Does the Rubber Meet the Road? Assessing the Potential of Devulcanization Technologies for the Innovation of Tire Rubber Recycling

Abstract

:1. Introduction

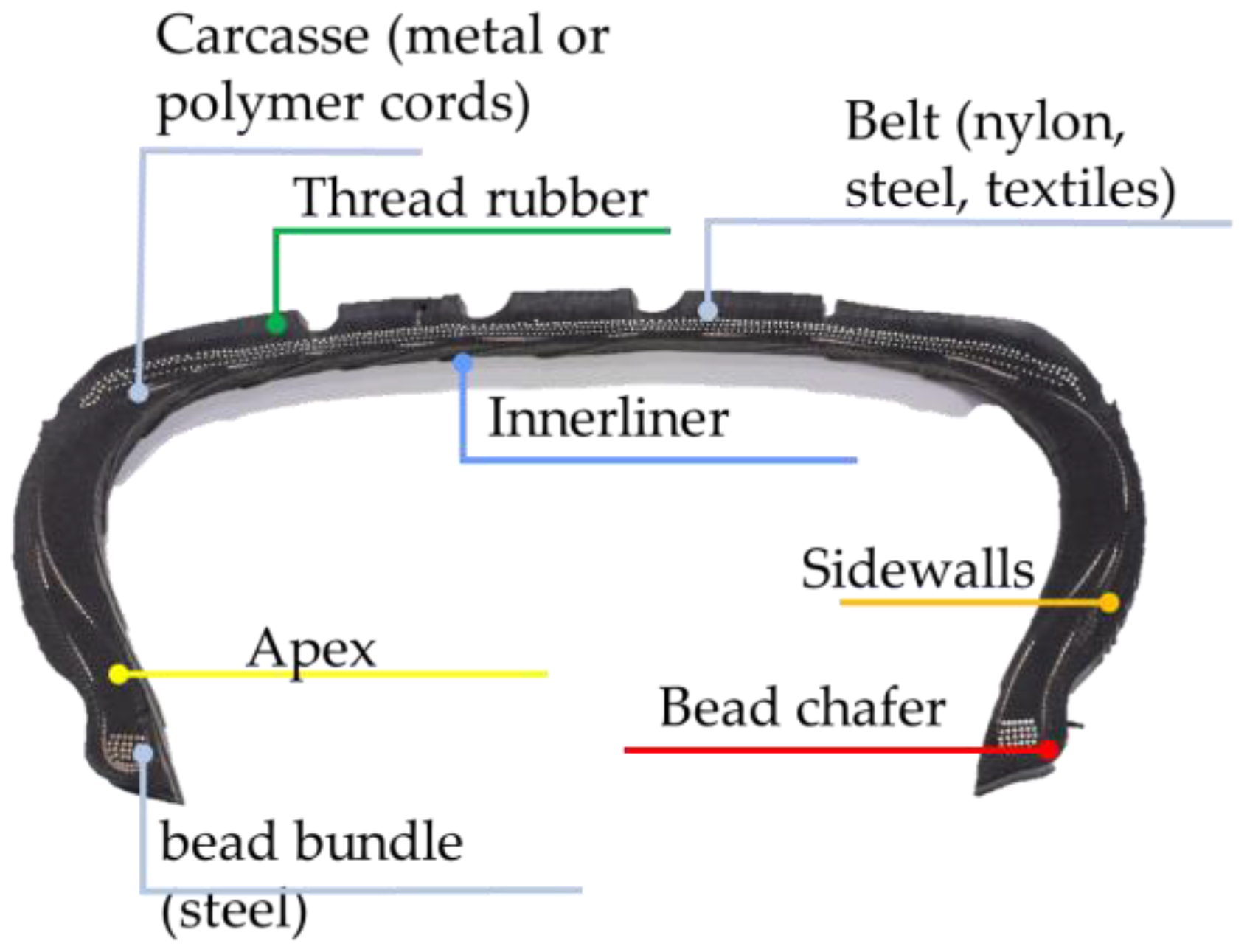

2. Background

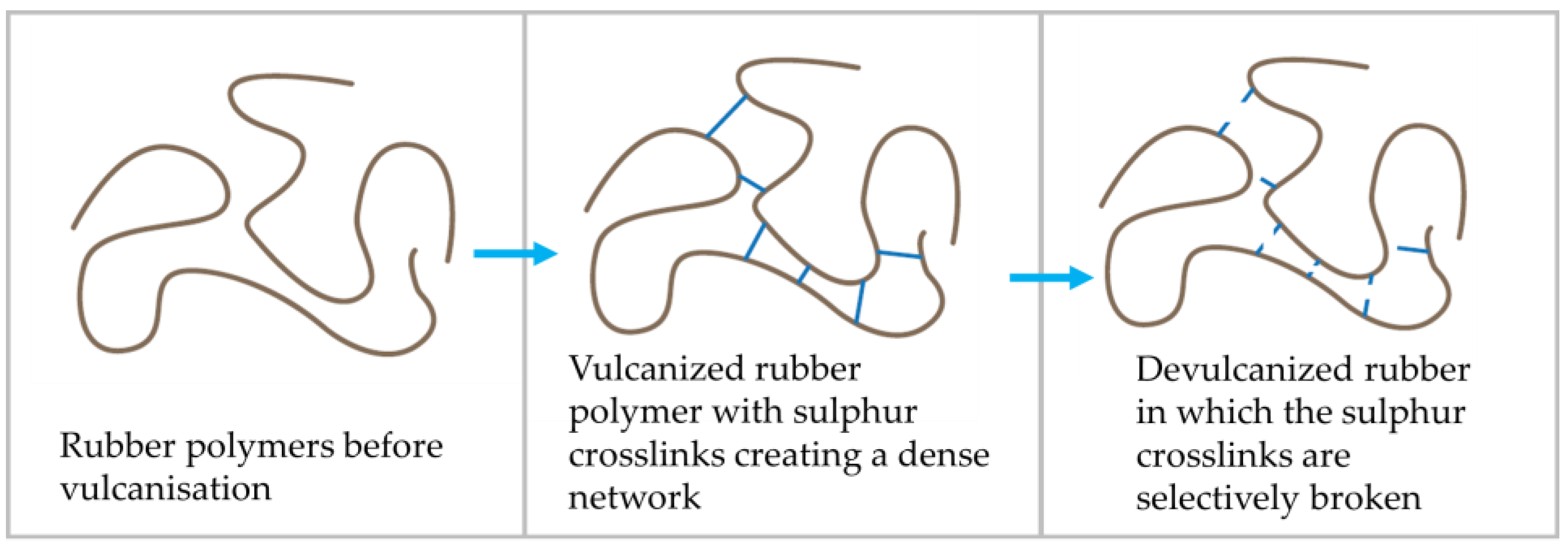

2.1. Devulcanization

2.2. Technological Innovation Systems

3. Methods

3.1. Participant Selection

3.2. Semi-Structured Interviews

3.3. Interview Analysis

4. Results

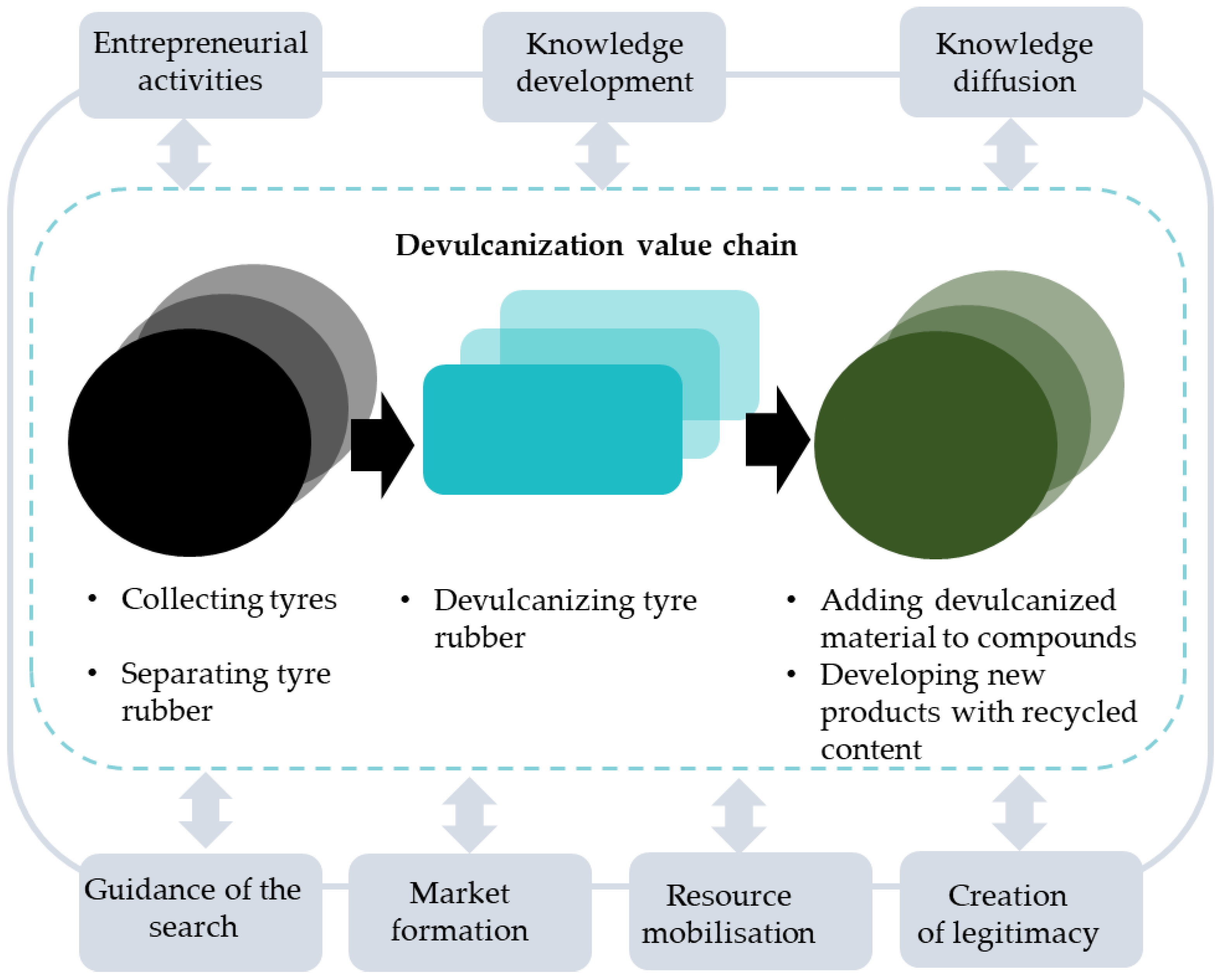

4.1. Key Industrial Activities in the Value Chain

- Using devulcanized rubber as a material for certain components of tires: Two respondents suggested that devulcanized material could be blended into rubber compounds for the less safety-critical parts of new tires.

- Using devulcanized rubber as a material for ‘general rubber goods’: This term refers to a wide range of markets and product demands, including conveyor belts and molded products for automotive parts.

- Using devulcanized rubber as a modifier in asphalt: Two respondents developed devulcanized material as a replacement or addition to SBS (styrene–butadiene–styrene), which is used as a modifier in asphalt to enhance abrasion resistance as well as resistance to high temperatures. Devulcanized rubber exhibited better results in asphalt than granulated rubber alone.

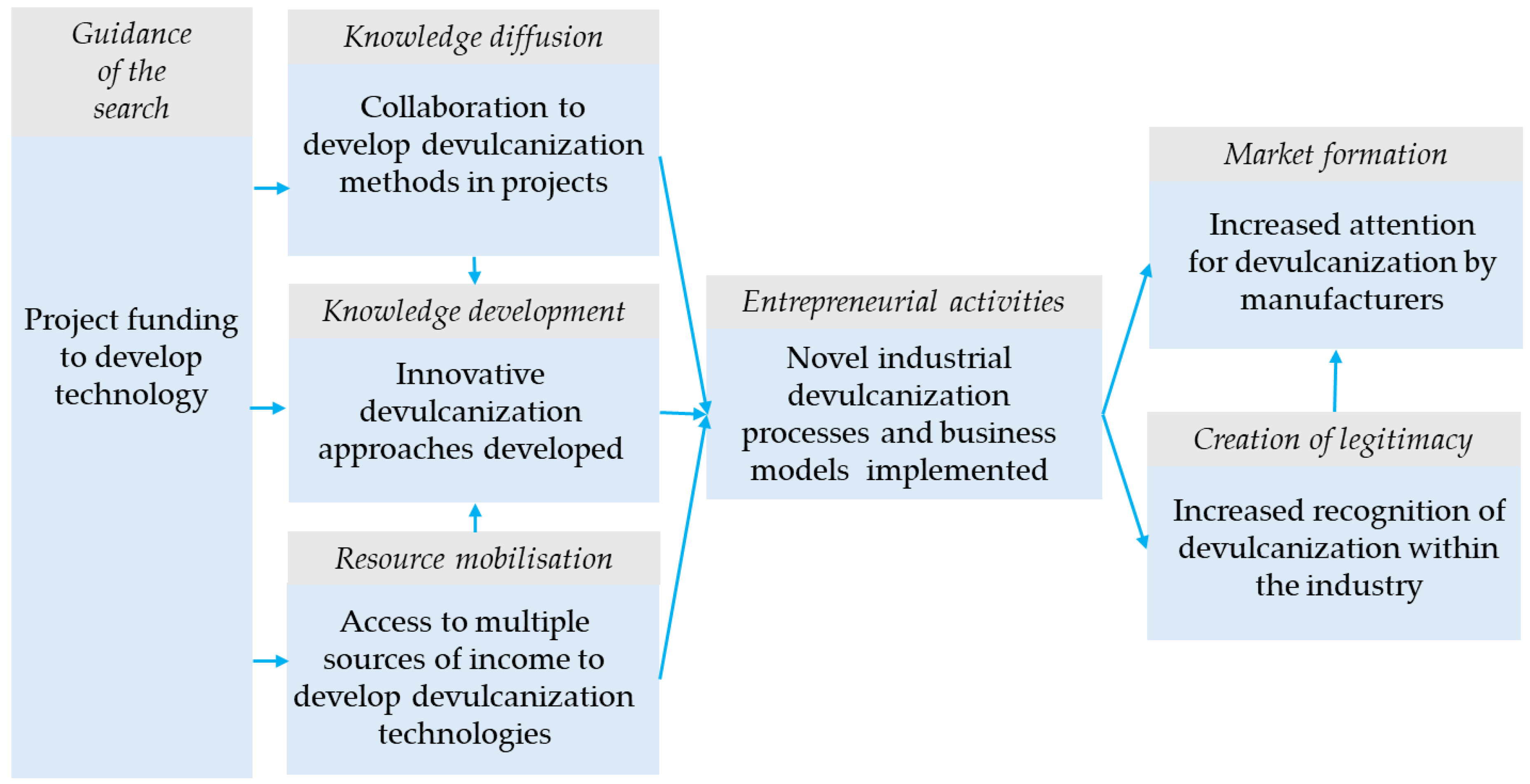

4.2. Technological Innovation System Functions

- Developers of the chemical process of devulcanization, primarily knowledge institutions, including universities and commercial knowledge institutes and, occasionally, suppliers of chemical devulcanization aids.

- Developers of machinery and other equipment who developed an industrial devulcanization process that allowed devulcanization to be scaled up to an industrial level.

- Tire and rubber goods manufacturers who led investigations into the extent to which devulcanized rubber compounds could replace virgin rubber and additives in new compounds for their applications.

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

- Opening statement for the interviews

Appendix B. Interview Topics

- General

- What is your position in the company?

- For how many years are you employed by/managing your company?

- How have you been involved with devulcanization in your company?

- Since when have you personally been working with devulcanization?

- Company

- What is the mission and vision of your company?

- Is your company part of a holding company and/or part of an international cooperation?

- (How) does your company aims to contribute to the circular economy?

- Tyre sorting

- What type of tyre rubber do devulcanize? What is the main source of the rubber (e.g., passenger car, truck, OTR)?

- Do you also devulcanize other sources of rubber than tyres?

- How it the tyre rubber supplied? Do you receive rubber from all brands and types of tyres or or do you choose for specific brands and types of tyres?

- If specific types of tyres are (or should be) used, how is information stored about the tyres?

- Up to what extend should tyres be sorted differently for you to make a transition to the circular economy?

- Material handling

- How do you receive the rubber from your suppler (e.g., cut, shredded, granulated?)

- How do you store the rubber before it is devulcanised?

- How do you take action to avoid the rubber to be contaminated or become humid during storage?

- Does the supplied rubber need to be dried?

- Up to what degree does the supplied rubber need extra cleaning or sieving before devulcanization?

- Up to what extent does rubber have to be handled differently if a leap is made to the circular economy?

- Characterize rubber and identify unwanted substances

- How do you characterize (measure) the quality of your supply?

- Up to what extend is your supply of tyre rubber of a consistent quality?

- How do you identify unwanted substances in tyre rubber?

- If there are any unwanted substances, what actions do you take?

- Separating components of tyres

- Are the specific types of rubber from tyres separated for devulcanization? If so, what equipment is used to separate the tyre rubber?

- Do you, or your suppler, set age limits on tyre rubber for devulcanization? If not, do you believe this will be needed?

- How is (or should) information be provided about the incoming tyres?

- Up to what extend should tyres be separated differently for you to make a transition to the circular economy?

- Devulcanization

- What is your definition of devulcanization/vision on devulcanization?

- What type of (devulcanization) technology do you use to devulcanize tyres?

- What types of rubber can be devulcanised with this type of technology? For what purposes is this rubber used?

- For how many years or months have you devulcanised tyre rubber?

- What capacity do you have to devulcanize tyres?

- How many tons of rubber have you processed in the previous year?

- How do you think that devulcanization needs to be further developed to meet the requirement of the circular economy?

- How do you contain the use of energy by devulcanization?

- Waste and emissions

- Do you have rubber waste from the recycling process? If so, how could you minimize this waste?

- What actions do you take to avoid any emmission from the devulcanization process?

- Allocating devulcanised rubber

- Is the devulcanised rubber blended into a new compoud or is it re-vulcanized without additional rubber or additives? If so, what type of rubber or compounds is added to the mix?

- For what types of products is the devulcanised rubber used? If it is used for tyres, what types of tyres? Agricultural, mining, truck, passenger car?

- What additional requirements from customers do you have to meet because you have included recycled material?

- What would increase the uptake of devulcanised rubber by customers?

- Up to what extent do market demands have to change to shift to the circular economy?

- General closing questions

- What are most important oppertunities for sorting and recycling tyre rubber by devulcanization?

- What are the most important barriers for sorting and recycling tyre rubber by devulcanization?

- Is there any information that you would like to add to this interview?

Appendix C. Code Groups

| Code Groups | Codes Applied |

| Supply of end-of-life tyre rubber | Collection of tyres |

| Humidity and contaminations in tyre rubber | |

| Pre-sorting types of tyres (passenger, truck, etc.) | |

| Selection of specific tyres for devulcanization | |

| Separate rubber components in tyres | |

| Supply of rubber (shredded, granulated; age) | |

| Devulcanization process | Definition of devulcanization and standards |

| Devulcanization process in use (time) | |

| Emissions from devulcanization | |

| Method or technology for devulcanization | |

| Scale of devulcanization line | |

| Allocating devulcanised rubber | Compounds made with devulcanised rubbers |

| Measure quality of re-vulcanized rubber | |

| Entrepreneurial activities | Business model and organisational structure |

| Position of respondent in organisation | |

| Acceptance and creation of legitimacy | Requirements set by customers for dev. rubber |

| Uptake of recycled material (in general) | |

| Knowledge development | IP devulcanization process |

| Research and development | |

| Knowledge diffusion | Business model and organisational agreements |

| Participation of org. in devulcanization projects | |

| Guidance of the search | Perceived barriers for the circular economy |

| Perceived opportunities for the circular economy | |

| Market formation | Types of products and markets for devulcanised rubber |

| Uptake of devulcanised rubber by customers | |

| Resource mobilisation | Business model and organisational structure |

| Creation of legitimacy | Requirements set by customers for dev. rubber |

| Uptake of recycled material (in general) |

References

- European Commission. Annex I of the plastics strategy. In List of Future EU Measures to Implement the Strategy; C.c. Energy, Environment: Brussels, Belgium, 2018. [Google Scholar]

- van Langen, S.K.; Vassillo, C.; Ghisellini, P.; Restaino, D.; Passaro, R.; Ulgiati, S. Promoting circular economy transition: A study about perceptions and awareness by different stakeholders groups. J. Clean. Prod. 2021, 316, 128166. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy–A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Bockstal, L.; Berchem, T.; Schmetz, Q.; Richel, A. Devulcanization and reclaiming of tires and rubber by physical and chemical processes: A review. J. Clean. Prod. 2019, 236, 117574. [Google Scholar] [CrossRef]

- ETRMA. European Tyre & Rubber Industry Statistics Report; ETRMA: Brussels, Belgium, 2011. [Google Scholar]

- ETRMA. In Europe 95% of All End of Life Tyres Were Collected and Treated in 2019; ETRMA: Brussels, Belgium, 2021. [Google Scholar]

- Valentini, F.; Pegoretti, A. End-of-life options of tyres. A review. Adv. Ind. Eng. Polym. Res. 2022, 5, 203–213. [Google Scholar] [CrossRef]

- Xiao, Z.; Pramanik, A.; Basak, A.K.; Prakash, C.; Shankar, S. Material recovery and recycling of waste tyres—A review. Clean. Mater. 2022, 5, 100115. [Google Scholar] [CrossRef]

- Noordermeer, J.W.; Dierkes, W.; Blume, A.; van Hoek, H.; Reuvekamp, L.; Dijkhuis, K.; Saiwari, S. Cradle-to-cradle devulcanization options for various elastomer types. Rubber World 2020, 262, 20–28. [Google Scholar]

- Ghosh, R.; Mani, C.; Krafczyk, R.; Schnell, R.; Paasche, A.; Talma, A.; Blume, A.; Dierkes, W.K. New route of tire rubber devulcanization using silanes. Polymers 2023, 15, 2848. [Google Scholar] [CrossRef]

- Saiwari, S.; Dierkes, W. 7-Regeneration and devulcanization. In Tire Waste and Recycling; Letcher, T.M., Shulman, V.L., Amirkhanian, S., Eds.; Academic Press: Cambridge, MA, USA, 2021; pp. 97–129. ISBN 978-0-12-820685-0. [Google Scholar]

- Tzoganakis, C. Understanding devulcanization, the path to a circular economy and potential market impact. Rubber World 2019, 5, 18–22. [Google Scholar]

- Markl, E.; Lackner, M. Devulcanization technologies for recycling of tire-derived rubber: A review. Materials 2020, 13, 1246. [Google Scholar] [CrossRef]

- CalRecovery. Evaluation of Waste Tyre Devulcanization Technologies. Contractor’s Report to the Board; Integrated Waste Management Board, Public Affairs Office: Sacramento, CA, USA, 2004. [Google Scholar]

- Wiśniewska, P.; Wang, S.; Formela, K. Waste tire rubber devulcanization technologies: State-of-the-art, limitations and future perspectives. Waste Manag. 2022, 150, 174–184. [Google Scholar] [CrossRef] [PubMed]

- De Jesus, A.; Antunes, P.; Santos, R.; Mendonça, S. Eco-innovation pathways to a circular economy: Envisioning priorities through a Delphi approach. J. Clean. Prod. 2019, 228, 1494–1513. [Google Scholar] [CrossRef]

- Saputra, R.; Walvekar, R.; Khalid, M.; Mubarak, N.M.; Sillanpää, M. Current progress in waste tire rubber devulcanization. Chemosphere 2021, 265, 129033. [Google Scholar] [CrossRef] [PubMed]

- Lacroix, F.; Seghar, S. In-Product-Sorting End-of-Life Tires for Effective Recycling by Devulcanization. In Tire Waste and Recycling; Letcher, T.M., Shulman, V.L., Amirkhanian, S., Eds.; Academic Press: Cambridge, MA, USA, 2021; pp. 130–144. ISBN 978-0-12-820685-0. [Google Scholar]

- Lee, H.L.; Schmidt, G. Using value chains to enhance innovation. Prod. Oper. Manag. 2017, 26, 617–632. [Google Scholar] [CrossRef]

- Johansen, M.R.; Christensen, T.B.; Ramos, T.M.; Syberg, K. A review of the plastic value chain from a circular economy perspective. J. Environ. Manag. 2022, 302, 113975. [Google Scholar] [CrossRef] [PubMed]

- Kersker, T.; Kovac, F.; Dague, M. The tire composite. Fibre Sci. Technol. 1969, 2, 41–57. [Google Scholar] [CrossRef]

- Asaro, L.; Gratton, M.; Seghar, S.; Aït Hocine, N. Recycling of rubber wastes by devulcanization. Resour. Conserv. Recycl. 2018, 133, 250–262. [Google Scholar] [CrossRef]

- Winkelman, H.A.; Busenburg, E.B. Effect of Stearic Acid on Reclaimed Rubber. Ind. Eng. Chem. 1929, 21, 730–732. [Google Scholar] [CrossRef]

- Dorigato, A.; Rigotti, D.; Fredi, G. Recent advances in the devulcanization technologies of industrially relevant sulfur-vulcanized elastomers. Adv. Ind. Eng. Polym. Res. 2023, 6, 288–309. [Google Scholar] [CrossRef]

- Van Hoek, J.W.; Heideman, G.; Noordermeer, J.W.; Dierkes, W.K.; Blume, A. Implications of the use of silica as active filler in passenger car tire compounds on their recycling options. Materials 2019, 12, 725. [Google Scholar] [CrossRef]

- Abbas-Abadi, M.S.; Kusenberg, M.; Shirazi, H.M.; Goshayeshi, B.; Van Geem, K.M. Towards full recyclability of end-of-life tires: Challenges and opportunities. J. Clean. Prod. 2022, 374, 134036. [Google Scholar] [CrossRef]

- Lapkovskis, V.; Mironovs, V.; Goljandin, D. Suitability of devulcanized crumb rubber for oil spills remediation. Energy Procedia 2018, 147, 351–357. [Google Scholar] [CrossRef]

- Simon, D.Á.; Bárány, T. Effective thermomechanical devulcanization of ground tire rubber with a co-rotating twin-screw extruder. Polym. Degrad. Stab. 2021, 190, 109626. [Google Scholar] [CrossRef]

- Mangili, I.; Lasagni, M.; Anzano, M.; Collina, E.; Tatangelo, V.; Franzetti, A.; Caracino, P.; Isayev, A.I. Mechanical and rheological properties of natural rubber compounds containing devulcanized ground tire rubber from several methods. Polym. Degrad. Stab. 2015, 121, 369–377. [Google Scholar] [CrossRef]

- de Sousa, F.D.B.; Ornaghi Júnior, H.L. From Devulcanization of Ground Tire Rubber by Microwaves to Revulcanization: A Revulcanization Kinetic Approach Using a Simple Prediction Model. ACS Sustain. Chem. Eng. 2020, 8, 16304–16319. [Google Scholar] [CrossRef]

- Formela, K.; Wąsowicz, D.; Formela, M.; Hejna, A.; Haponiuk, J. Curing characteristics, mechanical and thermal properties of reclaimed ground tire rubber cured with various vulcanizing systems. Iran. Polym. J. 2015, 24, 289–297. [Google Scholar] [CrossRef]

- Chaudhuri, A.; Subramanian, N.; Dora, M. Circular economy and digital capabilities of SMEs for providing value to customers: Combined resource-based view and ambidexterity perspective. J. Bus. Res. 2022, 142, 32–44. [Google Scholar] [CrossRef]

- Petersen, K.J.; Handfield, R.B.; Ragatz, G.L. Supplier integration into new product development: Coordinating product, process and supply chain design. J. Oper. Manag. 2005, 23, 371–388. [Google Scholar] [CrossRef]

- Markard, J.; Hekkert, M.; Jacobsson, S. The technological innovation systems framework: Response to six criticisms. Environ. Innov. Soc. Transit. 2015, 16, 76–86. [Google Scholar] [CrossRef]

- Hekkert, M.P.; Negro, S.O. Functions of innovation systems as a framework to understand sustainable technological change: Empirical evidence for earlier claims. Technol. Forecast. Soc. Chang. 2009, 76, 584–594. [Google Scholar] [CrossRef]

- Bergek, A.; Jacobsson, S.; Carlsson, B.; Lindmark, S.; Rickne, A. Analyzing the functional dynamics of technological innovation systems: A scheme of analysis. Res. Policy 2008, 37, 407–429. [Google Scholar] [CrossRef]

- Musiolik, J.; Markard, J.; Hekkert, M. Networks and network resources in technological innovation systems: Towards a conceptual framework for system building. Technol. Forecast. Soc. Chang. 2012, 79, 1032–1048. [Google Scholar] [CrossRef]

- Markard, J.; Truffer, B. Actor-oriented analysis of innovation systems: Exploring micro–meso level linkages in the case of stationary fuel cells. Technol. Anal. Strateg. Manag. 2008, 20, 443–464. [Google Scholar] [CrossRef]

- Jansma, S.R.; Gosselt, J.F.; de Jong, M.D. Technological start-ups in the innovation system: An actor-oriented perspective. Technol. Anal. Strateg. Manag. 2018, 30, 282–294. [Google Scholar] [CrossRef]

- Planko, J.; Cramer, J.; Hekkert, M.P.; Chappin, M.M.H. Combining the technological innovation systems framework with the entrepreneurs’ perspective on innovation. Technol. Anal. Strateg. Manag. 2017, 29, 614–625. [Google Scholar] [CrossRef]

- Chaminade, C.; Edquist, C. From theory to practice: The use of the systems of innovation approach in innovation policy. In Innovation, Science, and Institutional Change a Research Handbook; Oxford Academic: Oxford, UK, 2006; pp. 141–163. [Google Scholar]

- Lindholm-Dahlstrand, Å.; Andersson, M.; Carlsson, B. Entrepreneurial Experimentation: A Key Function in Entrepreneurial Systems of Innovation. Small Bus. Econ. 2019, 53, 591–610. [Google Scholar] [CrossRef]

- Campbell, S.; Greenwood, M.; Prior, S.; Shearer, T.; Walkem, K.; Young, S.; Bywaters, D.; Walker, K. Purposive sampling: Complex or simple? Research case examples. J. Res. Nurs. 2020, 25, 652–661. [Google Scholar] [CrossRef] [PubMed]

- Knott, E.; Rao, A.H.; Summers, K.; Teeger, C. Interviews in the social sciences. Nat. Rev. Methods Primers 2022, 2, 73. [Google Scholar] [CrossRef]

- Kallio, H.; Pietilä, A.M.; Johnson, M.; Kangasniemi, M. Systematic methodological review: Developing a framework for a qualitative semi-structured interview guide. J. Adv. Nurs. 2016, 72, 2954–2965. [Google Scholar] [CrossRef]

- Adeoye-Olatunde, O.A.; Olenik, N.L. Research and scholarly methods: Semi-structured interviews. J. Am. Coll. Clin. Pharm. 2021, 4, 1358–1367. [Google Scholar] [CrossRef]

- ISO. ISO 14000 Family. Available online: https://www.iso.org/standards/popular/iso-14000-family (accessed on 12 February 2024).

- ISO. ISO 9000 Family. Available online: https://www.iso.org/standards/popular/iso-9000-family (accessed on 12 February 2024).

- Ecovadis. How Does EcoVadis Rate Companies from Industries with High Environmental Impacts? Available online: https://support.ecovadis.com/hc/en-us/articles/4417945610130-How-does-EcoVadis-rate-companies-from-industries-with-high-environmental-impacts (accessed on 12 February 2024).

- Formela, K. Sustainable development of waste tires recycling technologies—Recent advances, challenges and future trends. Adv. Ind. Eng. Polym. Res. 2021, 4, 209–222. [Google Scholar] [CrossRef]

- Foschi, E.; Bonoli, A. The commitment of packaging industry in the framework of the European strategy for plastics in a circular economy. Adm. Sci. 2019, 9, 18. [Google Scholar] [CrossRef]

- Kahlert, S.; Bening, C.R. Why pledges alone will not get plastics recycled: Comparing recyclate production and anticipated demand. Resour. Conserv. Recycl. 2022, 181, 106279. [Google Scholar] [CrossRef]

- Lisiecki, M.; Damgaard, A.; Ragaert, K.; Astrup, T.F. Circular economy initiatives are no guarantee for increased plastic circularity: A framework for the systematic comparison of initiatives. Resour. Conserv. Recycl. 2023, 197, 107072. [Google Scholar] [CrossRef]

- Parlement, E. Packaging: New EU Rules to Reduce, Reuse and Recycle. Available online: https://www.europarl.europa.eu/news/en/press-room/20231023IPR08128/packaging-new-eu-rules-to-reduce-reuse-and-recycle (accessed on 15 February 2024).

- Walker, T.; Gramlich, D.; Dumont-Bergeron, A. The Case for a Plastic Tax: A Review of Its Benefits and Disadvantages Within a Circular Economy. In Sustainability; Wasieleski, D.M., Weber, J., Eds.; Emerald Publishing Limited: Leeds, UK, 2020; Volume 4, pp. 185–211. [Google Scholar]

- Huang, W. Sustainable management of different systems for recycling end-of-life tyres in China. Waste Manag. Res. 2021, 39, 966–974. [Google Scholar] [CrossRef]

- Li, X.; Xu, H.; Gao, Y.; Tao, Y. Comparison of end-of-life tire treatment technologies: A Chinese case study. Waste Manag. 2010, 30, 2235–2246. [Google Scholar] [CrossRef]

| System Function | Description of System Function | Related to Devulcanization Value Chain |

|---|---|---|

| Entrepreneurial activities | Entrepreneurs and other actors have the ability to bring early technology developments to the market with an initial business idea and then start experimenting to create new opportunities in markets. | Utilization of devulcanization technologies, development of business model, organization of the value chain |

| Knowledge development | Actors derive knowledge about technology, its conditions, and opportunities and applications from academic research to a more practical learning-by-doing process. | Knowledge generation regarding devulcanization from scientific research and other sources of information; utilization of intellectual property rights |

| Knowledge diffusion through networks | Actors gather and share information while engaging with other actors in value chains and in other settings. | Knowledge sharing through collaboration and participation in networks and projects |

| Guidance of the search | Actors seek approaches to address various strategic and practical problems. They are guided by factors such as governmental policies, specific industry standards and technical bottlenecks. | Identified barriers and barriers in the environment |

| Market formation | Actors introduce new technology into existing markets with established relationships, which may either facilitate or hinder the adoption of this technology. | Uptake of devulcanized material by customers (direct business to business sales), requirements that are set by these customers |

| Resource mobilization | Actors require financial resources and other types of resources to introduce the new technology, including a company’s facilities and human capital. | Sources of funding, capabilities in business model |

| Acceptance and creation of legitimacy | When actors introduce a new technology, it can be immediately accepted by the industry, but it can also challenge the status quo, leading to opposition that the actors must face. | Purchase of devulcanized material by their customers and, more generally, the uptake of recycled material in their markets |

| Tire manufacturers | 5 |

| Commercial research organizations | 5 |

| Suppliers of machines and equipment | 6 |

| Suppliers of chemicals | 3 |

| Recyclers | 17 |

| Total | 36 |

| # | Description of Key Activities Related to Devulcanization | Types of Tire Material Collected | Capacity | Type of Process | Applications for Devulcanization |

|---|---|---|---|---|---|

| 1. | Recycling rubber and developing technology and equipment; IP development for own use | Passenger car and truck tires | R&D-scale | Milling process (use of kinetic energy) | Asphalt |

| 2 | Devulcanizing rubber and licensing IP to other companies | Passenger car and truck tires | 2 ton/h | Thermo-mechanical process with chemicals | General rubber goods and truck tires |

| 3 | Sorting and separating tire rubber; devulcanized tire rubber in the past, now consultancy for other companies | Passenger car and truck tires | 2 ton/h, when it comes on stream | Thermo-mechanical process | General rubber goods and truck tires |

| 4 | Sorting and separating tire rubber and devulcanizing tire rubber | Passenger car, truck and bicycle tires and inner liners | 1.5 ton/h | Thermo-mechanical process with chemicals | General rubber goods |

| 5 | Supplying devulcanization equipment; owns a production line for separating tire rubber and devulcanization for R&D | Passenger car tires | R&D-scale | Thermo-mechanical process with chemicals | General rubber goods |

| 6 | Sorting and separating tire rubber and devulcanizing tire rubber | Passenger car tires | 0.75 ton/h | Thermo-mechanical process with chemicals | Asphalt and general rubber goods |

| 7 | Setting up a logistical system for tire collection and testing devulcanization equipment with a partner | Off the road and airplane tires | Startup | Thermo-mechanical process | General rubber goods |

| 8 | Devulcanizing rubber, developing devulcanization method and devulcanization aids (chemicals); aims to license IP to other companies in the near future | Passenger car and truck tires (whole tires and treads) | 1.5 ton/h | Thermo-mechanical process with chemicals | General rubber goods |

| 9 | Researching rubber devulcanization in collaboration with companies (knowledge institute) | Passenger car and truck tires | Laboratory scale and at site of clients | Thermo-mechanical process with chemicals | General rubber goods |

| 10 | Devulcanizing various types of tire rubber | Truck tire treads and inner liners | +/− 2.5 ton/h | Thermo-mechanical process | Truck tires and general rubber goods |

| 11 | Researching devulcanization with companies; owns a line for devulcanization for R&D purposes and has just completed a project on tire devulcanization (knowledge institute) | Passenger car and truck tires | 0.03 ton/h | Microwave | General rubber goods |

| 12 | Researching and developing the application of devulcanized rubber in rubber compounds of new tires (tire producer) | Truck tires (whole tires and treads) | Research at lab-scale | Receives material from thermo-mechanical process with chemicals | Truck tires |

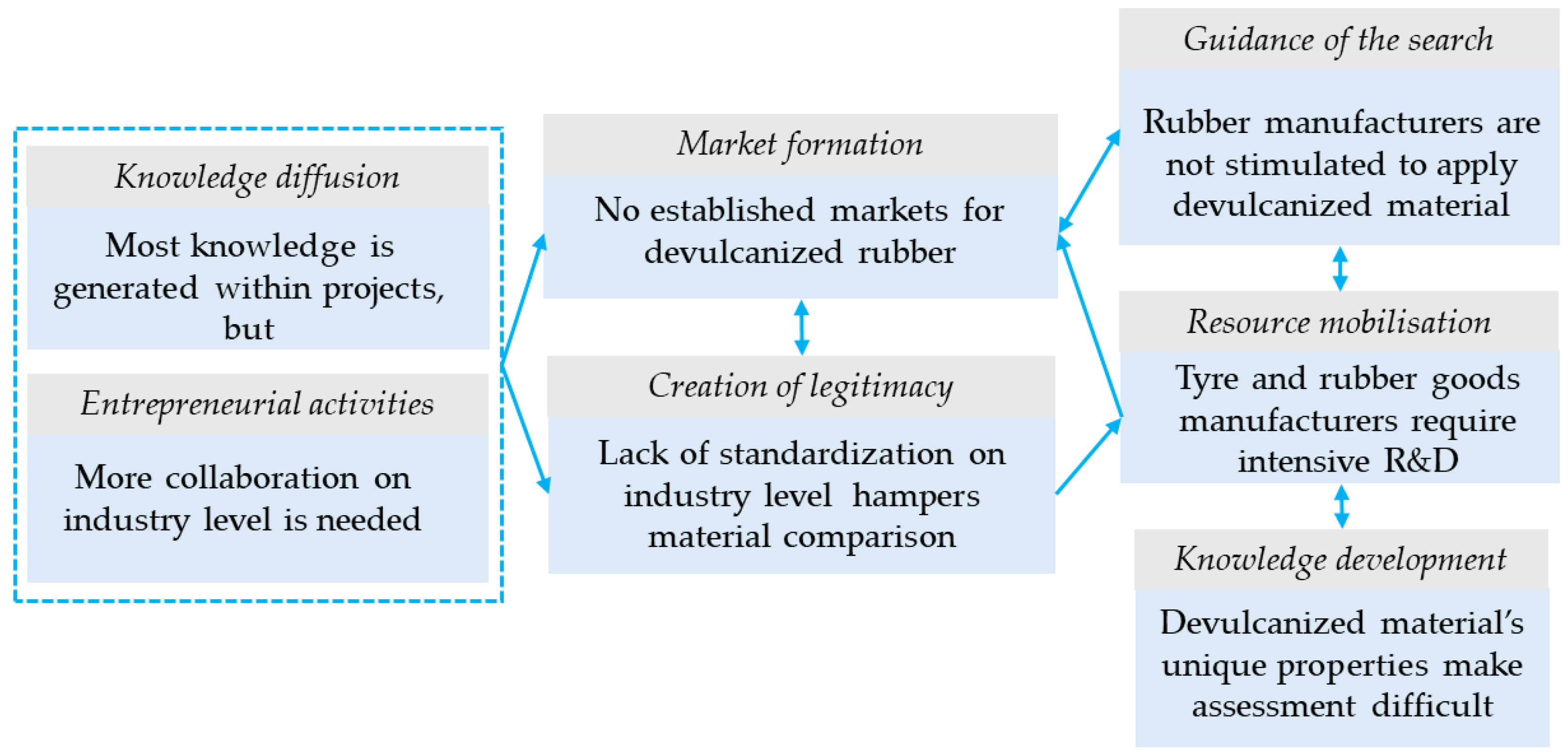

| System Function | Opportunities | Barriers |

|---|---|---|

| Entrepreneurial Activities | Technologies and business models tailored to devulcanize different types of tire rubber | Collaboration in the value chain and engagements from tire and rubber goods manufacturers is needed |

| Knowledge Development | A large number of new devulcanization technologies were developed for devulcanization on an industrial scale | Due to variation in devulcanization technologies and different supplies of end-of-life tire rubber, it is hard to compare the composition and quality of devulcanized rubber |

| Knowledge Diffusion | Various knowledge institutes, recycling companies and suppliers of equipment and chemicals collaborated with the aim to develop industrial devulcanization methods in projects | Knowledge generated within projects often remains contained within the project boundaries |

| Guidance of the Search | Governments funded projects to stimulate the development of devulcanization | In the regulatory landscape, most tire and rubber goods producers do not have financial incentives to replace virgin rubber with devulcanized material in their products |

| Market Formation | The attention paid to devulcanization by tire and rubber goods manufacturers is increasing | No established market exists for upscaling devulcanization on an industrial level; more launching customers are needed, especially ones that not only conduct research and development but also purchase devulcanized material |

| Resource Mobilization | Companies had access to multiple sources of income for the development of technology from investors as well as subsidies from governments | Tire and rubber goods manufacturers need to perform extensive research and development to incorporate devulcanized rubber in products, a process which incurs significant resources |

| Acceptance and Creation of Legitimacy | Increased attention for devulcanization within the industry | Assessing devulcanized rubber needs additional efforts due to its different properties compared to virgin rubber; there are no industry-wide definitions, protocols or standards for assessing devulcanized material |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roetman, E.; Joustra, J.; Heideman, G.; Balkenende, R. Does the Rubber Meet the Road? Assessing the Potential of Devulcanization Technologies for the Innovation of Tire Rubber Recycling. Sustainability 2024, 16, 2900. https://doi.org/10.3390/su16072900

Roetman E, Joustra J, Heideman G, Balkenende R. Does the Rubber Meet the Road? Assessing the Potential of Devulcanization Technologies for the Innovation of Tire Rubber Recycling. Sustainability. 2024; 16(7):2900. https://doi.org/10.3390/su16072900

Chicago/Turabian StyleRoetman, Eric, Jelle Joustra, Geert Heideman, and Ruud Balkenende. 2024. "Does the Rubber Meet the Road? Assessing the Potential of Devulcanization Technologies for the Innovation of Tire Rubber Recycling" Sustainability 16, no. 7: 2900. https://doi.org/10.3390/su16072900

APA StyleRoetman, E., Joustra, J., Heideman, G., & Balkenende, R. (2024). Does the Rubber Meet the Road? Assessing the Potential of Devulcanization Technologies for the Innovation of Tire Rubber Recycling. Sustainability, 16(7), 2900. https://doi.org/10.3390/su16072900