Biofuels and Their Blends—A Review of the Effect of Low Carbon Fuels on Engine Performance

Abstract

:1. Introduction

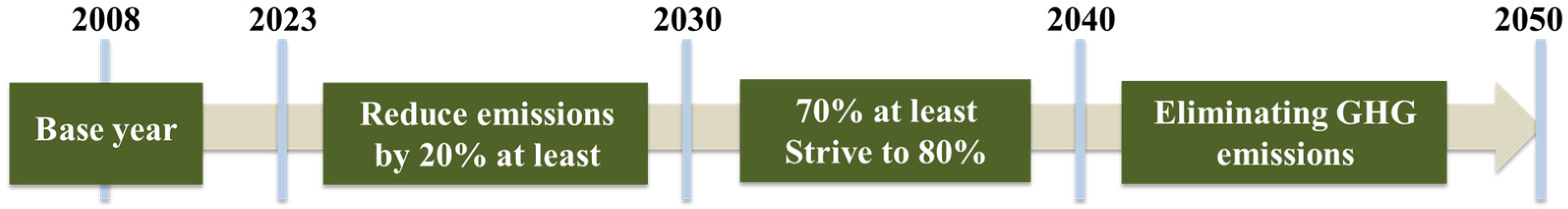

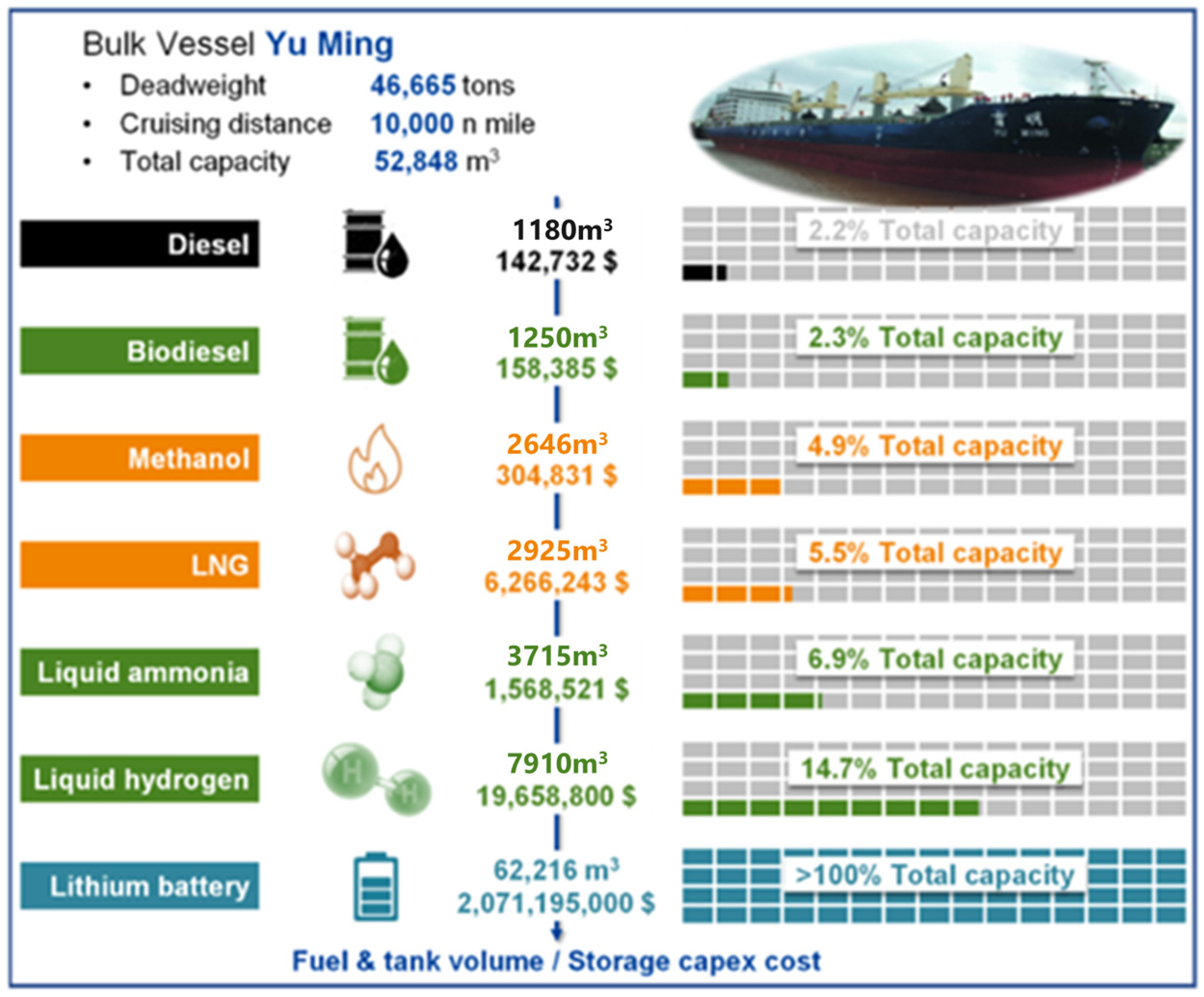

1.1. Research Background

1.2. Biofuel Introduction

1.2.1. The Generations of Biofuels Based on Their Raw Material Sources

1.2.2. First-Generation Biofuel

1.2.3. Second-Generation Biofuel

1.2.4. Third-Generation Biofuel

1.2.5. Other Generation Methods

2. Combustion Characteristics in IC Engines Fueled with Biofuels

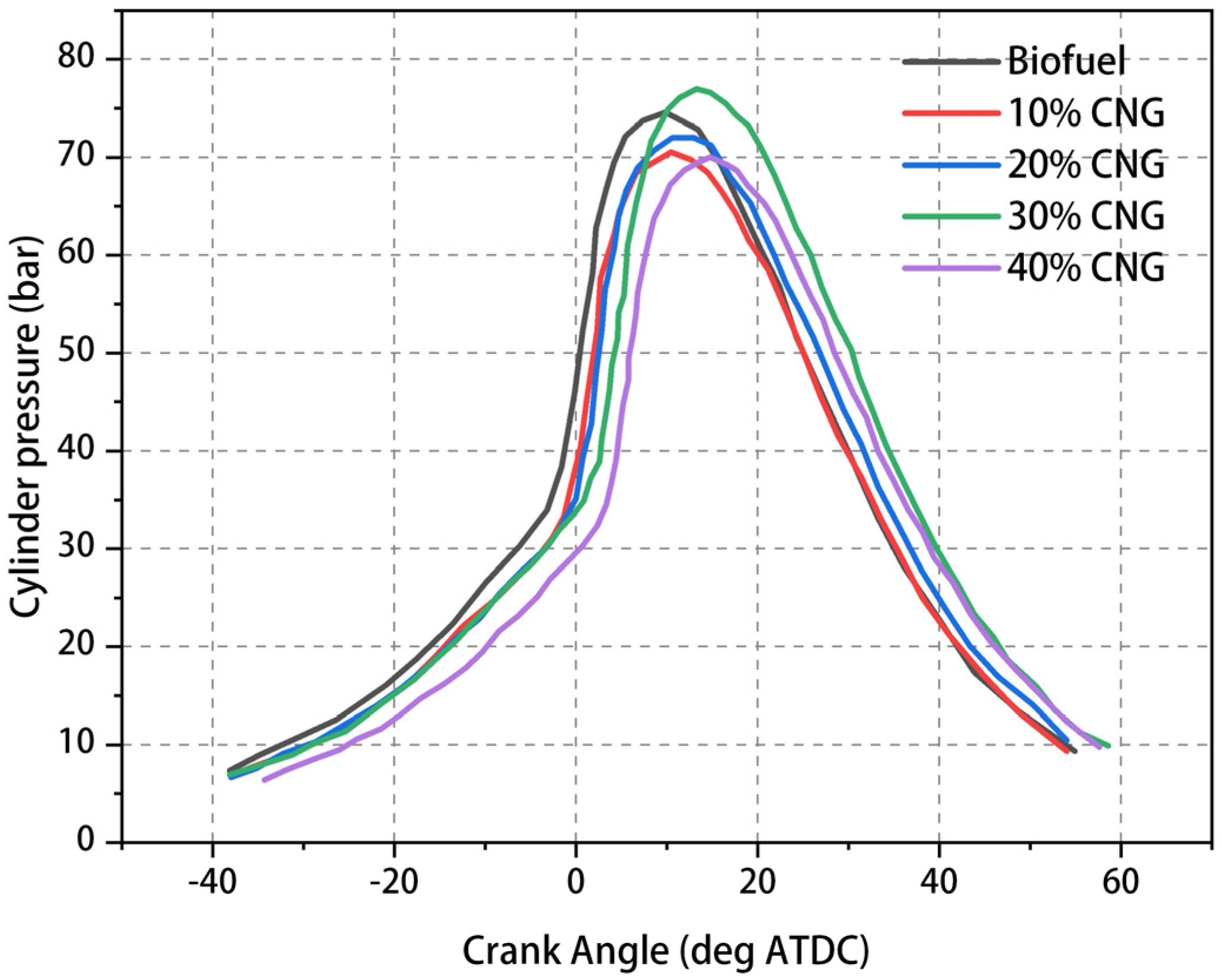

2.1. Cylinder Pressure

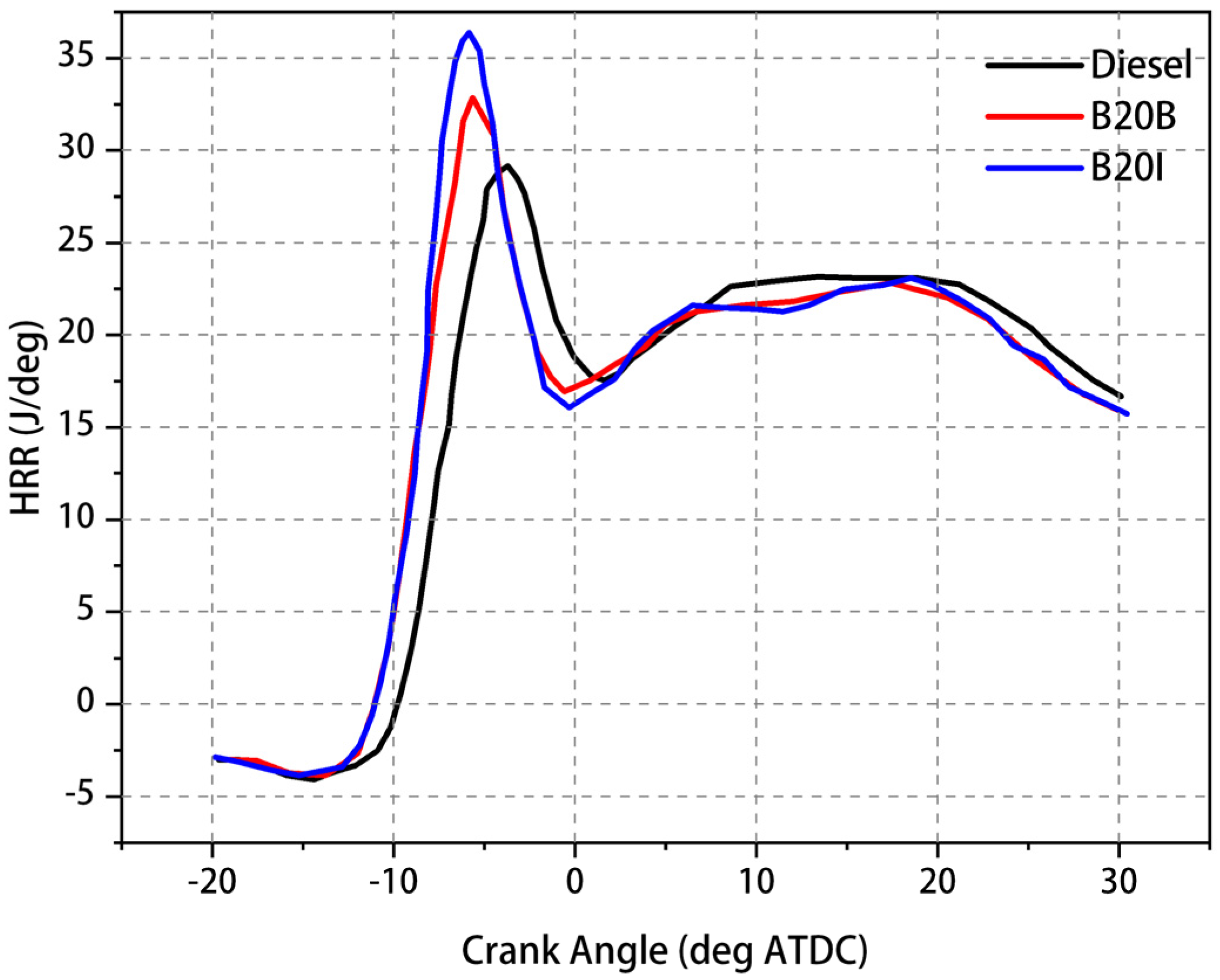

2.2. Heat Release Rate

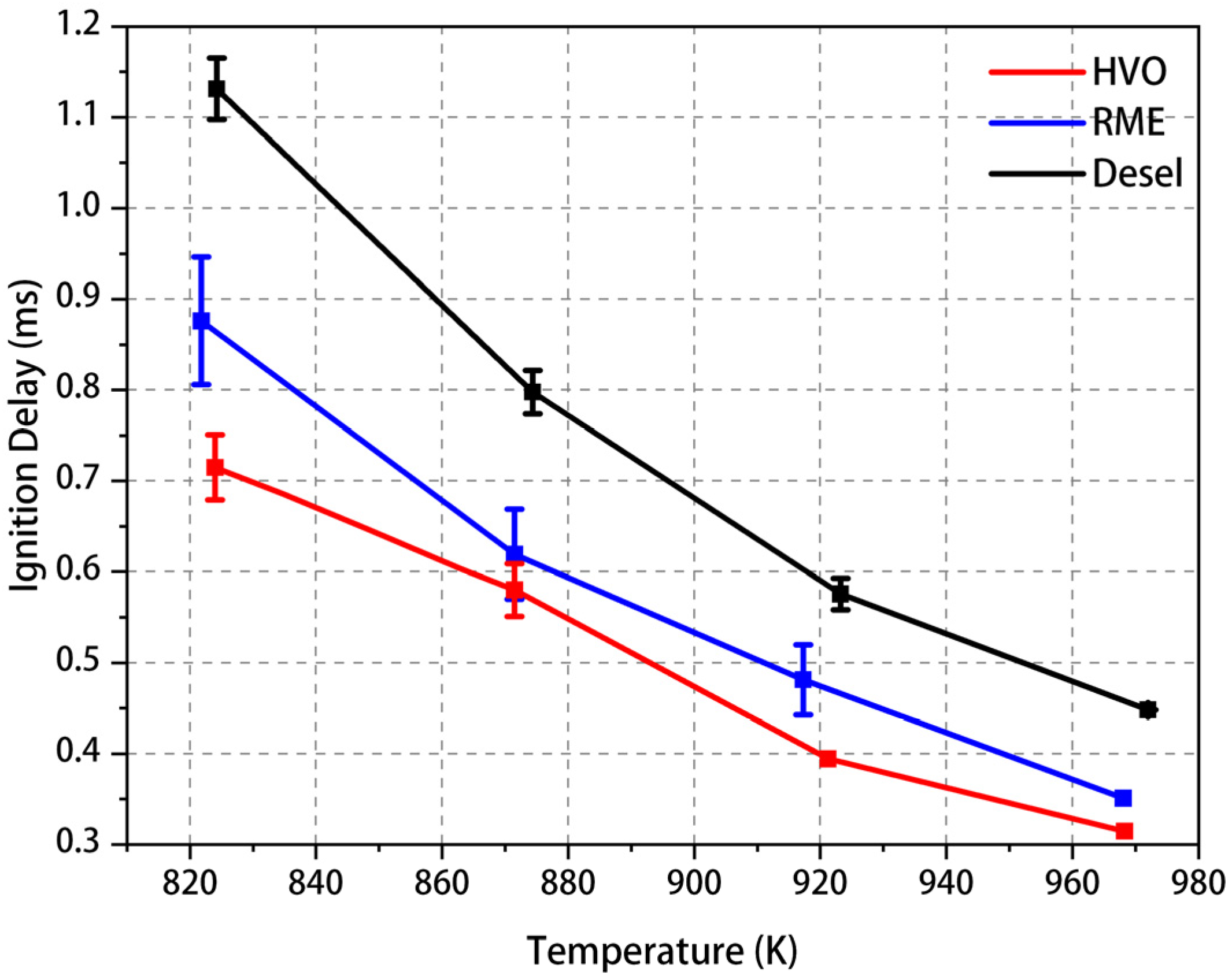

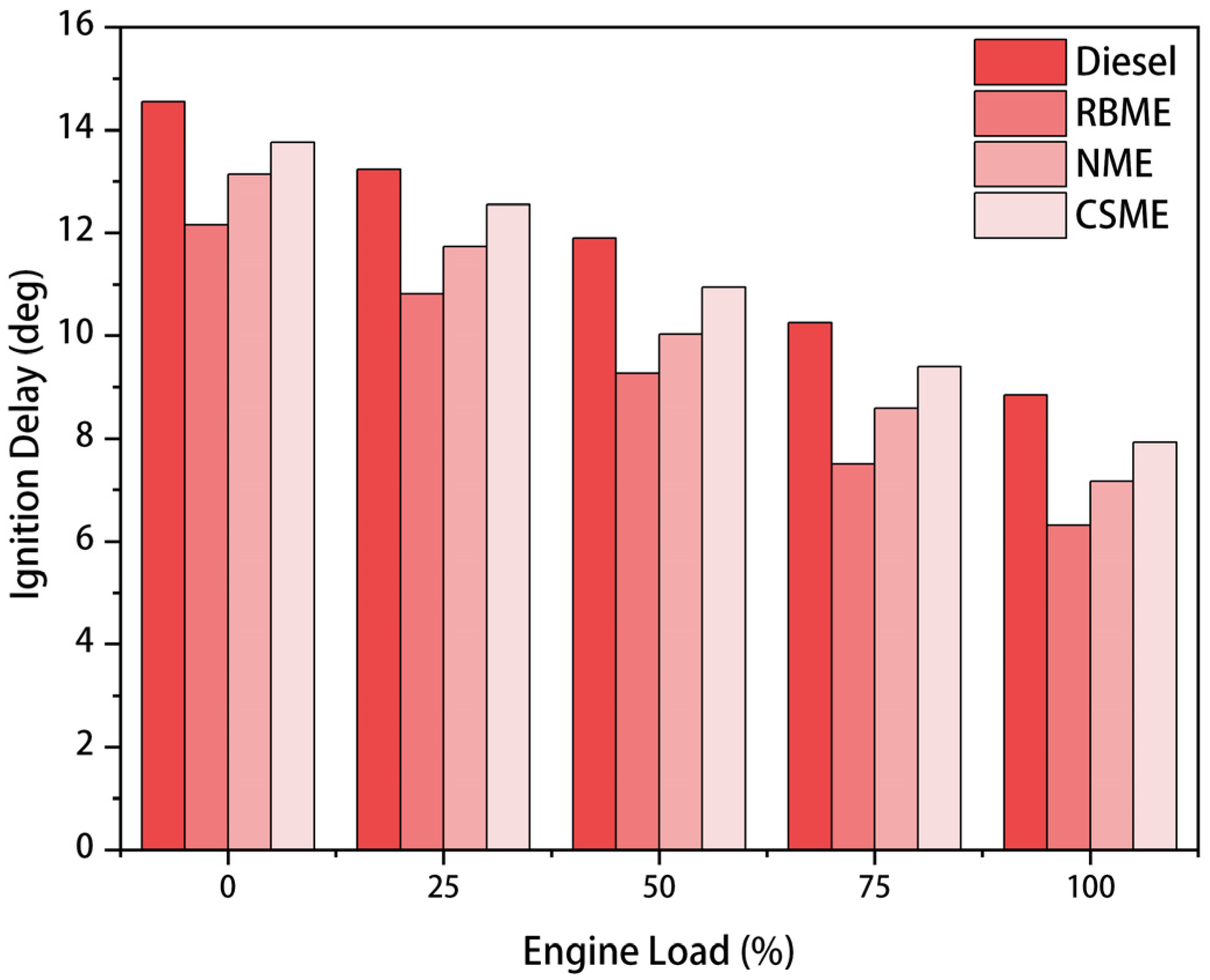

2.3. Ignition Delay

3. Performance Characteristics in IC Engines Fueled with Biofuels

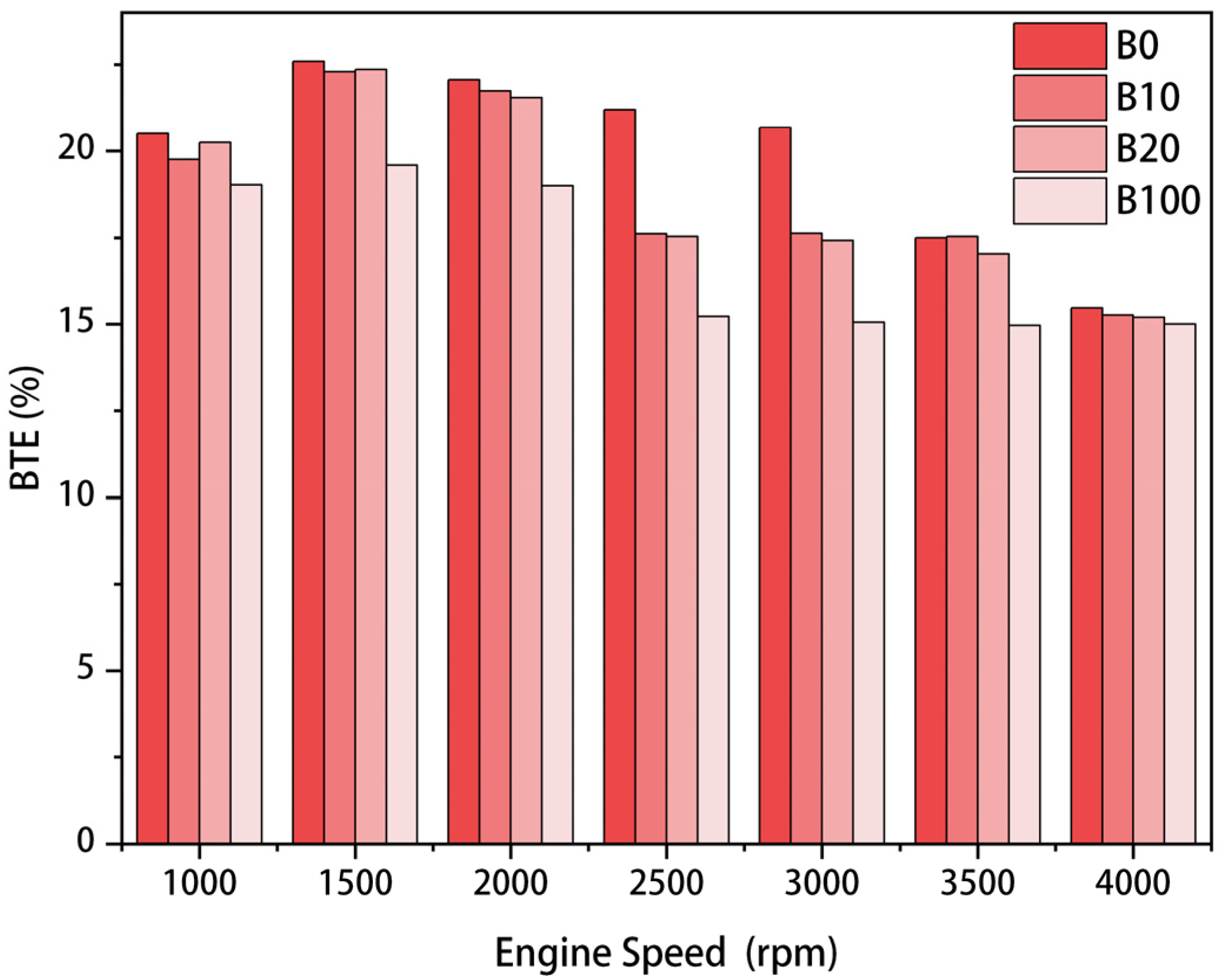

3.1. Brake Thermal Efficiency

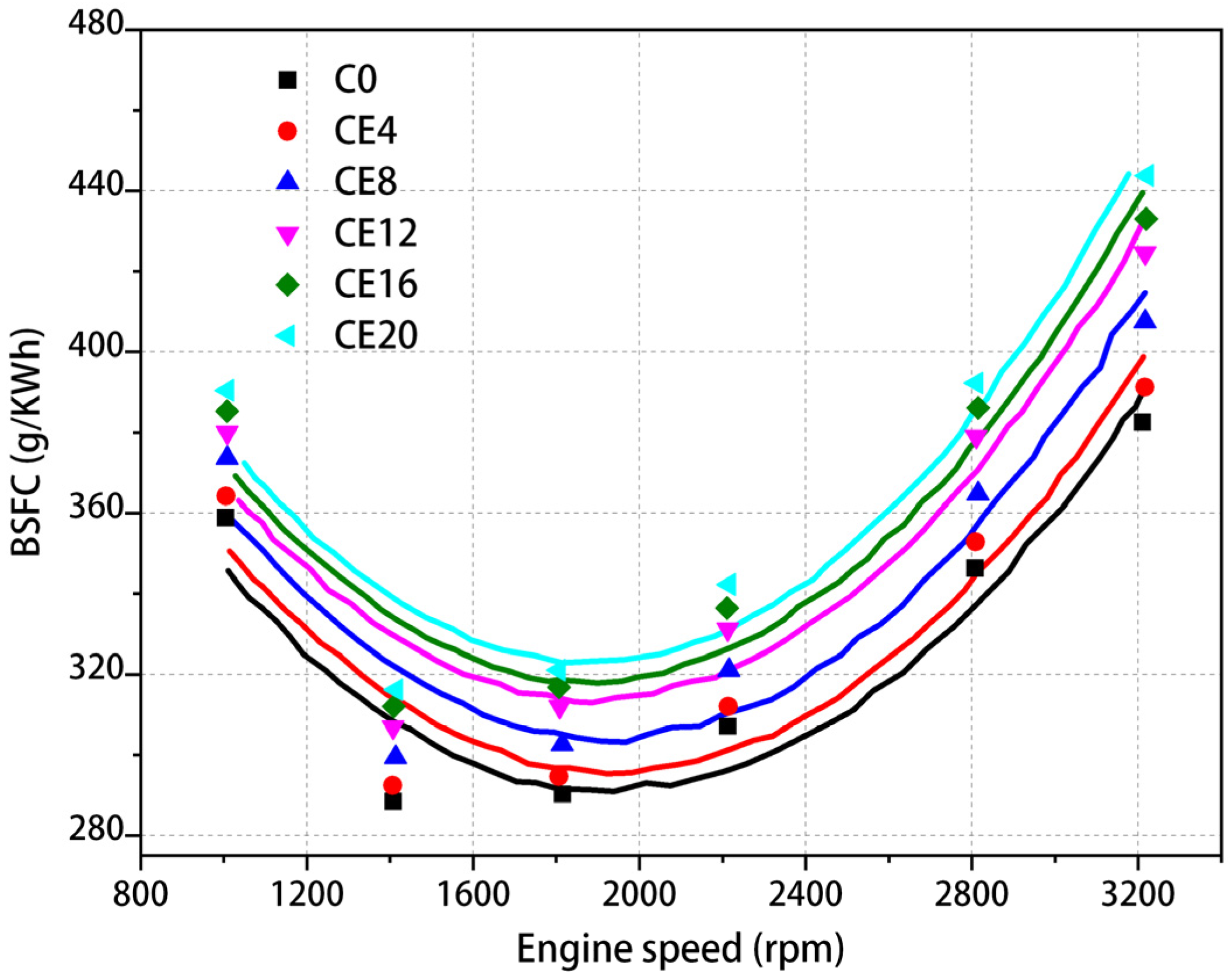

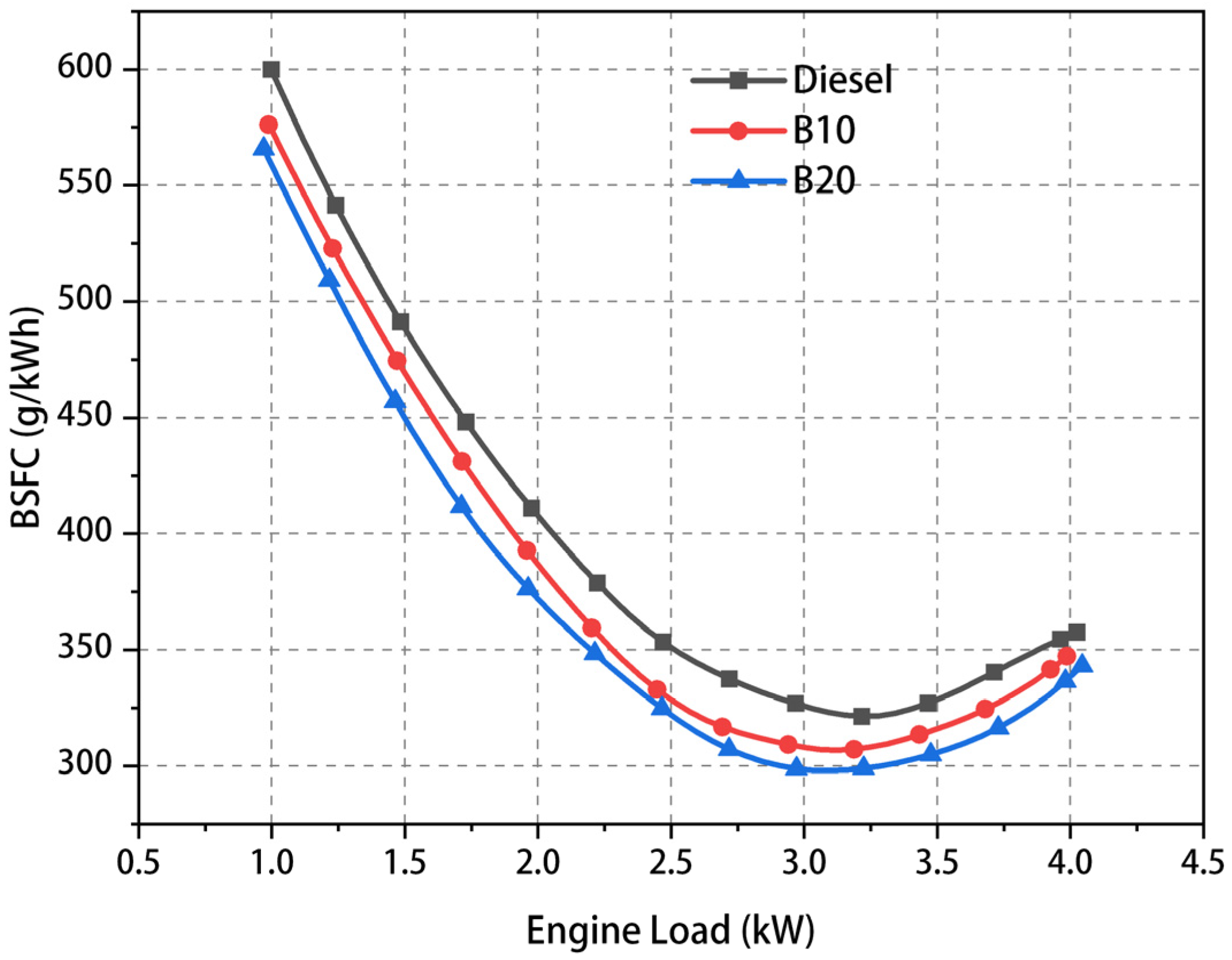

3.2. Brake Specific Fuel Consumption

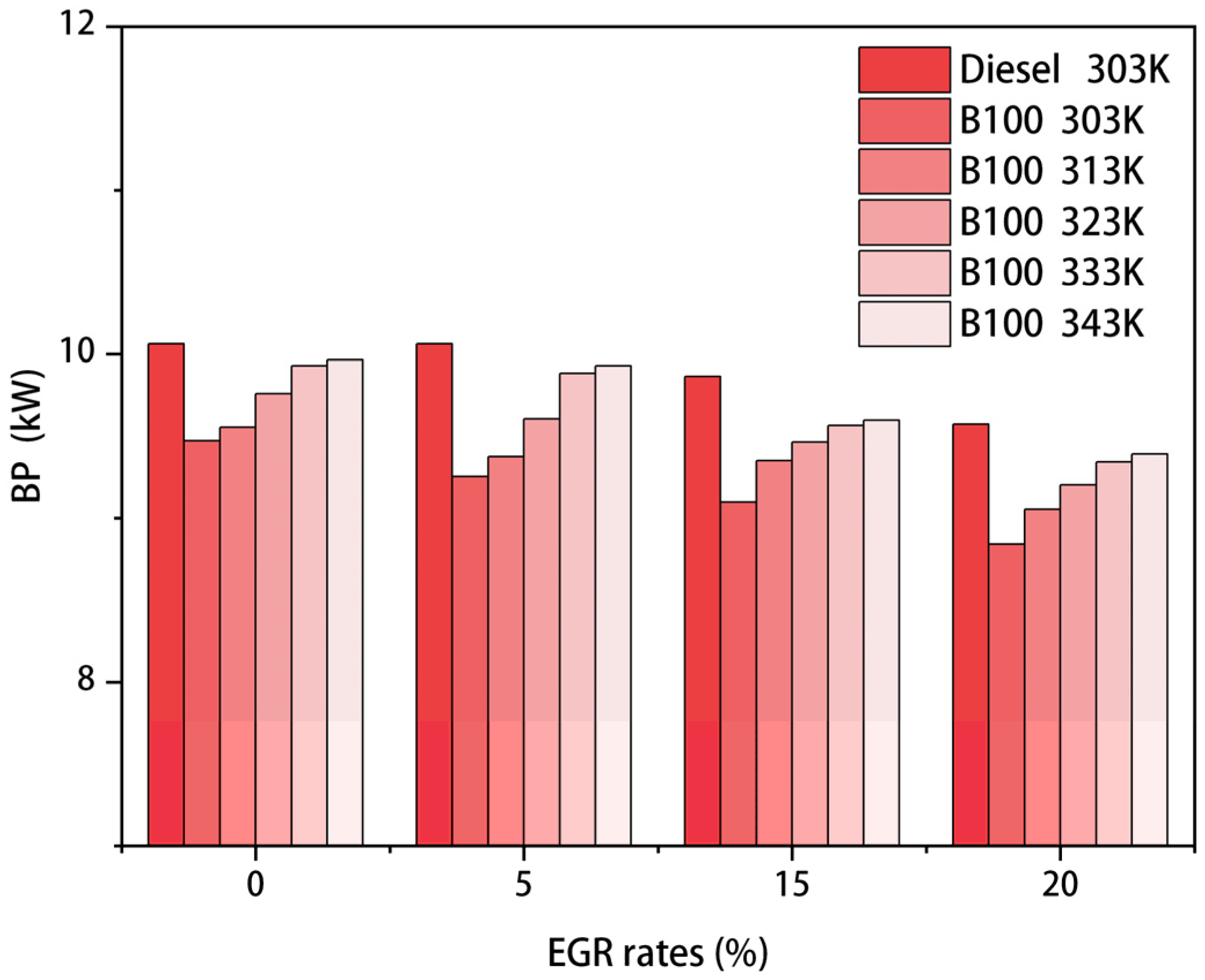

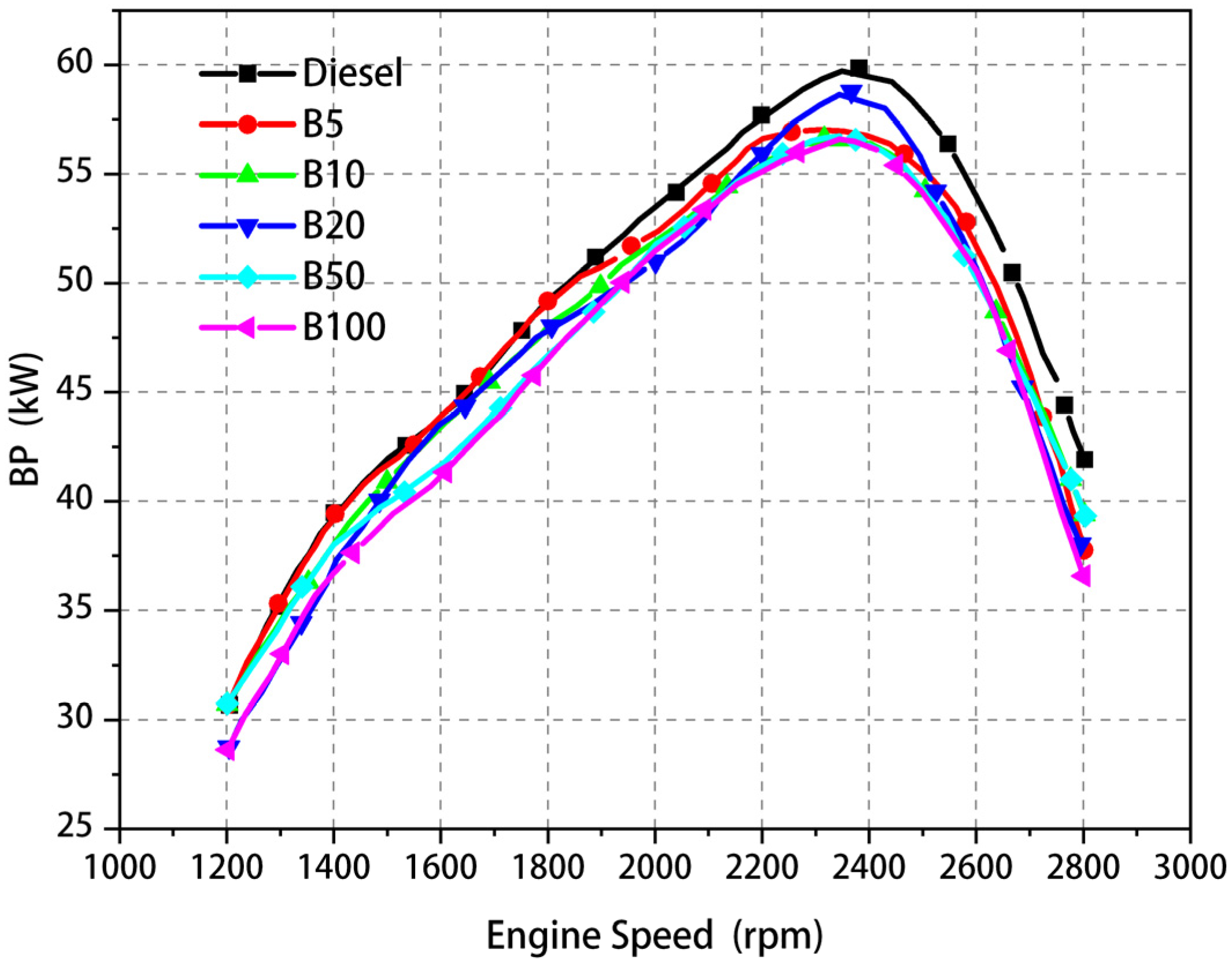

3.3. Brake Power

4. Emission Characteristics in IC Engines Fueled with Biofuels

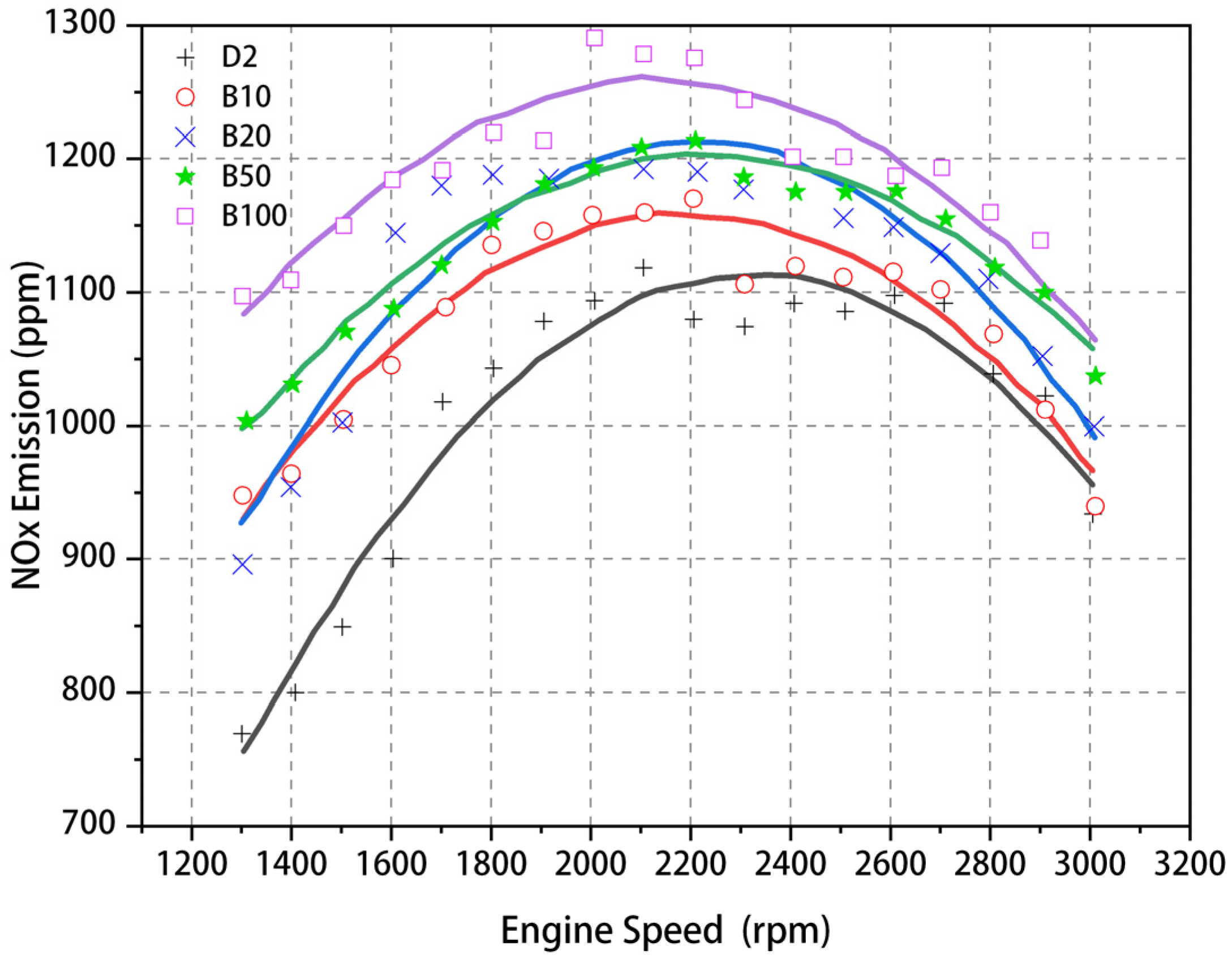

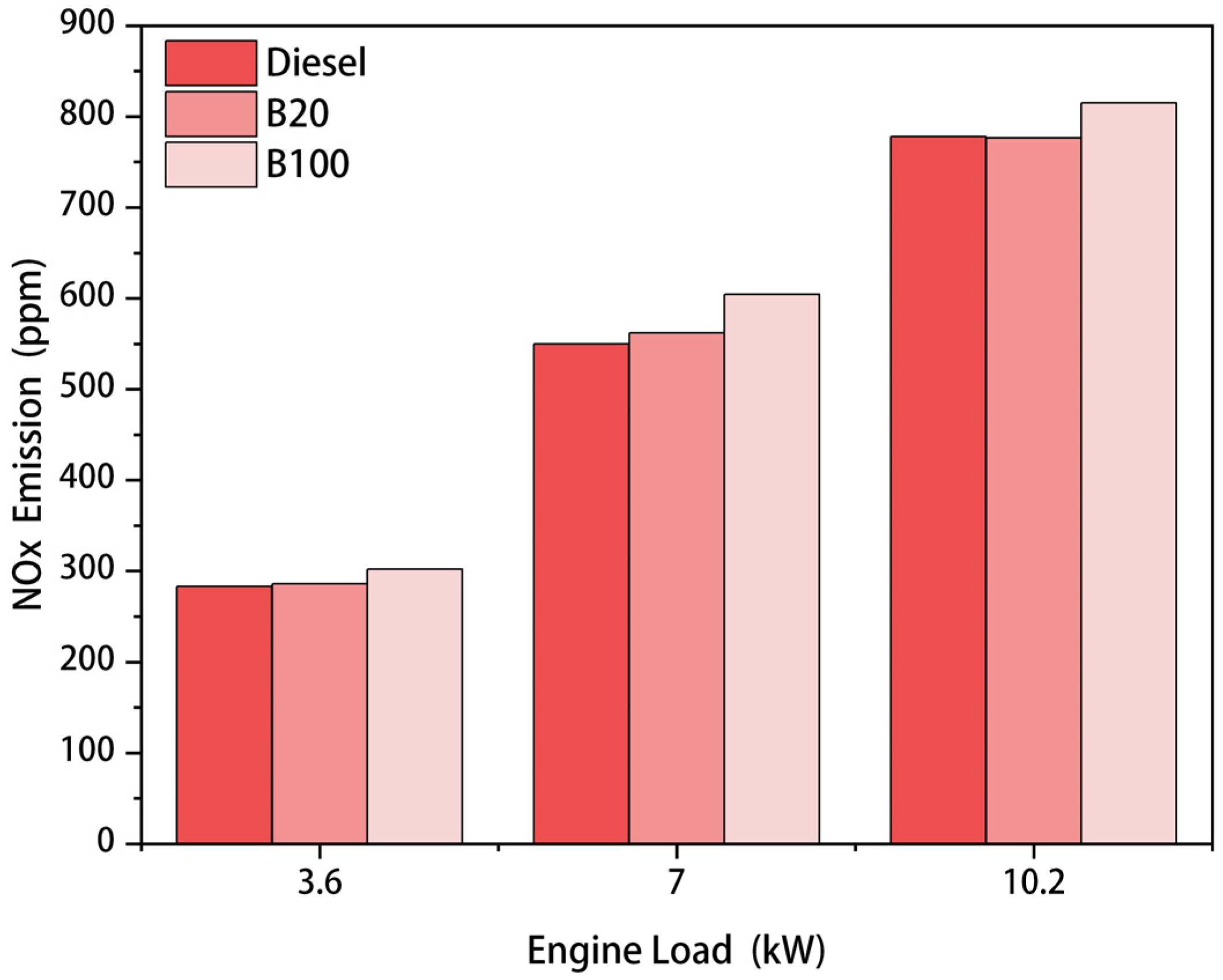

4.1. NOx Emission

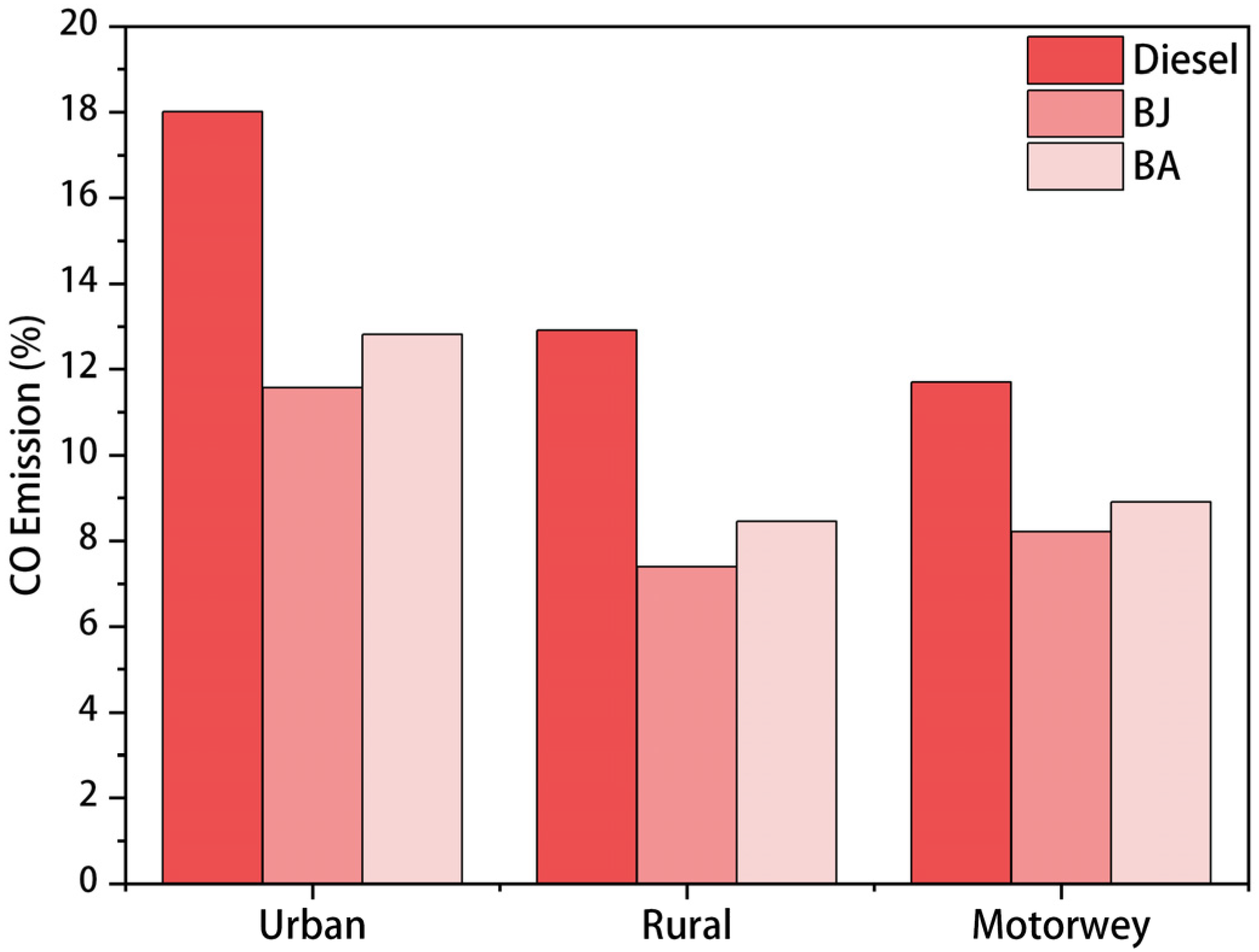

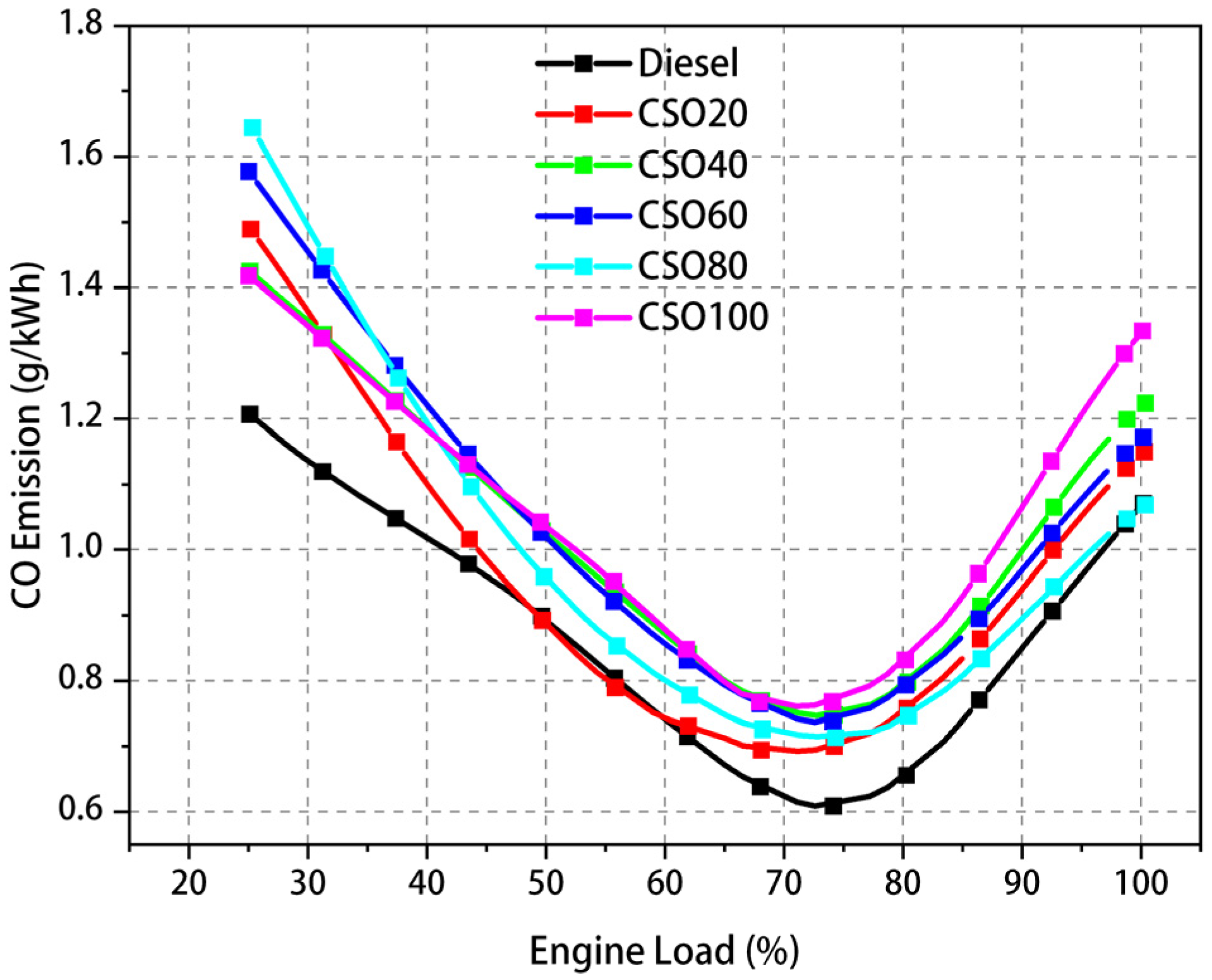

4.2. CO Emission

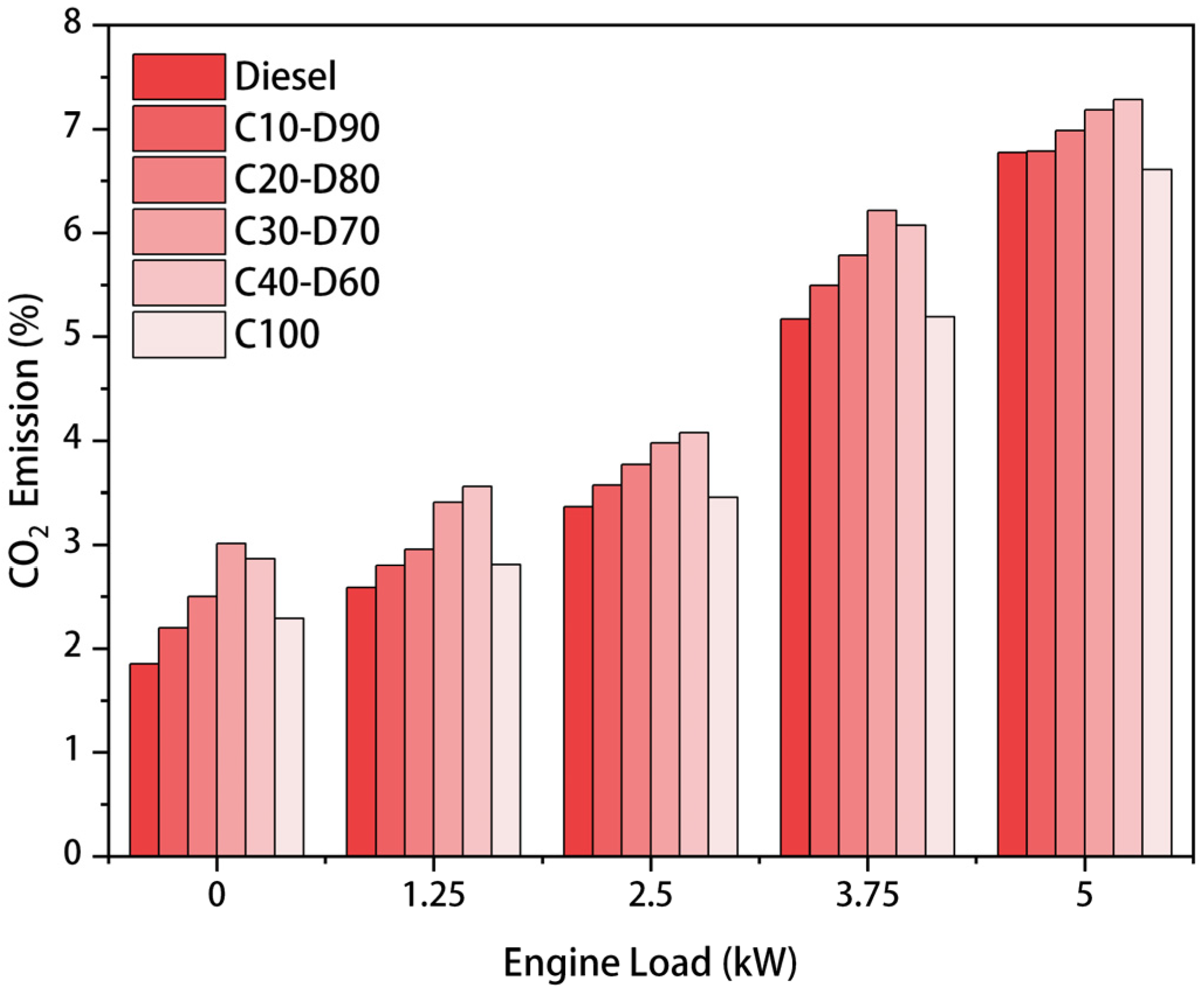

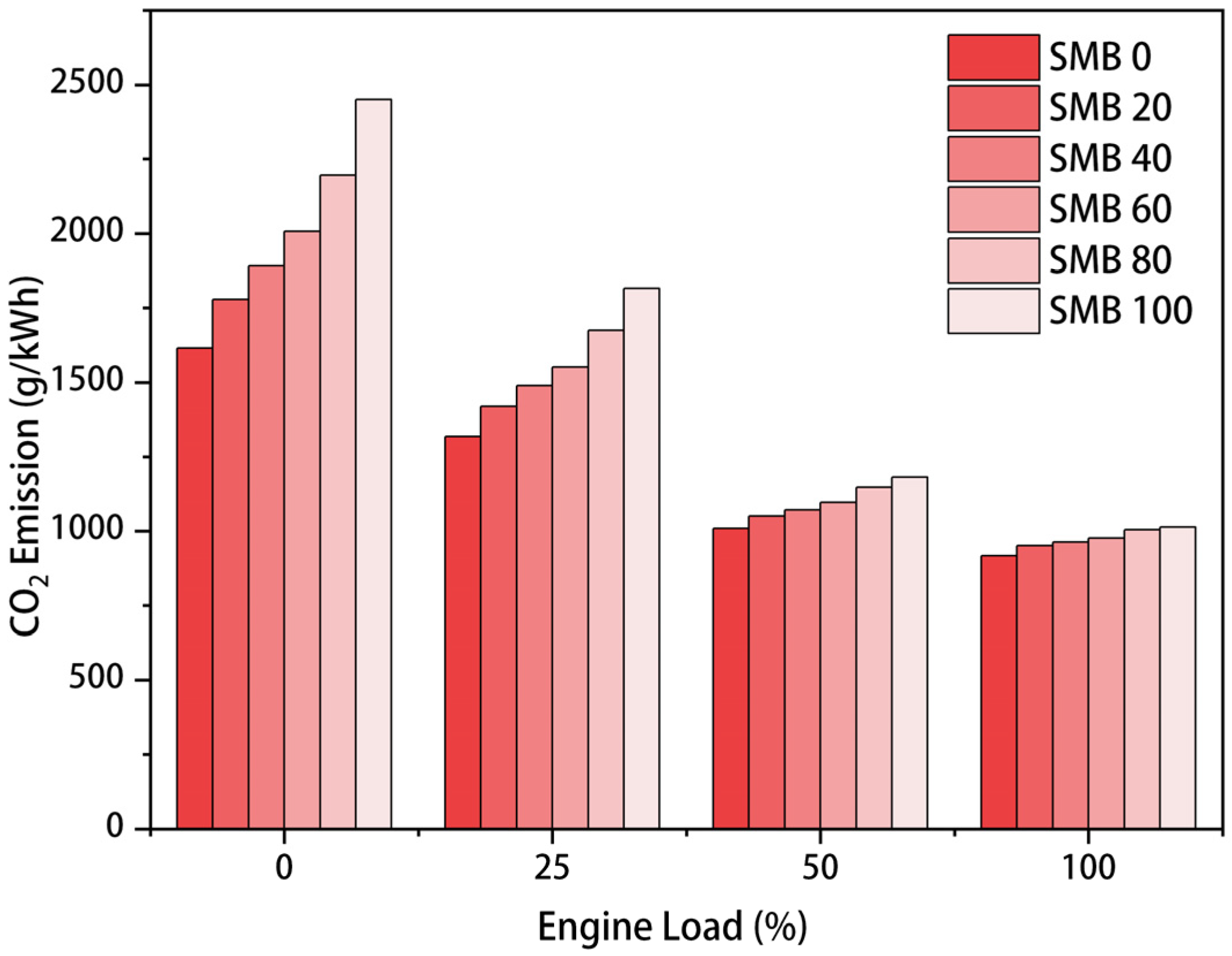

4.3. CO2 Emission

5. Conclusions

- The main factors influencing engine combustion when comparing these three generations of biofuels (categorized by their raw material) with traditional diesel fuel include oxygen content, LHV, cetane number, viscosity and other properties.

- Among the three generations of biofuels classified by raw materials, the first-generation biofuels are primarily made from animal fats or edible plant oils. Producing these biofuels incurs significant costs. Moreover, they compete with food crops for growing space. Second-generation biofuels are mainly produced from non-edible plants or waste oils. Compared to the first generation, these biofuels are less dependent on land resources, easier to obtain and have lower costs. The third-generation biofuels are primarily made from microalgae oils which have the lowest requirements for growing environments and will not compete with food crops for land resources. However, the third-generation biofuels are more difficult to produce, leading to lower production volumes than the other two generations of biofuels. From the perspective of raw material acquisition, all three generations of biofuels have their own problems.

- Since most of these three generations of biofuels are prepared through esterification, the main components of the resulting biofuels are esters. The LHV of these esters is generally slightly lower than that of traditional diesel fuel, leading to higher fuel consumption when using biofuels or blends of biofuels with traditional diesel fuel to generate the same amount of heat. Typically, this increase in fuel consumption is around 5% to 10% higher than that of traditional diesel fuel. However, there are also cases where the LHV of certain biofuels is higher, depending on the specific nature of the esters.

- Generally, biofuels have higher cetane numbers and oxygen content compared to traditional diesel fuel. This indicates that the combustion performance of most biofuels is typically better than traditional diesel fuel, with lower ID and thermal losses, resulting in higher combustion efficiency.

- Due to the characteristics of biofuels, such as low LHV, high viscosity and high density, the combustion of biofuels or blends of biofuels with traditional diesel fuel can be adversely affected. This ultimately results in lower performance characteristics for most biofuels. For example, their BTE and BP are typically 10–20% lower than those of traditional diesel fuel. Additionally, their CP and HRR are also slightly lower compared to those of traditional diesel fuel. In this respect, the performance of the three generations of biofuels is consistent.

- Due to the high oxygen content in the three generations of biofuels, the peak cylinder temperature during the combustion of biofuels or blends of biofuels with traditional diesel fuel is higher than that of traditional diesel fuel. Additionally, biofuels often contain unsaturated long-chain fatty acids, which can result in NOx emission of biofuels being more than 10% higher than that of traditional diesel fuel.

- Similarly, the high oxygen content in the three generations of biofuels facilitates the oxidation of unburned CO to CO2 during combustion, resulting in a significant decrease in CO emission, with reductions often exceeding 30% and even 50%.

- The CO2 emission of the three generations of biofuels is less consistent. Some researchers suggest that more complete combustion of biofuels leads to the conversion of CO to CO2, resulting in a decrease in CO emission and an increase in CO2 emission. Others argue that the lower carbon-to-hydrogen ratio of biofuels leads to reductions in both CO and CO2 emissions. In summary, the CO2 emission from biofuels depends on their inherent properties or feedstock, while it is reduced greatly from the view of the life cycle circulation of CO2. Additionally, according to the conclusion of the literature, microalgae biofuels tend to have lower carbon-to-hydrogen ratios and are more likely to exhibit lower CO and CO2 emissions. Therefore, microalgae biofuels still have an advantage over the other two generations of biofuels.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kong, F.; Wang, Y.; Wang, X. How to understand carbon neutrality in the context of climate change? With special reference to China. Sustain. Environ. 2022, 8, 2062824. [Google Scholar] [CrossRef]

- Ohara, T.; Akimoto, H.; Kurokawa, J.-I.; Horii, N.; Yamaji, K.; Yan, X.; Hayasaka, T. An Asian emission inventory of anthropogenic emission sources for the period 1980–2020. Atmos. Chem. Phys. 2007, 7, 4419–4444. [Google Scholar] [CrossRef]

- Walker, T.R.; Adebambo, O.; Del Aguila Feijoo, M.C.; Elhaimer, E.; Hossain, T.; Edwards, S.J.; Morrison, C.E.; Romo, J.; Sharma, N.; Taylor, S.; et al. Environmental Effects of Marine Transportation. In World Seas: An Environmental Evaluation; Academic Press: London, UK, 2019; pp. 505–530. [Google Scholar]

- The International Maritime Organization’s Initial Greenhouse Gas Strategy; International Council on Clean Transportation: Washington, DC, USA, 2018.

- Trainer, T. Renewable Energy Cannot Sustain a Consumer Society; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Li, Q.; Li, Q.; Han, Y. A numerical investigation on kick control with the displacement kill method during a well test in a deep-water gas reservoir: A case study. Processes 2024, 12, 2090. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wang, F.; Wu, J.; Wang, Y. The carrying behavior of water-based fracturing fluid in shale reservoir fractures and molecular dynamics of sand-carrying mechanism. Processes 2024, 12, 2051. [Google Scholar] [CrossRef]

- Bilgili, L. Comparative assessment of alternative marine fuels in life cycle perspective. Renew. Sustain. Energy Rev. 2021, 144, 110985. [Google Scholar] [CrossRef]

- Wood, D.A. A review and outlook for the global LNG trade. J. Nat. Gas Sci. Eng. 2012, 9, 16–27. [Google Scholar] [CrossRef]

- Dalena, F.; Senatore, A.; Marino, A.; Gordano, A.; Basile, M.; Basile, A. Methanol production and applications: An overview. In Methanol; Elsevier: Amsterdam, The Netherlands, 2018; pp. 3–28. [Google Scholar]

- Yadav, O.; Valera, H.; Dulani, D.; Krishnan, U.; Agarwal, A.K. Safety Aspects of Methanol as Fuel. In Methanol: A Sustainable Transport Fuel for CI Engines; Springer: Berlin/Heidelberg, Germany, 2021; pp. 117–138. [Google Scholar]

- Aziz, M.; Wijayanta, A.T.; Nandiyanto, A.B.D. Ammonia as Effective Hydrogen Storage: A Review on Production, Storage and Utilization. Energies 2020, 13, 3062. [Google Scholar] [CrossRef]

- Kesieme, U.; Pazouki, K.; Murphy, A.; Chrysanthou, A. Biofuel as an alternative shipping fuel: Technological, environmental and economic assessment. Sustain. Energy Fuels 2019, 3, 899–909. [Google Scholar] [CrossRef]

- MacLean, H.L.; Lave, L.B.; Lankey, R.; Joshi, S. A Life-Cycle Comparison of Alternative Automobile Fuels. J. Air Waste Manag. Assoc. 2000, 50, 1769–1779. [Google Scholar] [CrossRef]

- Sorguven, E.; Özilgen, M. Thermodynamic assessment of algal biodiesel utilization. Renew. Energy 2010, 35, 1956–1966. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.L.; Sharma, S.; Kumar Sharma, P.; Jhalani, A. A review on feedstocks, production processes, and yield for different generations of biodiesel. Fuel 2020, 262, 116553. [Google Scholar] [CrossRef]

- Gopinath, A.; Sairam, K.; Velraj, R.; Kumaresan, G. Effects of the properties and the structural configurations of fatty acid methyl esters on the properties of biodiesel fuel: A review. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2014, 229, 357–390. [Google Scholar] [CrossRef]

- Morone, P.; Cottoni, L.; Giudice, F. Biofuels: Technology, economics, and policy issues. In Handbook of Biofuels Production; Elsevier: Amsterdam, The Netherlands, 2023; pp. 55–92. [Google Scholar]

- Chalkley, A.P. Diesel Engines for Land and Marine Work; Constable, Limited: London, UK, 1919.

- Yliskylä-Peuralahti, J. Sustainable Energy Transitions in Maritime Transport. J. Sustain. Mobil. 2016, 3, 67–93. [Google Scholar] [CrossRef]

- Martin, M.A. First generation biofuels compete. New Biotechnol. 2010, 27, 596–608. [Google Scholar] [CrossRef] [PubMed]

- Bhuiya, M.M.K.; Rasul, M.G.; Khan, M.M.K.; Ashwath, N.; Azad, A.K. Prospects of 2nd generation biodiesel as a sustainable fuel—Part: 1 selection of feedstocks, oil extraction techniques and conversion technologies. Renew. Sustain. Energy Rev. 2016, 55, 1109–1128. [Google Scholar] [CrossRef]

- Sarwer, A.; Hussain, M.; Al-Muhtaseb, A.A.H.; Inayat, A.; Rafiq, S.; Khurram, M.S.; Ul-Haq, N.; Shah, N.S.; Alaud Din, A.; Ahmad, I. Suitability of biofuels production on commercial scale from various feedstocks: A critical review. ChemBioEng Rev. 2022, 9, 423–441. [Google Scholar] [CrossRef]

- Sarwer, A.; Hamed, S.M.; Osman, A.I.; Jamil, F.; Al-Muhtaseb, A.A.H.; Alhajeri, N.S.; Rooney, D.W. Algal biomass valorization for biofuel production and carbon sequestration: A review. Environ. Chem. Lett. 2022, 20, 2797–2851. [Google Scholar] [CrossRef]

- Chen, J.; Li, Q.; Chang, C.; Bai, J.; Liu, L.; Fang, S.; Li, H. Techno-economic analysis of biodiesel production from microalgae: A review. Trends Renew. Energy 2017, 3, 141–152. [Google Scholar] [CrossRef]

- Aatola, H.; Larmi, M.; Sarjovaara, T.; Mikkonen, S. Hydrotreated vegetable oil (HVO) as a renewable diesel fuel: Trade-off between NOX, particulate emission, and fuel consumption of a heavy duty engine. SAE Int. J. Engines 2009, 1, 1251–1262. [Google Scholar] [CrossRef]

- Dahmen, N.; Dinjus, E.; Kolb, T.; Arnold, U.; Leibold, H.; Stahl, R. State of the art of the bioliq® process for synthetic biofuels production. Environ. Prog. Sustain. Energy 2012, 31, 176–181. [Google Scholar] [CrossRef]

- Yasar, F.; Altun, S. The effect of microalgae biodiesel on combustion, performance and emission characteristics of a diesel power generator. Therm. Sci. 2018, 22, 1481–1492. [Google Scholar] [CrossRef]

- Puškár, M.; Kopas, M.; Puškár, D.; Lumnitzer, J.; Faltinová, E. Method for reduction of the NOx emissions in marine auxiliary diesel engine using the fuel mixtures containing biodiesel using HCCI combustion. Mar. Pollut. Bull. 2018, 127, 752–760. [Google Scholar] [CrossRef] [PubMed]

- Ramachandran, E.; Krishnaiah, R.; Venkatesan, E.P.; Parida, S.; Reddy Dwarshala, S.K.; Khan, S.A.; Asif, M.; Linul, E. Prediction of RCCI combustion fueled with CNG and algal biodiesel to sustain efficient diesel engines using machine learning techniques. Case Stud. Therm. Eng. 2023, 51, 103630. [Google Scholar] [CrossRef]

- Sharif, S.K.; Nageswara Rao, B.; Jagadish, D. Comparative performance and emission studies of the CI engine with Nodularia Spumigena microalgae biodiesel versus different vegetable oil derived biodiesel. SN Appl. Sci. 2020, 2, 858. [Google Scholar] [CrossRef]

- Mourad, M.; Mahmoud, K.R.; NourEldeen, E.-S.H. Improving diesel engine performance and emissions characteristics fuelled with biodiesel. Fuel 2021, 302, 121097. [Google Scholar] [CrossRef]

- Elkelawy, M.; Bastawissi, H.A.-E.; El Shenawy, E.; Taha, M.; Panchal, H.; Sadasivuni, K.K. Study of performance, combustion, and emissions parameters of DI-diesel engine fueled with algae biodiesel/diesel/n-pentane blends. Energy Convers. Manag. X 2021, 10, 100058. [Google Scholar] [CrossRef]

- Sathish, T.; Singaravelu, D.K. Combustion Analysis Using Third Generation Biofuels in Diesel Engine; NISCAIR-CSIR: New Delhi, India, 2020. [Google Scholar]

- Zhang, Z.; Jiaqiang, E.; Deng, Y.; Pham, M.; Zuo, W.; Peng, Q.; Yin, Z. Effects of fatty acid methyl esters proportion on combustion and emission characteristics of a biodiesel fueled marine diesel engine. Energy Convers. Manag. 2018, 159, 244–253. [Google Scholar] [CrossRef]

- Bjørgen, K.O.P.; Emberson, D.R.; Løvås, T. Combustion and soot characteristics of hydrotreated vegetable oil compression-ignited spray flames. Fuel 2020, 266, 116942. [Google Scholar] [CrossRef]

- Dhamodaran, G.; Krishnan, R.; Pochareddy, Y.K.; Pyarelal, H.M.; Sivasubramanian, H.; Ganeshram, A.K. A comparative study of combustion, emission, and performance characteristics of rice-bran-, neem-, and cottonseed-oil biodiesels with varying degree of unsaturation. Fuel 2017, 187, 296–305. [Google Scholar] [CrossRef]

- Elumalai, R.; Ravi, K. Strategy to reduce carbon emissions by adopting ammonia–Algal biodiesel in RCCI engine and optimize the fuel concoction using RSM methodology. Int. J. Hydrogen Energy 2022, 47, 39701–39718. [Google Scholar] [CrossRef]

- Thomas, J.J.; Sabu, V.; Nagarajan, G.; Kumar, S.; Basrin, G. Influence of waste vegetable oil biodiesel and hexanol on a reactivity controlled compression ignition engine combustion and emissions. Energy 2020, 206, 118199. [Google Scholar] [CrossRef]

- Dhar, A.; Agarwal, A.K. Performance, emissions and combustion characteristics of Karanja biodiesel in a transportation engine. Fuel 2014, 119, 70–80. [Google Scholar] [CrossRef]

- Perumal, V.; Ilangkumaran, M. Experimental analysis of engine performance, combustion and emission using pongamia biodiesel as fuel in CI engine. Energy 2017, 129, 228–236. [Google Scholar] [CrossRef]

- Sanjid, A.; Kalam, M.; Masjuki, H.; Rahman, S.A.; Abedin, M. Combustion, performance and emission characteristics of a DI diesel engine fueled with Brassica juncea methyl ester and its blends. RSC Adv. 2014, 4, 36973–36982. [Google Scholar] [CrossRef]

- Savariraj, S.; Ganapathy, T.; Saravanan, C. Experimental investigation of performance and emission characteristics of mahua biodiesel in diesel engine. ISRN Renew. Energy 2011, 2011, 405182. [Google Scholar] [CrossRef]

- MohamedMusthafa, M.; Sivapirakasam, S.; Udayakumar, M. Comparative studies on fly ash coated low heat rejection diesel engine on performance and emission characteristics fueled by rice bran and pongamia methyl ester and their blend with diesel. Energy 2011, 36, 2343–2351. [Google Scholar] [CrossRef]

- Mohite, A.; Jyoti Bora, B.; Sharma, P.; Medhi, B.J.; Barik, D.; Balasubramanian, D.; Nguyen, V.G.; Js, F.J.; Cuong Le, H.; Kamalakannan, J.; et al. Maximizing efficiency and environmental benefits of an algae biodiesel-hydrogen dual fuel engine through operational parameter optimization using response surface methodology. Int. J. Hydrogen Energy 2023, 52, 1395–1407. [Google Scholar] [CrossRef]

- Ramesha, D.; Kumara, G.P.; Lalsaheb; Mohammed, A.V.; Mohammad, H.A.; Kasma, M.A. An experimental study on usage of plastic oil and B20 algae biodiesel blend as substitute fuel to diesel engine. Environ. Sci. Pollut. Res. 2016, 23, 9432–9439. [Google Scholar] [CrossRef]

- Mrityunjayaswamy, K.; Ramesha, D.; Premkumara, G.; Rana Pratapa Reddy, N. Performance and emissions characteristics of a compression ignition engine using blends of bio-oil as a fuel. J. Middle Eur. Constr. Des. Cars 2011, 9, 40–44. [Google Scholar]

- Annamalai, B.; Murugesan, P. The combined effect of hydrogen enrichment and exhaust gas recirculation on the combustion stability, performance and emissions of CI engine energized by algae biodiesel. Int. J. Hydrogen Energy 2023, 50, 524–546. [Google Scholar] [CrossRef]

- Suhel, A.; Rahim, N.A.; Rahman, M.R.A.; Ahmad, K.A.B. Engine’s behaviour on magnetite nanoparticles as additive and hydrogen addition of chicken fat methyl ester fuelled DICI engine: A dual fuel approach. Int. J. Hydrogen Energy 2021, 46, 14824–14843. [Google Scholar] [CrossRef]

- Jegan, C.D.; Selvakumaran, T.; Karthe, M.; Hemachandu, P.; Gopinathan, R.; Sathish, T.; Ağbulut, Ü. Influences of various metal oxide-based nanosized particles-added algae biodiesel on engine characteristics. Energy 2023, 284, 128633. [Google Scholar] [CrossRef]

- Özgür, T.; Özcanli, M.; Aydin, K. Investigation of nanoparticle additives to biodiesel for improvement of the performance and exhaust emissions in a compression ignition engine. Int. J. Green Energy 2015, 12, 51–56. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K. Eco friendly biofuels for CI engine applications. In Advances in Eco-Fuels for a Sustainable Environment; Elsevier: Amsterdam, The Netherlands, 2019; pp. 407–440. [Google Scholar]

- Ramalingam, S.; Rajendran, S. Assessment of performance, combustion, and emission behavior of novel annona biodiesel-operated diesel engine. In Advances in Eco-Fuels for a Sustainable Environment; Elsevier: Amsterdam, The Netherlands, 2019; pp. 391–405. [Google Scholar]

- Wahlen, B.D.; Morgan, M.R.; McCurdy, A.T.; Willis, R.M.; Morgan, M.D.; Dye, D.J.; Bugbee, B.; Wood, B.D.; Seefeldt, L.C. Biodiesel from microalgae, yeast, and bacteria: Engine performance and exhaust emissions. Energy Fuels 2013, 27, 220–228. [Google Scholar] [CrossRef]

- Buyukkaya, E. Effects of biodiesel on a DI diesel engine performance, emission and combustion characteristics. Fuel 2010, 89, 3099–3105. [Google Scholar] [CrossRef]

- Çelik, M.; Örs, İ.; Bayindirli, C.; Demiralp, M. Experimental investigation of impact of addition of bioethanol in different biodiesels, on performance, combustion and emission characteristics. J. Mech. Sci. Technol. 2017, 31, 5581–5592. [Google Scholar] [CrossRef]

- Yesilyurt, M.K.; Eryilmaz, T.; Arslan, M. A comparative analysis of the engine performance, exhaust emissions and combustion behaviors of a compression ignition engine fuelled with biodiesel/diesel/1-butanol (C4 alcohol) and biodiesel/diesel/n-pentanol (C5 alcohol) fuel blends. Energy 2018, 165, 1332–1351. [Google Scholar] [CrossRef]

- Baiju, B.; Naik, M.; Das, L. A comparative evaluation of compression ignition engine characteristics using methyl and ethyl esters of Karanja oil. Renew. Energy 2009, 34, 1616–1621. [Google Scholar] [CrossRef]

- Krishania, N.; Rajak, U.; Nath Verma, T.; Kumar Birru, A.; Pugazhendhi, A. Effect of microalgae, tyre pyrolysis oil and Jatropha biodiesel enriched with diesel fuel on performance and emission characteristics of CI engine. Fuel 2020, 278, 118252. [Google Scholar] [CrossRef]

- Attar, H.M.; Wu, D.; Harvey, A.P. Performance, emissions and durability studies on diesel engine fuelled with a preheated raw microalgal oil. Proceedings 2020, 58, 4. [Google Scholar] [CrossRef]

- Mao, G.; Shi, K.; Zhang, C.; Li, J.; Chen, S.; Wang, P. Biodiesel fuel from Chlorella vulgaris and effects of its low-level blends on the performance, emissions, and combustion characteristics of a nonroad diesel engine. J. Energy Eng. 2020, 146, 04020016. [Google Scholar] [CrossRef]

- Indrareddy, N.; Venkateswarlu, K.; Konijeti, R. Experimental investigation of algae biofuel–diesel blends on performance of a CRDI diesel engine. Int. J. Ambient Energy 2022, 43, 2218–2225. [Google Scholar] [CrossRef]

- El-Baz, F.K.; Gad, M.S.; Abdo, S.M.; Abed, K.A.; Matter, I.M. Performance and exhaust emissions of a diesel engine burning algal biodiesel blends. Int. J. Mech. Mechatron. Eng. 2016, 16, 151–158. [Google Scholar]

- Govindasamy, P.; Antony, G.; Rajaguru, K.; Saravanan, K. Experimental investigation of the effect of compression ratio in a direct injection diesel engine fueled with spirulina algae biodiesel. J. Appl. Fluid Mech. 2018, 11, 107–114. [Google Scholar]

- Tayari, S.; Abedi, R. Effect of Chlorella vulgaris methyl ester enriched with hydrogen on performance and emission characteristics of CI engine. Fuel 2019, 256, 115906. [Google Scholar] [CrossRef]

- Zareh, P.; Zare, A.A.; Ghobadian, B. Comparative assessment of performance and emission characteristics of castor, coconut and waste cooking based biodiesel as fuel in a diesel engine. Energy 2017, 139, 883–894. [Google Scholar] [CrossRef]

- Al-lwayzy, S.H.; Yusaf, T. Diesel engine performance and exhaust gas emissions using Microalgae Chlorella protothecoides biodiesel. Renew. Energy 2017, 101, 690–701. [Google Scholar] [CrossRef]

- Tüccar, G.; Aydın, K. Evaluation of methyl ester of microalgae oil as fuel in a diesel engine. Fuel 2013, 112, 203–207. [Google Scholar] [CrossRef]

- Ahmed, A.S. Biodiesel production from macro algae as a green fuel for diesel engine. J. Energy Environ. 2010, 2, 1–5. [Google Scholar]

- Beatrice, C.; Bertoli, C.; D’alessio, J.; Del Giacomo, N.; Lazzaro, M.; Massoli, P. Experimental characterization of combustion behaviour of new diesel fuels for low emission engines. Combust. Sci. Technol. 1996, 120, 335–355. [Google Scholar] [CrossRef]

- Senthil, R.; Silambarasan, R. Annona: A new biodiesel for diesel engine: A comparative experimental investigation. J. Energy Inst. 2015, 88, 459–469. [Google Scholar] [CrossRef]

- Can, Ö.; Öztürk, E.; Yücesu, H.S. Combustion and exhaust emissions of canola biodiesel blends in a single cylinder DI diesel engine. Renew. Energy 2017, 109, 73–82. [Google Scholar] [CrossRef]

- Hawley, J.G.; Brace, C.J.; Wallace, F.J. Emissions in Cl Engines. In Handbook of Air Pollution from Internal Combustion Engines: Pollutant Formation and Control; Academic Press: Cambridge, MA, USA, 1998; 280p. [Google Scholar]

- Kshirsagar, C.M.; Anand, R. Artificial neural network applied forecast on a parametric study of Calophyllum inophyllum methyl ester-diesel engine out responses. Appl. Energy 2017, 189, 555–567. [Google Scholar] [CrossRef]

- Özener, O.; Yüksek, L.; Ergenç, A.T.; Özkan, M. Effects of soybean biodiesel on a DI diesel engine performance, emission and combustion characteristics. Fuel 2014, 115, 875–883. [Google Scholar] [CrossRef]

- Boehman, A.L.; Morris, D.; Szybist, J.; Esen, E. The impact of the bulk modulus of diesel fuels on fuel injection timing. Energy Fuels 2004, 18, 1877–1882. [Google Scholar] [CrossRef]

- Abu-Jrai, A.; Yamin, J.A.; Al-Muhtaseb, A.A.H.; Hararah, M.A. Combustion characteristics and engine emissions of a diesel engine fueled with diesel and treated waste cooking oil blends. Chem. Eng. J. 2011, 172, 129–136. [Google Scholar] [CrossRef]

- Gharehghani, A.; Mirsalim, M.; Hosseini, R. Effects of waste fish oil biodiesel on diesel engine combustion characteristics and emission. Renew. Energy 2017, 101, 930–936. [Google Scholar] [CrossRef]

- Khandal, S.; Banapurmath, N.; Gaitonde, V. Effect of exhaust gas recirculation, fuel injection pressure and injection timing on the performance of common rail direct injection engine powered with honge biodiesel (BHO). Energy 2017, 139, 828–841. [Google Scholar] [CrossRef]

- Vallinayagam, R.; Vedharaj, S.; Yang, W.M.; Raghavan, V.; Saravanan, C.G.; Lee, P.S.; Chua, K.J.E.; Chou, S.K. Investigation of evaporation and engine characteristics of pine oil biofuel fumigated in the inlet manifold of a diesel engine. Appl. Energy 2014, 115, 514–524. [Google Scholar] [CrossRef]

- Islam, M.A.; Rahman, M.M.; Heimann, K.; Nabi, M.N.; Ristovski, Z.D.; Dowell, A.; Thomas, G.; Feng, B.; von Alvensleben, N.; Brown, R.J. Combustion analysis of microalgae methyl ester in a common rail direct injection diesel engine. Fuel 2015, 143, 351–360. [Google Scholar] [CrossRef]

- Yadav, M.; Chavan, S.B.; Singh, R.; Bux, F.; Sharma, Y.C. Experimental study on emissions of algal biodiesel and its blends on a diesel engine. J. Taiwan Inst. Chem. Eng. 2019, 96, 160–168. [Google Scholar] [CrossRef]

- Joshi, M. Combustion analysis of ci engine fuelled with algae biofuel blends. J. Therm. Eng. 2019, 5, 214–220. [Google Scholar] [CrossRef]

- Bajpai, S.; Sahoo, P.; Das, L. Feasibility of blending karanja vegetable oil in petro-diesel and utilization in a direct injection diesel engine. Fuel 2009, 88, 705–711. [Google Scholar] [CrossRef]

- Jagadevkumar, A.; Pravin, V. In Evaluation of performance and emission characeristics of heterotrophic chlorella protothecoides microalgae biodiesel and its blends with diesel in a direct injection diesel engine. J. Phys. Conf. Ser. 2020, 1473, 012043. [Google Scholar] [CrossRef]

- Puhan, S.; Nagarajan, G.; Vedaraman, N.; Ramabramhmam, B.V. Mahua Oil (Madhuca Indica Oil) Derivatives as a Renewable Fuel for Diesel Engine Systems in India: A Performance and Emissions Comparative Study. Int. J. Green Energy 2007, 4, 89–104. [Google Scholar] [CrossRef]

- Rizwanul Fattah, I.M.; Hassan, M.H.; Kalam, M.A.; Atabani, A.E.; Abedin, M.J. Synthetic phenolic antioxidants to biodiesel: Path toward NOx reduction of an unmodified indirect injection diesel engine. J. Clean. Prod. 2014, 79, 82–90. [Google Scholar] [CrossRef]

- Buyukkaya, E.; Benli, S.; Karaaslan, S.; Guru, M. Effects of trout-oil methyl ester on a diesel engine performance and emission characteristics. Energy Convers. Manag. 2013, 69, 41–48. [Google Scholar] [CrossRef]

- Sakthivel, G.; Nagarajan, G.; Ilangkumaran, M.; Gaikwad, A.B. Comparative analysis of performance, emission and combustion parameters of diesel engine fuelled with ethyl ester of fish oil and its diesel blends. Fuel 2014, 132, 116–124. [Google Scholar] [CrossRef]

- Tripathi, S.; Subramanian, K.A. Experimental investigation of utilization of Soya soap stock based acid oil biodiesel in an automotive compression ignition engine. Appl. Energy 2017, 198, 332–346. [Google Scholar] [CrossRef]

- Palash, S.M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E.; Rizwanul Fattah, I.M.; Sanjid, A. Biodiesel production, characterization, diesel engine performance, and emission characteristics of methyl esters from Aphanamixis polystachya oil of Bangladesh. Energy Convers. Manag. 2015, 91, 149–157. [Google Scholar] [CrossRef]

- Ruhul, A.M.; Kalam, M.A.; Masjuki, H.H.; Shahir, S.A.; Alabdulkarem, A.; Teoh, Y.H.; How, H.G.; Reham, S.S. Evaluating combustion, performance and emission characteristics of Millettia pinnata and Croton megalocarpus biodiesel blends in a diesel engine. Energy 2017, 141, 2362–2376. [Google Scholar] [CrossRef]

- Yatish, K.V.; Lalithamba, H.S.; Suresh, R.; Harsha Hebbar, H.R. Optimization of bauhinia variegata biodiesel production and its performance, combustion and emission study on diesel engine. Renew. Energy 2018, 122, 561–575. [Google Scholar] [CrossRef]

- Perumal, V.; Ilangkumaran, M. Experimental analysis of operating characteristics of a direct injection diesel engine fuelled with Cleome viscosa biodiesel. Fuel 2018, 224, 379–387. [Google Scholar] [CrossRef]

- Singh, D.; Singal, S.K.; Garg, M.O.; Maiti, P.; Mishra, S.; Ghosh, P.K. Transient performance and emission characteristics of a heavy-duty diesel engine fuelled with microalga Chlorella variabilis and Jatropha curcas biodiesels. Energy Convers. Manag. 2015, 106, 892–900. [Google Scholar] [CrossRef]

- Rahman, M.A.; Aziz, M.A.; Ruhul, A.M.; Rashid, M.M. Biodiesel production process optimization from Spirulina maxima microalgae and performance investigation in a diesel engine. J. Mech. Sci. Technol. 2017, 31, 3025–3033. [Google Scholar] [CrossRef]

- Aydın, S. Comprehensive analysis of combustion, performance and emissions of power generator diesel engine fueled with different source of biodiesel blends. Energy 2020, 205, 118074. [Google Scholar] [CrossRef]

- Morsy, M.H. Assessment of a direct injection diesel engine fumigated with ethanol/water mixtures. Energy Convers. Manag. 2015, 94, 406–414. [Google Scholar] [CrossRef]

- Daho, T.; Vaitilingom, G.; Ouiminga, S.K.; Piriou, B.; Zongo, A.S.; Ouoba, S.; Koulidiati, J. Influence of engine load and fuel droplet size on performance of a CI engine fueled with cottonseed oil and its blends with diesel fuel. Appl. Energy 2013, 111, 1046–1053. [Google Scholar] [CrossRef]

- Arangarajan, M.; Raja, A.; Syed Aalam, C. Performance enhancement of CRDI Diesel Engine by chlorella vulgaris microalgae—Derived methyl ester with high pressure fuel injection. Res. J. Chem. Environ. 2020, 24, 93–101. [Google Scholar]

- Roskilly, A.P.; Nanda, S.K.; Wang, Y.D.; Chirkowski, J. The performance and the gaseous emissions of two small marine craft diesel engines fuelled with biodiesel. Appl. Therm. Eng. 2008, 28, 872–880. [Google Scholar] [CrossRef]

- Dhinesh, B.; Isaac JoshuaRamesh Lalvani, J.; Parthasarathy, M.; Annamalai, K. An assessment on performance, emission and combustion characteristics of single cylinder diesel engine powered by Cymbopogon flexuosus biofuel. Energy Convers. Manag. 2016, 117, 466–474. [Google Scholar] [CrossRef]

- Serin, H.; Yıldızhan, Ş. Hydrogen addition to tea seed oil biodiesel: Performance and emission characteristics. Int. J. Hydrogen Energy 2018, 43, 18020–18027. [Google Scholar] [CrossRef]

- Chandra Sekhar, S.; Karuppasamy, K.; Vedaraman, N.; Kabeel, A.E.; Sathyamurthy, R.; Elkelawy, M.; Alm ElDin Bastawissi, H. Biodiesel production process optimization from Pithecellobium dulce seed oil: Performance, combustion, and emission analysis on compression ignition engine fuelled with diesel/biodiesel blends. Energy Convers. Manag. 2018, 161, 141–154. [Google Scholar] [CrossRef]

- Sharon, H.; Karuppasamy, K.; Soban Kumar, D.R.; Sundaresan, A. A test on DI diesel engine fueled with methyl esters of used palm oil. Renew. Energy 2012, 47, 160–166. [Google Scholar] [CrossRef]

- Dubey, P.; Gupta, R. Effects of dual bio-fuel (Jatropha biodiesel and turpentine oil) on a single cylinder naturally aspirated diesel engine without EGR. Appl. Therm. Eng. 2017, 115, 1137–1147. [Google Scholar] [CrossRef]

- Rajak, U.; Nashine, P.; Verma, T.N. Effect of spirulina microalgae biodiesel enriched with diesel fuel on performance and emission characteristics of CI engine. Fuel 2020, 268, 117305. [Google Scholar] [CrossRef]

- Tarabet, L.; Loubar, K.; Lounici, M.S.; Khiari, K.; Belmrabet, T.; Tazerout, M. Experimental investigation of DI diesel engine operating with eucalyptus biodiesel/natural gas under dual fuel mode. Fuel 2014, 133, 129–138. [Google Scholar] [CrossRef]

- Tayari, S.; Abedi, R.; Rahi, A. Comparative assessment of engine performance and emissions fueled with three different biodiesel generations. Renew. Energy 2020, 147, 1058–1069. [Google Scholar] [CrossRef]

- Xue, J. Combustion characteristics, engine performances and emissions of waste edible oil biodiesel in diesel engine. Renew. Sustain. Energy Rev. 2013, 23, 350–365. [Google Scholar] [CrossRef]

- Pleanjai, S.; Gheewala, S.H.; Garivait, S. Greenhouse gas emissions from production and use of used cooking oil methyl ester as transport fuel in Thailand. J. Clean. Prod. 2009, 17, 873–876. [Google Scholar] [CrossRef]

| Viscosity | Cetane Number | LHV | Flash Point | Density | |

|---|---|---|---|---|---|

| mm2/s | MJ/kg | °C | kg/m3 | ||

| Rapeseed oil methyl ester | 4.92 | 47.2 | 39.9 | / | 0.89 |

| Corn oil methyl ester | 2.45–2.56 | 58.4–59 | 44.9–45 | / | / |

| Soybean oil methyl ester | 4.1–4.5 | 45–57 | 33.5–39.8 | 130–165 | 0.84–0.88 |

| Sunflower oil methyl ester | 4.04 | 51.25 | / | 179 | 0.88 |

| Lard methyl ester | 4.45 | / | 40.1 | 134 | 0.895 |

| Fatty acid methyl ester | 4.43 | 55.2 | 38.3 | 165 | 0.882 |

| Trout oil methyl ester | 4.25 | 51.3 | 37.8 | 116 | 0.885 |

| Fish oil ethyl ester | 4.74 | 52.6 | 40.1 | 114 | 0.885 |

| Tea seed methyl ester | 4.95 | 52 | 37.5 | >120 | 0.884 |

| Pithecellobium dulce seed methyl ester | 3.54 | 68 | 39.5 | 158 | 0.87 |

| Diesel fuel | 2.94 | 50 | 42.8 | 70.5 | 0.83 |

| Viscosity | Cetane Number | LHV | Flash Point | Density | |

|---|---|---|---|---|---|

| mm2/s | MJ/kg | °C | kg/m3 | ||

| Jatropha oil methyl ester | 2.35–5.48 | 51–63.3 | 38.5–41.6 | 172–175 | 0.85–0.88 |

| Palm oil methyl ester | 4.6 | 56.5–62 | 38.3–40.5 | 184.8 | 0.87 |

| Rice bran oil methyl ester | 8.04 | / | 39 | 173 | 0.896 |

| Waste oil methyl ester | 4.57–4.9 | 44–52 | 40.5–41 | <120 | 0.86–0.89 |

| Waste cooking oil methyl ester | 4.95 | 48.7 | 40.4 | 116 | 0.862 |

| Honge oil biofuel | 5.6 | 42 | 36 | 163 | 0.89 |

| Pine oil biofuel | 1.3 | 11 | 42.8 | 52 | 0.875 |

| Karanja vegetable biofuel | 6.95 | 55 | 37 | 205 | 0.883 |

| Millettia pinnata biofuel | 5.04 | 55 | 38 | 181 | 0.867 |

| Eucalyptus biofuel | 2.99 | 53 | 40 | 105 | 0.896 |

| Rubber seed oil biofuel | 5.81–5.96 | 43 | 38.5 | / | 0.860–0.881 |

| Diesel fuel | 2.94 | 50 | 42.8 | 70.5 | 0.83 |

| Viscosity | Cetane Number | LHV | Flash Point | Density | |

|---|---|---|---|---|---|

| mm2/s | MJ/kg | °C | kg/m3 | ||

| Microalgae oil biofuel | 4.49 | 57 | 37.6 | 141 | 0.881 |

| Chaetoceros gracili biofuel | 3.4 | 51 | 39.5 | / | 0.885 |

| Crypthecodinium cohnii methyl ester | 5.06 | 46.5 | 37.4 | / | 0.912 |

| Chlorella algae biofuel | 4.85 | 58.6 | 38.8 | 157 | 0.867 |

| Spirulina maxima microalgae biofuel | 4.47 | 55 | 38.43 | 178 | 0.872 |

| Microalgae Chlorella protothecoides biofuel | 4.22 | 52 | 37.5 | 124 | 0.9 |

| Spirulina microalgae biofuel | 5.26 | 52.2 | 41 | >128 | 0.861 |

| Diesel fuel | 2.94 | 50 | 42.8 | 70.5 | 0.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, Q.; Duan, Y.; Liang, D.; Li, T.; Luo, H.; Chen, R. Biofuels and Their Blends—A Review of the Effect of Low Carbon Fuels on Engine Performance. Sustainability 2024, 16, 10300. https://doi.org/10.3390/su162310300

Xiong Q, Duan Y, Liang D, Li T, Luo H, Chen R. Biofuels and Their Blends—A Review of the Effect of Low Carbon Fuels on Engine Performance. Sustainability. 2024; 16(23):10300. https://doi.org/10.3390/su162310300

Chicago/Turabian StyleXiong, Qian, Yulong Duan, Dezhi Liang, Tie Li, Hongliang Luo, and Run Chen. 2024. "Biofuels and Their Blends—A Review of the Effect of Low Carbon Fuels on Engine Performance" Sustainability 16, no. 23: 10300. https://doi.org/10.3390/su162310300

APA StyleXiong, Q., Duan, Y., Liang, D., Li, T., Luo, H., & Chen, R. (2024). Biofuels and Their Blends—A Review of the Effect of Low Carbon Fuels on Engine Performance. Sustainability, 16(23), 10300. https://doi.org/10.3390/su162310300