Assessing the Environmental Impacts of the Valorization of Creole-Antillean Avocado via an Extractive-Based Biorefinery in the Montes de María Region

Abstract

:1. Introduction

2. Materials and Methods

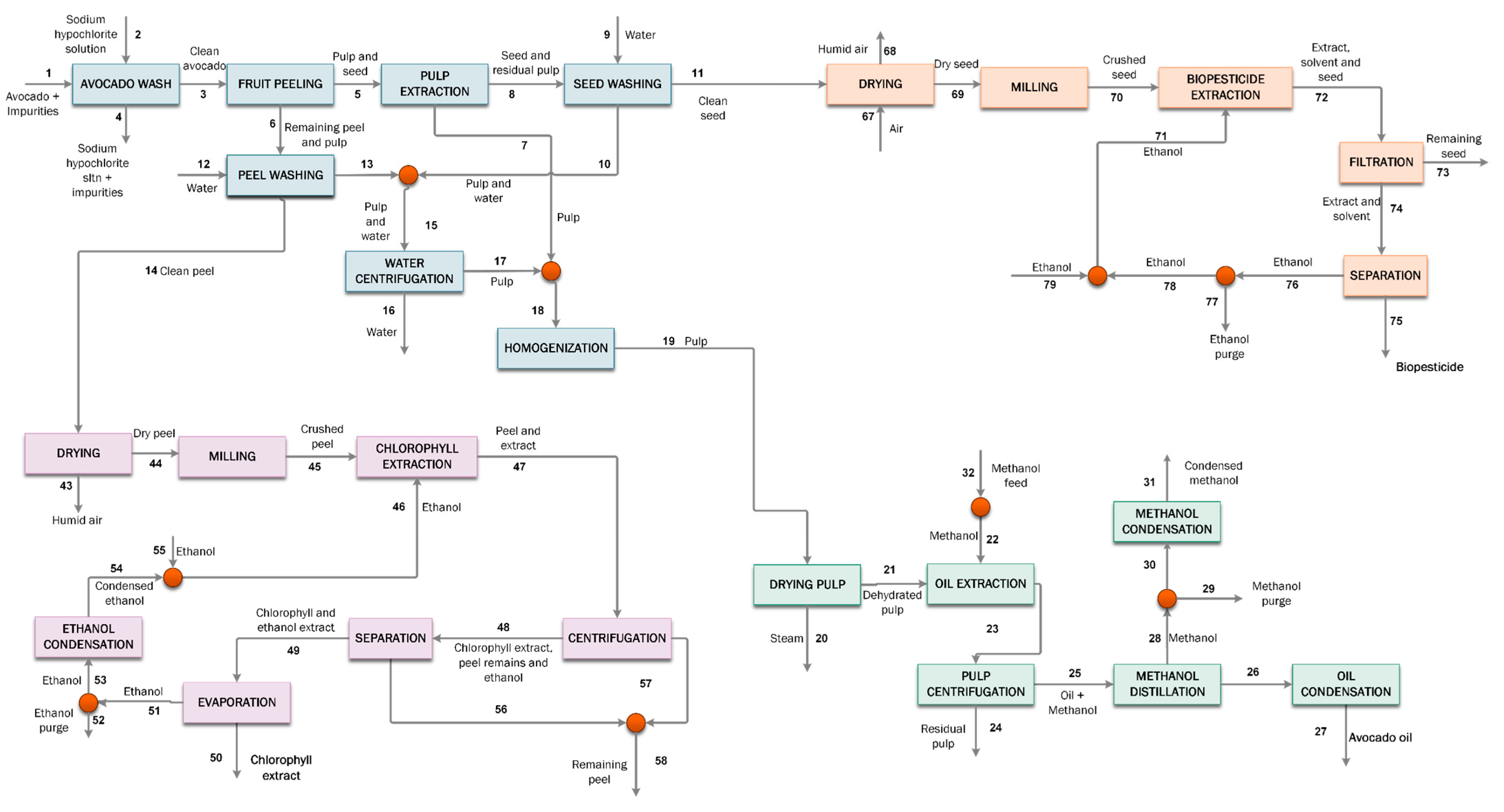

2.1. Process Description

2.1.1. Bio-Oil Production from Avocado Pulp

2.1.2. Chlorophyll Production from Avocado Peel

2.1.3. Biopesticide Production from Avocado Seeds

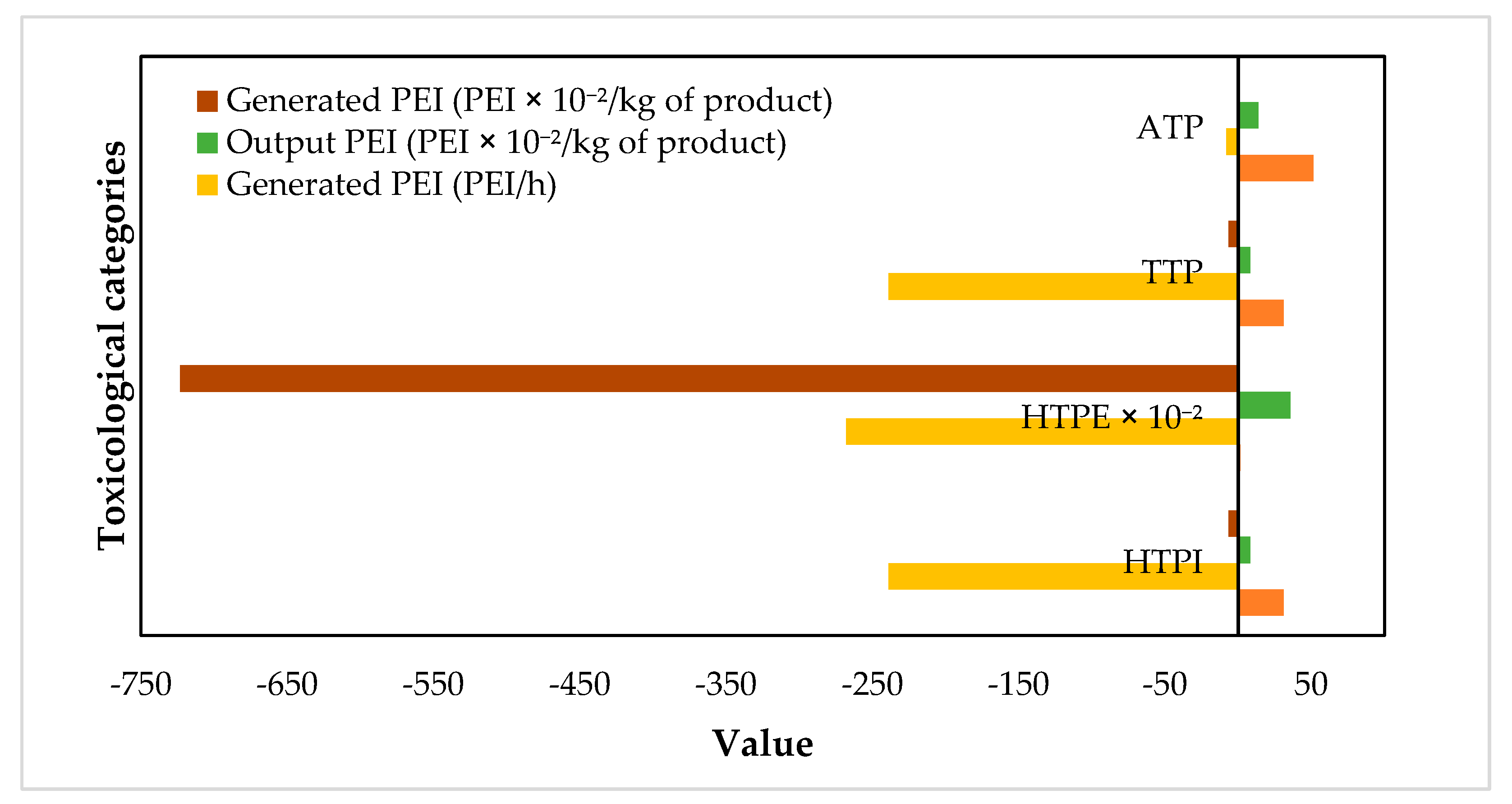

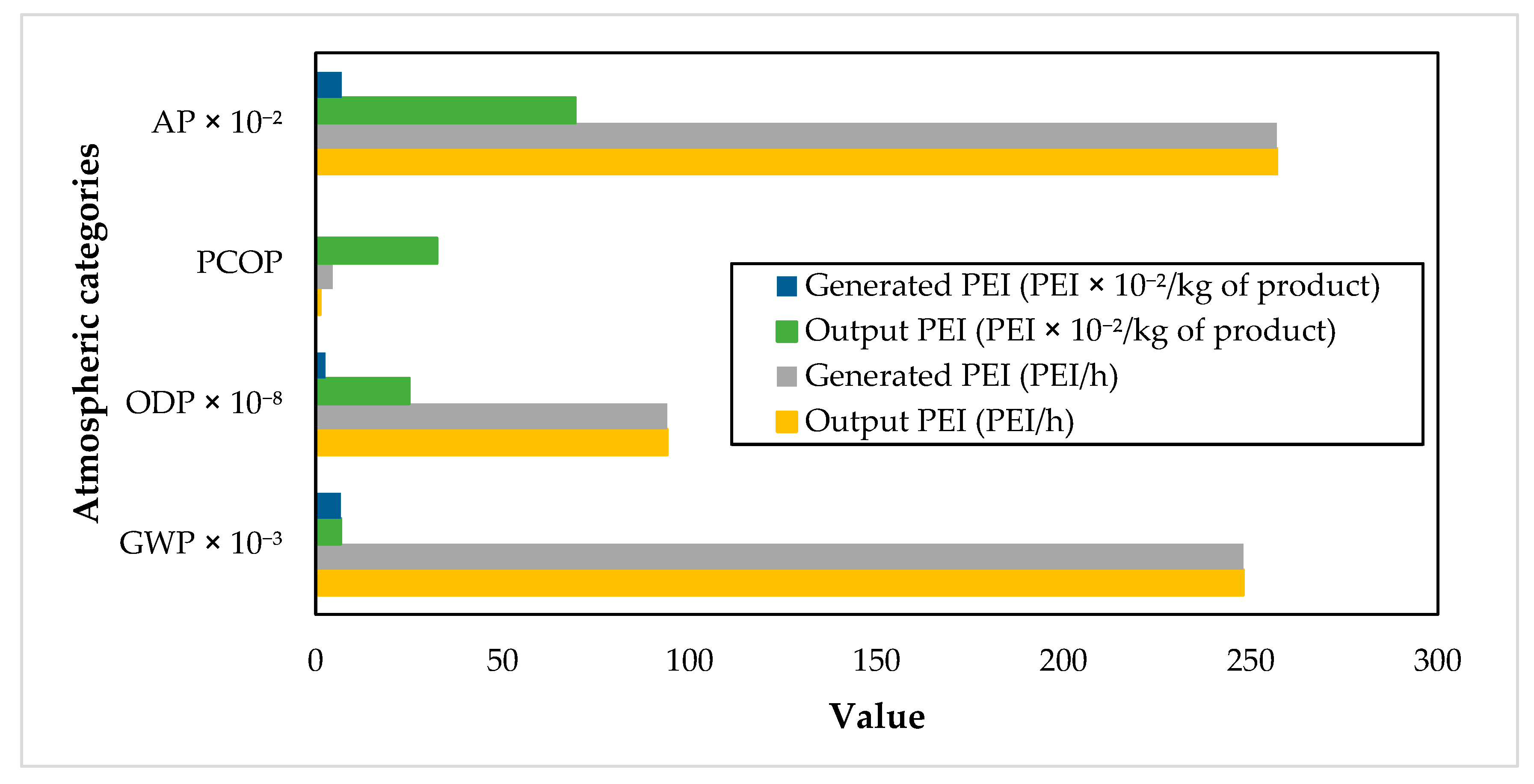

2.2. Waste Reduction (WAR) Algorithm

3. Results and Discussion

3.1. Overall Impacts of the Extractive-Based Creole-Antillean Avocado Biorefinery

3.2. Toxicological Impacts of the Biorefinery

3.3. Atmospheric Impacts of the Extractive-Based Creole-Antillean Avocado Biorefinery

3.4. Impacts of the Energy Source

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cherubini, F. The biorefinery concept: Using biomass instead of oil for producing energy and chemicals. Energy Convers. Manag. 2010, 51, 1412–1421. [Google Scholar] [CrossRef]

- Gamero, E.; Ruppert, S.; Miehe, R.; Sauer, A. Process model and life cycle assessment of biorefinery concept using agricultural and industrial residues for biohydrogen production. Energies 2024, 17, 4282. [Google Scholar] [CrossRef]

- Villa-Rodríguez, J.A.; Molina-Corral, F.J.; Ayala-Zavala, J.F.; Olivas, G.I.; González-Aguilar, G.A. Effect of maturity stage on the content of fatty acids and antioxidant activity of ‘Hass’ avocado. Food Res. Int. 2011, 44, 1231–1237. [Google Scholar] [CrossRef]

- Bangar, S.P.; Dunno, K.; Dhull, S.B.; Siroha, A.K.; Changan, S.; Maqsood, S.; Rusu, A.V. Avocado seed discoveries: Chemical composition, biological properties, and industrial food applications. Food Chem. X 2022, 16, 100507. [Google Scholar] [CrossRef] [PubMed]

- Ramirez, S.Q.; Sánchez, B.M.; Jimenez, S.C.; Castañeda, W.R.; Ramirez, D.G. Avocado and coffee supply chains specialization in Colombia. Procedia Comput. Sci. 2019, 158, 573–581. [Google Scholar] [CrossRef]

- Martínez Donado, C.A.; Pérez Ortega, D.A. Capacidades Socio Empresariales Para El Fortalecimiento de los Procesos de Innovación Organizacional de la Cadena Productiva de Aguacate en los Montes de María. 2023. Available online: https://repositorio.cecar.edu.co/items/df5f4e31-be2f-4179-a149-66443a1ac483 (accessed on 2 December 2024).

- Garcia-Vallejo, M.C.; Agudelo Patiño, T.; Poveda-Giraldo, J.A.; Piedrahita-Rodríguez, S.; Cardona Alzate, C.A. Alternatives for the valorization of avocado waste generated in the different links of the value chain based on a life-cycle analysis approach. Agronomy 2023, 13, 2229. [Google Scholar] [CrossRef]

- Rocha, T.M.; Marcelino, P.R.F.; Da Costa, R.A.M.; Rubio-Ribeaux, D.; Barbosa, F.G.; da Silva, S.S. Agricultural bioinputs obtained by solid-state fermentation: From production in biorefineries to sustainable agriculture. Sustainability 2024, 16, 1076. [Google Scholar] [CrossRef]

- Prado-Acebo, I.; Cubero-Cardoso, J.; Lu-Chau, T.A.; Eibes, G. Integral multi-valorization of agro-industrial wastes: A review. Waste Manag. 2024, 183, 42–52. [Google Scholar] [CrossRef]

- Bare, J. TRACI 2.0: The tool for the reduction and assessment of chemical and other environmental impacts 2.0. Clean. Technol. Environ. Policy 2011, 13, 687–696. [Google Scholar] [CrossRef]

- Anastas, P.T.; Warner, J.C. Green Chemistry: Theory and Practice; Oxford University Press: Oxford, UK, 2000. [Google Scholar]

- Vega, G.C.; Sohn, J.; Bruun, S.; Olsen, S.I.; Birkved, M. Maximizing environmental impact savings potential through innovative biorefinery alternatives: An application of the TM-LCA framework for regional scale impact assessment. Sustainability 2019, 11, 3836. [Google Scholar] [CrossRef]

- Gu, S.; Yang, L.; Liang, X.; Zhou, J. Life cycle assessment and process optimization of precipitated nanosilica—A case study in China. Energies 2024, 17, 5621. [Google Scholar] [CrossRef]

- Park, Y.S.; Egilmez, G.; Kucukvar, M. Cradle-to-gate life cycle analysis of agricultural and food production in the US: A TRACI impact assessment. In Sustainability Challenges in the Agrofood Sector; John Wiley & Sons: Hoboken, NJ, USA, 2017; pp. 274–306. [Google Scholar]

- Herrera-Rodríguez, T.; Parejo-Palacio, V.; González-Delgado, Á. Evaluación ambiental mediante algoritmo de reducción de residuos WAR de la producción de aceite y biochar a partir de aguacate criollo en el norte de Colombia. Rev. Ing-Nova 2023, 2, 11–22. [Google Scholar] [CrossRef]

- Young, D.M.; Cabezas, H. Designing sustainable processes with simulation: The waste reduction (WAR) algorithm. Comput. Chem. Eng. 1999, 23, 1477–1491. [Google Scholar] [CrossRef]

- González-Delgado, Á.D.; Moreno-Sader, K.A.; Martínez-Consuegra, J.D. Biorrefinación Sostenible del Camarón: Desarrollos Desde la Ingeniería de Procesos Asistida por Computador; Corporación Universitaria Minuto de Dios-UNIMINUTO: Bogotá, Colombia, 2022; Available online: https://repository.uniminuto.edu/items/023c3a1a-8788-45b0-b03a-0fbee032808d (accessed on 2 December 2024).

- Meramo-Hurtado, S.; Alarcón-Suesca, C.; González-Delgado, Á.D. Exergetic sensibility analysis and environmental evaluation of chitosan production from shrimp exoskeleton in Colombia. J. Clean. Prod. 2020, 248, 119285. [Google Scholar] [CrossRef]

- Smith, J.M.; Van Ness, H.C.; Abbott, M.M.; Swihart, M.T. Introduction to Chemical Engineering Thermodynamics; McGraw-Hill Education: New York, NY, USA, 2022. [Google Scholar]

- Moreno-Sader, K.A.; Martínez-Consuegra, J.; González-Delgado, Á.D. An integrated biorefinery approach via material recycle/reuse networks for the extraction of value-added components from shrimp: Computer-aided simulation and environmental assessment. Food Bioprod. Process. 2021, 127, 443–453. [Google Scholar] [CrossRef]

- González-Delgado, Á.D.; Barajas-Solano, A.F.; Leon-Pulido, J. Evaluating the sustainability and inherent safety of a crude palm oil production process in North-Colombia. Appl. Sci. 2021, 11, 1046. [Google Scholar] [CrossRef]

- Ariza Ortega, J.A.; López-Valdez, F.; Ramos Cassellis, M.E.; Diaz-Reyes, J.; Martínez Zavala, A. Efecto de diferentes métodos de extracción sobre el perfil de ácidos grasos en el aceite de aguacate (Persea americana Mill. var. Hass). Rev. Venez. Cienc. Tecnol. Alimentos. 2011, 2, 263–276. [Google Scholar]

- Weemaes, C.; Ooms, V.; Ludikhuyze, L.; Van Den Broeck, I.; Van Loey, A.; Hendrickx, M. Pressure-temperature degradation of green color in broccoli juice. J. Food Sci. 1999, 64, 504–508. [Google Scholar] [CrossRef]

- Setyawan, P.; Puriwangi, C.; Sukardi, S. Phytochemical properties of avocado seed: A review. IOP Conf. Ser. Earth Environ. Sci. 2021, 733, 012090. [Google Scholar] [CrossRef]

- Cabezas, H.; Bare, J.C.; Mallick, S.K. Pollution prevention with chemical process simulators: The generalized waste reduction (WAR) algorithm—Full version. Comput. Chem. Eng. 1999, 23, 623–634. [Google Scholar] [CrossRef]

- Borole, A.P. Sustainable and efficient pathways for bioenergy recovery from low-value process streams via bioelectrochemical systems in biorefineries. Sustainability 2015, 7, 11713–11726. [Google Scholar] [CrossRef]

- Meramo-Hurtado, S.I.; Puello, P.; Rodríguez, J. Computer-aided environmental assessment applied for estimation of ecological impacts derived from topological pathways based on lignocellulosic biomass transformation. Appl. Sci. 2020, 10, 6586. [Google Scholar] [CrossRef]

- Moncada, B.J.; Aristizábal, M.V.; Cardona, C.A. Design strategies for sustainable biorefineries. Biochem. Eng. J. 2016, 116, 122–134. [Google Scholar] [CrossRef]

- Arango-Manrique, S.; Agudelo Patiño, T.; Matallana Pérez, L.G.; Ortiz-Sanchez, M.; Cardona Alzate, C.A. Conceptual design and economic optimization of different valorization routes for orange peel waste: The application of the biorefinery concept for an integral use of raw material. Processes 2024, 12, 2298. [Google Scholar] [CrossRef]

- Moncada, J.; Tamayo, J.A.; Cardona, C.A. Integrating first, second, and third generation biorefineries: Incorporating microalgae into the sugarcane biorefinery. Chem. Eng. Sci. 2014, 118, 126–140. [Google Scholar] [CrossRef]

- Rodríguez-Martínez, B.; Romaní, A.; Eibes, G.; Garrote, G.; Gullón, B.; Del Río, P.G. Potential and prospects for utilization of avocado by-products in integrated biorefineries. Bioresour. Technol. 2022, 364, 128034. [Google Scholar] [CrossRef]

- Solis, C.M.A.; Juan, J.L.G.S.; Mayol, A.P.; Sy, C.L.; Ubando, A.T.; Culaba, A.B. A multi-objective life cycle optimization model of an integrated algal biorefinery toward a sustainable circular bioeconomy considering resource recirculation. Energies 2021, 14, 1416. [Google Scholar] [CrossRef]

- Gómez, J.A.; Matallana, L.G.; Teixeira, J.A.; Sánchez, Ó.J. A framework for the design of sustainable multi-input second-generation biorefineries through process simulation: A case study for the valorization of lignocellulosic and starchy waste from the plantain agro-industry. Chem. Eng. Res. Des. 2023, 195, 551–571. [Google Scholar] [CrossRef]

- Ortiz-Sanchez, M.; Solarte-Toro, J.C.; González-Aguirre, J.A.; Peltonen, K.E.; Richard, P.; Cardona-Alzate, C.A. Pre-feasibility analysis of the production of mucic acid from orange peel waste under the biorefinery concept. Biochem. Eng. J. 2020, 161, 107680. [Google Scholar] [CrossRef]

| Stream Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature (°C) | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Pressure (bar) | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Mass flows (kg/h) | 1102 | 2241 | 1243 | 2100 | 1040 | 203 | 747 | 293 | 103 | 191 | 205 | 435 | 511 | 127 | 702 | 593 |

| Mass Fractions | ||||||||||||||||

| Sodium hypochlorite | - | 2.0 × 10−4 | 3.6 × 10−6 | 2.1 × 10−4 | - | 2.2 × 10−5 | - | - | - | - | - | - | 8.8 × 10−6 | - | 6.4 × 10−6 | 7.1 × 10−6 |

| Water | 0.66 | 0.99 | 0.71 | 0.99 | 0.77 | 0.38 | 0.88 | 0.49 | 1 | 0.74 | 0.52 | 1 | 0.94 | 0.24 | 0.89 | 0.99 |

| Leucine | 0.01 | - | 0.01 | - | 0.01 | 0.02 | 0.01 | 0.03 | - | 0.02 | 0.02 | - | - | 0.02 | 0.01 | 0 |

| Glucose | 0.18 | - | 0.16 | - | 0.11 | 0.43 | 0.06 | 0.24 | - | 0.01 | 0.32 | - | 0 | 0.67 | 0.01 | 0 |

| Calcium oxide | 0.03 | - | 0.01 | 0.01 | 0.02 | 0.01 | 0.01 | 0.03 | - | 0 | 0.05 | - | 6.7 × 10−4 | 0.01 | 1.0 × 10−3 | 0 |

| Lauric acid | 2.4 × 10−5 | - | 2.1 × 10−5 | - | 2.0 × 10−5 | 2.6 × 10−5 | 1.0 × 10−5 | 4.4 × 10−5 | - | 6.8 × 10−5 | - | - | 1.0 × 10−5 | - | 2.6 × 10−5 | 1.7 × 10−5 |

| Myristic acid | 2.1 × 10−4 | - | 1.9 × 10−4 | - | 1.8 × 10−4 | 2.3 × 10−4 | 9.4 × 10−5 | 4.0 × 10−4 | - | 6.1 × 10−4 | - | - | 9.1 × 10−5 | - | 2.3 × 10−4 | 1.6 × 10−5 |

| Pentadecanoic acid | 2.4 × 10−5 | - | 2.1 × 10−5 | - | 2.0 × 10−5 | 2.6 × 10−5 | 1.0 × 10−5 | 4.4 × 10−5 | - | 6.8 × 10−5 | - | - | 1.0 × 10−5 | - | 2.6 × 10−5 | 1.7 × 10−6 |

| Palmitic acid | 0.04 | - | 0.04 | - | 0.03 | 0.04 | 0.02 | 0.08 | - | 0.12 | - | - | 0.02 | - | 0.05 | 3.0 × 10−3 |

| Heptadecanoic acid | 4.7 × 10−5 | - | 4.2 × 10−5 | - | 4.0 × 10−5 | 5.1 × 10−5 | 2.1 × 10−5 | 8.8 × 10−5 | - | 1.4 × 10−4 | - | - | 2.0 × 10−5 | - | 5.2 × 10−5 | 3.5 × 10−6 |

| Stearic acid | 1.3 × 10−3 | - | 1.1 × 10−3 | - | 1.1 × 10−3 | 1.4 × 10−3 | 5.7 × 10−4 | 2.4 × 10−3 | - | 3.7 × 10−3 | - | - | 5.6 × 10−4 | - | 1.4 × 10−3 | 9.5 × 10−5 |

| Oleic acid | 0.05 | - | 0.04 | - | 0.03 | 0.07 | 0.02 | 0.08 | - | 0.1 | 0.02 | - | 0.02 | 0.03 | 0.04 | 2.9 × 10−3 |

| Linoleic acid | 0.02 | - | 0.02 | - | 0.02 | 0.02 | 0.01 | 0.04 | - | - | 0.06 | - | 0.01 | - | 0.01 | 4.5 × 10−4 |

| Linolenic acid | 3.2 × 10−3 | - | 2.9 × 10−3 | - | 2.7 × 10−3 | 3.5 × 10−3 | 1.4 × 10−3 | 0.01 | - | - | 0.01 | - | 1.4 × 10−3 | - | 1.0 × 10−3 | 6.8 × 10−5 |

| Arachidic acid | 6.4 × 10−4 | - | 5.6 × 10−4 | - | 5.4 × 10−4 | 6.9 × 10−4 | 2.8 × 10−4 | 1.2 × 10−3 | - | - | 1.7 × 10−3 | - | 2.7 × 10−4 | - | 2.0 × 10−4 | 1.3 × 10−5 |

| Isophytol | 2.7 × 10−3 | - | 2.4 × 10−3 | - | - | 0.01 | - | - | - | - | - | - | - | 0.02 | - | - |

| Tannins | 2.6 × 10−3 | - | 2.3 × 10−3 | - | 2.8 × 10−3 | - | 1.5 × 10−3 | 0.01 | - | - | 0.01 | - | - | - | - | - |

| Flavonoids | 2.1 × 10−4 | - | 1.8 × 10−4 | - | 2.2 × 10−4 | - | 1.1 × 10−4 | 4.8 × 10−4 | - | - | 6.9 × 10−4 | - | - | - | - | - |

| Phenols | 9.9 × 10−4 | - | 8.8 × 10−4 | - | 1.1 × 10−2 | - | 5.5 × 10−4 | 2.3 × 10−3 | - | - | 3.3 × 10−3 | - | - | - | - | - |

| Stream Number | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature (°C) | 25 | 25 | 25 | 70 | 70 | 25 | 24 | 24 | 24 | 70 | 18 | 70 | 70 | 70 | 30 | 25 |

| Pressure (bar) | 1 | 1 | 1 | 0.3 | 0.3 | 1 | 0.3 | 0.3 | 0.3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Mass flows (kg/h) | 108 | 855 | 855 | 689 | 167 | 32 | 199 | 13 | 186 | 151 | 151 | 35 | 1 | 34 | 34 | 32 |

| Mass Fractions | ||||||||||||||||

| Hexane | - | - | - | - | - | 1.00 | 0.16 | 2.4 × 10−3 | 0.17 | - | - | 0.92 | 0.92 | 0.92 | 0.92 | 1.0 |

| Sodium hypochlorite | 2.3 × 10−6 | 2.9 × 10−7 | 2.9 × 10−7 | - | 1.4 × 10−6 | - | 1.2 × 10−6 | 1.87 × 10−8 | 1.3 × 10−6 | 1.6 × 10−6 | 1.6 × 10−6 | - | - | - | - | - |

| Water | 0.32 | 0.81 | 0.81 | 1.00 | 0.02 | - | 0.01 | 2.1 × 10−4 | 0.01 | 5.7 × 10−6 | 5.7 × 10−6 | 0.08 | 0.08 | 0.08 | 0.08 | - |

| Leucine | 0.03 | 0.01 | 0.01 | - | 0.05 | - | 0.04 | 0.05 | 0.04 | 0.05 | 0.05 | - | - | - | - | - |

| Glucose | 0.04 | 0.05 | 0.05 | - | 0.28 | - | 0.23 | 0.28 | 0.23 | 0.28 | 0.28 | - | - | - | - | - |

| Calcium oxide | 0.01 | 0.01 | 0.01 | - | 0.04 | - | 0.03 | 0.04 | 0.03 | 0.04 | 0.04 | - | - | - | - | - |

| Lauric acid | 1.6 × 10−4 | 2.9 × 10−5 | 2.9 × 10−5 | - | 1.4 × 10−4 | - | 1.2 × 10−4 | 1.5 × 10−4 | 1.2 × 10−4 | 1.5 × 10−4 | 1.5 × 10−4 | - | - | - | - | - |

| Myristic acid | 1.4 × 10−3 | 2.6 × 10−4 | 2.6 × 10−4 | - | 1.3 × 10−3 | - | 1.1 × 10−3 | 1.3 × 10−3 | 1.1 × 10−3 | 1.3 × 10−3 | 1.3 × 10−3 | - | - | - | - | - |

| Pentadecanoic acid | 1.6 × 10−4 | 2.9 × 10−5 | 2.9 × 10−5 | - | 1.4 × 10−4 | - | 1.2 × 10−4 | 1.5 × 10−4 | 1.2 × 10−4 | 1.5 × 10−4 | 1.5 × 10−4 | - | - | - | - | - |

| Palmitic acid | 0.28 | 0.05 | 0.05 | - | 0.26 | - | 0.22 | 0.27 | 0.22 | 0.27 | 0.27 | - | - | - | - | - |

| Heptadecanoic acid | 3.2 × 10−4 | 5.8 × 10−5 | 5.8 × 10−5 | - | 2.9 × 10−4 | - | 2.5 × 10−4 | 3.0 × 10−4 | 2.4 × 10−4 | 3.0 × 10−4 | 3.0 × 10−4 | - | - | - | - | - |

| Stearic acid | 0.01 | 1.6 × 10−3 | 1.6 × 10−3 | - | 0.01 | - | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | - | - | - | - | - |

| Oleic acid | 0.27 | 0.05 | 0.05 | - | 0.25 | - | 0.21 | 0.26 | 0.21 | 0.26 | 0.26 | - | - | - | - | - |

| Linoleic acid | 0.04 | 0.01 | 0.01 | - | 0.07 | - | 0.06 | 0.07 | 0.06 | 0.07 | 0.07 | - | - | - | - | - |

| Linolenic acid | 0.01 | 2.0 × 10−3 | 2.0 × 10−3 | - | 0.01 | - | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | - | - | - | - | - |

| Arachidic acid | 1.2 × 10−3 | 4.0 × 10−4 | 4.0 × 10−4 | - | 2.0 × 10−3 | - | 1.7 × 10−3 | 2.0 × 10−3 | 1.7 × 10−3 | 2.0 × 10−3 | 2.0 × 10−3 | - | - | - | - | - |

| Tannins | - | 1.3 × 10−3 | 1.3 × 10−3 | - | 0.01 | - | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | - | - | - | - | - |

| Flavonoids | - | 1.0 × 10−4 | 1.0 × 10−4 | - | 5.1 × 10−4 | - | 4.3 × 10−4 | 5.2 × 10−4 | 4.2 × 10−4 | 5.2 × 10−4 | 5.2 × 10−4 | - | - | - | - | - |

| Phenols | - | 4.8 × 10−4 | 4.8 × 10−4 | - | 2.4 × 10−3 | - | 2.0 × 10−3 | 2.5 × 10−3 | 2.0 × 10−3 | 2.5 × 10−3 | 2.5 × 10−3 | - | - | - | - | - |

| Stream Number | 33 | 34 | 35 | 36 | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 | 46 | 47 | 48 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature (°C) | 50 | 50 | 50 | 34 | 33 | 33 | 33 | 33 | 33 | 33 | 40 | 40 | 40 | 25 | 35 | 40 |

| Pressure (bar) | 0.1 | 0.1 | 0.1 | 1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 1 | 1 | 0.1 |

| Mass flows (kg/h) | 25 | 102 | 102 | 255 | 357 | 41 | 106 | 316 | 65 | 251 | 248 | 25 | 223 | 32.1 | 223 | 3 |

| Mass Fractions | ||||||||||||||||

| Water | 1.0 | 0.06 | 0.06 | 0.14 | 0.11 | 0.05 | 0.02 | 0.12 | - | 0.15 | 0.16 | 0.16 | 0.16 | - | 0.16 | 0.03 |

| Leucine | - | 0.03 | 0.03 | - | 0.01 | 0.02 | 0.03 | 0.01 | 0.03 | - | - | - | - | - | - | - |

| Glucose | - | 0.83 | 0.83 | - | 0.24 | 0.62 | 0.80 | 0.19 | 0.91 | - | - | - | - | - | - | - |

| Calcium oxide | - | 0.01 | 0.01 | - | 4.2 × 10−3 | 0.01 | 0.01 | 3.3 × 10−3 | 0.02 | - | - | - | - | - | - | - |

| Oleic acid | - | 0.03 | 0.03 | - | 0.01 | 0.02 | 0.03 | 0.01 | 0.04 | - | - | - | - | - | - | - |

| Ethanol | - | - | - | 0.86 | 0.62 | 0.27 | 0.10 | 0.66 | - | 0.83 | 0.84 | 0.84 | 0.84 | 1.0 | 0.84 | 0.07 |

| Isophytol | - | 0.03 | 0.03 | 6.3 × 10−5 | 0.01 | 3.6 × 10−3 | 1.4 × 10−3 | 0.01 | - | 0.01 | 7.2 × 10−5 | 7.2 × 10−5 | 7.2 × 10−5 | - | 7.2 × 10−5 | 0.90 |

| Stream Number | 49 | 50 | 51 | 52 | 53 | 54 | 55 | 56 | 57 | 58 | 59 | 60 | 61 | 62 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature (°C) | 25.0 | 70.0 | 42.5 | 23.7 | 23.7 | 73.0 | 73.0 | 73.0 | 81.0 | 81.0 | 81.0 | 70.0 | 77.9 | 81.0 |

| Pressure (bar) | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Mass flows (kg/h) | 205.0 | 912.6 | 923.1 | 194.5 | 194.5 | 441.1 | 26.7 | 414.5 | 230.5 | 207.5 | 23.1 | 223.6 | 246.7 | 183.9 |

| Mass Fractions | ||||||||||||||

| Sodium hypochlorite | 0.52 | 2.0 × 10−3 | 0.01 | 0.49 | 0.49 | 0.23 | 0.08 | 0.24 | 0.22 | 0.22 | 0.22 | - | 0.02 | 0.26 |

| Water | 0.02 | - | - | 0.02 | 0.02 | 0.01 | 0.03 | 0.01 | - | - | - | - | - | 0.02 |

| Leucine | 0.32 | - | - | 0.34 | 0.34 | 0.15 | 0.50 | 0.13 | - | - | - | - | - | 0.29 |

| Glucose | 0.05 | - | - | 0.05 | 0.05 | 0.02 | 0.07 | 0.02 | - | - | - | - | - | 0.04 |

| Calcium oxide | 0.02 | - | - | 0.02 | 0.02 | 0.01 | 0.02 | 0.01 | - | - | - | - | - | 0.01 |

| Oleic acid | 0.06 | - | - | 0.06 | 0.06 | 0.03 | 0.09 | 0.02 | - | - | - | - | - | 0.05 |

| Linoleic acid | 0.01 | - | - | 0.01 | 0.01 | 4.0 × 10−3 | 0.01 | 3.4 × 10−3 | - | - | - | - | - | 0.01 |

| Linolenic acid | 1.7 × 10−3 | - | - | 1.8 × 10−3 | 1.8 × 10−3 | 7.9 × 10−4 | 2.6 × 10−3 | 6.7 × 10−4 | - | - | - | - | - | 1.5 × 10−3 |

| Arachidic acid | - | - | - | - | - | 0.55 | 0.18 | 0.57 | 0.78 | 0.78 | 0.78 | 1.00 | 0.98 | 0.30 |

| Tannins | 0.01 | - | - | 0.01 | 0.01 | 0.00 | 0.01 | 3.5 × 10−3 | - | - | - | - | - | 0.01 |

| Flavonoids | 6.9 × 10−4 | - | - | 7.3 × 10−4 | 7.3 × 10−4 | 3.2 × 10−4 | 1.1 × 10−3 | 2.7 × 10−4 | - | - | - | - | - | 6.2 × 10−4 |

| Phenols | 3.3 × 10−3 | - | - | 3.5 × 10−3 | 3.5 × 10−3 | 1.5 × 10−3 | 0.01 | 1.3 × 10−3 | - | - | - | - | - | 3.0 × 10−3 |

| Air | - | 0.99 | 0.99 | - | - | - | - | - | - | - | - | - | - | - |

| Category | Unit | Description | Equation | Consideration |

|---|---|---|---|---|

| HTPI | PEI/kg of product | Human toxicity potential by ingestion. | LD50 is the lethal dose value by ingestion that would kill 50% of a sample population of rats, given in mg chemical/kg rat. | |

| HTPE | PEI/kg of product | Human toxicity potential by exposure. | The TLV is the maximum concentration of a substance in the air that a person can be safely exposed to for 8 h a day, 40 h a week, without adverse effects, measured in mg/m3. | |

| ATP | PEI/kg of product | Aquatic toxicity potential. | LD50 is the lethal dose by ingestion that kills 50% of a sample population of Pimephales promelas (a fish species), measured in mg/L. | |

| TTP | PEI/kg of product | Terrestrial toxicity potential. | LD50 is the lethal dose value by ingestion that would kill 50% of a sample population of rats, given in mg chemical/kg rat. |

| Category | Unit | Description | Equation | Consideration |

|---|---|---|---|---|

| ODP | PEI/kg of product | Ozone depletion potential. | CFC-11 is the ratio of ozone depletion by a unit of gas is the emitted gas mass in kg. | |

| GWP | PEI/kg of product | Global warming potential. | is the heat absorption per unit of greenhouse gas i, for carbon dioxide. and are the concentrations of gas i and CO2 at time t. t is the GWP evaluation period, usually 100 years, and is the gas mass in kilograms. | |

| PCOP | PEI/kg of product | Photochemical oxidant potential. | is the ozone concentration change from emitting volatile organic compound i, with specific to ethylene. and represent the integrated emissions of compound i and ethylene up to time t. t is time, and is the mass of emitted volatile organic compound in kilograms. | |

| AP | PEI/kg of product | Acidification potential. | is the acidification potential of component i, with specific to SO2. and are the mass units for substance i and SO2. is the emitted mass of component i in kilograms. |

| Subprocess | Stage | Output PEI/h | Contribution Considering Residues |

|---|---|---|---|

| Bio-oil | Pulp drying | 10 | 7.84 |

| Methanol distillation | 0.38 | 0.30 | |

| Bio-oil cooling | 4.91 | 3.85 | |

| Methanol condensation | 10.8 | 8.49 | |

| Chlorophyll | Peel drying | 0.072 | 0.06 |

| Evaporation | 6.49 | 5.09 | |

| Acetone condensation | 4.9 | 3.81 | |

| Biopesticide | Seed drying | 8.98 | 7.04 |

| Fractional distillation | 81.0 | 63.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valdez-Valdes, S.A.; Tejeda-Benitez, L.P.; González-Delgado, Á.D. Assessing the Environmental Impacts of the Valorization of Creole-Antillean Avocado via an Extractive-Based Biorefinery in the Montes de María Region. Sustainability 2024, 16, 11057. https://doi.org/10.3390/su162411057

Valdez-Valdes SA, Tejeda-Benitez LP, González-Delgado ÁD. Assessing the Environmental Impacts of the Valorization of Creole-Antillean Avocado via an Extractive-Based Biorefinery in the Montes de María Region. Sustainability. 2024; 16(24):11057. https://doi.org/10.3390/su162411057

Chicago/Turabian StyleValdez-Valdes, Stefany A., Lesly P. Tejeda-Benitez, and Ángel D. González-Delgado. 2024. "Assessing the Environmental Impacts of the Valorization of Creole-Antillean Avocado via an Extractive-Based Biorefinery in the Montes de María Region" Sustainability 16, no. 24: 11057. https://doi.org/10.3390/su162411057

APA StyleValdez-Valdes, S. A., Tejeda-Benitez, L. P., & González-Delgado, Á. D. (2024). Assessing the Environmental Impacts of the Valorization of Creole-Antillean Avocado via an Extractive-Based Biorefinery in the Montes de María Region. Sustainability, 16(24), 11057. https://doi.org/10.3390/su162411057