Abstract

In a circular economy, the efficient utilization of all materials as valuable resources, with a focus on minimizing waste, is paramount. This study shows the possibilities of upgrading the lowest-valued residuals from the forest industry into a new product with both liming and fertilizing properties on forest soil. Hydrothermal carbonized sludge mixed with bark and ash in the proportions of 45:10:45 was densified into fertilizer pellets that meet the nutrient requirements of 120 kg N per hectare when 7 tons of pellets is spread in forests. The pellets met a high-quality result according to durability and density, which were above 95% and 900 kg/m3. However, pellets exposed to wet and cold conditions lost their hardness, making the pellets dissolve over time. Small amounts, <5‰, of nutrients, alkali ions, and heavy metals leached out from the pellets under all conditions, indicating good properties for forest soil amendment. The conclusion is that it is possible to close the circle of nutrients by using innovative thinking around forest industrial residual products.

1. Introduction

In Sweden, about 50% of felled forest is used for pulp and paper production [1]. However, when logging these trees, nutrients and minerals that the trees have taken up are also leaving the forest. During their lifespan, trees absorb macro-nutrients, such as nitrogen, phosphorus, potassium, calcium, and magnesium. When the tree absorbs cations like calcium (Ca2+) and magnesium (Mg2+), the tree simultaneously emits acidifying protons (H+). In addition, depending on the tree’s soil, it absorbs other substances, such as heavy metals. The balance is restored if the tree dies and degrades in the same place it was growing up. However, nutrient depletion and an acidifying effect remain if the tree with the nutrients and alkali cations are transported out of the forest. For sustainable forestry, these substances have to be returned.

In a circular economy, all resources are used for as long as possible without becoming waste. To redirect to a sustainable circular bioeconomy, we need to use the forest’s resources more independently. So, when wood fibers from forests are used to produce paper products, it is an excellent strategy to seek nutrients for recycling from the mill’s residual streams.

In pulp and paper mills, these nutrients and minerals are accumulated in ashes and sludge from industrial wastewater treatment. Ash and sludge are disposed of today as waste materials. Recycling or reusing these biobased waste materials for forest growth will support the decarbonization of the forest sectors. Other organic material, such as bark, is burned for energy recovery, and inorganic substances, such as calcium, magnesium, and phosphorus, eventually accumulate in the ash. Along with the inorganic nutrients are also the heavy metals in the wood ash. As methods are developed to recycle beneficial nutrients and base cations, strategies must also be developed to avoid recycling excessive heavy metals.

Today, commercial mineral fertilizers are commonly used to increase growth. When it comes to nitrogen, it is customary to spread 150 kg of nitrogen per hectare [2]. Mineral fertilizers come with large costs and a big carbon footprint [3], including between 3 and 8 tons CO2-eq/tons of produced ammonium nitrate or urea. Furthermore, ammonium based nutrients can be leached out of the soil and create eutrophication in the surrounding water; therefore, fertilization needs to be done carefully and with protective zones of 25 m to watercourses and other sensitive biotopes.

Ash from biofuel boilers is also spread in forest land to reduce soil acidification and to recycle the essential nutrients phosphorus and potassium [2]. However, nitrogen is converted to NOx gases at high temperatures, and ash is often completely nitrogen-free. Therefore, if nitrogen is the limited nutrient in the forest soil, ash will not have a fertilizing effect. On the other hand, if the ash can be enriched with nitrogen, spreading the ash can counteract acidification during fertilization. So, in a circular economy where all resources should be used as long as possible, it is vital to take care of residual nitrogen-rich products.

The organic material in the wood that is not used for products or that can be energy-recycled ends up in the process effluents. Process effluents are generally treated with biological methods, and nutrients, such as nitrogen and phosphorus, accumulate in the sludge. In a large pulp and paper mill, about 5–10 tons of dry matter biosludge is formed daily. The sludge contains essential nutrients, such as nitrogen and phosphorus. Biosludge is today a resource handled as waste, but the challenge is that it is wet and difficult to dewater. Currently, it is processed through co-incineration with other, more energy-rich fuels. In order to increase the energy value of the biosludge, it can be processed into biochar [4]. Unlike biosludge, biochar is stable and can be handled and transported. In addition to its high energy value, biochar has good properties as a soil amendment that can be applied back in the forest to improve the soil quality [5].

There are several ways to carbonize organic material to create biochar. Traditionally, biochar is produced through pyrolysis. Biochar and pyrolysis gases are formed under oxygen-free conditions and high temperatures (500–900 °C). When used for soil amendment, biochar also reduces the climate effect. The charring process delays the mineralization of the organic material and, depending on the charring process, biochar can be stable for hundreds to thousands of years and mitigate climate change.

However, the material needs to be dry before it is pyrolyzed, and wet sludge requires a lot of energy to dry. Therefore, a more common way to upgrade bioresources containing much water is to use hydrothermal processes, such as hydrothermal liquefaction (HTL), supercritical water gasification (SCWG), and hydrothermal carbonization (HTC). HTL is used for bio-oil production, and SCWG generates H2-rich syngas, while the HTC process generates hydrochar. In the liquid phase, water-soluble organics, like sugars and volatile fatty acids, are found. Some of the nutrients are also dissolved and found in the liquid phase. During the HTC process, the material and water are carbonized at relatively low temperatures (180–260 °C) and with a pressure rate of 2–6 MPa [6,7]. Because the material does not need to be dried before the HTC process, the technology is suitable for handling sludge. A smaller part, approximately 15%, of hydrochar is stable for degradation compared to biochar [4,8,9]. Hydrochar as a soil improver is not as investigated as the use of pyrochar. During the HTC process, toxic organic compounds like PAH and phenols may be formed. The temperature during the process is one important factor. At temperatures below 220 °C, only low concentrations of harmful compounds are found [10]. However, some studies show promising results. Baronti [11] showed hydrochar improved poplar growth during a two-year field trial. Pine plants grown at nurseries are grown in peat. The peat lack nutrients, and the plants need to be fertilized. Eskandari [12] showed that hydrochar and biofuel ash could reduce the need for fertilizer. Pine seedlings that were allowed to germinate and grow in peat mixed with 20% hydrochar and 6% ash only needed half of a fertilizer dose to develop as well as the reference seedlings that grew only in peat but received a 100% dose of fertilizer [12].

Furthermore, the transportation of hydrochar and ash in the form of powder is a challenge. The low bulk density increases the transportation cost and adds challenges related to storage and handling. Another major challenge is when biochar and ash become a blend, with variability in particle sizes. The variability of particles segregates the material during storage and transportation. This can lead to inefficient or non-uniform distribution of the material into the forest fields. In addition, it can create pockets of highly concentrated hydrochar or biofuel ash, which can further impact the performance. In their review of biomass densification, Tumuluru et al.[13] identified various systems, such as pellet mills, briquette presses, cubers, agglomerators, and tablet presses, for converting raw biomass material into densified products. Among these systems, a pellet mill is widely used for making densified products from biomass material [13]. Typically, pelletization increases the bulk density by about 3–5 times [14]. The bulk density increase depends on the type of densification system and the process conditions tested [13]. There are many studies on the pelleting of biomass, and, in general, two types of pellets are produced: white pellets, based on raw biomass, and black pellets, based on thermal pretreatment biomass. In white pellet production, the lignin acts as a one-binding agent [15], where the lignin goes through a glass transition phase during pelleting and binds the biomass particles together [16,17,18,19]. Lignin is one binding agent; other biomass components that go through the glass transition phases are waxes and the hemicelluloses, xylan and galactan [20,21,22], which also create additional bonds between the particles due to the temperature generated during the pelletizing process [20,21,22].

The black pellet pelletization of biochars produced at a high temperature of around 400 °C is particularly challenging [23], which means that the HTC process is preferred, especially if the HTC process temperatures are below 260 °C and the nature of lignin will not be influenced [24]. Fakkaew [25] studied hydrochar pellets from fecal sludge in a single pellet press blended with lignin, starch, and calcium hydroxide and found that the optimum mixing rate was when 15% starch together with hydrochar and no water were added [25]. These authors also found that adding water decreased the bulk density as well as the compressive strength of the pellets. Mittapalli [26] co-pelletized hydrochar with yard waste in a single pellet press and found that the hydrochar pellets, co-pelletized with yard waste, were less brittle. Saqib [27] used molasses as a binder with hydrochar and pelletized these in a single pellet press and concluded that molasses played an important role when formatting pellets. Few studies on hydrochar pellets have been performed, and Gallant [7] discussed in their mini-review die temperatures, moisture contents, applied pressure, and types of binders when pelletizing hydrochar and found some recommendations related to pelletizing parameters of hydrochar. However, the experimental investigations behind recommendations are based on single pellet press techniques [6,7,23], and it has been shown that it is difficult to evaluate results between different single pellet press studies because inlet data in these studies often vary [28]. During single pellet press studies, parameters, such as press ratio, are not evaluated, and translating the result into a continuous pellet press is challenging. This means there is a gap of knowledge related to pelletization of hydrochar in a continuous pellet press.

Continuous pellet presses have difficulties with the variation of raw material flows [27], and when blends are to be pelletized, it is essential to know the material properties [14,29,30]. When it comes to a pulp and paper mill, bark, the outermost layer of the tree stem, is separated during the process; even if the bark is often used as energy, it is a rest product from the process. Fuel pellets containing bark are limited mainly based on the high ash content, which is significantly higher than wood, and it can also be augmented through mineral contamination [31]. The amount of ash produced through the combustion of bark pellets can be 4–10 times higher than that produced by wood pellets [32]. However, if the pellets are not intended to be incinerated but instead used as fertilization pellets, the ash and the minerals become a resource. Beyond that, a small amount of bark is added to pellet production to increase the pellets’ durability [32]. Bark also contains a large amount of extractives [31], which can act as a lubricant within the die channel [33]. Studies of hydrochar pelleting have shown that by adding a lubricant binder, the pelletizing process is more energy-efficient [34], and hydrochar seems to need binders [7].

The Swedish Forest Agency has guidelines for heavy metals based on the recommended 3 tons per hectare of approved ash and 150 kg of nitrogen per hectare. Mixing hydrochar with biofuel ash and bark can create a material for combined fertilization and ash recycling. As a compact product, the material can be more economically transported, and problems with dusting can be avoided. Furthermore, by pressing the fertilizers into pellets, nutrients and alkali cations will likely leach into the soil more slowly than if they are leached into the soil spread in the form of powder. Hydrochar fertilizer pellets are a new product type with no published experience of pellet quality or leaching properties or how they are affected when spread in boreal forests in summer and winter conditions.

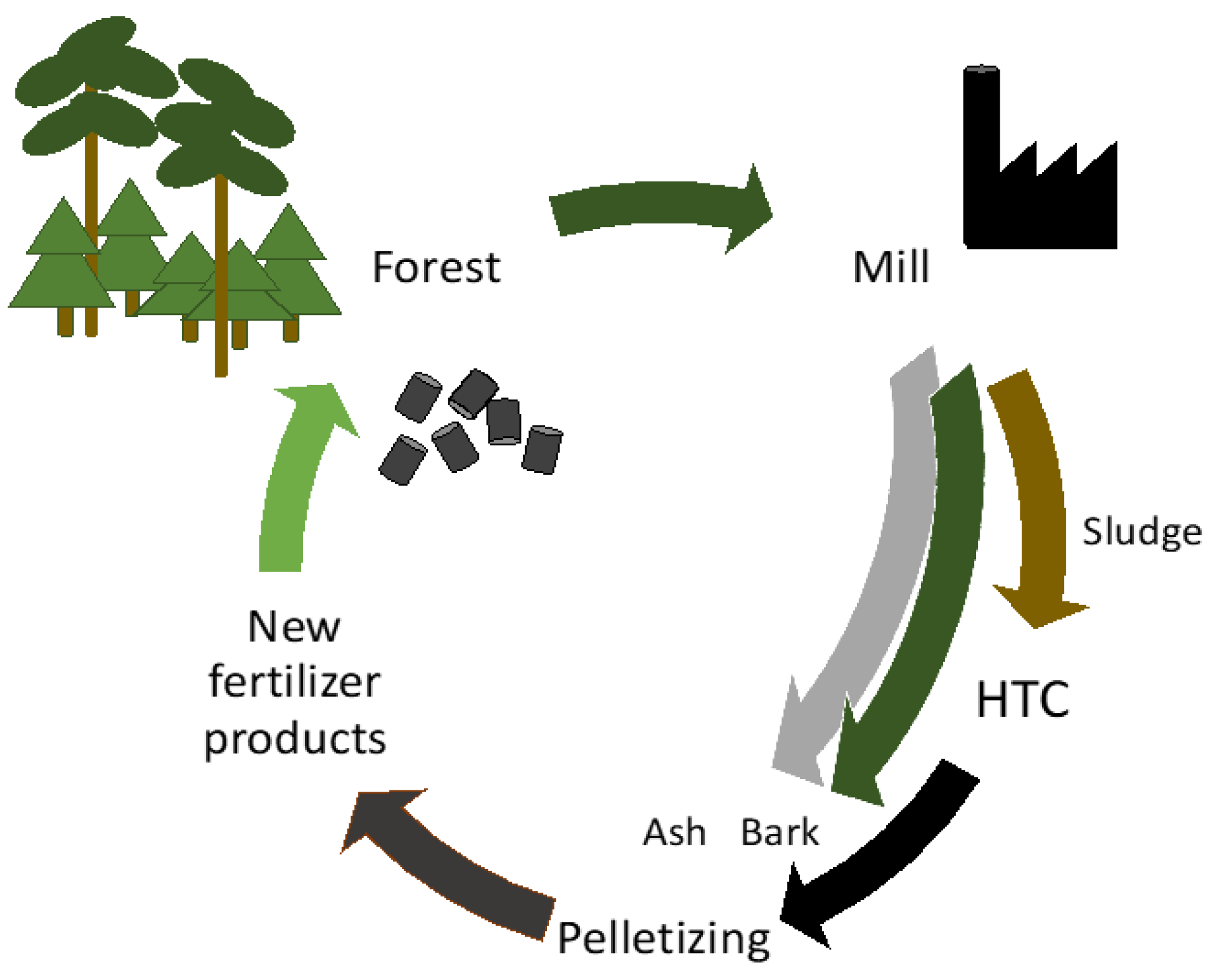

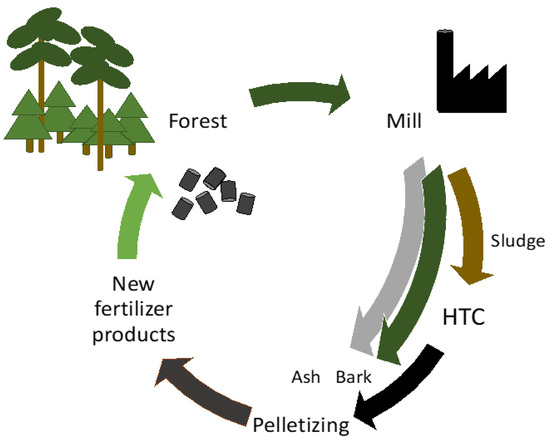

This study aims to use hydrochar produced from pulp and paper mill sludge, mix it with bark and ash, and pelletize these materials to produce a soil amendment with a double purpose as fertilizer and as a liming agent. As far as the authors know, similar issues have never been published. The main idea is to show the possibilities of upgrading residual products from the forest industry and to show a method for returning nutrients to nature, as depicted in Figure 1.

Figure 1.

The principle behind this study is to utilize residual products from the forest industry and upgrade these to a biochar-based nutrient pellet, divided into three focus areas: (1) related to possibilities to mix these waste products into fertilizers, (2) analyze pelletabilites of the mix, and (3) evaluate what happens when these pellets are exposed to water and low temperature. The experiments were designed to mimic natural conditions in a boreal forest.

This study aims to find the optimal blend of hydrochar ash and bark for the production of a soil amendment for boreal forests with dual purposes as a fertilizer and as a liming agent while ensuring that heavy metal spreading limitations are not exceeded. Additionally, it aims to assess whether a blend of hydrochar, spruce bark, and ash can be pelletized in a continuous pellet press, and if the resulting pellet quality is suitable for storage, transportation, and spreading in the forest. Furthermore, this study intends to gather data on the efficacy of these pellets as forest soil amendments by evaluating leakage of nutrients, alkali ions, and heavy metals during both the summer and winter seasons.

2. Materials and Methods

The methods are explained in the following three sections: Section 2.1 describes the materials used in this study, including a description of how the distribution between hydrochar, bark, and ash was decided. Section 2.2 is related to pelletization and evaluation of the pellets, and Section 2.3 is a mass flow analysis where the pellets produced in Section 2.2 are simulated to be spread in the forest. Quantities are compared with the Swedish Forest Agency’s guidelines when 3–4 tons/hectare of approved ash is spread in Swedish forests.

2.1. Materials Used and Distribution of the Blends

In this study, hydrochar derived from forest industrial biosludge has been used. The biosludge from Stora Enso Mill in Heinola, Finland, was carbonized with OxyPower Hydrothermal Carbonization (HTC). The production reactor was delivered by C-Green and had a capacity to produce 16,000 tons of hydrochar annually. The HTC process was conducted at 270 °C and approximately 20 bar, and the sludge had a moisture content of approximately 80%. The hydrochar was enriched with fly ash from Stora Enso Skoghall Sweden mill’s biofuel boiler and the spruce bark from Stora Enso Timber AB in Grums, Sweden. The hydrochar and ash used in this study were analyzed with plasma-induced mass spectroscopy methods SS-EN 16174 [35], SS-EN 16171 [36], ISO 11885 [37] SYNLAB analytical, and Services Sweden AB. The results are reported in Table 1. Furthermore, a study conducted by a Swedish environmental institute analyzed the concentration of nutrients and alkali ions in spruce bark from eight Scandinavian locations [38]. The concentration of heavy metal in spruce bark is based on Krogell [31], and their results related to spruce bark are also reported in Table 1.

Table 1.

Concentration of nutrients, alkali ions, and heavy metals in the material used to produce pellets for soil amendment [34].

By mixing hydrochar and ash, a product used both as fertilizer and as a liming agent for forest soil may be formed. However, it is crucial to ensure that the amount of heavy metals does not exceed limiting regulations. In this study, the Swedish Forest Agency’s recommendations for spreading ash have been used to find the right proportions between hydrocarbon and ash without exceeding the limits. According to the Swedish Forestry Agency, 3 to 4 tons of approved ash can be spread in the forest to remediate soil acidity.

The first step in finding the correct mix blend for the fertilizer application was based on the hydrochar needing to achieve 150 kg N/ha. Then, the amount of ash necessary in the blend was calculated to fulfill the other criteria based on the Forestry Agency recommendations for nutrients, alkali ions, and heavy metals. The result showed that a 50/50 relationship between hydrochar and ash fulfilled the recommendations; thus, the first chosen distribution ratio of hydrochar/ash was 50/50. To evaluate the role of bark as an additive, 10% was added to the blend, meaning that the total mix was 45/10/45 of hydrochar, bark, and ash.

Physical Properties of the Material

The ash did not need any preparations. The hydrochar and the spruce bark were dried in a bed dryer at 50 °C until about 10% (wb) moisture content was reached. The drier was constructed at Karlstad University. The hydrochar was used in the delivered size, and the spruce bark was milled in an IKA Pilotina MU equipped with an impact mill system and an 8 mm sieve. For particle size distribution, the sawdust was sieved for 10 min using a shaking machine from Pascall Engineering with six different sieve sizes: 4.0, 2.8, 1.4, 0.71, 0.5, 0.25, and 0.12 mm. The bulk density of raw material was tested according to ISO 17828:2015 [39], with the deviation that a 0.5 L jar was used.

Based on results from Section 2.1, two test series of about 5 kg were blended, one with 50/50 hydrochar/ash and one with 45/10/45 HC/bark/ash; the weight properties were based on dry substance. Both of the blend ratios were conditioned to reach a moisture content of 20% (wb) for pelletizing based on earlier studies [23], and the blending process was performed with a SoRoTo 100 L mixer (Glostrup, Danmark), in 10 min.

2.2. Pelletizing and Pellet Physical Properties

2.2.1. Pelletizing

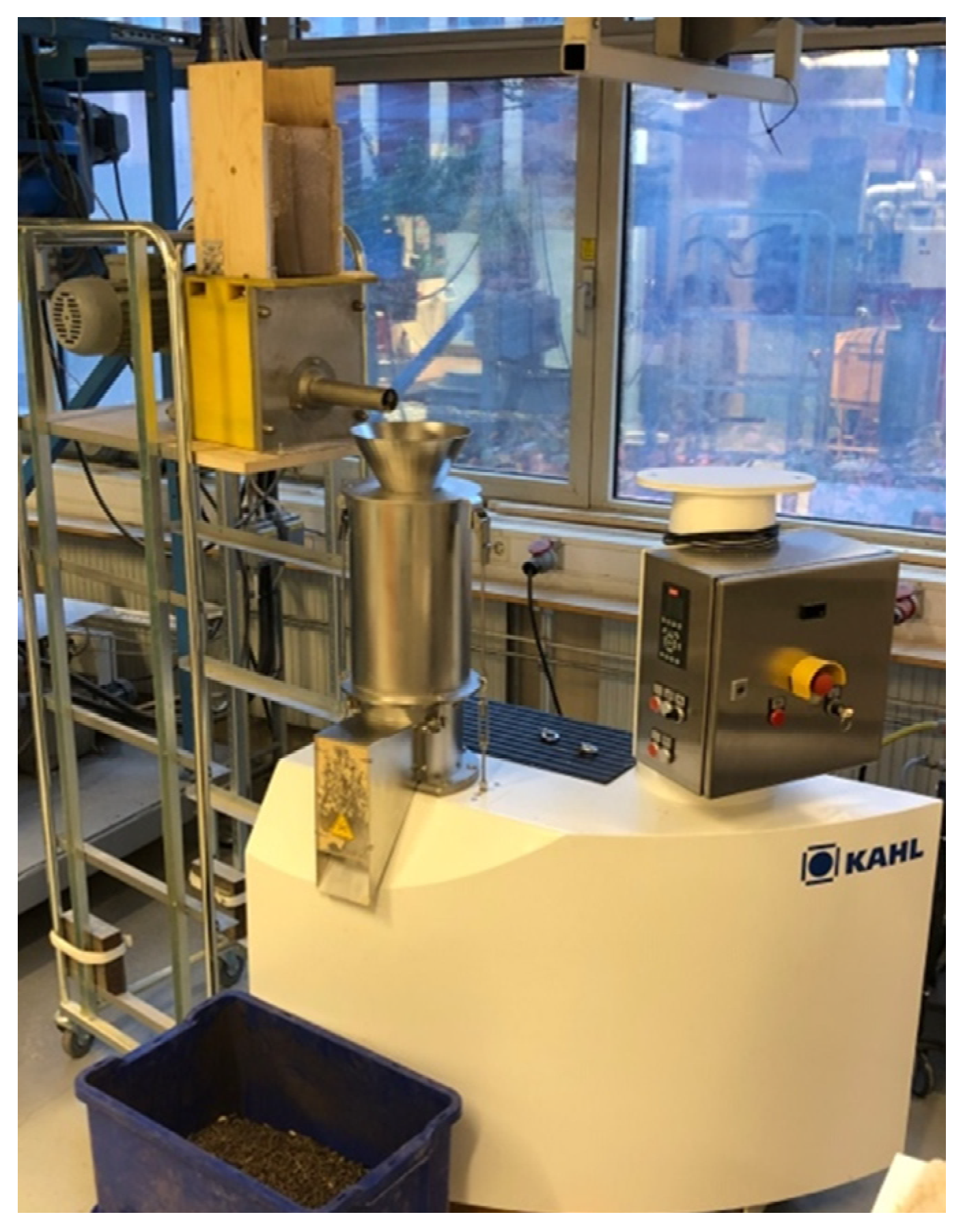

The pellet production was performed at Karlstad University, Sweden’s Environmental and Energy Systems section. The pellets unit was a lab scale, flat die pellet press (Model 14-175, Amandus Kahl, Hamburg, Germany) with a maximum power rate of 3 kW and a 20 kg/h production capacity equipped with a feeder (Figure 2). The chosen die had 6 mm diameter holes and a presslength of 24 mm, which gave a press ratio of 4. The test run started with the pelletizing of a neutral material consisting of sawdust, oats, and rapeseed oil until stable temperature conditions were reached, and then the test material was added to the process and pelletized until a homogeneous material of only biochar pellets was produced before the test was started. The flow rate of raw material to the pellet press was kept constant through a feeder. The feeder was designed and constructed at Karlstad University. No steam or preheating of the material was used before pelletization.

Figure 2.

Picture of used pellet press, an Amandus Kahl 14-175, with feeding system.

2.2.2. Physical Pellet Properties

Six tests were performed to evaluate the pellets: solid pellet density, loose and bulk density, loose and tapped macro-porosity, and pellet durability. Loose pellet bulk density is defined as the density obtained just by randomly filling a jar with pellets, while tapped and standardized bulk density has a moment of release or tapping against a hard surface to obtain a packed pellet. The methodology within this study for loose and tapped density and macro-porosity followed [40]; thus, more information and a complete description of the methodology can be found there. However, in general, the methodology behind loose bulk density was that randomly selected pellets were poured from a height of about 100 mm from a 14.3 cl plastic jar, and the top surface was carefully flattened so that the pellet was adapted to the experimental volume, which corresponds to the bulk weight with pellets filled in a loose state. When the tapped bulk was calculated, the pellet-filled jar was tapped fifty times against a hard wooden surface to simulate a settling behavior during transport, and then the top surface was carefully flattened so that the pellet was adapted to the experimental volume. Three trials were performed for booth loose and tapped bulk density; an average value is presented as kg/m3. Also, according to ISO 17828:2015, the bulk density was performed, with the deviation that a 0.5 L jar was used.

For solid pellet density, the length and diameter of fifty pellets were measured using a digital caliper, and their weight was noted using a digital wave. Pellets with irregular ends were ground smooth with sandpaper before measurement. The solid pellet density result is an average value with the unit kg/m3.

Macro-porosity is defined as the percentage of the volume of voids among the pellets when they are held in bulk to the overall fill volume [40]. For macro-porosity, three different measurements were made, and the average value presented by the general method was that at the same time as the loose and tapped bulk density was determined the number of pellets per jar was also counted. The total amount of pellets was then multiplied by the average volume of a solid pellet, and the ratio between the volume of the solid pellets and the volume of the jar gave the macro-porosity. Finally, the pellet durability (%) was determined according to ISO 17831-1:2015 [41], and the moisture content (%) according to SS EN 14774-1 (2009) [42], with the deviation that the test sample was less than 100 g.

2.2.3. Fourier Transform Infrared Spectroscopic Analysis (FT-IR)

Pellet quality can be measured in several ways to understand whether fuel pellets have quality standards related to pellet durability, bulk density, moisture content, and ash content. Research studies evaluate pellet quality mechanically outside of the standard by testing pellet hardness, springback effect, and moisture uptake. However, when new materials are tested, knowledge and understanding of structural chemistry should be evaluated to comprehend the mechanism of bonding in biomass pellets and how these parameters are affected by the pelletizing properties because polar functional groups play a vital role in enhancing and identifying the type of attraction forces between particles during pelleting. The raw material and pellets with different ash hydrochar and bark blends were analyzed with FTIR. The method is based on earlier studies [43,44,45,46,47] by using Fourier transform infrared—Attenuated total reflectance spectroscopy (FTIR–ATR) (Perkin Elmer Spectrum Two spectrometer, Waltham, MA, USA) in an attenuated total reflectance mode, and the spectra were scanned in the range of 4000–600 cm−1.

2.3. Pellet Properties after Being Spread in the Forest

To determine if the mixture’s content complies with the Swedish Forest Agency’s guidelines, the concentration in the blended material was compared with the amount of nutrients, alkali cations, and heavy metals spread when 3 tons of approved ash was spread per hectare. To mimic winter conditions in forest land, pellets were mixed with wet peat and frozen in a lab freezer at −18 °C. Ten pellets from both test series 50/50 and 45/10/45 were placed in jars with 10 g of peat and 20 mL of rainwater (pH 6.4). A total of 10 jars were completed (2 per test series). Each jar included ten pellets mixed with 10 g of moisturized peat. The series of tests conducted is given below.

- (0)

- The control, not stored in moist peat.

- (1)

- Stored wet 1 day at room temperature.

- (2)

- Stored wet 8 days at room temperature.

- (3)

- Stored wet 1 day at room temperature and then stored in a freezer at −18 °C for 1 day.

- (4)

- Stored wet 1 day at room temperature and stored in a freezer at −18 °C for 7 days.

After the storing period, the jar was thawed when needed. The pellets were carefully picked out, and their quality was tested according to pellet hardness (kg), which was determined using a KAHL motor-driven hardness tester (K3175-0011, Reinbek, Germany). The hardness tester has a small cone that is electronically driven forward toward the side of the pellet, and the resistance is measured by compressing a feather or spring; when the pellet breaks, the hardness is measured visually. Depending on the pellet quality, different feathers are used; in this test, a 3.5 mm and a 2.5 mm feather were used, and the 2.5 mm feather was used for pellets after being stored in peat. The hardness results are presented as the average of ten pellets.

The remaining peat in the sample was dried in an oven at 50 °C for 24 h. Nutrients and heavy metals within the dried peat were measured with a portable Bruker S1 titan 800 X-ray fluorescence spectrometer (pXRF) Bruker Handheld LLC (Billerica, MA, USA). Kennewick, USA. The use of pXRF has been shown to be an easy way to measure nutrients in, for instance, soil [48] and organic waste [49] with relatively good accuracy. An S1 Titan 800 was used to scan each sample with a configuration called soil mode. Each measurement lasts one minute and includes three different phases, the accuracy of which improves through each phase. During measurements, the peat was placed in a sample cup containing approximately 15 mL.

3. Results and Discussion

The results and discussion section is divided into four parts. Section 3.1 presents and discusses the amount of pellets needed in the forest. Section 3.2 relates to the pelletizing properties, and Section 3.3 relates to tests to mimic winter situations. Section 3.4 discusses the project’s novelty, experience, challenges, and future work.

3.1. Distribution Ratio between Hydrochar Bark and Ash

To reach the desired 150 kg N/ha [2], 4.05 tons of hydrochar must be spread on forest soil. To reach the Swedish Forest Agency’s guidelines regarding the amount of macro-nutrients, alkali cations, and heavy metals, 8.11 tons/ha of pellets with hydrochar and ash 50/50 can be spread (see Table 2 and Table 3). With this new type of recirculated fertilizer, more than double the amount of material must be transported to the forest and spread compared to traditional ash spreading of 3 tons/ha. The positive effects are better use of waste materials at the mills and less use of fossil-based fertilizers. When 10% bark is added to the pellets, the total spread amount of pellets has to increase to 8.77 tons/ha to reach the criteria of 150 kg N/ha (Table 2).

Table 2.

Amount and volume of pellets spread to fulfill the criteria of 150 and 120 kg N per hectare.

Table 3.

Amount of substances needed when the criteria from 150 kg N/ha by the Swedish Forestry Agency recommended amounts of nutrients, alkali ions, and heavy metals are fulfilled and when 120 kg N/ha is reached. Underlined nitrogen is not reached, bold number criteria is not reached.

With the tested blends of hydrochar ash (50/50) and bark (45/10/45), the potassium level was slightly lower than the recommendations from the Swedish Forestry Agency. Ash approved as soil amendment has to give >90 kg K/ha. With 8.11 tons of pellets per hectare, only 82 kg/ha are reached, as seen in Table 3 in bold numbers. The other macro-nutrients exceed by far the recommended values. Most heavy metals do not exceed the recommended numbers. However, as Table 3 shows, Vanadium and nickel give slight to high concentrations, >210 g/ha, when 150 kg N/ha is spread. To avoid the problem, fewer pellets can be spread. When 6.5 ton 50/50 pellets are used, 120 kg N/ha and all required concentrations of heavy metals are fulfilled. This is preferred on soils with a higher nutritional status.

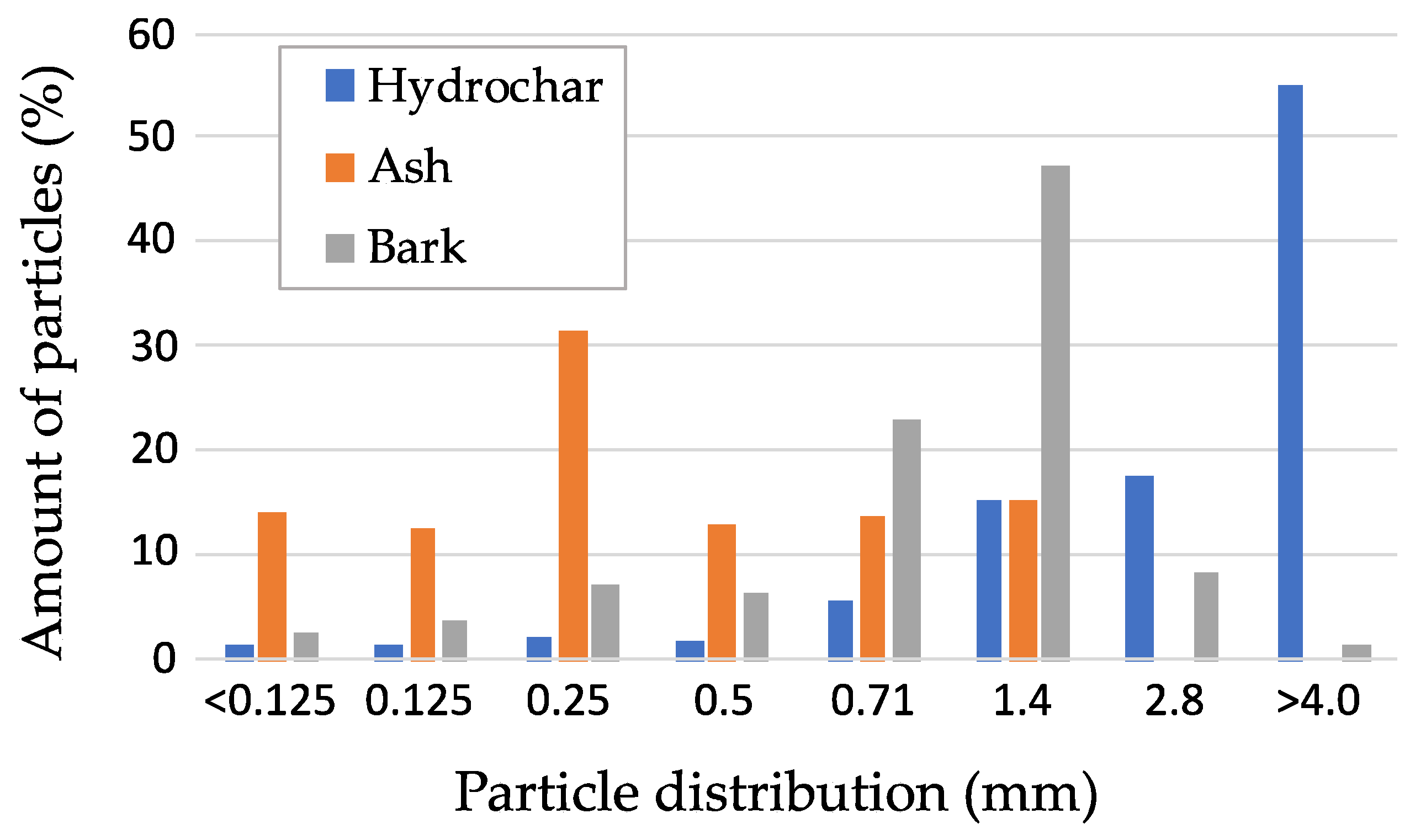

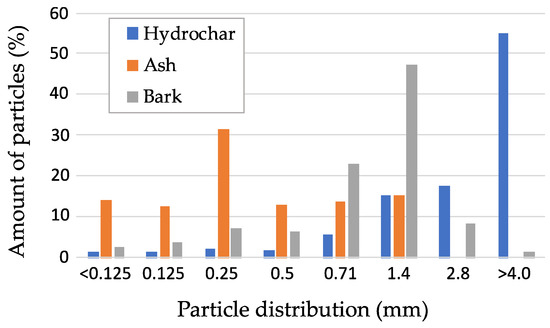

The material was pretreated in different ways. The ash was used as it was delivered with a bulk density and particle distribution, as shown in Table 4 and Figure 3. The bark was ground, and, as shown in Table 4 and Figure 3, the density of the bark is lower than that of the other materials, and the particle distribution is more even for the bark than for the other materials. The material with the highest bulk density was pure hydrochar, including the most significant particle variation. In general, HTC has many small particles clumped together, which is smaller than the data shown in Figure 3. The data presented are hydrochar as it is after drying in a bed dryer. The small particles are clumped together during this drying stage, which we see in Figure 3. However, we have chosen to present the results based on how the particle distribution looked when blended. It must be said that some of the larger lumps were broken in the blending process. In any case, grinding the hydrochar would generate dust, which leads to a work environment problem, and in an industrial application, the authors recommend not grinding the material but instead using it in its existing form.

Table 4.

Bulk density for all included materials as they were used.

Figure 3.

Particle distribution for all materials after being sieved into 8 different sizes.

3.2. Pelletizing and Pellet Properties

Both mixtures of hydrochar pellets went well when pelletized, even if the mixture with bark, 45/10/45, was easier to pelletize (see Figure 4). When the 50/50 mixture was produced, the starting process took longer before the actual production started, and as Table 5 shows, the die temperature was higher for 50/50, indicating a higher friction level. Also, the power was slightly higher even if the variation was low. However, both batches produced fine and hard pellets with high glossiness and a hard surface, indicating that a press ratio of four works when hydrochar is mixed with ash and bark.

Figure 4.

Picture of 50/50 hydrochar/ash pellets and 45/10/45 hydrochar/bark/ash pellets.

Table 5.

Operation data from the pellet press during production.

Initial experiments in a single pellet press indicated that a moisture content of 20% (wb) was appropriate for the material [23]. The pellets for this study were produced in a continuous pellets press at a moisture content of 18% (wb). The results indicated that the moisture content could be decreased further. As shown in Table 6, the raw material loses about 4% (wb) moisture during the densification step just through the die, which is relatively high. In ordinary white pellet production, a drop of around 2% (wb) is more typical for raw material to warm pellets. The pellet press has a power rate of around 1.6 kW, about 50% of the maximum, and low die temperatures. This indicates that the optimal moisture content is probably lower than tested in this study, and more tests have to be performed to evaluate the optimum moisture content for different storage, transportation, and application needs.

Table 6.

Pellet properties after being stored for 1 month and moisture during pelletization.

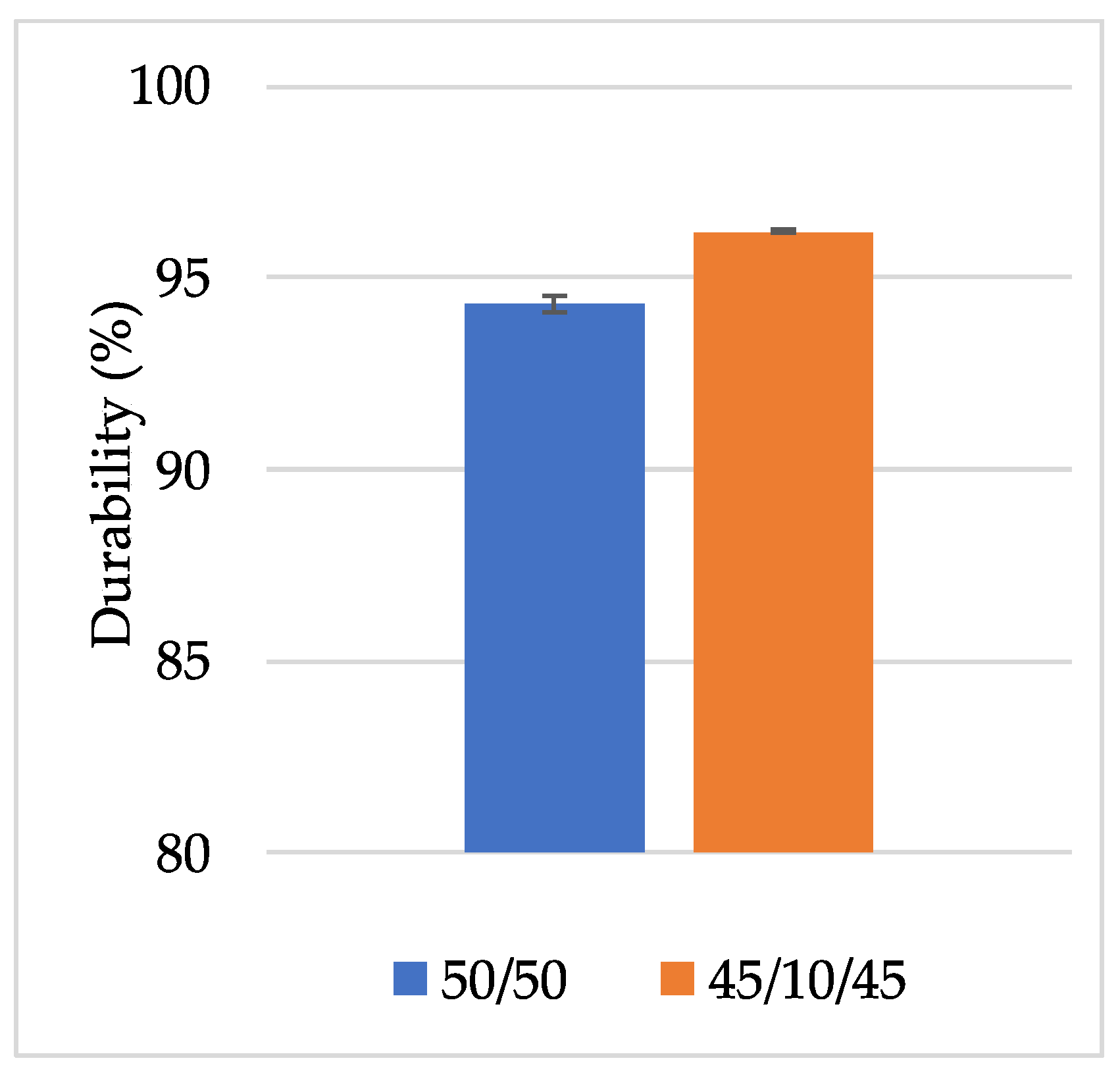

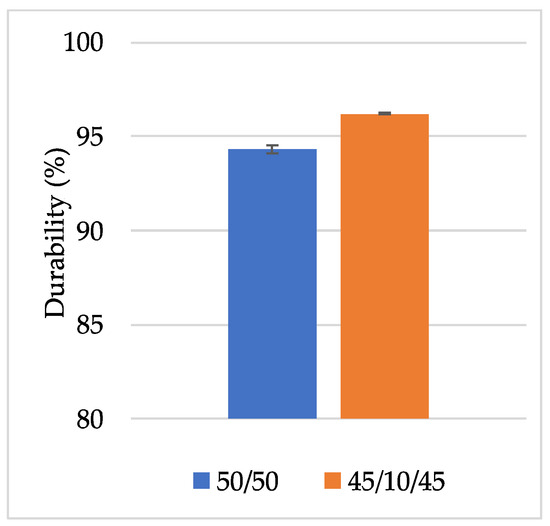

The bulk density for hydrochar pellets is high, as shown in Table 6; for 50/50, the bulk density over 900 kg/m3 is significantly higher than that of ordinary white fuel pellets, which is 600–750 kg/m3. Table 6 shows that the bulk density is higher for pellets not mixed with bark. However, as seen in Table 4, bark’s bulk density is lower than hydrochar and ash. As seen in Table 5, the power need and temperature during pelletization are lower for the mix with bark, meaning that bark is a lubricant in the pelleting process, which is consistent with other studies [33]. So, it is likely that the pellets with bark can increase their bulk density by increasing the presslength slightly. Furthermore, the porosity data (see Table 7) indicated that the pellets made with the bark in the blend had lower values, indicating that the particle packing was better during the pelleting process. Also, the durability data (See Figure 5) indicated that adding bark pellets is better than only ash and hydrochar blend pellets. The durability data show that adding bark improved the durability to >95%. Based on binding phenomena of biomass particles during pelleting, the lignin in the biomass acts as binding agent [13]. However, waxes and hemicelluloses may also create bonds at the temperature in the die [20,21,22]. Further studies are needed related to which bark components play the most significant role. However, we can conclude that the durability for 45/10/45 pellets is 96.2% compared to 94.4% for 50/50 pellets, which shows that bark acts as a good binder to both ash and hydrochar (See Figure 5).

Table 7.

Pellet properties, including solid pellet density and loose and tapped macro-porosity.

Figure 5.

Pellet durability on 50/50 hydrochar/ash, and 45/10/45 hydrochar/bark/ash mixture.

Also, packing the particle in the die due to shorter residence time due to the presence of bark can be the reason for a slight reduction in the bulk density of the bark blend pellets. When it comes to durability, it is clear that adding bark to hydrochar and ash creates a more durable pellet (see 6). Likely, the reason behind an increase in the mechanical quality of the bark-blended pellets can be attributed to lignin; however, these bondings are not tested, and extractives or carbohydrates have been found to generate even better bondings than lignin [33], so further studies are needed. The pellets produced based on this study using the two blends have met the ISO standards regarding moisture and bulk density, and for 45/10/45 also durability (BD800+ (>900 kg/m3), DU95.0− (<90%), and DU95.0 (≥95%) and M08 (moisture ≤ 8%)) (See Figure 5).

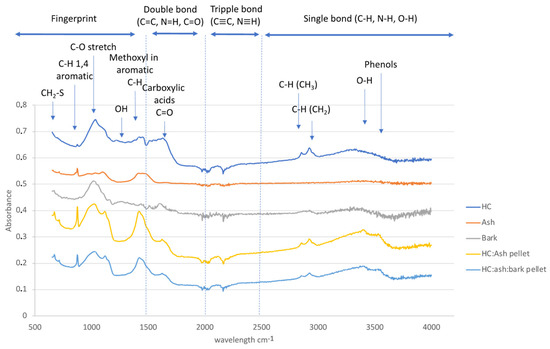

Fourier Transform Infrared Spectroscopic Analysis (FT-IR)

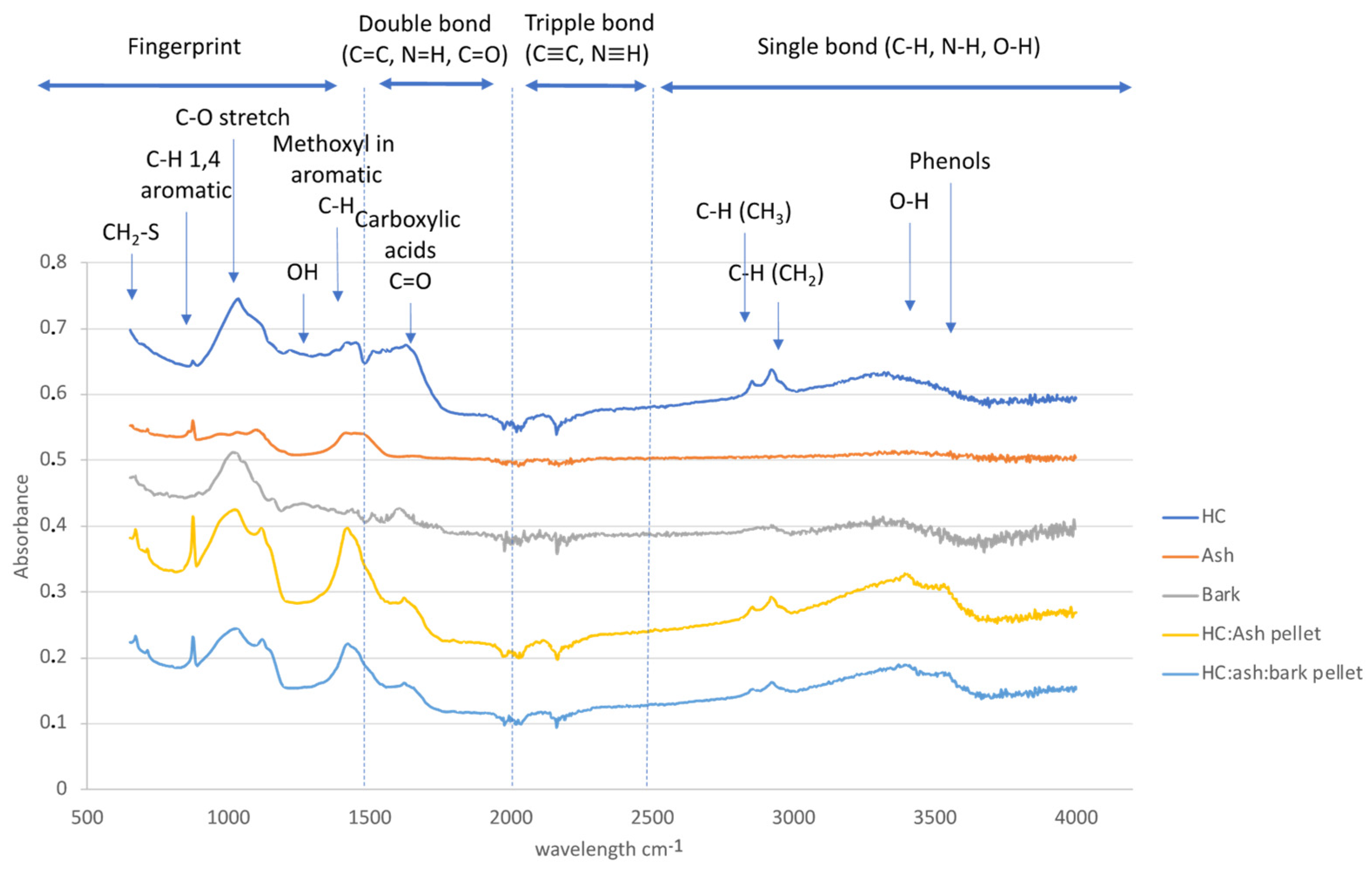

Pellet quality can be measured in several ways, and fuel pellets have quality standards related to pellet durability, bulk density, moisture content, and ash content. Research studies evaluate pellet quality mechanically outside of the standard by testing pellet hardness, springback effect, and moisture uptake. However, when new materials are tested, knowledge and understanding of structural chemistry should be evaluated to comprehend the mechanism of bonding in biomass pellets and how these parameters are affected by the pelletizing properties because polar functional groups play a vital role in enhancing and identifying the type of attraction forces between particles during pelleting [43,45]. One way to evaluate this is through FT-IR spectra, where peak position and intensity determine the functional group type and concentration. Using Fourier transform infrared–Attenuated total reflectance spectroscopy (FTIR–ATR) (Perkin Elmer Spectrum Two spectrometer) in an attenuated total reflectance mode, spectra were scanned in the range of 4000–600 cm−1 at a resolution of 4 cm−1 [46,47].

Figure 6 presents the results from FT-IR spectra from pure hydrochar, pure ash, pure bark, and pellets from a mixture of hydrochar/ash 50/50 and hydrochar/bark/ash 45/10/45. The characteristic peaks for methoxyl groups (2880 and 1940 cm−1) in HC remain after pelletization. Also, the broad band for -OH (3400 cm−1) and C-O stretch (1050 cm−1) in cellulose remains. However, the absorbance connected with the active groups and carboxylic acids C=O (1610 cm−1) and -OH (1655, 1225 cm−1) decreases. Meanwhile, absorbance connected to aromates and phenolic groups in lignin (860 cm−1 guaiacyl groups, 1425 cm−1 methoxyl in lignin, 3555 cm−1 phenolic) increases during pelletization. The results indicate that carboxylic acids react to the high temperature and pressure during pelletization, making the structure of lignin and other aromatic compounds more visible for FT-IR. The glass transition temperature for lignin may be reached, which may move lignin to the pellet’s surface.

Figure 6.

FT-IR spectra over hydrochar powder (HC), ash powder (ash), bark powder (bark), hydrochar and ash 50/50 pellets, and, finally, hydrochar/bark/ash pellet 45/10/45.

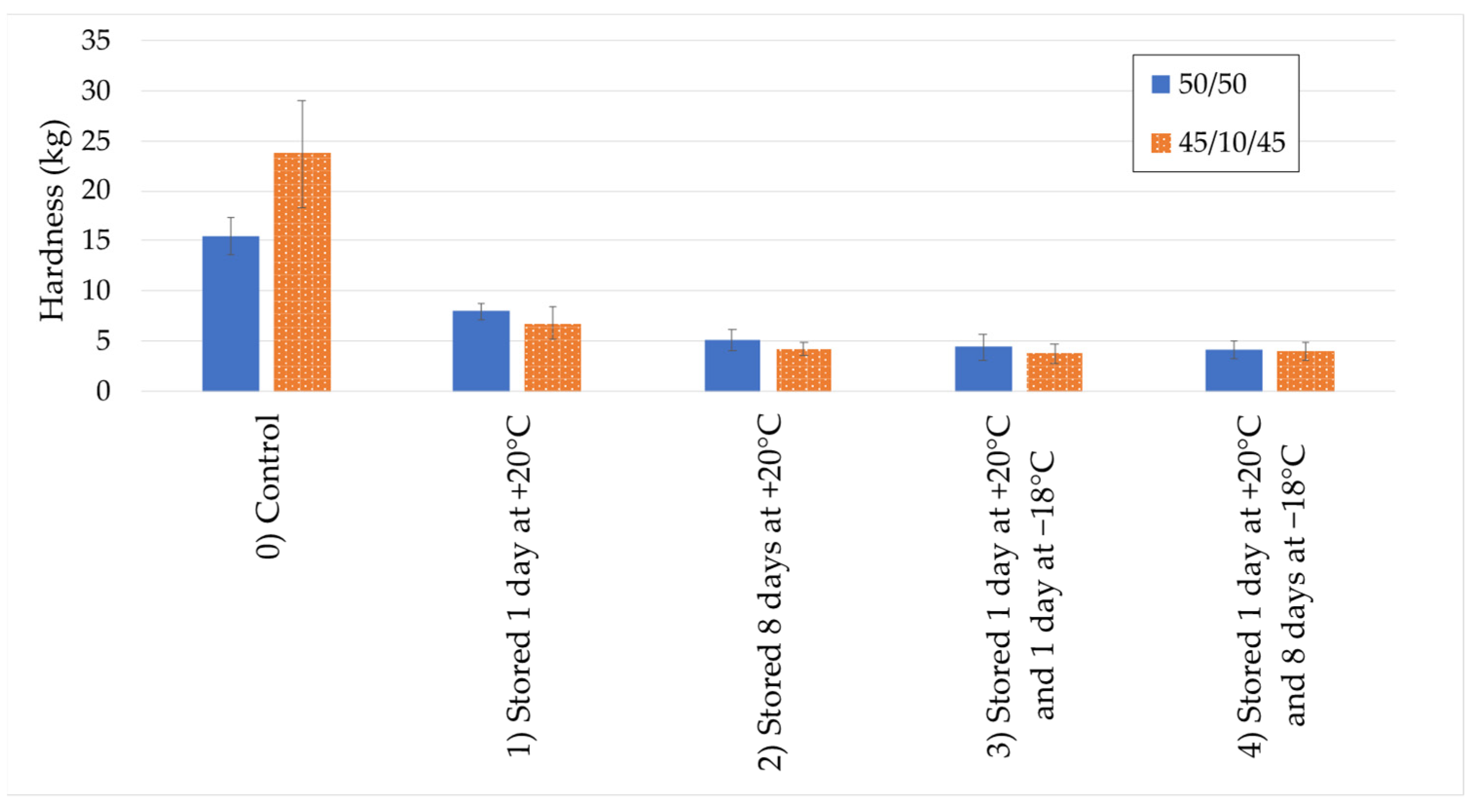

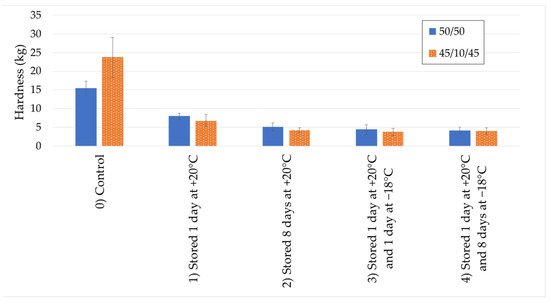

3.3. Pellet Properties in the Forest-like Environment

The pellets must have high hardness and durability to avoid problems during storage and transportation. It is also important that the pellets’ quality is good enough to be spread with mechanical spreaders. However, when the pellets are used as a soil amendment and placed on the ground, it is beneficial if they slowly break down into powder. The results show that the two pellet types are strong enough for transportation and storage. However, as soon as the pellets are exposed to water or frozen, they lose hardness, going from approximately 20 kg to 5 kg (Figure 7).

Figure 7.

KAHL hardness variations from 50/50 and 45/10/45 pellets after being placed in wet peat and stored at room temperature and freezer from 24 h up to 24 h and 1 week.

Adding bark initially gives harder pellets and higher durability (Figure 5 and control Figure 7). When exposed to water, the bark seems to adsorb the water better than the hydrophobic hydrochar. When frozen, the water breaks the pellets efficiently. The hardness decreases after one day in the freezer. Seven extra days in the freezer had only a minor effect on hardness. The results thus indicate that adding bark on purpose to increase durability also positively affects fertilizer pellets, as the pellet will retain its shape better after transport into the forest than without bark.

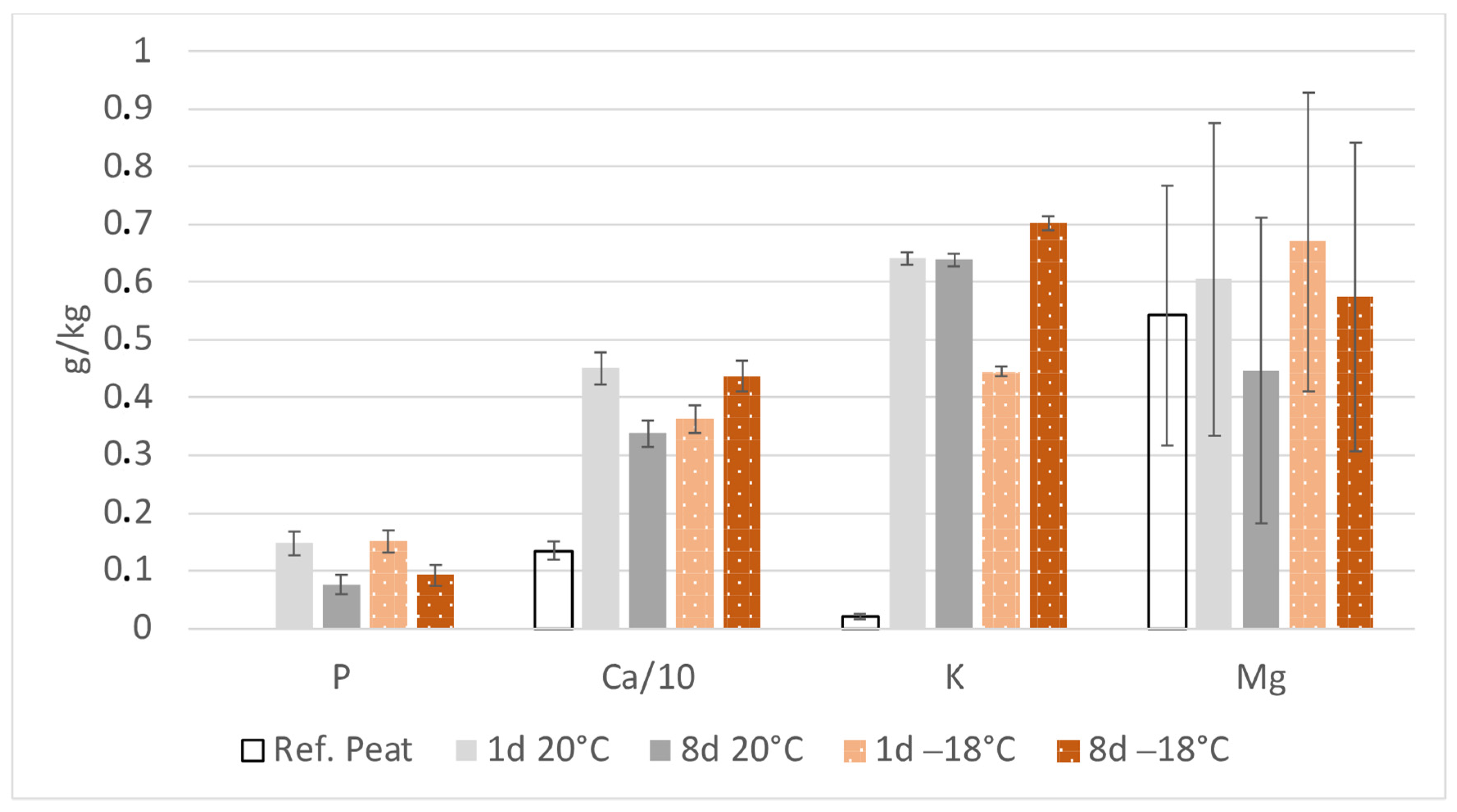

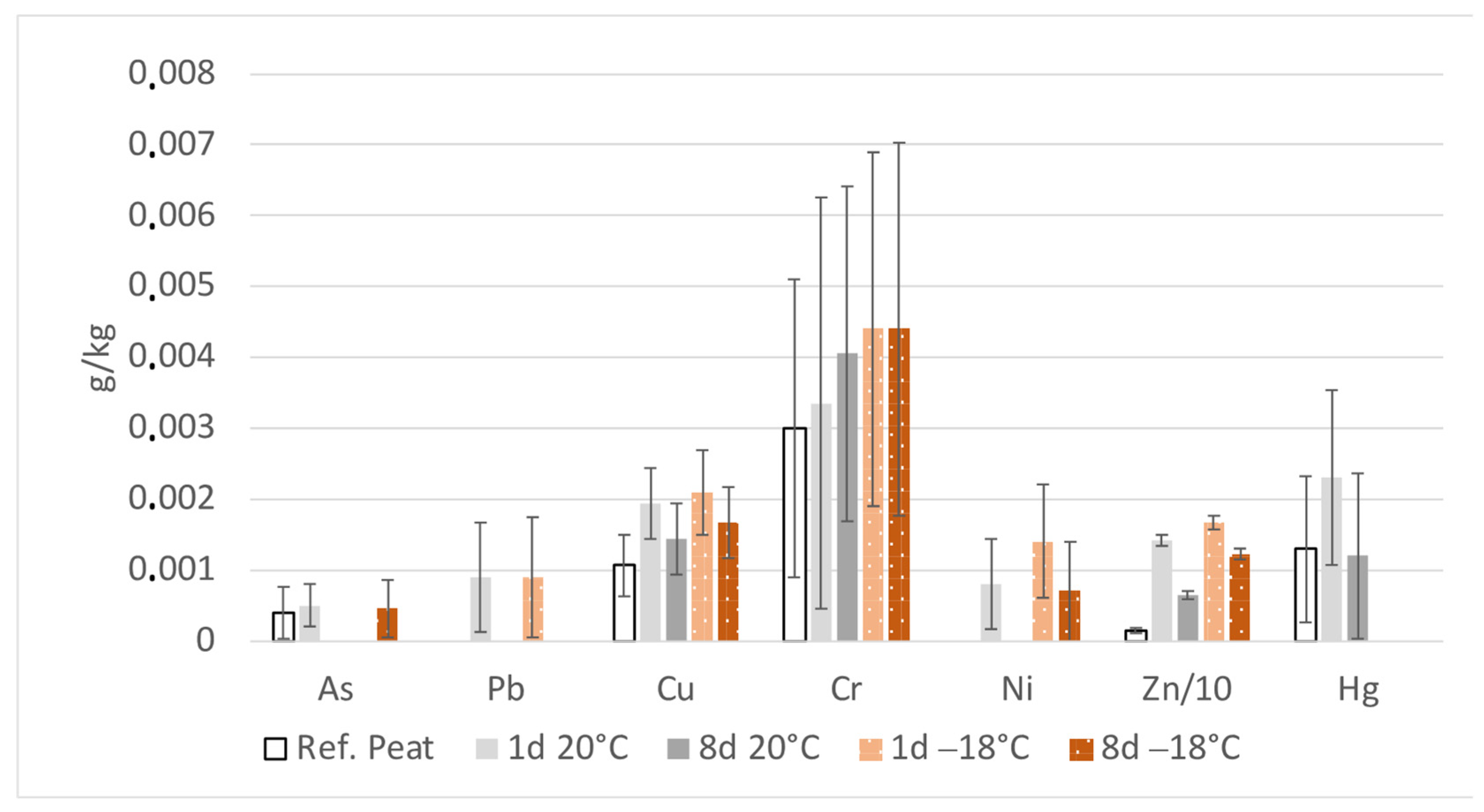

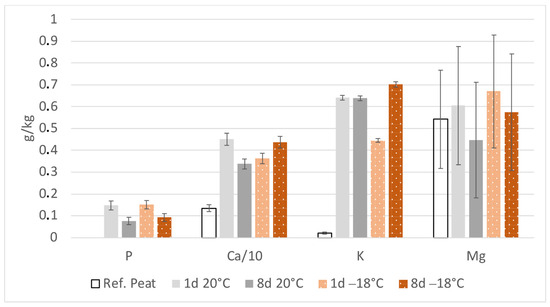

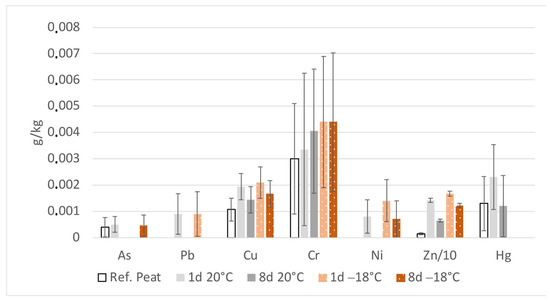

Another critical parameter is the pellet’s ability to leach macro-nutrients and heavy metals to the forest soil. Figure 8 and Figure 9 show the concentration of nutrients, alkali ions, and heavy metals in peat after exposure to hydrochar, ash pellets, water, and freezing temperature. To obtain measurable concentrations of inorganic substances and to compare the effect of different temperatures and winter conditions, 10 g of pellets was mixed with 10 g of peat. This is a much higher concentration of pellets in the peat than if 7–8 tons of pellets was spread per hectare of forest.

Figure 8.

Concentration of macro-nutrients in surrounding peat leached from pellets made of 50:50 hydrochar:ash after exposure to water and winter temperatures (5 g pellets/5 g peat). The concentration of calcium is presented/10 due to its high concentration.

Figure 9.

Concentration of heavy metals in surrounding peat leached from pellets made of 50:50 hydrochar:ash after exposure to water and winter temperatures (5 g pellets/5 g peat). The concentration of zinc is presented /10 due to its high concentration.

The results presented in Figure 8 and Table 8 show that some of the macro-nutrients leach out when exposed to moist peat. Standard deviations for assays performed with the pXRF are displayed as error bars for each macro-nutrient. The pXRF instrument give less certain values for magnesium and chromium compared to the other metals. For the reference test presented in Figure 8, the amount of phosphor was under the limit of detection. In Figure 9, some measurements for arsenic, lead, and nickel were under the detection limit.

Table 8.

The p-value from t-test analysis between reference peat and peat exposed to hydrochar:ash 50:50 pellets 1 day in moist conditions plus 7 days in −18 °C. Also, the amount of macro-nutrients in the pellets leached to the peat.

The difference between 1 day in moist conditions and 7 days in the freezer is small. The results indicate that the initial leaching is due to macro-nutrients on the surface of the hydrochar. Extra days in water or after freezing have little effect on leaching, indicating that the macro-nutrients in the hydrochar and ash are bound to the particles.

According to Figure 9 and Table 8, only a small percentage of the heavy metals in the pellets leach out to the surrounding peat. The leaching does not increase when the pellets are exposed to water or frozen, even if the pellets’ hardness is affected. The results indicate that the heavy metals are bound to the hydrochar particles and will not leach more when the pellets do not disintegrate. In previous studies, hydrochar positively affected pine seedling growth [11,12], indicating that the nutrients are bioavailable even though they are bound to the hydrochar. The results indicate that hydrochar immobilizes the substances and avoids the environmental impact of leaching. The nutrients will not cause eutrophication in water bodies close to the area fertilized with hydrochar. Moreover, heavy metals will not leach and cause a toxic impact on the surrounding environment.

The amount of heavy metals leached from the pellets to the peat was very low (Figure 8). In some cases, the concentration was under the detection limit. T-tests were conducted to further analyze if there is a difference between peat and peat exposed to hydrochar:ash 50:50 pellets 1 day in moist conditions and 8 days frozen at −18°C. In Table 8, the p-value from the t-test shows, with 95% confidence, that there is no difference between the reference peat and peat exposed to hydrochar:ash 50:50 pellets frozen for 7 days for all substances except chromium.

Results from the measurements with the pXRF may be affected by the pretreatment of the samples as they have been ground and mixed with devices containing metal. In the process of making pellets, some pretreatment is required where certain contamination can occur. In the event of a changed process or increased production, this should be investigated and considered. Also, a large amount of organic material and moisture content might, according to the literature [49], affect the accuracy of the results. To avoid this source of error, the samples should be dried before they are measured. In this study, only dry substances were measured.

3.4. Future Possibilities for Sustainable Resource Recovery

The aim of this study was to show an efficient method for returning macro-nutrients to nature by upgrading residual products from the forest industry, which is entirely in line with a sustainable bioeconomy cycle. The promising results indicate that upgrading the least valuable waste found at a pulp and paper mill, sludge and ash, into a promising new type of soil amendment with double purposes as a fertilizer and liming agent is possible. In the long run, this may contribute to restoring nutrient depletion and acidification of forest soils due to heavy forestry. It may also lead to more sustainable waste management at the mills and a smaller carbon footprint compared to using commercial mineral forest fertilizers. The new double-purpose product may increase the willingness of forest owners to use it. Additionally, a small part of the hydrochar can be considered stable and mitigate carbon change.

For future industrial use, it is crucial that the material can be handled, stored, and transported without dusting and material losses. This study shows that the mixed material can be pelletized into resilient, hard pellets. A third waste material, bark, can be added to the new product with benefits. Bark does not contribute nutrients but rather smoothing properties that decrease energy use during pelletization. The pellets’ quality indicates that the pellets will remain resilient during transportation, but they will lose hardness when exposed to water and freezing temperatures as in nature. The pellets will, therefore, not be visible in nature, and the hydrochar and ash materials will be blended with the soil.

This study has also raised several new research avenues. For example, how should these pellets be evaluated related to mechanical properties? Today, we have more or less quality parameters related to pellets for other purposes, such as energy. These fertilizer pellets are intended to be spread in the forest, and nutrient and heavy metal leaching from a hydrochar/ash pellet is a new research field; what should be the recommendations? However, even if more research is needed, the authors have shown that generating a hydrochar/ash pellets loop based on forestry waste is a new way of thinking about recycling and a sustainable bioeconomic system because a large pulp and paper mill can form about 5–10 tons of dry matter biosludge per day; as such, the recycling system presented in this study has great potential.

Today, sludge is burned for destruction. Co-combustion with a fuel of high energy value is needed because sludge has a very high moisture content. The HTC process is exothermic, and little or no additional energy is needed for the process. However, drying the hydrochar before pelletizing requires heat, and the pelletizing process itself requires electrical input. The environmental benefits and drawbacks of the full production process need to be further studied.

With the new product, large amounts of material, 7–8 tons per hectare, have to be spread in the forest to achieve the same effect as today’s use of ash and mineral fertilizer. More transportation will lead to larger CO2 emissions. To determine the total environmental benefits of the new hydrochar:ash product, further LCA studies are planned for ongoing projects.

To make sure this pelletized product is suitable as forest soil amendment, production of pellets, storage, transportation, and spreading have to be tested with industrial-scale machinery.

Because the new product leaches nutrients slowly, the hydrochar:ash pellets may be transported and spread with the harvest to avoid extra transportation of material. However, the time of a tree’s lifespan that is most suitable for fertilizing with this new product needs to be studied further.

In this study, preliminary leaching experiments were performed. The experiments have to be repeated in natural conditions, and more effects than soil chemistry have to be recorded. For example, the hydrochar:ash pellets’ effect on moss grass, berries, and other plants has to be studied. Also, the important ecosystem of fungi has to be studied to make sure the new fertilizer does not disturb the delicate ecosystem of forest soil. These experiments have been initiated, and the results will be evaluated within the next couple of years.

4. Conclusions

This study has indicated that it is possible to use pulp and paper mill waste materials to produce a new pelletized product of hydrochar, spruce bark, and biofuel ash with liming and fertilizing properties on forest soil. These pellets have quality attributes of bulk density and durability suitable for industrial handling and transportation. By mixing hydrochar, spruce bark, and ash in the proportions of 45:10:45, it is possible to produce a product to be spread on forest soil. By spreading 7 tons per hectare of the mixed material, the soil can be enriched with 120 kg N per hectare, and the concentrations of other macro-nutrients, liming agents, and heavy metals are within the regulated concentrations. The current research has indicated that it is possible to press hydrochar and ash into pellets in a continuous process. The addition of spruce bark lowers the energy consumption in the pellet press and increases the durability of the pellet, but the major disadvantage is that 8% more pellets per hectare are required. Pellets exposed to wet and cold conditions mimicking borealis winter conditions lose their hardness. Small amounts of nutrients, alkali ions, and heavy metals leach out from the pellets under all conditions, indicating good properties for forest soil amendment. Further studies are needed to establish the total environmental benefits or drawbacks of the full process of producing, pelletizing, transporting, and using the new type of nutrition pellets. Also, new evaluation methods are needed for both mechanical properties and leaching properties for these types of nutrition pellets.

Author Contributions

Conceptualization, M.S. and S.F.; methodology, M.S. and S.F.; analysis, M.S., S.F., L.B. and J.S.T.; data curation, M.S., S.F., L.B. and J.S.T.; writing—original draft preparation, M.S., S.F., L.B. and J.S.T.; writing—review and editing, M.S., S.F., L.B. and J.S.T.; project administration, M.S.; funding acquisition, M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the NärSkog project, financed by Vinnova Sweden’s innovation agency (2019-04457).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

Thanks to the students in the Master of Science program in Energy and Environmental Engineering, Pål Aasberg and Elise Harryson, who, in their project, contributed to pelletizing and performing parts of the study. Also, thanks to the NärSkog project, financed by Vinnova Sweden’s innovation agency (2019-04457), and C-Green and Stora Enso AB, who produced the materials used in this study.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Skogsindustrierna.se. Om Skogsindustrin/Branschstatistik/Skogsindustrins Virkesforsörjning; Skogsindustrierna: Stockholm, Sweden, 2023. [Google Scholar]

- Drott, A.; Anderson, S.; Eriksson, H. Regler Och Rekommendationer for Skogsbransleuttag Och Kompensationsatgarder. Kunskaplsunderlag; Skogsindustrierna: Stockholm, Sweden, 2019. [Google Scholar]

- Wendołowski, M. Fertilizer Carbon Footprint Calculator. Fertilizer FOCUS. 2019. Available online: https://www.fertilizerseurope.com/wp-content/uploads/2019/11/Fertilizer-Carbon-Footprint-Calculator-Fertilizer-Focus-Magazine.pdf (accessed on 19 March 2024).

- Ding, Y.; Liu, Y.; Liu, S.; Li, Z.; Tan, X.; Huang, X.; Zeng, G.; Zhou, L.; Zheng, B. Biochar to improve soil fertility. A review. Agron. Sustain. Dev. 2016, 36, 36. [Google Scholar] [CrossRef]

- Mohammadi, A.; Sandberg, M.; Venkatesh, G.; Eskandari, S.; Dalgaard, T.; Joseph, S.; Granström, K. Environmental analysis of producing biochar and energy recovery from pulp and paper mill biosludge. J. Ind. Ecol. 2019, 23, 1039–1051. [Google Scholar] [CrossRef]

- Shen, Y. A review on hydrothermal carbonization of biomass and plastic wastes to energy products. Biomass Bioenergy 2020, 134, 105479. [Google Scholar] [CrossRef]

- Gallant, R.; Farooque, A.A.; He, S.; Kang, K.; Hu, Y. A Mini-Review: Biowaste-Derived Fuel Pellet by Hydrothermal Carbonization Followed by Pelletizing. Sustainability 2022, 14, 12530. [Google Scholar] [CrossRef]

- Fernando, F.; Belda, R.M. Biochar versus hydrochar as growth media constituents for ornamental plant cultivation. Sci. Agric. 2018, 75, 304–312. [Google Scholar]

- Fornes, F.; Belda, R.M. Use of raw and acidified biochar as consotituents of growth media for forest seedling production. New Forest 2019, 50, 1063–1086. [Google Scholar] [CrossRef]

- Hao, S.; Zhu, X.; Liu, Y.; Qian, F.; Fang, Z.; Shi, Q.; Zhang, S.; Chen, J.; Ren, Z.J. Production temperature effects on the structure of hydrochar-derived dissolved organic matter and associated toxicity. Environ. Sci. Technol. 2018, 52, 7486–7495. [Google Scholar] [CrossRef] [PubMed]

- Baronti, S.; Alberti, G.; Camin, F.; Criscuoli, I.; Genesio, L.; Mass, R.; Vaccari, F.; Luca, Z.; Franco, M. Hydrochar enhances growth of poplar for bioenergywhile marginally contributing to direct soil carbonsequestration. Bioenergy 2017, 9, 1618–1626. [Google Scholar]

- Eskandari, S.; Mohammadi, A.; Sandberg, M.; Eckstein, R.L.; Hedberg, K.; Granström, K. Hydrochar-amended substrates for production of containerized pine tree seedlings under different fertilization regimes. Agronomy 2019, 9, 350. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefining 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Tumuluru, J.S. Pelleting of pine and switchgrass blends: Effect of process variables and blend ratio on the pellet quality and energy consumption. Energies 2019, 12, 1198. [Google Scholar] [CrossRef]

- Whittaker, C.; Shield, I. Factors affecting wood, energy grass and straw pellet durability—A review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stover and switchgrass. Bioresour. Technol. 2010, 101, 1082–1090. [Google Scholar] [CrossRef]

- Wilson, T.O. Factors Affecting Wood Pellet Durability. Master’s Thesis, The Pennsylvania State University, State College, PA, USA, 2010. [Google Scholar]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. A study of bonding and failure mechanisms in fuel pellets from different biomass resources. Biomass Bioenergy 2011, 35, 910–918. [Google Scholar] [CrossRef]

- Stelte, W.; Clemons, C.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B.; Sanadi, A.R. Fuel Pellets from Wheat Straw: The Effect of Lignin Glass Transition and Surface Waxes on Pelletizing Properties. Bioenergy Res. 2012, 5, 450–458. [Google Scholar] [CrossRef]

- Stelte, W.; Clemons, C.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B.; Sanadi, A.R. Thermal transitions of the amorphous polymers in wheat straw. Ind. Crops Prod. 2011, 34, 1053–1056. [Google Scholar] [CrossRef]

- Frodeson, S.; Henriksson, G.; Berghel, J. Pelletizing Pure Biomass Substances to Investigate the Mechanical Properties and Bonding Mechanisms. BioResources 2018, 21, 1202–1222. [Google Scholar] [CrossRef]

- Frodeson, S.; Lindén, P.; Henriksson, G.; Berghel, J. Compression of Biomass Substances—A Study on Springback Effects and Color Formation in Pellet Manufacture. Appl. Sci. 2019, 9, 4302. [Google Scholar] [CrossRef]

- Mohammadi, A. Overview of the benefits and challenges associated with pelletizing biochar. Processes 2021, 9, 1591. [Google Scholar] [CrossRef]

- Reza, M.T.; Lynam, J.G.; Vasquez, V.R.; Coronella, C.J. Pelletization of biochar from hydrothermally carbonized wood. Environ. Prog. Sustain. Energy 2012, 31, 225–234. [Google Scholar] [CrossRef]

- Fakkaew, K.; Koottatep, T.; Jairuang, S.; Polprasert, C. Hydrochar pellet produced from hydrothermal carbonization of fecal sludge. Biomass Convers. Biorefinery 2021, 13, 5157–5164. [Google Scholar] [CrossRef]

- Mittapalli, S.; Sharma, H.B.; Dubey, B.K. Hydrothermal carbonization of anaerobic granular sludge and co-pelletization of hydrochar with yard waste. Bioresour. Technol. Rep. 2021, 14, 100691. [Google Scholar] [CrossRef]

- Ul Saqib, N.; Sarmah, A.K.; Baroutian, S. Effect of temperature on the fuel properties of food waste and coal blend treated under co-hydrothermal carbonization. Waste Manag. 2019, 89, 236–246. [Google Scholar] [CrossRef] [PubMed]

- Berghel, J.; Ståhl, M.; Frodeson, S.; Pichler, W.; Weigl-Kuska, M. A comparison of relevant data and results from single pellet press research is Mission Impossible: A review. Bioresour. Technol. Rep. 2022, 18, 101054. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Fillerup, E. Briquetting characteristics of woody and herbaceous biomass blends: Impact on physical properties, chemical composition, and calorific value. Biofuels Bioprod. Biorefining 2020, 14, 1105–1124. [Google Scholar] [CrossRef]

- Tumuluru, J.S. Explore the Potential to Formulate Feedstock Blends from Diverse Biomass inputs for Improved Processing Performance at Lower Costs; Idaho National Lab. (INL): Idaho Falls, ID, USA, 2021. [Google Scholar]

- Krogell, J.; Holmbom, B.; Pranovich, A.; Hemming, J.; Willför, S. Extraction and chemical characterization of Norway spruce inner and outer bark. Nord. Pulp Pap. Res. J. 2012, 27, 6–17. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. The Pellet Handbook; Earthscan Ltd.: Calgary, AB, Canada, 2010. [Google Scholar]

- Frodeson, S.; Anukam, A.I.; Berghel, J.; Ståhl, M.; Lasanthi Kudahettige Nilsson, R.; Henriksson, G.; Bosede Aladejana, E. Densification of Wood—Influence on Mechanical and Chemical Properties when 11 Naturally Occurring Substances in Wood Are Mixed with Beech and Pine. Energies 2021, 14, 5895. [Google Scholar] [CrossRef]

- Xia, X.; Xiao, H.; Yang, Z.; Xie, X.; Bhimani, J. Pelletization characteristics of the hydrothermal pretreated rice straw with added binders. Arab. J. Sci. Eng. 2018, 43, 4811–4820. [Google Scholar] [CrossRef]

- BS-EN 16174; Sludge, treated biowaste and soil. Digestion of aqua regia soluble fractions of elements. British-Adopted European Standard: Northampton, UK, 2012.

- SS-EN 16171; Sludge, Treated Biowaste And Soil—Determination Of Elements Using Inductively Coupled Plasma Mass Spectrometry (ICP-MS). Swedish Standards Institute: Stockholm, Sweden, 2016.

- ISO 11885:2007; Water Quality—Determination of Selected Elements by Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES). ISO: Geneva, Switzerland, 2007.

- Hellsten, S.; Helmisaari, H.-S.; Melin, Y.; Skovsgaard, J.P.; Wängberg, I.; Kaakinen, S.; Kukkola, M.; Saarsalmi, A.; Petersson, H.; Akselsson, C. Halter av Baskatjoner, Fosfor Och Kväve i Stubbar i Sverige, Finland och Danmark; IVL Svenska Miljöinstitutet: Stockholm, Sweden, 2009. [Google Scholar]

- ISO 17828; Solid Biofuels—Determination of Bulk Density. ISO: Geneva, Switzerland, 2015.

- Igathinathane, C.; Tumuluru, J.S.; Sokhansanj, S.; Bi, X.; Lim, C.J.; Melin, S.; Mohammad, E. Simple and inexpensive method of wood pellets macro-porosity measurement. Bioresour. Technol. 2010, 101, 6528–6537. [Google Scholar] [CrossRef]

- ISO 17831-1; Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes. ISO: Geneva, Switzerland, 2015.

- SS EN 14774-1; Solid Biofuels—Determination of Moisture Content-Oven Dry Method-Part 1: Total moisture—Reference method. Swedish Standards Institute: Stockholm, Sweden, 2009.

- Mohammadi, A.; Anukam, A.I.; Granström, K.; Eskandari, S.; Zywalewska, M.; Sandberg, M.; Aladejana, E.B. Effects of wood ash on physicochemical and morphological characteristics of sludge-derived hydrochar pellets relevant to soil and energy applications. Biomass Bioenergy 2022, 163, 106531. [Google Scholar] [CrossRef]

- Anukam, A.I.; Berghel, J.; Frodeson, S.; Famewo, E.B.; Nyamukamba, P. Characterization of pure and blended pellets made from Norway spruce and Pea starch: A comparative study of bonding mechanism relevant to quality. Energies 2019, 12, 4415. [Google Scholar] [CrossRef]

- Anukam, A.; Berghel, J.; Henrikson, G.; Frodeson, S.; Ståhl, M. A review of the mechanism of bonding in densified biomass pellets. Renew. Sustain. Energy Rev. 2021, 148, 111249. [Google Scholar] [CrossRef]

- Anukam, A.I.; Berghel, J.; Famewo, E.B.; Frodeson, S. Improving the Understanding of the Bonding Mechanism of Primary Components of Biomass Pellets through the Use of Advanced Analytical Instruments. J. Wood Chem. Technol. 2020, 40, 15–32. [Google Scholar] [CrossRef]

- Toscano, G.; Maceratesi, V.; Leoni, E.; Stipa, P.; Laudadio, E.; Sabbatini, S. FTIR spectroscopy for determination of the raw materials used in wood pellet production. Fuel 2022, 313, 123017. [Google Scholar] [CrossRef]

- Weindorf, D.C.; Zhu, Y.; Haggard, B.; Lofton, J.; Chakraborty, S.; Bakr, N.; Zhang, W.; Weindorf, W.C.; Legoria, M. Enhanced pedon horizonation using portable X-ray fluorescence spectrometry. Soil Sci. Soc. Am. J. 2012, 76, 522–531. [Google Scholar] [CrossRef]

- López-Núñez, R. Portable X-ray Fluorescence Analysis of Organic Amendments: A Review. Appl. Sci. 2022, 12, 6944. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).