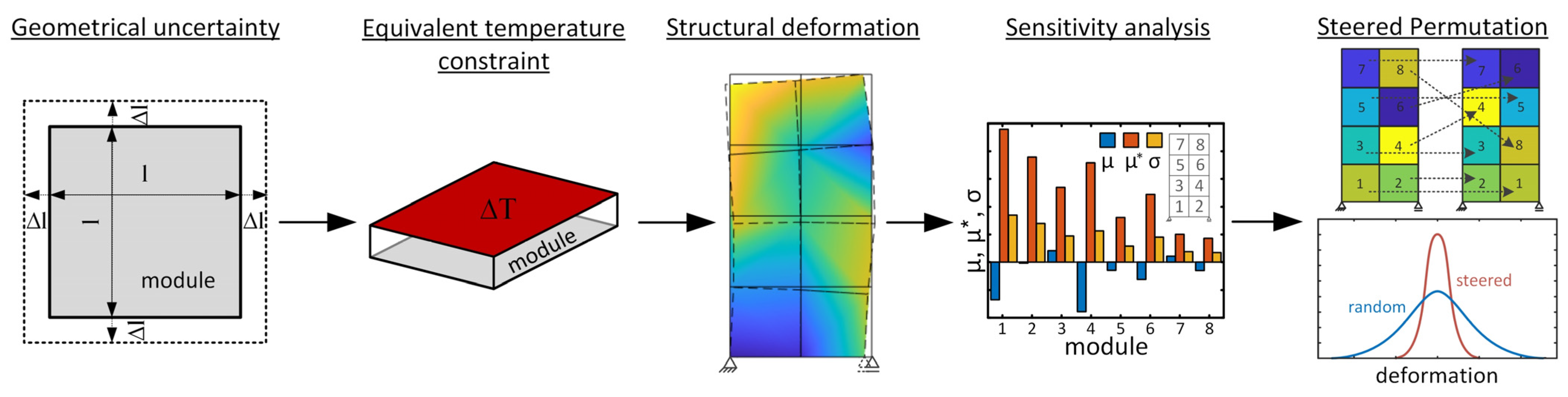

Sensitivity-Based Permutation to Balance Geometric Inaccuracies in Modular Structures

Abstract

1. Introduction

2. Materials and Methods

2.1. Tolerances of Concrete Modules

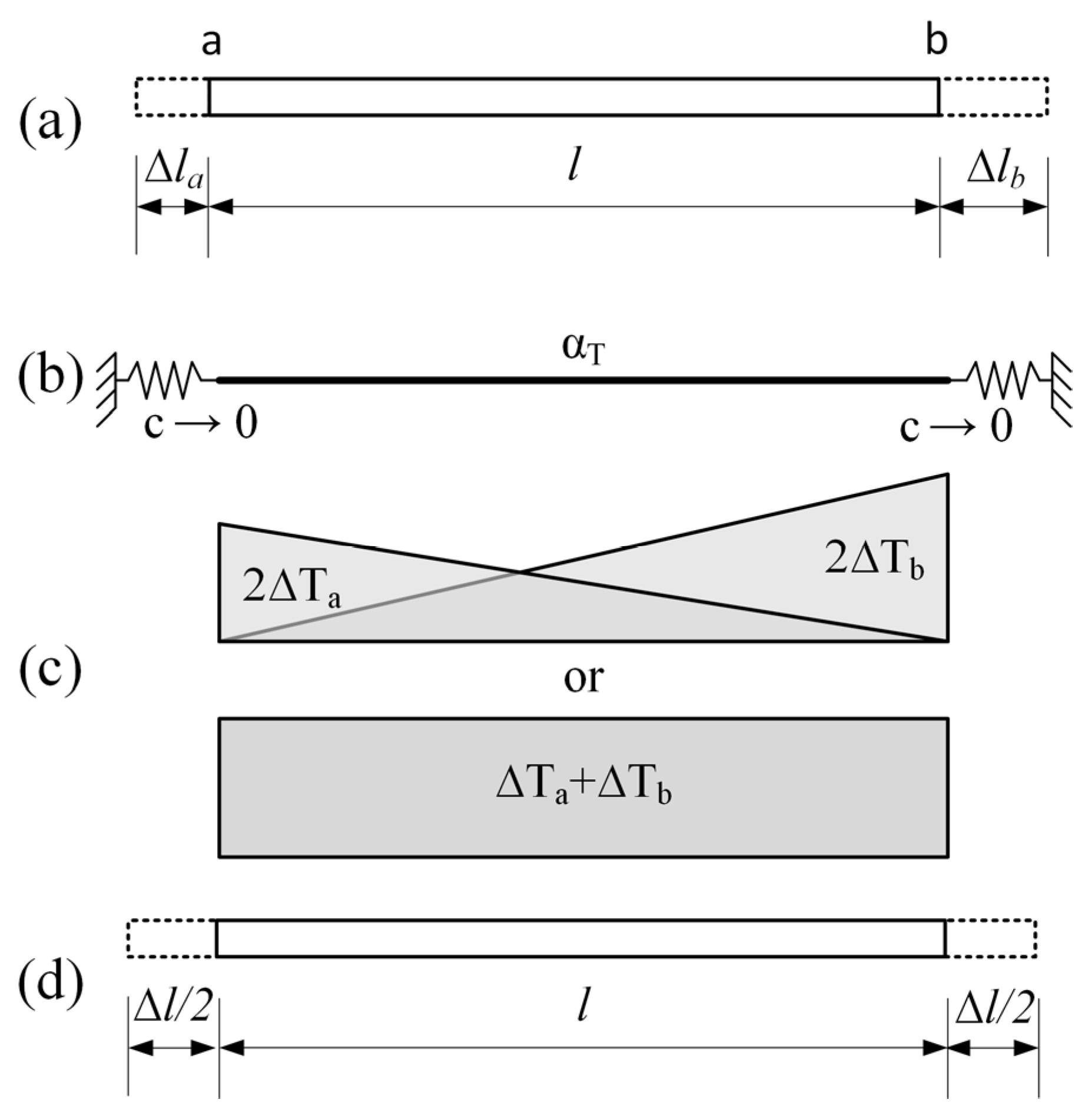

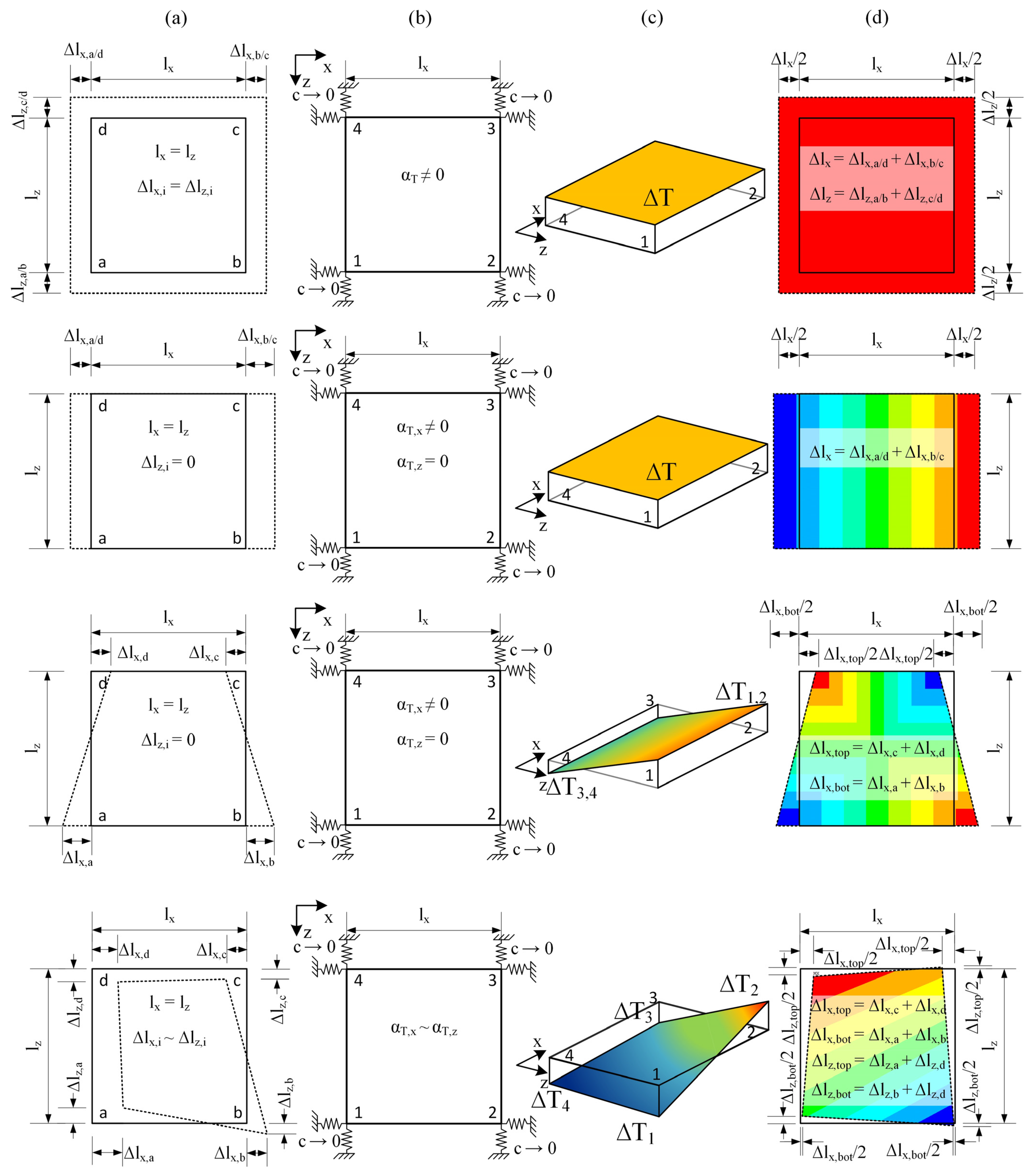

2.2. Modelling Geometric Deviations Using Temperature Constraints

- Constant plane deformation in both directions ( ∆T = const.);

- Constant plane deformation in one direction ( ∆T = const.);

- Linear variable deformation over the height ( ∆T1 = ∆T2, ∆T3 = ∆T4);

- (Almost) arbitrary deformation at the nodes ( ∆T = var.).

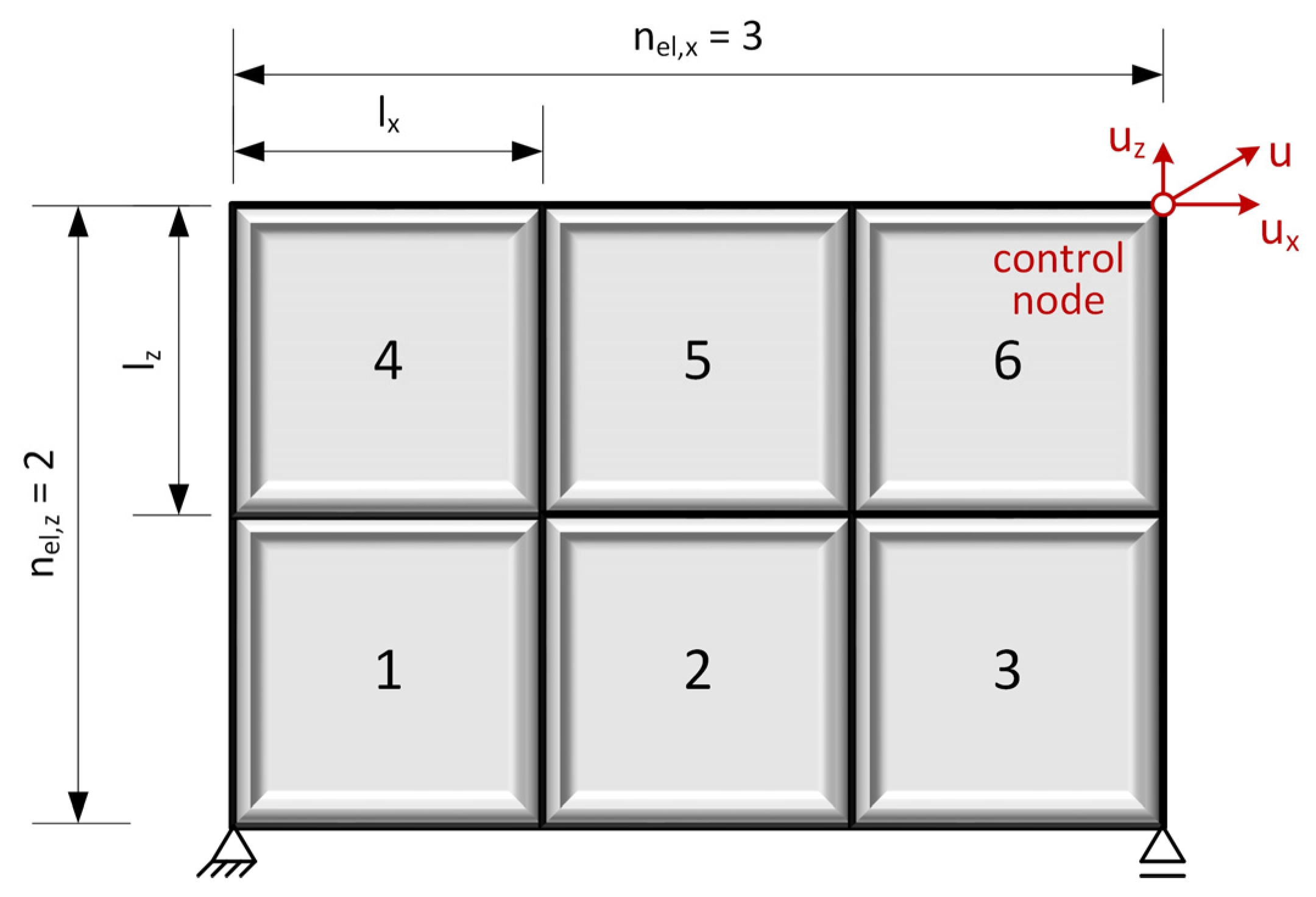

2.3. Extension to (Plane) Structures Consisting of Several Modules—Superposition of Geometric Deviations Due to Temperature Constraints

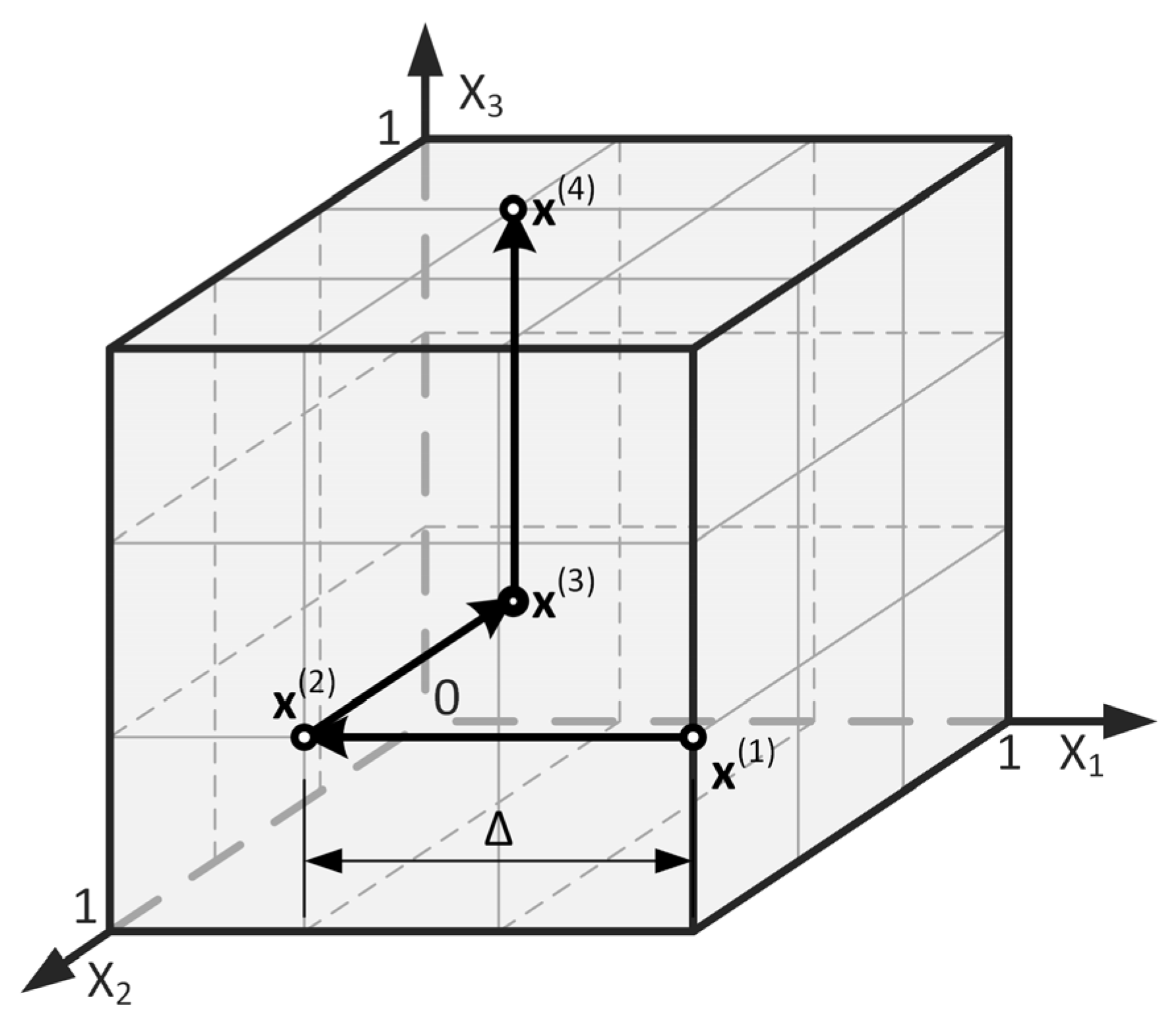

2.4. Sensitivity Analysis of Modular Structures

2.5. Sensitivity-Based Permutation of Modules

3. Results

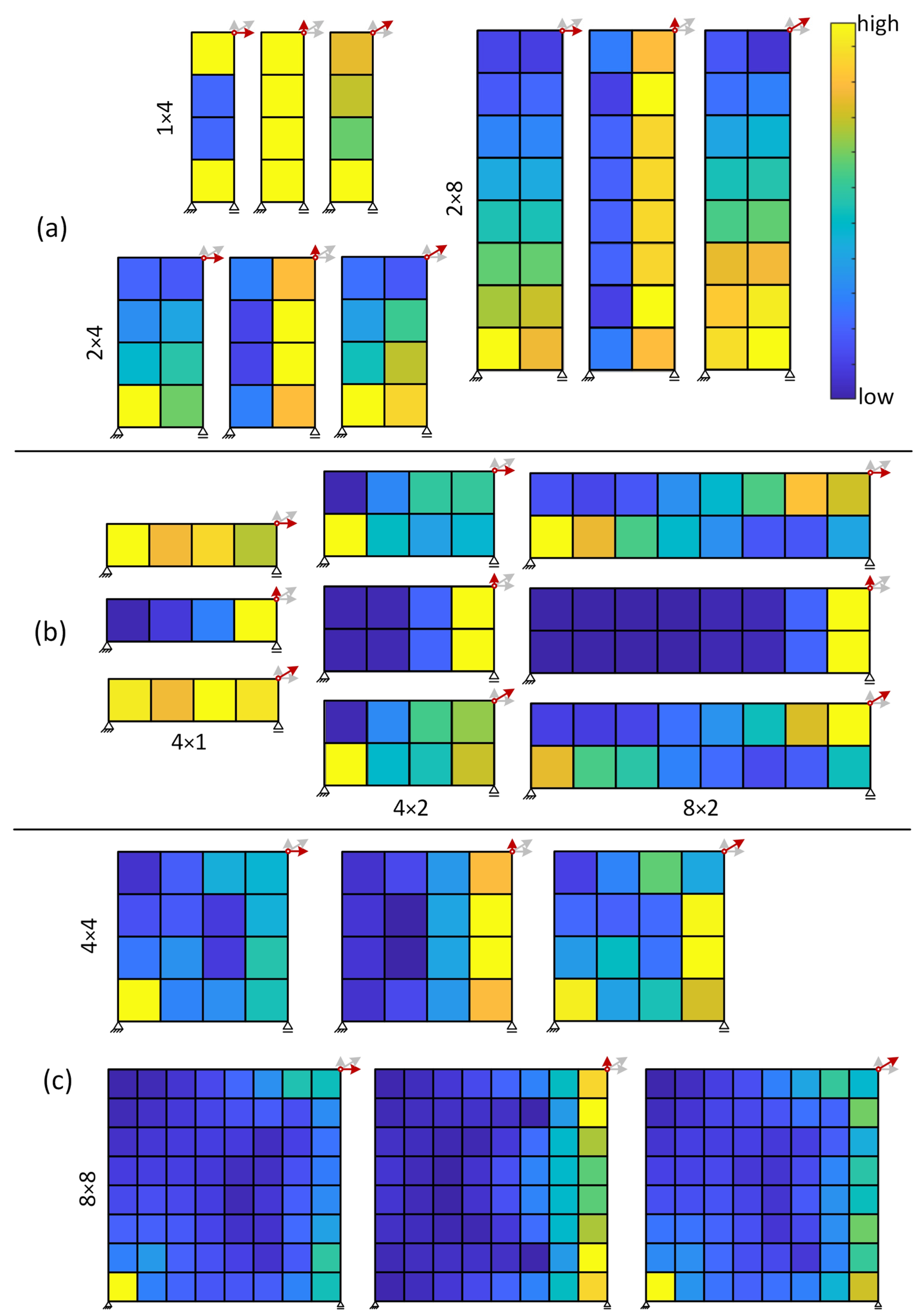

3.1. Sensitivity Analysis

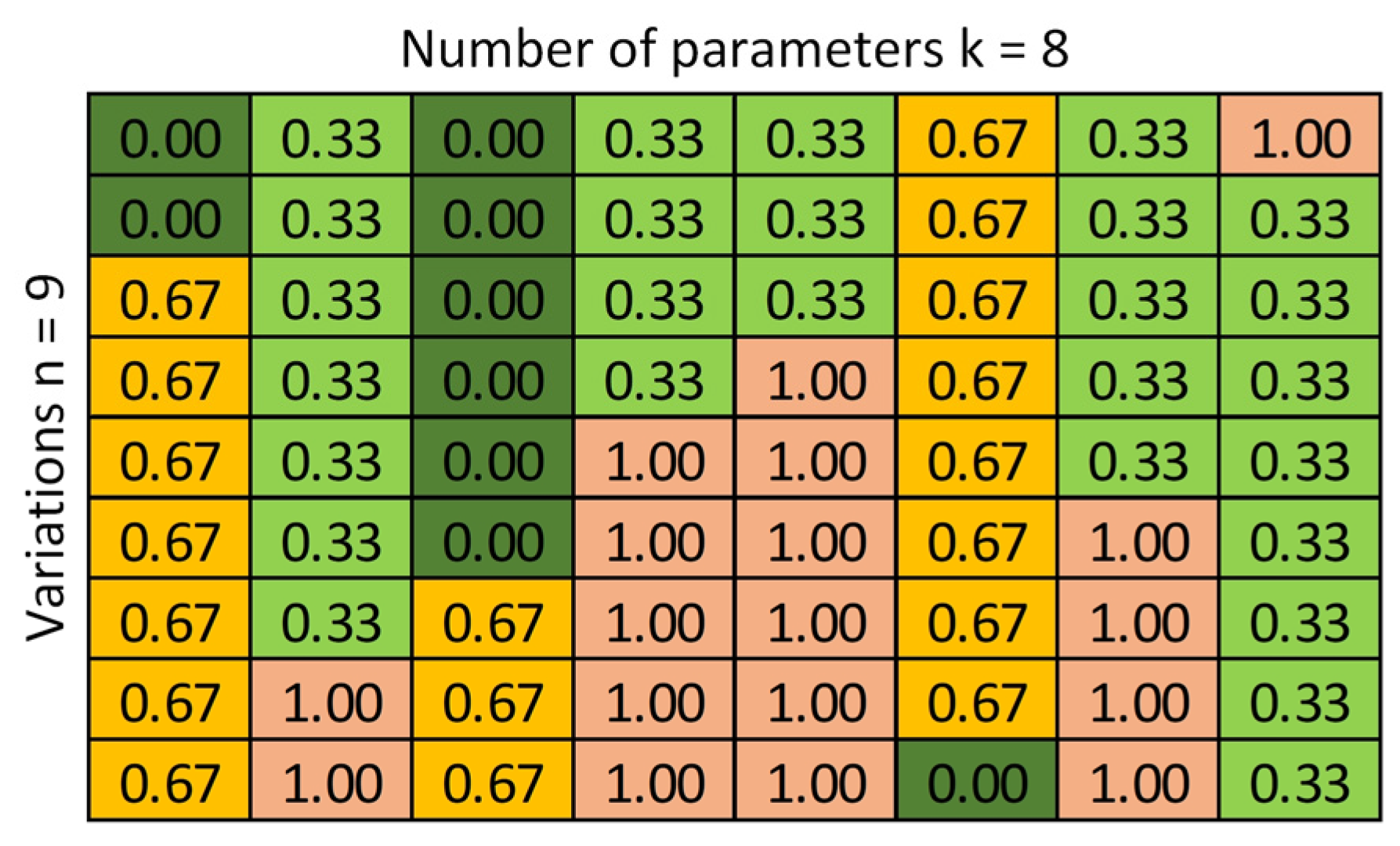

3.1.1. Sampling of Inaccuracies

3.1.2. Sensitivity Analysis of Exemplary Modular Structures

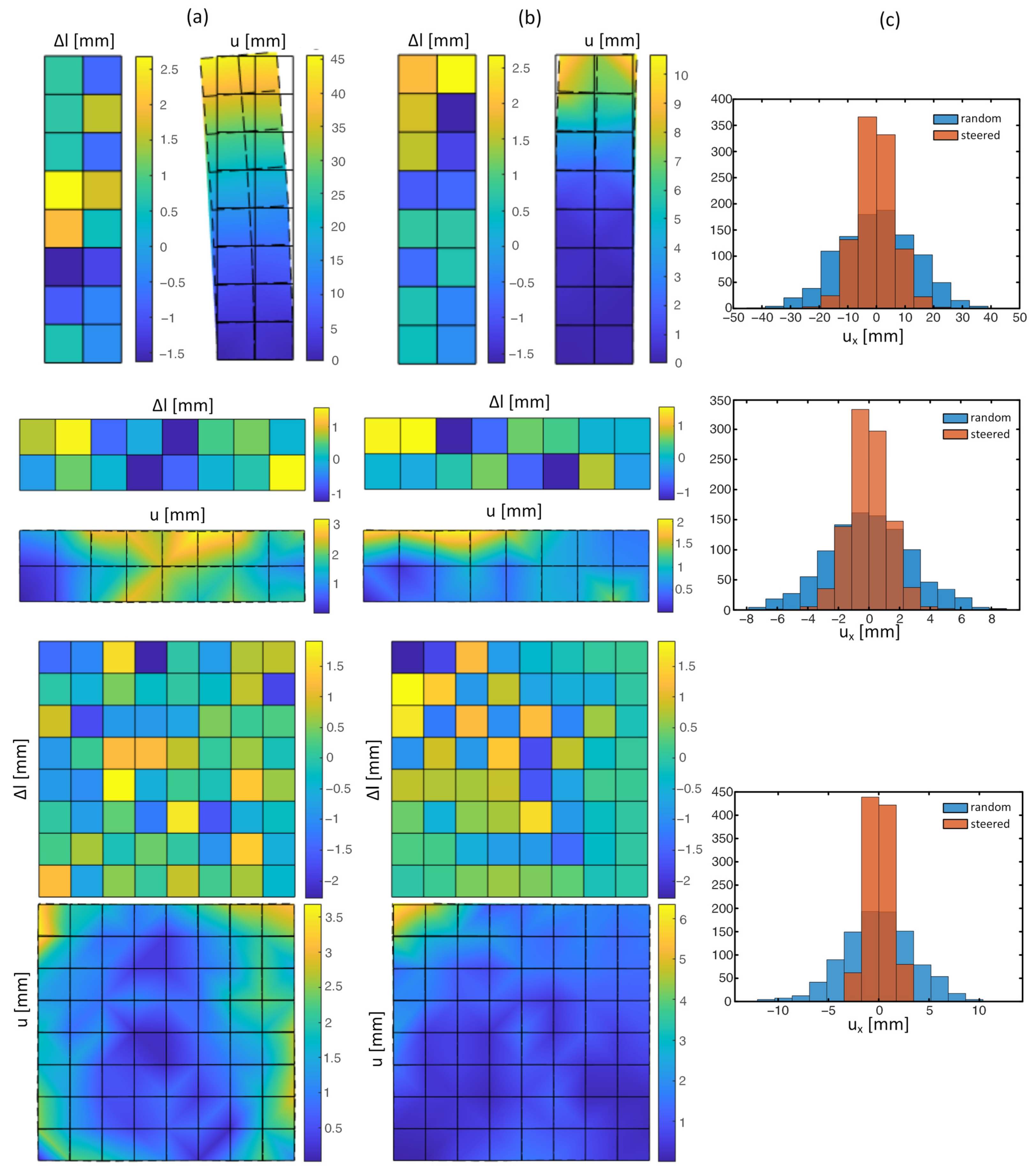

3.2. Sensitivity-Based Permutation to Reduce Structural Inaccuracies

4. Discussion

4.1. Modeling Inaccuracies with Temperature Constraint

- Constant deformation in one direction.

- Constant, proportional deformations for both directions in the plane.

- Linearly variable deformation in one direction.

- Linearly variable, proportional deformation in both directions.

4.2. Sensitivity-Based Permutation Approach

5. Conclusions

- Versatile but not arbitrary geometric deviations can be modeled through the equivalent temperature approach. In an FE environment, corresponding temperature constraints are directly applied to the nodes of the modules. But, deviations are not explicitly prescribable at the nodes, just indirectly for a module. Nevertheless, this approach is considered sufficiently accurate to model geometric inaccuracies within modular structures.

- Deviations in (internally) static-overdetermined modular structures cause eigenstresses which must be absorbed by the modules, in assembly.

- In the chosen statically determinate system, which resembles a simply supported beam, the horizontal deformations of the investigated structures dominate. For column-like modular structures, this bearing configuration results in particularly high deformations due to inclination.

- Modules at the fixed support always exhibit the greatest impact on the absolute deformation at the control node regardless of the type of structure. The impact on the structural inaccuracy decreases the higher the position of the module for column-like structures.

- Sensitivity-based permutation with the EE method reduces the total deformations at the control node by at least 43% on average. The scatter of deformation is also significantly reduced by at least 50% for columns and beams or 69% for walls. Modules with high inaccuracies that otherwise would be disposed of due to tolerance requirements can still be used in areas of low influence. A resource-efficient and sustainable design is ensured.

- The sensitivity-based permutation approach can easily be adapted to evaluate other system responses rather than deformations, e.g., strains, stresses, or internal forces.

- With respect to sustainability, this method provides two crucial advantages. First, the reworking and disposal of modules can be reduced or even avoided due to the tolerance-compensating placement. Second, the modular design enables the exchange of modules in the structure, e.g., to extend the service lifetime of the whole structure without deconstruction. Hereby, the approach of temperature constraints can be adapted to minimize the eigenstresses of the module for exchange by temperature induction of the adjacent modules, which will be the focus of future investigations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kolbeck, L.; Kovaleva, D.; Manny, A.; Stieler, D.; Rettinger, M.; Renz, R.; Tošić, Z.; Teschemacher, T.; Stindt, J.; Forman, P.; et al. Modularisation Strategies for Individualised Precast Construction—Conceptual Fundamentals and Research Directions. Designs 2023, 7, 143. [Google Scholar] [CrossRef]

- Steinle, A.; Bachmann, H.; Tillmann, M. Precast Concrete Structures, 2nd ed.; Ernst & Sohn: Berlin, Germany, 2019; ISBN 978-3-433-03225-1. [Google Scholar]

- Oettel, V.; Empelmann, M. Structural behavior of profiled dry joints between precast ultra-high performance fiber reinforced concrete elements. Struct. Concr. 2019, 20, 446–454. [Google Scholar] [CrossRef]

- Manny, A.; Stempniewski, L.; Albers, A.; Simons, K. Conceptual design and investigation of an innovative joint for the rapid and precise assembly of precast UHPC elements. Eng. Struct. 2022, 265, 114454. [Google Scholar] [CrossRef]

- Kim, Y.-J.; Chin, W.-J.; Jeon, S.-J. Interface Shear Strength at Various Joint Types in High-Strength Precast Concrete Structures. Materials 2020, 13, 4364. [Google Scholar] [CrossRef] [PubMed]

- Baghdadi, A.; Heristchian, M.; Kloft, H. Connections placement optimization approach toward new prefabricated building systems. Eng. Struct. 2021, 233, 111648. [Google Scholar] [CrossRef]

- Baghdadi, A.; Heristchian, M.; Ledderose, L.; Kloft, H. Experimental and numerical assessment of new precast concrete connections under bending loads. Eng. Struct. 2020, 212, 110456. [Google Scholar] [CrossRef]

- Bischof, P.; Mata-Falcón, J.; Burger, J.; Gebhard, L.; Kaufmann, W. Experimental exploration of digitally fabricated connections for structural concrete. Eng. Struct. 2023, 285, 115994. [Google Scholar] [CrossRef]

- Rajanayagam, H.; Poologanathan, K.; Gatheeshgar, P.; Varelis, G.E.; Sherlock, P.; Nagaratnam, B.; Hackney, P. A-State-Of-The-Art review on modular building connections. Structures 2021, 34, 1903–1922. [Google Scholar] [CrossRef]

- Thai, H.-T.; Ngo, T.; Uy, B. A review on modular construction for high-rise buildings. Structures 2020, 28, 1265–1290. [Google Scholar] [CrossRef]

- Rettinger, M.; Prziwarzinski, A.; Meyer, M.; Kolbeck, L.; Tošić, Z.; Hückler, A.; Lordick, D.; Borrmann, A.; Haist, M.; Lohaus, L.; et al. Modulare Fußgängerbrücken aus seriell hergestellten Betonfertigteilen. Beton Stahlbetonbau 2023, 118, 803–814. [Google Scholar] [CrossRef]

- Teschemacher, T.; Bletzinger, K.-U. CAD-integrated parametric modular construction design. Eng. Rep. 2023, 5, e12632. [Google Scholar] [CrossRef]

- Stieler, D.; Schwinn, T.; Menges, A. Automatisierte Bauteilzerlegung für Betonfertigteile aus additiv hergestellten Schalungen. Beton Stahlbetonbau 2022, 117, 324–332. [Google Scholar] [CrossRef]

- Markowski, J.; Meyer, M.; Haist, M.; Lohaus, L. Duktilitätssteigernde Bewehrungssysteme für fließgefertigte Stabelemente aus UHFB. Beton Stahlbetonbau 2022, 117, 998–1007. [Google Scholar] [CrossRef]

- Blandini, L.; Kovaleva, D.; Haufe, C.N.; Nething, C.; Nigl, D.; Nitzlader, M.; Smirnova, M.; Strahm, B.; Bosch, M.; Funaro, D.; et al. Leicht bauen mit Beton—ausgewählte Forschungsarbeiten des ILEK—Teil 2: Strukturleichtbau. Beton Stahlbetonbau 2023, 118, 320–331. [Google Scholar] [CrossRef]

- Gappmaier, P.; Reichenbach, S.; Kromoser, B. Automated Production Process for Structure-Optimised Concrete Elements. In Building for the Future: Durable, Sustainable, Resilient; Ilki, A., Çavunt, D., Çavunt, Y.S., Eds.; Springer Nature Switzerland: Cham, Switzerland, 2023; pp. 1577–1585. ISBN 978-3-031-32510-6. [Google Scholar]

- Stoiber, N.; Kromoser, B. Topology optimization in concrete construction: A systematic review on numerical and experimental investigations. Struct Multidisc Optim 2021, 64, 1725–1749. [Google Scholar] [CrossRef]

- Stindt, J.; Forman, P.; Mark, P. Influence of Rapid Heat Treatment on the Shrinkage and Strength of High-Performance Concrete. Materials 2021, 14, 4102. [Google Scholar] [CrossRef] [PubMed]

- Schoening, J.; Della Pietra, R.; Hegger, J.; Tue, N.V. Verbindungen von Fertigteilen aus UHPC. Bautechnik 2013, 90, 304–313. [Google Scholar] [CrossRef]

- Shahtaheri, Y.; Rausch, C.; West, J.; Haas, C.; Nahangi, M. Managing risk in modular construction using dimensional and geometric tolerance strategies. Autom. Constr. 2017, 83, 303–315. [Google Scholar] [CrossRef]

- Liu, Y.; Yao, F.; Ji, Y.; Tong, W.; Liu, G.; Li, H.X.; Hu, X. Quality Control for Offsite Construction: Review and Future Directions. J. Constr. Eng. Manag. 2022, 148, 03122003. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, Y.; Li, J. Review on automated quality inspection of precast concrete components. Autom. Constr. 2023, 150, 104828. [Google Scholar] [CrossRef]

- Du Plessis, A.; Boshoff, W.P. A review of X-ray computed tomography of concrete and asphalt construction materials. Constr. Build. Mater. 2019, 199, 637–651. [Google Scholar] [CrossRef]

- Mendricky, R. Determination of measurement accuracy of optical 3D scanners. MM Sci. J. 2016, 2016, 1565–1572. [Google Scholar] [CrossRef]

- Sun, K.; Tran, T.-H.; Guhathakurta, J.; Simon, S. FL-MISR: Fast large-scale multi-image super-resolution for computed tomography based on multi-GPU acceleration. J. Real-Time Image Proc. 2022, 19, 331–344. [Google Scholar] [CrossRef]

- Ballast, D.K. Handbook of Construction Tolerances, 2nd ed.; Wiley: Hoboken, NJ, USA, 2007; ISBN 978-0-471-93151-5. [Google Scholar]

- Rausch, C.; Nahangi, M.; Haas, C.; Liang, W. Monte Carlo simulation for tolerance analysis in prefabrication and offsite construction. Autom. Constr. 2019, 103, 300–314. [Google Scholar] [CrossRef]

- Long, H.; Luo, X.; Liu, J.; Dong, S. The Analysis and Application of Installation Tolerances in Prefabricated Construction Based on the Dimensional Chain Theory. Buildings 2023, 13, 1799. [Google Scholar] [CrossRef]

- Talebi, S.; Koskela, L.; Tzortzopoulos, P.; Kagioglou, M. Tolerance Management in Construction: A Conceptual Framework. Sustainability 2020, 12, 1039. [Google Scholar] [CrossRef]

- Wagner, R.; Kuhnle, A.; Lanza, G. Optimising Matching Strategies for High Precision Products by Functional Models and Machine Learning Algorithms. In Proceedings of the 7th WGP-Jahreskongress, Aachen, Germany, 5–6 October 2017; Schmitt, R.H., Schuh, G., Eds.; pp. 231–239. [Google Scholar]

- Kaveh, A.; Zolghadr, A. Meta-heuristic methods for optimization of truss structures with vibration frequency constraints. Acta Mech 2018, 229, 3971–3992. [Google Scholar] [CrossRef]

- Alberdi, R.; Khandelwal, K. Comparison of robustness of metaheuristic algorithms for steel frame optimization. Eng. Struct. 2015, 102, 40–60. [Google Scholar] [CrossRef]

- Nigdeli, S.M.; Bekdaş, G.; Yang, X.-S. Metaheuristic Optimization of Reinforced Concrete Footings. KSCE J. Civ. Eng. 2018, 22, 4555–4563. [Google Scholar] [CrossRef]

- Stindt, J.; Frey, A.M.; Forman, P.; Mark, P.; Lanza, G. CO2 reduction of resolved wall structures: A load-bearing capacity-based modularization and assembly approach. Eng. Struct. 2024, 300, 117197. [Google Scholar] [CrossRef]

- Morris, M.D. Factorial Sampling Plans for Preliminary Computational Experiments. Technometrics 1991, 33, 161. [Google Scholar] [CrossRef]

- Campolongo, F.; Cariboni, J.; Saltelli, A. An effective screening design for sensitivity analysis of large models. Environ. Model. Softw. 2007, 22, 1509–1518. [Google Scholar] [CrossRef]

- de Zanet, G.; Viquerat, A. Screening methods for sensitivity analysis applied to thin composite laminated structures. Thin-Walled Struct. 2022, 172, 108870. [Google Scholar] [CrossRef]

- Forman, P.; Mark, P. Fertigungstoleranzen von Betonfertigteilen für die modulare Bauweise. Beton Stahlbetonbau 2022, 117, 286–295. [Google Scholar] [CrossRef]

- Bazant, Z.P. Criteria for Rational Prediction of Creep and Shrinkage of Concrete. In SP-194: The Adam Neville Symposium: Creep and Shrinkage-Structural Design Effects; American Concrete Institute: Indianapolis, IN, USA, 2000; ISBN 9780870316920. [Google Scholar]

- Toutenburg, H.; Knöfel, P. Six Sigma: Methoden und Statistik für die Praxis, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 9783540851370. [Google Scholar]

- Saltelli, A.; Ratto, M.; Andres, T. Global Sensitivity Analysis: The Primer, 1st ed.; Wiley-Interscience: Hoboken, NJ, USA, 2008; ISBN 0470059974. [Google Scholar]

- Helton, J.C.; Davis, F.J. Latin hypercube sampling and the propagation of uncertainty in analyses of complex systems. Reliab. Eng. Syst. Saf. 2003, 81, 23–69. [Google Scholar] [CrossRef]

- McKay, M.D.; Beckman, R.J.; Conover, W.J. Comparison of Three Methods for Selecting Values of Input Variables in the Analysis of Output from a Computer Code. Technometrics 1979, 21, 239–245. [Google Scholar] [CrossRef]

- Sobol’, I. On the distribution of points in a cube and the approximate evaluation of integrals. USSR Comput. Math. Math. Phys. 1967, 7, 86–112. [Google Scholar] [CrossRef]

- Sanio, D.; Obel, M.; Mark, P. Screening methods to reduce complex models of existing structures. In Proceedings of the 17th International Probabilistic Workshop (IPW), Edinburgh, UK, 11–13 September 2019; pp. 51–56. [Google Scholar]

- Sanio, D.; Ahrens, M.A.; Mark, P. Lifetime predictions of prestressed concrete bridges—Evaluating parameters of relevance using Sobol’ indices. Civ. Eng. Des. 2022, 4, 143–153. [Google Scholar] [CrossRef]

- Campolongo, F.; Saltelli, A. Sensitivity analysis of an environmental model: An application of different analysis methods. Reliab. Eng. Syst. Saf. 1997, 57, 49–69. [Google Scholar] [CrossRef]

- Campolongo, F.; Tarantola, S.; Saltelli, A. Tackling quantitatively large dimensionality problems. Comput. Phys. Commun. 1999, 117, 75–85. [Google Scholar] [CrossRef]

- Singh, R.; Kukshal, V.; Yadav, V.S. A Review on Forward and Inverse Kinematics of Classical Serial Manipulators. In Advances in Engineering Design; Rakesh, P.K., Sharma, A.K., Singh, I., Eds.; Springer: Singapore, 2021; pp. 417–428. ISBN 978-981-33-4017-6. [Google Scholar]

- Saltelli, A.; Annoni, P.; Azzini, I.; Campolongo, F.; Ratto, M.; Tarantola, S. Variance based sensitivity analysis of model output. Design and estimator for the total sensitivity index. Comput. Phys. Commun. 2010, 181, 259–270. [Google Scholar] [CrossRef]

- Kosse, S.; Vogt, O.; Wolf, M.; König, M.; Gerhard, D. Digital Twin Framework for Enabling Serial Construction. Front. Built Environ. 2022, 8, 864722. [Google Scholar] [CrossRef]

- Kosse, S.; Vogt, O.; Wolf, M.; König, M.; Gerhard, D. Requirements Management for Flow Production of Precast Concrete Modules. In Advances in Information Technology in Civil and Building Engineering; Skatulla, S., Beushausen, H., Eds.; Springer International Publishing: Cham, Switzerland, 2024; pp. 687–701. ISBN 978-3-031-35398-7. [Google Scholar]

- Kalasapudi, V.S.; Tang, P.; Zhang, C.; Diosdado, J.; Ganapathy, R. Adaptive 3D Imaging and Tolerance Analysis of Prefabricated Components for Accelerated Construction. Procedia Eng. 2015, 118, 1060–1067. [Google Scholar] [CrossRef]

- Kim, M.-K.; Wang, Q.; Park, J.-W.; Cheng, J.C.; Sohn, H.; Chang, C.-C. Automated dimensional quality assurance of full-scale precast concrete elements using laser scanning and BIM. Autom. Constr. 2016, 72, 102–114. [Google Scholar] [CrossRef]

| Type of Modular Structure | Number of Modules | Deformation [mm] | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ux | uz | u | ||||||||||||

| Random | Steered | Random | Steered | Random | Steered | |||||||||

| nel,x | nel,z | Mean | Std | Mean | Std | Mean | Std | Mean | Std | Mean | Std | Mean | Std | |

| Column | 2 | 8 | 0 | 13.38 | −0.37 | 6.74 | 0 | 3.59 | 0.14 | 3.42 | 11.38 | 7.88 | 6.44 | 3.96 |

| Beam | 8 | 2 | 0 | 2.76 | 0 | 1.32 | 0 | 1.82 | 0.03 | 0.7 | 2.9 | 1.58 | 1.26 | 0.78 |

| Wall | 8 | 8 | 0 | 3.54 | 0.01 | 1.17 | 0 | 2.85 | −0.02 | 0.94 | 3.93 | 2.29 | 1.32 | 0.71 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Forman, P.; Ahrens, M.A.; Mark, P. Sensitivity-Based Permutation to Balance Geometric Inaccuracies in Modular Structures. Sustainability 2024, 16, 3016. https://doi.org/10.3390/su16073016

Forman P, Ahrens MA, Mark P. Sensitivity-Based Permutation to Balance Geometric Inaccuracies in Modular Structures. Sustainability. 2024; 16(7):3016. https://doi.org/10.3390/su16073016

Chicago/Turabian StyleForman, Patrick, Mark Alexander Ahrens, and Peter Mark. 2024. "Sensitivity-Based Permutation to Balance Geometric Inaccuracies in Modular Structures" Sustainability 16, no. 7: 3016. https://doi.org/10.3390/su16073016

APA StyleForman, P., Ahrens, M. A., & Mark, P. (2024). Sensitivity-Based Permutation to Balance Geometric Inaccuracies in Modular Structures. Sustainability, 16(7), 3016. https://doi.org/10.3390/su16073016