Insulation Mattresses Based on Textile Waste and Recycled Plastic Waste Fibres, Integrating Natural Fibres of Vegetable or Animal Origin. Materials 2022, 15, 1348. [Google Scholar] [CrossRef]

- Van Rensburg, M.L.; Nkomo, S.L.; Mkhize, N.M. Life cycle and End-of-Life management options in the footwear industry: A review. Waste Manag. Res. 2020, 38, 599–613. [Google Scholar] [CrossRef]

- Healy, A.; Dunning, D.; Chockalingam, N. Effect of insole material on plantar pressure. Footwear Sci. 2011, 3, S69–S70. [Google Scholar] [CrossRef]

- Gnanasundaram, S.; Ranganathan, M.; Das, B.N.; Mandal, A.B. Surface modified and medicated polyurethane materials capable of controlling microorganisms causing foot skin infection in athletes. Colloids Surf. B Biointerfaces 2013, 102, 139–145. [Google Scholar] [CrossRef]

- Morais, D.S.; Guedes, R.M.; Lopes, M.A. Antimicrobial approaches for textiles: From research to market. Materials 2016, 9, 498. [Google Scholar] [CrossRef]

- Tania, I.S.; Ali, M.; Arafat, M.T. Processing techniques of antimicrobial textiles. In Antimicrobial Textiles from Natural Resources; Woodhead Publishing: Sawston, UK, 2021; pp. 189–215. [Google Scholar] [CrossRef]

- Bratchenya, L.A.; Tolochkova, O.N.; Lebedeva, M.V. Creation of nonwoven shoe materials with improved hygienic properties. Fibre Chem. 2012, 43, 369–371. [Google Scholar] [CrossRef]

- Rajan, T.P.; Souza, L.D.; Ramakrishnan, G.; Zakriya, G.M. Comfort properties of functional warp-knitted polyester spacer fabrics for shoe insole applications. J. Ind. Text. 2014, 45, 1239–1251. [Google Scholar] [CrossRef]

- Fatkullina, R.R.; Yarullin, R.M.; Abutalipova, L.N.; Khadysov, B.A. Effect of Low-Temperature Plasma Treatment on The Properties of a Complex Wool-Containing Material. J. Phys. Conf. Ser. 2022, 2379, 012002. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, H.; Yuan, T.; Ma, L.; Liu, N.; Sun, P. Friction-induced noise of vehicle wiper-windshield system: A review. Results Eng. 2023, 20, 101557. [Google Scholar] [CrossRef]

- Azam, F.; Ali, H.; Ahmad, F.; Rasheed, A.; Ahmad, S.; Ali, M.U.; Nawab, Y. A Fibrous Nonwoven Hydrogel Composite for Shoe Insole with Enhanced Mechanical and Comfort Properties. J. Polym. Environ. 2023, 32, 399–410. [Google Scholar] [CrossRef]

- Wang, S.; Hou, W.; Wei, L.; Dai, J.; Jia, H.; Liu, X.; Xu, B. Structure and properties of composite antibacterial PET fibers. J. Appl. Polym. Sci. 2009, 112, 1927–1932. [Google Scholar] [CrossRef]

- Smith, L.; Ali, M.; Agrissais, M.; Mulligan, S.; Koh, L.; Martin, N. A comparative life cycle assessment of dental restorative materials. Dent. Mater. 2022, 39, 13–24. [Google Scholar] [CrossRef]

- Messaoud, M.; Vaesken, A.; Aneja, A.; Schacher, L.; Adolphe, D.C.; Schaffhauser, J.-B.; Strehle, P. Physical and mechanical characterizations of recyclable insole product based on new 3D textile structure developed by the use of a patented vertical-lapping process. J. Ind. Text. 2013, 44, 497–512. [Google Scholar] [CrossRef]

- Sadeghi, B.; Marfavi, Y.; AliAkbari, R.; Kowsari, E.; Ajdari, F.B.; Ramakrishna, S. Recent Studies on Recycled PET Fibers: Production and Applications: A Review. Mater. Circ. Econ. 2021, 3, 4. [Google Scholar] [CrossRef]

- Cognard, P. Adhesives and Sealants: General Knowledge, Application of Techniques, New Curing Techniques. 2006. Available online: https://books.google.com.pk/books?hl=en&lr=&id=4UjQAEmjghUC&oi=fnd&pg=PP1&dq=21.%09P.+Cognard,+Adhesives+and+Sealants:+General+Knowledge,+Application+of+techniques,+new+curing+techniques.+2006.+&ots=O0HdE_8NhE&sig=cWFq68VhISizjqsvHZgaGTxEG5s&redir_esc=y#v=onepage&q=21.%09P.%20Cognard%2C%20Adhesives%20and%20Sealants%3A%20General%20Knowledge%2C%20Application%20of%20techniques%2C%20new%20curing%20techniques.%202006.&f=false (accessed on 16 October 2024).

- Afroz, S.; Azady, M.A.R.; Akter, Y.; Al Ragib, A.; Hasan, Z.; Rahaman, M.S.; Islam, J.M. Self-cleaning textiles: Structure, fabrication and applications. In Fundamentals of Natural Fibres and Textiles; Woodhead Publishing: Sawston, UK, 2021; pp. 557–597. [Google Scholar] [CrossRef]

- ISO 105-C03; Colour Fastness to Washing. International Organization for Standardization: Geneva, Switzerland, 1989.

- Hribernik, S.; Pivec, T.; Kurečič, M.; Kolar, M.; Stana-Kleinschek, K. Optimization of the sol-gel–assisted procedure for binding of silver onto modal fibres. In Proceedings of the 7th central European Conference 2012 Fibre-Grade Polymers, Portorose, Slovenia, 15–17 September 2012. [Google Scholar]

- Dabolina, I.; Abu-Rous, M.; Lapkovska, E. A Fast Training Method of a Fabric Hand-Feel Panel under Industry Conditions, and Its Conformity with Other Human and Instrumental Approaches. Appl. Sci. 2022, 12, 12344. [Google Scholar] [CrossRef]

- AATCC-202; Relative Hand Value of Textiles: Instrumental. American Association of Textile Chemists and Colorists: Research Triangle Park, NC, USA, 2012.

- Yim; Ka, Y. Correlation between Fabric Specifications and Fabric Hand Characteristics for Warp Knitted Fabrics. Master’s Thesis, Hong Kong Polytechnic University, Hong Kong, China, 2016.

- McQueen, R.; Batcheller, J.; Mah, T.; Hooper, P. Development of a protocol to assess fabric suitability for testing liquid moisture transport properties. J. Text. Inst. 2013, 104, 900–905. [Google Scholar] [CrossRef]

- AATCC TM 195; Liquid Moisture Management Properties of Textile Fabrics. American Association of Textile Chemists and Colorists: Research Triangle Park, NC, USA, 2009.

- Öner, E.; Atasağun, H.G.; Okur, A.; Beden, A.R.; Durur, G. Evaluation of moisture management properties on knitted fabrics. J. Text. Inst. 2013, 104, 699–707. [Google Scholar] [CrossRef]

- AATCC147; Antibacterial Activity of Textile Materials: Parallel Streak. American Association of Textile Chemists and Colorists: Research Triangle Park, NC, USA, 1976.

- Yıldırım, F.F.; Avinc, O.; Yavas, A.; Sevgisunar, G. Sustainable Antifungal and Antibacterial Textiles Using Natural Resources. In Sustainability in the Textile and Apparel Industries; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- AATCC 100; Antibacterial Finishes on Textile Materials: Assessment. American Association of Textile Chemists and Colorists: Research Triangle Park, NC, USA, 1961.

- Aksit, A.; Camlibel, N.O.; Zeren, E.T.; Kutlu, B. Development of antibacterial fabrics by treatment with Ag-doped TiO2 nanoparticles. J. Text. Inst. 2017, 108, 2046–2056. [Google Scholar] [CrossRef]

- ISO13934-1; Textiles—Tensile Properties of Fabrics—Part 1: Determination of Maximum Force and Elongation at Maximum Force Using the Strip Method. International Organization for Standardization: Geneva, Switzerland, 2013.

- von Maubeuge, K.P.; Ehrenberg, H. Comparison of peel bond and shear tensile test methods for needlepunched geosynthetic clay liners. Geotext. Geomembr. 2000, 18, 203–214. [Google Scholar] [CrossRef]

- ISO12947; Determination of the abrasion resistance of fabrics by the Martindale method. International Organization for Standardization: Geneva, Switzerland, 1998.

- Kara, S.; Yesilpinar, S.; Aksit, A. Permeability properties and abrasion resistance of coated polypropylene fabrics. Fibres Text 2018, 25, 40–47. [Google Scholar]

- Wang, W.Y.; Yim, H.H.L.; Kan, C.W.; Chanuntawaree, S.; Chonsakorn, S.; Udon, S.; Peangsai, M.; Mongkholrattanasit, R. A study of relative hand value of quick dry inner wear. Key Eng. Mater. 2020, 831, 171–176. [Google Scholar] [CrossRef]

- Qutaba, S.; Azhari, A.; Asmelash, M.; Haider, M.; Lusi, N. Development of fiber metal laminate composite with different glass fiber GSM. Mater. Today Proc. 2023, 1. [Google Scholar] [CrossRef]

- Li, J.; He, J.; Huang, Y. Role of alginate in antibacterial finishing of textiles. Int. J. Biol. Macromol. 2017, 94, 466–473. [Google Scholar] [CrossRef]

- Patil, S.; Mahapatra, A.; Gotmare, V.D.; Patil, P.G.; Bharimalla, A.K.; Arputharaj, A. Effect of different mercerization techniques on tactile comfort of cotton fabric. Indian J. Fibre Text. Res. 2019, 44, 217–222. [Google Scholar]

- Hasan, Z.; Asif, A.K.M.A.H.; Razzaque, A.; Hasan, R.; Sur, S.; Faruque, O. An Experimental Investigation of Different Washing Processes on Various Properties of Stretch Denim Fabric. J. Mater. Sci. Chem. Eng. 2021, 9, 1–15. [Google Scholar] [CrossRef]

- Venkataraman, D.; Shabani, E.; Park, J.H. Advancement of Nonwoven Fabrics in Personal Protective Equipment. Materials 2023, 16, 3964. [Google Scholar] [CrossRef]

- Vick, C.B.; Okkonen, E.A. Strength and durability of one-part polyurethane adhesive bonds to wood. For. Prod. J. 1998, 48, 71–76. [Google Scholar]

- Deǧirmenci, Z.; Çelik, N. The effects of selected improving methods on wrinkle resistance of warp knitted and laminated car seat cover fabrics. J. Ind. Text. 2013, 44, 245–256. [Google Scholar] [CrossRef]

- Zelova, K.; Glombikova, V. The effect of cyclic wrinkling on the durability of waterproof breathable functional outdoor materials for sportswear. J. Text. Inst. 2024, 1–14. [Google Scholar] [CrossRef]

- Soni, S.; Babel, R.; Saxena, S.; Arputharaj, A.; Raja, A.; Srivastava, M. Enhancing Cotton Fabric Softness and Wrinkle Resistance through Optimized Formulation of Nano ZnO and Benzalkonium Chloride-Enriched Rinse-Cycle Softener. Ecol. Environ. Conserv. 2024, 30, S431–S438. [Google Scholar] [CrossRef]

- Uyanık, S. A Comparative Study on Moisture Management Properties of Cotton/Elastane Plain Knit Fabrics Having Different Elastane Ratio. Fibers Polym. 2022, 23, 2316–2329. [Google Scholar] [CrossRef]

- Dalhat, M. Improving hydrophobicity of asphalt surfaces using pulverized recycled polyethylene terephthalate: Towards efficient roofing/waterproofing. Mater. Today Commun. 2024, 39, 109166. [Google Scholar] [CrossRef]

- Pinho, E.; Magalhães, L.; Henriques, M.; Oliveira, R. Antimicrobial activity assessment of textiles: Standard methods comparison. Ann. Microbiol. 2010, 61, 493–498. [Google Scholar] [CrossRef]

- Sivaramakrishnan, C.N. Antimicrobial finishes. Colourage 2007, 54, 3–4. [Google Scholar]

- Luo, Y.; Wang, C.; Wang, L.; Ding, X.; Wu, X. Effect of a novel press washing mode on appearance and mechanical properties of silk garments: Comparison with hand washing and front-loading machine washing. J. Text. Inst. 2022, 114, 959–973. [Google Scholar] [CrossRef]

- Xu, T.; Goldthorpe, I.A. Mitigating the Impact of Thermoplastic Polyurethane Films on the Performance of Electronic Textiles. In Proceedings of the 2022 IEEE International Flexible Electronics Technology Conference (IFETC), Qingdao, China, 21–24 August 2022; pp. 1–2. [Google Scholar]

- Chen, N.; Silberstein, M.N. A micromechanics-based damage model for non-woven fiber networks. Int. J. Solids Struct. 2018, 160, 18–31. [Google Scholar] [CrossRef]

- Bin Ying, W.; Yu, Z.; Kim, D.H.; Lee, K.J.; Hu, H.; Liu, Y.; Kong, Z.; Wang, K.; Shang, J.; Zhang, R.; et al. Waterproof, Highly Tough, and Fast Self-Healing Polyurethane for Durable Electronic Skin. ACS Appl. Mater. Interfaces 2020, 12, 11072–11083. [Google Scholar] [CrossRef]

| Factors | Levels | ||

|---|---|---|---|

| GSM of Non-woven Fabric | 100 | 200 | 300 |

| Finish Concentration (% on the weight of fabric) | 5 | 10 | 15 |

| Washing | 0 | 5 | 10 |

| Run Order | Samples | GSM | Antibacterial Finish | Washing |

|---|---|---|---|---|

| 1 | F | 200 | 15% | 0 cycles |

| 2 | G | 300 | 5% | 5 cycles |

| 3 | R | 300 | 15% | 5 cycles |

| 4 | Y | 300 | 5% | 10 cycles |

| 5 | X | 200 | 15% | 10 cycles |

| 6 | B | 100 | 10% | 0 cycles |

| 7 | E | 200 | 10% | 0 cycles |

| 8 | S | 100 | 5% | 10 cycles |

| 9 | K | 100 | 10% | 5 cycles |

| 10 | C | 100 | 15% | 0 cycles |

| 11 | YZ | 300 | 15% | 10 cycles |

| 12 | L | 100 | 15% | 5 cycles |

| 13 | W | 200 | 10% | 10 cycles |

| 14 | U | 100 | 15% | 10 cycles |

| 15 | G | 300 | 5% | 0 cycles |

| 16 | Z | 300 | 10% | 10 cycles |

| 17 | H | 300 | 10% | 0 cycles |

| 18 | I | 300 | 15% | 0 cycles |

| 19 | T | 100 | 10% | 10 cycles |

| 20 | D | 200 | 5% | 0 cycles |

| 21 | V | 200 | 5% | 10 cycles |

| 22 | N | 200 | 10% | 5 cycles |

| 23 | J | 100 | 5% | 5 cycles |

| 24 | O | 200 | 15% | 5 cycles |

| 25 | Q | 300 | 10% | 5 cycles |

| 26 | M | 200 | 5% | 5 cycles |

| 27 | A | 100 | 5% | 0 cycles |

| Samples | Antibacterial Finish | Washing Cycles | Bacterial Growth in the Sample Contact Area | Clear Zone Inhibition (mm) |

|---|---|---|---|---|

| P | 5% | 5 | No | 0.00 |

| Y | 5% | 10 | No | 0.00 |

| YZ | 15% | 10 | No | 0.00 |

| G | 5% | 0 | No | 0.00 |

| I | 15% | 0 | No | 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naseem, Z.; Zainab, I.; Batool, S.R.; Uzun, M.; Ioanid, A.; Nazeer, M.A. An Innovative Approach to Enhance the Durability and Sustainability of Shoe Insoles. Sustainability 2024, 16, 9195. https://doi.org/10.3390/su16219195

Naseem Z, Zainab I, Batool SR, Uzun M, Ioanid A, Nazeer MA. An Innovative Approach to Enhance the Durability and Sustainability of Shoe Insoles. Sustainability. 2024; 16(21):9195. https://doi.org/10.3390/su16219195

Chicago/Turabian StyleNaseem, Zohra, Iqra Zainab, Syeda Rubab Batool, Muhammet Uzun, Alexandra Ioanid, and Muhammad Anwaar Nazeer. 2024. "An Innovative Approach to Enhance the Durability and Sustainability of Shoe Insoles" Sustainability 16, no. 21: 9195. https://doi.org/10.3390/su16219195

APA StyleNaseem, Z., Zainab, I., Batool, S. R., Uzun, M., Ioanid, A., & Nazeer, M. A. (2024). An Innovative Approach to Enhance the Durability and Sustainability of Shoe Insoles. Sustainability, 16(21), 9195. https://doi.org/10.3390/su16219195