Cotton–Cork Blended Fabric: An Innovative and Sustainable Apparel Textile for the Fashion Industry

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. Tensile Strength

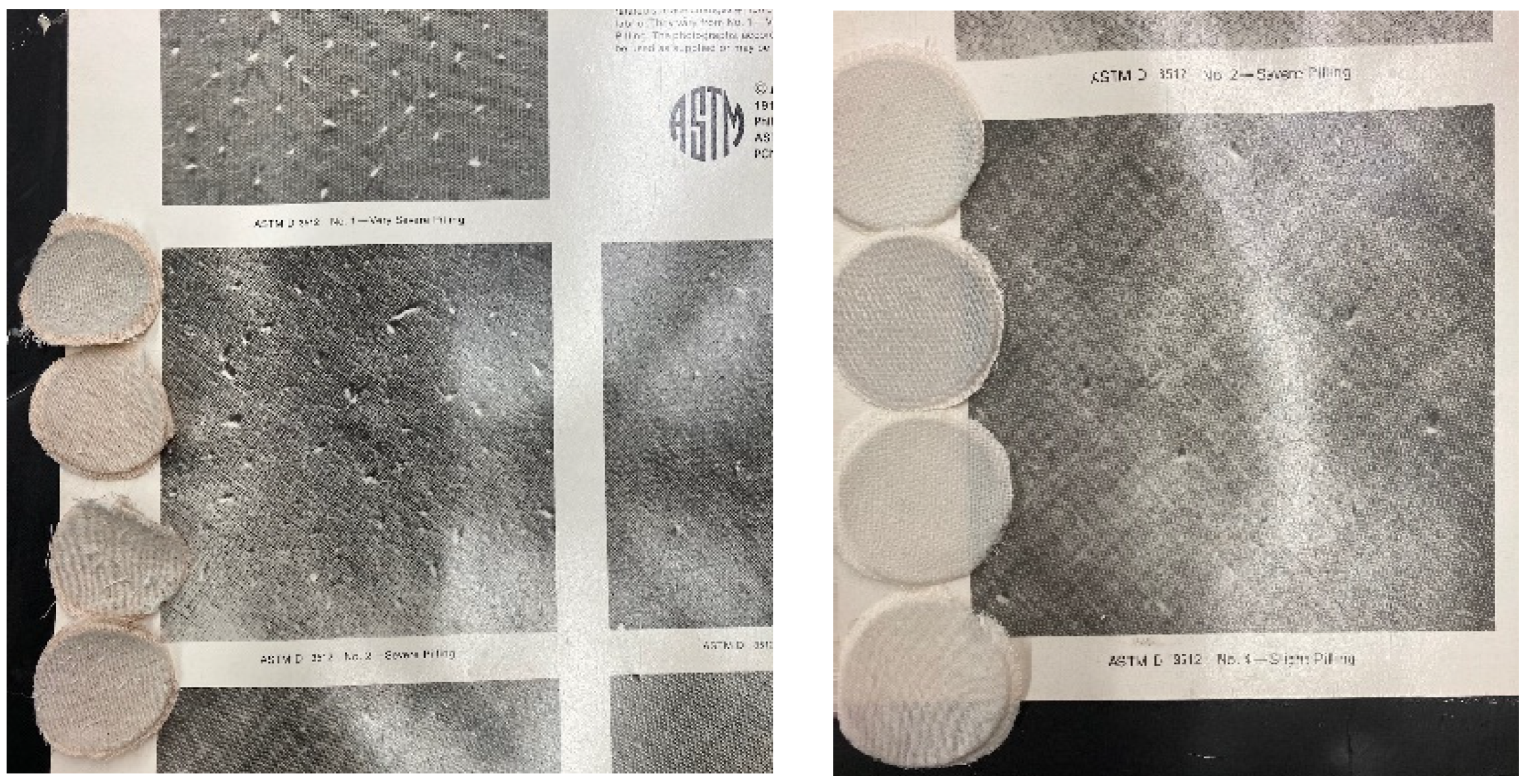

3.2. Abrasion Resistance

3.3. Wrinkle Recovery Angle Test (WRA)

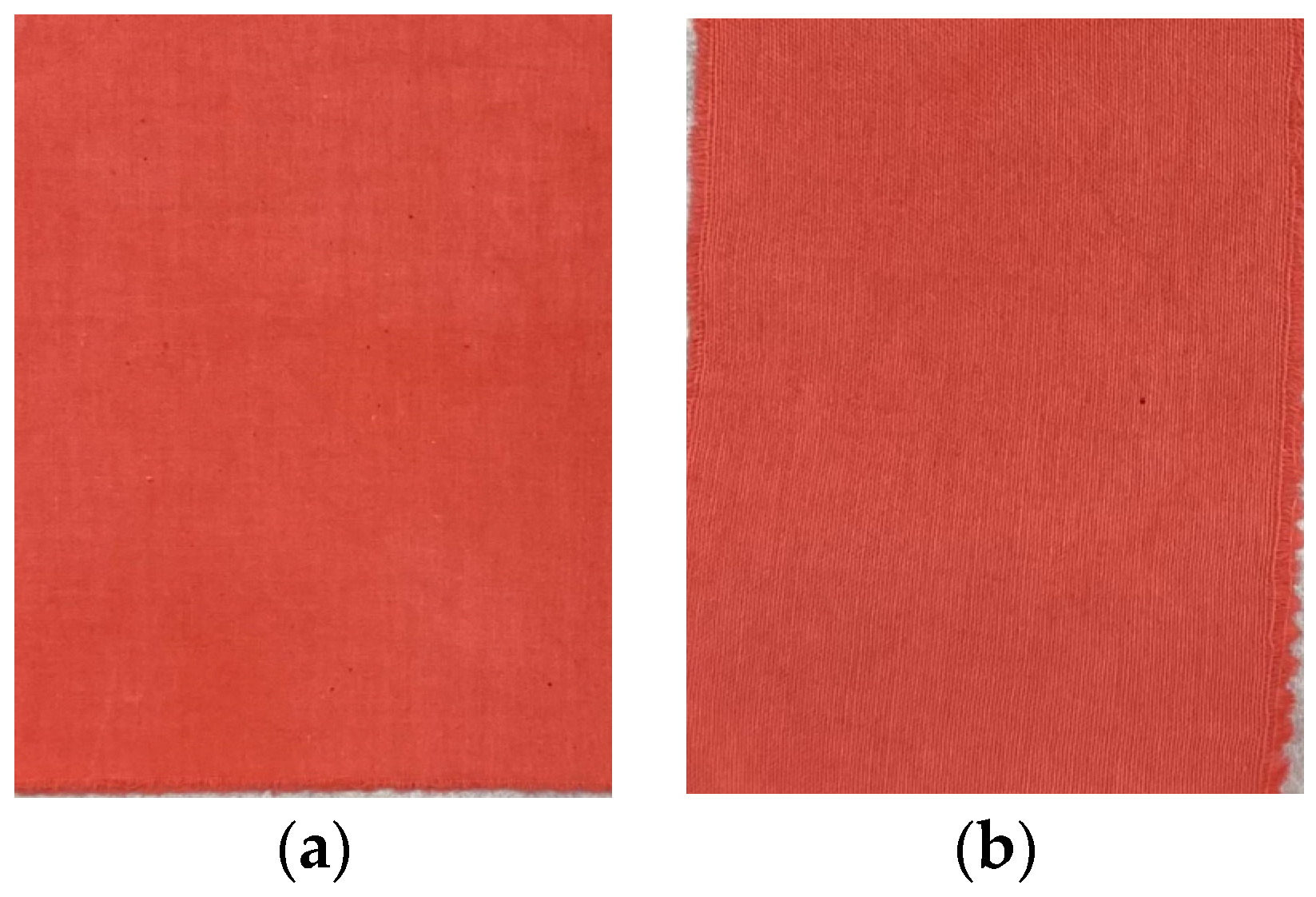

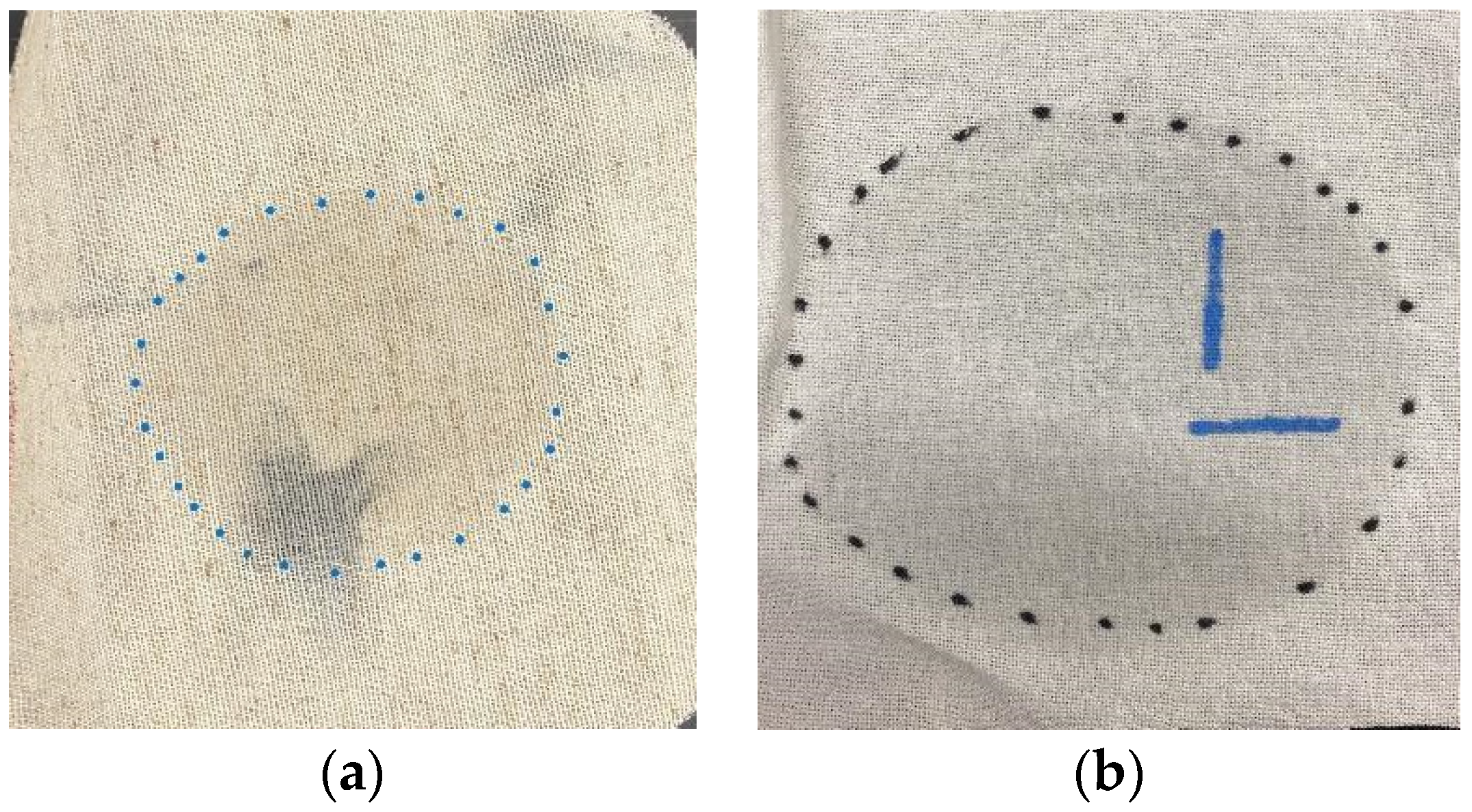

3.4. Dyeability

3.5. Thermal Insulation

3.6. Moisture Management Test

3.7. Shrinkage Test

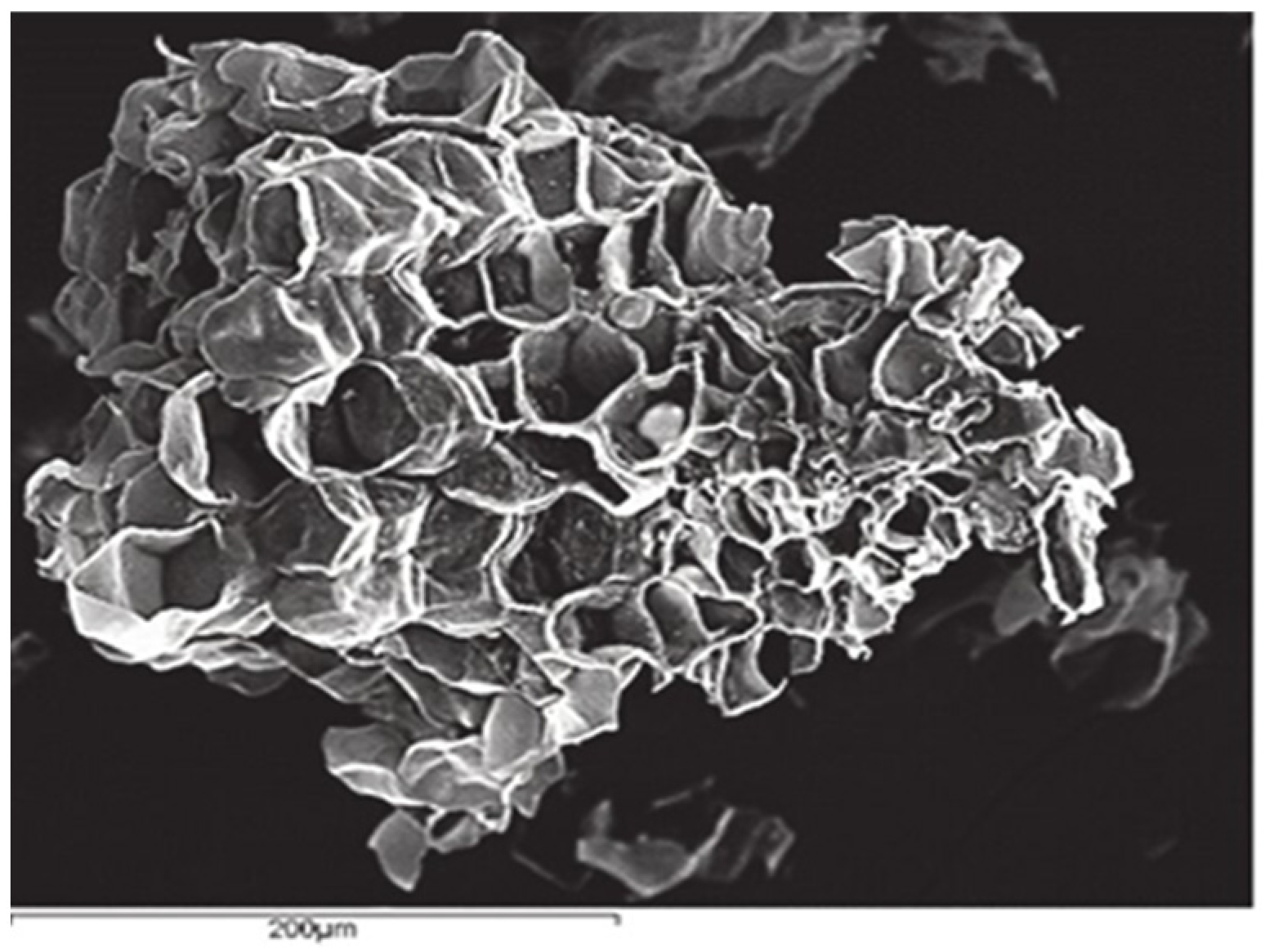

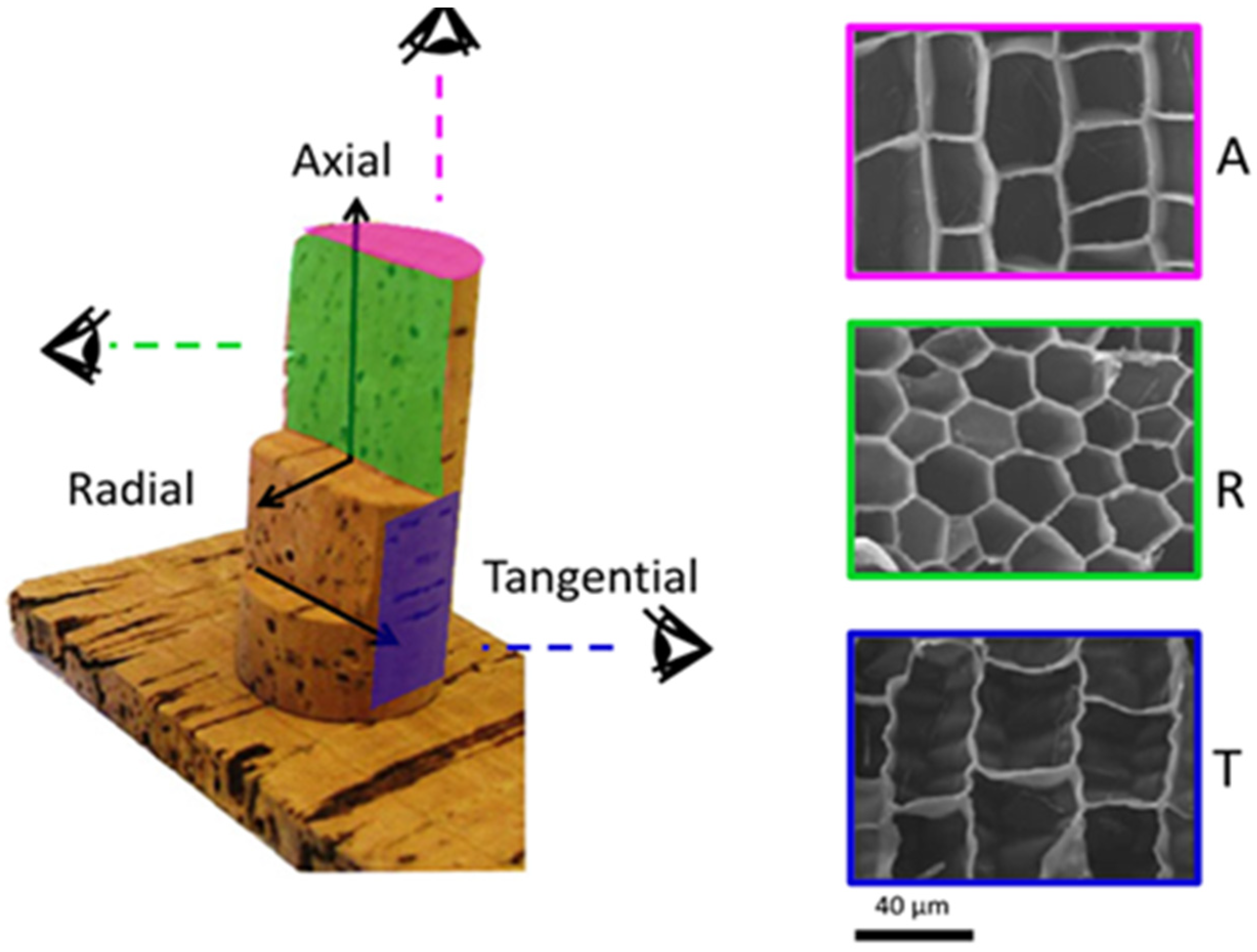

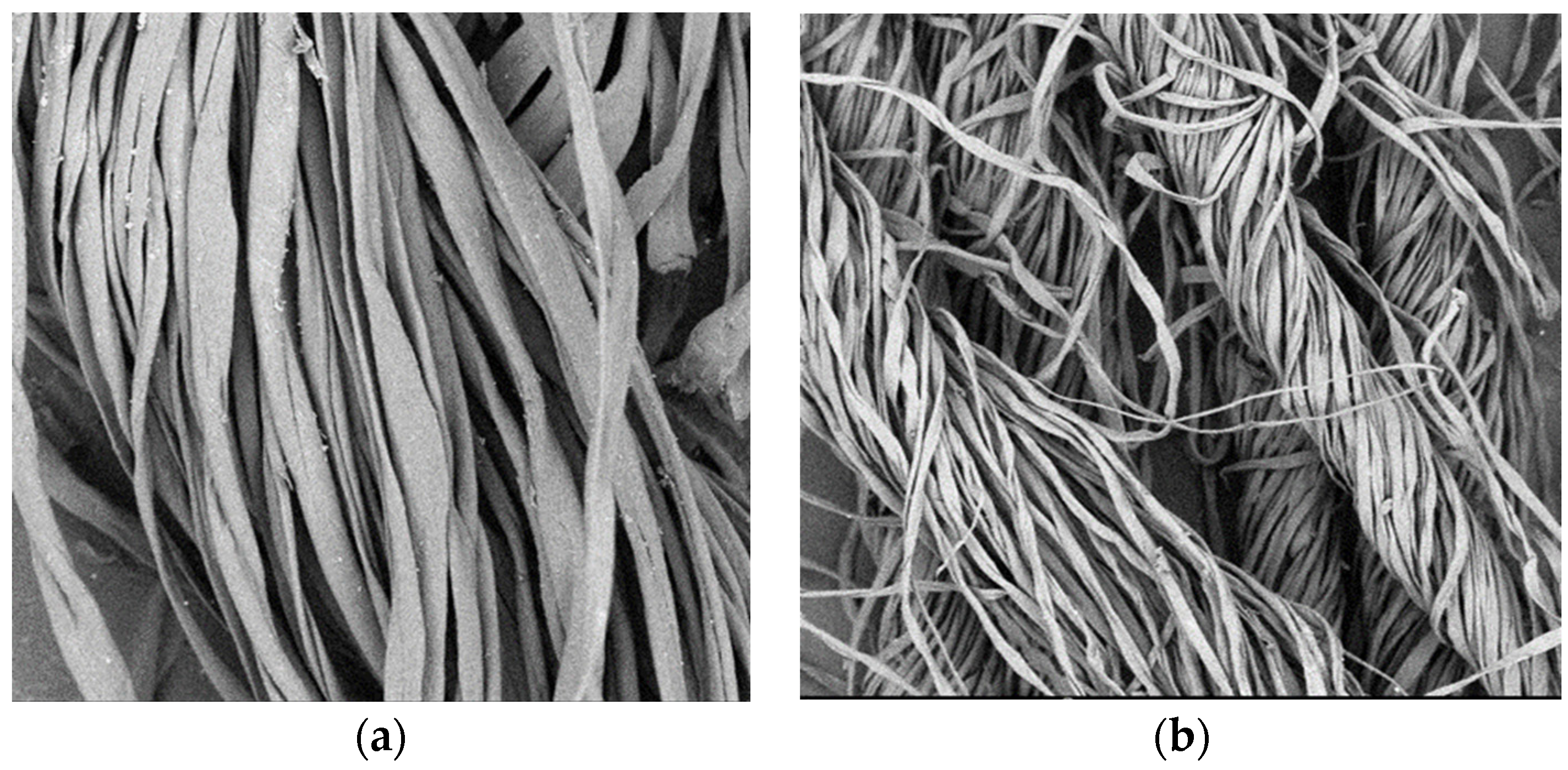

3.8. Scanning Electron Micrograph (SEM)

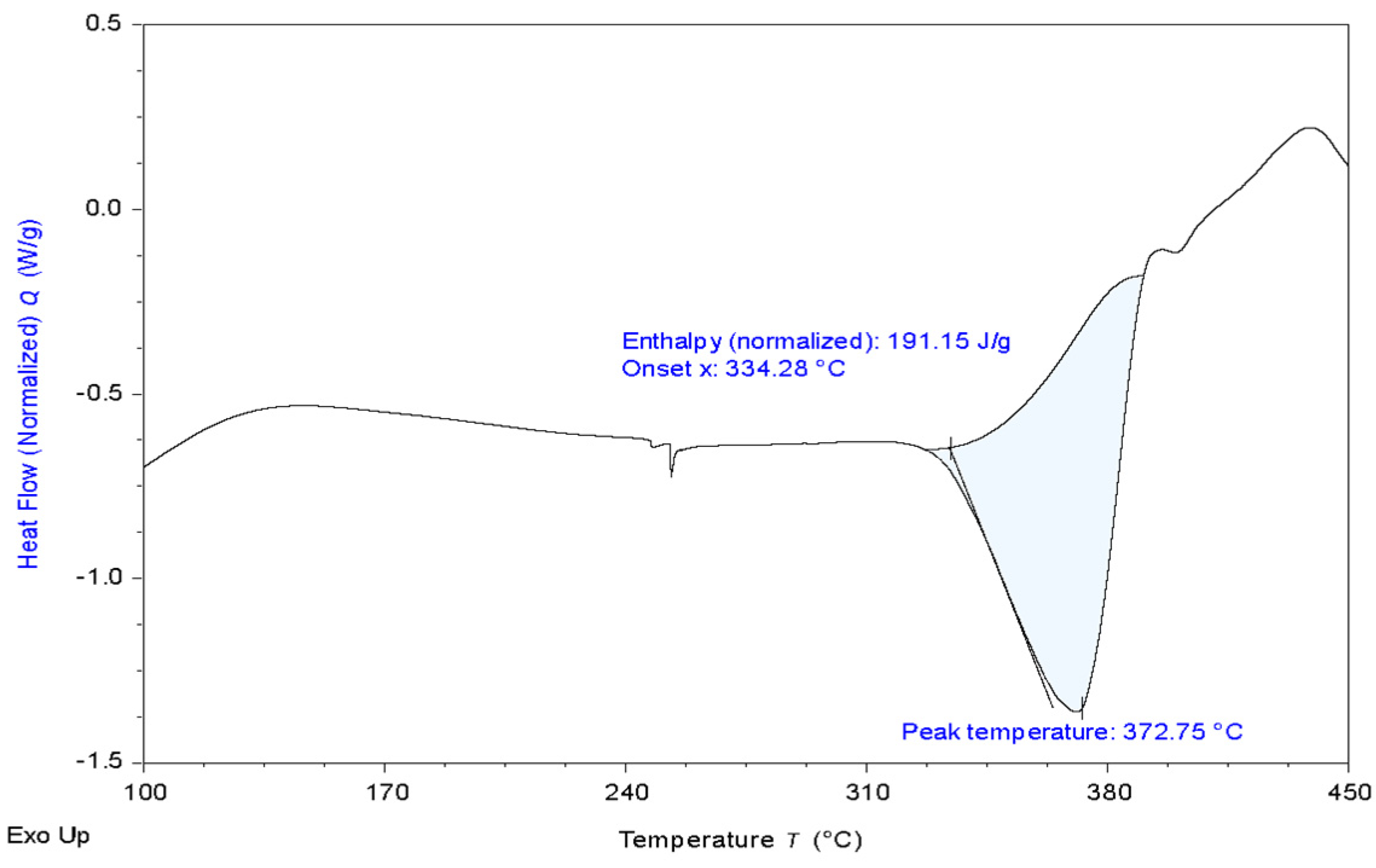

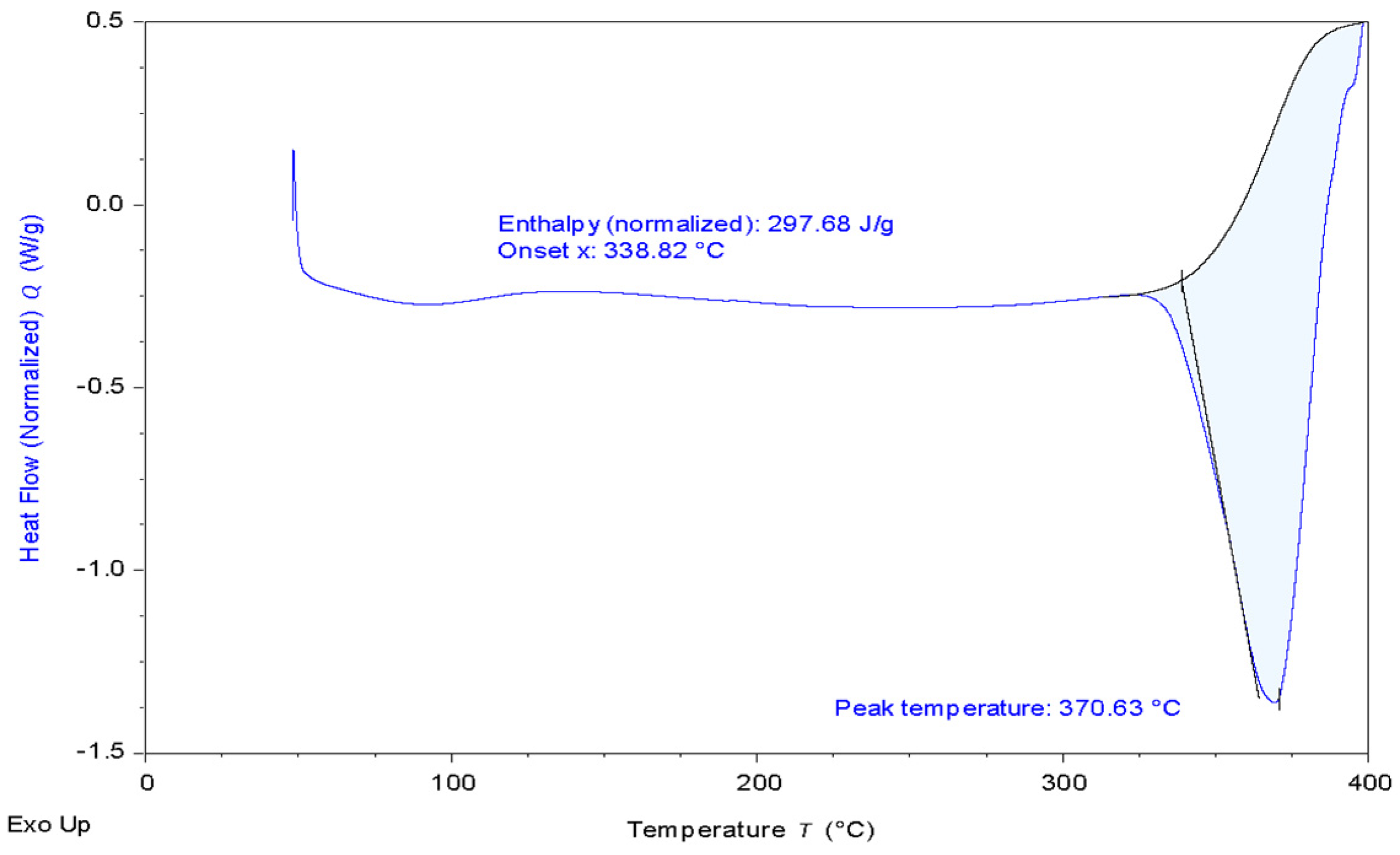

3.9. Differential Scanning Calorimetry DSC

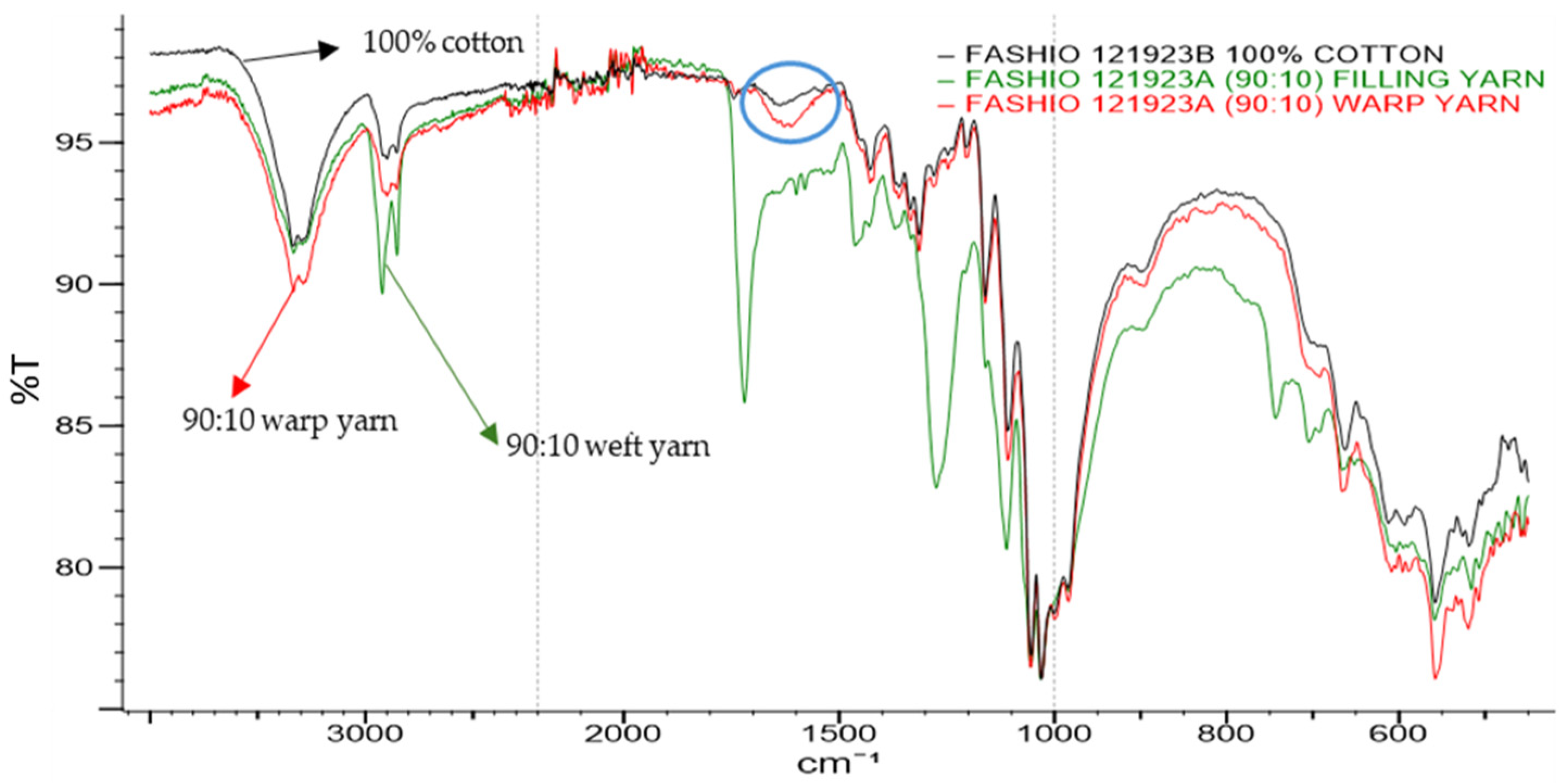

3.10. Fourier Transform Near-Infrared Spectroscopy (FTIR)

4. Discussion

4.1. Tensile Strength

4.2. Abrasion Resistance

4.3. Wrinkle Recovery Angle Test (WRA)

4.4. Dyeability

4.5. Thermal Insulation

4.6. Moisture Management Test

4.7. Shrinkage Test

4.8. Scanning Electron Micrograph SEM

4.9. Differential Scanning Calorimetry DSC

4.10. Fourier Transform Near-Infrared Spectroscopy FTIR

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arya, P.; Ghosh, S.; Das, D. Development of non-formaldehyde wrinkle resistant finish for cotton using carboxylic acids. Indian J. Fibre Text. Res. 2020, 45, 123–145. [Google Scholar]

- Mateo, C.P.; Van der Meer, Y.; Seide, G. Analysis of the polyester clothing value chain to identify key intervention points for sustainability. Environ. Sci. Eur. 2021, 33, 2. [Google Scholar] [CrossRef] [PubMed]

- Smelik, A. Polyester: A Cultural History. Fash. Pract. 2023, 15, 279–299. [Google Scholar] [CrossRef]

- Hsieh, Y.L. Chemical structure and properties of cotton. In Cotton: Science and Technology; Woodhead Publishing: Cambridge, UK, 2007; pp. 1–34. [Google Scholar]

- Kumar, P.; Ram, C.S.; Srivastava, J.P.; Behura, A.K.; Kumar, A. Synthesis of Cotton Fiber, and Its Structure. In Natural and Synthetic Fiber Reinforced Composites: Synthesis, Properties, and Applications, 1st ed.; Wiley Online Library: Hoboken, NJ, USA, 2022; pp. 17–36. [Google Scholar]

- Ansell, M.P.; Mwaikambo, L.Y. The structure of cotton and other plant fibres. In Handbook of Textile Fibre Structure Natural Regenerated, Inorganic and Specialist Fibres; Eichhorn, J.H.S.J., Ed.; Woodhead Publishing: Cambridge, UK, 2009; pp. 62–94. [Google Scholar]

- Lagorce-Tachon, A.; Mairesse, F.; Karbowiak, T.; Gougeon, R.D.; Bellat, J.-P.; Sliwa, T.; Simon, J.-M. Contribution of image processing for analyzing the cellular structure of cork. J. Chemom. 2018, 32, e2988. [Google Scholar] [CrossRef]

- Gil, L. Cork: A strategic material. Front. Chem. 2015, 1, 1–3. [Google Scholar] [CrossRef] [PubMed]

- Gil, L. New Cork-Based Materials and Applications. Materials 2015, 8, 625–637. [Google Scholar] [CrossRef] [PubMed]

- Uzun, M. Mechanical, sound absorption and thermal properties of cork fabric. Indian J. Fibre Text. Res. 2023, 48, 157–166. [Google Scholar]

- Pereira, H. Chemical composition and variability of cork from Quercus suber L. Wood Sci. Technol. 1988, 22, 211–218. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F.; Haley, B.A. Cellular Materials in Nature and Medicine; Cambridge University Press: Cambridge, UK, 2010; Available online: https://www.google.com/books/edition/Cellular_Materials_in_Nature_and_Medicin/AKxiS4AKpyEC?hl=en&gbpv=1&dq=Gibson,+L.J.%3B+Ashby,+M.F.%3B+Haley,+B.+Cellular+Materials+in+Nature+and+Medicine+.+2010.&pg=PR9&printsec=frontcover (accessed on 30 March 2024).

- Pereira, H. The Rationale behind Cork Properties: A Review of Structure and Chemistry. BioResources 2015, 10, 6207–6229. [Google Scholar] [CrossRef]

- Graca, J.; Pereira, H. Feruloyl Esters of a-Hydroxyacids in Cork Suberin. J. Wood Chem. Technol. 1998, 18, 207–217. [Google Scholar] [CrossRef]

- Graca, J. Suberin: The Biopolyester at the Frontier of Plants. Front. Chem. 2015, 3, 62. [Google Scholar] [CrossRef] [PubMed]

- Silva, S.P.; Sabino, M.A.; Fernandes, E.M.; Corello, V.M.; Boesel, L.F.; Reis, R.L. Cork: Properties, capabilities, and applications. Int. Mater. Rev. 2005, 50, 345–365. [Google Scholar] [CrossRef]

- Miranda, I.; Gominho, J.; Pereira, H. Cellular structure, and chemical composition of cork from the Chinese cork oak (Quercusvariabilis). J. Wood Sci. 2013, 59, 1–9. [Google Scholar] [CrossRef]

- Cordeiro, N.; Belgacem, N.M.; Gandini, A.; Pascoal Neto, C. Cork Suberin as a New Source of Chemicals: 2. Crystallinity, Thermal and Rheological Properties. Bioresour. Technol. 1998, 63, 153–158. [Google Scholar] [CrossRef]

- Leite, C.; Pereira, H. Cork-Containing Barks—A Review. Front. Mater. 2017, 3, 63. [Google Scholar] [CrossRef]

- Von Holle, B.; Delcourt, H.R.; Simberloff, D. The importance of biological inertia in plant community resistance to invasion. J. Veg. Sci. 2003, 14, 425–432. [Google Scholar] [CrossRef]

- Akhavan-Safar, A.; Barbosa, A.Q.; Silva, L.F.; Ayatollahi, M.R. Micro failure analysis of adhesively bonded joints enhanced with natural cork particles: Impact of overlap length and particles volume fraction. Frat. Ed Integrità Strutt. 2018, 46, 266–274. [Google Scholar] [CrossRef]

- Mestre, A.; Gil, L. Cork for Sustainable Product Design. Ciência Tecnol. Dos Mater. 2011, 23, 52–63. [Google Scholar]

- ASTM D4632; Standard Test Method for Grab Breaking Load and Elongation of Geotextiles. ASTM International: West Conshohocken, PN, USA, 2003.

- ASTM D3512; Standard Test Method for Pilling Resistance and Other Related Surface Changes of Textile Fabrics: Random Tumble Pilling Tester. ASTM International: West Conshohocken, PN, USA, 2022.

- Yamato, Y.; Kurazumi, Y.; Fukagawa, K.; Tobita, K.; Kondo, E. Assessment of method for measuring clo value using human body—Assessment of method for measuring clo value that assumes human body temperature adjustment. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 111, p. 06050. [Google Scholar]

- ASTM F1868; Standard Test Method for Thermal and Evaporative Resistance of Clothing Materials Using a Sweating Hot Plate. ASTM International: West Conshohocken, PN, USA, 2023.

- Alvaredo-Atienza, Á.; Chen, L.; San-Miguel, V.; Ridruejo, Á.; Fernández-Blázquez, J.P. Fabrication and Characterization of PEEK/PEI Multilayer Composites. Ploymers 2020, 12, 2765. [Google Scholar] [CrossRef]

- Chen, J.; Guo, Q.; Zhao, Z.; Wang, X.; Duan, C. Structures and Mechanical Properties of PEEK/PEI/PES Plastics Alloys Blent by Extrusion Molding Used for Cable Insulating Jacketing. Procedia Eng. 2012, 96, 96–104. [Google Scholar] [CrossRef]

- Doumeng, M.; Makhlouf, L.; Berthet, F.; Marsan, O.; Delbe, K.; Denape, J.; Chabert, F. A comparative study of the crystallinity of polyetheretherketone by using density, DSC, XRD, and Raman spectroscopy techniques. Polym. Test. 2021, 93, 106878. [Google Scholar] [CrossRef]

- Hergenrother, P.M. Recent Advances in High Temperature Polymers. Polym. J. 1987, 19, 73–83. [Google Scholar] [CrossRef]

- Ling, X.; Jing, X.; Zhang, C.; Chen, S. Polyether Ether Ketone (PEEK) Properties and Its Application Status. IOP Conf. Ser. Earth Environ. Sci. 2020, 453, e012080. [Google Scholar] [CrossRef]

- Wang, Y.; Cakmak, M. Ketone-Based Thermoplastics. In Handbook of Thermoplastics; CRC Press: Boca Raton, FL, USA, 2016; pp. 461–490. [Google Scholar]

- Chung, C.; Lee, M.; Choe, E.K. Characterization of cotton fabric scouring by FT-IR ATR spectroscopy. Carbohydr. Polym. 2004, 58, 417–420. [Google Scholar] [CrossRef]

- Costa, R.; Lourenço, A.; Oliveira, V.; Pereira, H. Chemical characterization of cork, phloem and wood from different Quercus suber provenances and trees. Heliyon 2019, 5, e02910. [Google Scholar] [CrossRef] [PubMed]

- Portella, E.H.; Romanzini, D.; Angrizani, C.C.; Amico, S.C.; Zattera, A.J. Influence of Stacking Sequence on the Mechanical and Dynamic Mechanical Properties of Cotton/Glass Fiber Reinforced Polyester Composites. Mater. Res. 2016, 19, 542–547. [Google Scholar] [CrossRef]

- Marques, A.V.; Pereira, H.; Rodrigues, J.; Meier, D.; Faix, O. Isolation and comparative characterization of a Björkman lignin from the saponified cork of Douglas-fir bark. J. Anal. Appl. Pyrolysis 2006, 77, 169–176. [Google Scholar] [CrossRef]

- Marques, A.V.; Pereira, H.; Meier, D.; Faix, O. Quantitative Analysis of Cork (Quercus suber L.) and Milled Cork Lignin by FTIR Spectroscopy, Analytical Pyroiysis, and Total Hydrolysis. Holzforschung 1994, 48, 43–50. [Google Scholar] [CrossRef]

- Prades, C.; Garc’ıa-Olmo, J.; Romero-Prieto, T.; GarcIa de Ceca, J.L.; Lopez-Luque, R. Methodology for cork plank characterization (Quercus suber L.) by near-infrared spectroscopy and image analysis. Meas. Sci. Technol. 2010, 21, 065602. [Google Scholar] [CrossRef]

- Abd El-Hady, M.M.; Farouk, A.; Sharaf, S. Multiwalled-Carbon-Nanotubes (MWCNTs)–GPTMS/Tannic-Acid-Nanocomposite-Coated Cotton Fabric for Sustainable Antibacterial Properties and Electrical Conductivity. Coatings 2022, 12, 178. [Google Scholar] [CrossRef]

- Abd El-Hady, M.M.; Sharaf, S.; Farouk, A. Highly hydrophobic and UV protective properties of cotton fabric using layer by layer self-assembly technique. Cellulose 2019, 27, 1099–1110. [Google Scholar] [CrossRef]

- Romanzini, D.; Junior, H.O.; Amico, S.C.; Zattera, A.J. Preparation and Characterization of Ramie-Glass Fiber Reinforced Polymer Matrix Hybrid Composites. Mater. Res. 2012, 15, 415–420. [Google Scholar] [CrossRef]

- IR Spectrum Table and Chart. From Photometry and Reflectrometry by Milipore Sigma. 2023. Available online: https://www.sigmaaldrich.com/US/en/technical-documents/technical-article/analytical-chemistry/photometry-and-reflectometry/ir-spectrum-table (accessed on 30 March 2024).

- Rosa, E.M.; Fortes, M.A. Water Absorption by Cork. Wood Fiber Sci. 1993, 24, 339–348. [Google Scholar]

| No. of Samples | 100% Cotton Muslin | 90:10 Cotton–Cork Blend | ||

|---|---|---|---|---|

| Warp (lbs.) | Weft (lbs.) | Warp (lbs.) | Weft (lbs.) | |

| 1 | 48.56 | 33.96 | 61.87 | 51.87 |

| 2 | 49.15 | 34.67 | 59.86 | 50.57 |

| 3 | 49.12 | 34.85 | 63.34 | 54.68 |

| 4 | 47.53 | 31.97 | 60.42 | 49.89 |

| Average | 48.59 | 33.86 | 61.37 | 51.75 |

| No. of Samples | 90:10 Cotton–Cork Blend | 100% Cotton | ||

|---|---|---|---|---|

| Warp (degree) | Weft (degree) | Warp (degree) | Weft (degree) | |

| 1 | 150 | 132 | 115 | 115 |

| 2 | 145 | 136 | 105 | 135 |

| 3 | 135 | 130 | 97 | 75 |

| 4 | 105 | 130 | 82 | 80 |

| 5 | 125 | 135 | 88 | 85 |

| 6 | 143 | 130 | 110 | 110 |

| Average | 133.8 | 132.2 | 99.5 | 100 |

| Wash Cycles | 100% Cotton Muslin | 90:10 Cotton–Cork Blend | ||||||

|---|---|---|---|---|---|---|---|---|

| Warp (inches) | Weft (inches) | % Shrinkage Warp | % Shrinkage Weft | Warp (inches) | Weft (inches) | % Shrinkage Warp | % Shrinkage Weft | |

| 0 | 5 | 5 | NA | NA | 5 | 5 | NA | NA |

| 1 | 4.95 | 4.8 | 0.25 | 1 | 4.9 | 4.95 | 0.5 | 0.25 |

| 2 | 4.85 | 4.95 | 0.75 | 0.25 | 4.9 | 4.8 | 0.5 | 1 |

| 3 | 4.85 | 4.95 | 0 | 0 | 4.85 | 4.75 | 0.75 | 1.25 |

| 4 | 4.85 | 4.95 | 0 | 0 | 4.85 | 4.75 | 0 | 0 |

| 5 | 4.85 | 4.95 | 0 | 0 | 4.85 | 4.75 | 0 | 0 |

| 6 | 4.85 | 4.95 | 0 | 0 | 4.85 | 4.75 | 0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arya, P.; Sarkar, A.K. Cotton–Cork Blended Fabric: An Innovative and Sustainable Apparel Textile for the Fashion Industry. Sustainability 2024, 16, 3098. https://doi.org/10.3390/su16083098

Arya P, Sarkar AK. Cotton–Cork Blended Fabric: An Innovative and Sustainable Apparel Textile for the Fashion Industry. Sustainability. 2024; 16(8):3098. https://doi.org/10.3390/su16083098

Chicago/Turabian StyleArya, Preeti, and Ajoy K. Sarkar. 2024. "Cotton–Cork Blended Fabric: An Innovative and Sustainable Apparel Textile for the Fashion Industry" Sustainability 16, no. 8: 3098. https://doi.org/10.3390/su16083098

APA StyleArya, P., & Sarkar, A. K. (2024). Cotton–Cork Blended Fabric: An Innovative and Sustainable Apparel Textile for the Fashion Industry. Sustainability, 16(8), 3098. https://doi.org/10.3390/su16083098