Comparative Study and Evaluation of Sediment Deposition and Migration Characteristics of New Sustainable Filter Media in Micro-Irrigation Sand Filters

Abstract

1. Introduction

2. Materials and Methods

2.1. Filtration Media

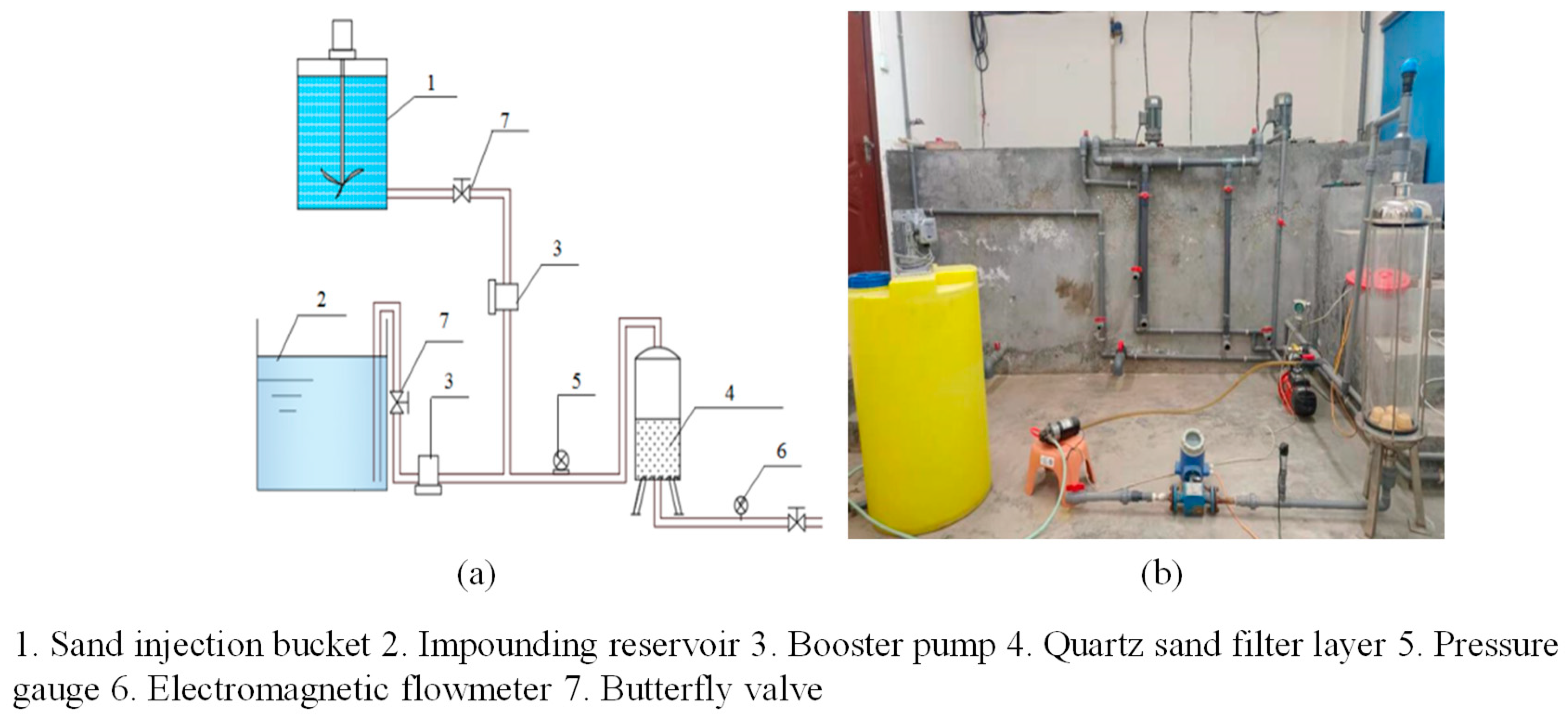

2.2. Experimental Setup

2.3. Sandy Water Configuration

2.4. Filtration Steps

2.5. Test Indices and Measurement Methods

- (1)

- Sediment retention in the filter layer: The sediment retention quality of each of the four filter layers in the nine columns was assessed using the test method involving collecting, separating, and drying.

- (2)

- Sediment retention uniformity: The uniformity of sediment retention in the filter layer was obtained by calculating the standard deviation of the sediment retention in the four filter layers of a single filter column.

- (3)

- Particle-size distribution of the filter-layer sediment: A BT-9300H laser particle-size distribution meter (0.1–716.0 µm) was used to analyze the particle size of the sediment samples retained by the filter layer. The particle-size distributions of the sediments retained in the four filter layers of the nine columns were obtained.

- (4)

- Pressure and flow rate: A pressure gauge and flow meter were arranged at the inlet and outlet of the filter model, respectively. Readings were recorded once every minute during the test to calculate and analyze the changes in the flow rate of different particle sizes as well as the changes in the pressure drop of the filtration system.

3. Results and Discussion

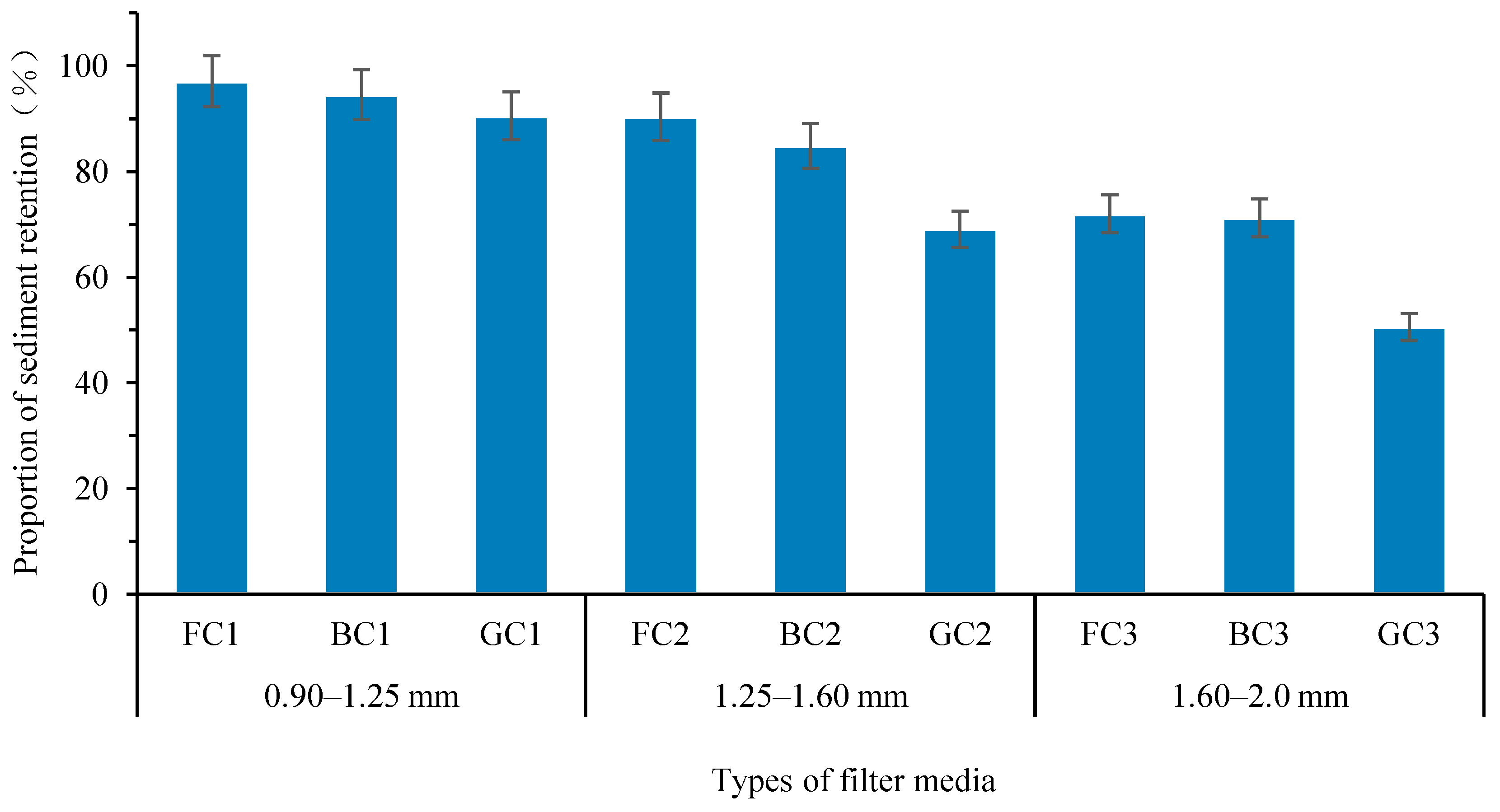

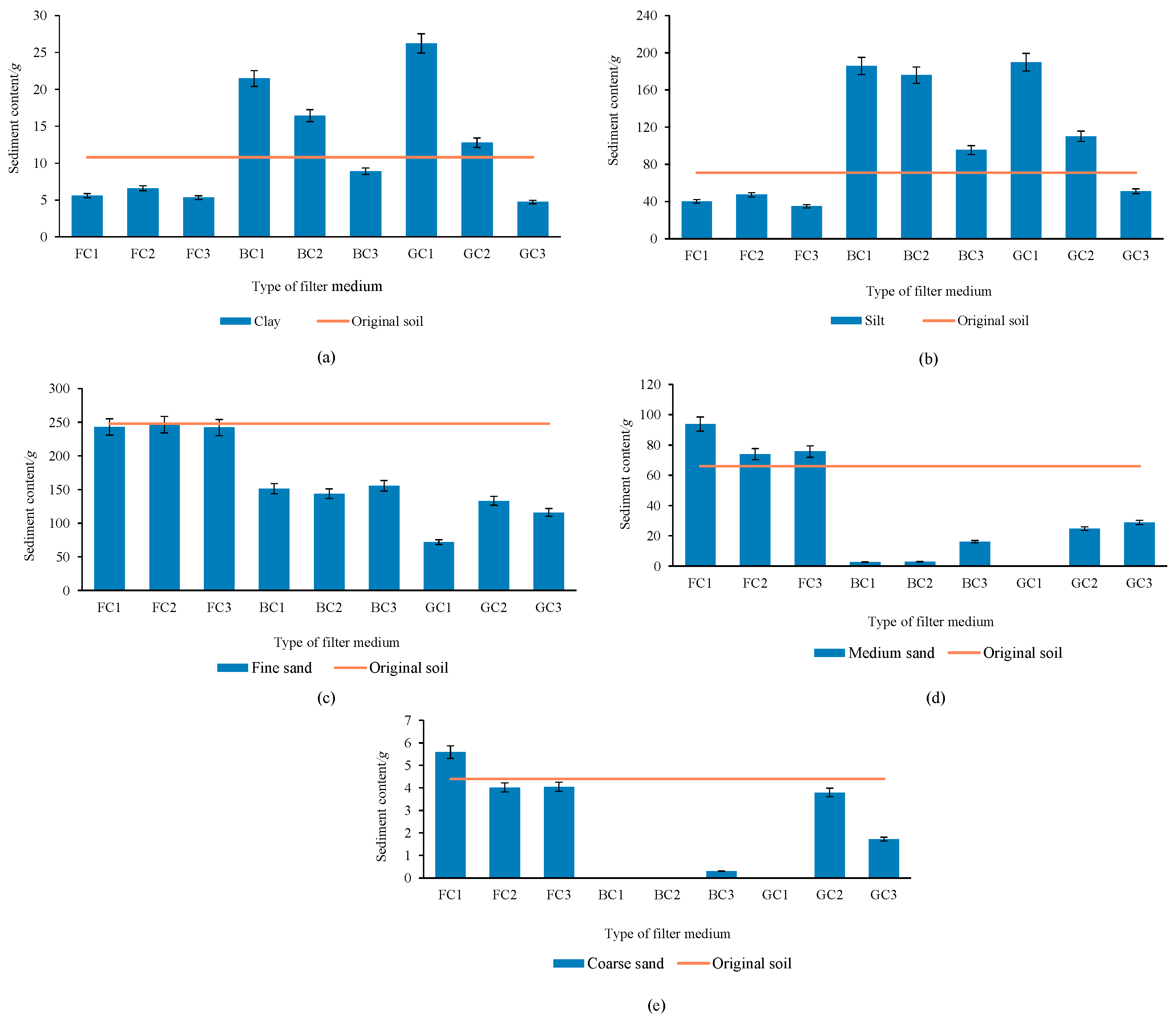

3.1. Quality Analysis of the Sediment Retained in the Filter Column

| Medium Size (mm) | 0.90–1.25 (n = 3) | 1.25–1.60 (n = 3) | 1.60–2.00 (n = 3) | F | LSD |

|---|---|---|---|---|---|

| Sediment retention ratio (%) | 94.04 ± 3.32 | 81.40 ± 11.02 | 64.59 ± 12.13 | 7.026 * | [0.9, 1.25] [1.6, 2.0] |

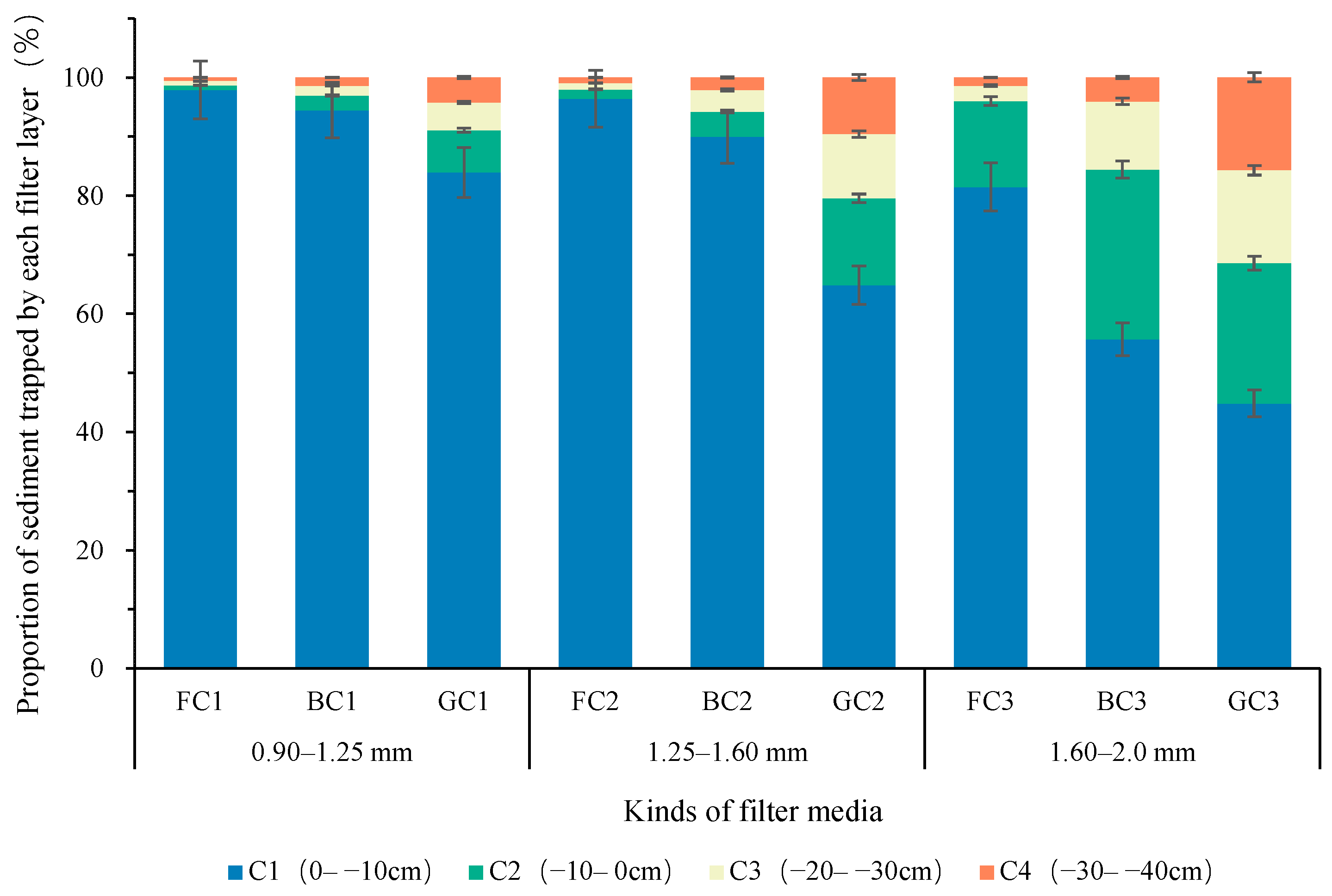

3.2. Analysis of Sediment Uniformity of Filter Column Interception

3.3. Analysis of the Sediment Mass Fraction in Water after Filtration

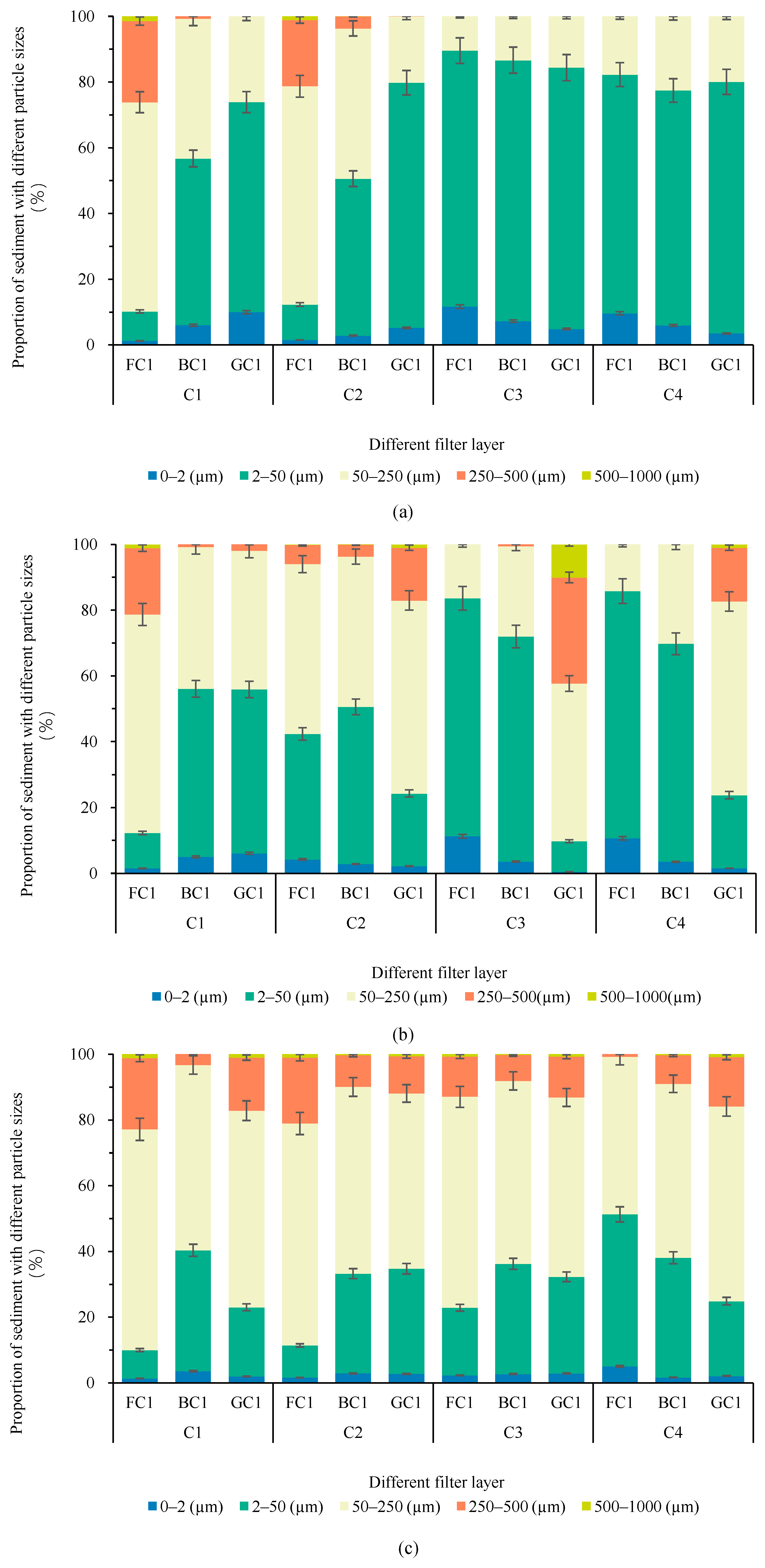

3.4. Analysis of Sediment Particle Size in Filter Layers

3.5. Analysis of the Particle Size of Sediment Deposited in the Filter Layers

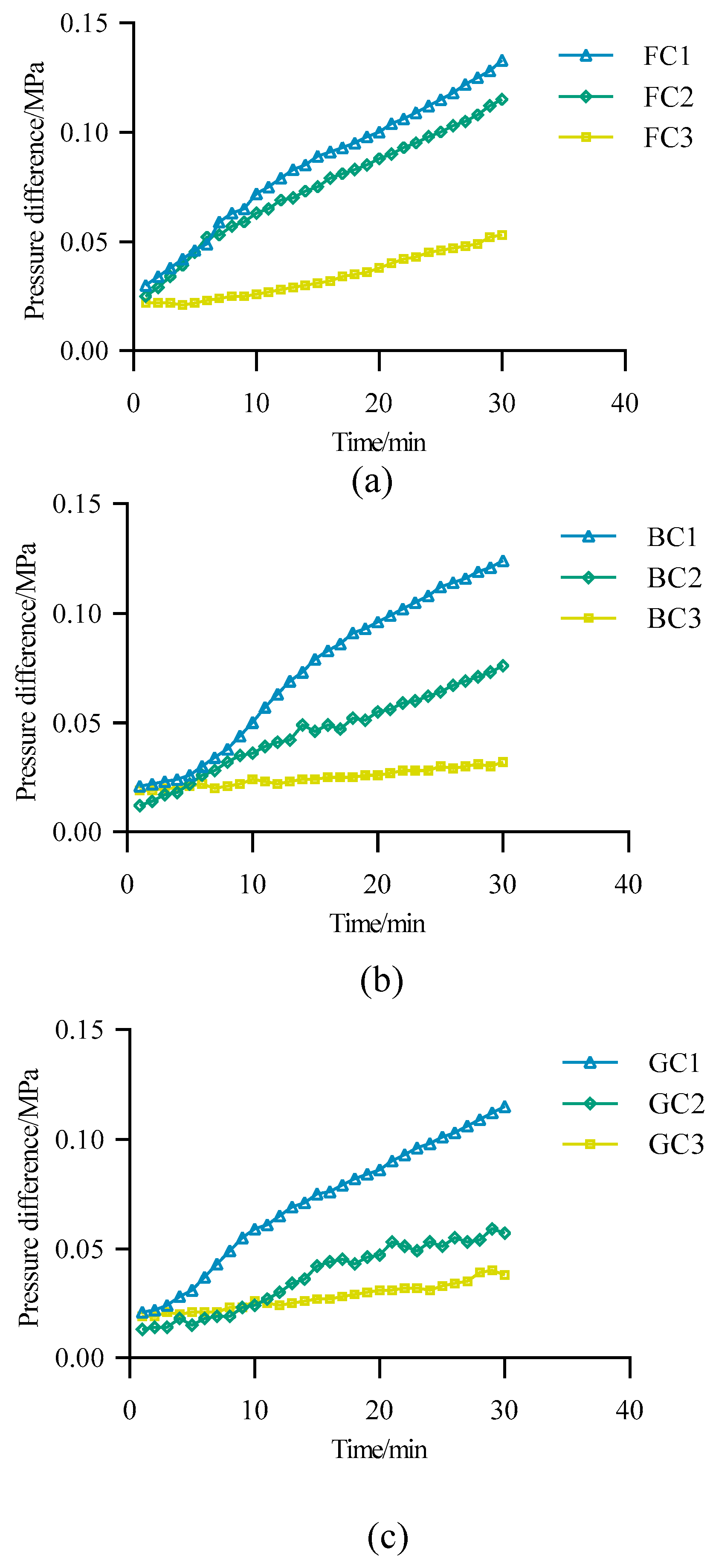

3.6. Analysis of Filtration Hydraulic Performance

3.7. Evaluation of the Filtration Performance of Different Filter Media

| Membership | FC1 | FC2 | FC3 | BC1 | BC2 | BC3 |

|---|---|---|---|---|---|---|

| VU1 | 0.00 | 0.08 | 0.41 | 0.18 | 0.34 | 1.00 |

| VU2 | 1.00 | 0.90 | 0.80 | 0.80 | 0.70 | 0.60 |

| VU3 | 0.16 | 0.31 | 0.80 | 0.00 | 0.53 | 1.00 |

| VU4 | 1.00 | 0.91 | 0.77 | 0.76 | 0.56 | 0.00 |

| VU5 | 0.00 | 0.10 | 0.2 | 0.80 | 0.90 | 1.00 |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Good, P.; Booth, B.B.B.; Chadwick, R.; Hawkins, E.; Jonko, A.; Lowe, J.A. Large differences in regional precipitation change between a first and second 2 K of global warming. Nat. Commun. 2016, 7, 13667. [Google Scholar] [CrossRef] [PubMed]

- Salehi, M. Global water shortage and potable water safety; Today’s concern and tomorrow’s crisis. Environ. Int. 2022, 158, 106936. [Google Scholar] [CrossRef] [PubMed]

- Cui, Y.; Zhou, Y.; Jin, J.; Wu, C.; Zhang, L.; Ning, S. Quantitative evaluation and diagnosis of water resources carrying capacity (WRCC) based on dynamic difference degree coefficient in the Yellow River irrigation district. Front. Earth Sci. 2022, 10, 816055. [Google Scholar] [CrossRef]

- Zhang, W.; Lv, C.; Zhao, X.; Dong, A.; Niu, W. The influence mechanism of the main suspended particles of Yellow River sand on the emitter clogging—An attempt to improve the irrigation water utilization efficiency in Yellow River basin. Agric. Water Manag. 2021, 258, 107202. [Google Scholar] [CrossRef]

- Liu, L.; Hou, P.; Liu, Z.; Wu, N.; Li, W.; Wu, R.; Wang, H.; Ma, Y.; Li, Y. Selection of suitable drip-emitters for Yellow River water drip irrigation. Trans. Chin. Soc. Agric. Eng. 2021, 37, 99–107. [Google Scholar] [CrossRef]

- Tao, H.; Shen, P.; Li, Q.; Jiang, Y.; Yang, W.; Wei, J. Research on head loss of pre-pump micro-pressure filter under clean water conditions. Water Supply 2022, 22, 3271–3282. [Google Scholar] [CrossRef]

- de Deus, F.P.; Mesquita, M.; Testezlaf, R.; de Almeida, R.C.; de Oliveira, H.F.E. Methodology for hydraulic characterisation of the sand filter backwashing processes used in micro irrigation. MethodsX 2020, 7, 100962. [Google Scholar] [CrossRef]

- Dold, B. Sourcing of critical elements and industrial minerals from mine waste—The final evolutionary step back to sustainability of humankind? J. Geochem. Explor. 2020, 219, 106638. [Google Scholar] [CrossRef]

- Napotnik, J.A.; Baker, D.; Jellison, K.L. Effect of sand bed depth and medium age on Escherichia coli and turbidity removal in biosand filters. Environ. Sci. Technol. 2017, 51, 3402–3409. [Google Scholar] [CrossRef]

- Young-Rojanschi, C.; Madramootoo, C. Intermittent versus continuous operation of biosand filters. Water Res. 2014, 49, 1–10. [Google Scholar] [CrossRef]

- Hu, Y.; Wu, W.; Liu, H.; Huang, Y.; Bi, X.; Liao, R.; Yin, S. Dimensional Analysis Model of Head Loss for Sand Media Filters in a Drip Irrigation System Using Reclaimed Water. Water 2022, 14, 961. [Google Scholar] [CrossRef]

- Mesquita, M.; Testezlaf, R.; Ramirez, J. The effect of media bed characteristics and internal auxiliary elements on sand filter head loss. Agric. Water Manag. 2012, 115, 178–185. [Google Scholar] [CrossRef]

- Cai, J.M. Study on Flow Resistance Distribution of Sand Filter and Filtration Characteristics of Different Granular Filter Media; Chinese Academy of Agricultural Sciences: Beijing, China, 2021. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Lye, C.Q.; Dhir, R.K. The role of glass waste in the production of ceramic-based products and other applications: A review. J. Clean. Prod. 2017, 167, 346–364. [Google Scholar] [CrossRef]

- Salzmann, R.D.; Ackerman, J.N.; Cicek, N. Pilot-scale, on-site investigation of crushed recycled glass as tertiary filter media for municipal lagoon wastewater treatment. Environ. Technol. 2022, 43, 51–59. [Google Scholar] [CrossRef] [PubMed]

- Soyer, E.; Akgiray, Ö.; Eldem, N.Ö.; Saatçı, A.M. Crushed recycled glass as a filter medium and comparison with silica sand. Clean—Soil, Air, Water 2010, 38, 927–935. [Google Scholar] [CrossRef]

- Hunce, S.Y.; Soyer, E.; Akgiray, Ö. Use of filterability index in granular filtration: Effect of filter medium type, size and shape. Water Supply 2018, 19, 382–391. [Google Scholar] [CrossRef]

- Zhao, P.; Zhai, G.; Deng, Z.; Cai, J.; Zhang, W. Experimental study on the feasibility of using glass beads as micro-irrigation filter. J. Irrig. Drain. 2018, 37, 65–70. [Google Scholar] [CrossRef]

- Bové, J.; Arbat, G.; Duran-Ros, M.; Pujol, T.; Velayos, J.; de Cartagena, F.R.; Puig-Bargués, J. Pressure drop across sand and recycled glass media used in micro irrigation filters. Biosyst. Eng. 2015, 137, 55–63. [Google Scholar] [CrossRef]

- Ramezanianpour, M.; Truong, Q.; Jensen, M.; Yuki, I. Treatment of septic tank discharge using crushed glass filter media. J. Environ. Eng. 2023, 149, 04023017. [Google Scholar] [CrossRef]

- Li, Q.; Wu, Z.; Tao, H.; Aihemaiti, M.; Jiang, Y.; Yang, W. Establishment of prediction models of trapped sediment mass and total filtration efficiency of pre-pump micro-pressure filter. Irrig. Sci. 2022, 40, 203–216. [Google Scholar] [CrossRef]

- Nieto, P.G.; García-Gonzalo, E.; Puig-Bargués, J.; Solé-Torres, C.; Duran-Ros, M.; Arbat, G. A new predictive model for the outlet turbidity in micro-irrigation sand filters fed with effluents using Gaussian process regression. Comput. Electron. Agric. 2020, 170, 105292. [Google Scholar] [CrossRef]

- Liang, H. Detection summarization on particulate matter in water. Guangdong Chem. Ind. 2010, 37, 296–298. [Google Scholar] [CrossRef]

- GB/T 50485–2020; Technical Standard for Micro-Irrigation Engineering. Ministry of Housing and Urban-Rural Development: Beijing, China, 2020.

- Yu, Y.; Xu, W.; Song, S.; Yang, H.; Zhang, Y. Influence of red loam particles, fertilizer concentration and irrigation method on clogging of different irrigation emitters. Trans. Chin. Soc. Agric. Eng. 2018, 34, 92–99. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, Z.; Zhang, K.; Luo, C.; Niu, W.; Yu, L. Influence of particle size and concentration of sediment on clogging of labyrinth channels emitters. Trans. Chin. Soc. Agric. Eng. 2014, 30, 99–108. [Google Scholar] [CrossRef]

- Yul, F.A.; Denur, D. Rancang bangun alat penjernih air berbasis backwash menggunakan metode quality function deployment (QFD). J. Tek. Ind. Terintegrasi 2021, 4, 15–20. [Google Scholar] [CrossRef]

- Graciano-Uribe, J.; Pujol, T.; Hincapie-Zuluaga, D.; Puig-Bargués, J.; Duran-Ros, M.; Arbat, G.; de Cartagena, F.R. Bed expansion at backwashing in pressurised porous media filters for drip irrigation: Numerical simulations and analytical equations. Biosyst. Eng. 2022, 223, 277–294. [Google Scholar] [CrossRef]

- Hou, P.; Xiao, Y.; Wu, N. Cascade relationship between the emitter structure-sedimentationclogging behavior in drip irrigation systems with Yellow River water. J. Hydraul. Eng. 2020, 51, 1372–1382. [Google Scholar] [CrossRef]

- Wang, X.; Jin, B.; Fan, E.; Zhang, J.; Wang, Q.; Ding, S. Numerical simulation of water-sediment two-phase flow in emitter under high frequency pulse. Trans. Chin. Soc. Agric. Mach. 2020, 51, 277–283. [Google Scholar] [CrossRef]

- Song, L.; Cai, J.; Zhai, G.; Feng, J.; Zhang, W. Sediment deposition and migration feature in the filter layer of micro-irrigation sand filter. Trans. Chin. Soc. Agric. Eng. 2023, 39, 76–83. [Google Scholar] [CrossRef]

- Li, J.H.; Zhai, G.L.; Liu, Q.X.; Li, G.Q. Study on the method of determination of the shape coefficient of sand particle in micro-irrigation based on Ergun equation. Water Sav. Irrig. 2020, 12, 1–5. [Google Scholar] [CrossRef]

- Lemons, A.; Branz, A.; Kimirei, M.; Hawkins, T.; Lantagne, D. Assessment of the quality, effectiveness, and acceptability of ceramic water filters in Tanzania. J. Water Sanit. Hyg. Dev. 2016, 6, 195–204. [Google Scholar] [CrossRef]

- Lee, S.-I.; Choi, J.-Y.; Choi, W. Effect of Groove Shape on Head Loss and Filtration Performance of Disc Filters. Water 2021, 13, 1683. [Google Scholar] [CrossRef]

- del Pozo, D.F.; Ahmad, A.; Rehman, U.; Verliefde, A.; Nopens, I. A novel CFD model to predict effluent solids concentration and pressure drop in deep bed granular filters for water treatment. Sep. Purif. Technol. 2022, 295, 121232. [Google Scholar] [CrossRef]

- Nieto, P.J.G.; García–Gonzalo, E.; Arbat, G.; Duran–Ros, M.; de Cartagena, F.R.; Puig-Bargués, J. Pressure drop modelling in sand filters in micro-irrigation using gradient boosted regression trees. Biosyst. Eng. 2018, 171, 41–51. [Google Scholar] [CrossRef]

- Qin, Z.; Pletcher, R.H. A statistical model of pressure drop increase with deposition in granular filters. Adv. Powder Technol. 2015, 26, 49–55. [Google Scholar] [CrossRef][Green Version]

- Wu, W.; Chen, W.; Liu, H.; Yin, S.; Niu, Y. A new model for head loss assessment of screen filters developed with dimensional analysis in drip irrigation systems. Irrig. Drain. 2014, 63, 523–531. [Google Scholar] [CrossRef]

| Filter-Column Type | FC1 | BC1 | GC1 | FC2 | BC2 | GC2 | FC3 | BC3 | GC3 |

|---|---|---|---|---|---|---|---|---|---|

| R2 | 0.9844 | 0.9816 | 0.9826 | 0.984 | 0.9855 | 0.9539 | 0.9665 | 0.9653 | 0.9596 |

| K (×10−3) | 3.39 | 3.97 | 3.28 | 2.86 | 2.1 | 1.74 | 1.15 | 0.43 | 0.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, L.; Cai, J.; Zhai, G.; Feng, J.; Fan, Y.; Han, J.; Hao, P.; Ma, N.; Miao, F. Comparative Study and Evaluation of Sediment Deposition and Migration Characteristics of New Sustainable Filter Media in Micro-Irrigation Sand Filters. Sustainability 2024, 16, 3256. https://doi.org/10.3390/su16083256

Song L, Cai J, Zhai G, Feng J, Fan Y, Han J, Hao P, Ma N, Miao F. Comparative Study and Evaluation of Sediment Deposition and Migration Characteristics of New Sustainable Filter Media in Micro-Irrigation Sand Filters. Sustainability. 2024; 16(8):3256. https://doi.org/10.3390/su16083256

Chicago/Turabian StyleSong, Lei, Jiumao Cai, Guoliang Zhai, Junjie Feng, Yongshen Fan, Jinzhao Han, Pingping Hao, Ning Ma, and Faqiang Miao. 2024. "Comparative Study and Evaluation of Sediment Deposition and Migration Characteristics of New Sustainable Filter Media in Micro-Irrigation Sand Filters" Sustainability 16, no. 8: 3256. https://doi.org/10.3390/su16083256

APA StyleSong, L., Cai, J., Zhai, G., Feng, J., Fan, Y., Han, J., Hao, P., Ma, N., & Miao, F. (2024). Comparative Study and Evaluation of Sediment Deposition and Migration Characteristics of New Sustainable Filter Media in Micro-Irrigation Sand Filters. Sustainability, 16(8), 3256. https://doi.org/10.3390/su16083256