Driving Factors in Carbon Emission Reduction in Prefabricated Building Supply Chains Based on Structural Equation Modelling

Abstract

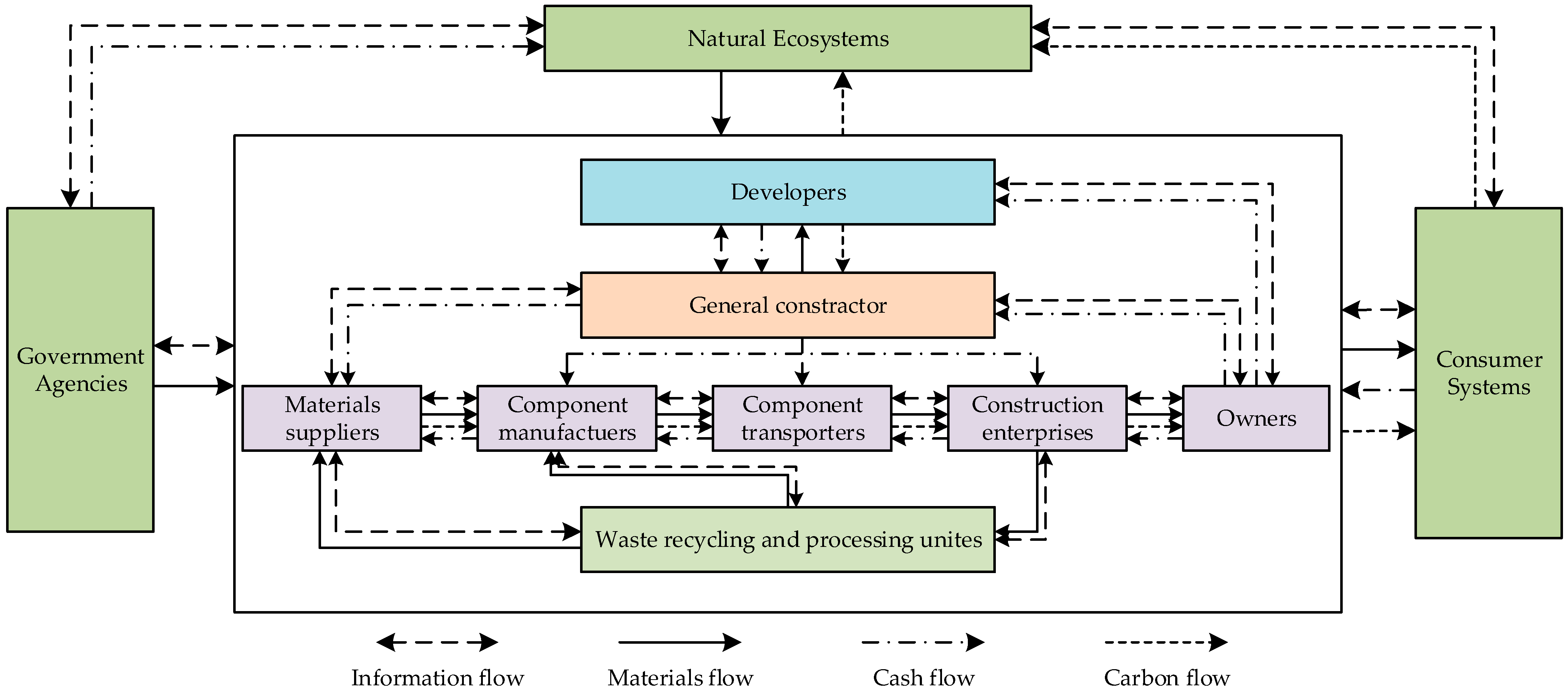

:1. Introduction

2. Literature Review

3. Materials and Methods

3.1. Structural Equation Modeling

| Primary Indicators | Secondary Indicators | Descriptions | References |

|---|---|---|---|

| Government-driven (GD) | Government subsidy policy (GD1) | Government subsidies can increase the carbon emission reduction rate of enterprises and increase the total carbon emissions of the reverse supply chain. | [37,38] |

| Government carbon emission cap standards (GD2) | Carbon emission quota policies and carbon emission tax policies are conducive to the expansion of enterprise scale, optimization, and upgrading of enterprises, thereby reducing carbon emissions. | [38] | |

| Government supervision (GD3) | The government supervises the behavior and emission parameters of PBSC companies. | [39] | |

| Market-driven (MD) | Low-carbon awareness of enterprise (MD1) | The trade-off between economic benefits and environmental benefits of participating companies in PBSCs. | [40,41] |

| Low-carbon awareness of user (MD2) | Increased environmental awareness among users increases the carbon emission reduction rate. | [42] | |

| Low-carbon construction costs (MD3) | The lower the cost of low-carbon construction, the higher the likelihood that companies will adopt low-carbon behaviors. | [33] | |

| Competition among enterprises (MD4) | Companies take more carbon emission reduction measures to maintain market competitiveness. | [43] | |

| Prefabrication rate (MD5) | The higher the prefabrication rate, the more obvious the environmental benefits of PBs. | [44] | |

| Economic-driven (ED) | Regional economic development level (ED1) | The level of regional economic level affects the scale of PBs, thereby affecting the carbon emission reduction efforts of PBs. | [45] |

| Technology R&D capital investment (ED2) | Capital investment affects the research and development of innovative technologies, which in turn affects the efficiency of carbon emission reduction. | [46] | |

| Corporate capital flow (ED3) | The capital liquidity of enterprises affects the choice of low-carbon behaviors of enterprises. | [47] | |

| Clean energy usage funds (TD4) | Use clean energy to produce energy to improve the emission reduction efficiency of PBs. | [6] | |

| Technology-driven (TD) | Standardized design level (TD1) | A higher level of standardized design can effectively reduce resource consumption. | [48] |

| Low-carbon production technology (TD2) | Adopt production processes that reduce raw material loss and pollution during the production process. | [49] | |

| Level of recycling of building materials (TD2) | Recycling of building materials can reduce waste of resources | [41] | |

| Low-carbon construction technology (TD4) | Adopting low-carbon construction can reduce carbon emissions during the construction phase. | [50] | |

| Low carbon design of building structure (TD5) | Building structure design affects carbon emissions during building use, such as adaptability, durability, etc. | [49,51] | |

| Supply chain coordination-driven (SCCD) | Low-carbon leadership of core enterprises (SCDD1) | Construction units control corporate low-carbon behavior over their corporate low-carbon leadership. | [41] |

| PBSC enterprise information sharing (SCDD2) | Good information sharing and communication among PBSC companies can effectively help companies choose the best low-carbon measures. | [52] | |

| PBSC enterprise logistics and transportation level (GD3) | Efficient logistics and transportation can effectively reduce energy consumption and reduce the impact on the environment. | [17] | |

| Carbon emission reduction in PBSCs (CEPBSCs) | Direct carbon emission reduction (DCE) | Direct carbon reduction reduces the amount of carbon emissions released into the environment by affecting construction production activities. | [53] |

| Indirect carbon emission reduction (ICE) | Indirect carbon emission reduction reduces carbon emissions by affecting the production activities of other industries. |

3.2. PBSCs Carbon Emission-Reduction Driving Factor Indicator System

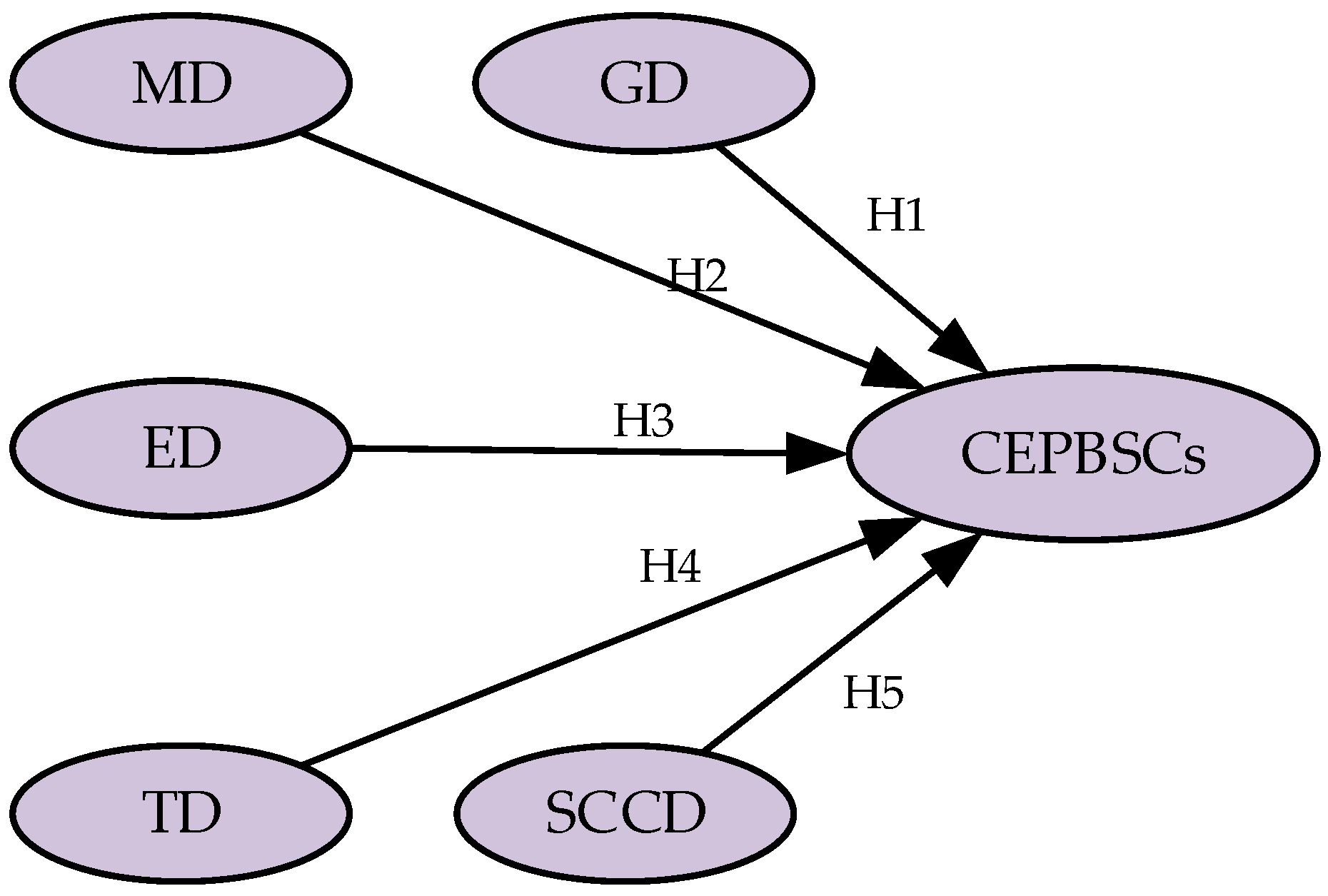

3.3. Research Hypothesis

3.3.1. Government-Driven Dimension

3.3.2. Market-Driven Dimension

3.3.3. Economic-Driven Dimension

3.3.4. Technology-Driven Dimension

3.3.5. Supply Chain Coordination-Driven Dimension

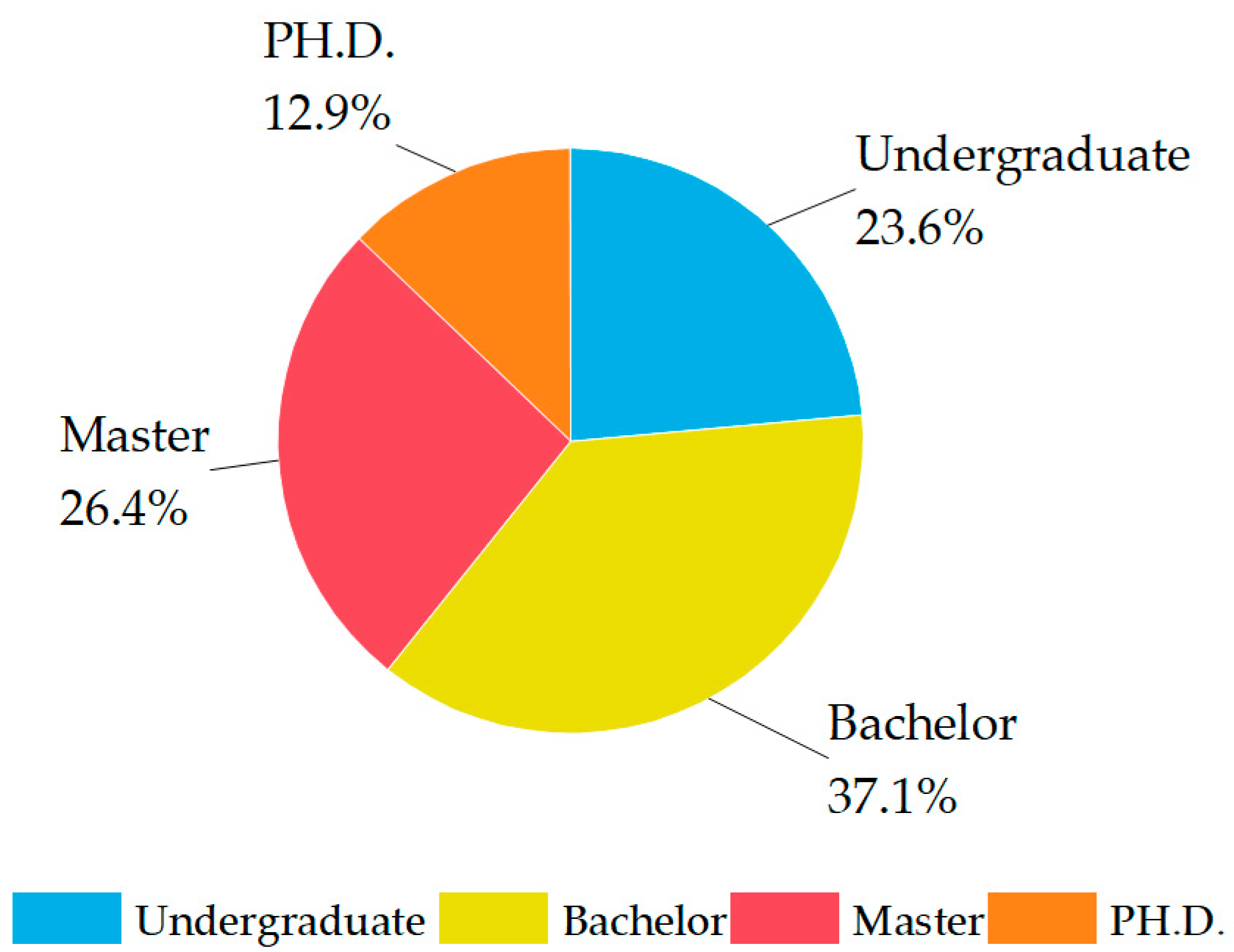

3.4. Data Collection

3.5. Data Analysis

3.5.1. Component Analysis

3.5.2. Reliability and Validity Test

4. Results

4.1. Model and Path Assumption Results

4.2. Weight Analysis of Driving Factors for Carbon Emission Reduction through PBSCs

5. Discussion

5.1. Technology-Driven Dimension

5.2. Economic-Driven Dimension

5.3. Market-Driven Dimension

5.4. Government-Driven Dimension

5.5. Supply Chain Coordination-Driven Dimension

5.6. Suggestions on Carbon Emission-Reduction Drive for PBSCs

6. Conclusions

- (1)

- Through literature analysis and field research combined with the PEST theory, a total of 20 driving factors for carbon emission reduction through PBSCs were identified from the five dimensions of government, market, economy, technology, and supply chain coordination. A hypothetical model of carbon emission reduction through PBSCs was established, and a questionnaire was designed. Principal component analysis and reliability and validity testing were used to verify the rationality of the questionnaire and the collected data. Finally, the driving factors for carbon emission reduction through PBSCs were summarized.

- (2)

- Based on the research hypothesis, SEM of the carbon emission-reduction driving forces of PBSCs was established. The model passed the fitness test and verified that the five proposed hypotheses were all true. Through quantitative analysis of the path coefficients, it was concluded that the importances of the driving factors for carbon emission reduction through PBSCs is as follows: technology-driven > economic-driven > market-driven > government-driven > supply chain coordination-driven. The weight calculation of the direct indicators of driving factors found that standardized design level, low-carbon design of building structure, technology R&D capital investment, low-carbon construction costs, and government subsidy policy are the main driving factors for carbon emission reduction through PBSCs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Part 1 | ||||

| 1. What is your age? | A. 20–30 years old | B. 31–40 years old | C. 41–50 years old | D. over 50 years old |

| 2. What is your academic qualification? | A. Undergraduate | B. Bachelor | C. Master | D. PH.D. |

| 3. How many years have you been engaged in work (research) related to PBs? | A. 1–2 years | B. 3–4 years | C. 5–6 years | D. 7 years and above |

| 4. What is your workplace? | A. Government department | B. Manufacturer of PB-components | C. Universities | |

| D. Construction | E. Design institutes | F. Owner’s | G. Others | |

| Part 2 | ||||

| Importance rating scale | 1-extremely low; 2-very low; 3-low; 4-medium; 5-high; 6 very high; 7-extremely high | |||

| Government-Driven | ||||

| 1. How important do you think the government subsidy policy is to the carbon emission reduction of the PBSCs? | ||||

| 2. How important do you think the government carbon emission cap standards is to the carbon emission reduction of the PBSCs? | ||||

| 3. How important do you think the government supervision is to the carbon emission reduction of the PBSCs? | ||||

| Market-Driven | ||||

| 1. How important do you think the low-carbon awareness of enterprise is to the carbon emission reduction of the PBSCs? | ||||

| 2. How important do you think the low-carbon awareness of user is to the carbon emission reduction of the PBSCs? | ||||

| 3. How important do you think the low-carbon construction costs is to the carbon emission reduction of the PBSCs? | ||||

| 4. How important do you think the competition among enterprises is to the carbon emission reduction of the PBSCs? | ||||

| 5. How important do you think the prefabrication rate is to the carbon emission reduction of the PBSCs? | ||||

| Economic-Driven | ||||

| 1. How important do you think the regional economic development level is to the carbon emission reduction of the PBSCs? | ||||

| 2. How important do you think the technology R&D capital investment is to the carbon emission reduction of the PBSCs? | ||||

| 3. How important do you think the corporate capital flow is to the carbon emission reduction of the PBSCs? | ||||

| 4. How important do you think the clean energy usage funds is to the carbon emission reduction of the PBSCs? | ||||

| Technology-Driven | ||||

| 1. How important do you think the standardized design level is to the carbon emission reduction of the PBSCs? | ||||

| 2. How important do you think the low-carbon production technology is to the carbon emission reduction of the PBSCs? | ||||

| 3. How important do you think the level of recycling of building materials is to the carbon emission reduction of the PBSCs? | ||||

| 4. How important do you think the low-carbon construction technology is to the carbon emission reduction of the PBSCs? | ||||

| 5. How important do you think the low carbon design of building structure is to the carbon emission reduction of the PBSCs? | ||||

| Supply chain coordination-Driven | ||||

| 1. How important do you think the low-carbon leadership of core enterprises is to the carbon emission reduction of the PBSCs? | ||||

| 2. How important do you think the PBSCs enterprise information sharing is to the carbon emission reduction of the PBSCs? | ||||

| 3. How important do you think the enterprise logistics and transportation level is to the carbon emission reduction of the PBSCs? | ||||

| 1.What do you think are the direct carbon emission reduction benefits of the PBSCs? | ||||

| 2. What do you think are the indirect carbon emission reduction benefits of the PBSCs? | ||||

References

- Dai, D.; Wang, Y. Research on the coordination of government subsidies, carbon emission reduction and pricing in multi-cycle supply chains under the “dual carbon” goal. Comput. Integr. Manuf. Syst. 2023, 1, 22. [Google Scholar]

- Zheng, X.; Xu, X. Research on carbon emissions in the whole life cycle of prefabricated buildings based on LCA: A case study of a light steel prefabricated integrated villa in Chongqing. Constr. Econ. 2019, 40, 107–111. [Google Scholar]

- Cao, X.; Miao, C.; Pan, H. Comparative analysis and research on carbon emissions of prefabricated concrete and cast-in-place buildings based on carbon emission model. Build. Struct. 2021, 51 (Suppl. S2), 1233–1237. [Google Scholar]

- Li, J.; Liu, S. Research on carbon footprint evaluation of prefabricated concrete in the building stage. Constr. Econ. 2021, 42, 101–105. [Google Scholar]

- Li, M.; Chen, W.; Li, L. Research on carbon emission calculation and influencing factors in the stage of prefabricated buildings. J. Saf. Environ. 2023, 1, 10. [Google Scholar]

- Du, Q.; Pang, Q.; Bao, T. Critical factors influencing carbon emissions of prefabricated building supply chains in China. J. Clean. Prod. 2021, 280, 124398. [Google Scholar] [CrossRef]

- Li, D.; Wang, Y. The construction unit takes the initiative to adopt the driving and hindrance factors of prefabricated buildings. J. Civ. Eng. Manag. 2019, 36, 7–11. [Google Scholar]

- Sun, S.; Chen, Y.; Wang, A. An Evaluation Model of Carbon Emission Reduction Effect of Prefabricated Buildings Based on Cloud Model from the Perspective of Construction Supply Chain. Buildings 2022, 12, 1534. [Google Scholar] [CrossRef]

- Zhang, R.; Li, L. Research on Evolutionary Game and Simulation of Information Sharing in Prefabricated Building Supply Chain. Sustainability 2023, 15, 9885. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, W.; He, K. Research on the distribution of benefits in the green supply chain of prefabricated buildings. Constr. Econ. 2023, 44, 79–87. [Google Scholar] [CrossRef]

- Wang, X.; Du, Q.; Li, C. Exploration in carbon emission reduction effect of low-carbon practices in prefabricated building supply chain. J. Clean. Prod. 2022, 368, 133153. [Google Scholar] [CrossRef]

- Xiao, Z.; Zhang, S.; Feng, J. Evolutionary game of information sharing in prefabricated building supply chain based on blockchain technology. J. Civ. Eng. Manag. 2023, 40, 91–97. [Google Scholar]

- Gao, Y.; Li, Z.; Zhang, H. Carbon emission analysis of the whole process of prefabricated building construction based on LCA. J. Eng. Manag. 2018, 32, 30–34. [Google Scholar]

- Du, Q.; Yang, M.; Wang, Y. Dynamic simulation for carbon emission reduction effects of the prefabricated building supply chain under environmental policies. Sustain. Cities Soc. 2024, 100, 105027. [Google Scholar] [CrossRef]

- Wu, L.; Ye, K.; Makarand, H. A comparison study on environmental policies for expressway construction projects between China and the US: A tiered analysis approach. J. Environ. Manag. 2022, 305, 114298. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Yu, S. Research on the driving mechanism and influencing path of green building development based on SEM. J. Civ. Eng. Manag. 2021, 38, 91–97. [Google Scholar]

- Dong, S.; Wang, L.; Huang, Y. Research on carbon emissions in the logistics and distribution process of prefabricated building prefabricated components. Logist. Sci-Tech 2023, 46, 17–21. [Google Scholar]

- Xie, W.; Li, X.; Yang, T. Research on carbon emission measurement in the construction stage of prefabricated buildings. J. Eng. Manag. 2022, 36, 52–57. [Google Scholar]

- Sun, Y.; Liu, J.; Xia, B. Research on carbon emission evaluation in the stage of prefabricated buildings. J. Shenyang Jianzhu Univ. (Nat. Sci.) 2018, 34, 881–888. [Google Scholar]

- Xu, K.; Kang, H.; Wang, W. Carbon Emission Estimation of Assembled Composite Concrete Beams during Construction. Energies 2021, 14, 1810. [Google Scholar] [CrossRef]

- Omar, W.; Doh, J.; Panuwatwanich, K. Assessment of the embodied carbon in precast concrete wall panels using a hybrid life cycle assessment approach in Malaysia. Sustain. Cities Soc. 2014, 10, 101–111. [Google Scholar] [CrossRef]

- Pons, O.; Wadel, G. Environmental impacts of prefabricated school buildings in Catalonia. Habitat Int. 2011, 35, 553–563. [Google Scholar] [CrossRef]

- Waltho, C.; Elhedhli, S.; Gzara, F. Green supply chain network design: A review focused on policy adoption and emission quantification. Int. J. Prod. Econ. 2019, 208, 305–318. [Google Scholar] [CrossRef]

- Ding, X.; Xu, X.; Wang, Q. Research on the influencing factors of carbon emission of prefabricated buildings based on DPSIR and improved TOPSIS model. J. Eng. Manag. 2022, 36, 47–51. [Google Scholar]

- Liu, Z.; Zhang, Y.; Ouyang, H. Sustainability evaluation of prefabricated building supply chain based on cloud-matter-element theory. J. Civ. Eng. Manag. 2020, 37, 109–115. [Google Scholar]

- Gao, D.; Zhang, Y.; Ouyang, H. Sustainable development analysis of prefabricated buildings from the perspective of supply chain management. J. Eng. Manag. 2019, 33, 15–20. [Google Scholar]

- Khan, M.; Hussain, M.; Saber, M. Information sharing in a sustainable supply chain. Int. J. Prod. Econ. 2016, 181, 208–214. [Google Scholar] [CrossRef]

- Zhang, L.; Wei, W.; Chen, L. Evaluation of Hidden Cost Risk of Prefabricated Construction Based on SEM-MEECM. Appl. Sci. 2023, 13, 7902. [Google Scholar] [CrossRef]

- Zhang, J.; Wei, W.; Chen, K. Research on the evaluation of implicit cost control level of prefabricated buildings based on SEM-MEA. Build. Sci. 2023, 39, 202–210. [Google Scholar]

- Chen, W.; Wu, Y.; Zhou, S. Analysis of influencing factors of prefabricated building construction cost based on SEM. J. Civ. Eng. Manag. 2019, 36, 50–55. [Google Scholar]

- Ding, X.; Xu, X.; Wang, Q. Research on the influencing factors of carbon emission reduction of prefabricated building prefabricated components based on SEM. Build. Energy Effic. 2023, 51, 123–128. [Google Scholar]

- Dai, H.; Qin, Y. Delphi-ISM-MICMAC based correlation study of constraints on the promotion of prefabricated concrete buildings. J. Beijing Univ. Archit. 2020, 36, 85–94. [Google Scholar]

- Sun, H.; Fang, Y.; Yin, M. Research on the Restrictive Factors of Vigorous Promotion of Prefabricated Buildings in Yancheng under the Background of “Double Carbon”. Sustainability 2023, 15, 1737. [Google Scholar] [CrossRef]

- Grace, B.; Schoolmaster, D.R., Jr.; Guntenspergen, G.R.; Little, A.M.; Mitchell, B.R.; Miller, K.M.; Schweiger, E.W. Guidelines for a graph-theoretic implementation of structural equation modeling. Synth. Integr. 2012, 3, 1–44. [Google Scholar] [CrossRef]

- Wang, Q.; Pan, M.; Guo, X. Research on the formation mechanism of green railroad construction capacity based on structural equation modeling. J. Railw. Sci. Eng. 2024, 21, 1–9. [Google Scholar] [CrossRef]

- Wu, M. Structural Equation Modeling-AMOS Operations and Applications, 1st ed.; Chongqing University Publishing House: Chongqing, China, 2013; pp. 1–45. [Google Scholar]

- Jiang, L.; Tang, J.; Rao, W. The impact of reward and punishment mechanism on carbon emission reduction and recycling price in reverse supply chain from the perspective of carbon neutrality. J. Ind. Eng. Eng. Manag. 2024, 2, 1–18. [Google Scholar]

- Karlsson, I.; Rootzén, J.; Johnsson, F. Reaching net-zero carbon emissions in construction supply chains -Analysis of a Swedish road construction project. Renew. Sustain. Energy Rev. 2020, 120, 109651. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, W.; Yuan, Y. An Integrated Carbon Policy-Based Interactive Strategy for Carbon Reduction and Economic Development in a Construction Material Supply Chain. Sustainability 2017, 9, 2107. [Google Scholar] [CrossRef]

- An, H.; Kuang, Y.; Yang, W. Analysis of the motivation of prefabricated building supply chain integration based on SEM. J. Civ. Eng. Manag. 2020, 37, 50–56. [Google Scholar]

- Liu, J.; Liu, X.; Li, Z. Research on the influencing factors of carbon emission in the stage of modular integration of buildings from the perspective of stakeholders. J. Saf. Environ. 2023, 1–12. [Google Scholar] [CrossRef]

- Zhao, Y.; Sun, S.; Liu, L. Research on the driving factors and paths of carbon emission reduction of prefabricated buildings. Constr. Econ. 2022, 40, 90–95. [Google Scholar]

- Luthra, S.; Garg, D.; Haleem, A. The impacts of critical success factors for implementing green supply chain management towards sustainability: An empirical investigation of Indian automobile industry. J. Clean. Prod. 2016, 121, 146–158. [Google Scholar] [CrossRef]

- Guo, F.; Zhang, Y.; Chang, Y. Carbon Emissions of Assembly Buildings Constrained by Flexible Resource: A Study on Cost Optimization. Buildings 2022, 13, 90. [Google Scholar] [CrossRef]

- Pan, Y.; Wu, S. Research on the Mechanism of Improving the Landing Effect of Assembly Building Based on System Dynamics--Taking Jiangsu Province as an Example. Constr. Econ. 2020, 40. [Google Scholar] [CrossRef]

- Zhu, R.; Li, L. SEM-Based Analysis of Carbon Emission Reduction Pathway Study during the Materialization Stage of Prefabricated Buildings: Evidence from Shenyang and Guiyang, China. J. Environ. Public Health 2022, 2022, 9721446. [Google Scholar] [CrossRef] [PubMed]

- Qin, J.; Han, Y.; Wei, G. The value of advance payment financing to carbon emission reduction and production in a supply chain with game theory analysis. Int. J. Prod. Res. 2020, 558, 2200–2219. [Google Scholar] [CrossRef]

- Sun, H.; Liu, Q.; Li, Y. Factors Influencing Carbon Emissions of Assembled Building Construction Enterprises. J. Sustain. Dev. Green Build. 2023, 1, 1–7. [Google Scholar]

- Chen, H.; Zhou, Y.; Feng, W. Factors That Influence the Quantification of the Embodied Carbon Emission of Prefabricated Buildings: A Systematic Review, Meta-Analysis and the Way Forward. Buildings 2022, 12, 1265. [Google Scholar] [CrossRef]

- Sun, S.; Chen, Y.; Ma, L. Analysis of the contribution factors of prefabricated buildings based on the theory of carbon neutrality. Concrete 2022, 11, 133–137. [Google Scholar]

- Zhao, Y.; Sun, Q.; Wei, W. Research on the impact of building structure design on carbon emissions. Build. Struct. 2023, 53, 19–23. [Google Scholar]

- Mei, T.; Qin, Y.; Li, P. Influence Mechanism of Construction Supply Chain Information Collaboration Based on Structural Equation Model. Sustainability 2023, 15, 2155. [Google Scholar] [CrossRef]

- Sun, Y.; Hao, S.; Long, X. A study on the measurement and influencing factors of carbon emissions in China’s construction sector. Build. Environ. 2023, 229, 109912. [Google Scholar] [CrossRef]

- Li, W.; Zhang, T.; Liu, M. Simulation of prefabricated building industry policy and evaluation of energy conservation and emission reduction benefits based on system dynamics. Ind. Constr. 2022, 52, 196–205. [Google Scholar]

- Chen, T.; Ling, W.; Wang, L. Research on low-carbon behavior decision-making of chemical enterprises based on carbon trading and green credit. Chin. J. Manag. Sci. 2023, 1–14. [Google Scholar] [CrossRef]

- Sun, J.; Lu, Y.; Teng, C. Research on the impact of blockchain technology on low-carbon supply chain cooperation strategy. Chin. J. Manag. Sci. 2023, 1–15. [Google Scholar] [CrossRef]

- Wu, Z.; Huang, H.; Chen, X. Research on the low-carbon transformation countermeasures of the construction industry under the “dual carbon” goal. Strateg. Study CAE 2023, 25, 202–209. [Google Scholar] [CrossRef]

- Dai, D.; Wang, Y. Research on the coordinated decision-making of carbon emission reduction in multi-cycle supply chain under the “dual carbon” goal. J. Chongqing Technol. Bus. Univ. (Nat. Sci. Ed.) 2023, 40, 1–8. [Google Scholar]

- Brown, J. Likert items and scales of measurement. Statistics 2011, 15, 10–14. [Google Scholar]

- Lefcheck, S. Piecewise SEM: Piecewise structural equation modelling in r for ecology, evolution, and systematics. Methods Ecol. Evol. 2016, 7, 573–579. [Google Scholar] [CrossRef]

- Yang, X.; Peng, D.; Xie, F. Research on the Impact of Perceived Risk Perception on User Trust and Behavior Based on TAM/TPB: A Case Study of Yu’e Bao, a Payment Value-added Product. Manag. Rev. 2016, 28, 21–27. [Google Scholar]

- Li, J.; Liu, Y. Calculation model of carbon emissions of construction projects based on the whole life cycle. J. Eng. Manag. 2015, 29, 12–16. [Google Scholar]

- Wu, L.; Li, S.; Liao, C. Analysis and research of carbon emissions in the whole process of prefabricated building construction. Constr. Technol. 2023, 52, 81–86. [Google Scholar]

- Wang, Y.; Zhao, J.; Gao, N. Application of intelligent construction technology in EPC mode of prefabricated buildings and research on carbon emissions. Concrete 2023, 1–8. Available online: https://kns.cnki.net/kcms2/article/abstract?v=ttOPOQ75YvLjuyGwSxxsubJ-zc1-MhzEq7lwiwt9GM6XX7YYK6t8sT5JCF89JYSwRi0R5hcBbQuQPNvBCemrILEj4RYqgqU9Ac2HBzWoZkoMBeki5cBSCrL2ieZtbO3exJtLiUgGCYk=&%20uniplatform=NZKPT (accessed on 10 December 2023).

- Saeed, H.; Aame, M.; Rehan, M. A multi-facet BIM based approach for Green Building design of new multi-family residential building using LEED system. Int. J. Constr. Manag. 2023, 23, 2024–2038. [Google Scholar]

- Yang, H.; Liu, Y.; Wang, Y. Analysis of the sustainable development direction of prefabricated buildings based on lean construction. Constr. Econ. 2023, 44, 89–96. [Google Scholar]

- Yazeed, A.; Krishanu, R.; Liang, H. Thermal performance of different construction materials used in New Zealand dwellings comparatively to international practice—A systematic literature review. J. Build. Eng. 2023, 72, 106346. [Google Scholar]

- Fang, L.; Tang, H. The Effect of Carbon Emission Trading on Corporate Carbon Emission Reduction: A Quasi-Natural Reality Based on the Data of Chinese Listed Companies. J. Shaanxi Norm. Univ. (Philos. Soc. Sci. Ed.) 2022, 51, 14–29. [Google Scholar]

- An, M.; Liu, M.; Wu, H. Research on the carbon emission reduction effect of prefabricated building demonstration city policy on the construction industry and its mechanism. Acta Sci. Circumstantiae 2024, 44, 1–13. [Google Scholar]

- Qi, B.; Zhu, Y.; Ma, B. Research on the comprehensive benefit analysis method of prefabricated buildings. Constr. Technol. 2016, 45, 39–43. [Google Scholar]

| KMO Sampling Suitability Quantity | 0.751 | |

| Bartlett’s test of sphericity | Approximate chi-square | 3221.699 |

| degrees of freedom | 231 | |

| Significance | 0.000 | |

| No. | Initial Eigenvalue | Extraction Sums of Squared Loadings | Rotation Sums of Squared Loadings | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Total | Percentage Variance/% | Sum/% | Total | Percentage Variance/% | Sum/% | Total | Percentage Variance/% | Sum/% | |

| 1 | 3.678 | 16.717 | 16.717 | 3.678 | 16.717 | 16.717 | 3.497 | 15.895 | 15.895 |

| 2 | 3.218 | 14.627 | 31.344 | 3.218 | 14.627 | 31.344 | 3.209 | 14.587 | 30.481 |

| 3 | 3.079 | 13.994 | 45.338 | 3.079 | 13.994 | 45.338 | 3.080 | 14.000 | 44.482 |

| 4 | 2.298 | 10.446 | 55.784 | 2.298 | 10.446 | 55.784 | 2.398 | 10.901 | 55.383 |

| 5 | 2.251 | 10.234 | 66.018 | 2.251 | 10.234 | 66.018 | 2.283 | 10.376 | 65.759 |

| 6 | 1.581 | 7.188 | 73.206 | 1.581 | 7.188 | 73.206 | 1.638 | 7.447 | 73.206 |

| 7 | 0.704 | 3.198 | 76.404 | ||||||

| …… | |||||||||

| Latent Variable | Item | Factor Loadings | CR | AVE | Cronbach’s Alpha |

|---|---|---|---|---|---|

| GD | GD1 | 0.718 | 0.898 | 0.7485 | 0.828 |

| GD2 | 0.936 | ||||

| GD3 | 0.924 | ||||

| MD | MD1 | 0.806 | 0.8969 | 0.6352 | 0.856 |

| MD2 | 0.831 | ||||

| MD3 | 0.812 | ||||

| MD4 | 0.763 | ||||

| MD5 | 0.771 | ||||

| ED | ED1 | 0.886 | 0.9291 | 0.7661 | 0.898 |

| ED2 | 0.876 | ||||

| ED3 | 0.868 | ||||

| ED4 | 0.871 | ||||

| TD | TD1 | 0.830 | 0.918 | 0.6915 | 0.890 |

| TD2 | 0.814 | ||||

| TD3 | 0.817 | ||||

| TD4 | 0.837 | ||||

| TD5 | 0.859 | ||||

| SCCD | SCCD1 | 0.868 | 0.9134 | 0.7786 | 0.865 |

| SCCD2 | 0.888 | ||||

| SCCD3 | 0.891 | ||||

| CEPBSCs | DCE | 0.885 | 0.884 | 0.7921 | 0.759 |

| ICE | 0.895 |

| AVE | GD | MD | ED | TD | SCCD | CEPBSCs | |

|---|---|---|---|---|---|---|---|

| GD | 0.7485 | 0.865 | |||||

| MD | 0.6352 | 0.570 | 0.797 | ||||

| ED | 0.7661 | 0.492 | 0.480 | 0.875 | |||

| TD | 0.6915 | 0.577 | 0.525 | 0.504 | 0.832 | ||

| SCCD | 0.7786 | 0.478 | 0.496 | 0.502 | 0.439 | 0.882 | |

| CEPBSCs | 0.7921 | 0.594 | 0.578 | 0.554 | 0.568 | 0.592 | 0.890 |

| Index | Absolute Fitness | Value-Added Fitness | Simple Fitness | |||||

|---|---|---|---|---|---|---|---|---|

| χ2/d.f. | GFI | RMSEA | NFI | IFI | CFI | PGFI | PNFI | |

| Recommendations | <3.000 | >0.900 | <0.100 | >0.900 | >0.900 | >0.900 | >0.500 | >0.500 |

| Initial model | 2.460 | 0.840 | 0.073 | 0.849 | 0.832 | 0.870 | 0.754 | 0.783 |

| Judgment of fitness | Yes | No | Yes | No | No | No | Yes | Yes |

| Modified model | 1.584 | 0.910 | 0.063 | 0.905 | 0.942 | 0.942 | 0.760 | 0.787 |

| Judgment of fitness | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Hypotheses | Relationship | Standardized Factor Loadings | p-Value | Support |

|---|---|---|---|---|

| H1 | GD→CEPBSCs | 0.337 | *** | yes |

| H2 | MD→CEPBSCs | 0.413 | 0.004 | yes |

| H3 | ED→CEPBSCs | 0.452 | 0.007 | yes |

| H4 | TD→CEPBSCs | 0.488 | *** | yes |

| H5 | SCCD→CEPBSCs | 0.297 | 0.023 | yes |

| Latent Variable | First-Level Weight | Sort | Item | Second-Level Weight | Sort |

|---|---|---|---|---|---|

| GD | 0.171 | 4 | GD1 | 0.387 | 1 |

| GD2 | 0.287 | 3 | |||

| GD3 | 0.326 | 2 | |||

| MD | 0.206 | 3 | MD1 | 0.192 | 4 |

| MD2 | 0.212 | 2 | |||

| MD3 | 0.217 | 1 | |||

| MD4 | 0.176 | 5 | |||

| MD5 | 0.202 | 3 | |||

| ED | 0.226 | 2 | ED1 | 0.232 | 4 |

| ED2 | 0.281 | 1 | |||

| ED3 | 0.225 | 3 | |||

| ED4 | 0.261 | 2 | |||

| TD | 0.246 | 1 | TD1 | 0.209 | 1 |

| TD2 | 0.195 | 4 | |||

| TD3 | 0.202 | 3 | |||

| TD4 | 0.188 | 5 | |||

| TD5 | 0.205 | 2 | |||

| SCCD | 0.151 | 5 | SCCD1 | 0.354 | 1 |

| SCCD2 | 0.309 | 3 | |||

| SCCD3 | 0.336 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.; Fan, G.; Liu, Z. Driving Factors in Carbon Emission Reduction in Prefabricated Building Supply Chains Based on Structural Equation Modelling. Sustainability 2024, 16, 3150. https://doi.org/10.3390/su16083150

Liu W, Fan G, Liu Z. Driving Factors in Carbon Emission Reduction in Prefabricated Building Supply Chains Based on Structural Equation Modelling. Sustainability. 2024; 16(8):3150. https://doi.org/10.3390/su16083150

Chicago/Turabian StyleLiu, Wei, Guohao Fan, and Zixuan Liu. 2024. "Driving Factors in Carbon Emission Reduction in Prefabricated Building Supply Chains Based on Structural Equation Modelling" Sustainability 16, no. 8: 3150. https://doi.org/10.3390/su16083150