Bioreceptive Ceramic Surfaces: Material Experimentations for Responsible Research and Design Innovation in Circular Economy Transition and “Ecological Augmentation”

Abstract

:1. Introduction

1.1. Responsible Research and Innovation (RRI) and Material Experimentation

1.2. Bioreceptive Surfaces

- Primary or intrinsic bioreceptivity: Indicates the initial potential of a material to be colonized, and its properties remain identical even after the appearance of the first organisms.

- Secondary bioreceptivity: The potential for colonization changes (increases or decreases) due to variations in material properties caused by the action of the colonizing organisms or environmental factors.

- Tertiary bioreceptivity: Material property variations are due to human action, influencing the material’s primary or secondary bioreceptivity.

- Extrinsic bioreceptivity: The potential for surface colonization is not directly and exclusively related to the material properties but is influenced by a layer of materials (soil, dust, organic particles) that can promote or inhibit biological growth. This occurs, for example, in the colonization of surfaces by heterotrophs (such as mosses and lichens) following and depending on the growth of phototrophic organisms or “pioneers” like algae and cyanobacteria [31,32]. The latter changes the chemical environment, creating new conditions for other species to enter, forming mutualistic reactions with the previous ones or replacing them [33].

2. Materials and Methods

2.1. Design Process Setup

- Micro-porosity: Micro-porosity refers to the intrinsic properties of the material, particularly its physical characteristics of surface roughness and porosity. The combination of these factors can contribute to the adhesion of cells to the material support, create an optimal microclimate for their growth, and achieve the proper levels of water permeability and nutrients necessary for their development, promoting what is termed as the primary or intrinsic bioreceptivity of the material (see Section 1.2). Micro-porosity is managed by blending organic waste materials (such as cardboard and coffee) with clay-based mixtures, which disappear during baking, leaving voids or irregularities in their place. These voids and their density determine the intrinsic porosity of the biscuit (fired ceramic material) and vary its surface roughness, influencing its greater or lesser predisposition to bioreceptivity. In addition, this phase also pays particular attention to the structural resistance of the material, modulating the percentages of organic waste filler within the maximum limits above which the material would lose the minimum mechanical properties for the architectural and construction uses it is intended for.

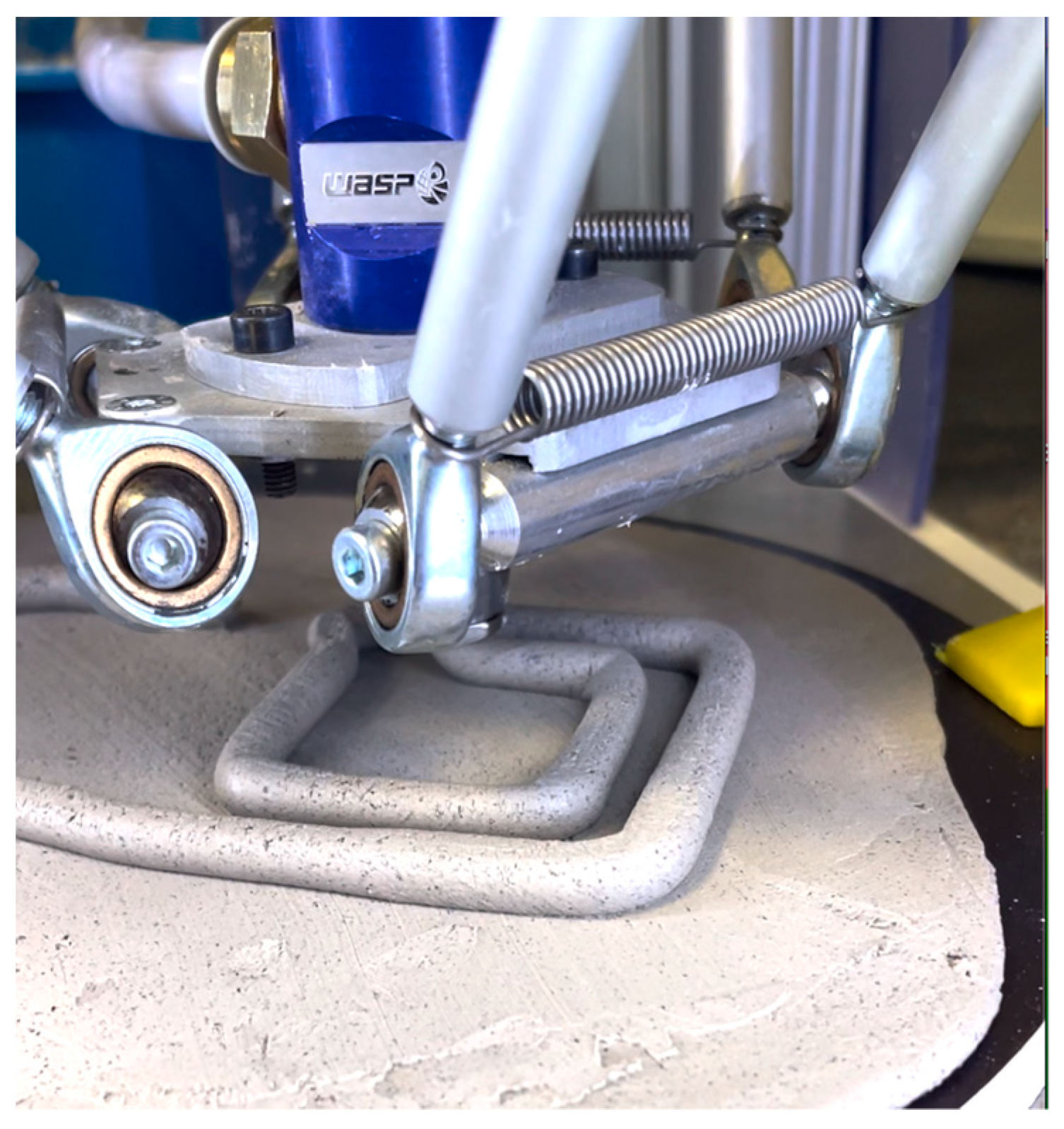

- Meso-porosity: Meso-porosity refers to the “architectural” characteristics of the material support, specifically surface geometry and filling. This concept strongly derives from “scaffold design”, which, to recapitulate the complexity and heterogeneity of biological tissues, distributes material porosity according to spatial grids, facilitating the integration of cells into the support and the movement of water, nutrients, and spores throughout the volume [64]. Furthermore, if programmed and varied, such meso-porosities can direct cell behavior, establishing areas of greater or lesser biocolonization within the same element and guiding emerging aesthetics and functionalities. In this case, meso-porosity was achieved by applying an additional waste material to the surface of the samples using the impression technique to mimic the random textures of travertine (a typical Roman marble, see Figure 1) and study the influence of surface meso-structures on bioreceptivity (see Section 2.2). In the future, this will enable the creation of variable aesthetics or actual figures by alternating zones of greater or lesser biocolonization enhancement. Among the future directions, the project also envisages the use of digital and computational tools (such as parametric design and 3D printing) to design geometrically defined meso-porosities (see Section 3).

- Macro-porosity: Macro-porosity refers to the overall geometry of the object in its final form. It can relate to the overall morphology of the elements or specific surface geometries that can further contribute to the material’s ability to retain water, protect cells from weathering, etc., as demonstrated on various occasions [43,65,66]. In the project at hand, macro-porosity was intentionally uniform for all samples, which were designed as flat square tiles for cladding facades. This choice is justified by the desire to adhere to hologrammatic logic among different levels, which requires a definitive understanding of the lower levels to add additional parameters at the macro level. However, 3D printing will also allow us to create overall morphologies and predetermined geometries in the future.

2.1.1. Study of the Material Support: The White Earthenware

2.1.2. Selection of Waste Materials: Coffee Grounds and Cardboard Pulp

2.1.3. Study of Living Matter and Growth Conditions

2.2. Experimental Process

2.2.1. Processing Waste Material

2.2.2. Processing Clay-Based Mixtures

2.2.3. Processing and Baking Clay-Based Mixtures

2.2.4. Biological Matter Harvesting

2.3. Validation Experiments

- The intrinsic porosity of the material and how the type of pores influences it: This was validated by calculating the percentage variation in weight of the clay-based material mixed with organic waste and fired compared to the weight of a “target” sample, characterized by the exact dimensions (15 × 15 × 0.5 cm) but with an entirely white clay mixture. The dry weight variation is a valid and easily understandable measure for assessing how much the organic waste-induced porosity is directly proportional to the percentage decrease in the sample’s weight compared to the target value.

- The subsequent permeability of the material and its ability to retain capillary water inside was calculated by measuring the weights of the samples at different states and comparing them with the dry weight. As the first value, the percentage increase in weight after immersing the samples in water for two minutes was calculated. This allowed us to study each material’s ability to absorb water, i.e., their permeability. Subsequently, the samples were left to air-dry at room temperature and weighed on three other occasions: after 30 min, after 1 h, and after 3 h. This was carried out to estimate each material’s water retention capacity, i.e., their ability to retain water. The choice of these methods and timings derives from the desire to simulate a real context where weather conditions such as rain can wet the clay-based materials and allow water to run off before the sun and heat dry them. This point also helps us understand whether and how meso-porosity affects permeability and water retention despite its primary purpose being to create niches favorable to cell deposition.

3. Results and Discussion

3.1. Micro-Porosity

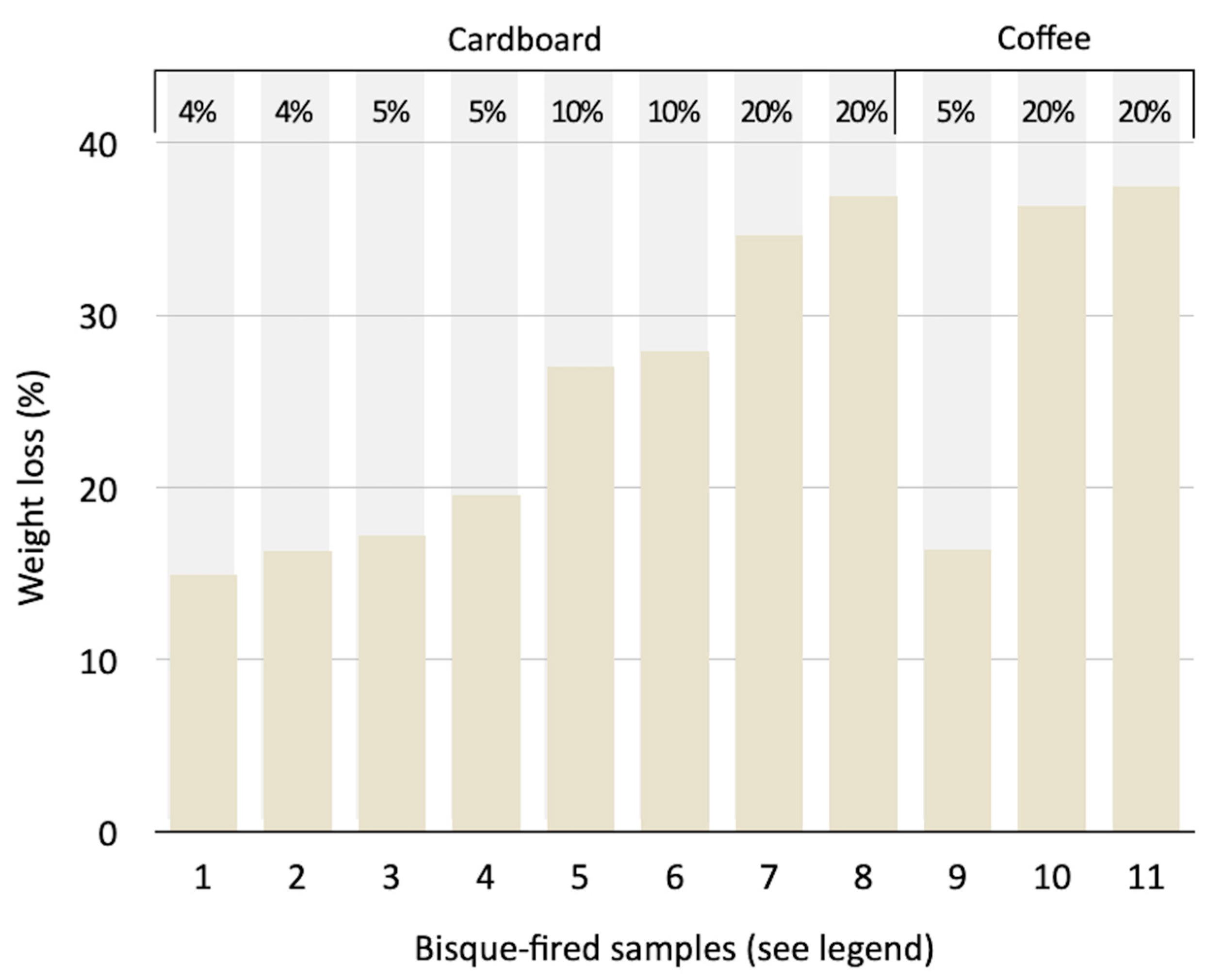

- The Intrinsic porosity of the material and the influence of pore type: In Figure 11, the graph depicts the percentage variation in weight of each sample (1–11) after firing and drying compared to the weight of a “target” sample made of pure white earthenware (223.44 g). Firstly, from the comparison, we can easily infer that, with the increase in the percentage of organic waste mixed with the clay-based mixture, the weight loss in the samples is more significant, increasing porosity. This holds for both samples mixed with cardboard and those mixed with coffee. From the comparison between the two, we can deduce that the weight loss is slightly lower in the samples treated with cardboard. This is probably due to the morphology of the pores and the volatile substances resulting from the respective wastes: The fibrous porosity of cardboard occupies a slightly lower density than the granular porosity of coffee. At the same time, the latter releases a greater quantity of carbon during firing [88]. However, optimal results were achieved with both wastes, with weight losses up to 37.43%.

- Fluid permeability and water retention: In Figure 12a, the graph shows the percentage variation in weight of each sample (1–11) compared to the dry weight after various phases: (1) 2-min immersion (beige) and the subsequent (2) 30 min (green), (3) 60 min (orange), and (4) 180 min (red) of air-drying under ambient conditions. From the analysis of the percentage increase in weight after the immersion phase (Figure 12b), we can infer that the weight increase is directly proportional to the quantity of organic waste used and, therefore, porosity for both coffee and cardboard pulp. Furthermore, the latter seems to provide more excellent permeability to the material, again justifiable by the morphology of the pores, which, by creating actual channels for water flow, can promote its absorption and “trapping”. However, in the drying phase (Figure 12b–e), coffee appears more performative because the channels created by the waste paper’s fibrous structure also facilitate the outward water flow.

3.2. Meso-Porosity

- Intrinsic material porosity and the influence of pore types: From the graph in Figure 12a–e, essential considerations can also be made regarding surface meso-porosity. In particular, we can confirm that its primary role is not the creation of greater porosity. Comparing the results of samples with the same amount of organic filler but with different surface conformations (1–2, 3–4, 5–6, 7–8, 10–11), we can see that the % weight variation is negligible, hovering around one percentage point.

- Fluid permeability and water retention: In the graph in Figure 12e, the quantity of absorbed and trapped water in different pairs of materials with different surface conformations is also compared. In particular, an unexpected result can be deduced: samples without meso-structure (1, 3, 5, 10) retain water inside them for a longer time compared to others. Even though no significant variations were observed in the first 30 min, as time passed and the water began to evaporate, the textured samples experienced a more significant average weight reduction. This is probably because the water is not “trapped” as in the pores and tends to evaporate more quickly, although this is partly offset by the absorption of “stagnant” niches over time. Finally, we can observe that in the case of textured samples, coffee accelerates weight loss; this is because, being inherently less permeable, it takes more time to absorb the “stagnant” niches, losing water through evaporation.

3.3. Hologrammatic Principle

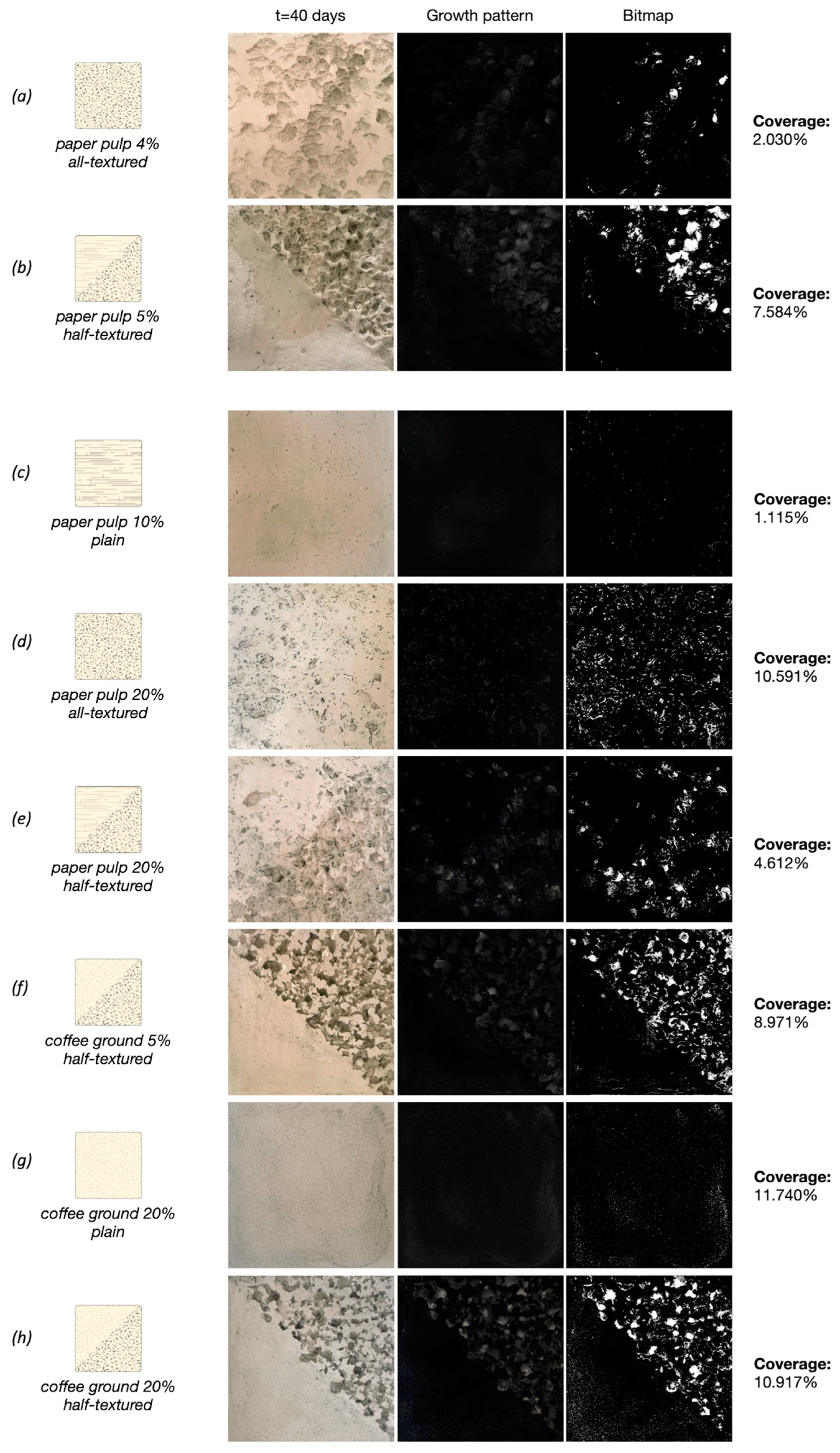

- Meso-porosities primarily serve as cell deposition niches, allowing for biofilm growth intensity to be established by varying its depth and intricacy. These niches provide accommodation for cells and shelter them from external factors (such as high solar brightness), promoting their proliferation (see all samples, especially (a,b), (d–f), (h)). It has been shown on other occasions that physical characteristics, such as the surface inhomogeneity of materials and the presence of niches, have a more significant influence on bioreceptivity than chemical properties [98,99]. These factors create an optimal microclimate for anchored cells, accumulating water, dust, shade, and nutrients [40]. This aspect could be significant for forming future 3D-printed meso-structures with specific morphologies and depths to coordinate biological growth as desired. The team is already conducting preliminary experiments in this direction.

- The guidance for cells provided by meso-porosities can be amplified at the micro-porosity level, where varying the quantity and type of intrinsic material pores can influence fluid and nutrient permeability and retention. In particular, increasing the quantity of waste also increases biological coverage (see all samples, especially the different coverages of samples (a) and (d), (f) and (g), and (h)). However, factors of final product strength, especially in structural elements, must be considered and are inversely proportional to the quantity of waste.

- Micro-porosity offers exciting insights into surface roughness, which can be exploited to enhance cell adhesion and create subtly shaded areas of green. For example, the growth rate is high in samples augmented with coffee waste, even if not very visible (see sample (g)). This is because the waste’s granular morphology makes the surfaces rougher and filled with micro-niches to which cells easily adhere. Material roughness and porosity provide better adhesion for organisms, whilst porosity and micro-groove formation affect water retention [39].

- The quantity of absorbed water is not directly proportional to biological growth. In some cases, such as in samples (c) and (e), the high absorption and retention water rates are not compensated by the desired growth pattern and coverage. Water retention likely influences this aspect: water needs to wet the material support but not stagnate for too long to allow microorganisms to interact with cells and form a biofilm. This explains why coffee-based samples show higher growth potential, as they can flow water more rapidly, retaining only the necessary moisture (see samples (f), (g), and (h)). This result is consistent with other research addressing the issue of water access and retention in bioreceptivity. The latter acts as protection against fluctuations in environmental conditions and solar radiation, as well as impacts on the extension of vegetative life [95], while the water flow is crucial for its capillary movement across surfaces and reaching potential hotspots where microclimates can benefit from excess quantities [43,66].

- The size of niches should be manageable. In addition to depth, the size and morphology of niches are essential parameters. Smaller and open niches demonstrated more excellent permeability to biological life. They can more effectively “trap” cells and prevent them from washing away with water or air. This is evident in sample (a), where the large and shallow irregularities did not result in high green concentrations, and conversely, in sample (g), which, despite low visibility, has the highest biological coverage percentage. However, this aspect is not considered a problem to overcome but rather an additional opportunity to vary bioreceptivity rates through design.

- The results of this research work align with similar research works investigating the role of micro-, meso-, and macro-porosities on materials’ bioreceptivity. The work of Cheng and Lharchi [66], for example, investigated the role of macro-form, micro-grooves and material porosity in 3D-printed ceramic structures, finding that micro-grooves given by the layer-by-layer stratification make up an area of high-growth potential due to high water and nutrient retention, while the overall 3D-printed geometries affect the creation of microclimates and the water flow’s direction. Mustafa et al. defined design guidelines for meso- and macro-geometries affecting bioreceptivity, highlighting, as in this research work, the hologrammatic correlation between scales [43].

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Spišáková, M.; Mandičák, T.; Mésároš, P.; Špak, M. Waste Management in a Sustainable Circular Economy as a Part of Design of Construction. Appl. Sci. 2022, 12, 4553. [Google Scholar] [CrossRef]

- Silva, N.; Morioka, S. Contributions of Modularity to the Circular Economy: A Systematic Review of Literature. J. Build. Eng. 2021, 44, 103322. [Google Scholar] [CrossRef]

- Antonelli, P.; Tannir, A. Broken Nature: XXII Triennale di Milano; Electa: Firenze, Italy, 2019; p. 360. [Google Scholar]

- Bellini, O.E. International Conference Virtual City and Territory. In Proceedings of the Atti del 9° Congresso “Città e Territorio Virtuale: Città Memoria Gente”, Roma, Italy, 2–4 October 2014; Cerasoli, M., Ed.; RomaTre-Press: Roma, Italy, 2014; pp. 56–66. [Google Scholar]

- Ricci, M. Come il fiume nella città. J. Sustain. Des. 2020, 21, 1–7. [Google Scholar]

- Waldheim, C. Landscape as Urbanism; Priceton University Press: Princeton, NJ, USA, 2022; ISBN 978-0-691-16790-9. [Google Scholar]

- COMIECO. 28° Rapporto Annuale Comieco Sulla Raccolta Differenziata di Carta e Cartone in Italia; Comieco: Milan, Italy, 2022. [Google Scholar]

- Bergonzoli, S.; Del Giudice, A.; Gallucci, F.; Scarfone, A. @CREA Energia Con i Fondi di Caffè; CREA Futuro: Rome, Italy, 2023. [Google Scholar]

- Baldassarre, B.; Schepers, M.; Bocken, N.; Cuppen, E.; Korevaar, G.; Calabretta, G. Industrial Symbiosis: Towards a Design Process for Eco-Industrial Clusters by Integrating Circular Economy and Industrial Ecology Perspectives. J. Clean. Prod. 2019, 216, 446–460. [Google Scholar] [CrossRef]

- Cigola, M. Le Cartiere Storiche Del Basso Lazio: Censimento e Catalogazione Degli Apparati Grafici e Cartografici; Ciolfi Editore: Milan, Italy, 2000; ISBN 978-88-86810-12-8. [Google Scholar]

- ISPRA. Rapporto Rifiuti Speciali Edizione 2023; ISPRA: Ispra, Italy, 2023.

- ISPRA. Rapporto Rifiuti Urbani Edizione 2022; ISPRA: Ispra, Italy, 2022.

- Morra, G. La Sostenibilità Nel Mondo Del Caffè: Le Aziende Leader Nel Settore Italiano. Master’s Thesis, Università Ca’ Foscari di Venezia, Venice, Italy, 2022. [Google Scholar]

- Palmieri, N.; Fernando, A.; Suardi, A.; Bagnato, V.; Pari, R.; Stefanoni, W.; Latterini, F.; Alfano, V.; Bergonzoli, S.; Lazar, S. The Coffee Grounds: Insights bt coffee shops. In Proceedings of the 29th EUBCE, Marseille, France, 26–29 April 2021. [Google Scholar]

- Stilgoe, J.; Owen, R.; Macnaghten, P. Developing a Framework for Responsible Innovation. Res. Policy 2013, 42, 1568–1580. [Google Scholar] [CrossRef]

- Gurzawska, A.; Mäkinen, M.; Brey, P. Implementation of Responsible Research and Innovation (RRI) Practices in Industry: Providing the Right Incentives. Sustainability 2017, 9, 1759. [Google Scholar] [CrossRef]

- RRIstart—Responsible Research & Innovation. Available online: https://rristart.eu/ (accessed on 25 January 2024).

- Schomberg, R. A Vision of Responsible Research and Innovation. In Responsible Innovation: Managing the Responsible Emergence of Science and Innovation in Society; Owen, R., Bessant, J., Eds.; John Wiley: London, UK, 2013; pp. 1–35. [Google Scholar]

- Owen, R.; von Schomberg, R.; Macnaghten, P. An Unfinished Journey? Reflections on a Decade of Responsible Research and Innovation. J. Responsible Innov. 2021, 8, 217–233. [Google Scholar] [CrossRef]

- Ryan, M.; Popa, E.O.; Blok, V.; Declich, A.; Berliri, M.; Alfonsi, A.; Veloudis, S. A Model of Social Responsibility for Start-Ups: Developing a Cross-Fertilisation of Responsible Innovation, the Lean Start-up Approach, and the Quadruple Helix Approach. J. Responsible Innov. 2023, 10, 2264615. [Google Scholar] [CrossRef]

- Popa, E.O.; Blok, V.; Wesselink, R. A Processual Approach to Friction in Quadruple Helix Collaborations. Sci. Public Policy 2020, 47, 876–889. [Google Scholar] [CrossRef]

- RRI Tools. Available online: https://rri-tools.eu/ (accessed on 25 January 2024).

- Chertow, M. Industrial Symbiosis: Literature and Taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef]

- Guillitte, O. Bioreceptivity: A New Concept for Building Ecology Studies. Sci. Total Environ. 1995, 167, 215–220. [Google Scholar] [CrossRef]

- Miller, A.Z.; Sanmartín, P.; Pereira-Pardo, L.; Dionísio, A.; Saiz-Jimenez, C.; Macedo, M.F.; Prieto, B. Bioreceptivity of Building Stones: A Review. Sci. Total Environ. 2012, 426, 1–12. [Google Scholar] [CrossRef]

- Ottele, M.; Koleva, D.; van Breugel, K.; Haas, E.; Fraay, A.; van Bohemen, H. Concrete as a Multifunctional Ecological Building Material: A New Approach to Green Our Environment. In Proceedings of the The 19th International Symposium Ecology&Safety, Sofia, Bulgaria, 23–26 October 2010; Genov, I., Ed.; InfoInvest: Velingrad, Bulgaria, 2010; pp. 223–234. [Google Scholar]

- Elbert, W.; Weber, B.; Burrows, S.; Steinkamp, J.; Büdel, B.; Andreae, M.O.; Pöschl, U. Contribution of Cryptogamic Covers to the Global Cycles of Carbon and Nitrogen. Nat. Geosci. 2012, 5, 459–462. [Google Scholar] [CrossRef]

- Haynes, A.; Popek, R.; Boles, M.; Paton-Walsh, C.; Robinson, S.A. Roadside Moss Turfs in South East Australia Capture More Particulate Matter along an Urban Gradient than a Common Native Tree Species. Atmosphere 2019, 10, 224. [Google Scholar] [CrossRef]

- Glime, J.M. Bryophyte Ecology; Michigan Tech: Houghton, MI, USA, 2017; p. 85. [Google Scholar]

- Sanmartín, P.; Miller, A.Z.; Prieto, B.; Viles, H.A. Revisiting and Reanalysing the Concept of Bioreceptivity 25 Years On. Sci. Total Environ. 2021, 770, 145314. [Google Scholar] [CrossRef]

- Kala, R.; Pandey, V.D. Cyanobacterial Extracellular Polymeric Substances and their role in Biodeterioration of Temples and Monuments. J. Mt. Res. 2023, 18, 173–180. [Google Scholar] [CrossRef]

- Soares, F.; Trovão, J.; Tiago, I.; Cardoso, S.M.; Gil, F.; Catarino, L.; Portugal, A. Phototrophic Colonization in Dolomitic Limestone: Comparison between Single vs. Artificial Multispecies. Geomicrobiol. J. 2023, 40, 434–445. [Google Scholar] [CrossRef]

- Connell, J.H.; Slatyer, R.O. Mechanisms of Succession in Natural Communities and Their Role in Community Stability and Organization. Am. Nat. 1977, 111, 1119–1144. [Google Scholar] [CrossRef]

- Bremer, P.; Flint, S.; Brooks, J.; Palmer, J. (Eds.) Introduction to Biofilms: Definition and Basic Concepts. In Biofilms in the Dairy Industry; Wiley Library: Hoboken, NJ, USA, 2015. [Google Scholar]

- Strieth, D.; Ulber, R.; Muffler, K. Application of Phototrophic Biofilms: From Fundamentals to Processes. Bioprocess Biosyst. Eng. 2017, 41, 295–312. [Google Scholar] [CrossRef]

- Albertano, P. Cyanobacterial Biofilms in Monuments and Caves. In Ecology of Cyanobacteria II: Their Diversity in Space and Time; Whitton, B.A., Ed.; Springer: Dordrecht, The Netherlands, 2012; pp. 317–343. ISBN 978-94-007-3855-3. [Google Scholar]

- Jones, A.A.; Bennett, P.C. Mineral Ecology: Surface Specific Colonization and Geochemical Drivers of Biofilm Accumulation, Composition, and Phylogeny. Front. Microbiol. 2017, 8, 186951. [Google Scholar] [CrossRef]

- Tomaselli, L.; Lamenti, G.; Bosco, M.; Tiano, P. Biodiversity of Photosynthetic Micro-Organisms Dwelling on Stone Monuments. Int. Biodeterior. Biodegrad. 2000, 46, 251–258. [Google Scholar] [CrossRef]

- Miller, A.Z.; Dionìsio, A.; Laiz, L.; Macedo, M.F.; San-Jimenez, C. The Influence of Inherent Properties of Building Limestones on Their Bioreceptivity to Phototrophic Microorganisms. Ann. Microbiol. 2009, 59, 705–713. [Google Scholar] [CrossRef]

- D’Orazio, M.; Cursio, G.; Graziani, L.; Aquilanti, L.; Osimani, A.; Clementi, F.; Yéprémian, C.; Lariccia, V.; Amoroso, S. Effects of Water Absorption and Surface Roughness on the Bioreceptivity of ETICS Compared to Clay Bricks. Build. Environ. 2014, 77, 20–28. [Google Scholar] [CrossRef]

- Tran, T.-H.; Hoang, N.-D. Estimation of Algal Colonization Growth on Mortar Surface Using a Hybridization of Machine Learning and Metaheuristic Optimization. Sādhanā 2017, 42, 929–939. [Google Scholar] [CrossRef]

- Manso, S.; Calvo-Torras, M.Á.; De Belie, N.; Segura, I.; Aguado, A. Evaluation of Natural Colonisation of Cementitious Materials: Effect of Bioreceptivity and Environmental Conditions. Sci. Total Environ. 2015, 512–513, 444–453. [Google Scholar] [CrossRef] [PubMed]

- Mustafa, K.F.; Prieto, A.; Ottele, M. The Role of Geometry on a Self-Sustaining Bio-Receptive Concrete Panel for Facade Application. Sustainability 2021, 13, 7453. [Google Scholar] [CrossRef]

- Cruz, M. The Inhabitable Flesh of Architecture, 1st ed.; Routledge: Abongdon, UK, 2013; p. 268. ISBN 9781409469346. [Google Scholar]

- Cruz, M.; Beckett, R. Bioreceptive Design: A Novel Approach to Biodigital Materiality. Archit. Res. Q. 2016, 20, 51–64. [Google Scholar] [CrossRef]

- Cruz, M. Poikilohydric Living Walls; Bartlett School of Architecture UCL: London, UK; p. 86. Available online: https://issuu.com/bartlettarchucl/docs/design-research-cruz-poikilohydric-walls-04 (accessed on 25 January 2024).

- Malik, S.; Hagopiaan, J.; Mohite, S.; Lintong, C.; Stoffels, L.; Giannakopouluos, S.; Backett, R.; Leung, C.; Ruiz, J.; Cruz, M.; et al. Robotic Extrusion of Algae-Laden Hydrogels for Large-Scale Applications. Glob. Chall. 2019, 4, 1900064. [Google Scholar] [CrossRef] [PubMed]

- Parker, B.; Cruz, M. Microbial to Tectonic. Antennae J. Nat. Vis. Cult. 2022, 59, 110–123. [Google Scholar]

- Winters, S. What If Our Clothes Where Alive and Phosynthesized? APRIA. May 2019, pp. 21–140. Available online: https://apria.artez.nl/what-if-our-clothes-were-alive-and-photosynthesized (accessed on 25 January 2024).

- Stonorov, T. FABRIC[Ated]: Fabric Innovation and Material Responsibility in Architecture; Taylor & Francis: Abingdon, UK, 2023; ISBN 978-1-00-086074-0. [Google Scholar]

- Urban Reef. Available online: https://www.urbanreef.nl/mission (accessed on 25 January 2024).

- Sochůrková, P.; Vaško, I.; Tsikolia, S.; Sviták, D.; Latour, M.; Oskam, P. Bioreceptivity as a Factor of Additive Fabrication Material Research on 3D Printed Structures Affecting Urban Spaces. eCAADe 2023, 2, 115–124. [Google Scholar]

- IOUS Studio. Available online: https://www.ious-studio.com/shop (accessed on 25 January 2024).

- Otto, F. Occupying and Connecting: Thoughts on Territories and Spheres of Influence with Particular Reference to Human Settlement: Thougts on Territories and... with Particular Reference to Human Settlement; Axel Menges: Stuttgart, Germany, 2008; ISBN 978-3-932565-11-3. [Google Scholar]

- Frayling, C. Research in Art and Design; Royal College of Art Research Papers; Royal College of Art: London, UK, 1993; ISBN 978-1-874175-55-1. [Google Scholar]

- Godin, D.; Zahedi, M. Aspects of Research through Design: A Literature Review. In Design’s Big Debates, Proceedings of the DRS International Conference 2014, 16–19 June, Umea, Sweden; Lim, Y., Niedderer, K., Redström, J., Stolterman, E., Valtonen, A., Eds.; Design Research Society: London, UK, 2014; ISBN 978-91-7601-068-6. [Google Scholar]

- Schon, D.A. The Reflective Practitioner How Professionals Think in Action; Basic Books, New York.—References; Scientific Research Publishing: Irvine, CA, USA, 1983; Available online: https://scirp.org/reference/referencespapers?referenceid=2569351 (accessed on 25 January 2024).

- Hutmacher, D.W.; Tandon, B.; Dalton, P.D. Scaffold Design and Fabrication. In Tissue Engineering, 3rd ed.; De Boer, J., Blitterswijk, C.A.V., Uquillas, J.A., Malik, N., Eds.; Academic Press: Cambridge, MA, USA, 2023; pp. 355–385. [Google Scholar]

- Mironov, V.; Trusk, T.; Kasyanov, V.; Little, S.; Swaja, R.; Markwald, R. Biofabrication: A 21st Century Manufacturing Paradigm. Biofabrication 2009, 1, 022001. [Google Scholar] [CrossRef] [PubMed]

- Langer, R.; Vacanti, J.P. Tissue Engineering. Science 1993, 260, 920–926. [Google Scholar] [CrossRef]

- Rotondi, C. How the Informed Relations between Physical, Digital and Biological Dimensions Are Changing the Design Practice, as well as the Sustainability Paradigm. Front. Bioeng. Biotechnol. 2023, 11, 1193353. [Google Scholar] [CrossRef]

- Moroni, L.; Boland, T.; Burdick, J.A.; De Maria, C.; Derby, B.; Forgacs, G.; Groll, J.; Li, Q.; Malda, J.; Mironov, V.A.; et al. Biofabrication: A Guide to Technology and Terminology. Trends Biotechnol. 2018, 36, 384–402. [Google Scholar] [CrossRef] [PubMed]

- Morin, E. Introduzione al Pensiero Complesso. Gli Strumenti per Affrontare la Sfida della Complessità; Sperling & Kupfer: Milano, Italy, 1993; p. 128. [Google Scholar]

- Moroni, L.; de Wijn, J.R.; van Blitterswijk, C.A. 3D Fiber-Deposited Scaffolds for Tissue Engineering: Influence of Pores Geometry and Architecture on Dynamic Mechanical Properties. Biomaterials 2006, 27, 974–985. [Google Scholar] [CrossRef]

- Abdallah, Y.K.; Estévez, A.T. 3D-Printed Bioreceptive Tiles of Reaction–Diffusion (Gierer-Meinhardt Model) for Multi-Scale Algal Strains’ Passive Immobilization. Buildings 2023, 13, 1972. [Google Scholar] [CrossRef]

- Cheng, A.; Lharchi, A. Parameters for Bio-Receptivity in 3D Printing. In Design for Climate Adaptation. Proceedings of the UIA World Congress of Architects of Copenhagen; Faircloth, B., Zari, P.M., Ramsgaard Thomsen, M., Tamke, M., Eds.; Springer: New York, NY, USA, 2023; pp. 701–715. ISBN 978-3-031-36319-1. [Google Scholar]

- Bergaya, F.; Lagaly, G. Chapter 1 General Introduction: Clays, Clay Minerals, and Clay Science. In Developments in Clay Science; Bergaya, F., Theng, B.K.G., Lagaly, G., Eds.; Handbook of Clay Science; Elsevier: Amsterdam, The Netherlands, 2006; Volume 1, pp. 1–18. [Google Scholar]

- Guggenheim, S.; Martin, R.T. Definition of Clay and Clay Mineral: Joint Report of the AIPEA and CMS Nomenclature Committees. Clay Miner. 1995, 30, 257–259. [Google Scholar] [CrossRef]

- Warlimont, H. Ceramics. In Springer Handbook of Materials Data; Warlimont, H., Martienssen, W., Eds.; Springer Handbooks; Springer International Publishing: Cham, Switzerland, 2018; pp. 445–488. ISBN 978-3-319-69743-7. [Google Scholar]

- Reeves, G.M.; Sims, I.; Cripps, J.C. Clay Materials Used in Construction; Geological Society of London: London, UK, 2006; ISBN 978-1-86239-184-0. [Google Scholar]

- Jordan, M.M.; Montero, M.A.; Meseguer, S.; Sanfeliu, T. Influence of Firing Temperature and Mineralogical Composition on Bending Strength and Porosity of Ceramic Tile Bodies. Appl. Clay Sci. 2008, 42, 266–271. [Google Scholar] [CrossRef]

- Cultrone, G.; Sebastián, E.; Elert, K.; de la Torre, M.J.; Cazalla, O.; Rodriguez–Navarro, C. Influence of Mineralogy and Firing Temperature on the Porosity of Bricks. J. Eur. Ceram. Soc. 2004, 24, 547–564. [Google Scholar] [CrossRef]

- Lyckfeldt, O.; Ferreira, J.M.F. Processing of Porous Ceramics by ‘Starch Consolidation’. J. Eur. Ceram. Soc. 1998, 18, 131–140. [Google Scholar] [CrossRef]

- Ohji, T.; Fukushima, M. Macro-Porous Ceramics: Processing and Properties. Int. Mater. Rev. 2012, 57, 115–131. [Google Scholar] [CrossRef]

- Jodati, H.; Yılmaz, B.; Evis, Z. A Review of Bioceramic Porous Scaffolds for Hard Tissue Applications: Effects of Structural Features. Ceram. Int. 2020, 46, 15725–15739. [Google Scholar] [CrossRef]

- Taurino, R.; Ferretti, D.; Cattani, L.; Bozzoli, F.; Bondioli, F. Lightweight Clay Bricks Manufactured by Using Locally Available Wine Industry Waste. J. Build. Eng. 2019, 26, 100892. [Google Scholar] [CrossRef]

- Maraveas, C. Production of Sustainable Construction Materials Using Agro-Wastes. Materials 2020, 13, 262. [Google Scholar] [CrossRef] [PubMed]

- Subashi De Silva, G.H.M.J.; Hansamali, E. Eco-Friendly Fired Clay Bricks Incorporated with Porcelain Ceramic Sludge. Constr. Build. Mater. 2019, 228, 116754. [Google Scholar] [CrossRef]

- Basheer Al-Naib, U. (Ed.) Introductory Chapter: A Brief Introduction to Porous Ceramic. In Recent Advances in Porous Ceramics; IntechOpen: Vienna, Austria, 2018; p. 230. ISBN 978-1-78923-653-8. [Google Scholar]

- Ahmad, S.; Iqbal, Y.; Muhammad, R. Effects of Coal and Wheat Husk Additives on the Physical, Thermal and Mechanical Properties of Clay Bricks. Boletín Soc. Española Cerámica Vidr. 2017, 56, 131–138. [Google Scholar] [CrossRef]

- Pia, G.; Casnedi, L.; Sanna, U. Porous Ceramic Materials by Pore-Forming Agent Method: An Intermingled Fractal Units Analysis and Procedure to Predict Thermal Conductivity. Ceram. Int. 2015, 41, 6350–6357. [Google Scholar] [CrossRef]

- Bories, C.; Borredon, M.-E.; Vedrenne, E.; Vilarem, G. Development of Eco-Friendly Porous Fired Clay Bricks Using Pore-Forming Agents: A Review. J. Environ. Manag. 2014, 143, 186–196. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.S.; Chen, G.F. (Eds.) Chapter One—General Introduction to Porous Materials. In Porous Materials; Butterworth-Heinemann: Boston, MA, USA, 2014; pp. 1–20. ISBN 978-0-12-407788-1. [Google Scholar]

- Salman, M.M.; Radhi, N.S.; Sabr, O.H.; Nhabih, H.T. Utilization of Diverse Cheap Materials as Pore Generating Agent to Manufacture Low-Cost Porous Ceramic. Cerâmica 2020, 66, 179–185. [Google Scholar] [CrossRef]

- Salleh, S.Z.; Awang Kechik, A.; Yusoff, A.H.; Taib, M.A.A.; Mohamad Nor, M.; Mohamad, M.; Tan, T.G.; Ali, A.; Masri, M.N.; Mohamed, J.J.; et al. Recycling Food, Agricultural, and Industrial Wastes as Pore-Forming Agents for Sustainable Porous Ceramic Production: A Review. J. Clean. Prod. 2021, 306, 127264. [Google Scholar] [CrossRef]

- Li, X.; Chertow, M.; Guo, S.; Johnson, E.; Jiang, D. Estimating Non-Hazardous Industrial Waste Generation by Sector, Location, and Year in the United States: A Methodological Framework and Case Example of Spent Foundry Sand. Waste Manag. 2020, 118, 563–572. [Google Scholar] [CrossRef]

- Gaeta, G.L.; Ghinoi, S.; Silvestri, F.; Tassinari, M. Innovation in the Solid Waste Management Industry: Integrating Neoclassical and Complexity Theory Perspectives. Waste Manag. 2021, 120, 50–58. [Google Scholar] [CrossRef]

- Serewane Deramne, R.; Lecomte-Nana, G.L.; Peyratout, C.; Naït-Ali, B.; Tchangbedji, G. Use of a Kaolinitic-Illitic Clay from Central African Republic and an Organic Waste for the Production of Porous Ceramic Materials. Int. J. Ceram. Eng. Sci. 2020, 2, 292–302. [Google Scholar] [CrossRef]

- Hadi, E.M.; Al-Hussien, H.J. Manufacturing Porous Ceramic from Iraqi Kaolin by Using Paper Pulp. Eng. Technol. J. 2017, 35, 227–236. [Google Scholar] [CrossRef]

- Pellizzari, S.; Genovesi, E. Neomateriali 2.0 Nell’economia Circolare; Edizioni Ambiente: Milano, Italy, 2021; p. 2012. ISBN 9788866272830. [Google Scholar]

- Gopi, S.; Pius, A.; Thomas, S. 11—Synthesis, Microstructure, and Properties of High-Strength Porous Ceramics. In Fundamental Biomaterials: Ceramics; Thomas, S., Balakrishnan, P., Sreekala, M.S., Eds.; Woodhead Publishing: Cambridge, UK, 2018; pp. 265–271. ISBN 978-0-08-102203-0. [Google Scholar]

- “Fototrofo”. Treccani. Available online: https://www.treccani.it/enciclopedia/fototrofo/# (accessed on 24 January 2024).

- Cattò, C.; Mu, A.; Moreau, J.W.; Wang, N.; Cappitelli, F.; Strugnell, R. Biofilm colonization of stone materials from an Australian outdoor sculpture: Importance of geometry and exposure. J. Environ. Manag. 2023, 339, 117948. [Google Scholar] [CrossRef]

- Su, Y. Revisiting Carbon, Nitrogen, and Phosphorus Metabolisms in Microalgae for Wastewater Treatment. Sci. Total Environ. 2021, 762, 144590. [Google Scholar] [CrossRef]

- Gorbushina, A.A. Life on the Rocks. Environ. Microbiol. 2007, 9, 1613–1631. [Google Scholar] [CrossRef]

- Hauer, T.; Mühlsteinová, R.; Bohunická, M.; Kaštovský, J.; Mareš, J. Diversity of Cyanobacteria on Rock Surfaces. Biodivers. Conserv. 2015, 24, 759–779. [Google Scholar] [CrossRef]

- Crispim, C.A.; Gaylarde, C.C. Cyanobacteria and Biodeterioration of Cultural Heritage: A Review. Microb. Ecol. 2005, 49, 1–9. [Google Scholar] [CrossRef]

- Veeger, M.; Ottelé, M.; Prieto, A. Making Bioreceptive Concrete: Formulation and Testing of Bioreceptive Concrete Mixtures. J. Build. Eng. 2021, 44, 102545. [Google Scholar] [CrossRef]

- Vázquez-Nion, D.; Silva, B.; Prieto, B. Influence of the Properties of Granitic Rocks on Their Bioreceptivity to Subaerial Phototrophic Biofilms. Sci. Total Environ. 2018, 610–611, 44–54. [Google Scholar] [CrossRef]

| Sample A | Sample B | Sample C | |

|---|---|---|---|

| Clay base | 666.7 g | 666.7 g | 666.7 g |

| Paper pulp | 26.7 g | 66.7 g | 133.5 g |

| Concentration (paper pulp/clay base) | 4% | 10% | 20% |

| Water | as needed | as needed | as needed |

| Coffee Grounds | Paper Pulp | |||

|---|---|---|---|---|

| Sample D1 | Sample D2 | Sample E1 | Sample E2 | |

| Waste component | 25 g | 100 g | 25 g | 100 g |

| Clay base | 500 g | 500 g | 500 g | 500 g |

| Concentration (waste component/clay base) | 5% | 20% | 5% | 20% |

| Water | as needed | as needed | as needed | as needed |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rotondi, C.; Gironi, C.; Ciufo, D.; Diana, M.; Lucibello, S. Bioreceptive Ceramic Surfaces: Material Experimentations for Responsible Research and Design Innovation in Circular Economy Transition and “Ecological Augmentation”. Sustainability 2024, 16, 3208. https://doi.org/10.3390/su16083208

Rotondi C, Gironi C, Ciufo D, Diana M, Lucibello S. Bioreceptive Ceramic Surfaces: Material Experimentations for Responsible Research and Design Innovation in Circular Economy Transition and “Ecological Augmentation”. Sustainability. 2024; 16(8):3208. https://doi.org/10.3390/su16083208

Chicago/Turabian StyleRotondi, Carmen, Camilla Gironi, Diana Ciufo, Maria Diana, and Sabrina Lucibello. 2024. "Bioreceptive Ceramic Surfaces: Material Experimentations for Responsible Research and Design Innovation in Circular Economy Transition and “Ecological Augmentation”" Sustainability 16, no. 8: 3208. https://doi.org/10.3390/su16083208

APA StyleRotondi, C., Gironi, C., Ciufo, D., Diana, M., & Lucibello, S. (2024). Bioreceptive Ceramic Surfaces: Material Experimentations for Responsible Research and Design Innovation in Circular Economy Transition and “Ecological Augmentation”. Sustainability, 16(8), 3208. https://doi.org/10.3390/su16083208